engine JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 11 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

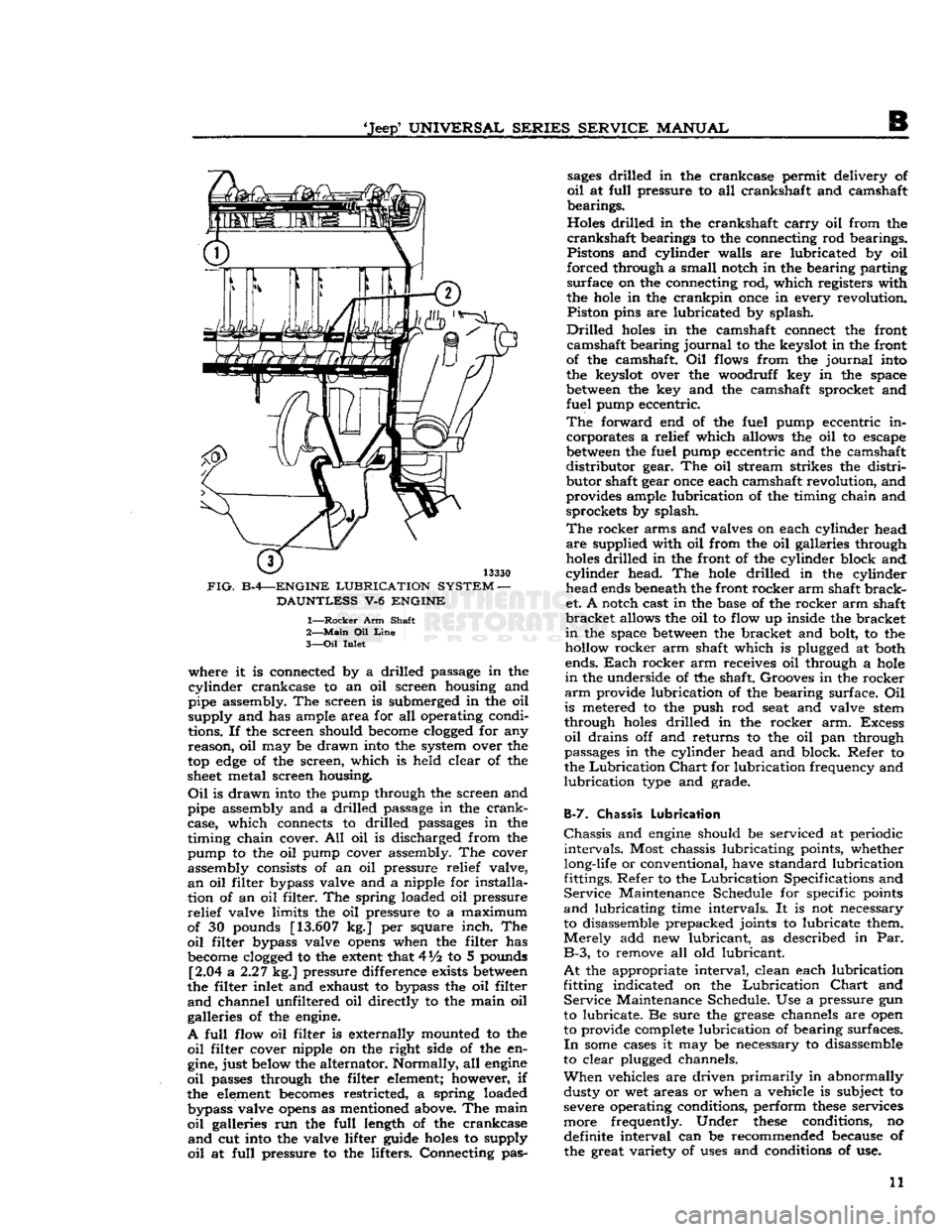

13330

FIG.

B-4—ENGINE

LUBRICATION

SYSTEM

—

DAUNTLESS

V-6

ENGINE

1—

Rocker

Arm Shaft

2—

Main

Oil

Line

3—

Oil

Inlet where it is connected by a drilled passage in the

cylinder

crankcase to an oil screen housing and

pipe assembly. The screen is submerged in the oil supply and has ample area for all operating condi

tions. If the screen should

become

clogged

for any reason, oil may be drawn into the system over the

top

edge

of the screen, which is held clear of the

sheet

metal screen housing.

Oil

is drawn into the pump through the screen and

pipe assembly and a drilled passage in the

crank

case, which connects to drilled passages in the

timing chain cover. All oil is discharged from the

pump to the oil pump cover assembly. The cover

assembly consists of an oil pressure relief valve,

an

oil filter bypass valve and a nipple for installa

tion of an oil filter. The spring loaded oil pressure

relief

valve limits the oil pressure to a maximum

of 30 pounds [13.607 kg.] per square inch. The

oil

filter bypass valve

opens

when the filter has

become

clogged

to the

extent

that

4V2

to 5 pounds [2.04 a 2.27 kg.] pressure difference exists

between

the filter inlet and exhaust to bypass the oil filter

and

channel unfiltered oil directly to the main oil galleries of the engine.

A

full flow oil filter is externally mounted to the

oil

filter cover nipple on the right side of the en gine, just below the alternator. Normally, all

engine

oil

passes through the filter element; however, if

the element

becomes

restricted, a spring loaded bypass valve

opens

as mentioned above. The main

oil

galleries run the full length of the crankcase

and

cut into the valve lifter guide

holes

to supply

oil

at full pressure to the lifters. Connecting pas

sages

drilled in the crankcase permit delivery of

oil

at full pressure to all crankshaft and camshaft

bearings.

Holes drilled in the crankshaft

carry

oil from the

crankshaft

bearings to the connecting rod bearings.

Pistons and cylinder walls are lubricated by oil

forced through a small notch in the bearing parting

surface on the connecting rod, which registers with

the

hole

in the crankpin

once

in every revolution. Piston pins are lubricated by splash.

Drilled

holes

in the camshaft connect the front camshaft bearing

journal

to the key slot in the front

of the camshaft. Oil flows from the

journal

into

the keyslot over the woodruff key in the space

between

the key and the camshaft sprocket and fuel pump eccentric.

The

forward end of the fuel pump eccentric in corporates a relief which allows the oil to escape

between

the fuel pump eccentric and the camshaft

distributor

gear. The oil stream strikes the distri

butor shaft gear

once

each camshaft revolution, and provides ample lubrication of the timing chain and

sprockets by splash.

The

rocker arms and valves on each cylinder head

are

supplied with oil from the oil galleries through

holes

drilled in the front of the cylinder block and

cylinder

head. The

hole

drilled in the cylinder

head ends beneath the front rocker

arm

shaft brack et. A notch cast in the base of the rocker arm shaft

bracket

allows the oil to flow up inside the bracket

in

the space

between

the bracket and bolt, to the

hollow rocker arm shaft which is plugged at both

ends.

Each

rocker arm receives oil through a

hole

in

the underside of the shaft. Grooves in the rocker

arm

provide lubrication of the bearing surface. Oil

is metered to the push rod seat and valve stem

through

holes

drilled in the rocker arm. Excess

oil

drains off and returns to the oil pan through

passages in the cylinder head and block. Refer to

the

Lubrication

Chart

for lubrication frequency and

lubrication

type and grade.

B-7.

Chassis

Lubrication

Chassis

and

engine

should be serviced at periodic

intervals.

Most chassis lubricating points, whether

long-life or conventional, have standard lubrication

fittings. Refer to the

Lubrication

Specifications and

Service

Maintenance Schedule for specific points

and

lubricating time intervals. It is not necessary

to disassemble prepacked joints to lubricate them.

Merely

add new lubricant, as described in Par.

B-3,

to remove all old lubricant.

At

the appropriate interval, clean each lubrication

fitting indicated on the Lubrication

Chart

and

Service

Maintenance Schedule. Use a pressure gun

to lubricate. Be sure the grease channels are open

to provide complete lubrication of bearing surfaces.

In

some

cases it may be necessary to disassemble

to clear plugged channels.

When

vehicles are driven primarily in abnormally dusty or wet areas or when a vehicle is subject to

severe operating conditions, perform

these

services

more frequently. Under

these

conditions, no definite interval can be recommended because of the great variety of

uses

and conditions of use. 11

Page 12 of 376

B

LUBRICATION B-3.

