engine JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 359 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

U

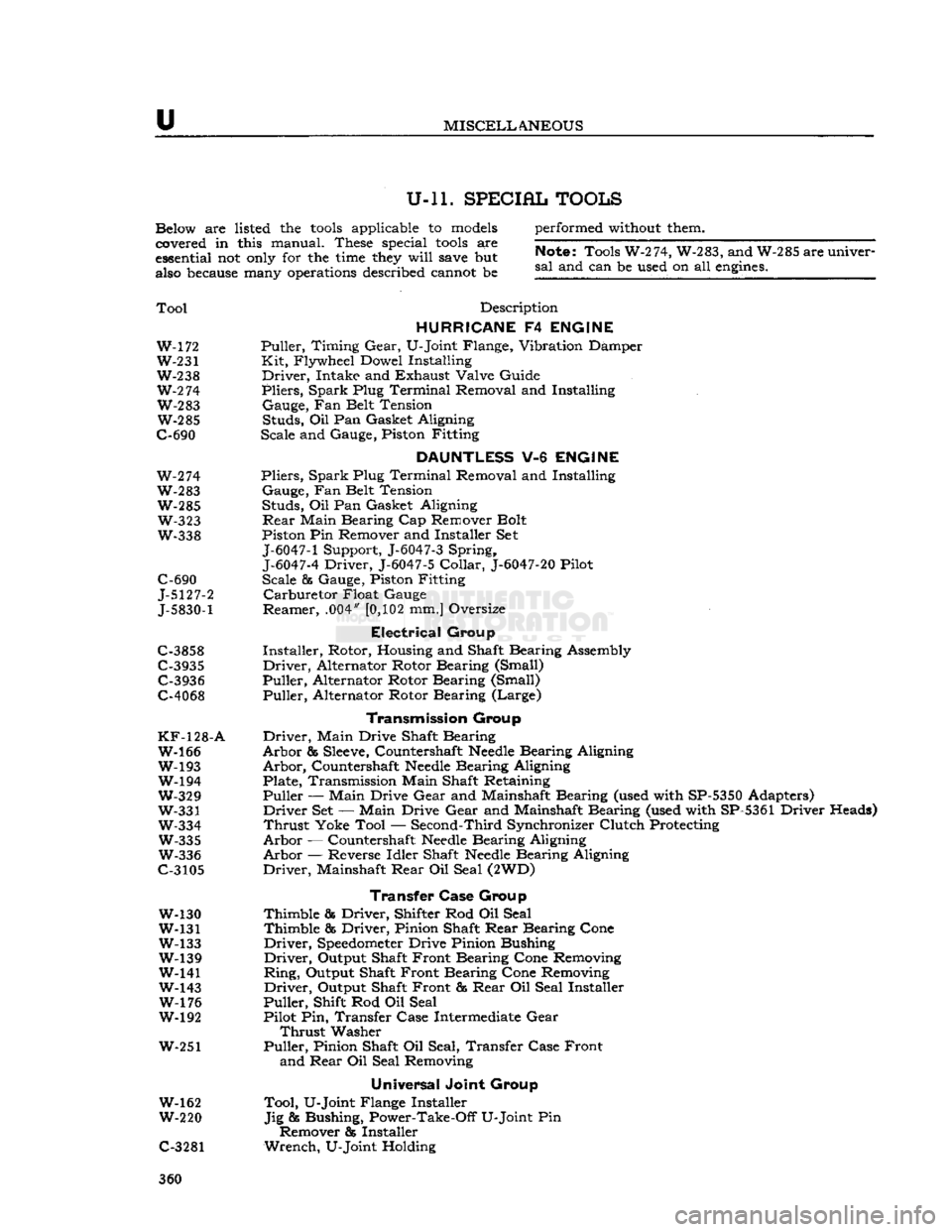

U-10. FRESH AIR HEATER AND

DEFROSTER

Refer to Fig. U-4.

Air

circulation of the

heater

and

defroster

unit

is

accomplished

by the use of a

12-volt,

two-speed

fan

motor.

Outside

air may be drawn

through

the

vehicle

fresh air

intake

shroud

into

the fan and

blown

out

across

the

heater

core

where

it is

heated

by the

hot circulating

coolant

from the

engine.

The

heated

air

then

enters

the transition

duct.

From the transi

tion

duct

the

heated

air

passes

into

the

heat

distri

butor

where

it is

distributed

to the

defroster

nozzle

and/or

floor

diffuser.

The

heater

and

defroster

controls

are

mounted

in the

control

panel

on the

instrument

panel. A

three-position

switch

mounted

in the

control

panel

operates

the

heater

fan.

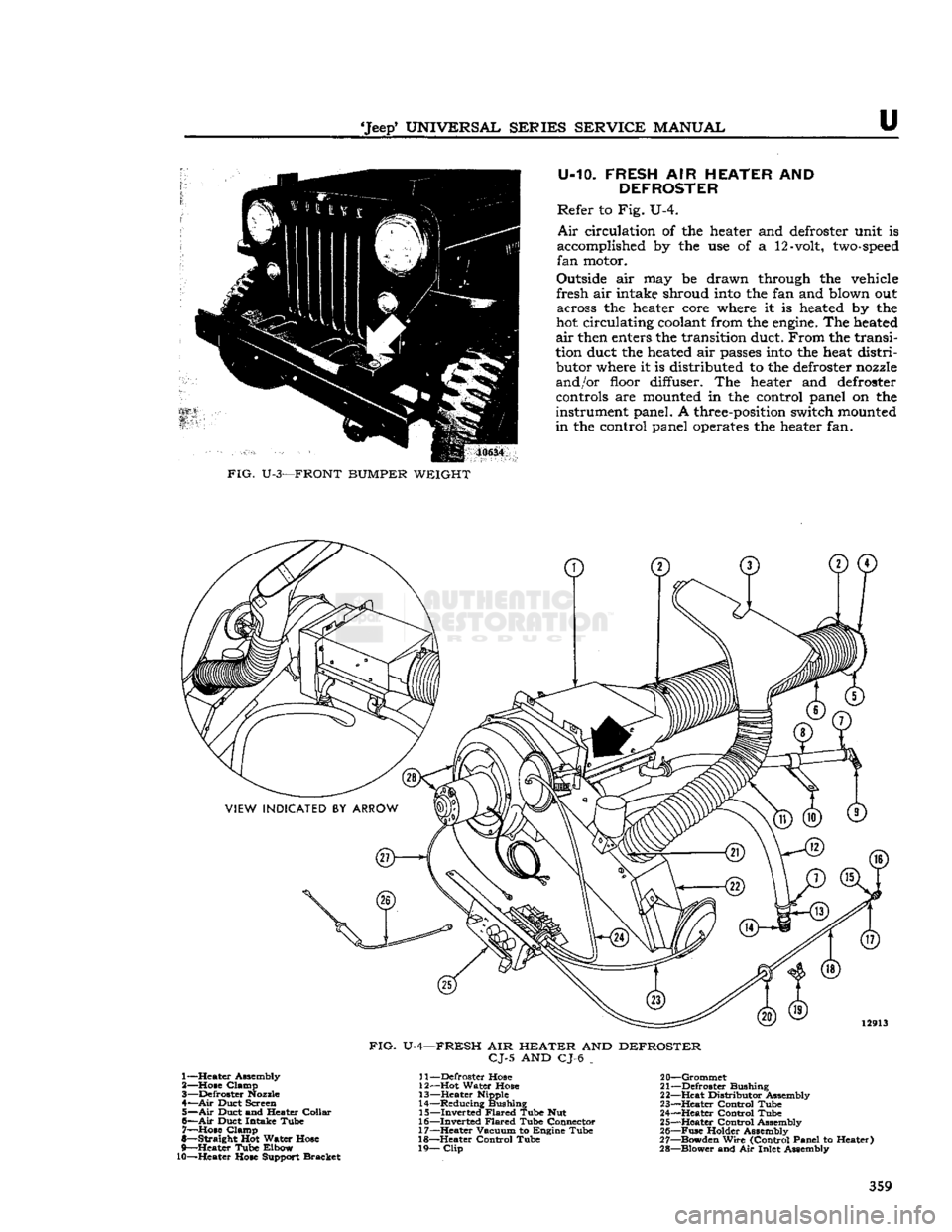

FIG.

