length JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 240 of 376

THREE-SPEED

TRANSMISSION

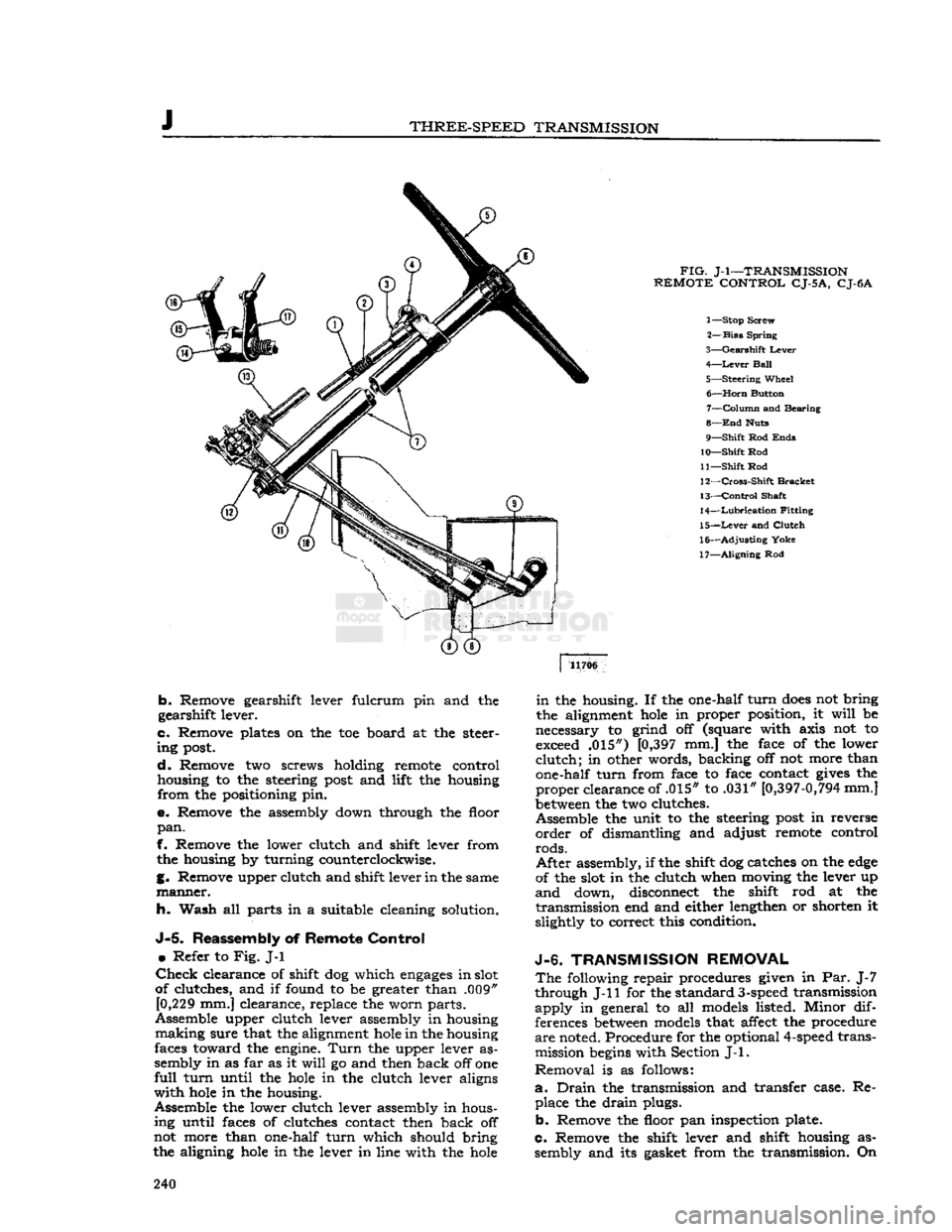

FIG.

J-l—TRANSMISSION

REMOTE

CONTROL

CJ-5

A,

CJ-6A

1— Stop Screw

2—

Bias

Spring

3—

Gearshift

Lever

4—

Lever

Ball

5—

Steering

Wheel 6—

Horn

Button 7—

Column

and Bearing

8—

End

Huts

9—

Shift

Rod

Ends

10—

Shift

Rod

11—

Shift

Rod

12—

Cross-Shift

Bracket

13—

Control

Shaft

14—

Lubrication

Fitting

15—

Lever

and

Clutch

16—

Adjusting

Yoke

17—

Aligning

Rod 11706

b.

Remove gearshift lever fulcrum pin and the

gearshift lever.

c.

Remove plates on the toe board at the steer

ing

post.

d.

Remove two screws holding remote control

housing to the steering

post

and lift the housing

from

the positioning pin.

e.

Remove the assembly down through the floor

pan.

f. Remove the lower clutch and shift lever from the housing by turning counterclockwise.

g. Remove upper clutch and shift lever in the same

manner.

h. Wash all parts in a suitable cleaning solution.

J-5.

Reassembly of

Remote

Control

•

Refer to

Fig.

J-l

Check

clearance of shift dog which

engages

in slot

of clutches, and if found to be greater than .009" [0,229 mm.] clearance, replace the worn parts.

Assemble upper clutch lever assembly in housing

making

sure that the alignment

hole

in the housing

faces toward the engine.

Turn

the upper lever as

sembly in as far as it

will

go and then back off one

full

turn

until the

hole

in the clutch lever aligns

with

hole

in the housing.

Assemble the lower clutch lever assembly in hous ing until faces of clutches contact then back off

not more than one-half

turn

which should bring

the aligning

hole

in the lever in line with the

hole

in

the housing. If the one-half

turn

does

not bring

the alignment

hole

in proper position, it

will

be

necessary to grind off (square with axis not to exceed .015") [0,397 mm.] the face of the lower

clutch;

in other words, backing off not more than

one-half

turn

from face to face contact

gives

the

proper

clearance of .015" to .031"

[0,397-0,794

mm.]

between

the two clutches.

Assemble the unit to the steering

post

in reverse

order

of dismantling and adjust remote control

rods.

After

assembly, if the shift dog catches on the

edge

of the slot in the clutch when moving the lever up

and

down, disconnect the shift rod at the

transmission

end and either lengthen or shorten it

slightly to correct this condition.

J-6.

TRANSMISSION

REMOVAL

The

following repair procedures given in Par. J-7

through J-ll for the standard

3-speed

transmission

apply

in general to all models listed. Minor dif

ferences

between

models that affect the procedure

are

noted. Procedure for the optional

4-speed

transmission

begins

with Section

J-l.

Removal

is as follows:

a.

Drain

the transmission and transfer case. Re place the

drain

plugs.

b.

Remove the floor pan inspection plate.

c.

