instrument panel JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 320 of 376

STEERING

SYSTEM

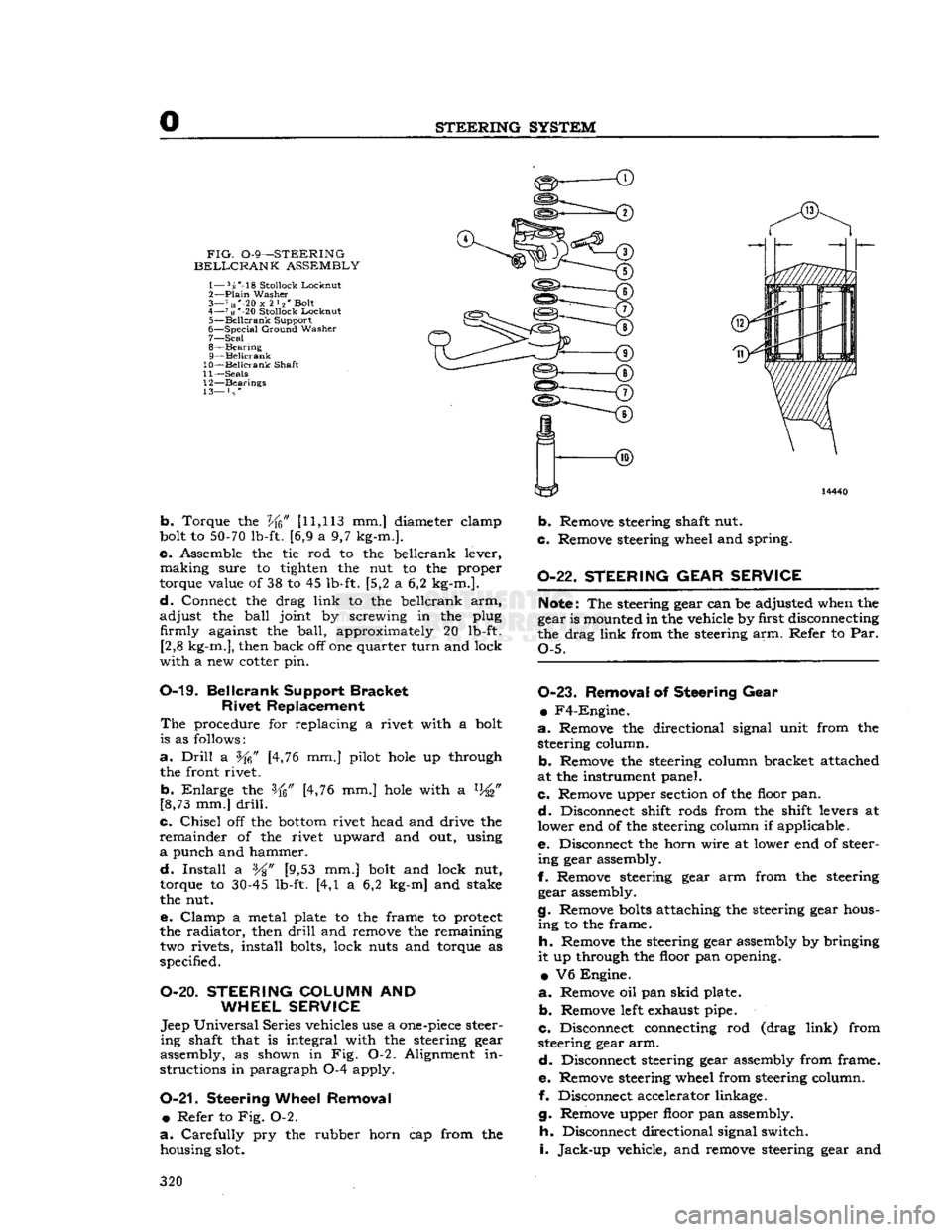

FIG.

0-9—STEERING

BELLCRANK

ASSEMBLY

1— 5s'-18

Stollock

Lockout

2—

Plain

Washer

3— 7 us"-20

x

2 l2' Bolt

4—

71«

*-20

Stollock

Locknut

5—

Beilcrank

Support

6—

Special

Ground

Washer

7— Seal

8—

Bearing

9— Beilcrank

10— Beilcrank

Shaft

11—

Seals

12—

Bearings

13— } s *

b.

Torque the

Vfc"

[11,113

mm.] diameter elamp

bolt to

50-70

lb-ft. [6,9 a 9,7 kg-m.].

c.

Assemble the tie rod to the beilcrank lever,

making

sure to tighten the nut to the proper

torque value of 38 to 45 lb-ft. [5,2 a 6,2 kg-m.].

d.

Connect the drag

link

to the beilcrank arm,

adjust

the

ball

joint by screwing in the plug firmly against the

ball,

approximately 20 lb-ft. [2,8 kg-m.], then back off one quarter

turn

and lock

with

a new cotter pin.

0-19.

Beilcrank

Support

Bracket

Rivet

Replacement

The

procedure for replacing a rivet with a bolt

is as follows:

a.

Drill

a [4,76 mm.] pilot

hole

up through

the front rivet.

b.

Enlarge

the [4,76 mm.]

hole

with a %"

[8,73 mm.]

drill.

c.

Chisel

off the

bottom

rivet head and drive the

remainder

of the rivet upward and out, using

a

punch and hammer.

d.

Install

a %" [9,53 mm.] bolt and lock nut,

torque to

30-45

lb-ft. [4,1 a 6,2 kg-m] and stake

the nut.

e.

Clamp

a metal plate to the frame to protect

the radiator, then

drill

and remove the remaining two rivets, install bolts, lock nuts and torque as

specified.

O-20.

STEERING

COLUMN

AND

WHEEL SERVICE

Jeep

Universal

Series vehicles use a

one-piece

steer

ing

shaft that is integral with the steering gear

assembly, as shown in Fig. 0-2. Alignment in

structions in paragraph 0-4 apply.

0-21.

Steering

Wheel Removal •

Refer to Fig. 0-2.

a.

Carefully

pry the rubber horn cap from the housing slot.

b.

Remove steering shaft nut.

c.

Remove steering wheel and spring.

0-22.

STEERING GEAR SERVICE

Note:

The steering gear can be adjusted when the

gear is mounted in the vehicle by first disconnecting

the drag

link

from the steering arm. Refer to Par.

Q-5.

0-23.