U-3—FRONT

BUMPER

WEIGHT

FIG.

U-4-

-FRESH

AIR

HEATER

AND

DEFROSTER

CJ-5

AND CJ-6 _ 1— Heater Assembly

2— Hose Clamp

3— Defroster

Nozzle

4—

Air

Duct Screen 5—

Air

Duct and Heater Collar

6—

Air

Duct Intake Tube 7— Hose Clamp

8— Straight Hot Water Hose

9— Heater Tube Elbow

10—Heater Hose Support Bracket

I

j—Defroster Hose

12— Hot Water Hose

13— Heater Nipple

14— Reducing Bushing

15— Inverted Flared Tube Nut

16— Inverted Flared Tube Connector

17— Heater Vacuum to Engine Tube

18— Heater Control Tube

19—

Clip

20— Grommet

21— Defroster Bushing

22— Heat Distributor Assembly

23— Heater Control Tube

24— Heater Control Tube

25— Heater Control Assembly

26—

Fuse

Holder Assembly

27— Bowden Wire (Control Panel to Heater)

28— Blower and Air Inlet Assembly 359

Page 360 of 376

u

MISCELLANEOUS

U-ll. SPECIAL TOOLS

Below are listed the

tools

applicable to

models

covered in this manual. These special

tools

are

essential not

only

for the

time

they

will

save

but

also

because

many

operations

described cannot be performed

without

them.

Note;

Tools W-274, W-283, and W-285 are univer

sal

and can be used on all

engines.

Tool

Description

HURRICANE

F4

ENGINE

W-172 Puller, Timing

Gear,

U-Joint Flange, Vibration Damper W-231 Kit, Flywheel Dowel Installing

W-238 Driver, Intake and Exhaust Valve Guide

W-2

74 Pliers, Spark Plug Terminal Removal and Installing W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning

C-690 Scale and Gauge, Piston Fitting

DAUNTLESS

V-6

ENGINE

W-274 Pliers, Spark Plug Terminal Removal and Installing

W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning W-323

Rear

Main Bearing Cap Remover Bolt

W-338 Piston Pin Remover and Installer Set

J-6047-1

Support, J-6047-3 Spring,

J-6047-4

Driver, J-6047-5

Collar,

J-6047-20

Pilot

C-690 Scale & Gauge, Piston Fitting

J-5127-2 Carburetor Float Gauge

J-5830-1

Reamer, .004"

[0,102

mm.] Oversize

Electrical

Group

C-3858 Installer, Rotor, Housing and Shaft Bearing Assembly

C-3935 Driver, Alternator Rotor Bearing (Small) C-3936 Puller, Alternator Rotor Bearing (Small)

C-4068 Puller, Alternator Rotor Bearing (Large)

Transmission

Group

KF-128-A

Driver, Main Drive Shaft Bearing W-166 Arbor &

Sleeve,

Countershaft

Needle

Bearing Aligning

W-193 Arbor, Countershaft

Needle

Bearing Aligning W-194 Plate, Transmission Main Shaft Retaining

W-329 Puller — Main Drive

Gear

and Mainshaft Bearing (used with SP-5350 Adapters)

W-331 Driver Set — Main Drive

Gear

and Mainshaft Bearing (used with SP-5361 Driver Heads)

W-334 Thrust Yoke Tool — Second-Third Synchronizer Clutch Protecting W-335 Arbor — Countershaft

Needle

Bearing Aligning

W-336 Arbor — Reverse Idler Shaft

Needle

Bearing Aligning

C-3105 Driver, Mainshaft

Rear

Oil Seal (2WD)

Transfer Case

Group

W-130 Thimble & Driver, Shifter Rod Oil Seal

W-131 Thimble & Driver, Pinion Shaft

Rear

Bearing Cone

W-133 Driver,

Speedometer

Drive Pinion Bushing W-139 Driver, Output Shaft Front Bearing Cone Removing

W-141 Ring, Output Shaft Front Bearing Cone Removing

W-143 Driver, Output Shaft Front &

Rear

Oil Seal Installer W-176 Puller, Shift Rod Oil Seal

W-192 Pilot Pin, Transfer Case Intermediate

Gear

Thrust

Washer

W-251 Puller, Pinion Shaft Oil Seal, Transfer Case Front and

Rear

Oil Seal Removing

Universal

Joint Group

W-162 Tool, U-Joint Flange Installer

W-220 Jig & Bushing, Power-Take-Off U-Joint Pin Remover & Installer

C-3281 Wrench, U-Joint Holding 360

Page 361 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

U

DESCRIPTION

—

Continued

AXLES

W-99* Gauge — Pinion & Ring

Gear

Setting

W-104-B* Puller — Tapered Roller Bearing Removing

W-126* Driver — Pinion Bearing Cup

W-128* Installer — Differential Inner Oil Seal W-129 Spreader — Differential

Carrier

Housing

W-138* Driver & Adapter —

King

Pin Bearing

W-144* Wrench — Wheel Bearing Adjusting Nut W-147* Driver — Pinion Oil Seal W-163* Puller

—-

Axle Shaft Drive Flange

W-186* Driver — Axle Shaft Oil Seal

W-188* Driver — Differential Case Bearing W-251* Puller — Pinion Oil Seal

W-262*

Sleeve

— Pinion Bearing Installing

W-263

Semi-Floating

Rear

Axle Shaft Oil Seal W-264* Driver — Pinion Outer Bearing Cup

W-297* Torque Wrench — Pinion Bearing Adjusting W-343* Remover

85

Installer —

Rear

Axle Bearing (Flanged Axle)

W-344* Installer — Pinion Inner Bearing Cups

C-319-A

Puller —

Rear

Wheel Hub (Tapered Axle Shaft)

C-690 Checking Scale —

King

Pin Bearing Preload DD-914-P Press — Tapered Roller Bearing Removing

DD-914-9 Reducer Ring — Differential & Pinion Bearings (Use with DD-914-P)

C-3

716 Driver — Differential

Carrier

Bearing C-4142

Gear

Rotating Tool —

Trac-Lok

Differential

**Jeep*

exclusive

tool

Steering

Group

C-3646 Puller, Steering Shaft Arm

Brake

Group

W-172 Puller, Parking Brake Drum

U-12.

STflNDfiRD

AND

RECOMMENDED

TOOLS

Tool

Description

ENGINE

W-292

Tester — Cooling

System

Thermostat

C-119 Indicator — Cylinder Bore C-385 Compressor — Piston Ring

C-647 Fixture — Spring Testing

C-823

Hone

— Cylinder Bore Refinishing

C-3012 Reamer — Cylinder Ridge

C-3250 Pliers — Radiator fis Heater

Hose

Wire Clamp

C-3411

Gauge — Pressure & Vacuum

C-3422-A Compressor — E-type Valve Spring

C-3501

Hone

— Cylinder

Deglazing

C-3514

Flusher — Cooling

System

C-3886 Fixture — Carburetor Holding C-3896-A Tachometer — Portable

C-3943 Gauge — Compression Checking

C-3952 Torque Wrench, 150

lb-ft.

