wheel JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 37 of 376

'Jeep9

UNIVERSAL SERIES SERVICE

MANUAL

D HURRICANE

F4

ENGINE

Contents

SUBJECT

PAR.

GENERAL...

D-l Description D-2

Engine

Ground Strap D-4

Engine

Mountings D-3

ENGINE REMOVAL

D-5

ENGINE DISASSEMBLY

D-6

Camshaft

.......

D-28

Clutch

D-24

Crankshaft.

D-26

Crankshaft

Pulley. D-l2

Cylinder

Head. .D-17

Distributor.

.D-13

Exhaust

Manifold D-8

Exhaust

Valves and Springs D-2

7

Flywheel.

. D-25

Front

End Plate D-23

Oil

Filler

Tube D-9

Oil

Gallery Plugs D-30

Oil

Pan. . ...D-19

Oil

Pump D-l4

Piston and Connecting Rods. . . D-20

Ream

Cylinder Bore Ridges. D-l8

Rocker

Arm Assemblies D-l6 Thermostat D-ll

Timing

Gear

Cover . . D-21

Timing

Gears D-22

Valve

Tappets D-29

Ventilation Valve D-l5

Water

Outlet Fitting D-10

Water

Pump D-7

ENGINE INSPECTION

AND

REPAIR.

.D-31

Camshaft

and Bearings. D-51

Camshaft

End-Play

. . .D-53

Camshaft

Front Bearing Replacement..... D-52

Checking

Connecting Rod

Crank

Pins D-42

Checking

Crankshaft Alignment .

.

D-40

Checking

Main Bearing Journals. D-41

Cleaning.

. D-33 Connecting Rod Bearing Inspection D-48

Connecting Rod Bearings D-47 Connecting Rod Side Play D-50

Core

Hole Expansion Plug D-72

Crankshaft

.

.

D-38, 39

Crankshaft

Main Bearing Inspection D-44

Crankshaft

Main Bearings D-43

Crankshaft

Rear

Bearing Seal D-63

Cylinder

Block D-32

Cylinder

Bores D-35

Cylinder

Head. . . D-73

Exhaust

Valve Seat Insert Replacement. .

.

D-60

Fitting

Crankshaft Main Bearings

Using

Plastigage

D-45

Fitting

Crankshaft Main Bearings

Using

Shim Stock D-46

Floating

Oil Intake D-64

Flywheel.

. . .D-67

Flywheel

Housing D-71

SUBJECT

FAR.

Flywheel

Inspection. D-6 8

Flywheel

Pilot Bushing D-70 Inspection D-3 4

Inspection of Valves, Springs and Guides. .D-57

Installing

Connecting Rod Bearings....... D-49

Oil

Pan D-66

Oil

Pump D-65

Piston Ring Application

Chart

D-3 7

Pistons, Rings, and Connecting Rods..... D-36

Refacing

Valves

.

D-58

Ring

Gear

Replacement D-69

Rocker

Arm Shaft Disassembly. D-75, 76

Rocker

Arm Shaft Reassembly.

.

D-77

Rocker

Arms D-74

Tappets and Cover. . D-62

Timing

Gears and Cover D-54, 55

Valve

Guide Replacement D-61

Valve

Seat Inspection and Refacing D-59

Valve,

Springs and Guides D-56

ENGINE REASSEMBLY

D-78

Camshaft

and

Thrust

Plate .D-81

Camshaft

Timing

Gear

D-91

Check

Crankshaft

End-Play.

............D-83

Clutch.

...D-89

Crankshaft

and Bearings................ D-82

Crankshaft

Pulley D-96

Crankshaft

Rear

Bearing Seal.. .

.

D-85

Crankshaft

Timing

Gear

D-84

Cylinder

Head D-98

Distributor

D-l

00

Flywheel

®. . .. D-87

Flywheel

Housing D-88

Front

End Plate D-86

Manifold.......

D-101

Oil

Filler

Tube D-102

Oil

Gallery Plug. D-79

Oil

Pan. D-97

Oil

Pump D-93

Pistons and Connecting Rods D-95

Rocker

Arm Assembly D-99

Spark

Plugs. .D-100

Tappets D-80

Timing

Gear

Cover D-94

Timing

Gear

Oil Jet D-92

Valves

and Springs ... D-90

Water

Outlet Fitting D-104

Water

Pump D-103

ENGINE INSTALLATION.

............D-105

FINAL IN-VEHICLE

ADJUSTMENTS.

.D-106

Check

Valve Timing . . D-109

Crankcase

Ventilation Valve. D-l 10

Oil

Filter

, . .

...D-lll

Valve

Adjustment D-107

Valve

Adjustment Procedure D-l08

SERVICE

DIAGNOSIS

D-112

SPECIFICATIONS D-l

13 37

Page 40 of 376

D

HURRICANE

F4

ENGINE ®

® ® ® ®

®

® @> ® ® ®® ® (§) 11759

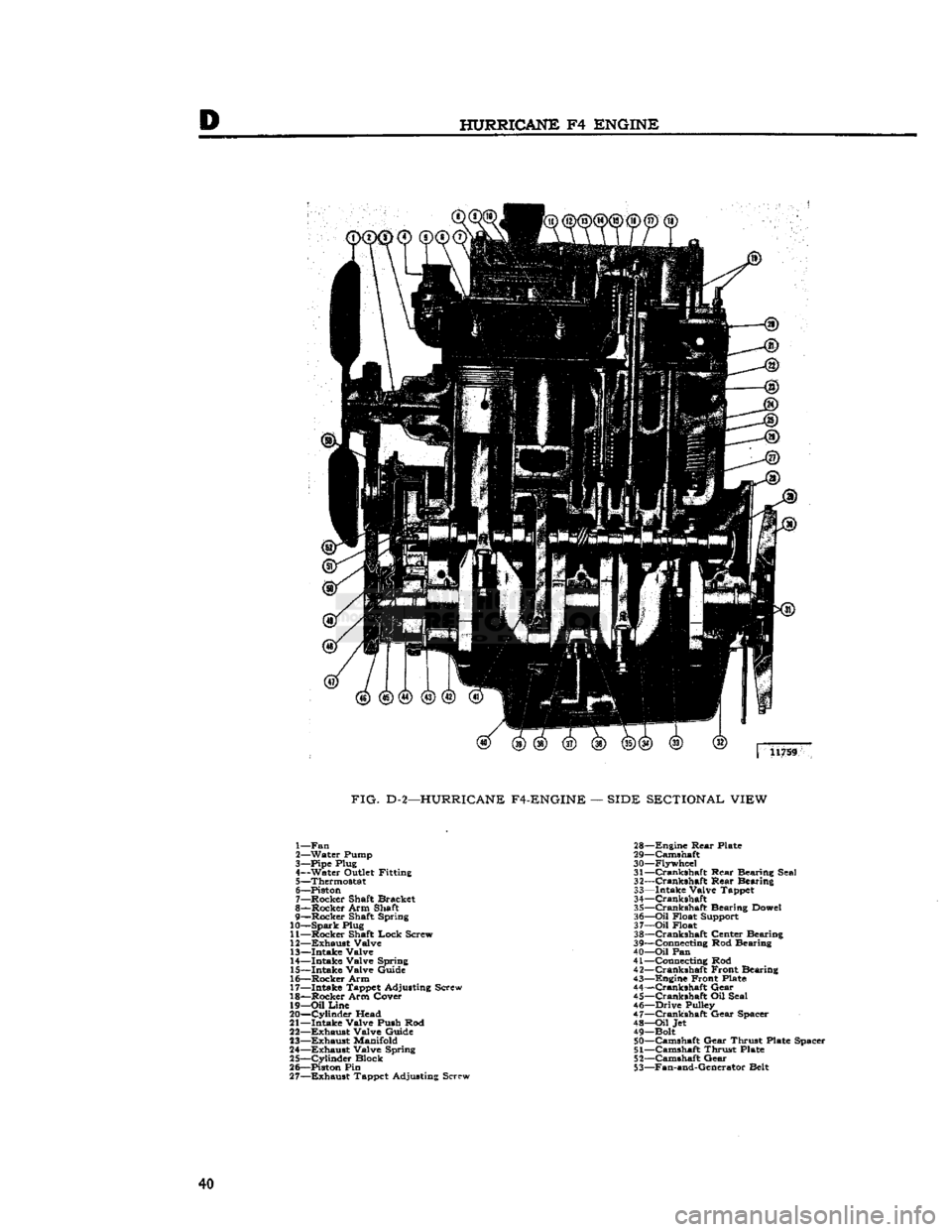

FIG.