Removal

of

Steering Gear

•

F4-Engine.

a.

Remove the directional signal unit from the steering column.

b.

Remove the steering column bracket attached

at the instrument panel.

c.

Remove upper section of the floor pan.

d.

Disconnect shift rods from the shift levers at

lower end of the steering column if applicable.

e.

Disconnect the horn wire at lower end of steer

ing

gear assembly.

f.

Remove steering gear arm from the steering gear assembly.

g.

Remove

bolts

attaching the steering gear hous

ing

to the frame.

h.

Remove the steering gear assembly by bringing

it

up through the floor pan opening.

•

V6 Engine.

a.

Remove oil pan

skid

plate.

b.

Remove

left

exhaust pipe.

c.

Disconnect connecting rod (drag

link)

from

steering gear arm.

d.

Disconnect steering gear assembly from frame.

e.

Remove steering wheel from steering column.

f. Disconnect accelerator linkage.

g.

Remove upper floor pan assembly.

h.

Disconnect directional signal switch.

i.

Jack-up

vehicle, and remove steering gear and

320

Page 324 of 376

p

BRAKES

13264

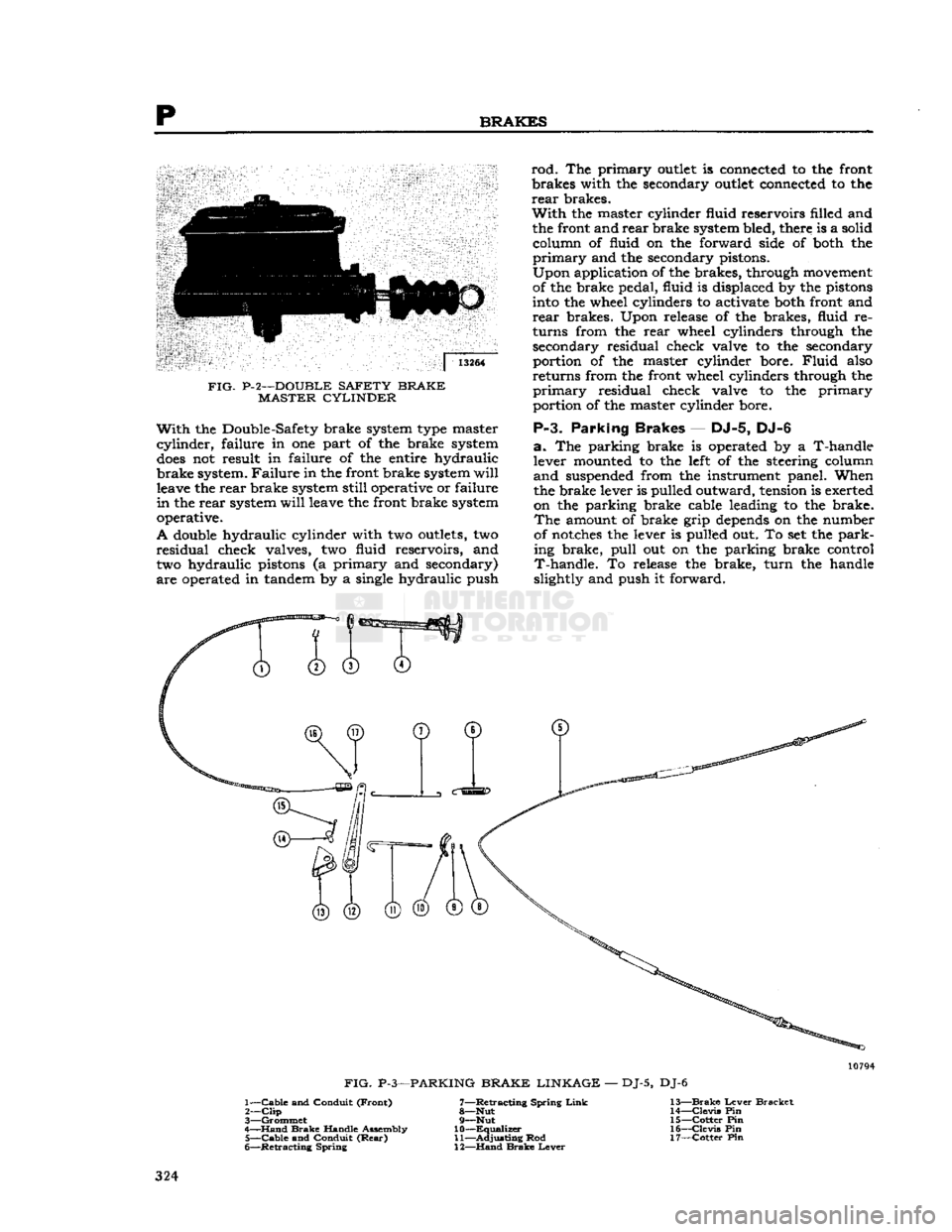

FIG- P-2—DOUBLE

SAFETY BRAKE

MASTER

CYLINDER

With

the Double-Safety brake system type master

cylinder,

failure

in one part of the brake system

does

not result in

failure

of the entire hydraulic

brake system. Failure in the

front

brake system

will

leave the rear brake system

still

operative or

failure

in

the rear system

will

leave the

front

brake system

operative.

A

double hydraulic

cylinder

with

two outlets, two

residual

check valves, two

fluid

reservoirs, and

two

hydraulic pistons (a

primary

and secondary)

are operated in tandem by a single hydraulic push

rod.

The

primary

outlet is connected to the

front

brakes

with

the secondary outlet connected to the rear brakes.

With

the master

cylinder

fluid

reservoirs

filled

and the

front

and rear brake system

bled,

there is a

solid

column

of

fluid

on the

forward

side of both the

primary

and the secondary pistons.

Upon

application

of the brakes, through movement

of

the brake pedal,

fluid

is displaced by the pistons

into

the wheel cylinders to activate both

front

and

rear brakes.

Upon

release

of the brakes,

fluid

re

turns

from

the rear wheel cylinders through the secondary residual check valve to the secondary

portion

of the master

cylinder

bore.

Fluid

also

returns

from

the

front

wheel cylinders through the

primary

residual check valve to the

primary

portion

of the master

cylinder

bore.

