service JEEP CHEROKEE 2023 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 198 of 276

196IN CASE OF EMERGENCY

13. Securely stow the jack, tools, chocks, and flat tire.

Reinstalling Jack and Tire Fastener

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the tire tread

can be sealed with a Tire Service Kit. Foreign objects (e.g.,

screws or nails) should not be removed from the tire. Tire

Service Kit can be used in outside temperatures down to

approximately -4°F (-20°C). This kit will provide a temporary tire seal, allowing you to

drive your vehicle up to 100 miles (160 km) with a

maximum speed of 50 mph (80 km/h).

TIRE SERVICE KIT STORAGE

The Tire Service Kit is stowed under the load floor behind

the rear seat.

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

TIRE SERVICE KIT COMPONENTS AND

O

PERATION

Tire Service Kit Components

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.1 — Sealant Bottle

2 — Deflation Button

3 — Power Button

4 — Sealant Hose (Clear)

5 — Pressure Gauge

6 — Mode Select Knob

7 — Power Plug (located on the bottom side of the Tire

Service Kit)

8 — Air Pump Hose (Black)

23_KL_OM_EN_USC_t.book Page 196

Page 199 of 276

IN CASE OF EMERGENCY197

(Continued)

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode

Push in the Mode Select Knob and turn to this

position for air pump operation only. Use the

Black Air Pump Hose when selecting this mode.

Selecting Sealant Mode

Push in the Mode Select Knob and turn to this

position to inject the Tire Service Kit Sealant

and to inflate the tire. Use the Sealant Hose

(clear hose) when selecting this mode.

Using The Power Button

Push and release the Power Button once to

turn on the Tire Service Kit. Push and release

the Power Button again to turn Off the Tire

Service Kit.

Using The Deflation Button

Push the Deflation Button to reduce the air

pressure in the tire if it becomes overinflated.

TIRE SERVICE KIT USAGE PRECAUTIONS

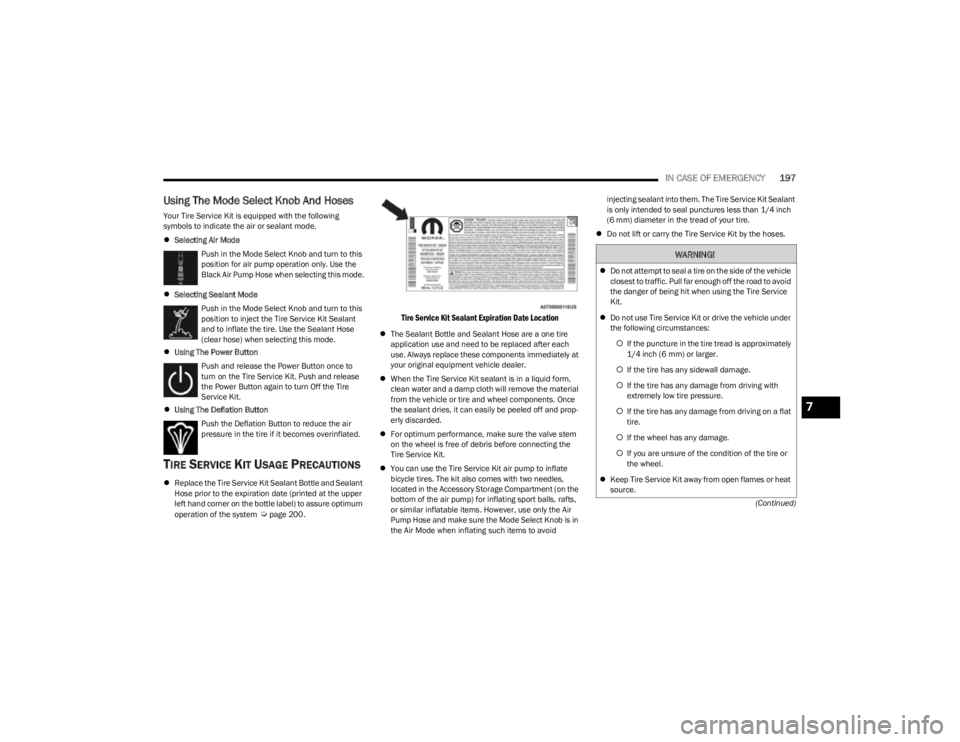

Replace the Tire Service Kit Sealant Bottle and Sealant

Hose prior to the expiration date (printed at the upper

left hand corner on the bottle label) to assure optimum

operation of the system

Úpage 200.