Remove the shift lever and shift housing as sembly and its gasket from the transmission. On 240

Page 246 of 376

J

THREE-SPEED

TRANSMISSION

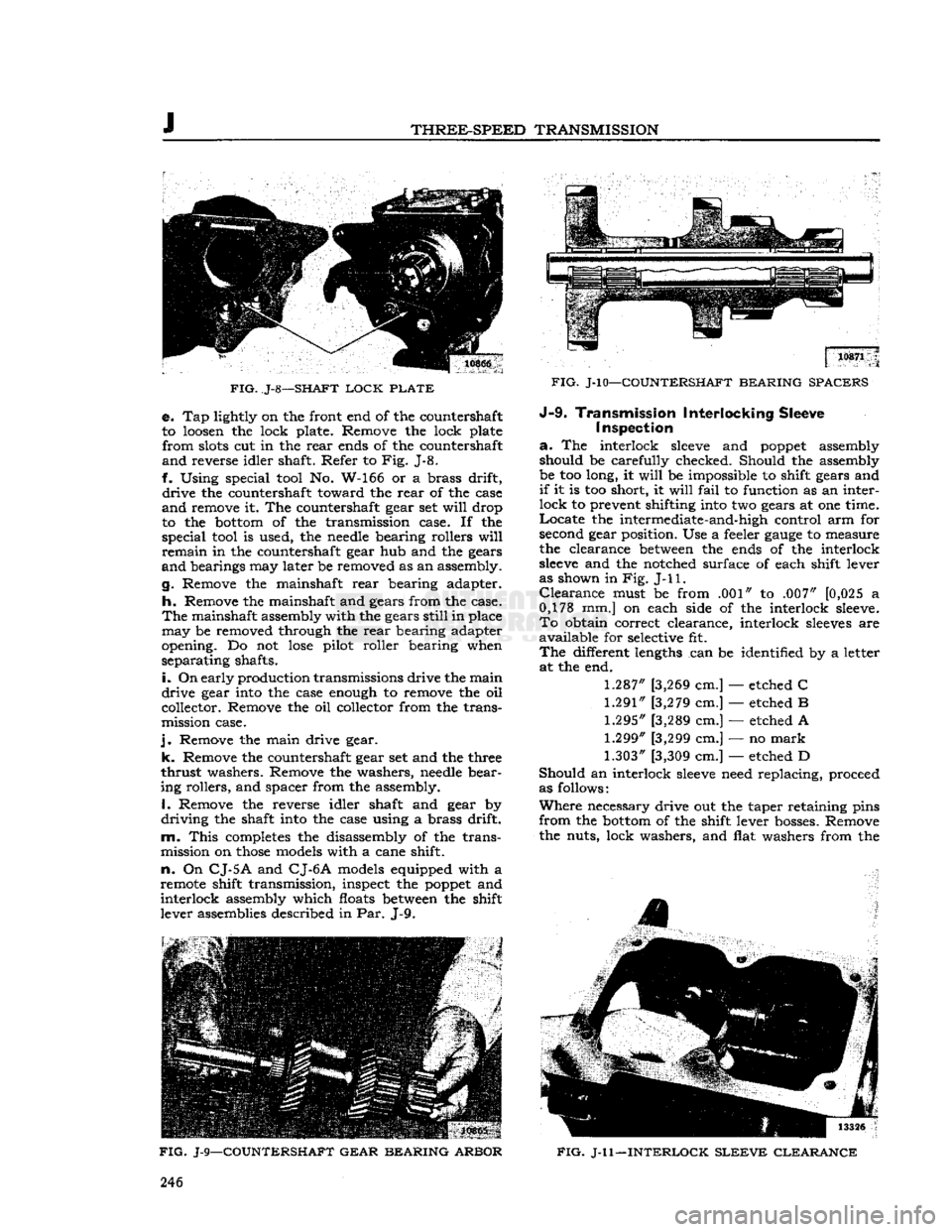

FIG.

J-8—SHAFT

LOCK

PLATE

e. Tap lightly on the front end of the countershaft

to loosen the lock plate. Remove the lock plate

from

slots cut in the

rear

ends of the countershaft

and

reverse idler shaft. Refer to Fig. J-8.

f. Using special tool No. W-166 or a brass drift,

drive

the countershaft toward the

rear

of the case

and

remove it. The countershaft gear set

will

drop

to the bottom of the transmission case. If the

special

tool is used, the needle bearing rollers

will

remain

in the countershaft gear hub and the gears

and

bearings may later be removed as an assembly.

g. Remove the mainshaft

rear

bearing adapter.

h.

Remove the mainshaft and gears from the case.

The

mainshaft assembly with the gears

still

in place

may

be removed through the

rear

bearing adapter

opening. Do not

lose

pilot roller bearing when

separating

shafts.

i.

On

early production transmissions drive the main

drive

gear into the case enough to remove the oil

collector. Remove the oil collector from the trans

mission case.

j.

Remove the main drive gear,

k.

Remove the countershaft gear set and the three

thrust

washers. Remove the washers, needle bear

ing rollers, and spacer from the assembly. 1, Remove the reverse idler shaft and gear by

driving

the shaft into the case using a brass drift,

m.

This

completes the disassembly of the trans

mission on

those

models with a cane shift,

n.

On

CJ-5

A

and

CJ-6 A

models equipped with a

remote shift transmission, inspect the poppet and

interlock

assembly which floats between the shift

lever assemblies described in Par. J-9.

FIG.

J-9—COUNTERSHAFT GEAR BEARING ARBOR

FIG.

J-l0—COUNTERSHAFT BEARING SPACERS J-9-

Transmission Interlocking Sleeve

I

inspection

a.

The interlock

sleeve

and poppet assembly should be carefully checked. Should the assembly

be too long, it

will

be impossible to shift gears and

if

it is too short, it

will

fail

to function as an inter

lock

to prevent shifting into two gears at one time.

Locate

the intermediate-and-high control arm for

second gear position. Use a feeler

gauge

to measure

the clearance between the ends of the interlock

sleeve

and the notched surface of each shift lever

as shown in Fig.

J-l

1.

Clearance

must be from .001" to .007" [0,025 a

0,178 mm.] on each side of the interlock sleeve.

To

obtain correct clearance, interlock

sleeves

are

available

for selective fit.

The

different lengths can be identified by a letter at the end.

1.287"

[3,269 cm.] — etched C

1.291"

[3,279 cm.] — etched B

1.295"

[3,289 cm.] — etched A

1.299"

[3,299 cm.] — no

mark

1.303"

[3,309 cm.] — etched D

Should

an interlock

sleeve

need replacing, proceed

as follows:

Where

necessary drive out the taper retaining pins

from

the bottom of the shift lever bosses. Remove

the nuts, lock washers, and flat washers from the

4

FIG.

J-l 1—INTERLOCK

SLEEVE

CLEARANCE

246

Page 275 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

L

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS

Contents

SUBJECT

PAR.

GENERAL

L-l

Needle

Bearing and Trunnion. . . L-2

Snap Ring Type Assembly L-4

Snap Ring Type Disassembly. . L-3

U-Bolt

Type Assembly L-6

U-Bolt

Type Disassembly .L-5

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS SPECIFICATIONS

L-7

L-1. GENERAL

The

drive of 'Jeep* 4-wheel-drive Universal

models

from the transfer case to the front and rear axles is through two tubular propeller shafts, each shaft having two cardan cross universal joints. The drive

of 'Jeep' 2-wheel-drive

models

from the transmission to the rear axle is through a tubular pro

peller shaft having two cardan cross universal

joints.

Propeller shafts and universal joints should be

10603

FIG.

L-l—UNIVERSAL JOINTS

1— Snap Ring

2—

Journal

3—

Bearing

4— Dust Cap

5—

Washer

6—

Rear

Tube 7—

Yoke

End

8—

Yoke

End

9—Front

Tube

10—

"U"

Bolt

11—

Retainer

12—

Gasket

13—

"U"

Bolt Nut

14—

Sleeve

15—

Front

Yoke End

16— Flange Yoke checked for foreign matter around the shafts,

dented

or

bent

shafts, and

loose

attaching

bolts.

L-2.

Needle Bearing

and

Trunnion Universal Joint

Each

shaft is equipped with a splined slip joint at one end to allow for variations in

length

caused by vehicle spring action.

Some

slip joints are marked

with arrows at the spline and

sleeve

yoke, Fig.

L-3.

When installing, align the arrows in the

same plane. If unmarked with arrows, align the

yokes

at the front and rear of the shaft in the same

parallel

plane. This is necessary to avoid vibration.

All

the universal joints used are similar in construc

tion

except

that

some

are of the "U"-bolt

type

and 10315

FIG.