D-2—HURRICANE F4-ENGINE

—

SIDE SECTIONAL VIEW

1— Fan

2— Water Pump

3— Pipe Plug

4— Water Outlet Fitting 5— Thermostat

6— Piston

7— Rocker Shaft Bracket

8— Rocker Arm Shaft

9— Rocker Shaft Spring

10—

Spark

Plug

11— Rocker Shaft Lock Screw

12—

Exhaust

Valve 13— Intake Valve

14— Intake Valve Spring

15— Intake Valve Guide

16— Rocker Arm

17— Intake Tappet Adjusting Screw

18— Rocker Arm Cover 19—

Oil

Line

20—

Cylinder

Head

21— Intake Valve Push Rod

22—

Exhaust

Valve Guide

23—

Exhaust

Manifold

24—

Exhaust

Valve Spring

25—

Cylinder

Block

26— Piston Pin 27—

Exhaust

Tappet Adjusting Screw 28—

Engine

Rear

Plate

29— Camshaft

30— Flywheel 31—

Crankshaft

Rear Bearing Seal

32—

Crankshaft

Rear Bearing

33— Intake Valve Tappet

34—

Crankshaft

35—

Crankshaft

Bearing Dowel

36—

Oil

Float Support

37—

Oil

Float

38—

Crankshaft

Center Bearing

39— Connecting Rod Bearing

40—

Oil

Pan

41— Connecting Rod

42—

Crankshaft

Front Bearing

43— Engine Front Plate

44—

Crankshaft

Gear

45—

Crankshaft

Oil Seal

46— Drive Pulley

47—

Crankshaft

Gear Spacer 48—

Oil

Jet

49— Bolt 50— Camshaft Gear Thrust Plate Spacer

51—

Camshaft Thrust Plate

52— Camshaft Gear

53— Fan-and-Generator Belt 40

Page 41 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

D

insulator

mountings attached to the frame side

rail

brackets. The

rear

of the engine-transmission

assembly is supported by a rubber insulator

mounting under the

rear

of the transmission on

the frame center cross member.

This

cross member

is bolted to the frame side

rails

so that it can be

dropped when removing the transmission or engine-

transmission

assembly. The rubber insulators allow

free side and vertical oscillation to effectively

neutralize

engine

vibration at the source.

The

rubber

insulator mountings should be inspected

for separation and deterioration by jacking the

power plant away from the frame, near the sup

ports. Vibration cannot be effectively absorbed by

separated or worn insulators. They should be re placed if faulty.

D-4.

Engine

Ground

Strap

To

be sure of an

effective

ground for the electrical

circuits,

a ground strap bridges the right front

engine

support to the chassis. The connections of this strap must be kept clean and tight for proper

operation of the electrical system.

D-5. ENGINE REMOVAL

Should

the

engine

require overhauling, it is neces

sary

to remove it from the vehicle. The following procedure covers removal of the

engine

only.

The

engine, transmission and transfer case may be

removed as a unit by removing (in addition to the following procedure) the radiator guard and the

access plates in the floor pan.

a.

Drain

the cooling system by opening the

drain

cocks at the

bottom

of the radiator and lower right

side of the cylinder block.

b.

Disconnect the battery at the positive terminal

to avoid the possibility of short

circuit.

c. Remove the air cleaner horn from the carburetor

and

disconnect the breather

hose

at the oil filler

pipe.

d.

Disconnect the carburetor choke and throttle controls by loosening the clamp

bolts

and set

screws.

e. Disconnect the fuel-tank-to-fuel-pump line at the fuel pump by unscrewing the connecting nut.

f- Plug the fuel line to prevent fuel leakage.

g. Remove the radiator and radiator grille support

rods.

h. Remove the upper and lower radiator

hoses

by

loosening the

hose

clamps and slipping the clamps

back

on the

hose.

If so equipped, remove the heater

hoses

(one to the water pump, one to the

rear

of

the cylinder head) in the same manner.

i.

Remove the four

bolts

from the fan hub and re

move

the fan hub and fan blades.

j.

Remove the four radiator attaching screws. Re

move

the radiator and shroud as one unit, k. Remove the starting motor cables. Remove the

starting

motor.

I.

Disconnect the wires from the alternator or

generator. Disconnect the ignition

primary

wire

at the ignition coil.

NOTE:

ON

ENGINES EQUIPPED WITH EX

HAUST

EMISSION CONTROL, REMOVE THE

AIR

PUMP,

AIR

DISTRIBUTION

MANI

FOLD,

AND

ANTI-BACKFIRE (DIVERTER)

VALVE.

SEE SECTION

Fl

FOR PROCEDURE.

m.

Disconnect the oil pressure and temperature

sending unit wires at the units.

n.

Disconnect the exhaust pipe at the exhaust

manifold by removing the stud nuts.

o.

Disconnect the

spark

plug cables at the plugs

and

remove the cable bracket from the rocker arm cover stud.

p.

Remove the rocker arm cover by removing the

attaching stud nuts.

q.

Attach a lifting bracket to the

engine

using

existing head bolt locations. Be sure the

bolts

selected

will

hold the

engine

with the weight

balanced.

Attach lifting bracket to a boom hoist,

or

other lifting device, and take up all slack,

r.

Remove the two nuts and

bolts

from each front

engine

support. Disconnect the

engine

ground strap.

Remove the

engine

supports.

Lower

the

engine

slightly to permit access to the two top

bolts

on

the flywheel housing.

s. Remove the

bolts

which attach the flywheel

housing to the engine.

t.

Pull

the

engine

forward, or

roll

the vehicle back

wards,

until the clutch clears the flywheel housing.

Lift

the

engine

from the vehicle.

D-6. ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some

of the operations of the procedure are also ap

plicable

separately with the

engine

in the vehicle,

provided

that wherever necessary the part of the

engine

to be worked on is first made accessible by

removal

of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have been removed

prior

to starting the disassembly

and

the oil has been drained.

In

addition to the instructions covering operations

for disassembling the

engine

out of the vehicle,

special

instructions are given to cover different

operations required when disassembly is

done

with the

engine

installed.

During

disassembly operations, the

engine

should

be mounted in a suitable

engine

repair

stand. Where

practicable,

modify or adapt an existing repair

stand

as necessary to accommodate the engine. If

an

engine

repair stand is not used, take care to

perform

disassembly operations in a manner that

will

protect personnel against an accident and the

engine

and its parts against damage.