Tire Service Kit Sealant Expiration Date Location

The Sealant Bottle and Sealant Hose are a one tire

application use and need to be replaced after each

use. Always replace these components immediately at

your original equipment vehicle dealer.

When the Tire Service Kit sealant is in a liquid form,

clean water and a damp cloth will remove the material

from the vehicle or tire and wheel components. Once

the sealant dries, it can easily be peeled off and prop -

erly discarded.

For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the

Tire Service Kit.

You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts,

or similar inflatable items. However, use only the Air

Pump Hose and make sure the Mode Select Knob is in

the Air Mode when inflating such items to avoid injecting sealant into them. The Tire Service Kit Sealant

is only intended to seal punctures less than 1/4 inch

(6 mm) diameter in the tread of your tire.

Do not lift or carry the Tire Service Kit by the hoses.

WARNING!

Do not attempt to seal a tire on the side of the vehicle

closest to traffic. Pull far enough off the road to avoid

the danger of being hit when using the Tire Service

Kit.

Do not use Tire Service Kit or drive the vehicle under

the following circumstances:

If the puncture in the tire tread is approximately

1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving with

extremely low tire pressure.

If the tire has any damage from driving on a flat

tire.

If the wheel has any damage.

If you are unsure of the condition of the tire or

the wheel.

Keep Tire Service Kit away from open flames or heat

source.

7

23_KL_OM_EN_USC_t.book Page 197

Page 200 of 276

198IN CASE OF EMERGENCY

SEALING A TIRE WITH TIRE SERVICE KIT

(A) Whenever You Stop To Use Tire Service

Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hoses and to reach the valve stem and keep the Tire Service Kit

flat on the ground. This will provide the best

positioning of the kit when injecting the sealant into

the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this

position before proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmission) and

place the ignition in the OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

5. Uncoil the Power Plug and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

(C) Injecting Tire Service Kit Sealant Into

The Deflated Tire:

Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the parking

brake engaged and the gear selector in NEUTRAL.

After pushing the Power Button, the sealant (white

fluid) will flow from the Sealant Bottle through the

Sealant Hose and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose:

1. Push the Power Button to turn Off the Tire Service

Kit. Disconnect the Sealant Hose from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose to the valve stem.

Check that the Mode Select Knob is in the Sealant

Mode position and not Air Mode. Push the Power

Button to turn On the Tire Service Kit.

2. Connect the Power Plug to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning ON

the Tire Service Kit.

3. The Sealant Bottle may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob is on Air Mode and the pump is

operating, air will dispense from the Air Pump Hose only,

not the Sealant Hose.

A loose Tire Service Kit thrown forward in a collision

or hard stop could endanger the occupants of the

vehicle. Always stow the Tire Service Kit in the place

provided. Failure to follow these warnings can result

in injuries that are serious or fatal to you, your

passengers, and others around you.

Take care not to allow the contents of Tire Service Kit

to come in contact with hair, eyes, or clothing. Tire

Service Kit sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately with plenty of

water if there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any contact

with clothing.

Tire Service Kit Sealant solution contains latex. In

case of an allergic reaction or rash, consult a physi -

cian immediately. Keep Tire Service Kit out of reach

of children. If swallowed, rinse mouth immediately

with plenty of water and drink plenty of water. Do not

induce vomiting! Consult a physician immediately.

WARNING!