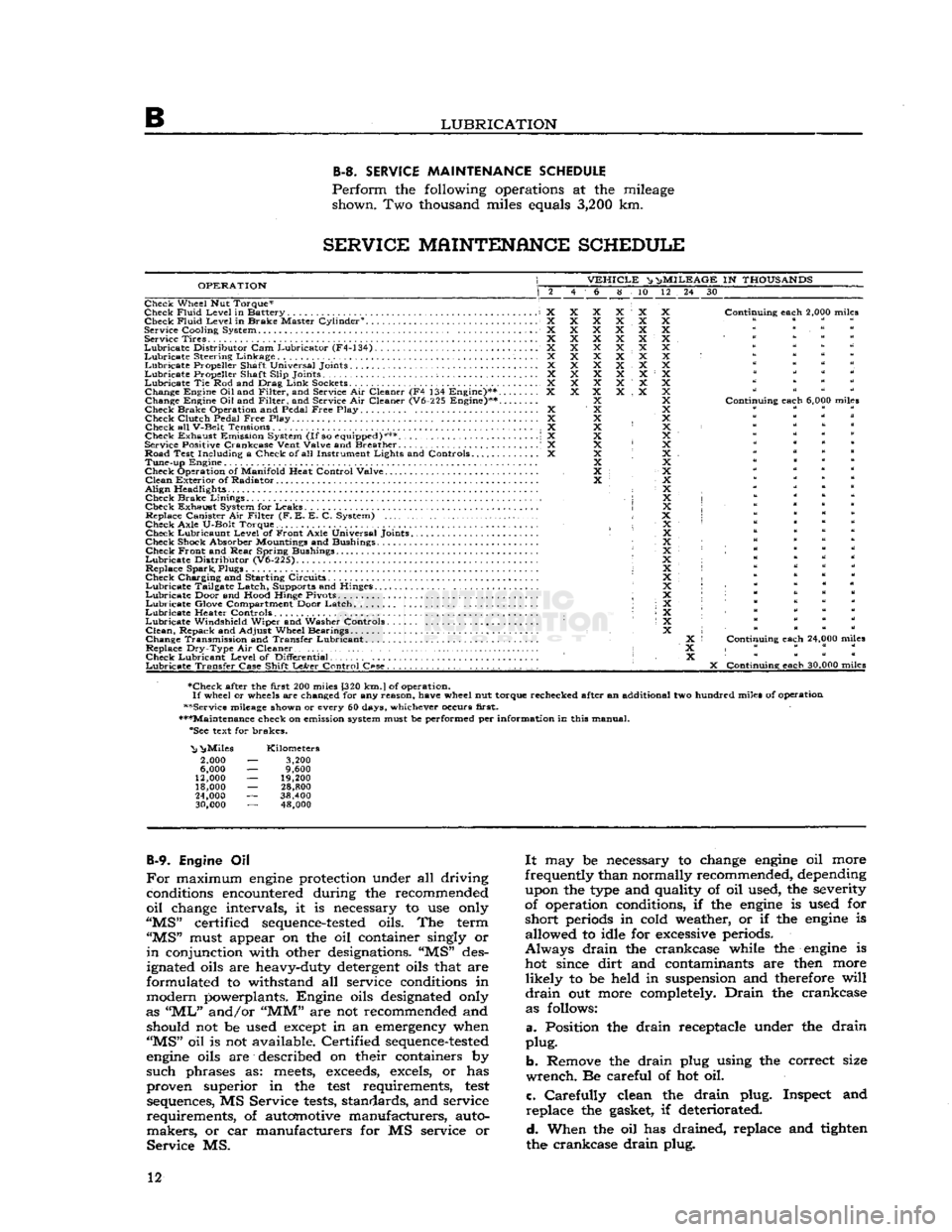

SERVICE

MAINTENANCE

SCHEDULE

Perform

the following operations at the mileage shown. Two thousand miles equals

3,200

km.

SERVICE

MAINTENANCE

SCHEDULE

OPERATION

VEHICLE

^ n>

MILEAGE

IN

THOUSANDS

6 8 10 12 24 30

Check Wheel Nut Torque*

Check

Fluid

Level

in Battery X Check

Fluid

Level

in Brake Master Cylinder0. X

Service

Cooling

System X Service Tires X

Lubricate

Distributor

Cam Lubricator (F4-134) X

Lubricate

Steering Linkage X

Lubricate

Propeller Shaft Universal Joints X

Lubricate

Propeller Shaft

Slip

Joints ; X

Lubricate

Tie Rod and Drag

Link

Sockets................................... X Change Engine

Oil

and

Filter,

and Service Air Cleaner (F4 134 Engine)** X

Change Engine Oil and

Filter,

and Service Air Cleaner (V6-225 Engine)**....

Check Brake Operation and Pedal

Free

Play X Check

Clutch

Pedal

Free

Play. .... X

Check all

V-Belt

Tensions X

Check Exhaust Emission System

(If

so equipped)*** \ X

Service Positive

Crankcase

Vent

Valve

and Breather . .' X

Road Test

Including

a Check of all Instrument

Lights

and Controls X Tune-up Engine

Check Operation of

Manifold

Heat

Control

Valve

Clean

Exterior of Radiator

Align

Headlights • Check Brake

Linings

,

Check Exhaust System for Leaks Replace Canister Air

Filter

(F. E. E. C. System)

Check

Axle

U-Bolt

Torque. Check Lubricaunt

Level

of Front

Axle

Universal Joints

Check Shock Absorber Mountings and Bushings Check Front and

Rear

Spring Bushings

Lubricate

Distributor

(V6-225).

Replace Spark, Plugs

Check Charging and Starting Circuits

Lubricate

Tailgate Latch, Supports and Hinges.

Lubricate

Door and

Hood

Hinge Pivots ;

Lubricate

Glove Compartment Door Latch

Lubricate

Heater Controls •

Lubricate

Windshield

Wiper and Washer Controls

Clean,

Repack and

Adjust

Wheel Bearings

Change Transmission and Transfer Lubricant. .

Replace

Dry-Type

Air Cleaner • Check Lubricant

Level

of

Differential

Lubricate

Transfer

Case

Shift

LeArer

Control

C«se.

. , . . . . . . . .

Continuing

each

2,000 miles

Continuing

each

6,000 miles

Continuing

each

24,000 miles

X

Continuing

each

30,000 miles

•Check after the

first

200 miles [320

km.

J

of operation.

If

wheel or wheels are changed for any

reason,

have

wheel nut torque rechecked after an additional two hundred miles of operation

••Service mileage shown or every 60 days, whichever occurs

first.

•••Maintenance check on emission system must be performed per

information

in this manual. "See text for brakes.

"Nj

^Miles

2,000

6,000

12,000

18,000

24,000

30,000

Kilometers

3,200

9,600

19,200

28,800

38,400 48,000

B-9.

Engine Oil

For

maximum

engine

protection under all driving conditions encountered during the recommended

oil

change intervals, it is necessary to use only

"MS"

certified

sequence-tested

oils. The term

"MS"

must appear on the oil container singly or

in

conjunction with other designations. "MS" des

ignated oils are heavy-duty detergent oils that are

formulated to withstand all service conditions in

modern powerplants. Engine oils designated only

as

"ML"

and/or

"MM"

are not recommended and should not be used except in an emergency when

"MS"

oil is not available. Certified

sequence-tested

engine

oils are described on their containers by

such

phrases as:

meets,

exceeds,

excels, or has

proven superior in the

test

requirements,

test

sequences, MS Service

tests,

standards, and service

requirements,

of automotive manufacturers, auto

makers,

or car manufacturers for MS service or

Service

MS.

It

may be necessary to change

engine

oil more

frequently than normally recommended, depending upon the type and quality of oil used, the severity

of operation conditions, if the

engine

is used for

short

periods in cold weather, or if the

engine

is allowed to idle for excessive periods.

Always

drain

the crankcase while the

engine

is hot since

dirt

and contaminants are then more

likely

to be held in suspension and therefore

will

drain

out more completely.

Drain

the crankcase as follows:

a.

Position the

drain

receptacle under the

drain

plug.

b.

Remove the

drain

plug using the correct size

wrench.

Be careful of hot oil.

c.

Carefully

clean the

drain

plug. Inspect and

replace

the gasket, if deteriorated.

d.

When the oil has drained, replace and tighten

the crankcase

drain

plug. 12

Page 13 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

B

e.

Check

for the presence of

excess

water in the

oil

that might indicate an internal leak from the

cooling system.

f.

Pour oil into the oil filler tube. Replace the oil

filler

cap.

B-10.

Engine Oil

Filter

Service —

Hurricane

F4 Engine

The

engine

oil filter assembly should be replaced at each

2000

miles

[3.200

km.] of normal

engine

use. To remove the filter, use oil filter wrench

C-4065.

To install a new filter, wipe the gasket —

contact surface with

engine

oil, screw on the unit

until

gasket contacts the sealing surface, and then tighten at least one

half

turn

more. DO NOT USE

TOOLS.

Turn

by hand only. When refilling the

engine

crankcase after filter has been changed be

sure

to add one extra quart [1 ltr.] of oil to

fill

filter

and oil passages. Run

engine

to make sure there is no leak at oil filter.