NOTE:

If the

engine

is being disassembled because

of possible valve failure, check the valve tappet

clearance

before disassembly. Improper valve

clearance

could be the possible cause of valve

failure,

indicating a need for more frequent valve

checks and adjustments. 41

Page 43 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

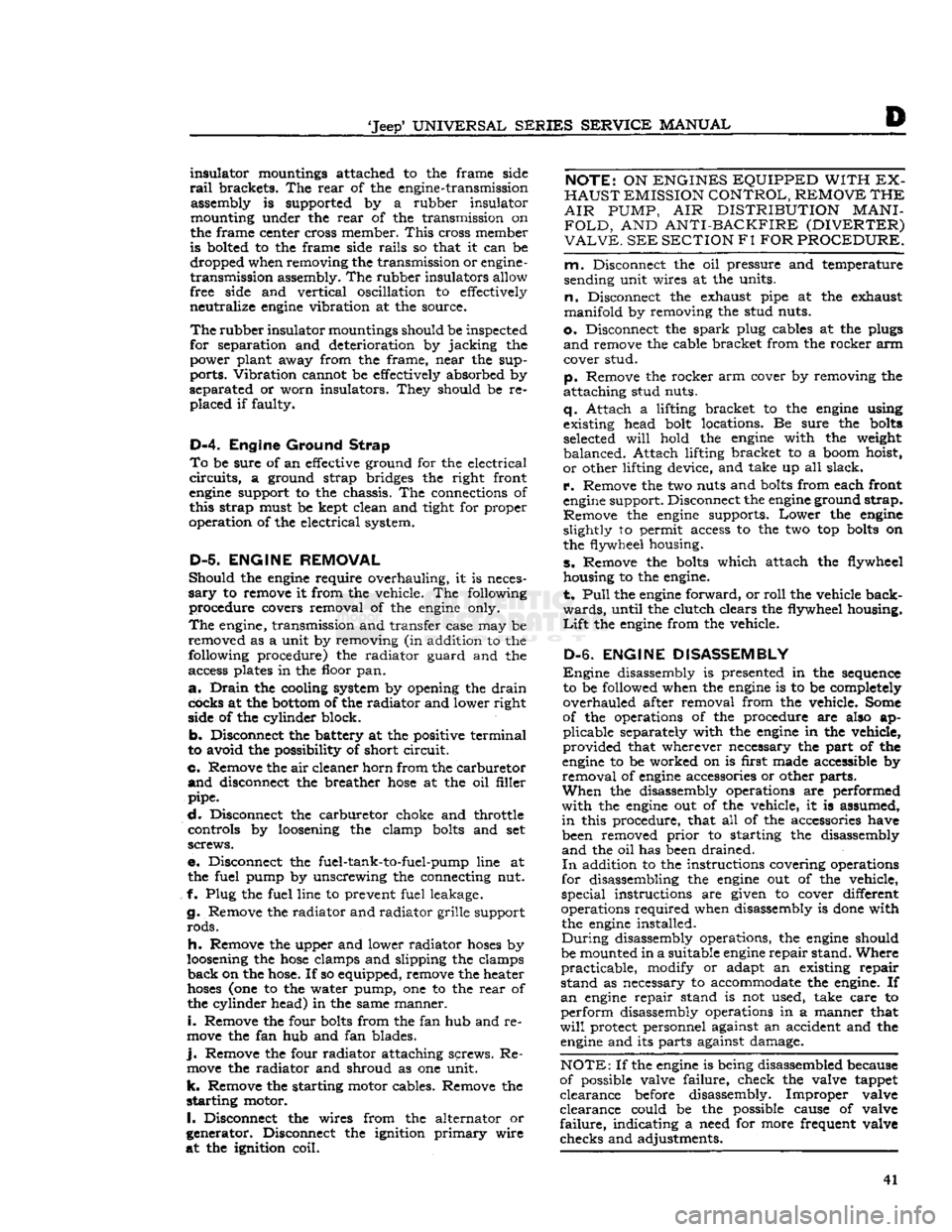

FIG.

D-4—F4-134

ENGINE

1— Dowel Bolt

2— Bolt

3— Flywheel Ring Gear

4— Flywheel 5—

Clutch

Pilot Bushing

6— Lockwasher

7— Nut

8— Flywheel Housing

9—

Cable

10— Engine Plate (Rear)

11— Woodruff Key

12— Camshaft Thrust Plate

13— Spacer

14— Camshaft Gear

15— Washer

16—

Crankshaft

Shim (.002 *)

17—

Crankshaft

Thrust Washer

18—

Crankshaft

Gear

19— Spacer

20—

Oil

Slinger

21—

Crankshaft

Oil Seal

22— Packing Ring

23—

Gear

Cover Gasket

24—

Gear

Cover

25—Pulley

26—

Crankshaft

Pulley Nut

27—

Timing

Indicator

28— Engine Support Front Insulator

29—

Front

Engine Plate

30— Bolt 31—

Front

Plate Gasket 14251

43

Page 44 of 376

D

HURRICANE

F4

ENGINE

Note:

Check

the condition of the rubber O-rings.

Defective O-rings could be the major cause of oil

leakage into cylinders. Always discard and replace

all

O-rings removed as only new O-rings should be installed at reassembly.

D-18.

Ream

Cylinder

Bore Ridges

To

prevent breaking the piston lands, the ridge

at the top of each cylinder bore must be removed

first.

To remove this ridge, use a cylinder ridge

reamer,

as shown in Fig. D-3 following the instruc

tions furnished by the reamer manufacturer. Use

care

not to cut below the top of the upper ring

travel

in the bore. Keep each piston top covered

with

an oil-soaked cloth to prevent cuttings from

falling

into the cylinder.

Note:

This

operation should be performed at this

time before the

engine

is rotated for the sequence

steps

following.

D-19.

Remove Oil Pan

Rotate the

engine

to the upside down position.

Remove the screws and lockwashers that attach

the oil pan to the cylinder block. Remove the oil

pan

and gasket.

Discard

the gasket.

D-20.

Remove Piston and Connecting

Rod

Assemblies

Remove the stamped locking nuts from the lower

end of each connecting rod bearing bolt. Remove

the connecting rod nuts. Remove the bearing cap evenly. Push the connecting rod and piston as

sembly out of the cylinder block with the handle end of a hammer until the piston rings are free from

the cylinder bore. Remove the piston and connecting rod assembly

from

the top of the cylinder block. Reassemble the

connecting rod bearing cap with the bearings in

place in the rod from which it was removed. Rotate

the crankshaft and follow the same procedure until

all

the piston and connecting rod assemblies are

removed.

Pistons and connecting rod assemblies may be removed for repair with the

engine

in the vehicle after draining the cooling system, removing the

oil

pan and the cylinder head, and reaming the ridges as previously described.

D-21.

Remove

Timing

Gear

Cover

Remove the bolts, nuts, and lockwashers, that at

tach

the timing gear cover to the engine. Remove

the cover, timing pointer, and cover gasket.

Dis

card

the gasket. Remove the crankshaft oil seal

from

the timing gear cover and discard the seal. Remove the oil slinger and spacer from the

crank

shaft.

D-22.