Swivel Head C-3953 Stand, Engine Repair

C-3959 Light — Ignition Timing

C-4065 Wrench — Oil Filter Removing

C-4080 Tester — Cooling

System

fig

Pressure Cap

ELECTRICAL

40B Hydrometer — Battery Service

W-291 Tester — Instrument

C-3674

Aimers —

Headlight

(Pair)

C-3829 Tester —

Diode

Polarity

C-3888 Tester — Volt-Ampere C-3950 Tester — 12V 60 Amp. Carbon Pile Resistor 361

Page 362 of 376

u

MISCELLANEOUS

U-12.

STANDARD

AND

RECOMMENDED TOOLS

(Continued)

Tool

Description

CLUTCH

W-296 Fixture — Adjusting

TRANSMISSION

C-3201

- A

Lo-Jack

— Floor Type

AXLE

C-637 Puller — Axle Shaft & Oil Seal

STEERING

DD-428 Gauge — Camber & Caster

DD-435 Turntables — Wheel Alignment C-3479 Gauge & Scribe — Toe-in Checking

BRAKES

C-416 Clamps — Brake Cylinder Retaining C-3080 Hone — Brake Cylinder

C-3496-B Bleeder — Hydraulic Pressure Type C-3785 Remover & Installer — Brake Return Spring

C-3920 Micrometer — Brake Drum Checking

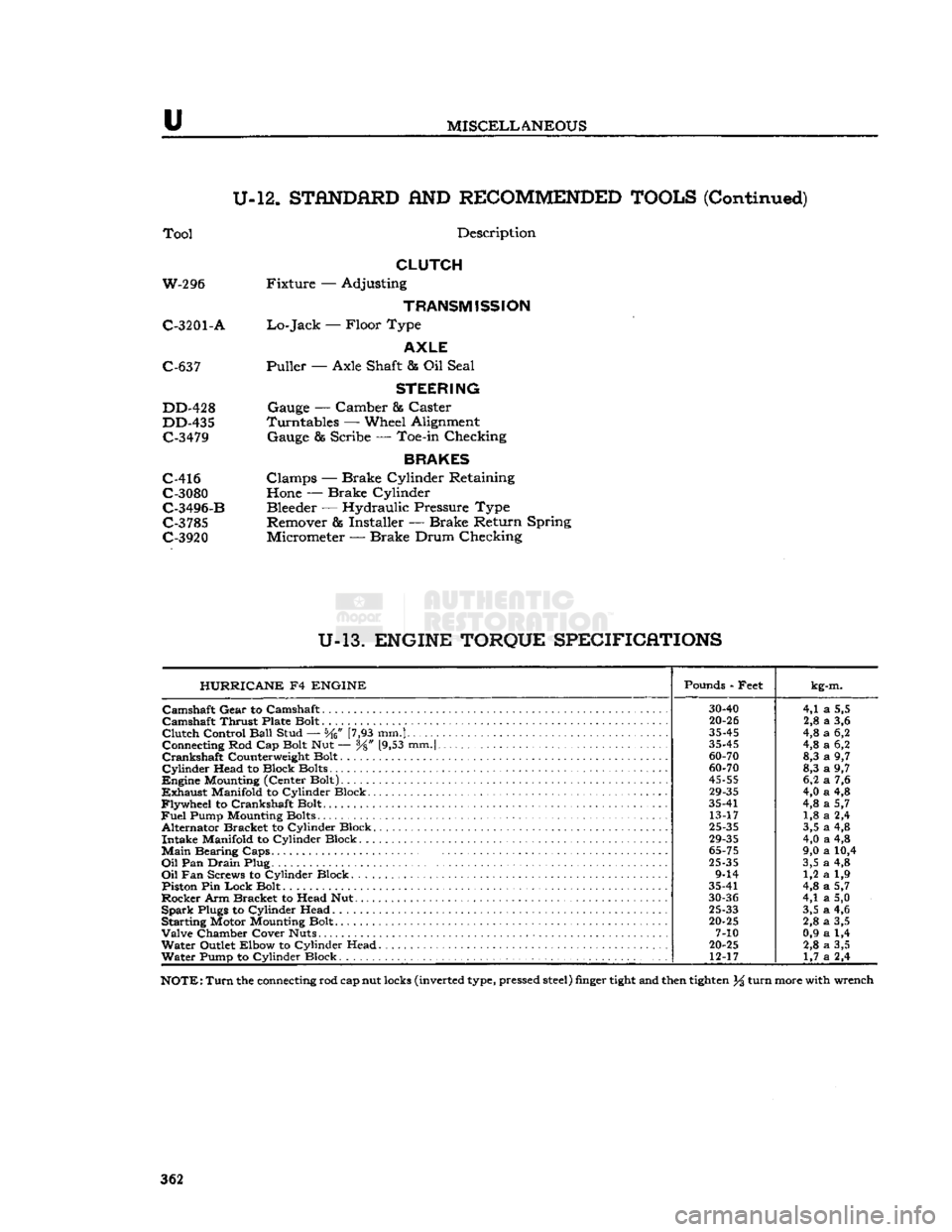

U-13.

ENGINE TORQUE SPECIFICATIONS HURRICANE

F4

ENGINE

Pounds - Feet

kg-m.

30-40

4,1

a

5,5

Camshaft

Thrust Plate Bolt

20-26

2,8

a

3,6

Clutch

Control

Ball

Stud — [7,93 mm.]

35-45

4,8

a

6,2

Connecting Rod Cap Bolt Nut — y8" [9,53 mm.|

35-45

4,8

a

6,2

60-70

8,3

a

9,7

Cylinder

Head to Block Bolts

60-70

8,3

a

9,7

45-55

6,2

a

7,6

29-35

4,0

a

4,8

Flywheel

to Crankshaft Bolt. 35-41

4,8

a

5,7

Fuel

Pump Mounting Bolts 13-17 1,8

a

2,4

Alternator Bracket to Cylinder Block.

25-35

3,5

a

4,8

29-35

4,0

a

4,8

Main

Bearing

Caps.

.

65-75

9,0

a

10,4

Oil

Pan

Drain

Plug

25-35

3,5

a

4,8

9-14 1,2

a

1,9

Piston Pin

Lock

Bolt 35-41

4,8

a

5,7

30-36

4,1

a

5,0

Spark

Plugs to Cylinder Head

25-33

3,5

a

4,6

Starting Motor Mounting Bolt.

20-25

2,8

a

3,5

7-10 0,9

a

1,4

Water

Outlet Elbow to Cylinder Head

20-25

2,8

a

3,5

Water

Pump to Cylinder Block 12-17

1,7

a

2,4

NOTE:

Turn

the connecting rod cap nut locks (inverted type, pressed

steel)