B-l 1.

Engine Oil

Filter

Service — Dauntless V-6 Engine

To

replace the oil filter, use oil filter wrench, Tool

C-4065,

to remove the filter. After the filter has

been removed from the oil pump housing located

on the right front side of the engine, wipe the

housing surface clean and oil the gasket on the base of the new filter to make a

good

seal. Screw

the new filter in position until its gasket contacts

the pump housing surface, then tighten at least

one-half

turn

until filter fits snug.

Note:

Tighten by hand only, do not use a tool to

tighten.

Replace

oil filter each

6000

miles

[9.600

km.] at

engine

oil change.

B-12.

Exhaust

Manifold

Heat

Control

Valve

— Dauntless V-6 Engine

A

thermally-actuated heat control valve is located at

rear

of the right exhaust manifold of the Daunt

less

V-6 engine.

This

valve has a bimetal thermo

static spring which holds the valve closed when

the

engine

is cold.

Each

time the vehicle is lubricated place a few drops of penetrating oil on the valve shaft bushings

and

then work the valve by hand making sure that

the lubricant is worked into the bushings.

Note:

If the valve shaft

does

not operate freely

penetrating oil should be used to free the shaft.

B-l 3.

Positive

Crankcase

Ventilation

System

Service

the ventilation system of the

engine

each

multiple of

6000

miles

[9.600

km.] on the odometer

after

initial

2000

miles

[3.200

km.] service. Re

place the ventilation valve each

12,000

miles

[19.200

km.].

For

information on servicing the positive crankcase

ventilation system on the

Hurricane

F4

engine

and

the Dauntless V-6 engine, refer to the Tune-up Section.

B-l4.

Distributor

— Hurricane F4 Engine

The

distributor shaft is lubricated through an oiler mounted on the side of the housing. Place three or four drops of light

engine

oil in the oiler each

2,000

miles

[3.200

km.]. Also place one drop of light

engine

oil on the wick located on the top of the

shaft, which is made accessible by removing the

rotor

arm. Sparingly apply cam lubricant to the

breaker

arm cam and place a drop of oil on the

breaker

arm pivot.

B-l

5.

Distributor

— Dauntless V-6 Engine

The

distributor has a lubricant reservoir that

car

ries

sufficient

lubricant

for the life of the distributor.

When

servicing breaker points, place one drop of

light

engine

oil on the wick located on the top of the shaft Also, apply cam lubricant sparingly to

the breaker arm cam, and place a drop of oil on the

breaker

arm pivot.

B-l6.

Generator

On

early production vehicles oilers are provided

at each end of the generator, for lubrication

pur

pose.

On late production vehicles one oiler is pro

vided at the

rear

(bushing end) of the generator for lubrication purpose. Place two to four drops of

light

engine

oil in each oiler every

2,000

miles

[3.200

km.].

B-l

7. Spark Plugs

Replace

spark

plugs. Refer to Section C.

B-18.

Starting

Circuit

Check

the starting

circuit.

Refer to Section H.

B-l

9. Charging

Circuit

Check

the charging

circuit.

Refer to Section H.

B-20.

Engine Tune-Up

Refer

to Section C of this manual.

B-21.

Adjust

Fan

Belt

Refer

to Section C.

B-22.

Exhaust Emission

Control

System or

Controlled

Combustion System

•

Refer to the appropriate section in this manual.

B-23.

Exhaust System

Check

the exhaust system for leaks. Refer to Section F.

B-24.

Fuel Evaporative Emission

Control

Canister Air

Filter

The

only service required for the

F.E.E.C.

system

is cleaning the air cleaner filter mounted at the

bottom

of the canister. The filter requires replace

ment at

12,000

mile intervals. Refer to Section

E,

Par. E-9 for service procedure.

B-25.

Oil Bath Air Cleaner

Some 'Jeep' Universal vehicles are equipped with

an

oil bath type air cleaner.

This

type air cleaner

thoroughly removes all dust from the air before it enters the carburetor, if it is properly serviced.

When

the vehicle is operated under normal condi

tions the air cleaner must be serviced at regular

intervals

as care of the air cleaner is extremely 13

Page 14 of 376

LUBRICATION

vital

to the life of the

engine.

When the vehicle

is operated under abnormal conditions, (for ex

ample when driven on secondary roads or through

fields) then service of the air cleaner must be more frequent

Note:

Under extreme continually dusty and dirty

conditions where the vehicle operates in clouds of dust and

dirt,

service the air cleaner daily.

a.

To service the air cleaner on vehicles equipped

with the

Hurricane

F4

engine

(Fig. B-5) unscrew

the eye

bolt

on the oil cup clamp and remove the

oil

cup from the cleaner body. Remove the oil from the cup and scrape all

dirt

from the inside, wash cup clean using a cleaning solution if neces

sary.

In summer

refill

the oil cup with IV2 pints [0,6 ltrs.] of

SAE-40

or 50 grade

engine

oil. In

winter

refill

using grade

SAE-20

engine

oil. For

servicing the air cleaner

body

(less

oil cup),

loosen

hose

clamp and remove

hose

from the cleaner. Detach breather

hose

from the fitting on the cleaner. Remove the two wing screws and lift the

cleaner from the vehicle. Agitate the cleaner

body

thoroughly in cleaning solution to clean the filtering

element.

Dry

element

with low pressure com pressed air. Reinstall the cleaner

body

and replace

the oil cup. Service the air cleaner every

2000

miles

[3.200

km.].

b. To service the oil bath air cleaner on vehicle

equipped with the Dauntless V-6

engine

(Fig. B-6),

first

remove the air cleaner from the carburetor

by unscrewing the wing nut. Remove the oil cup

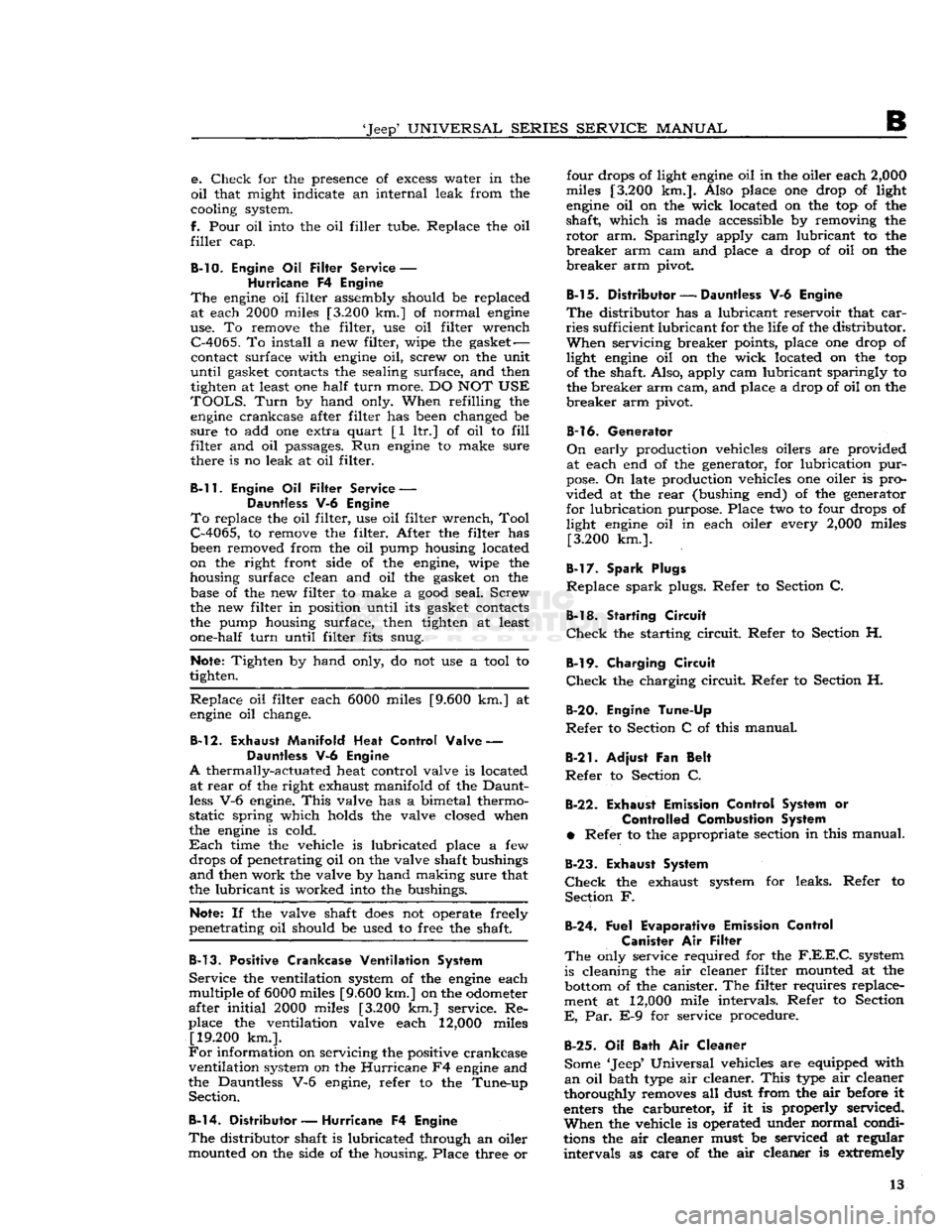

FIG.