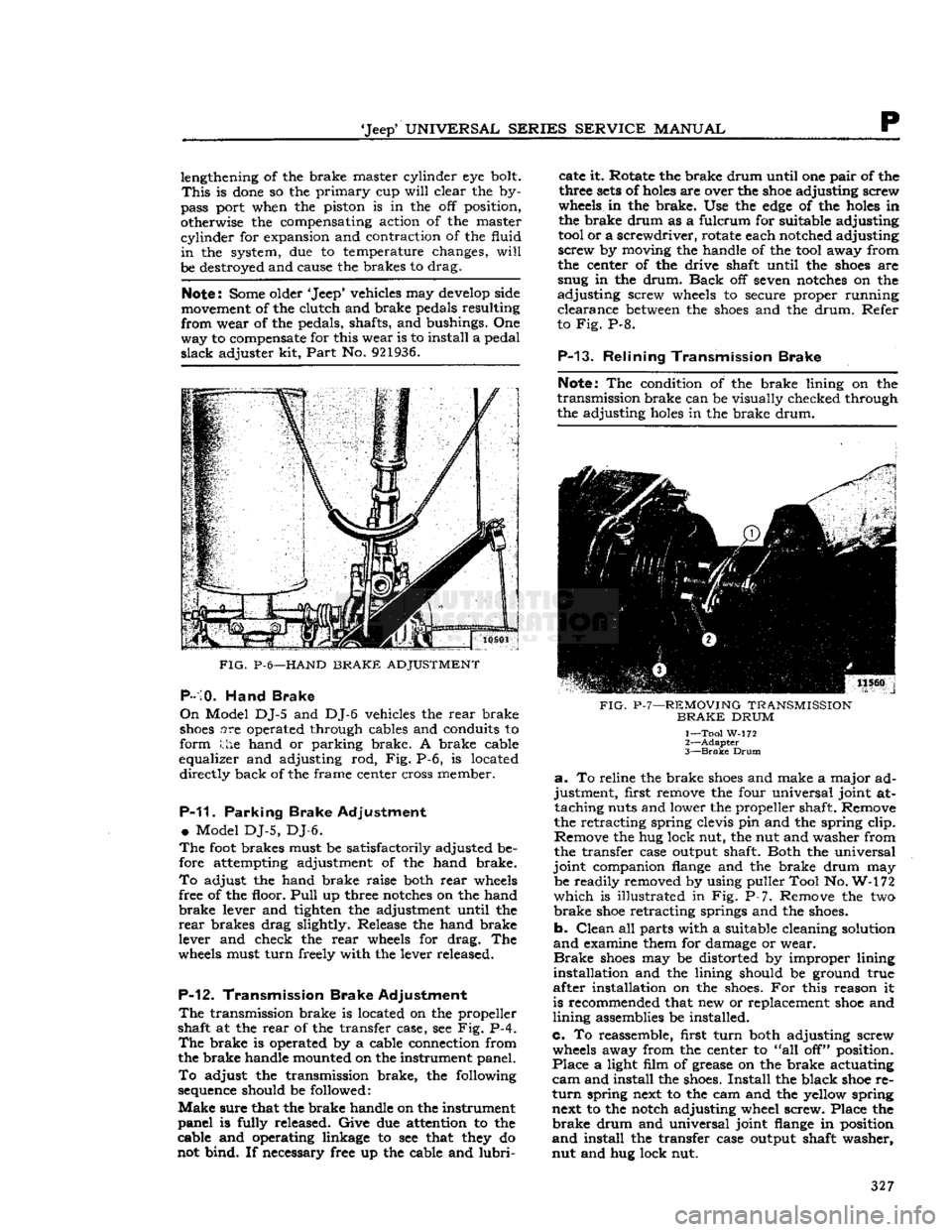

P-3.

Parking

Brakes

— DJ-5, DJ-6

a.

The parking brake is operated by a T-handle

lever

mounted to the

left

of the steering

column

and

suspended

from

the instrument panel. When

the brake lever is

pulled

outward, tension is exerted

on

the parking brake cable leading to the brake.

The

amount of brake

grip

depends

on the number

of

notches the lever is

pulled

out. To set the park

ing

brake,

pull

out on the parking brake

control

T-handle.

To

release

the brake,

turn

the handle

slightly

and push it

forward.

0

FIG.

P-3—PARKING

BRAKE LINKAGE

—

DJ-5,

DJ-6

1—

Cable

and

Conduit

(Front)

7—Retracting

Spring

Link

13—Brake

Lever

Bracket

2—

Clip

8—Nut

14—Clevis

Pin

3—

Grommet

9—Nut

15—Cotter

Pin

4—

Hand

Brake

Handle

Assembly

10—Equalizer

16—Clevis

Pin

5—

Cable

and

Conduit

(Rear)

11—Adjusting

Rod

17—Cotter

Pin

6—

Retracting

Spring

12—Hand

Brake

Lever

324

Page 327 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P

lengthening of the brake master cylinder eye bolt.

This

is

done

so the primary cup

will

clear the by

pass port when the piston is in the off position,

otherwise the compensating action of the master

cylinder

for expansion and contraction of the fluid

in

the system, due to temperature changes,

will

be destroyed and cause the brakes to drag.

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One

way to

compensate

for this wear is to install a pedal

slack

adjuster kit,

Part

No.

921936.

FIG.

P-6—HAND

BRAKE

ADJUSTMENT

P-10.

Hand Brake

On

Model DJ-5 and DJ-6 vehicles the rear brake

shoes

are operated through cables and conduits to

form the hand or parking brake. A brake cable

equalizer and adjusting rod, Fig. P-6, is located directly back of the frame center cross member.

P-11.

Parking Brake Adjustment

•

Model DJ-5, DJ-6.

The

foot

brakes must be satisfactorily adjusted be

fore attempting adjustment of the hand brake.

To

adjust the hand brake raise both rear

wheels

free of the floor.

Pull

up three

notches

on the hand

brake

lever and tighten the adjustment until the

rear

brakes drag slightly. Release the hand brake

lever and check the rear

wheels

for drag. The

wheels

must turn freely with the lever released.

P-12.

Transmission Brake Adjustment

The

transmission brake is located on the propeller

shaft at the rear of the transfer case, see Fig. P-4.

The

brake is operated by a cable connection from

the brake handle mounted on the instrument panel.