finger

tight

and then

tighten

% turn more with wrench

362

Page 363 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

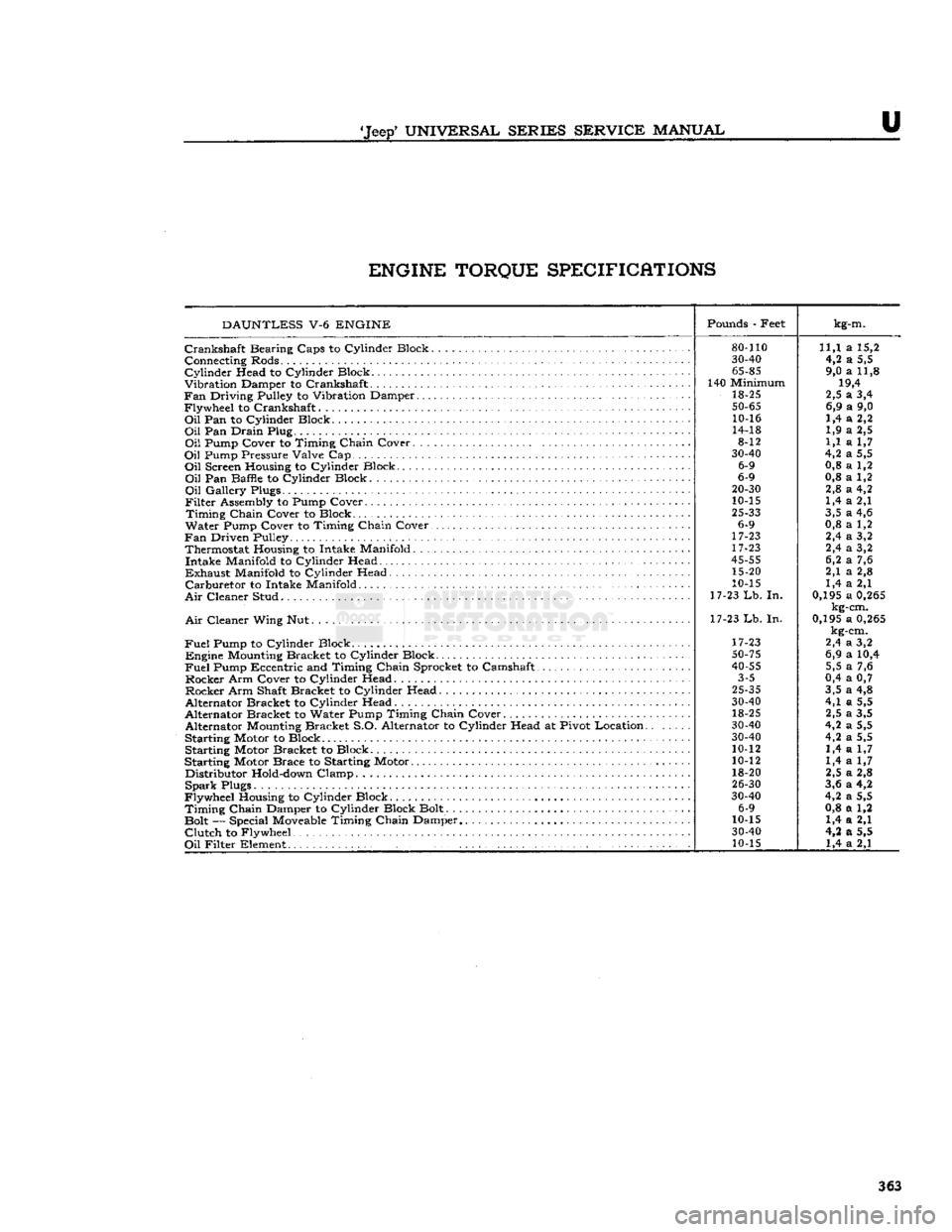

U ENGINE TORQUE SPECIFICATIONS

DAUNTLESS

V-6

ENGINE

Pounds

- Feet

kg-m.

80-110

11,1 a 15,2

30-40

4,2 a 5,5

65-85

9,0 a 11,8

140 Minimum 19,4

18-25 2,5 a 3,4

50-65

6,9 a 9,0

10-16 1,4 a 2,2

14-18 1,9 a 2,5

8-12 1,1 a 1,7

30-40

4,2 a 5,5

6-9 0,8 a 1,2

6-9 0,8 a 1,2

20-30

2,8 a 4,2

10-15 1,4 a 2,1

25-33

3,5 a 4,6

6-9 0,8 a 1,2

17-23 2,4 a 3,2

17-23 2,4 a 3,2

45-55

6,2 a 7,6

15-20 2,1 a 2,8

10-15 1,4 a 2,1

17-23

Lb.

In. 0,195 a

0,265

kg-cm.

17-23 Lb. In. 0,195 a

0,265

kg-cm.

17-23 2,4 a 3,2

50-75

6,9 a 10,4

40-55

5,5 a 7,6

3-5 0,4 a 0,7

25-35

3,5 a 4,8

30-40

4,1 a 5,5

18-25 2,5 a 3,5

30-40

4,2 a 5,5

30-40

4,2 a 5,5

10-12 1,4 a 1,7

10-12 1,4 a 1,7

18-20 2,5 a 2,8

26-30

3,6 a 4,2

30-40

4,2 a 5,5

6-9 0,8 a 1,2

10-15 1,4 a 2,1

30-40

4,2 a 5,5

10-15 1,4 a 2,1

Crankshaft

Bearing Caps to Cylinder Block.

Connecting Rods.

Cylinder

Head to Cylinder Block

Vibration Damper to Crankshaft

Fan

Driving Pulley to Vibration Damper

Flywheel to Crankshaft

Oil

Pan to Cylinder Block

Oil

Pan Drain Plug

Oil

Pump Cover to Timing Chain Cover. . .

Oil

Pump Pressure Valve Cap

Oil

Screen Housing to Cylinder Block

Oil

Pan Baffle to Cylinder Block

Oil

Gallery Plugs.

Filter

Assembly to Pump Cover

Timing

Chain Cover to Block

Water Pump Cover to Timing Chain Cover.

Fan

Driven Pulley Thermostat Housing to Intake Manifold. . . Intake Manifold to Cylinder Head

Exhaust

Manifold to Cylinder Head

Carburetor

to Intake Manifold

Air

Cleaner Stud

Air

Cleaner Wing Nut.

Fuel

Pump to Cylinder Block . . Engine

Mounting

Bracket to Cylinder Block

Fuel

Pump Eccentric and Timing Chain Sprocket to Camshaft

Rocker Arm Cover to Cylinder Head Rocker Arm Shaft Bracket to Cylinder Head

Alternator Bracket to Cylinder Head

Alternator Bracket to Water Pump Timing Chain Cover Alternator

Mounting

Bracket S.O. Alternator to Cylinder Head at Pivot Location.

Starting Motor to Block Starting Motor Bracket to Block

Starting Motor Brace to Starting Motor Distributor

Hold-down

Clamp

Spark

Plugs

Flywheel Housing to Cylinder Block

Timing

Chain Damper to Cylinder Block Bolt.