Remove

Timing

Gears

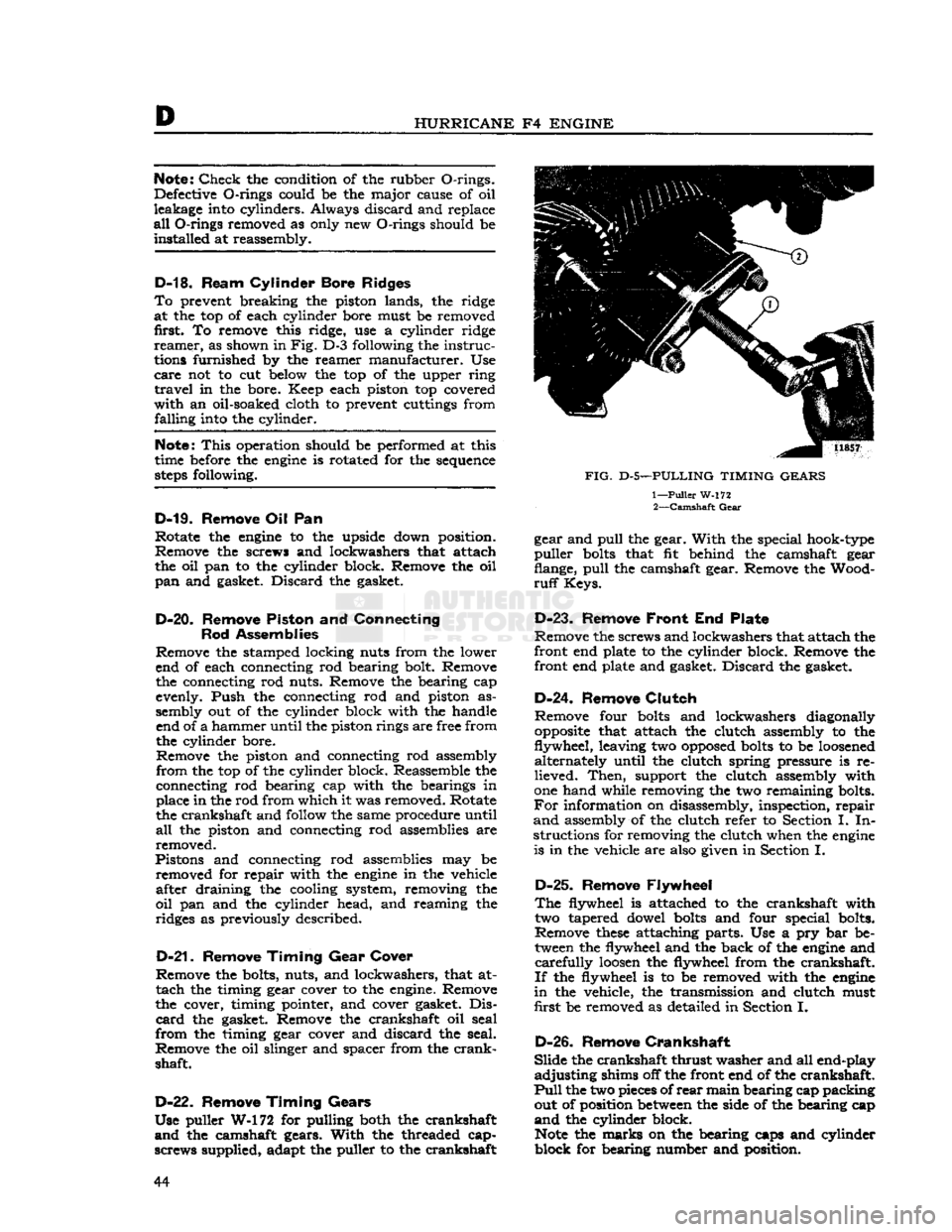

Use puller W-172 for pulling both the crankshaft

and

the camshaft gears.

With

the threaded cap-

screws supplied, adapt the puller to the crankshaft

FIG.

D-5—PULLING TIMING GEARS

1—

Puller

W-172 2—

Camshaft

Gear

gear and

pull

the gear.

With

the special hook-type

puller

bolts

that fit behind the camshaft gear

flange,

pull

the camshaft gear. Remove the Wood

ruff

Keys.

D-23.

Remove

Front

End Plate

Remove the screws and lockwashers that attach the

front end plate to the cylinder block. Remove the

front end plate and gasket.

Discard

the gasket.

D-24. Remove

Clutch

Remove four

bolts

and lockwashers diagonally

opposite

that attach the clutch assembly to the

flywheel, leaving two

opposed

bolts

to be

loosened

alternately until the clutch spring pressure is re

lieved.

Then,

support the clutch assembly with

one hand while removing the two remaining bolts.

For

information on disassembly, inspection, repair

and

assembly of the clutch refer to Section I. In

structions for removing the clutch when the

engine

is in the vehicle are also given in Section I.

D-25.

Remove Flywheel

The

flywheel is attached to the crankshaft with two tapered dowel

bolts

and four special bolts.

Remove

these

attaching parts. Use a pry bar be tween the flywheel and the back of the

engine

and

carefully

loosen

the flywheel from the crankshaft.

If

the flywheel is to be removed with the

engine

in

the vehicle, the transmission and clutch must

first be removed as detailed in Section I.

D-26.

Remove

Crankshaft

Slide

the crankshaft thrust washer and all end-play

adjusting

shims off the front end of the crankshaft.

Pull

the two pieces of

rear

main bearing cap packing out of position

between

the side of the bearing cap

and

the cylinder block.

Note

the marks on the bearing caps and cylinder

block for bearing number and position. 44

Page 45 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

D

Remove the screws and lockwashers that attach

the main bearing caps to the cylinder block. Use

a

lifting bar beneath the ends of each bearing cap.

Be

careful not to exert too much pressure to cause

damage to the cap or

dowels

and pry the caps free.

CAUTION:

If main bearing caps are not removed

carefully

by raising both sides of each cap evenly

until

free of the dowels, the

dowels

may be bent.

A

bent main bearing cap dowel can cause misalign ment of the cap and resultant

rapid

bearing wear

necessitating replacement. Therefore, remove each

main

bearing cap carefully. If there is reason to

believe any of the

dowels

have been bent during

the bearing cap removal, remove them and install

new

dowels

as detailed in Par. D-34c.

Remove the upper

half

of the

rear

main bearing

oil

seal from the cylinder block and the lower

half

from

the oil seal

groove

in the

rear

main bearing

cap.

Install

the main bearing caps and bearings on

the cylinder block in their original positions.

Note;

Removal of the crankshaft may be ac

complished only with the

engine

out of the vehicle.

D-27.

Remove

Exhaust

Valves and Springs

Access to the valve chamber is obtained by re moving the attaching parts and the valve spring

cover and gasket from the cylinder block. Use cloths

to block off the three

holes

in the exhaust valve

chamber to prevent the valve retaining locks falling

into the crankcase, should they be accidentally dropped.

With

a valve

/

spring compressor, compress the valve springs on

those

valves which are in the

closed position (valve seated against cylinder

block).

Remove the exhaust valve spring retainer

locks,

the exhaust valve spring retainer, and the exhaust valve spring. Close the other valves by

rotating the camshaft and repeat the above opera

tion for the other valves in the same manner.

Lift

out all the exhaust valves and tag or place them in

a

rack

to indicate the location where each was removed from the cylinder block. If a valve sticks in

the guide and cannot be easily lifted out,

pull

the valve upward as far as possible and remove the

spring.

Lower

the valve and remove any carbon

deposits

from the valve stem.

This

will

permit re moval of the valve.

For

intake valve and spring removal, see

Par.

D-l7.

D-28.

Remove Camshaft

a.

Push the intake and exhaust valve tappets into the cylinder block as far as possible so the ends of

the tappets are not in contact with the camshaft. b. Secure each tappet in the raised position by in

stalling a common clip-type clothes pin on the

shank

of each tappet or tie them up in the valve

chamber.

c. Remove the camshaft thrust plate attaching

screws.

Remove the camshaft thrust plate and

spacer.

d.

Pull

the camshaft forward out of the cylinder

block using care to prevent damage to the cam

shaft bearing surfaces.

D-29.

Remove Valve Tappets

Remove the intake and exhaust valve tappets from

the

bottom

or crankshaft side of the cylinder block

after the camshaft has been removed. Tag each

tappet or place them in a marked

rack

so they may be reassembled in their original positions.

D-30.

Remove Oil

Gallery

Plugs

Remove the plug at each end of the oil gallery in the cylinder block.

This

operation is only applicable

when the

engine

is out of the vehicle and

will

allow access to the oil gallery so it may be cleaned.

D-31. ENGINE INSPECTION

AND

REPAIR

The

inspection and repair procedures detailed here

in

are recommended to be followed when a com

plete

engine

overhaul is to be made with the

engine

out of the vehicle. These instructions can generally be applied individually with the

engine

in the

vehicle. Wherever the procedure differs due to

the

engine

being in the vehicle, the necessary

special

instructions are provided. Inspection and

repair

instructions are included to cover the

cylinder

block, cylinder head, crankshaft and bearings, connecting rods and bearings, oil pump, valves and tappets, pistons and rings, flywheel,

timing gears, and the camshaft and bearings. In addition, fitting operations for

these

engine

com

ponents

are included.