B-5—OIL

BATH AIR

CLEANER

-

HURRICANE F4 ENGINE 1—

Horn

7—Clamp

2—

Flexible

Connector

8—Oil

Cup

3—

Hon

Clamp

9—Clamp

A—Carburetor

Vent Tube 10—Hose 5— Body 11—Clamp

6—

Screw

and

Lock

Washer 13—Gasket

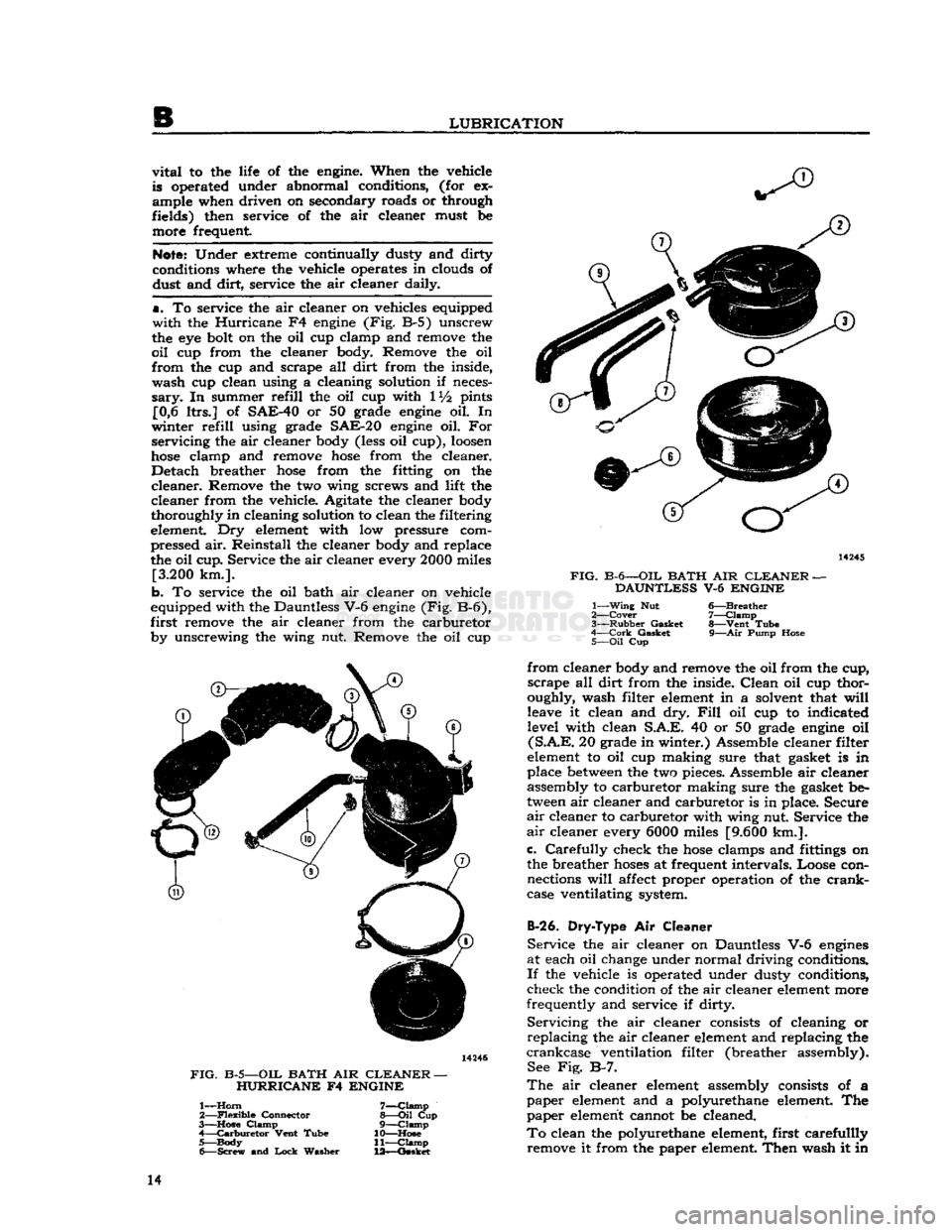

FIG.

B-6—OIL BATH AIR

CLEANER

-

DAUNTLESS V-6 ENGINE

1—WinB

Nut

2—

Cover

3—

Rubber

Gasket

4—

Cork

Gasket

5—

Oil

Cup 6—

Breather

7—

Clamp

8—

Vent

Tube 9—

Air

Pump Hose from cleaner

body

and remove the oil from the cup,

scrape all

dirt

from the inside.

Clean

oil cup thor

oughly, wash filter

element

in a solvent that

will

leave it clean and dry.

Fill

oil cup to indicated

level with clean

S.A.E.

40 or 50 grade

engine

oil

(S.A.E.

20 grade in winter.) Assemble cleaner filter

element

to oil cup making sure that gasket is in

place

between

the two pieces. Assemble air cleaner assembly to carburetor making sure the gasket

be

tween

air cleaner and carburetor is in place. Secure

air

cleaner to carburetor with wing nut. Service the

air

cleaner every

6000

miles

[9.600

km.],

c.

Carefully

check the

hose

clamps and

fittings

on

the breather

hoses

at frequent intervals. Loose connections

will

affect proper operation of the

crank

case ventilating system.

B-26. Dry-Type

Air Cleaner Service the air cleaner on Dauntless V-6

engines

at each oil change under normal driving conditions.

If

the vehicle is operated under dusty conditions,

check the condition of the air cleaner

element

more

frequently and service if dirty.

Servicing

the air cleaner consists of cleaning or replacing the air cleaner

element

and replacing the

crankcase

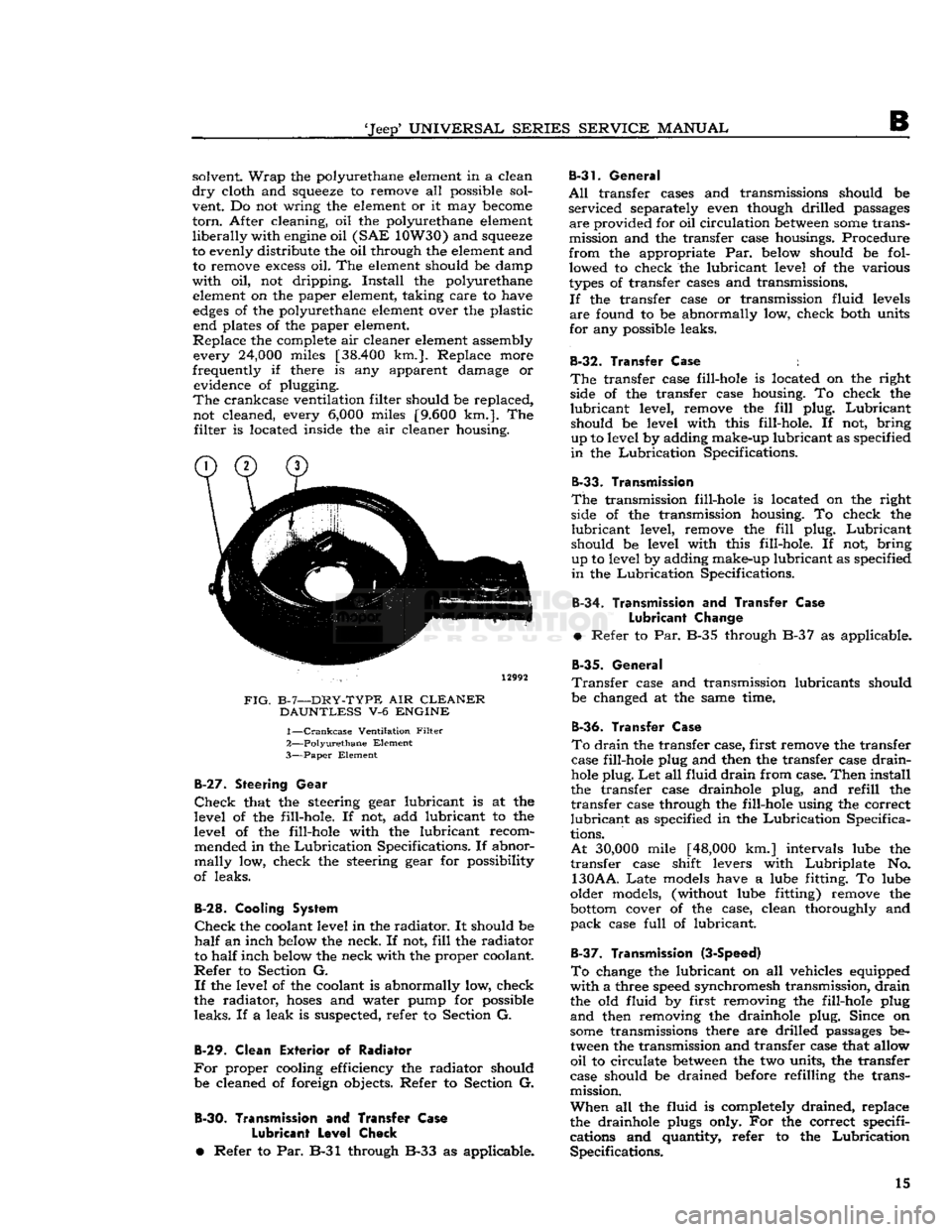

ventilation filter (breather assembly). See Fig. B-7.