Bolt — Special

Moveable

Timing Chain Damper

Clutch

to Flywheel

Oil

Filter Element .' 363

Page 364 of 376

u

MISCELLANEOUS

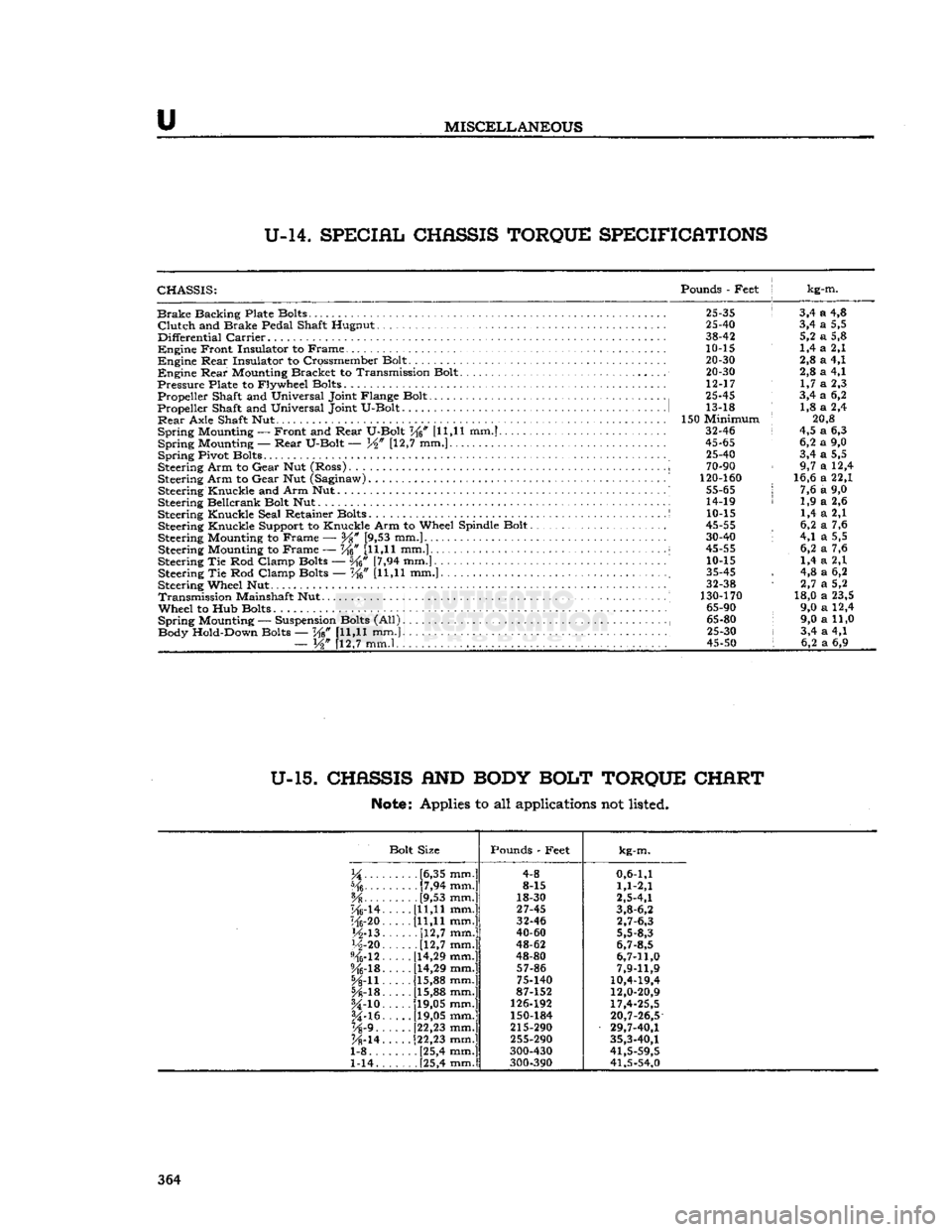

U-14.

SPECIAL

CHASSIS

TORQUE

SPECIFICATIONS

CHASSIS:

Pounds

-

Feet

j kg-m.

Brake

Backing Plate Bolts.

25-35 ! 3,4 a 4,8

Clutch

and

Brake Pedal Shaft Hugnut

25-40 3,4 a 5,5

Differential

Carrier

38-42 5,2 a 5,8

Engine

Front Insulator

to

Frame.

10-15 1,4 a 2,1

Engine

Rear

Insulator

to

Crossmember Bolt.

. . ... 20-30 2,8 a 4,1

Engine

Rear

Mounting Bracket

to

Transmission Bolt.

20-30 2,8 a 4,1

Pressure

Plate

to

Flywheel Bolts

12-17 1,7 a 2,3

Propeller Shaft

and

Universal Joint Flange Bolt

25-45 3,4 a 6,2

Propeller Shaft

and

Universal Joint U-Bolt

1 13-18 : 1,8 a 2,4

Rear

Axle Shaft

Nut 150

Minimum

; 20,8

Spring

Mounting

—

Front

and

Rear

U-Bolt

V^n [11,11 mm.] 32-46 i 4,5 a 6,3

Spring

Mounting —-

Rear

U-Bolt

— [12,7 mm.] 45-65 6,2 a 9,0

Spring

Pivot Bolts

." 25-40 3,4 a 5,5

Steering Arm

to

Gear

Nut

(Ross)

..

i

70-90 9,7 a 12,4

Steering Arm

to

Gear

Nut

(Saginaw)

' 120-160 16,6 a 22,1

Steering Knuckle

and

Arm Nut..........

55-65 j 7,6 a 9,0

Steering Bellcrank Bolt

Nut 14-19 < 1,9 a 2,6

Steering Knuckle Seal Retainer Bolts

S 10-15 1,4 a 2,1

Steering Knuckle Support

to

Knuckle Arm

to

Wheel Spindle Bolt

45-55 , 6,2 a 7,6

Steering Mounting

to

Frame

—

Y%

[9,53 mm.] 30-40 '• 4,1 a 5,5

Steering Mounting

to

Frame

— W [11,11

mm.]...

i 45-55 6,2 a 7,6

Steering

Tie Rod

Clamp Bolts

— [7,94 mm.] 10-15 1,4 a 2,1

Steering

Tie Rod

Clamp Bolts

— Ke" [U,H mm.] ; 35-45 , 4,8 a 6,2

Steering Wheel

Nut 32-38 1 2,7 a 5,2

Transmission

Mainshaft

Nut 130-170 18,0 a 23,5

Wheel

to Hub

Bolts

65-90 9,0 a 12,4

Spring

Mounting

—

Suspension Bolts

(All) , 65-80 9,0 a 11,0

Body Hold-Down Bolts

— W [11,11 mm.} 25-30 i 3,4 a 4,1

—

W [12,7 mm.l , . . 45-50 I 6,2 a 6,9

U-15.

CHASSIS

AND

BODY

BOLT

TORQUE

CHART

Note:

Applies to all applications not listed.

Bolt Size Pounds

-

Feet

kg-m.

.....

[6,35 mm.] 4-8

0,6-1,1

[7,94 mm.] 8-15

1,1-2,1

[9,53 mm.] 18-30

2,5-4,1

"Mrl4.

[11,11 mm.]

27-45

3,8-6,2

116-20. [11,11 mm.] 32-46

2,7-6,3

M-13.

[12,7

mm.]

40-60

5,5-8,3

H-20

[12,7

mm.]

48-62

6,7-8,5

%-12.

[14,29 mm.]

48-80

6,7-11,0

%-lB.

[14,29 mm.]

57-86

7,9-11,9

5A-n. [15,88 mm.]

75-140

10,4-19,4

[15,88 mm.] 87-152

12,0-20,9

U-io.

[19,05 mm.]

126-192

17,4-25,5

§4-16.

[19,05 mm.]

150-184

20,7-26,5

Vs'9..

[22,23 mm.]

215-290

29,7-40,1

K-14.

[22,23 mm.]

255-290

35,3-40,1

1-8 [25,4 mm.] 300-430

41,5-59,5

1-14. . [25,4 mm.]