L-2—ARROW MARKINGS

others of the "Snap Ring'* type. This difference

is in the attachment of the joints only. These universal joints have

needle

bearings and

are

so

designed

that correct assembly is a very sim

ple matter. No hand fitting or special

tools

are

required.

L-3.

Snap Ring Type Disassembly

This

type

joint is illustrated in Fig.

L-l.

To re-

FIG.

L-3—PROPELLER

SHAFT AND UNIVERSAL JOINT

1—

U-Bolt

Nut

2—

U-Bolt

Washer

3—U-Bolt

4—

Universal

Joint Journal 5—

Lubrication

Fitting 6— Snap Ring 7—

Universal

Joint

Sleeve

Yoke

8—

Rubber

Washer

9— Dust Cap

10—Propeller Shaft Tube 11440

275

Page 276 of 376

L

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS

move

the snap rings, pinch the ends

together

with

a

pair

of pliers. If the rings do not readily snap

out of the groove, tap the end of the bearing lightly

which

will

relieve pressure against the rings.

After

removing the snap rings, press on the end of

one bearing until the

opposite

bearing is pushed

from

the yoke arm.

Turn

the joint over and press

the first bearing back out of that arm by pressing

on the

exposed

end of the

journal

shaft. Use a

soft

ground drift with a flat face about [0,8 mm.]

smaller

in diameter than the

hole

in the yoke arm

and

drive it out, otherwise there is danger of damaging the bearing.

Repeat

this operation for the other two bearings,

then lift out

journal

assembly by sliding it to one

side.

L-4.

Snap

Ring

Type Assembly

Wash

all parts in cleaning solvent and inspect the

parte

after cleaning. Replace any parts that indicate

extensive

wear.

It is advisable to install new gaskets

on the

journal

assembly regardless of the condition of the old gaskets. Make certain that the grease

channel

in each

journal

trunnion is open.

Pack

the bearing

cones

one-third

full

of lubricant

and

install the rollers.

Draw

the bearings into the end yoke arm and seat

them firmly against the bearing shoulders. Hold

the bearings in a vertical position to prevent the

needles

from dropping out until the joint is as sembled. If the joint binds when assembled, tap

the arms lightly to relieve any pressure on the bear

ings at the end of the

journal.

L-5.

U-Bolt

Type Disassembly

Removal

of the attaching "U"-bolt releases one set

of bearing races. Slide the propeller shaft into the

yoke flange to remove them using care not to

lose

the rollers.

After

the removal of the one set of bearing races,

release the other set by removing the snap rings

in

the

sleeve

yoke by pinching the ends

together

with

a

pair

of pliers. Should the rings

fail

to snap

readily

from the groove, tap the end of the bearing

lightly,

which

will

relieve the pressure against them.

Press

on the end of one bearing, until the

opposite

bearing

is pushed out of the yoke arm.

Turn

the

universal

joint over and press the first bearing out

by pressing on the

exposed

end of the

journal

as

sembly. Use a

soft

ground drift with a flat face about

\{i

[0,8 mm.] smaller in diameter than the

hole

in the yoke

arm

and drive out the bearing.

Lift

the

journal

out by sliding to one side.

Clean

all

parts

and check for wear.

L-6.

U-Bolt Type Assembly

Wash

all parts in cleaning solvent and inspect the

parts

after cleaning. Replace any parts that indicate

extensive

wear.

It is advisable to install new gaskets

on the

journal

assembly regardless of the condition

of the old gaskets. Make certain that the grease

channel

in each

journal

trunnion is open.

Pack

the bearing

cones

one-third

full

of lubricant

and

install the rollers.

Draw

the bearings into the end yoke arm and seat

them firmly against the bearing shoulders. Hold the

bearings in a vertical position to prevent the

needles

from dropping out until the joint is as

sembled. If the joint binds when assembled, tap the arms lightly to relieve any pressure on the

bearings at the end of the

journal.

Tighten the

U-bolts equally. U-bolt torque wrench reading is 15 to 20 lb-ft. [2,07 a 2,76 kg-m.].

When

installing the assembly in the vehicle be sure

that the arrows on the propeller shaft and yoke

sleeve

are in alignment as shown in Fig. L-2, or

that the unmarked joints are aligned with the yokes in the same parallel plane.

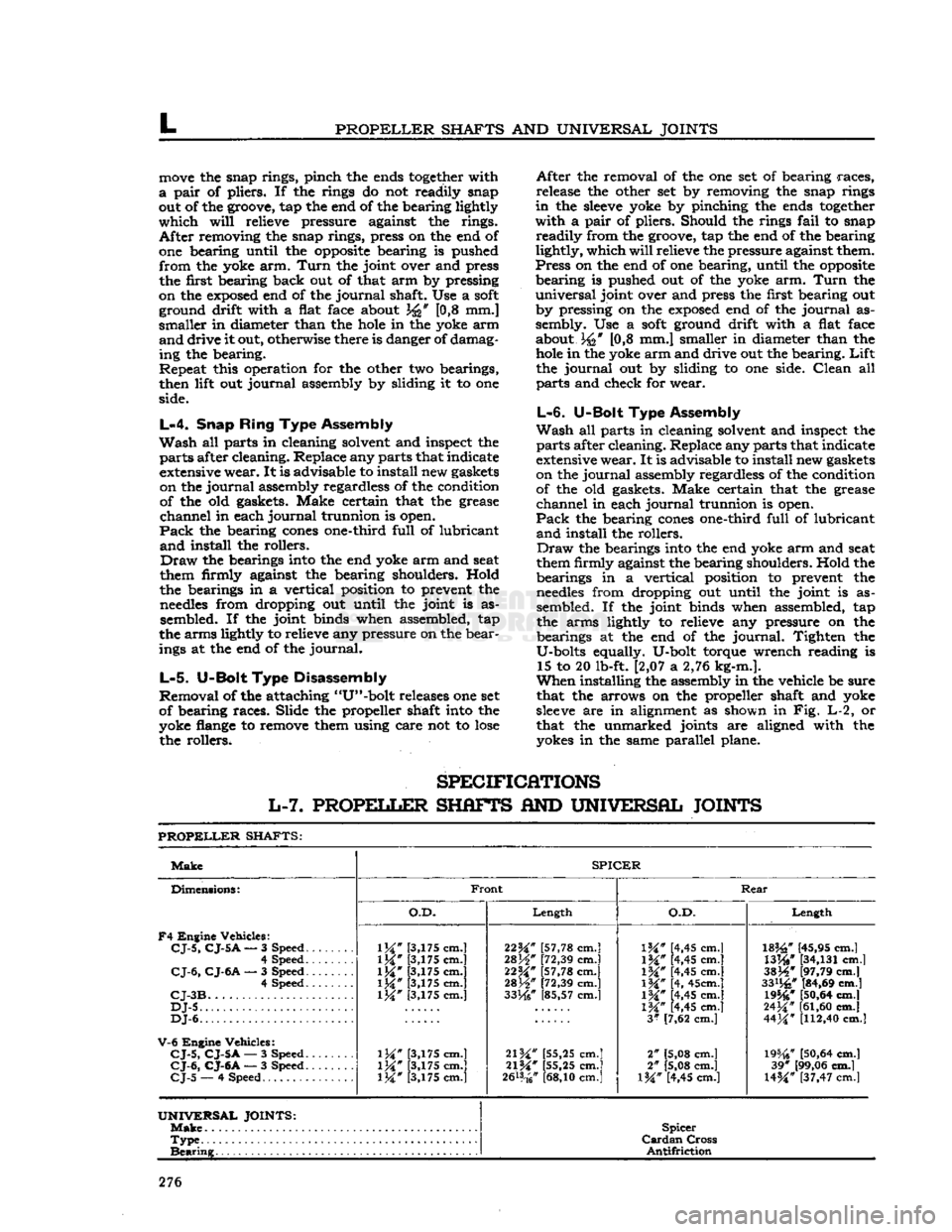

SPECIFICATIONS

L-7.