The

air cleaner

element

assembly consists of a

paper

element

and a polyurethane

element

The

paper

element

cannot be cleaned.

To

clean the polyurethane

element,

first carefullly remove it from the paper

element

Then

wash it in 14

Page 15 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

B

solvent.

Wrap

the polyurethane element in a clean

dry

cloth and

squeeze

to remove all possible sol

vent. Do not wring the element or it may

become

torn.

After cleaning, oil the polyurethane element

liberally

with

engine

oil

(SAE

10W30) and

squeeze

to evenly distribute the oil through the element and to remove

excess

oil. The element should be damp

with

oil, not dripping.

Install

the polyurethane element on the paper element, taking care to have

edges

of the polyurethane element over the plastic end plates of the paper element.

Replace

the complete air cleaner element assembly every

24,000

miles

[38.400

km.]. Replace more

frequently if there is any apparent damage or evidence of plugging.

The

crankcase ventilation filter should be replaced, not cleaned, every

6,000

miles

[9.600

km.]. The

filter

is located inside the air cleaner housing.

12992

FIG.

B-7—DRY-TYPE

AIR

CLEANER DAUNTLESS

V-6

ENGINE

1—

Crankcase

Ventilation

Filter

2—

Polyurethane

Element

3—

Paper

Element

B-27.

Steering

Gear

Check

that the steering gear lubricant is at the

level of the fill-hole. If not, add lubricant to the

level of the fill-hole with the lubricant recom mended in the

Lubrication

Specifications. If abnor

mally

low, check the steering gear for possibility

of leaks.

B-28.

Cooling System

Check

the coolant level in the

radiator.

It should be

half

an inch below the neck. If not,

fill

the radiator

to

half

inch below the neck with the proper coolant.

Refer

to Section G.

If

the level of the coolant is abnormally low, check

the radiator,

hoses

and water pump for possible

leaks.

If a leak is suspected, refer to Section G.

B-29.

Clean

Exterior

of Radiator

For

proper cooling efficiency the radiator should be cleaned of foreign objects. Refer to Section G.

B-30.

Transmission

and

Transfer Case

Lubricant

Level

Cheek

•

Refer to Par. B-31 through B-33 as applicable.

B-31.

General

All

transfer cases and transmissions should be

serviced

separately even though drilled passages

are

provided for oil circulation

between

some

trans

mission and the transfer case housings. Procedure

from

the appropriate Par. below should be fol lowed to check the lubricant level of the various

types

of transfer cases and transmissions.

If

the transfer case or transmission fluid levels

are

found to be abnormally low, check both units

for any possible leaks.

B-32.

Transfer

Case

:

The

transfer case fill-hole is located on the right side of the transfer case housing. To check the

lubricant

level, remove the

fill

plug.

Lubricant

should be level with this fill-hole. If not, bring up to level by adding make-up lubricant as specified

in

the

Lubrication

Specifications.

B-33.

Transmission

The

transmission fill-hole is located on the right side of the transmission housing. To check the

lubricant

level, remove the

fill

plug.

Lubricant

should be level with this fill-hole. If not, bring

up to level by adding make-up

lubricant

as specified

in

the

Lubrication

Specifications.

B-34.

Transmission and Transfer

Case

Lubricant

Change

•

Refer to Par. B-35 through B-37 as applicable.

B-35.

General

Transfer

case and transmission lubricants should

be changed at the same time.

B-36.

Transfer

Case

To

drain

the transfer case, first remove the transfer

case fill-hole plug and then the transfer case

drain-

hole

plug. Let all fluid

drain

from case.

Then

install

the transfer case drainhole plug, and

refill

the

transfer

case through the fill-hole using the correct

lubricant

as specified in the

Lubrication

Specifica

tions.

At

30,000

mile

[48,000

km.] intervals lube the

transfer

case shift levers with

Lubriplate

No.

130AA.

Late

models have a lube fitting. To lube

older models, (without lube fitting) remove the

bottom

cover of the case, clean thoroughly and

pack

case

full

of lubricant.

B-37.

Transmission (3-Speed)

To

change the lubricant on all vehicles equipped

with

a three speed synchromesh transmission,

drain

the old fluid by first removing the fill-hole plug

and

then removing the drainhole plug. Since on

some

transmissions there are drilled passages be tween the transmission and transfer case that allow

oil

to circulate

between

the two units, the transfer

case should be drained before refilling the trans

mission.

When

all the fluid is completely drained, replace

the drainhole plugs only. For the correct specifi

cations and quantity, refer to the

Lubrication

Specifications. 15

Page 16 of 376

B

LUBRICATION

Note:

Hard

shifting of the transmission gear in

cold weather is a positive indication that the

lubri

cant

is of the wrong viscosity or of poor quality

which

allows it to congeal.

B-38.

Optional

4-Speed

Transmission

and

Transfer Case

The

four-speed transmission and transfer case re

quire

separate lubrication for each unit as

they

have no cross-over oil passage. At each transmission

service check, the

fill

plugs of

both

four-speed

transmission

and transfer case should be pulled

and

the lubricant refilled to level if necessary.

B-39.

Transfer

Case

Linkage

The

transfer case shift linkage should be lubricated

periodically.

All

bearing surfaces that are assembled

with

studs and cotter pins should be disassembled, cleaned, and coated with a

good

waterproof grease.

The

bearing surfaces that cannot be disassembled

should be lubricated with a lubricant that

will

penetrate the bearing

area.

These bearings include

the two on the cross shaft assembly and the

threaded stud.

The

type

of penetrating lubricant recommended is

DuPont

"PM 7", No. 2911, or its equivalent.

B-40.

Brake Master Cylinder

Clean

the top of the

fill

cap and also the housing

area

around it. Remove the cap and observe the

fluid

level. It should be

half

an inch

below

the top

of the fill-hole. If not, add brake fluid to

half

inch

[1,3 cm.]

below

the top of the fill-hole. Use

only heavy-duty brake fluid conforming to speci

fication

SAE-J-1703.

Be sure to handle the brake

fluid

in clean dispensers and containers that

will

not introduce even the

slightest

amount of other

liquids

or foreign particles. Replace and tighten

the

fill

cap.

B-41.

Adjust Brakes

Refer

to Section P.

B-42.

Brake Linings

Refer

to Section P.

B-43.

Adjust Clutch

Refer

to Section I.

B-44.

Clutch Cross Shaft (Lever Type)

Lubricate

the clutch cross shaft in accordance with

specifications given in the

Lubrication

chart: see

Item

1. Chassis Bearings.

B-45.

Tie Rod and Drag

Link

Sockets

The

tie rod and drag

link

sockets

are equipped

with

lubrication

fittings

and should be lubricated

per

specifications given in the

Lubrication

chart: see Item 1. Chassis Bearings.

B-46.

Front

and

Rear Spring

Bushings

The

condition of the spring bushings is indicated

by the alignment of the spring pivot and spring

shackle

bolts.

Check

the alignment of

these

bolts,

and

check that nuts are

tightened

securely.

B-47.

Spring

Shackles

Rubber

bushings are provided on the spring

shackles.

These rubber bushings have no lubrication

fitting and it is very important that

they

never be lubricated.

B-48.

Shock Absorbers

Visually

check for broken mounts or bolts, worn

or

missing bushings on the shock absorbers. Refer

to Section S.

B-49.

Front and

Rear

Axle

U-Bolts

Torque

the front and

rear

axle U-bolts. Refer to Section S.

B-50. Front

and

Rear

Axle

Differentials

—

Lubricant Levels

The

lubricant

level of all front and

rear

differentials should be at the level of the fill-hole.

B-51.