To

adjust the transmission brake, the following

sequence

should be followed:

Make

sure that the brake handle on the instrument

panel is fully released. Give due attention to the

cable and operating linkage to see that

they

do

not bind. If necessary free up the cable and

lubri

cate it. Rotate the brake drum until one pair of the

three

sets

of

holes

are over the

shoe

adjusting screw

wheels

in the brake. Use the

edge

of the

holes

in

the brake drum as a fulcrum for suitable adjusting

tool

or a screwdriver, rotate each notched adjusting

screw by moving the handle of the

tool

away from

the center of the drive shaft until the

shoes

are

snug in the drum.

Back

off seven

notches

on the

adjusting screw

wheels

to secure proper running clearance

between

the

shoes

and the drum. Refer

to Fig. P-8.

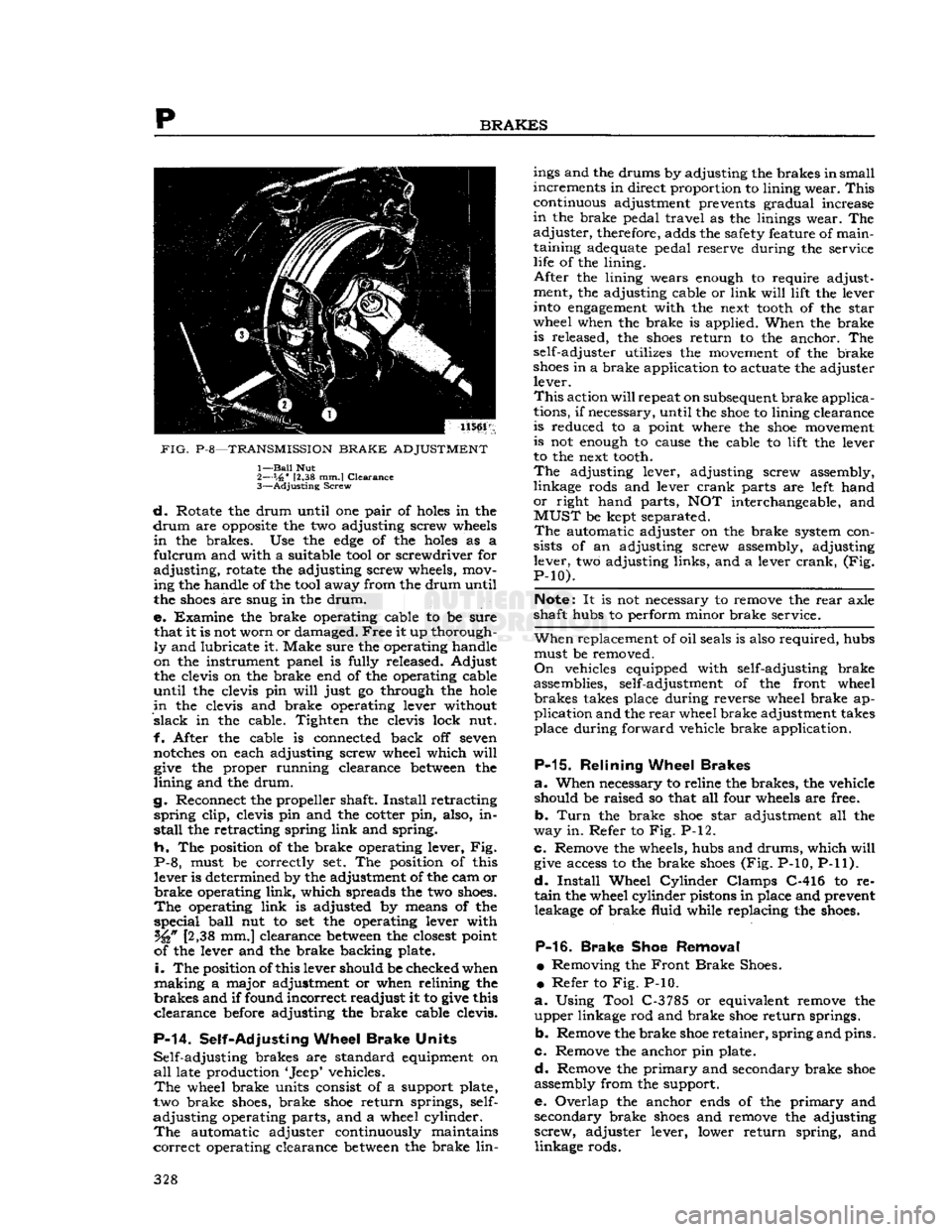

P-13.

Relining Transmission Brake

Note:

The condition of the brake lining on the

transmission brake can be visually checked through

the adjusting

holes

in the brake drum.

FIG.

P-7—REMOVING

TRANSMISSION

BRAKE

DRUM

1— Tool W-172

2—

Adapter

3—

Brake

Drum

a.

To reline the brake

shoes

and make a major ad

justment, first remove the four universal joint at taching nuts and lower the propeller shaft. Remove

the retracting spring clevis pin and the spring clip.

Remove the hug lock nut, the nut and washer from

the transfer case output shaft. Both the universal

joint companion

flange

and the brake drum may be readily removed by using puller Tool No. W-172

which

is illustrated in Fig. P-7. Remove the two

brake

shoe

retracting springs and the

shoes.

b. Clean all parts with a suitable cleaning solution

and

examine them for damage or wear.

Brake

shoes

may be distorted by improper lining

installation and the lining should be ground true

after installation on the

shoes.

For this reason it

is recommended that new or replacement

shoe

and

lining assemblies be installed.

c. To reassemble, first turn both adjusting screw

wheels

away from the center to "all off" position.

Place a light film of grease on the brake actuating

cam

and install the

shoes.

Install the black

shoe

re

turn

spring next to the cam and the yellow spring next to the notch adjusting wheel screw. Place the

brake

drum and universal joint

flange

in position

and

install the transfer case output shaft washer,

nut and hug lock nut. 327

Page 328 of 376

p

BRAKES

PIG.

P-8—TRANSMISSION

BRAKE

ADJUSTMENT

1—

Bail

Nut

2— s,6"

12,38 mm.I

Clearance

3—

Adjusting

Screw

d.

Rotate the

drum

until

one pair of holes in the

drum

are opposite the two adjusting screw wheels

in

the brakes. Use the

edge

of the holes as a

fulcrum

and

with

a suitable

tool

or screwdriver for

adjusting,

rotate the adjusting screw wheels,

mov

ing

the handle of the

tool

away

from

the

drum

until

the

shoes

are snug in the

drum.

e.

Examine the brake operating cable to be

sure

that

it is not

worn

or damaged. Free it up thorough

ly

and lubricate

it.