Important:

Before the inspection and repair pro

cedures listed below are begun, the

engine

serial

number must be checked for the presence of

code

letters denoting undersize bearings or oversize

pistons. Refer to Par. D-2.

D-32.

Cylinder

Block

The

cylinder block must be thoroughly cleaned, inspected and repaired as detailed in the following

paragraphs.

D-33.

Cleaning

The

cylinder block may be steam cleaned or cleaned

with

a suitable solvent. A scraper is recommended

to remove

hard

deposits, except on highly finished surfaces. Special attention must be directed to the

cleaning of the oil passages, valve chamber,

crank

case, and cylinder walls to remove all sludge,

dirt

and

carbon deposits. After cleaning, use air pressure to dry the block thoroughly.

D-34. Inspection

Examine

the cylinder block for minute cracks and

fractures.

Rusted valve springs or evidence of rust

in

the valve chamber or the cylinder walls is a

good

indication of a possible

crack

in the block,

a.

Examine all machined surfaces of the cylinder block for

burrs

and scores.

Check

for cylinder block

distortion by placing a straight

edge

along the

length of the cylinder head surface of the block.

With

a feeler

gauge,

check for clearance

between

the straight

edge

and the block, particularly be

tween adjacent cylinders. Maximum permissible

out of line for service is .010"

[0,254

mm.] over the

full

length of the block. 45

Page 54 of 376

D

HURRICANE

F4

ENGINE

against the hub of the crankshaft pulley.

Timing

gears are accessible for inspection or replacement

with

the

engine

installed in the vehicle after re moving the radiator, belt drive pulley, and timing

cover.

Should

it be necessary to replace the timing gears, attention must be given to the end float of both

the camshaft and crankshaft and to the running

clearance

of both gears. It is also advisable to

check

both the oil jet and oil passage to the

crank

shaft front bearing to be sure that they are clear.

D-55.

Inspection and

Repair

Check

the general condition of both gears and

inspect for evidence of excessive wear. Replace

excessively worn or damaged gears. Inspect the

cover and replace if bent or damaged. It is recom mended that the crankshaft oil seal in the cover

be replaced when the cover is removed to ensure a

good

seal around the crankshaft. To replace this

seal

with the

engine

in the vehicle

requires

removing

the radiator and water pump.

D-56.

Valves, Springs, and Guides

The

exhaust valves seat on the top of the cylinder

block

with the

stems

extending down through

replaceable valve guides. The exhaust valves are actuated by the camshaft through exhaust valve

tappets. The exhaust valve springs are assembled

and

locked on the lower end of the exhaust valve

stems. The retaining locks are the split type, which

fit in a recess on the valve

stems

and into the taper

in

the valve spring retainers.

Adjustment

of exhaust valves is by means of the

adjusting

screw threaded into the upper end of the

exhaust valve tappets. An exhaust valve rotator used as a valve spring retainer is installed on the

lower end of the exhaust valve.

This

valve rotator,

known

as "Roto Cap", is a spring-loaded

ball

bearing

device. On each lift, or opening stroke of

a

valve, the rotator

gives

the valve a slight positive

clockwise rotation.

The

intake valves operate in valve

guides

in the

cylinder

head and are actuated by rocker arms.

The

rocker arms are actuated by valve push rods

and

the intake valve tappets. The intake valve

springs,

the intake valve spring retainers, and the

intake

valve spring retainer locks make up the

remainder

of the valve operating parts. An intake

valve spring retainer oil seal which encircles the

upper

end of the intake valve

between

the valve

locks and the upper end of the valve spring re

tainer,

controls the passage of oil along the valve

stem and guide.

Note:

When

engine

trouble indicates defective

valves as a possible source of trouble, also check

all

vacuum line connections for possible leaks.

D-57.

Inspection of Valves, Springs,

and

Guides

Clean

the valves on a wire wheel, making sure that

all

carbon is removed from the top and the under

side of the heads and that all gum and varnish

deposits

are removed from the stems.

Polish

the valve

stems

with steel wool or crocus

cloth.

Visually

inspect all valves for warpage,

cracks,

or excessive burning and discard if one of

these

conditions exists. Replace any worn, pitted,

or

corroded valves that cannot be cleaned with a

wire

brush.

Replace any valves when

seats

are pitted, burned, or corroded so badly that they

cannot be cleaned up with a light refacing on a valve refacing machine.

Replace

valves with marks of scoring or abrasion visible on the stem. Replace any valves with bent

stems

which

will

be apparent when the valve is

mounted in the valve refacing machine.

Note:

Use only hard-face exhaust valves for

replacement.

Examine

the

stems

of valves which employ the

ball

bearing rotators.

Wear

marks around the

cir

cumference of the

stems

indicates that the valve is

rotating satisfactorily.

Vertical

heavy pressure

areas

indicate that the valve is not rotating and the valve spring retainer (Roto

Cap)

should be replaced

if

at fault.

Check

the diameter of the valve stem at two or three places along the length of the stem

with

a micrometer. The intake valve stem diameter is .3733" to .3738" [9,482 a

9,495

mm.]. The

exhaust valve stem diameter is .371" to .372"

[9,423

a

9,449

mm.].

Note:

Exhaust

and intake valve springs are

similar

in appearance. They must not be inter

changed as they have different spring

charac

teristics.