PROPELLER

SHAFTS

AND

UNIVERSAL JOINTS

PROPELLER

SHAFTS:

Make

SPICER

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

Front

Rear

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

O.D.

Length

O.D.

Length

Dimensions:

F4

Engine Vehicles:

CJ-5,

CJ-5

A

— 3 Speed.

......

4 Speed

CJ-6,

CJ-6A

— 3 Speed 4 Speed

CJ-3B

DJ-5

DJ-6.

V-6

Engine Vehicles:

CJ-5,

CJ-5A

— 3 Speed.

CJ-6,

CJ-6A

— 3 Speed.

CJ-5

— 4 Speed

1M"

[3,175 cm.]

1M*

[3,175 cm.]

\W

[3,175 cm.]

1M*

[3,175 cm.] [3,175 cm.]

\W

[3,175 cm.]

\W

[3,175 cm.] [3,175 cm.] 22^" [57,78 cm.]

28H"

[72,39 cm.]

22M*

[57,78 cm.]

mW

[72,39 cm.]

33He"

[85,57 cm.]

21W

[55,25 cm.]

21%"

[55,25 cm.]

2&*

cm.]

IK"

[4,45 cm.]

1M#

[4,45 cm.]

\%"

[4,45 cm.]

\%"

[4, 45cm.]

IW

[4,45 cm.]

1M*

[4,45 cm.]

3*

[7,62 cm.]

2" [5,08 cm.]

2" [5,08 cm.]

l%" [4,45 cm.]

182£"

[45,95 cm.]

WW

[34,131

cm.]

3SJ4*

[97,79 cm.]

33%"

[84,69 cm.] 19546*

[50,64

cm.]

24^"

[61,60

cm.]

44M*

[112,40

cm.]

19%?

[50,64

cm.] 39* [99,06 cm.]

U%"

[37,47 cm.l

UNIVERSAL

JOINTS:

Make

Spicer

Cardan

Cross

Antifriction

Type

Spicer

Cardan

Cross

Antifriction

Bearing

Spicer

Cardan

Cross

Antifriction

276

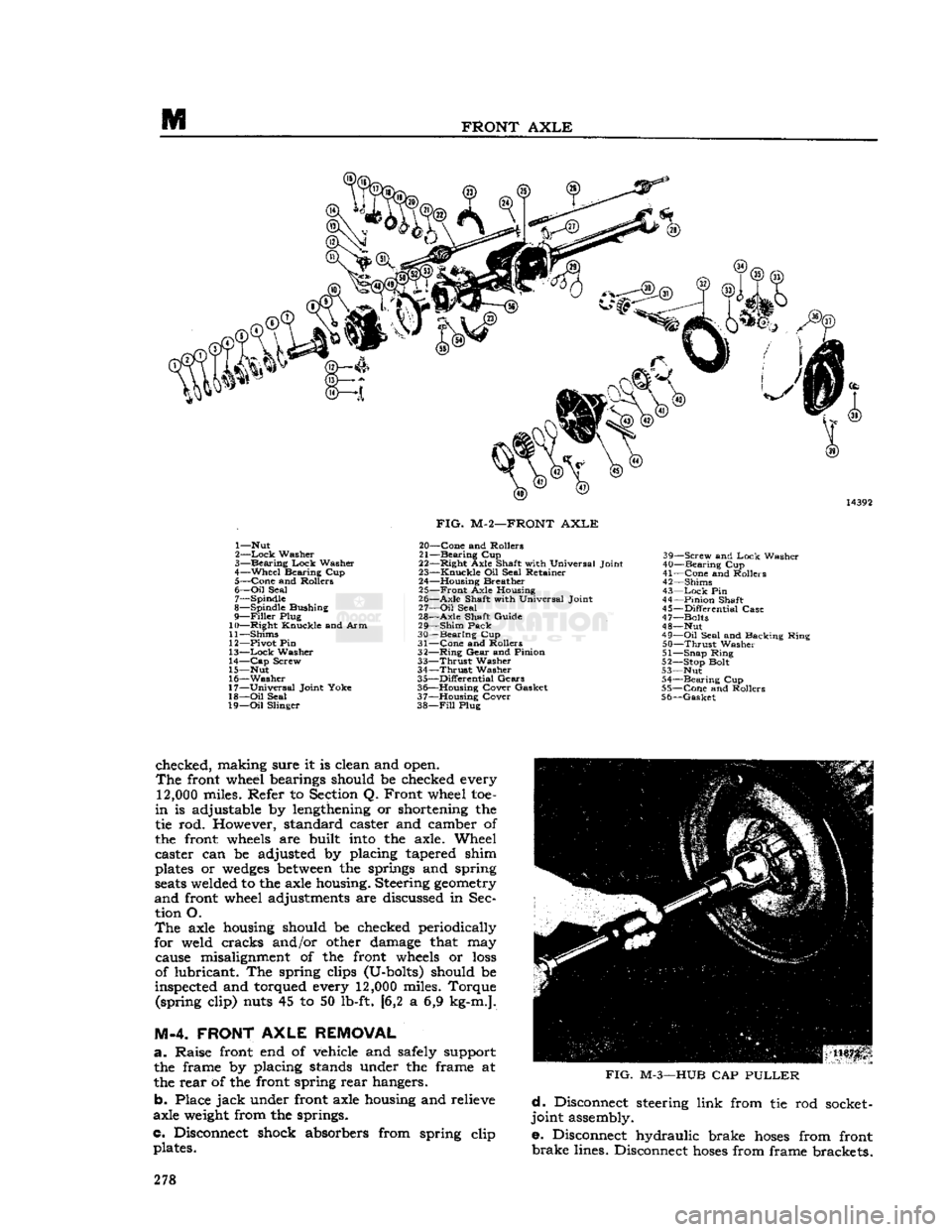

Page 278 of 376

M

FRONT

AXLE

1— Nut

2—

Lock

Washer

3—

Bearing

Lock

Washer

4—

Wheel

Bearing Cup 5—

Cone

and Rollers

6—

Oil

Seal 7— Spindle

8— Spindle Bushing

9—

Filler

Plug

10—

Right

Knuckle and Arm

11— Shims

12— Pivot Pin

13—

Lock

Washer

14—

Cap

Screw

15— Nut

16—

Washer

17—

Universal

Joint Yoke

18—

Oil

Seal

19—

Oil

Slinger

FIG.

M-2—FRONT

AXLE

20—

Cone

and Rollers

21—

Bearing

Cup

22—

Right

Axle Shaft with Universal Joint

23—

Knuckle

Oil Seal Retainer

24— Housing Breather 25—

Front

Axle Housing

26—

Axle

Shaft with Universal Joint

27—

Oil

Seal

28—

Axle

Shaft Guide

29—

Shim

Pack

30—

Bearing

Cup

31—

Cone

and Rollers

32—

Ring

Gear

and Pinion

33—

Thrust

Washer

34—

Thrust

Washer

35—

Differential

Gears

36— Housing Cover Gasket

37— Housing Cover

38—

Fill

Plug 39—

Screw

and

Lock

Washer

40—

Bearing

Cup

41—

Cone

and Rollers

42— Shims

43—

Lock

Pin

44—

Pinion

Shaft

45—

Differential

Case

47— Bolts

48— Nut

49—

Oil

Seal and Backing Ring

50—

Thrust

Washer

51— Snap Ring

52— Stop Bolt

53— Nut 54—

Bearing

Cup

55—

Cone

and Rollers

56—

Gasket

checked, making sure it is clean and open.