Front and

Rear

Axle

Differentials

—

Changing

Lubricant

B-52.

Conventional Differentials

To

remove the lubricant from the front or

rear

differential,

it is necessary to remove the housing cover. Let the lubricant

drain

out, and then flush

the differential with a flushing oil or light

engine

oil

to clean out the housing

(except

Powr-Lok

or

Trac-Lok

Differentials). Do not use water, steam,

kerosene, or

gasoline

for flushing.

Reinstall

the housing cover, replacing the gasket whenever necessary, torquing the cover

bolts

to 15 to 25 lb-ft. [2,1 a 3,4 kg-m.].

Remove the filler plug, and

refill

the differential

housing as specified in the

Lubrication

Specifica

tions.

B-53.

Powr-Lok

or

Trac-Lok Differential

Some vehicles may be equipped with the

Powr-Lok

or

Trac-Lok

Differential as optional equipment.

Special

lubricant and ordinary multipurpose gear

lubricants

must

not be used. Use only

'Jeep*

Differ

ential

Oil,

Part

No. 94557.

Powr-Lok

or

Trac-Lok

differentials may be cleaned

only by disassembling the unit and wiping with

clean

rags. Do not flush the unit. Refer to Sec

tion N.

B-54.

Front Axle Universal Joint

—

Lube

Check

the level of the front axle universal joint

lubricant

at each front wheel by removing the

fill-hole plug. The lubricant should be level with

the fill-hole. If required, add lubricant as specified

in

Lubrication

Specifications.

B-55.

Front

Axle

Universal

Joint

— Service

On

all 4-wheel drive vehicles the front axle

uni

versal

joint should be serviced by removing the shaft and thoroughly cleaning the universal joints

and

housing. For the correct procedures, refer to

Section M. 16

Page 17 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

B

Reinstall

the axle shafts, and

refill

the housings to

plug level using the universal joint lubricant

specified in

Lubrication

Specifications.

B-56.

Front

Axle Wheel Bearings

To

lubricate the wheel bearings, it is necessary

to remove, clean, repack, and adjust them. When

front wheel hubs and bearings are removed for

lubrication,

they should be thoroughly washed in a

suitable cleaning solvent. The bearings should be

carefully

dried and then given a thorough cleaning

and

inspection. Use a clean brush to remove all

particles

of old lubricant from bearings and hubs.

After

the bearings are cleaned, inspect them for

pitted races and rollers. Also, check the hub oil

seals.

Note:

Wheel bearing lithium base lubricants are

used at the factory for

initial

fill

of

these

bearings.

When

lithium base and sodium base lubricants are

mixed,

the result is a thinned-out mixture that

can

bleed through seals. It is therefore important

that lubricants with the correct base be used when

lubricating

the wheel bearings.

Should

leaks occur at wheel bearing seals, the leaks

may

be caused by a mixture of two

types

of

lubri

cants.

In such cases, the old lubricant should be

completely removed before new lubricant is added.

Wheel

bearings should be thoroughly cleaned,

lubricated

with lithium base and reinstalled.

Repack

the bearing

cones

and rollers with grease

and

reassemble hub in the reverse order of the

disassembly. Test the bearing adjustment as out

lined

in Section Q.

B-57.

Rear

Axle Wheel Bearings

The

Rear

wheel bearings an early models equipped

with

lubrication fittings with a vent opening

through the housings above each fitting should be

lubricated

sparingly, each

2,000

miles

[3.200

km.].

Use

a hand compressor and wheel bearing grease,

forcing

the grease through each lubrication fitting

until

it flows from the vent. Vent should be kept

clear

of obstruction or grease

will

back up into the

brakes.

Do not add grease after it flows from the

vent for it may be forced through the wheel key-

way

onto

the outside of the wheel and possibly

onto

the brake linings.

Rear

wheel bearings that do

not have lubrication fittings should be removed

each

12,000

miles

[19.200

km.] and the bearing

cleaned, inspected and repacked. Refer to proce

dure

in Par. B-56.

Note:

When servicing the Flanged Axle Unit

Bear

ing Assembly, refer to Section N, Par. N-5 for

proper

lubrication procedures.

B-58.

Propeller Shafts

and

Universal Joints

The

propeller shaft slip joints and universals should

be lubricated with a hand compressor grease gun so as to not damage the bearing seals. The units

should be lubricated with a

good

quality grease.

Refer

to the

Lubrication

Chart

for lubrication fre

quency and lubricant type and grade. B-59.

Lights

and

Controls

a.

Check

all interior and exterior lights and light

switches for proper operation, including: parking

lights, headlamps (high beam and low beam),

tail

lights, brake lights, directional lights, and in strument panel lights.

b.

Check

all instrument panel controls and

instru

ments for proper operation.

B-60.

Speedometer Cable

Remove the

speedometer

cable from its housing every

12,000

miles

[19.300

km.].

Clean

it thor

oughly and coat it with a

good

quality light graphite grease.

B-61.

Headlights

Refer

to Section H.

B-62.

Heater Controls

Apply

Lubriplate

130-A to all friction points and

pivot points on the heater controls panel unit as well as the pivot points at the dashpot. Apply

a

few drops of penetrating oil all along the Bowden

cable.

This

oil

will

penetrate into the center wire.

B-63.

Windshield Wiper and

Washer Controls

Lubricate

the friction points and the pivot points

on the windshield wiper transmission and linkage

arms

with a slight amount of

Lubriplate

130-A.

B-64.

Rotate Tires

Refer

to Section Q for the correct method of rotat ing the tires.

B-65.

Body Lube Points

•

Refer to Par. B-66 through B-68.

B-66.

Hood Hinge Pivot Points

Lubricate

the frictional points of the hood hinge

pivot points with a few drops of light-weight

engine

oil.

B-67.

Glove Compartment Door Latch

Sparingly

wipe

Lubriplate

130-A on the

glove

com

partment door latch.

B-68.

Tailgate Hinges

Lubricate

the friction points of the tailgate hinges

with

a few drops of light-weight

engine

oil.

B-69.

LUBRICATION

OF

OPTIONAL EQUIPMENT

B-70.

Pintle Hook

When

lubricating the vehicle, place a few drops of oil on the pintle hook and safety latch pivot pins.

B-7!.

Centrifugal Governor

Check

the oil level in the governor housing at each

vehicle lubrication. Use the same seasonal grade

oil

as is used in the

engine

and change oil at each

engine

oil change. Do not

fill

the housing above

the level indicating plug opening. Keep the vent

in

the filler plug open at all times. 17

Page 18 of 376

B

LUBRICATION

B-72.

Powr-Lok

or Trac-Lok

Differential

Refer

to Par. B-53.

B-73.

PARTS

REQUIRING

NO

LUBRICATION

B-74.

Water Pump Bearing,

Clutch

Release

Bearing

The

water pump and clutch release bearings are

prelubricated

for life when manufactured and cannot be relubricated.

B-7S.

Starter

Motor

Bearings

The

starting motor bearings are lubricated at assembly to last

between

normal rebuild periods.

B-76.

Alternator Bearings

The

alternator bearings are lubricated at assembly

and

require no further lubrication.

B-77.

Springs

The

vehicle springs should not be lubricated. At assembly the leaves are coated with a long-lasting

special

lubricant which is designed to last the life

of the springs. Spraying with the usual mixture of

oil

and kerosene has a tendency to wash this

lubri

cant

from

between

the leaves, making it necessary

to relubricate

often

to eliminate squeaking.

B-78.

Shock Absorbers

Hydraulic

direct-action shock absorbers are per manently sealed and require no periodic

lubrica

tion service. Shock absorber mounting bushings

are

not to be lubricated.

B-79.

LUBRICATION

REQUIREMENTS

FOR

OFF-HIGHWAY

OPERATION

Adequate lubrication

becomes

increasingly im portant when vehicles are used in off-highway

operation. Under

these

conditions all operating

parts

of both the

engine

and chassis are subjected

to unusual pressures. At the same time such operation is usually under abnormal dust and

dirt

conditions making additional precautions neces

sary.

The importance of correct lubrication for

the conditions of operation cannot be overestimated.

B-80.

Engine

Oil

It

is important, that the oil in a new or rebuilt

engine

be changed after the first

eight

or ten hours

of operation, and for heavy, dusty work, every 50

hours

thereafter. Watch the condition of the oil closely and change it immediately if it appears to

be contaminated.

i-Il.

Engine

Oil

Filter

Replace

the oil filter at the end of the first 100

hours

of service. Under extreme operating con ditions, more frequent replacement may be re

quired.

The condition of the oil is a reliable

indicator

of the condition of the filter element.

If

the oil

becomes

discolored and shows evidence

of contamination, change the filter without delay.

(Refer

to

Par.

B-10, B-ll for the correct procedure

for replacing the oil filter.)