300-390 41,5-54,0 364

Page 365 of 376

u

MISCELLANEOUS

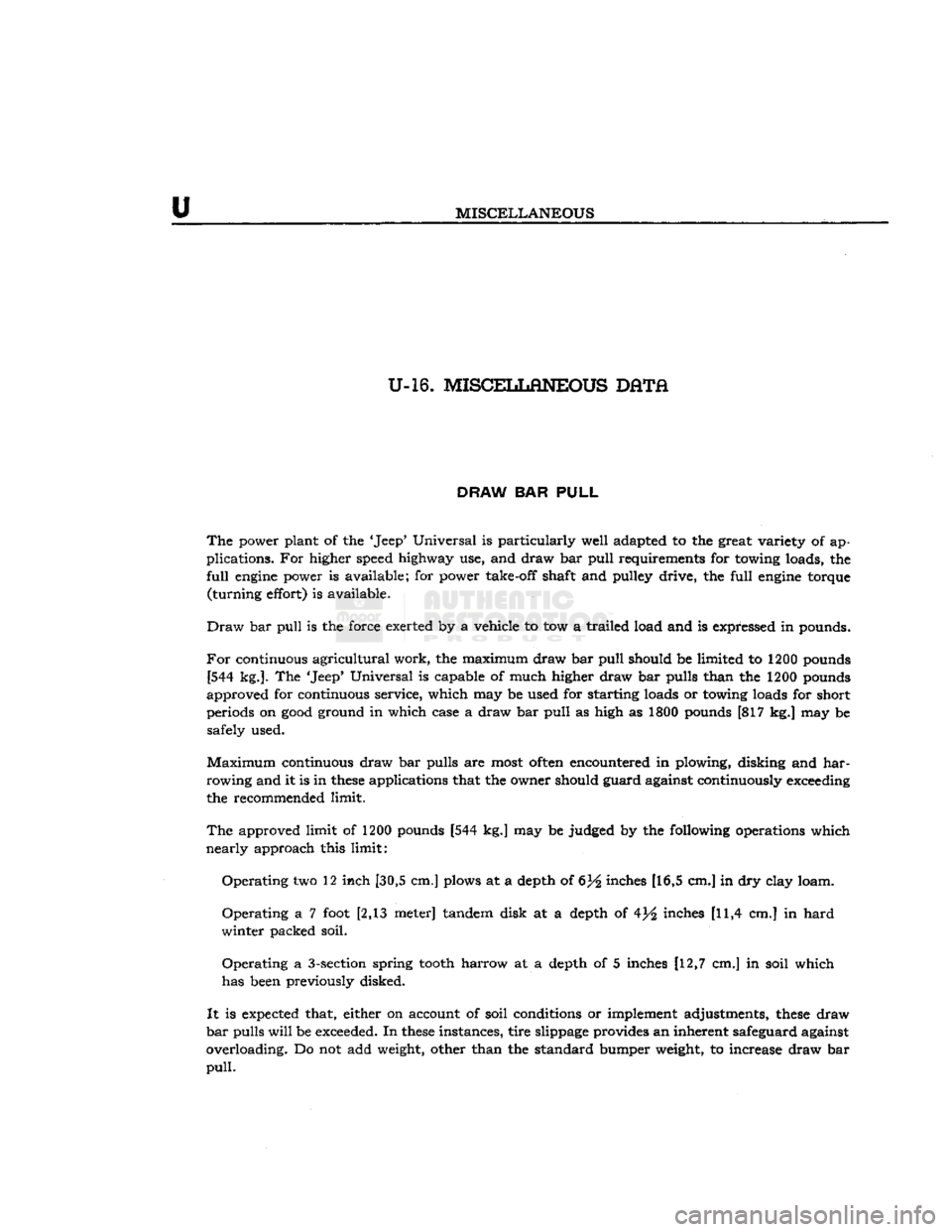

U-16. MISCELLtflNEOUS DATA

DRAW

BAR

PULL

The

power plant of the 'Jeep* Universal is particularly well adapted to the great variety of ap

plications. For higher speed highway use, and draw bar

pull

requirements for towing loads, the

full

engine

power is available; for power take-off shaft and pulley drive, the

full

engine

torque

(turning

effort) is available.

Draw

bar

pull

is the force exerted by a vehicle to tow a trailed load and is expressed in pounds.

For

continuous

agricultural

work, the maximum draw bar

pull

should be limited to 1200 pounds [544 kg.]. The 'Jeep' Universal is capable of much higher draw bar pulls than the 1200 pounds

approved for continuous service, which may be used for starting loads or towing loads for short

periods on

good

ground in which case a draw bar

pull

as high as 1800 pounds [817 kg.] may be

safely used.

Maximum

continuous draw bar pulls are most

often

encountered in plowing, disking and

har

rowing

and it is in

these

applications that the owner should guard against continuously exceeding

the recommended limit.

The

approved limit of 1200 pounds [544 kg.] may be judged by the following operations which

nearly

approach this limit:

Operating

two 12 inch [30,5 cm.] plows at a depth of 6)4 inches [16,5 cm.] in dry clay loam.

Operating

a 7

foot

[2,13 meter] tandem disk at a depth of 4j^ inches [11,4 cm.] in

hard

winter

packed soil.

Operating

a 3-section spring

tooth

harrow at a depth of 5 inches [12,7 cm.] in soil which

has been previously disked.

It

is expected that, either on account of soil conditions or implement adjustments,

these

draw

bar

pulls

will

be exceeded. In

these

instances, tire slippage provides an inherent safeguard against

overloading. Do not add weight, other than the standard bumper weight, to increase draw bar

pull.

Page 366 of 376

u

MISCELLANEOUS

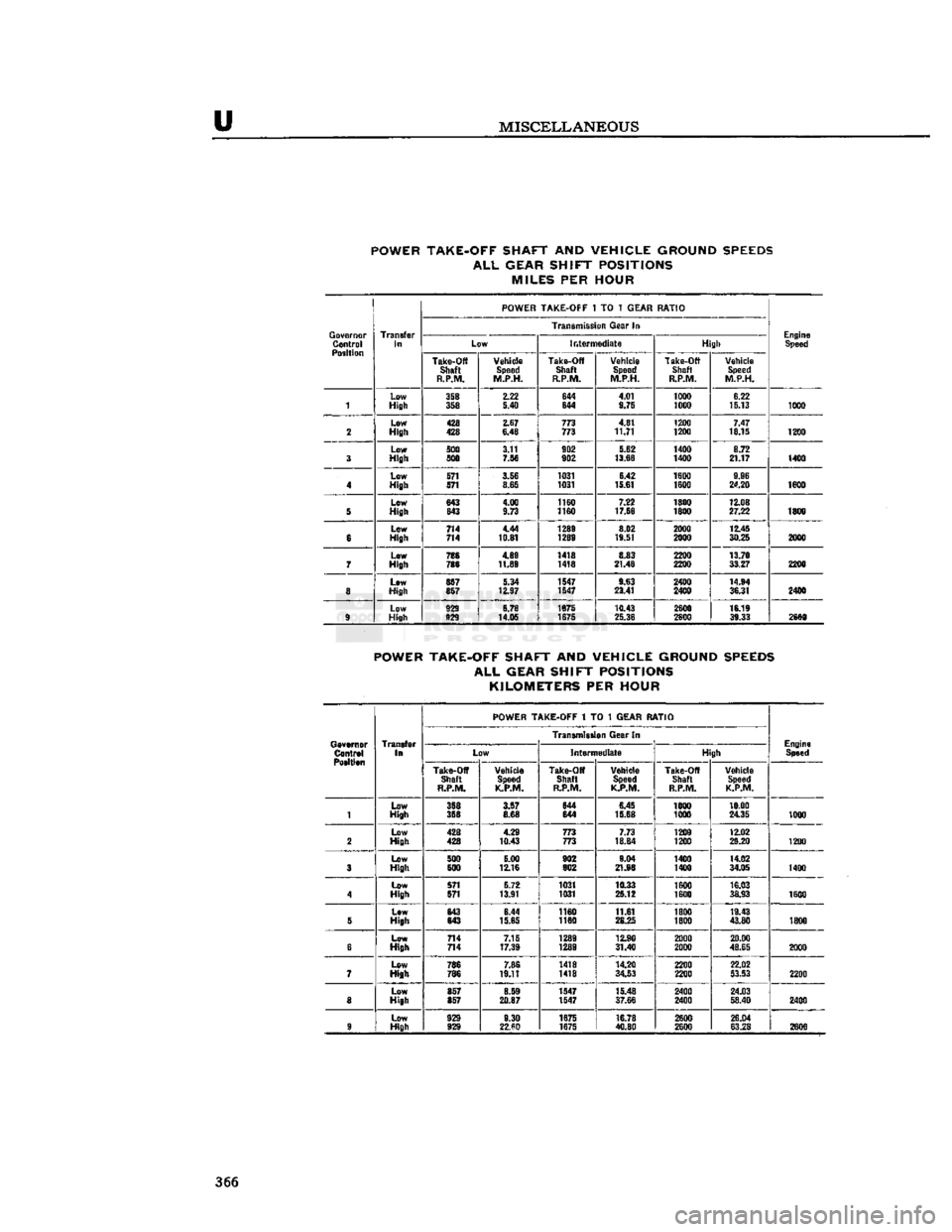

POWER TAKE-OFF SHAFT

AND

VEHICLE GROUND SPEEDS

ALL

GEAR SHIFT POSITIONS MILES

PER

HOUR

POWER TAKE-OFF

1 TO 1

GEAR RATIO

Governor Control

Position Transfer

In

Transmission Gear

In

Engine Speed

Governor

Control

Position Transfer

In Low

Intermediate

High Engine

Speed

Governor

Control

Position Take-Off

Shaft

R.P.M.