The

front wheel bearings should be checked every

12,000

miles. Refer to Section Q. Front wheel toe-

in

is adjustable by lengthening or shortening the

tie rod. However, standard caster and camber of

the front

wheels

are built

into

the axle. Wheel

caster can be adjusted by placing tapered shim

plates or

wedges

between

the springs and spring

seats

welded to the axle housing. Steering

geometry

and

front wheel adjustments are discussed in Sec tion O.

The

axle housing should be checked periodically

for weld cracks and/or other damage that may cause misalignment of the front

wheels

or

loss

of lubricant. The spring clips (U-bolts) should be

inspected and torqued every

12,000

miles. Torque (spring clip) nuts 45 to 50 lb-ft. [6,2 a 6,9 kg-m.].

M-4. FRONT

AXLE

REMOVAL

a.

Raise front end of vehicle

arid

safely support the frame by placing stands under the frame at

the rear of the front spring rear hangers.

b. Place

jack

under front axle housing and relieve

axle

weight

from the springs.

c. Disconnect shock absorbers from spring clip plates.

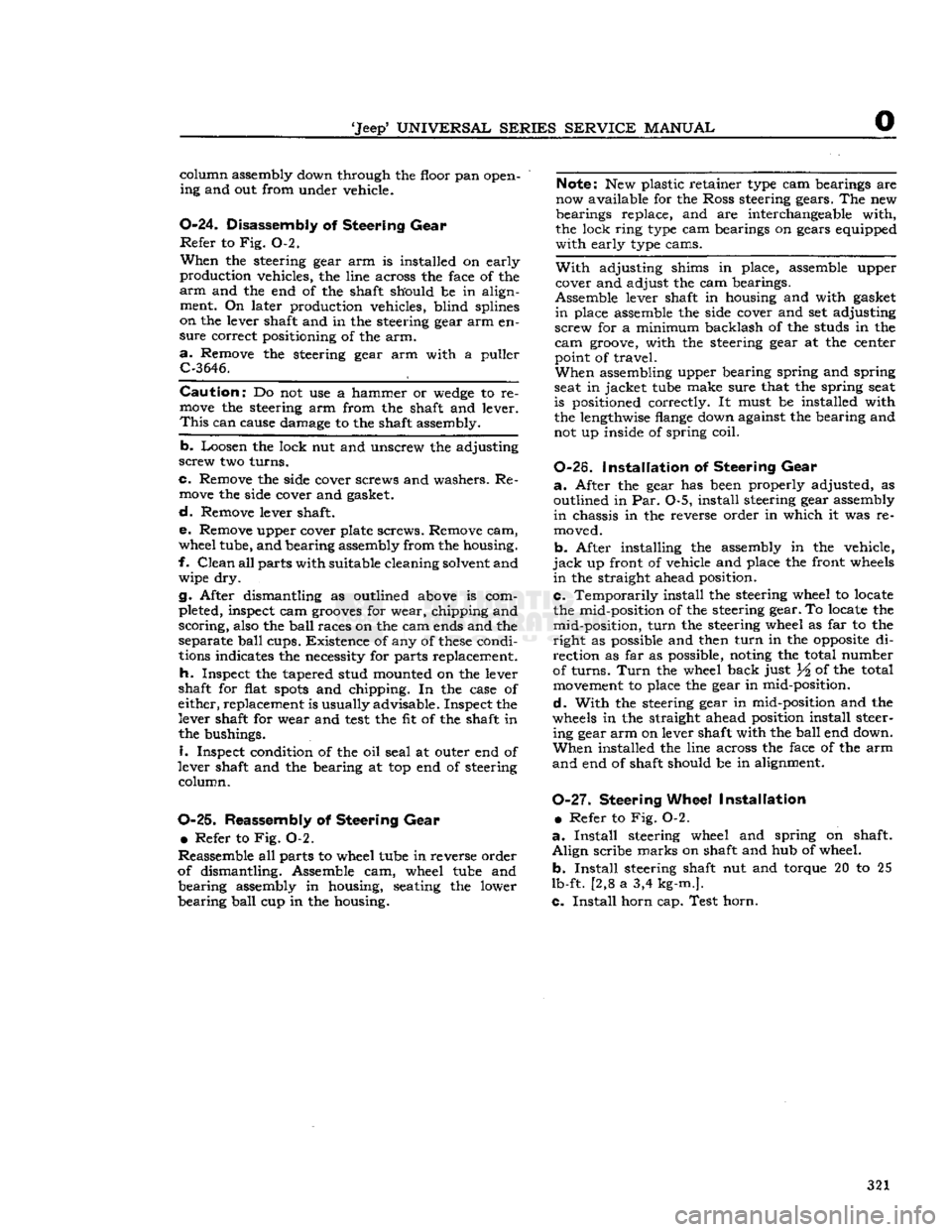

FIG.

M-3—HUB

CAP

PULLER

d.

Disconnect steering link from tie rod socket-

joint assembly.

e. Disconnect hydraulic brake

hoses

from front

brake

lines. Disconnect

hoses

from frame brackets. 278

Page 294 of 376

N

REAR AXLE

N-l2.

Differential Case

Disassembly

Refer

to

Fig.

N-3 and N-7.

a.

Remove

the

axle shafts. Refer

to

Par.

N-ll for

rear

axle removal

and

Par.

M-4 for

front axle

re

moval.

b.

Remove

the

housing cover

and

four

cap

screws

holding

the two

differential side bearing caps

in

position. Make sure there

are

matching letters

or

some

type

of

identification marks

on the

caps

and

housing

so

that each

cap can be

reinstalled

in the

same position

and

location from which

it is re

moved.

c.

Use

Spreader W-129,

as

shown

in

Fig. N-l9,

to

spread

the

housing.

Install

Hold-Down Clamps

W-129-18.

if

available,

to

keep

the

spreader

in

position.

Clamp

on a

dial

indicator.

From

the

side,

measure

the

carrier

spread.

Do not

spread

the

car

rier

more than

.020"

[0,508

mm.].

d.

Remove

the

dial

indicator.