23_KL_OM_EN_USC_t.book Page 198

Page 201 of 276

IN CASE OF EMERGENCY199

If the sealant (white fluid) does flow through the Sealant

Hose:

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose, the Pressure Gauge can read as high

as 70 psi (4.8 Bar). The Pressure Gauge will

decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the tire to

the pressure indicated on the tire pressure label on

the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure

Gauge.

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

NOTE:Never operate the compressor for longer than 20 minutes.

Risk of Overheating.

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing. If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Push the Power Button to turn off the Tire Service

Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle and place the sticker on the

instrument panel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location.

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location Úpage 198.

1. Push in the Mode Select Knob and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (black in color) and screw the fitting at the end of hose onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on Tire Service Kit and inflate the tire to the pressure indicated on the

tire and loading information label on the driver-side

door opening.

CAUTION!

The metal end fitting from Power Plug may get hot

after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end of

the Sealant Hose can result in sealant contacting

your skin, clothing, and the vehicle’s interior. It can

also result in sealant contacting internal Tire Service

Kit components which may cause permanent

damage to the kit.

WARNING!

Tire Service Kit is not a permanent flat tire repair. Have

the tire inspected and repaired or replaced after using

Tire Service Kit. Do not exceed 50 mph (80 km/h) until

the tire is repaired or replaced. Failure to follow this

warning can result in injuries that are serious or fatal to

you, your passengers, and others around you.

7

23_KL_OM_EN_USC_t.book Page 199

Page 202 of 276

200IN CASE OF EMERGENCY

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem,

reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

6. Replace the Sealant Bottle and Sealant Hose assembly at an authorized dealer as soon as possible

Úpage 200.

NOTE:When having the tire serviced, advise the authorized

dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand corner of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the button.

4. Clean any remaining sealant from the Tire Service Kit housing. 5. Position the new Sealant Bottle in the housing so that

the Sealant Hose aligns with the hose slot in the front

of the housing. Push and hold the Sealant Bottle

release button, then push the bottle into the housing

by holding the button. An audible click will be heard

indicating the bottle is locked into place. Release the

button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose and return the hose to its storage

area (located on top of the housing).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP STARTING

If your vehicle has a discharged battery, it can be jump

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump starting can be dangerous if done improperly,

so please follow the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow the

manufacturer’s operating instructions and precautions.