Vehicle

Speed

M.P.H. Take-Off

Shaft

R.P.M.

Vehicle

Speed

M.P.H. Take-Off

Shaft

R.P.M.

Vehicle

Speed

M.P.H.

1 Low

High

358

358 2.22

5.40 644

644

4.01

9.75 1000

1000 6.22

15.13 1000

2 Low

High

428

428 2.67

6.48 773

773 4.81

11.71 1200

1200

7.47

18.15 1200

3 Low

High

500

500 3.11

7.56 902

902 5.62

13.66 1400

1400 8.72

21.17 1400

4 Low

High

571

571 3.56

8.65

1031

1031

6.42

15.61 1600

1600 9.96

24.20

1600

5 Low

High

643

643 4.00

9.73 1160

1160 7.22

17.56 1800

1800 12.08

27.22

1800

e Low

High

714

714 4.44

10.81 1289

1289

8.02

19.51

2000

2000

12.45

30.25 2000

7 Low

High

786

788 489

11.89 1418

1418 8.83

21.48

2200

2200

13.70

33.27

2200

8 Low

High

857

857 5.34

12.97 1547

1547 9.63

23.41

2400

2400

14.84

36.31

2400

9 Low

High

928

929 5.78

14.05 1875

1675

10.43

25.36 2600

2600

16.19

39.33 2600

POWER TAKE-OFF SHAFT

AND

VEHICLE GROUND SPEEDS

ALL

GEAR SHIFT POSITIONS KILOMETERS

PER

HOUR

Governor Control

Position Transfer

In

POWER TAKE-OFF

1 TO 1

GEAR RATIO

Engine Speed

Governor

Control

Position Transfer

In

Transmission Gear

In

Engine

Speed

Governor

Control

Position Transfer

In Li

)W

Intern lediate

H" gh

Engine

Speed

Governor

Control

Position Transfer

In

Take-Off Shaft

R.P.M.

Vehicle

Speed

K.P.M.

Take-Off

Shaft

R.P.M.

Vehicle

Speed

K.P.M.

Take-Off

Shaft

R.P.M.

Vehicle

Speed

K.P.M.

1 Low

High

358

358 3.57

8.68 844

644

6.45

15.68 1000

1000 18.00

24.35

1000

2 Low

High

428

428 4.29

10.43 773

773 7.73

18.84 1200

1200 12.02

29.20

1200

3 Low

High

500

500 5.00

12.16 902

902 9.04

21.98 1400

1400 14.02

34.05

1400

4 Low

High

571

571 5.72

13.91 1031

1031

10.33

25.12

1600

1600 16.03

38.93

1600

5 Low

High

643

843 6.44

15.65 1160

1180

11.61

28.25

1800

1800 19.43

43.80

1806

6 Low

High

714

714 7.15

17.39 1289

1289 12.90

31.40

2000

2000 20.00

48.65 2000

7 Low

High

786

786

7.86

19.11 1418

1418 14.20

34.53

2200

2200 22.02

53.53

2200

8 Low

High

857

857 8.59

20.87

1547

1547 15.48

37.66

2400

2400 24.03

58.40

2400

9 Low

High

929

929 9.30

22.60

1675

1675 16.78

40.80

2600

2600 26.04

63.28 2600

366

Page 367 of 376

'Jeep9

UNIVERSAL

SERIES SERVICE

MANUAL

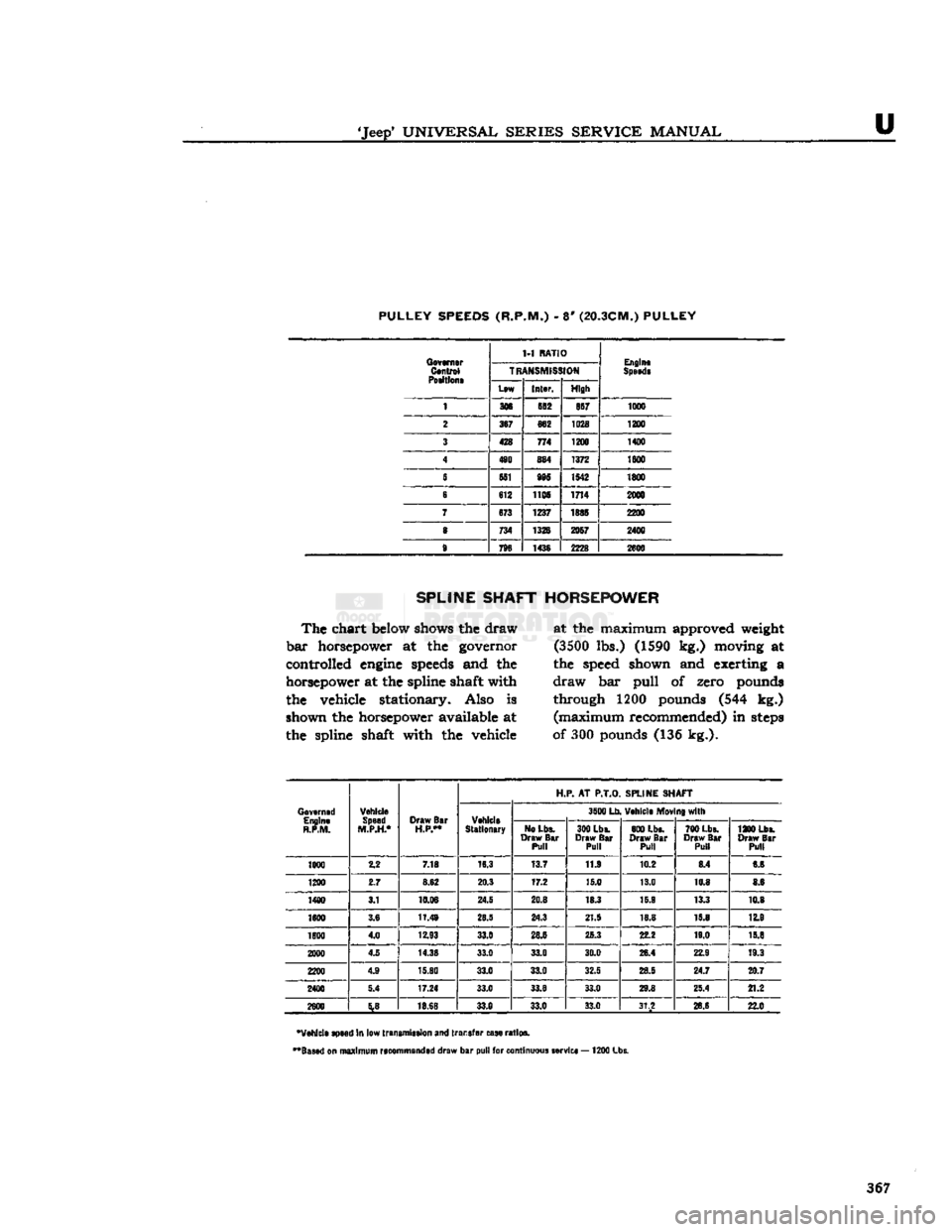

U PULLEY SPEEDS (R.P.M.)

- 8'

(20.3CM.) PULLEY

Governor

Control

Poeltlone

1-1

RATIO

Engine

Speede

Governor

Control

Poeltlone

TR

ANSMISS

HON

Engine

Speede

Governor

Control

Poeltlone

Lew

Inter.