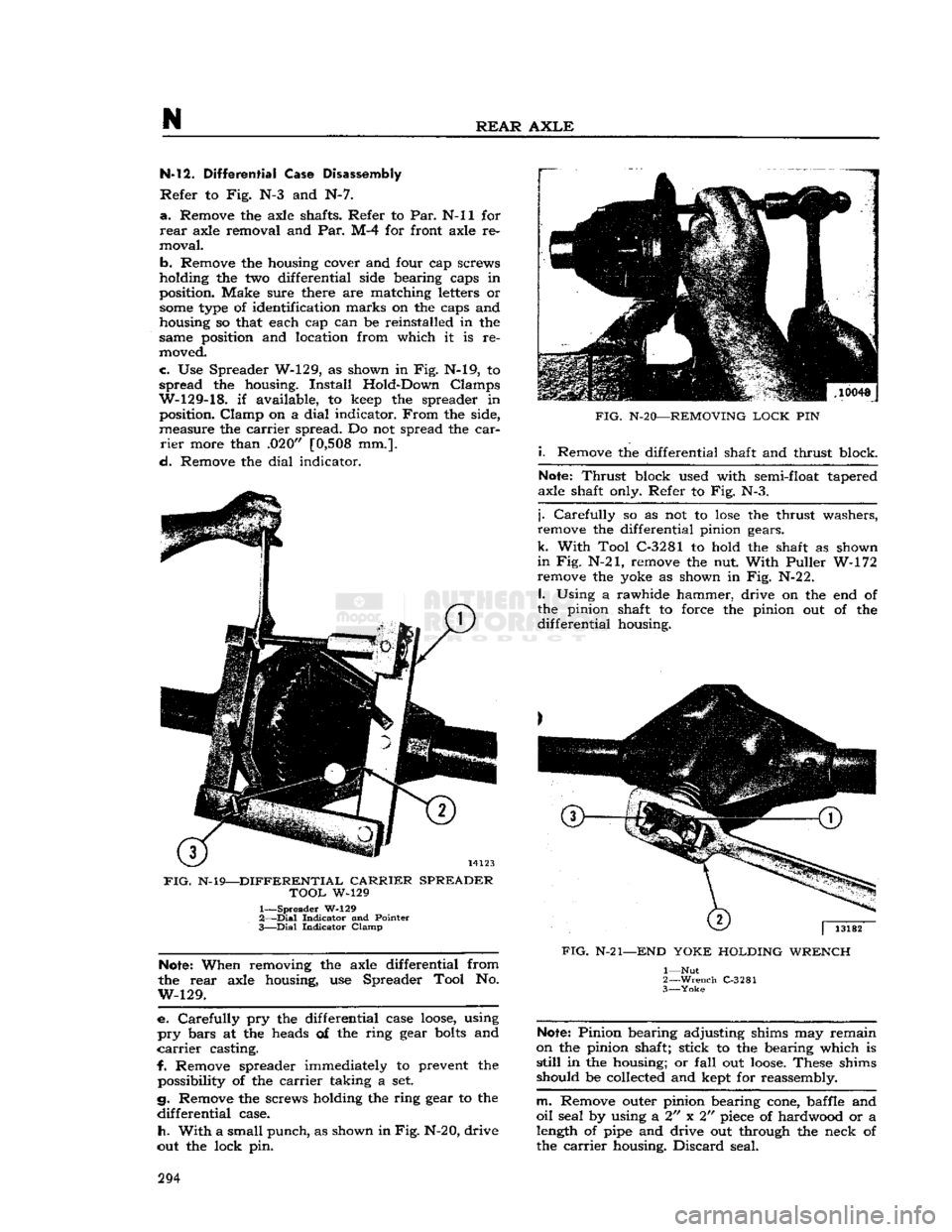

FIG.

N-19—DIFFERENTIAL

CARRIER

SPREADER

TOOL

W-129

1—

Spreader

W-129

2—

Dial

Indicator

and

Pointer

3—

Dial

Indicator

Clamp

Note:

When removing

the

axle differential from

the

rear

axle housing,

use

Spreader Tool

No.

W-129.

e.

Carefully

pry the

differential case

loose,

using

pry

bars

at the

heads

of the

ring gear

bolts

and

carrier

casting.

f.

Remove spreader immediately

to

prevent

the

possibility

of the

carrier

taking

a set.

g. Remove

the

screws holding

the

ring gear

to the

differential

case.

h.

With

a

small punch,

as

shown in

Fig.

N-20, drive

out

the

lock

pin.

FIG.

N-20—REMOVING

LOCK

PIN

i.

Remove

the

differential shaft

and

thrust block.

Note:

Thrust

block used with semi-float tapered

axle shaft only. Refer

to

Fig.

N-3.

j.

Carefully

so as not to

lose

the

thrust washers,

remove

the

differential pinion gears.

k.

With

Tool C-3281

to

hold

the

shaft

as

shown

in

Fig.

N-21,

remove

the nut.

With

Puller

W-172

remove

the

yoke

as

shown

in

Fig. N-2

2.

I.

Using

a

rawhide hammer, drive

on the end of

the pinion shaft

to

force

the

pinion

out of the

differential

housing.

FIG.

N-21—END

YOKE

HOLDING WRENCH

1— Nut

2—

Wrench

C-3281

3—

Yoke

Note:

Pinion bearing adjusting shims

may

remain

on

the

pinion shaft; stick

to the

bearing which

is

still

in the

housing;

or

fall

out

loose.

These shims

should

be

collected

and

kept

for

reassembly.

m.

Remove outer pinion bearing

cone,

baffle

and

oil

seal

by

using

a 2" x 2"

piece

of

hardwood

or a

length

of

pipe

and

drive

out

through

the

neck

of

the

carrier

housing.

Discard

seal. 294

Page 321 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

O

column assembly down through the floor pan open

ing and out from under vehicle.

0-24.

Disassembly

of

Steering

Gear

Refer

to Fig. 0-2.

When

the steering gear arm is installed on early

production vehicles, the line across the face of the

arm

and the end of the shaft should be in align ment. On later production vehicles, blind splines

on the lever shaft and in the steering gear arm en

sure

correct positioning of the arm.

a.

Remove the steering gear arm with a puller

C-3646.

Caution:

Do not use a hammer or

wedge

to re

move

the steering arm from the shaft and lever.

This

can cause damage to the shaft assembly.

b.

Loosen the lock nut and unscrew the adjusting

screw

two turns.

c.

Remove the side cover screws and washers. Re

move

the side cover and gasket.

d.

Remove lever shaft.

e.

Remove upper cover plate screws. Remove cam,

wheel tube, and bearing assembly from the housing.

f.

Clean

all parts with suitable cleaning solvent and wipe dry.

g.

After dismantling as outlined above is com

pleted, inspect cam

grooves

for wear, chipping and

scoring,

also the

ball

races on the cam ends and the

separate

ball

cups. Existence of any of

these

condi tions indicates the necessity for parts replacement.

h.

Inspect the tapered stud mounted on the lever

shaft for flat

spots

and chipping. In the case of

either, replacement is usually advisable. Inspect the

lever shaft for wear and

test

the fit of the shaft in

the bushings.

i.

Inspect condition of the oil seal at outer end of

lever shaft and the bearing at top end of steering

column.

0-25.

Reassembly

of

Steering

Gear

e Refer to Fig. 0-2.

Reassemble all parts to wheel tube in reverse order

of dismantling. Assemble cam, wheel tube and

bearing

assembly in housing, seating the lower

bearing

ball

cup in the housing.

Note:

New plastic retainer type cam bearings are

now available for the Ross steering gears. The new

bearings replace, and are interchangeable with,

the lock ring type cam bearings on gears equipped

with

early type cams.

With

adjusting shims in place, assemble upper

cover and adjust the cam bearings.

Assemble lever shaft in housing and with gasket

in

place assemble the side cover and set adjusting

screw

for a minimum backlash of the studs in the

cam

groove, with the steering gear at the center

point of travel.

When

assembling upper bearing spring and spring

seat in jacket tube make sure that the spring seat

is positioned correctly. It must be installed with

the lengthwise flange down against the bearing and

not up inside of spring coil.

0-26.

Installation

of

Steering

Gear

a.

After the gear has been properly adjusted, as

outlined in Par. 0-5, install steering gear assembly

in

chassis in the reverse order in which it was re

moved.

b.

After installing the assembly in the vehicle,

jack

up front of vehicle and place the front wheels

in

the straight ahead position.

c.

Temporarily install the steering wheel to locate

the mid-position of the steering gear. To locate the mid-position,

turn

the steering wheel as far to the

right

as possible and then

turn

in the

opposite

di

rection

as far as possible, noting the total number

of turns.

Turn

the wheel back just ^ of the total movement to place the gear in mid-position.

d.

With

the steering gear in mid-position and the

wheels in the straight ahead position install steer ing gear arm on lever shaft with the

ball

end down.

When

installed the line across the face of the arm

and

end of shaft should be in alignment.

0-27.

Steering

Wheel

Installation

•

Refer to Fig. 0-2.

a.

Install

steering wheel and spring on shaft.

Align

scribe marks on shaft and hub of wheel.

b.

Install

steering shaft nut and torque 20 to 25

lb-ft. [2,8 a 3,4 kg-m.].

c.