Make

sure

the operating handle

on

the instrument panel is

fully

released.

Adjust

the clevis on the brake end of the operating cable

until

the clevis pin

will

just go through the hole

in

the clevis and brake operating lever

without

slack

in the cable.

Tighten

the clevis

lock

nut.

f.

After

the cable is connected back off seven

notches on each adjusting screw wheel

which

will

give

the proper

running

clearance between the

lining

and the

drum.

g.

Reconnect the propeller shaft.

Install

retracting

spring

clip,

clevis pin and the cotter pin, also, in

stall

the retracting spring

link

and spring.

h. The

position

of the brake operating lever, Fig.

P-8, must be correctly set. The

position

of this

lever

is determined by the adjustment of the cam or

brake operating

link,

which

spreads

the two

shoes.

The

operating

link

is adjusted by

means

of the

special

ball

nut to set the operating lever

with

[2,38

mm.] clearance between the closest

point

of

the lever and the brake backing plate.

i.

The

position

of

this

lever should be checked when

making

a major adjustment or when

relining

the

brakes and

if

found

incorrect readjust it to give this

clearance before adjusting the brake cable

clevis.

P-14.

Self-Adjusting

Wheel

Brake

Units

Self-adjusting

brakes are standard equipment on

all

late production

'Jeep'

vehicles.

The

wheel brake units consist of a support plate,

two

brake

shoes,

brake

shoe

return springs, self-

adjusting

operating parts, and a wheel

cylinder.

The

automatic adjuster continuously maintains

correct

operating clearance between the brake

lin

ings

and the drums by adjusting the brakes

in

small

increments in direct

proportion

to

lining

wear. This

continuous

adjustment prevents gradual increase

in

the brake pedal

travel

as the

linings

wear. The

adjuster, therefore,

adds

the safety feature of

main

taining

adequate

pedal reserve

during

the service

life

of the

lining.

After

the

lining

wears enough to require adjustment, the adjusting cable or

link

will lift

the lever

into

engagement

with

the next

tooth

of the

star

wheel

when the brake is applied. When the brake

is

released, the

shoes

return to the anchor. The

self-adjuster

utilizes

the movement of the brake

shoes

in a brake application to

actuate

the adjuster

lever.

This

action

will

repeat

on

subsequent

brake applica

tions,

if

necessary,

until

the

shoe

to

lining

clearance

is

reduced to a

point

where the

shoe

movement

is

not enough to

cause

the cable to

lift

the lever

to

the next

tooth.

The

adjusting lever, adjusting screw assembly,

linkage

rods and lever crank parts are

left

hand

or

right

hand parts, NOT interchangeable, and

MUST

be kept

separated.

The

automatic adjuster on the brake system con

sists

of an adjusting screw assembly, adjusting

lever,

two adjusting

links,

and a lever crank, (Fig.

P-10).

Note:

It is not

necessary

to remove the rear axle

shaft hubs to

perform

minor

brake service.

When

replacement of

oil

seals

is also required, hubs must be removed.

On

vehicles equipped

with

self-adjusting brake

assemblies, self-adjustment of the

front

wheel brakes

takes

place

during

reverse wheel brake ap

plication

and the rear wheel brake adjustment

takes

place

during

forward

vehicle brake application.

P-15.

Relining

Wheel

Brakes

a.

When

necessary

to reline the brakes, the vehicle

should

be raised so that all

four

wheels are free.

b.

Turn

the brake

shoe

star

adjustment all the

way

in. Refer to Fig. P-12.

c.

Remove the wheels, hubs and drums,

which

will

give

access

to the brake

shoes

(Fig.

P-10, P-11).

d.

Install

Wheel

Cylinder

Clamps C-416 to re

tain

the wheel

cylinder

pistons in place and prevent leakage of brake

fluid

while

replacing the

shoes.

P-16.

Brake

Shoe

Removal

•

Removing the Front Brake

Shoes.

•

Refer to Fig. P-10.

a.

Using

Tool

C-3785

or equivalent remove the

upper linkage rod and brake

shoe

return springs.

b.

Remove the brake

shoe

retainer, spring and pins.

c. Remove the anchor pin plate.

d.

Remove the

primary

and secondary brake

shoe

assembly

from

the support.

e.

Overlap the anchor

ends

of the

primary

and

secondary brake

shoes

and remove the adjusting

screw, adjuster lever,

lower

return spring, and

linkage

rods. 328

Page 351 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

BODY

Contents

SUBJECT

PAR.