High

1 306

682

857 1000

2

367

662

1028 1200

3

428

774 1200 1400

4

480 884

1372 1600

S

5S1 985 1542

1800

e 612 1105

1714 2000

7 673

1237 1885 2200

8

734 1326

2057 2400

9

796 1436

2228 2600

SPLINE SHAFT HORSEPOWER

The

chart

below shows

the

draw

bar

horsepower

at the

governor

controlled

engine

speeds

and

the

horsepower

at

the

spline shaft with

the vehicle stationary. Also

is

shown

the

horsepower available

at

the spline shaft with

the

vehicle at

the

maximum approved weight

(3500

lbs.) (1590

kg.)

moving

at

the speed shown

and

exerting

a

draw

bar

pull

of

zero pounds through

1200

pounds

(544 kg.)

(maximum

recommended)

in

steps

of 300 pounds

(136

kg.).

Governed Engine

R.P.M. Vehicle

Speed

M.P.H.* Draw

Bar

H.P**

H.P.

AT

P.T.O.

SPLINE SHAFT

Governed Engine

R.P.M. Vehicle

Speed

M.P.H.* Draw

Bar

H.P**

Vehicle

Stationary 3600

Lb

Vehicle

Mov

ng with

Governed

Engine

R.P.M. Vehicle

Speed

M.P.H.* Draw

Bar

H.P**

Vehicle

Stationary

No

Lbs.

Draw

Bar

Pull 300 Lbs.

Draw

Bar

Pull 800 Lbs.

Draw

Bar

Pull 700

Lbs.

Draw

Bar

Pull 1200

Lbs.

Draw

Bar

Pull

1000 2.2

7.18 16.3

13.7 11.9

10.2

8.4 6.6

1200 2.7 8.62 20.3

17.2

15.0 13.0

10.8 8.6

1400 3.1 10.06

24.5 20.8 18.3

15.9 13.3 10.8

1600 3.6

11.49 28.5 24.3 21.5

18.8 15.8 12.9

1800 4.0

12.93 33.0

28.6 25.3

22.2 19.0

15.8

2000 4.5

14.38 33.0 33.0

30.0 26.4 22.9

19.3

2200 4.9

15.80

33.0 33.0 32.5

28.5

24.7 20.7

2400 5.4 17.24

33.0 33.0 33.0 29.8 25.4

21.2

2600

%B

18.68 33.0

33.0 33.0

31.2 26.6

22.0

'Vehicle speed

in

low transmission

and

transfer case ratios.

••Based

on

maximum recommended draw

bar

pull

for

continuous service

—

1200

Lbs. 367

Page 368 of 376

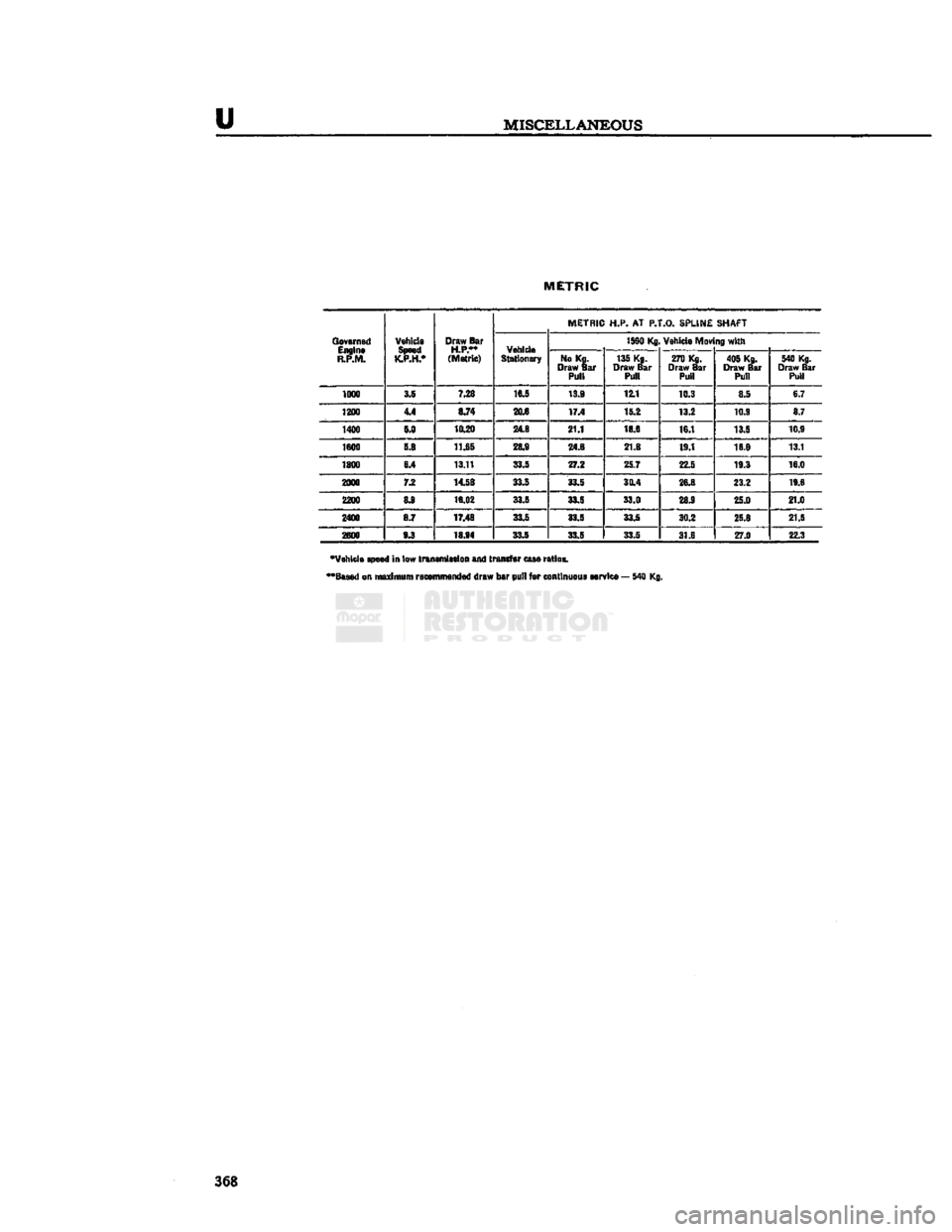

MISCELLANEOUS

METRIC

Governed Engine

R.P.M. Vehicle

Speed

K.P.H.* Draw Bar

H.P.**

(Metric) METRIC H.P. AT

P.T.O.

SPLINE SHAFT

Governed Engine

R.P.M. Vehicle

Speed

K.P.H.* Draw Bar

H.P.**

(Metric) Vehicle

Stationary 1590 Kg

Vehicle Mov ng with

Governed

Engine

R.P.M. Vehicle

Speed

K.P.H.* Draw Bar

H.P.**

(Metric) Vehicle

Stationary No Kg.

Draw Bar Pull 135 Kg.

Draw Bar Pull 270 Kg.

Draw Bar Pull 405 Kg.

Draw Bar Pull 540 Kg.

Draw Bar Pull

1000 S.§

7.28 16J

13.9 12.1

10.3 8.5 6.7

1200 44 8.74 20.6

17.4 15.2

13.2 10.9 8.7

1400 S.0

10.20

248

21.1 18.6

16.1 13.5 10.9

1800 5.8 11.65 28.9

24.6 21.8 19.1

18.8 13.1

1800 6.4 13.11 33.5

27.2 25.7

22.5 19.3 16.0

2000 7.2 14.58

33.5 33.5 30.4

26.8 23.2 19.6

1200 8.9

16.02

33J 33.5

33.0 28.9

25.0 21.0

2400 8.7 17.48 33.5

33.5 33.5

30.2 25.8 21.5

2600 9.3

18.94 33J 33.5 33 5

31.6 270 22.3

"Vehicle speed in low transmission and transfer case ratios.

••Based

on maximum recommended draw bar pull for continuous service — 540 Kg. 368