Install

horn cap. Test horn.

321

Page 326 of 376

p

BRAKES

be either a defective master cylinder or the use of

low grade brake fluid which has expanded because

of heat. Use standard duty brake fluid conforming to

SAE-J1703

specification.

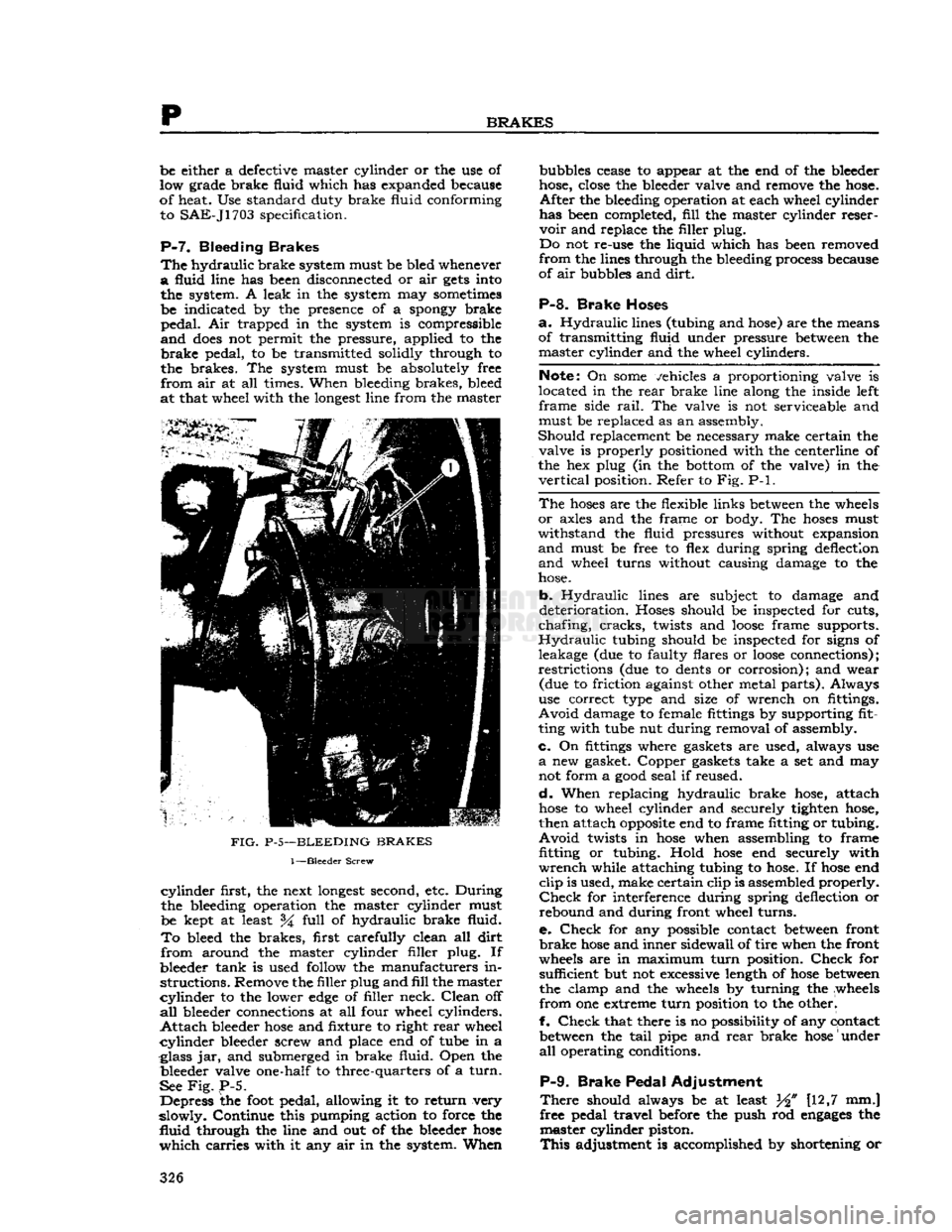

P-7.

Bleeding

Brakes

The

hydraulic

brake system must be bled whenever

a

fluid line has been disconnected or air

gets

into the system. A leak in the system may sometimes

be indicated by the presence of a spongy brake

pedal.

Air trapped in the system is compressible

and

does

not permit the pressure, applied to the

brake

pedal, to be transmitted solidly through to

the brakes. The system must be absolutely free

from

air at all times. When bleeding brakes, bleed

at that wheel with the

longest

line from the master

FIG.

P-5—BLEEDING

BRAKES

1—Bleeder

Screw

cylinder

first, the next

longest

second, etc. During

the bleeding operation the master cylinder must

be kept at least %

full

of hydraulic brake fluid.

To

bleed the brakes, first carefully clean all

dirt

from

around the master cylinder filler plug. If

bleeder tank is used follow the manufacturers in

structions.

Remove the filler plug and

fill

the master

cylinder

to the lower

edge

of filler neck.

Clean

off

all

bleeder connections at all four wheel cylinders.

Attach

bleeder

hose

and fixture to right

rear

wheel

cylinder

bleeder screw and place end of tube in a

glass jar, and submerged in brake fluid. Open the bleeder valve one-half to three-quarters of a

turn.

See

Fig.

P-5.

Depress the

foot

pedal, allowing it to return very

slowly. Continue this pumping action to force the

fluid

through the line and out of the bleeder

hose

which

carries with it any air in the system. When bubbles cease to appear at the end of the bleeder

hose, close the bleeder valve and remove the hose.

After

the bleeding operation at each wheel cylinder

has been completed,

fill

the master cylinder reser

voir

and replace the filler plug.

Do not re-use the liquid which has been removed

from

the lines through the bleeding process because

of air bubbles and

dirt.

P-8.

Brake Hoses

a.

Hydraulic

lines (tubing and hose) are the means

of transmitting fluid under pressure between the master cylinder and the wheel cylinders.

Note:

On

some

vehicles a proportioning valve is

located in the

rear

brake line along the inside left

frame

side

rail.

The valve is not serviceable and

must be replaced as an assembly.

Should

replacement be necessary make certain the valve is properly positioned with the centerline of

the hex plug (in the bottom of the valve) in the

vertical

position. Refer to Fig. P-l.

The

hoses

are the flexible links between the wheels

or

axles and the frame or body. The

hoses

must

withstand

the fluid pressures without expansion

and

must be free to flex during spring deflection

and

wheel turns without causing damage to the

hose.

b.

Hydraulic

lines are subject to damage and

deterioration. Hoses should be inspected for cuts,

chafing,

cracks,

twists and

loose

frame supports.

Hydraulic

tubing should be inspected for signs of

leakage (due to faulty flares or

loose

connections);

restrictions

(due to dents or corrosion); and wear (due to friction against other metal parts). Always

use correct type and size of wrench on fittings.

Avoid

damage to female fittings by supporting fit

ting with tube nut during removal of assembly.

c.

On fittings where gaskets are used, always use

a

new gasket. Copper gaskets take a set and may

not form a

good

seal if reused.

d.

When replacing hydraulic brake hose, attach

hose

to wheel cylinder and securely tighten hose,

then attach

opposite

end to frame fitting or tubing.

Avoid

twists in

hose

when assembling to frame fitting

or

tubing. Hold

hose

end securely with

wrench

while attaching tubing to hose. If

hose

end

clip

is used, make certain clip is assembled properly.

Check

for interference during spring deflection or

rebound and during front wheel turns.

e.

Check

for any possible contact between front

brake

hose

and inner sidewall of tire when the front

wheels are in maximum

turn

position.

Check

for sufficient but not excessive length of

hose

between

the clamp and the wheels by turning the wheels

from

one extreme

turn

position to the otherl

f.