Brake

and

Clutch

Pedal Pads T-7

Canvas

Tops T-5

Care

of

Fabric

Tops. : T-6

Front

Seat Adjustment. . . T-8

Passenger Seat Safety

Catch

. .T-9

Windshield

T-2, T-3

Windshield

Glass and Weatherstrip T-4

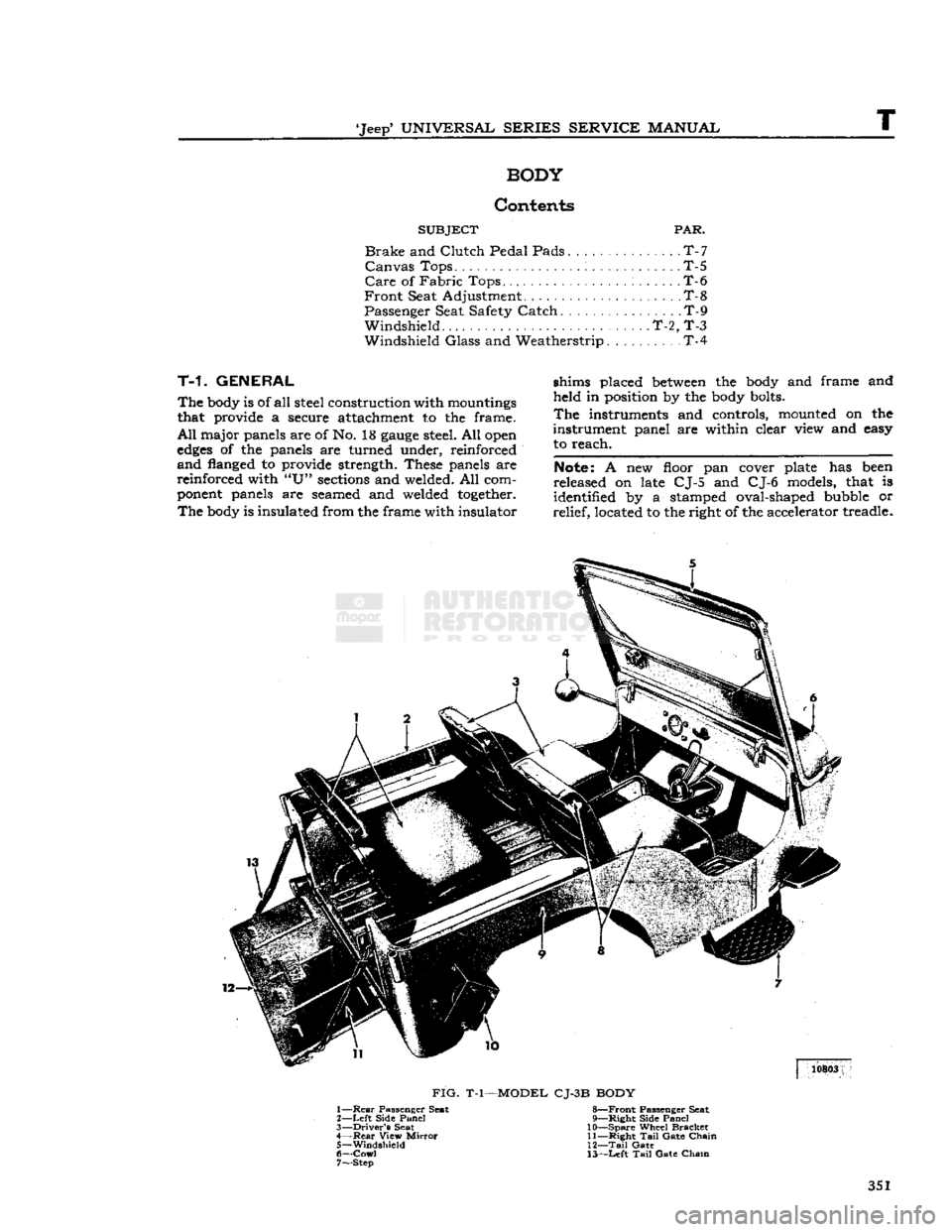

T-1.

GENERAL

The

body

is of

all

steel construction with mountings

that provide a secure attachment to the frame.

All

major panels are of No. 18

gauge

steel. All

open

edges

of the panels are turned under, reinforced

and

flanged to provide strength. These panels are reinforced with

"U"

sections

and welded. All com

ponent

panels are seamed and welded

together.

The

body

is insulated from the frame with insulator shims placed

between

the

body

and frame and

held in position by the

body

bolts.

The

instruments and controls, mounted on the

instrument panel are within clear view and easy

to reach.

Note:

A new floor pan cover plate has

been

released on late CJ-5 and CJ-6 models, that is

identified by a stamped oval-shaped bubble or

relief, located to the right of the accelerator treadle.

FIG.

T-l—MODEL CJ-3B BODY

1—

Rear

Passenger Seat 8—Front Passenger Seat

2—

Left

Side

Panel

9—Right Side

Panel

3—

Driver's

Seat 10—Spare Wheel

Bracket

4—

Rear

View

Mirror

11—Right

Tail

Gate

Chain

5—

Windshield

12—Tail

Gate

6—

Cowl

13—Left

Tail

Gate

Chain

7— Step

351

Page 352 of 376

BODY

10728

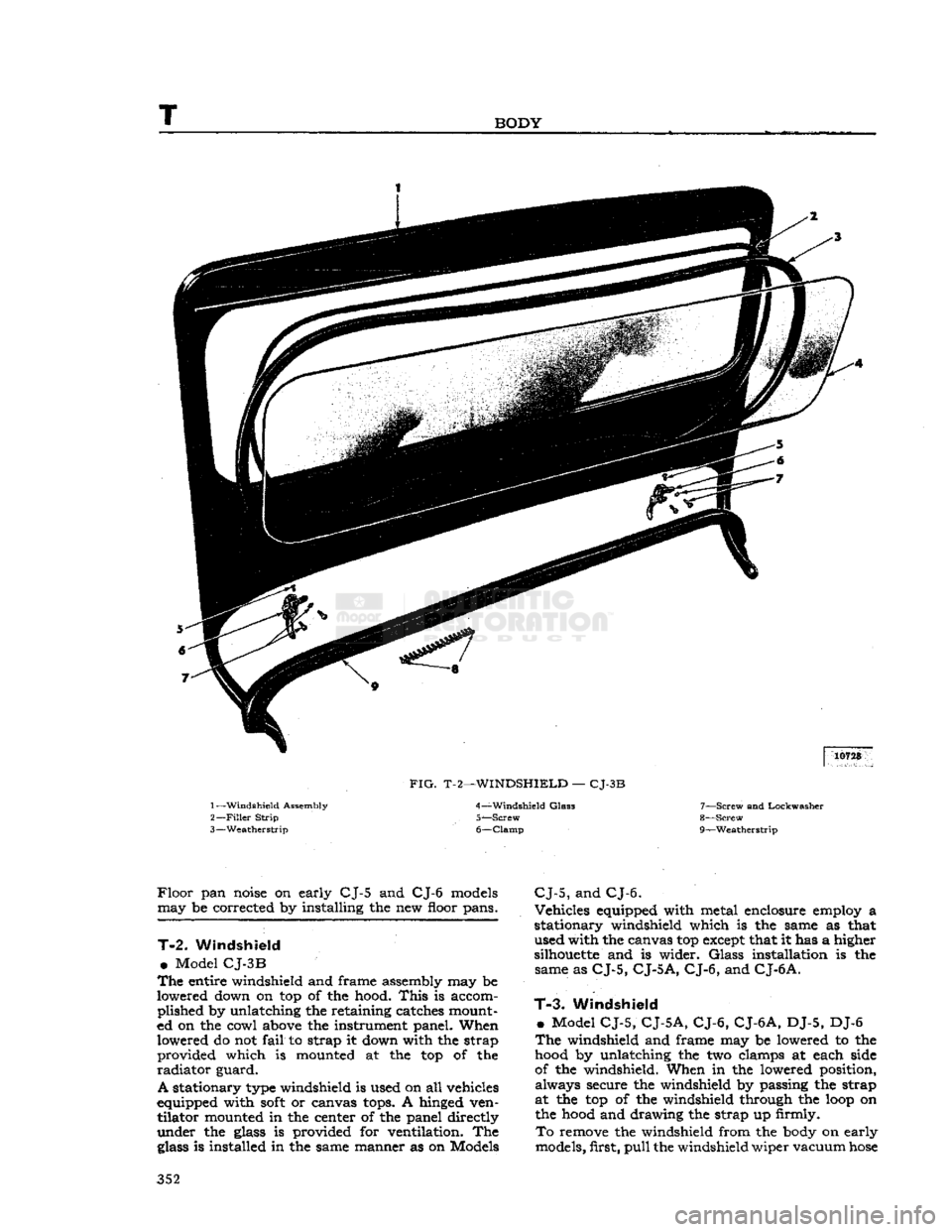

FIG.