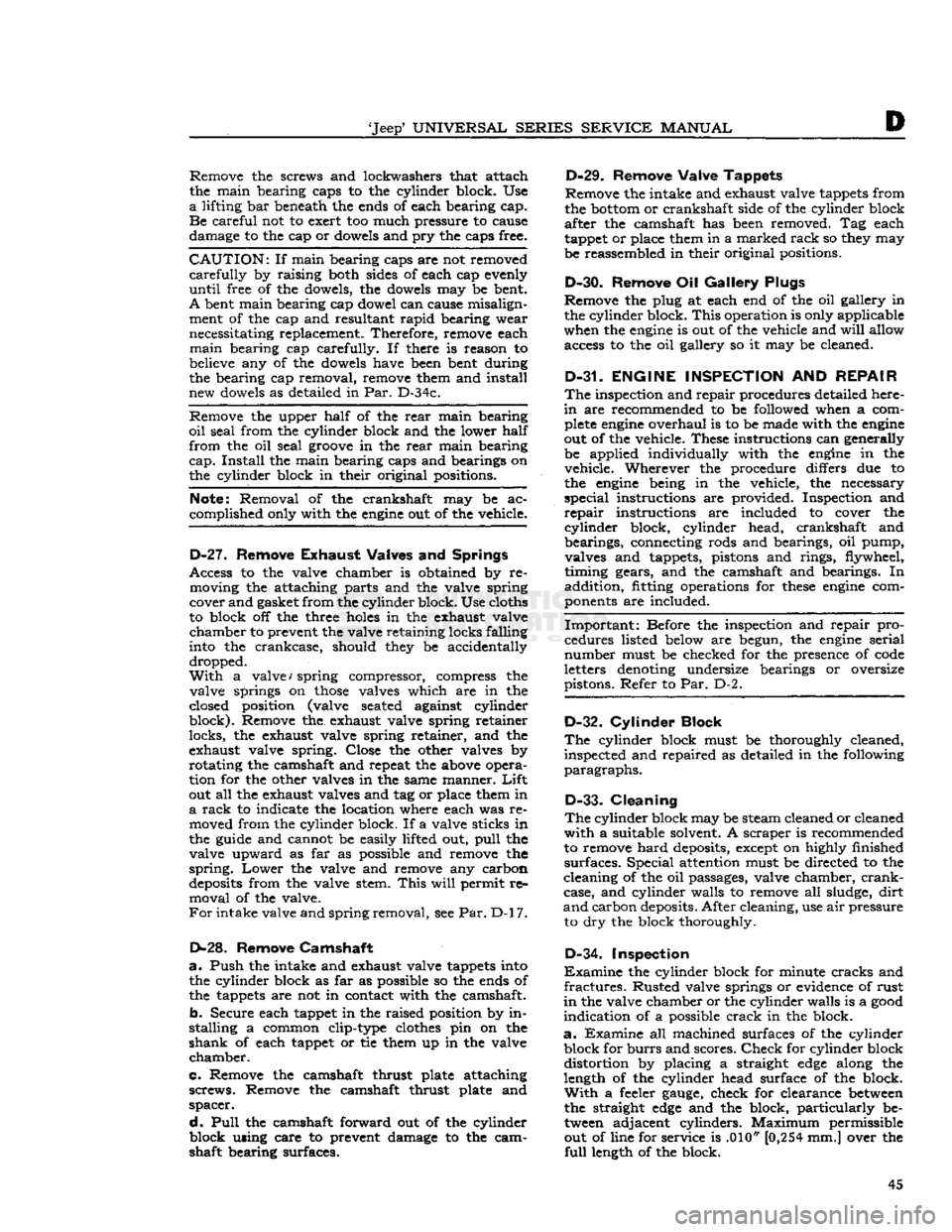

Wash

the valve springs thoroughly in solvent.

Visually

examine the springs and replace any that

are

deformed or obviously damaged. Examine for

corrosion

from moisture or acid etching which might

FIG.

D-19—TESTING

VALVE

SPRING

1—

Torque

Wrench

2—

Spring

Testing

Fixture

3—

Valve

Spring

54

Page 59 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

D

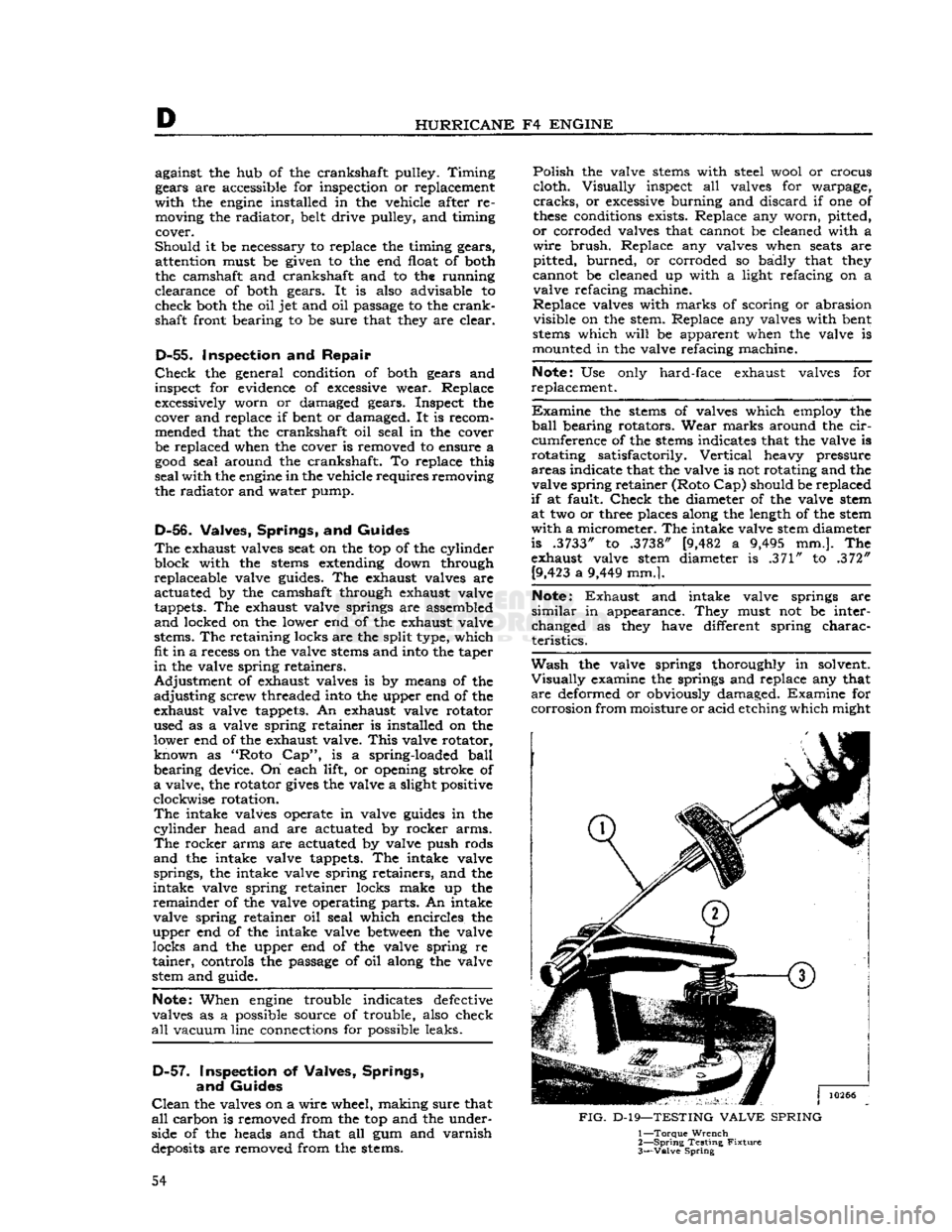

10262

FIG.