B-82.

Air Cleaner

Care

of the air cleaner is extremely vital to the life of the engine. Pay particular attention to the

amount of dust and

dirt

in the air taken into the

engine

through the air cleaner. When dust is not

noticeable in the air, service the air cleaner each scheduled maintenance period. Whenever the air is

noticeably dusty (for example when the vehicle is

driven

on secondary roads or through fields) then

service the air cleaner more frequently. Under extreme continually dusty and dirty conditions

where the vehicle operates in clouds of dust and

dirt,

service the air cleaner daily. (Refer to Par.

B-24

thru

B-26 for service procedures.)

B-83.

Chassis

Lubrication

The

period of lubrication depends entirely upon the type of work being done. Using the specified

interval

given in the Service Maintenance Schedule as a guide, lubricate at safe intervals required for

the particular type of operation. Under extremely

dusty conditions lubricate

these

points daily. Be

sure

to force enough lubricant into each fitting to force out the old lubricant which might be con

taminated with grit and which would cause

rapid

wear

if allowed to remain.

Do not place lubricant on the various

ball

and socket joints or pivot points of the lift linkage as

dirt

will

accumulate to form an abrasive mix

ture.

It is

best

to simply wipe

these

parts clean

with

a cloth.

B-84.

Front

Axle

Shaft Universal Joints

For

off-highway use remove the universal joints twice yearly, thoroughly clean both the housings

and

joints with a suitable solvent, and

refill

the

housings to the

fill

plug opening levels with the

correct

lubricant as given in the

Lubrication

Specifications.

B-85.

Transmission and Transfer

Case

The

combined capacity of the two housings is

small

for economy, making it important that the

lubricant

be changed at regular intervals. For off-highway use

drain

both housings every 300

hours

of operation and

refill

to the

fill

plug opening

levels. Refer to B-35 through B-37 when changing

lubricant.

B-86.

Front and

Rear

Axle

Differentials

Because of the higher pressure developed in the

axle assemblies with heavy duty operation,

drain,

flush,

and

refill

the differential assemblies each 300 hours of operation. Use only flushing oil or light

engine

oil to clean out the housings (except

Powr-Lok

and

Trac-Lok

differentials). Refer to

Par.

B-52 and B-53 for draining and flushing

differential.

18

Page 19 of 376

Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

c

TUNE-UP

Contents

SUBJECT

PAR.

GENERAL

C-l

TUNE-UP

.C-2

Air

Cleaner

C-21

Battery

. C-3

Carburetor

Adjustments

C-2 5

Coil

C-20

Crankcase

Ventilation C-6

Cylinder

Compression C-9

Cylinder

Head(s) .C-5

Dash

Pot Adjustments .C-26

Distributor

Service C-10

thru

C-13

Distributor

Resistance Test C-l6

Fan

Belt

C-2 7

Fuel

Lines

and Screens

C-2

2

C-l.

GENERAL

An

engine tune-up should be performed for all

Jeep Vehicles each 6000 miles [9.600 km.] or at the end of each 250 hours off-the-road operation,

to ensure best possible performance at all times.

The

tune-up should follow the sequence given in

this section.

Because of federal laws limiting exhaust emissions,

it

is even more important that the engine tune-up is

done

accurately, using the specifications listed

on the tune-up sticker found in each engine com

partment.

Note;

To ensure proper operation and effectiveness

of the exhaust emission control system, and to

comply with

Federal

and State requirements, a

recheck

of ignition timing, idle speed and idle mix

ture

and necessary adjustments must be performed

after the first

2,000

miles [3.200 km.] of vehicle

operation.

A

minor engine tune-up should be performed every

6,000

miles [9.600 km.] or at the end of 250 hours

of off-the-road use.

Major

engine tune-up should

be performed every 12,000 miles [19.300 km.].

The

parts of units which affect power and perform

ance may be divided into three groups:

(1) Units affecting compression

(2) Units affecting ignition

(3) Units affecting carburetion

The

tune-up procedure should cover

these

groups

in

the order given. While the items affecting com

pression and ignition may be handled according

to personal preference, correction of items in the

carburetion

group should not be attempted until

all

items affecting compression and ignition have

been satisfactorily corrected.

Note:

To make sure hydro-carbon and carbon

monoxide emissions

will

be within limits, it is very

impotrant

that the adjustments be followed exactly

as listed on the sticker found in each engine compartment.

SUBJECT

PAR.

Fuel

Pump . . C-23

Heat

Control

Valve C-7

Ignition

Cables C-19

Ignition

Timing

. C-14

Ignition

Wires C-l8

Manifold

C-5

Manifold

Vacuum C-24

Point

Dwell C-17

Primary

Circuit

Tests

.................

C-15

Spark

Plugs C-4

Tappets

C-8

ROAD TEST C-2

8

SERVICE

DIAGNOSIS

. : C-29

TUNE-UP SPECIFICATIONS..

C-30

Minor

engine tune-up consists of the following.

Inspect

and correct as required:

Battery

cables and connections.

Alternator

and regulator wiring.

Primary

— Secondary wiring, distributor cap.

Cylinder

head torque.

Contact

point dwell.

Vacuum

and centrifugal advance.

Ignition

timing.

Spark

plugs for correct air gap.

Adjust

idle speed and idle air mixture.

Adjust

all drive belt tensions.

Clean

carburetor air cleaner.

Lubricate

exhaust manifold damper.

Major

engine tune-up includes the following.

Inspect

and correct as required:

Battery

condition and charging

circuit.

Clean,

lubricate

and tighten battery cable connec

tions.

Ingition

system.

Spark

plugs; replace if necessary or clean and gap.

Compression

check.

Primary—Secondary

wiring, distributor cap.

Replace

contact points and condenser.

Lubricate

distributor cam with cam grease.

Adjust

contact points.

Check

vacuum and centrifugal advance. Set ignition timing.

Torque

cylinder head.

Adjust

idle speed and idle air mixture.

Replace

fuel filter element (every 12,000 miles [19.300

km.]).

Adjust

all drive belt tensions.

IMPORTANT: SPECIFICATIONS

FOR EN-

GINE

RPM.

DISTRIBUTOR POINT DWELL,

AND IGNITION TIMING GIVEN

IN

TUNE- UP SECTION

C

REFER

TO

VEHICLES

WITH

AND WITHOUT EXHAUST EMISSION CON

TROL

SYSTEMS.

FOR

VEHICLES

EQUIPPED WITH EXHAUST

EMISSION CONTROL SYSTEMS ALSO

REFER

TO

SECTION

Fl (F4-134

ENGINE)

AND

F2 (V6-225

ENGINE).

19

Page 20 of 376

c

TUNE-UP

C-2.

TUNE-UP SEQUENCE

The

following

Pars.

C-3 through

C-2

7

give the

sequence and describe the services to be performed

when tuning the engine.

C-3.

Clean

and

Check

Battery

Inspect

battery and cables. If the battery is not

satisfactory, install a fully-charged battery to allow

completion of the tune-up.

Note: If the battery fails any of the following tests,

remember that the cause may be other electrical

trouble, and not necessarily only a defective battery.

Refer

to Section H for electrical troubleshooting

and

tests.

a.

Check

the specific gravity of the eletrolyte in

each cell of the battery. A hydrometer reading of 1.260 indicates that the battery is fully charged.

If

the reading is 1.225 or below, the battery

needs

recharging.

If one or more cells is 25 "points" (.025)

or

more lower than the other cells, this indicates

that the cell is shorted, the cell is about to

fail,

or

there is a

crack

in the battery partition in the case.

Unless the battery is repaired or replaced, battery trouble

will

soon be experienced.

b.

Check

the electrolyte level in each cell, add

distilled

water to maintain the solution %" [9.5

mm.] above the plates. Avoid overfilling. Replace

the filler caps and tighten securely. It is important

to keep the electrolyte level above the plates at

all

times because plates that are exposed for any

length of time

will

be seriously damaged.

c.

Check

the wing nuts on the hold-down frame

for tightness. Tighten them only with finger pres

sure,

never with pliers or a wrench. Excessive pres

sure

could damage the battery case.

d.

Clean

the battery terminals and cable connec-

FIG.

C-l—FRAME

GROUND

STRAP

—

HURRICANE

F4

1—

Right

Front

Engine Mount

2—

Frame

Ground

Strap

DAUNTLESS

V-6

tors.

Prepare a strong solution of baking soda and

water

and brush it around the terminals to remove

any

corrosion that is present. The cell caps must

be tight and their vents sealed to prevent cleaning

solution entering the cells. After cleaning install

cable connectors on terminals and coat the ter

minals

and connectors with heavy grease.

e. Inspect the battery cables and replace if badly

corroded

or frayed.

Check

tightness of terminal

screws to ensure

good

electrical connections.