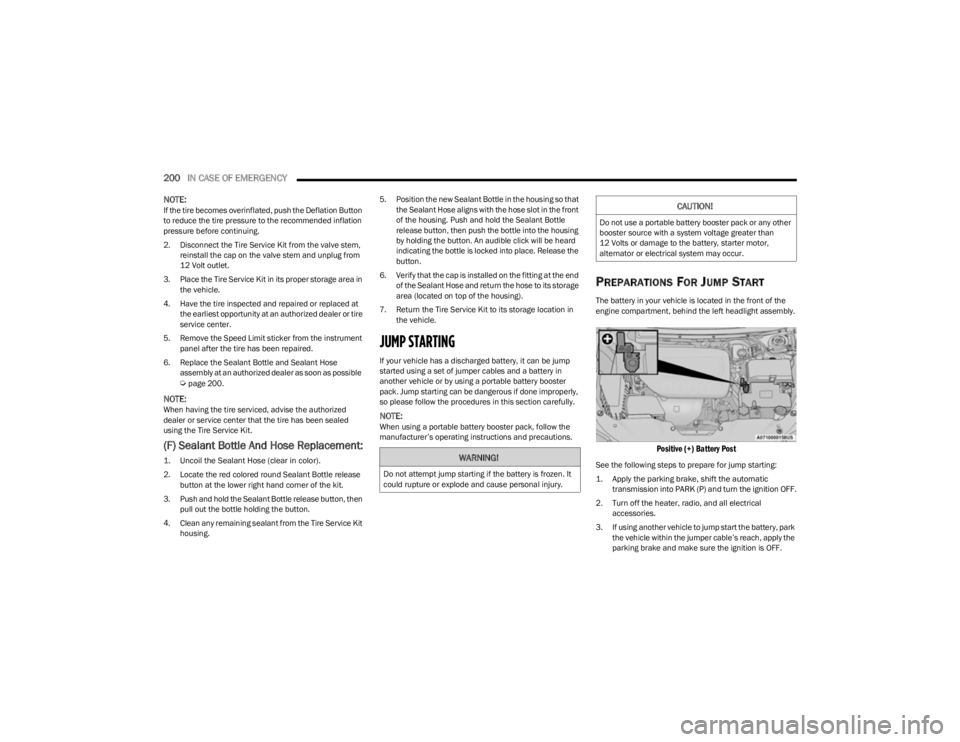

PREPARATIONS FOR JUMP START

The battery in your vehicle is located in the front of the

engine compartment, behind the left headlight assembly.

Positive (+) Battery Post

See the following steps to prepare for jump starting:

1. Apply the parking brake, shift the automatic transmission into PARK (P) and turn the ignition OFF.

2. Turn off the heater, radio, and all electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper cable’s reach, apply the

parking brake and make sure the ignition is OFF.WARNING!

Do not attempt jump starting if the battery is frozen. It

could rupture or explode and cause personal injury.

CAUTION!

Do not use a portable battery booster pack or any other

booster source with a system voltage greater than

12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

23_KL_OM_EN_USC_t.book Page 200

Page 205 of 276

IN CASE OF EMERGENCY203

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be serviced by

an authorized dealer.

Potential signs of vehicle overheating:

Temperature gauge is at HOT (H)

Strong smell of coolant

White smoke coming from engine or exhaust

Coolant bottle coolant has bubbles present

In the event it is observed that the temperature gauge is

moving towards or close to the HOT (H) position, you can

reduce the potential for overheating by taking the

appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the transmission in

NEUTRAL (N), but do not increase the engine idle speed

while preventing vehicle motion with the brakes.

If your Air Conditioner (A/C) is on, turn it off. The A/C

system adds heat to the engine cooling system and

turning the A/C off can help remove this heat.

You can also turn the temperature control to maximum

heat, the mode control to floor and the blower control

to high. This allows the heater core to act as a supple -

ment to the radiator and aids in removing heat from the

engine cooling system.

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector cannot be

moved out of the PARK (P) position, you can use the

following procedure to temporarily move the gear selector:

1. Turn the engine OFF.

2. Apply the parking brake.

3. Using a screwdriver or similar tool, carefully separate the shifter bezel and boot assembly from the center

console, and raise it up to access the gear selector

mechanism.

Shifter Bezel/Boot

4. Press and maintain firm pressure on the brake pedal.

5. Insert a small screwdriver or similar tool down into the gear selector override access hole (at the right

front corner of the gear selector assembly), and push

and hold the override release lever down.

Override Access Hole

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If you

see or hear steam coming from under the hood, do not

open the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap when

the radiator or coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could damage your

vehicle. If the temperature gauge reads “H,” pull over

and stop the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops back into

the normal range. If the pointer remains on the “H” and

you hear continuous chimes, turn the engine off

immediately and call for service.