T-2—WINDSHIELD

—

CJ-3B

1—

Windshield

Assembly

2—

Filler

Strip

3—

Weatherstrip 4—

Windshield

Glas3

5—

Screw

6—

Clamp

7—

Screw

and Lockwasher

8—

Screw

r

9— —Weatherstrip

Floor

pan

noise

on early CJ-5 and CJ-6

models

may be corrected by installing the new floor pans.

T-2.

Windshield

•

Model

CJ-3B

The

entire windshield and frame assembly may be

lowered down on top of the hood.

This

is accom plished by unlatching the retaining catches mount

ed on the cowl

above

the instrument panel. When lowered do not

fail

to strap it down with the strap provided which is mounted at the top of the

radiator

guard.

A

stationary

type

windshield is used on all vehicles

equipped with

soft

or canvas

tops.

A hinged ven tilator mounted in the center of the panel directly

under the

glass

is provided for ventilation. The

glass

is installed in the same manner as on Models

CJ-5,

and

CJ-6.

Vehicles equipped with metal enclosure employ a

stationary windshield which is the same as that used with the canvas top

except

that it has a higher

silhouette

and is wider.

Glass

installation is the same as

CJ-5,

CJ-5

A, CJ-6,

and

CJ-6

A.

T-3.

Windshield

»

Model

CJ-5, CJ-5A, CJ-6, CJ-6A,

DJ-5, DJ-6

The

windshield and frame may be lowered to the

hood

by unlatching the two clamps at each side

of the windshield. When in the lowered position, always secure the windshield by passing the strap

at the top of the windshield through the

loop

on the

hood

and drawing the strap up firmly.

To

remove the windshield from the

body

on early

models, first,

pull

the windshield wiper vacuum

hose

352

Page 357 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

u

MISCEIiLaNEOUS

Contents

SUBJECT

PAR.

Abbreviations

U-15

Extra

Equipment U-2

Front

Bumper Weight U-9

Governor

U-3

Governor

Adjustment U-4

Governor

Maintenance. U-6

U-1. GENERAL

Miscellaneous information included in this sectioi

includes coverage of extra equipment, special

tools,

torque specifications, and charts and tables.

U-2. EXTRA

EQUIPMENT

Much

of the utility of the

*

Jeep*

Universal

is due to

the extra equipment which has been designed to adapt it for farming and industry. The mainte

nance and use of

some

of this equipment is out

lined

in this section.

U-3.

Governor Assembly

The

Novi governor is supplied for models equipped

with

the F4 engine.

This

is a centrifugal type governor and is illustrated in Fig. U-2. Complete

installation

instructions are supplied with each

assembly. Adjustment and operating procedures

are

given below.

U-4.

Governor Adjustment

a.

Adjust the carburetor to obtain smooth

engine

idle at 600 rpm., then

stop

the engine.

b.

Check

throttle linkage to ensure maximum

throttle opening. Be certain that throttle and

governor linkage is free.

c.

Place the carburetor throttle in wide-open posi tion and

pull

the governor control handle out to

the last notch. Adjust the governor to bellcrank

rod

so that the linkage

will

hold the carburetor

throttle in wide-open position.

d.

Close the governor control and start the

engine

Again

pull

the control out to the last notch and

adjust

the length of the cable at adjusting yoke so

that the

engine

will

run at

2600

rpm. Close the

control

to recheck the linkage for free action and

to make sure the

engine

will

return to 600 rpm.

idle speed.

If

the

engine

runs faster than this speed,

loosen

the lock nut which locks the governor hand control

handle on the dash to the rod and back off the

handle until the carburetor idle speed adjusting

screw

bears on the stop. Tighten the lock nut.

In

the absence of electrical tachometer equipment,

engine

speed may be determined by the speedom

eter. Safely

jack

up the

rear

wheels and be sure the front wheel drive is not

engaged.

When driving

the

rear

wheels in high or direct transmission gear,

the

speedometer

will

read from 13j^ to 15 mph. [21.6 to 24.0 kph.] at an

engine

speed of from 900

to 1000 rpm.

SUBJECT

PAR.

Heater

U-10 Miscellaneous Data U-16

Pintle

Hook 1X7

Special

Tools. U-ll

Torque

Specifications U-13, 14, 15

Standard

and Recommended Tools

j.

.U-12

U-5.

Novi Governor Operation /

The

Novi governor is directly belted to the F4

engine

as no clutch is provided to disconnect the

drive.

To

operate the vehicle

WITHOUT

governor con

trol,

push the governor hand control all the way

IN

against the instrument panel.

To

operate the vehicle

WITH

governor control,

pull

the governor hand control handle out. The

hand

control has nine notched positions. Pulling the

control

out to the first notch

sets

the controlled

engine

speed at approximately 1000 rpm. and each successive notch increases the speed 200 rpm.

until

2600

rpm. is reached in the ninth notch. The

hand

control may be released by turning the han dle one-quarter

turn

in either direction.

When

the

engine

is being operated under governor

control

(hand control out) the controlled

engine

speed may be

exceeded

at any time by depressing

the

foot

accelerator in the conventional manner to

secure a greater carburetor throttle opening than

that determined by the governor hand control

setting.

U-6.

Governor Maintenance

The

belt tension may be adjusted by raising or

lowering the governor in the slotted

holes

in the mounting bracket. Keep the pulleys and belt free

of

dirt

and oil. Belt slippage

will

affect governor

operation and a tight belt may cause

rapid

wear

of the governor shaft and bearings. Adjust it to

allow Yi' [12,7 mm.] depression midway

between

the pulleys with thumb pressure.