D-26—FLOATING OIL INTAKE AND PAN 1—

Oil

Float

2—

Gasket

3—

Oil

Float Support

4—

Screw and Lockwasher 5—

Oil

Pan Gasket

6—

Oil

Pan 7—

Bolt

and Lockwasher

8—

Drain

Plug

9—

Drain

Plug Gasket

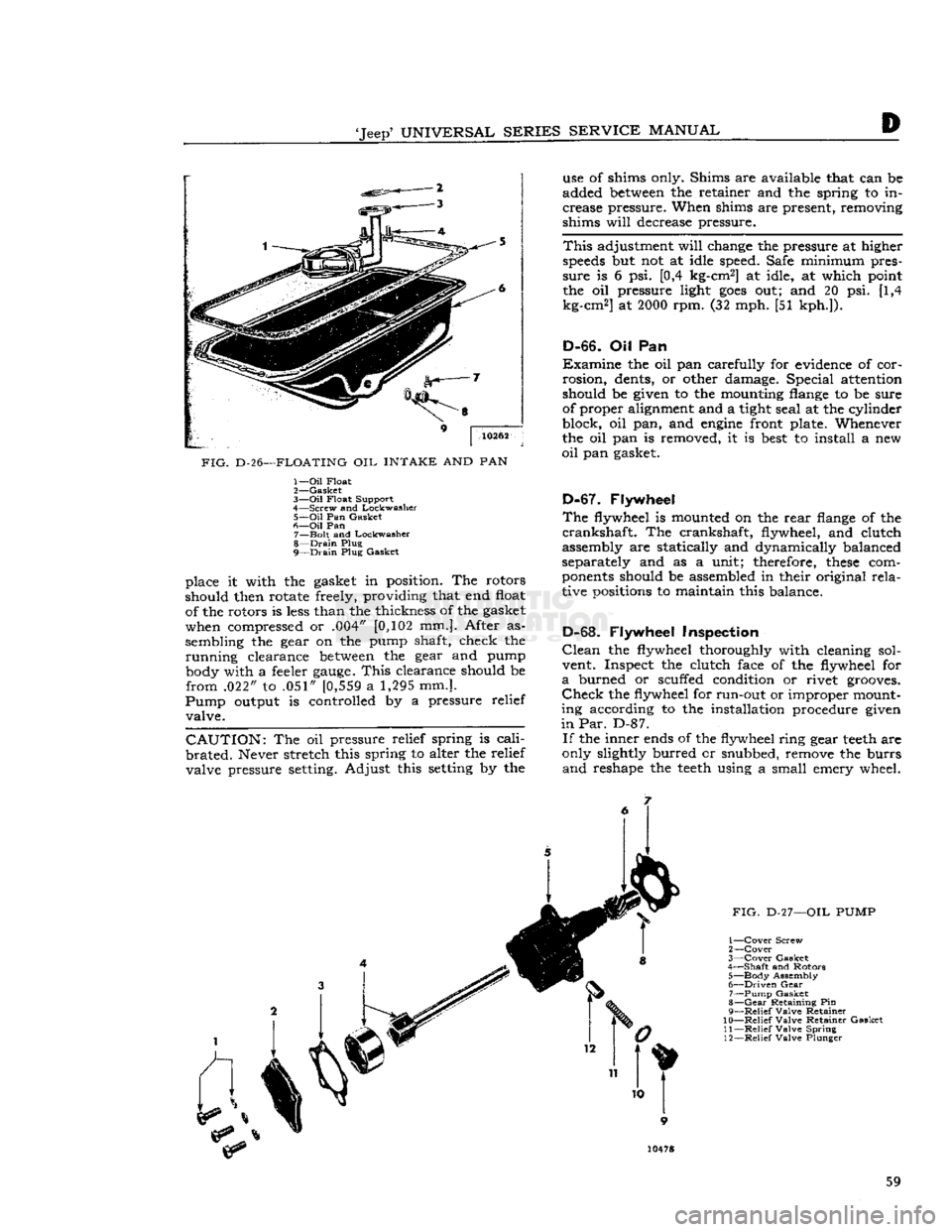

place it with the gasket in position. The rotors

should then rotate freely, providing that end float of the rotors is

less

than the thickness of the gasket

when compressed or .004" [0,102 mm.]. After as

sembling the gear on the pump shaft, check the

running

clearance

between

the gear and pump body with a feeler

gauge.

This

clearance should be

from

.022" to .051" [0,559 a 1,295 mm.].

Pump

output is controlled by a pressure relief valve.

CAUTION:

The oil pressure relief spring is

cali

brated.

Never stretch this spring to alter the relief valve pressure setting. Adjust this setting by the use of shims only. Shims are available that can be

added

between

the retainer and the spring to in

crease pressure. When shims are present, removing

shims

will

decrease pressure.

This

adjustment

will

change the pressure at higher

speeds

but not at idle speed. Safe minimum pres

sure

is 6 psi. [0,4 kg-cm2] at idle, at which point

the oil pressure light

goes

out; and 20 psi. [1,4

kg-cm2] at

2000

rpm. (32 mph. [51 kph.]).

D-66.

Oil Pan

Examine

the oil pan carefully for evidence of cor

rosion,

dents, or other damage. Special attention

should be given to the mounting flange to be sure of proper alignment and a tight seal at the cylinder

block, oil pan, and

engine

front plate. Whenever

the oil pan is removed, it is

best

to install a new

oil

pan gasket.

D-67.

Flywheel

The

flywheel is mounted on the

rear

flange of the

crankshaft.

The crankshaft, flywheel, and clutch

assembly are statically and dynamically balanced

separately and as a unit; therefore,

these

com

ponents

should be assembled in their original

rela

tive positions to maintain this balance.

D-68.

Flywheel Inspection

Clean

the flywheel thoroughly with cleaning sol vent. Inspect the clutch face of the flywheel for

a

burned or scuffed condition or rivet grooves.

Check

the flywheel for run-out or improper mount

ing according to the installation procedure given

in Par.

D-87.

If

the inner ends of the flywheel ring gear

teeth

are

only slightly burred cr snubbed, remove the burrs

and

reshape the

teeth

using a small emery wheel. 59

Page 60 of 376

HURRICANE

F4

ENGINE

FIG.

D-28-

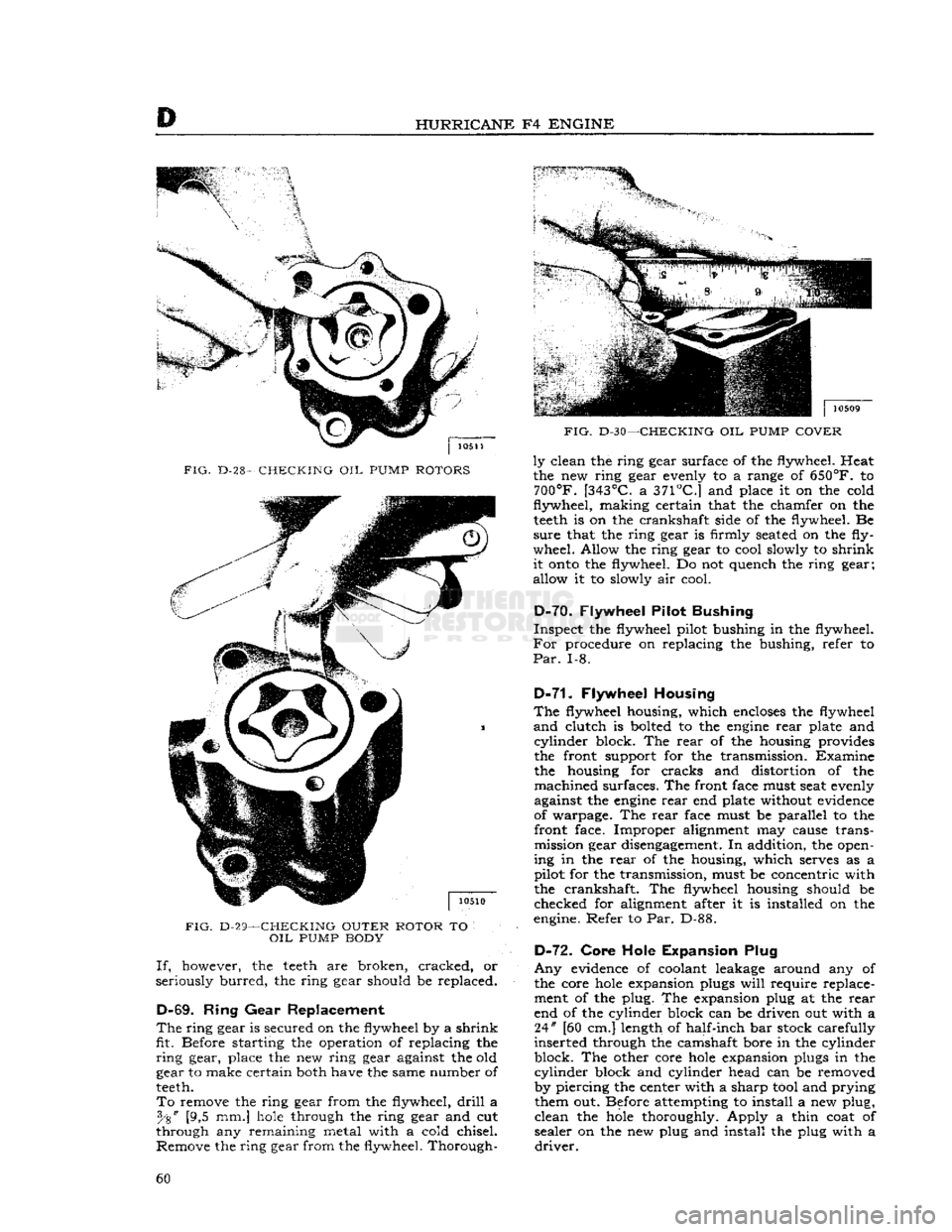

CHECKING

OIL

PUMP

ROTORS

FIG.

D-29—CHECKING OUTER ROTOR

TO

OIL

PUMP

BODY If,

however, the

teeth

are broken, cracked, or

seriously

burred,

the ring gear should be replaced.

D-69.

Ring

Gear

Replacement

The

ring

gear

is secured on the flywheel by a

shrink

fit. Before starting the operation of replacing the

ring

gear, place the new ring gear against the old

gear to make certain both have the same number of

teeth.