7

23_KL_OM_EN_USC_t.book Page 203

Page 207 of 276

IN CASE OF EMERGENCY205

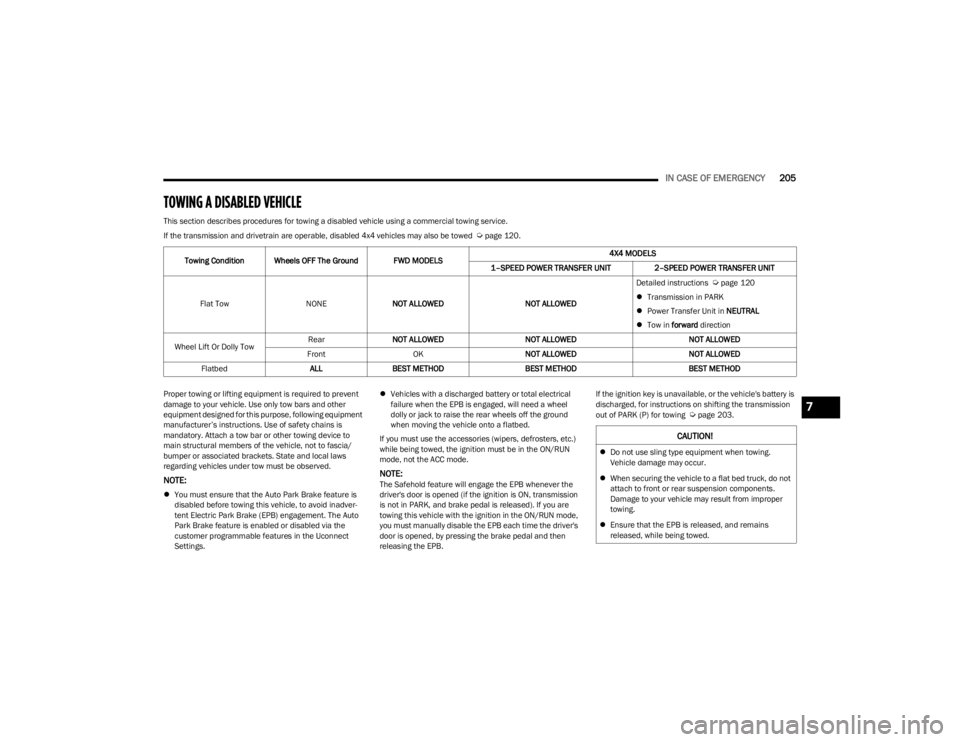

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

If the transmission and drivetrain are operable, disabled 4x4 vehicles may also be towed

Úpage 120.

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equipment

manufacturer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

main structural members of the vehicle, not to fascia/

bumper or associated brackets. State and local laws

regarding vehicles under tow must be observed.

NOTE:

You must ensure that the Auto Park Brake feature is

disabled before towing this vehicle, to avoid inadver -

tent Electric Park Brake (EPB) engagement. The Auto

Park Brake feature is enabled or disabled via the

customer programmable features in the Uconnect

Settings.

Vehicles with a discharged battery or total electrical

failure when the EPB is engaged, will need a wheel

dolly or jack to raise the rear wheels off the ground

when moving the vehicle onto a flatbed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode, not the ACC mode.

NOTE:The Safehold feature will engage the EPB whenever the

driver's door is opened (if the ignition is ON, transmission

is not in PARK, and brake pedal is released). If you are

towing this vehicle with the ignition in the ON/RUN mode,

you must manually disable the EPB each time the driver's

door is opened, by pressing the brake pedal and then

releasing the EPB. If the ignition key is unavailable, or the vehicle's battery is

discharged, for instructions on shifting the transmission

out of PARK (P) for towing

Úpage 203.

Towing Condition Wheels OFF The Ground FWD MODELS

4X4 MODELS

1–SPEED POWER TRANSFER UNIT 2–SPEED POWER TRANSFER UNIT

Flat Tow NONENOT ALLOWED NOT ALLOWEDDetailed instructions

Úpage 120

Transmission in PARK

Power Transfer Unit in NEUTRAL

Tow in forward direction

Wheel Lift Or Dolly Tow Rear

NOT ALLOWED NOT ALLOWED NOT ALLOWED

Front OK NOT ALLOWED NOT ALLOWED

Flatbed ALLBEST METHOD BEST METHOD BEST METHOD

CAUTION!

Do not use sling type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flat bed truck, do not

attach to front or rear suspension components.

Damage to your vehicle may result from improper

towing.

Ensure that the EPB is released, and remains

released, while being towed.

7

23_KL_OM_EN_USC_t.book Page 205

Page 210 of 276

208

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, or extremely hot or cold

ambient temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next 500 miles

(805 km).An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

an authorized dealer, the message can be reset by

referring to the steps described under Instrument Cluster

Display

Úpage 64.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), 12 months or

350 hours of engine run time, whichever comes first. The

350 hours of engine run or idle time is generally only a

concern for fleet customers.