There

is little wear of the internal parts for they

operate in oil. The governor housings are equipped

with

both

fill

and

drain

plugs and also with level

indicating

plugs.

Check

the oil level at each vehicle

lubrication

and change the oil each time the en

gine

oil is changed using the same grade oil used

in

the engine.

Caution:

Do not

fill

the governor housing above

the level plug. Overfilling

will

prevent governor

control

and possibly cause damage to governor in

ternal

parts. The capacity of

these

governors is two fluid ounces [59,15 cm3]. The filler plug is

also a vent which should be cleaned thoroughly at

each oil change to be sure that the vent operates.

U-7.

Pintle Hook

The

standard type pintle hook, Fig. U-1, affords a

safe, easy hitch for towing a

trailer

or other vehicle. 357

Page 359 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

U

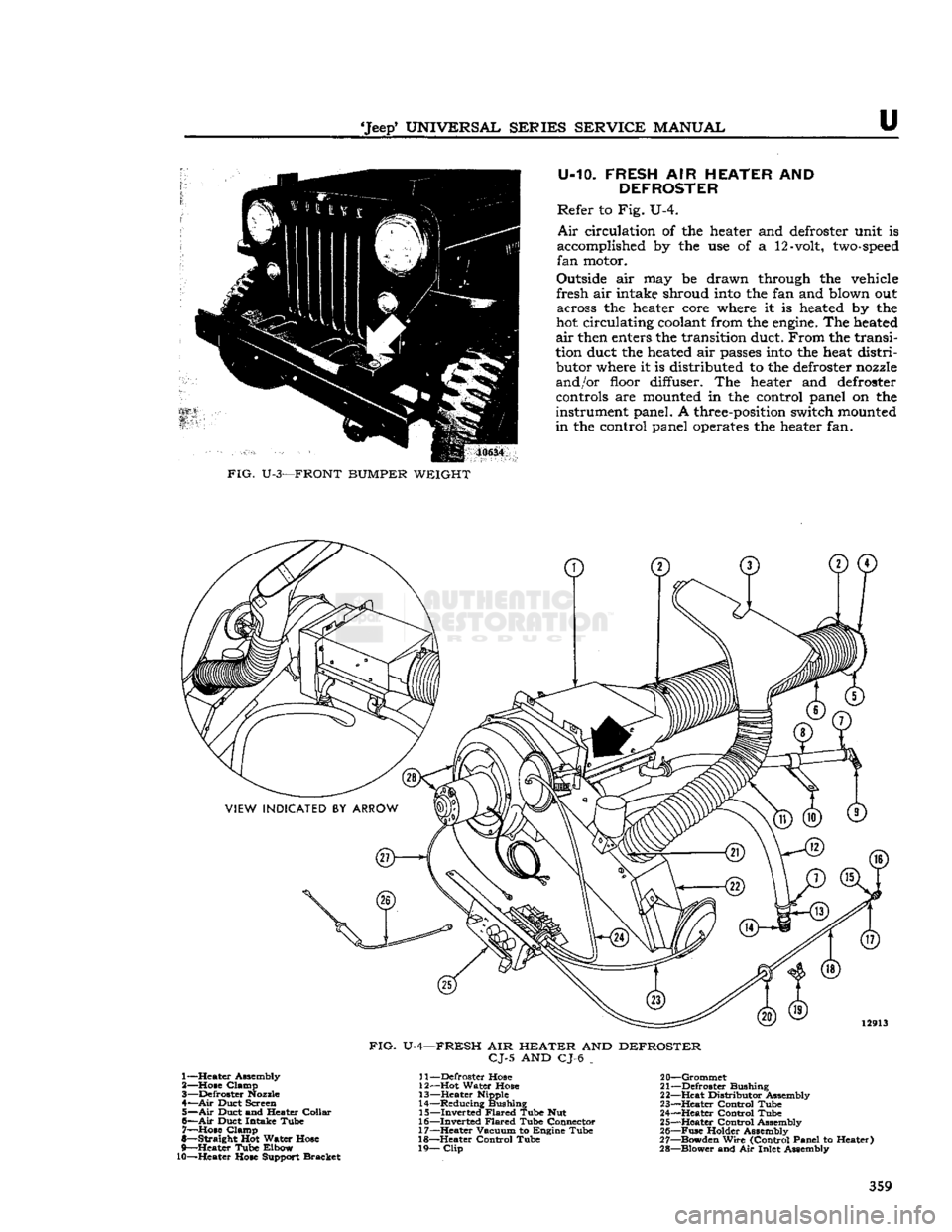

U-10. FRESH AIR HEATER AND

DEFROSTER

Refer to Fig. U-4.

Air

circulation of the

heater

and

defroster

unit

is

accomplished

by the use of a

12-volt,

two-speed

fan

motor.

Outside

air may be drawn

through

the

vehicle

fresh air

intake

shroud

into

the fan and

blown

out

across

the

heater

core

where

it is

heated

by the

hot circulating

coolant

from the

engine.

The

heated

air

then

enters

the transition

duct.

From the transi

tion

duct

the

heated

air

passes

into

the

heat

distri

butor

where

it is

distributed

to the

defroster

nozzle

and/or

floor

diffuser.

The

heater

and

defroster

controls

are

mounted

in the

control

panel

on the

instrument

panel. A

three-position

switch

mounted

in the

control

panel

operates

the

heater

fan.

FIG.

U-3—FRONT

BUMPER

WEIGHT

FIG.

U-4-

-FRESH

AIR

HEATER

AND

DEFROSTER

CJ-5

AND CJ-6 _ 1— Heater Assembly

2— Hose Clamp

3— Defroster

Nozzle

4—

Air

Duct Screen 5—

Air

Duct and Heater Collar

6—

Air

Duct Intake Tube 7— Hose Clamp

8— Straight Hot Water Hose

9— Heater Tube Elbow

10—Heater Hose Support Bracket

I

j—Defroster Hose

12— Hot Water Hose

13— Heater Nipple

14— Reducing Bushing

15— Inverted Flared Tube Nut

16— Inverted Flared Tube Connector

17— Heater Vacuum to Engine Tube

18— Heater Control Tube

19—

Clip

20— Grommet

21— Defroster Bushing

22— Heat Distributor Assembly

23— Heater Control Tube

24— Heater Control Tube

25— Heater Control Assembly

26—

Fuse

Holder Assembly

27— Bowden Wire (Control Panel to Heater)

28— Blower and Air Inlet Assembly 359