To

remove the ring gear from the flywheel,

drill

a [9,5 mm.]

hole

through the ring gear and cut

through any remaining metal with a cold chisel. Remove the ring gear from the flywheel. Thorough-

FIG.

D-30—CHECKING

OIL

PUMP

COVER

ly

clean the ring gear surface of the flywheel. Heat

the new ring gear evenly to a range of

650°F.

to

700°F.

[343°C.

a

371°C.]

and place it on the cold

flywheel,

making

certain that the chamfer on the

teeth

is on the crankshaft side of the flywheel. Be

sure

that the ring gear is firmly seated on the fly

wheel. Allow the ring gear to cool slowly to

shrink

it

onto

the flywheel. Do not quench the ring gear;

allow it to slowly air cool.

D-7Q.

Flywheel Pilot Bushing

Inspect

the flywheel pilot bushing in the flywheel.

For

procedure on replacing the bushing, refer to

Par.

1-8.

D-71.

Flywheel Housing

The

flywheel housing, which

encloses

the flywheel

and

clutch is bolted to the

engine

rear

plate and

cylinder

block. The

rear

of the housing provides

the front support for the transmission. Examine the housing for cracks and distortion of the

machined

surfaces. The front face must seat evenly

against the

engine

rear

end plate without evidence

of warpage. The

rear

face must be parallel to the front face. Improper alignment may cause transmission gear disengagement. In addition, the open

ing in the

rear

of the housing, which serves as a

pilot for the transmission, must be concentric with the crankshaft. The flywheel housing should be

checked for alignment after it is installed on the

engine. Refer to Par. D-88.

D-72.

Core Hole Expansion Plug

Any

evidence of coolant leakage around any of

the core

hole

expansion plugs

will

require replace ment of the plug. The expansion plug at the

rear

end of the cylinder block can be driven out with a 24" [60 cm.] length of half-inch bar stock carefully

inserted through the camshaft bore in the cylinder

block. The other core

hole

expansion plugs in the

cylinder

block and cylinder head can be removed

by piercing the center with a sharp tool and prying them out. Before attempting to install a new plug,

clean

the

hole

thoroughly. Apply a thin coat of

sealer on the new plug and install the plug with a

driver.

60

Page 64 of 376

D

HURRICANE

F4

ENGINE

FIG.

D-34—GAUGING

CRANKSHAFT

END

PLAY

FIG.

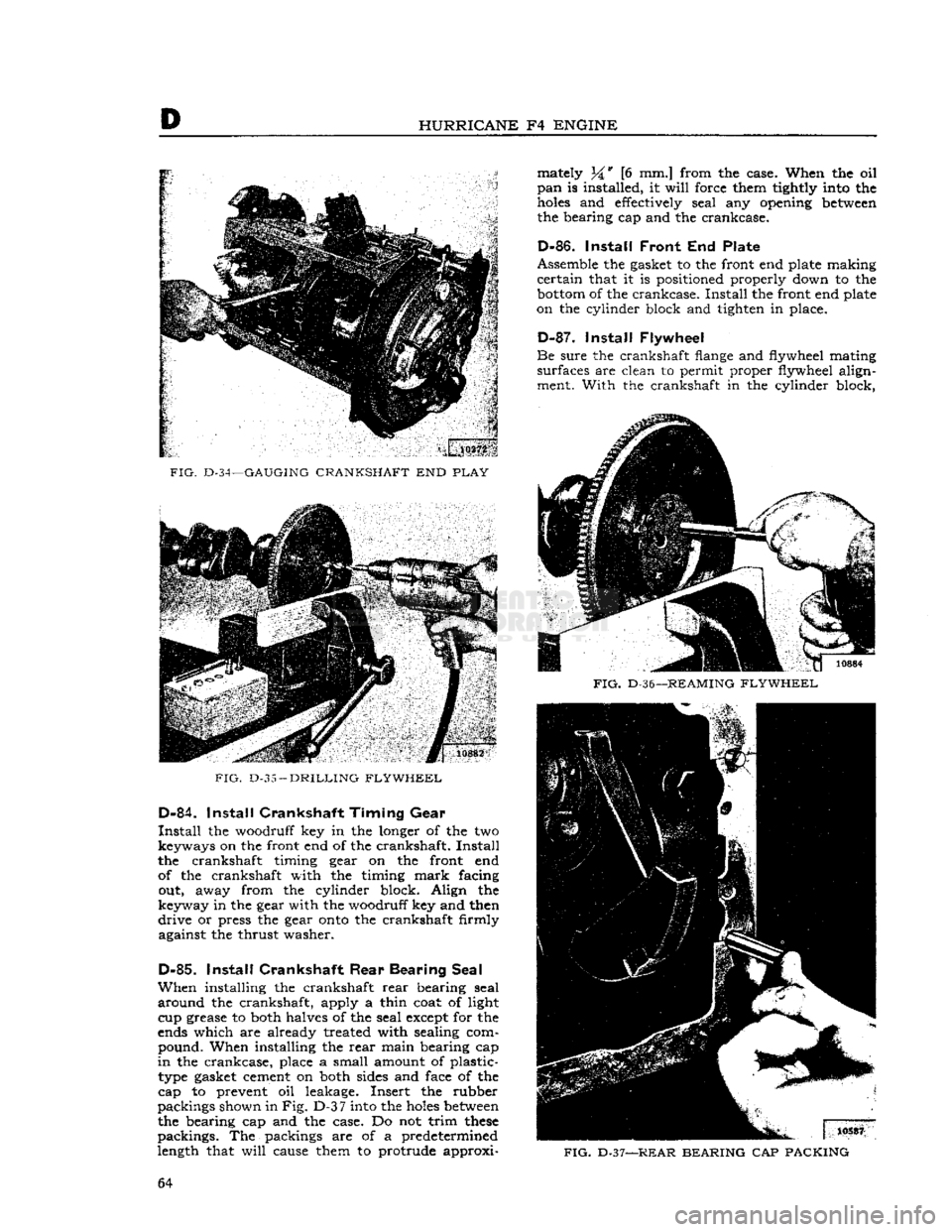

D-35

—

DRILLING FLYWHEEL

D-84.

Install

Crankshaft Timing

Gear

Install

the woodruff key in the longer of the two keyways on the front end of the crankshaft.

Install

the crankshaft timing gear on the front end of the crankshaft with the timing

mark

facing out, away from the cylinder block. Align the

keyway in the gear with the woodruff key and then

drive

or press the gear

onto

the crankshaft firmly against the thrust washer.

D-85.

Install

Crankshaft

Rear

Bearing Seal

When

installing the crankshaft

rear

bearing seal

around

the crankshaft, apply a thin coat of light cup grease to both halves of the seal except for the

ends which are already treated with sealing com pound. When installing the

rear

main bearing cap

in

the crankcase, place a small amount of plastic- type gasket cement on both sides and face of the

cap to prevent oil leakage. Insert the rubber

packings shown in

Fig. D-3

7

into the

holes

between

the bearing cap and the case. Do not trim

these

packings. The packings are of a predetermined

length that

will

cause them to protrude approxi mately 34* [6 mm.] from the case. When the oil

pan

is installed, it

will

force them tightly into the

holes

and effectively seal any opening

between

the bearing cap and the crankcase.

D-86.

Install

Front

End Plate

Assemble the gasket to the front end plate making

certain

that it is positioned properly down to the

bottom

of the crankcase.

Install

the front end plate

on the cylinder block and tighten in place.

D-87.

Install

Flywheel

Be

sure the crankshaft flange and flywheel mating

surfaces are clean to permit proper flywheel align ment. With the crankshaft in the cylinder block,

FIG.

D-36—

REAMING FLYWHEEL

FIG.

D-37—REAR

BEARING

CAP

PACKING

64