At Every Fuel Stop:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns

on.

Check the fluid levels of the coolant reservoir and

brake master cylinder; fill as needed.

Check function of all interior and exterior lights.

23_KL_OM_EN_USC_t.book Page 208

Page 213 of 276

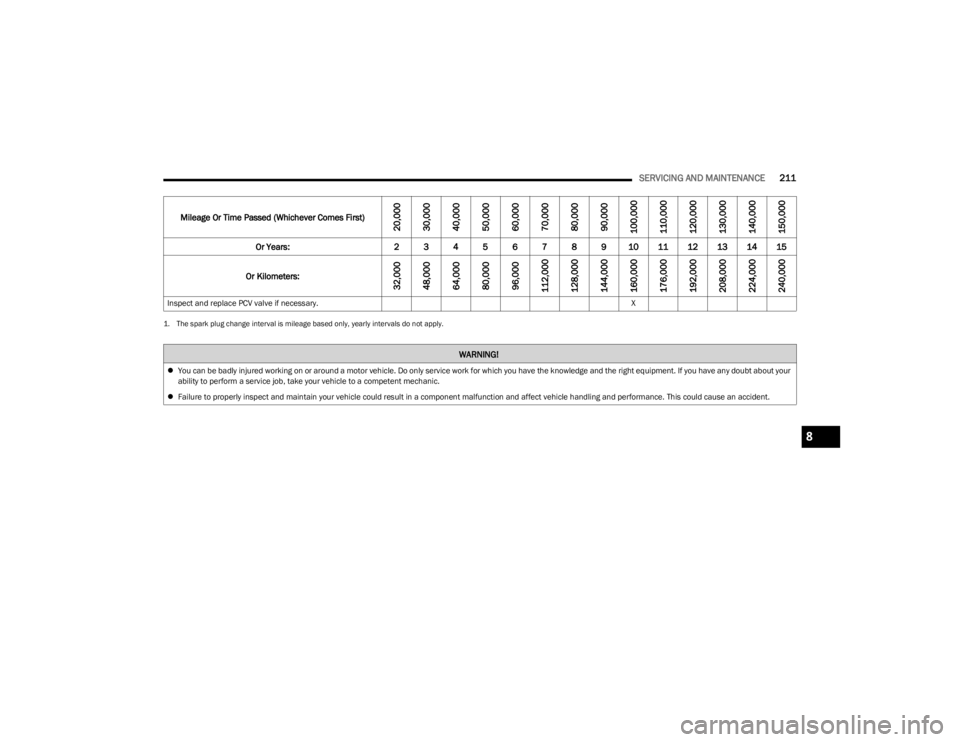

SERVICING AND MAINTENANCE211

Inspect and replace PCV valve if necessary. X

1. The spark plug change interval is mileage based only, yearly intervals do not apply.

Mileage Or Time Passed (Whichever Comes First)20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your

ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.

8

23_KL_OM_EN_USC_t.book Page 211

Page 217 of 276

SERVICING AND MAINTENANCE215

PRESSURE WASHING

Cleaning the engine compartment with a high pressure

washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for your vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control systems may

void your warranty and could result in civil penalties being

assessed against you.

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluid Úpage 256.

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified by the

API. The manufacturer only recommends API trademark

oils.

The API Starburst trademark certifies 0W-20,

0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40 and

5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils, only

use synthetic API approved engine oils.

Synthetic engine oils which do not have both the correct

API trademark and the correct SAE viscosity grade

numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

CAUTION!

It is essential when replacing the cables on the

battery that the positive cable is attached to the posi -

tive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

CAUTION!

Precautions have been taken to safeguard all parts and

connections however, the pressures generated by these

machines is such that complete protection against

water ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or around a motor

vehicle. Only do service work for which you have the

knowledge and the proper equipment. If you have any

doubt about your ability to perform a service job, take

your vehicle to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is

not covered by the New Vehicle Limited Warranty.

8

23_KL_OM_EN_USC_t.book Page 215