Check

the tightness of the negative ground cable connec tion at the engine to ensure a

good

ground con nection.

f.

Load

test

the battery. Connect a voltmeter across the battery. Run the starting motor for 15 seconds.

If

the voltage

does

not drop below 10 volts on a 12 volt battery the battery is satisfactory. If the

voltage falls below

these

values, yet the specific

gravity

is above

1.225,

the condition of the battery

is questionable.

g.

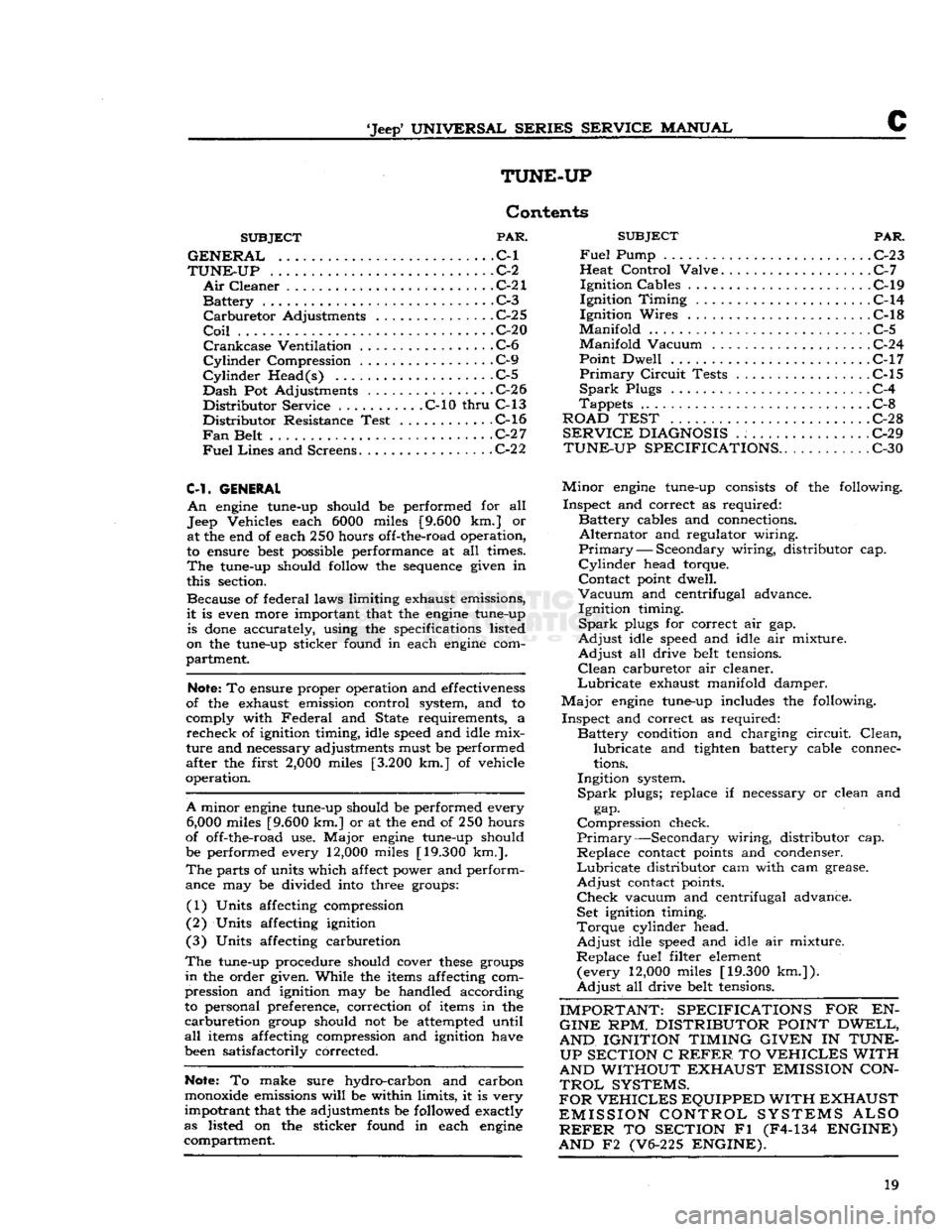

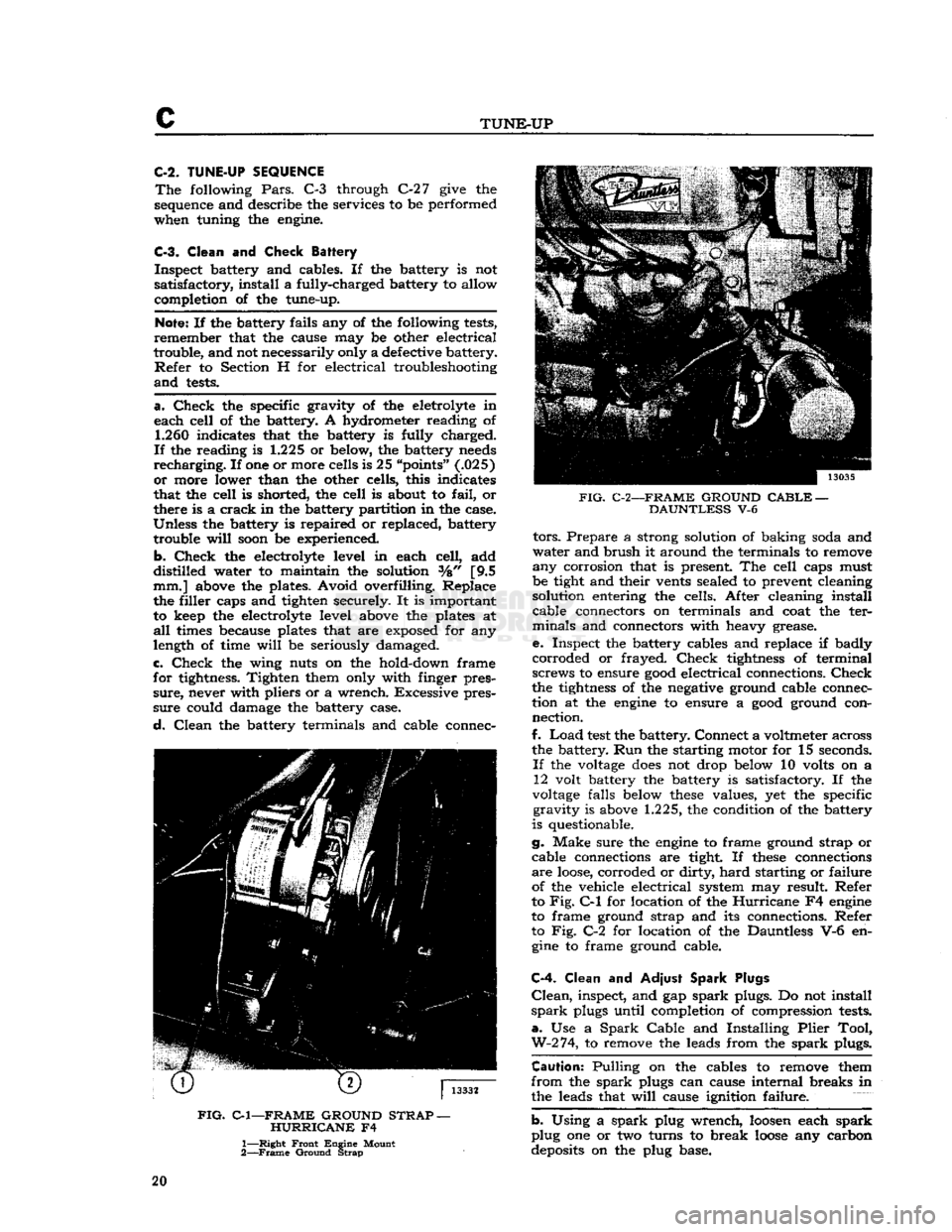

Make sure the engine to frame ground strap or

cable connections are tight. If

these

connections

are

loose,

corroded or dirty,

hard

starting or failure

of the vehicle electrical system may result. Refer

to

Fig.

C-l

for location of the

Hurricane

F4 engine

to frame ground strap and its connections. Refer to Fig. C-2 for location of the Dauntless V-6 en gine to frame ground cable.

C-4.

Clean and

Adjust

Spark Plugs

Clean,

inspect, and gap

spark

plugs. Do not install

spark

plugs until completion of compression tests.

a.

Use a

Spark

Cable

and Installing

Plier

Tool,

W-2

74,

to remove the leads from the

spark

plugs.

Caution:

Pulling on the cables to remove them

from

the

spark

plugs can cause internal breaks in

the leads that

will

cause ignition failure.

b.

Using a

spark

plug wrench, loosen each

spark

plug one or two turns to break

loose

any carbon

deposits on the plug base. 20