Check

that there is no possibility of any contact between the

tail

pipe and

rear

brake

hose

under

all

operating conditions.

P-9.

Brake Pedal Adjustment

There

should always be at least W [12,7 mm.]

free pedal travel before the push rod

engages

the master cylinder piston.

This

adjustment is accomplished by shortening or 326

Page 327 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P

lengthening of the brake master cylinder eye bolt.

This

is

done

so the primary cup

will

clear the by

pass port when the piston is in the off position,

otherwise the compensating action of the master

cylinder

for expansion and contraction of the fluid

in

the system, due to temperature changes,

will

be destroyed and cause the brakes to drag.

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One

way to

compensate

for this wear is to install a pedal

slack

adjuster kit,

Part

No.

921936.

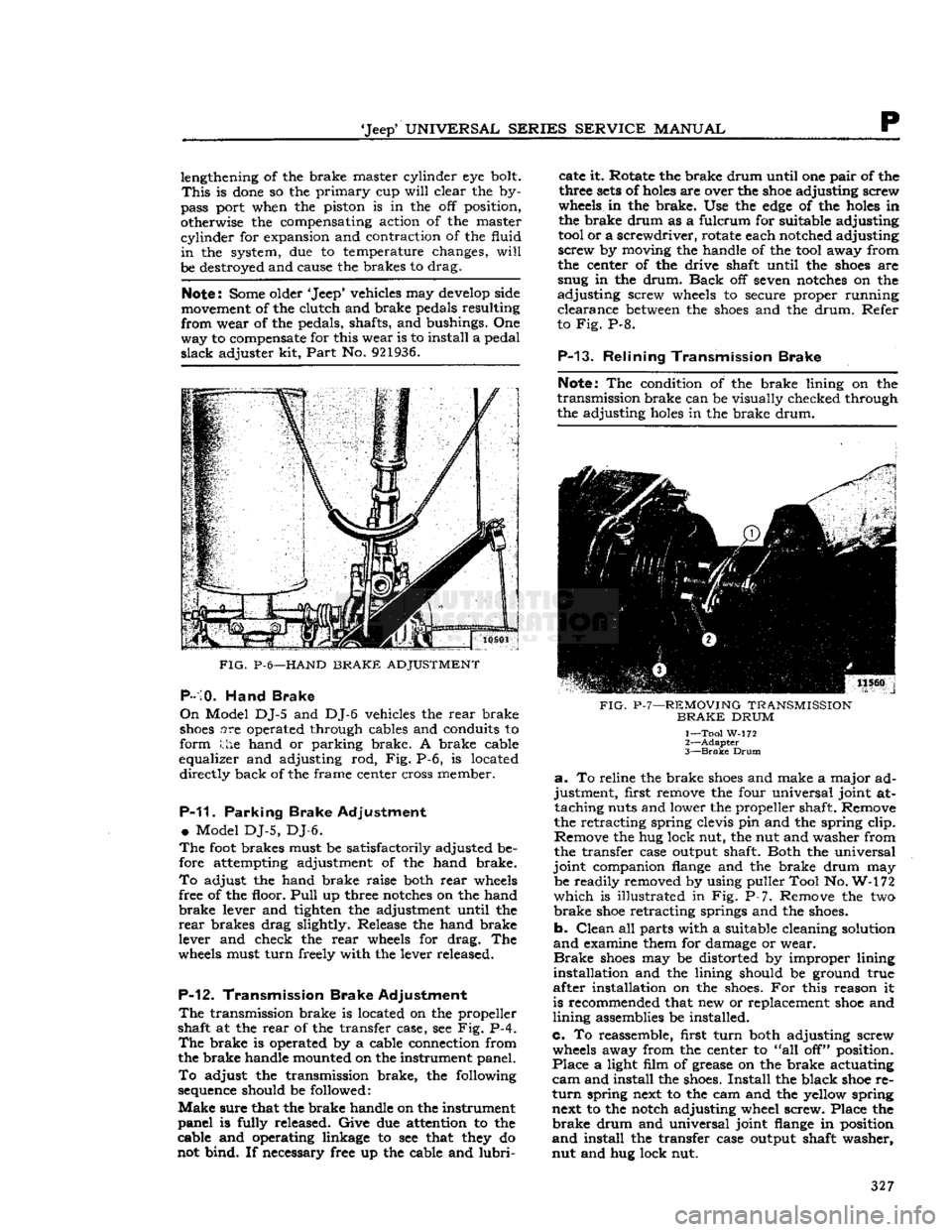

FIG.

P-6—HAND

BRAKE

ADJUSTMENT

P-10.

Hand Brake

On

Model DJ-5 and DJ-6 vehicles the rear brake

shoes

are operated through cables and conduits to

form the hand or parking brake. A brake cable

equalizer and adjusting rod, Fig. P-6, is located directly back of the frame center cross member.

P-11.

Parking Brake Adjustment

•

Model DJ-5, DJ-6.

The

foot

brakes must be satisfactorily adjusted be

fore attempting adjustment of the hand brake.

To

adjust the hand brake raise both rear

wheels

free of the floor.

Pull

up three

notches

on the hand

brake

lever and tighten the adjustment until the

rear

brakes drag slightly. Release the hand brake

lever and check the rear

wheels

for drag. The

wheels

must turn freely with the lever released.

P-12.

Transmission Brake Adjustment

The

transmission brake is located on the propeller

shaft at the rear of the transfer case, see Fig. P-4.

The

brake is operated by a cable connection from

the brake handle mounted on the instrument panel.

To

adjust the transmission brake, the following

sequence

should be followed:

Make

sure that the brake handle on the instrument

panel is fully released. Give due attention to the

cable and operating linkage to see that

they

do

not bind. If necessary free up the cable and

lubri

cate it. Rotate the brake drum until one pair of the

three

sets

of

holes

are over the

shoe

adjusting screw

wheels

in the brake. Use the

edge

of the

holes

in

the brake drum as a fulcrum for suitable adjusting

tool

or a screwdriver, rotate each notched adjusting

screw by moving the handle of the

tool

away from

the center of the drive shaft until the

shoes

are

snug in the drum.

Back

off seven

notches

on the

adjusting screw

wheels

to secure proper running clearance

between

the

shoes

and the drum. Refer

to Fig. P-8.

P-13.

Relining Transmission Brake

Note:

The condition of the brake lining on the

transmission brake can be visually checked through

the adjusting

holes

in the brake drum.

FIG.

P-7—REMOVING

TRANSMISSION

BRAKE

DRUM

1— Tool W-172

2—

Adapter

3—

Brake

Drum

a.

To reline the brake

shoes

and make a major ad

justment, first remove the four universal joint at taching nuts and lower the propeller shaft. Remove

the retracting spring clevis pin and the spring clip.

Remove the hug lock nut, the nut and washer from

the transfer case output shaft. Both the universal

joint companion

flange

and the brake drum may be readily removed by using puller Tool No. W-172

which

is illustrated in Fig. P-7. Remove the two

brake

shoe

retracting springs and the

shoes.

b. Clean all parts with a suitable cleaning solution

and

examine them for damage or wear.

Brake

shoes

may be distorted by improper lining

installation and the lining should be ground true

after installation on the

shoes.

For this reason it

is recommended that new or replacement

shoe

and

lining assemblies be installed.

c. To reassemble, first turn both adjusting screw

wheels

away from the center to "all off" position.

Place a light film of grease on the brake actuating

cam

and install the

shoes.

Install the black

shoe

re

turn

spring next to the cam and the yellow spring next to the notch adjusting wheel screw. Place the

brake

drum and universal joint

flange

in position

and

install the transfer case output shaft washer,

nut and hug lock nut. 327

Page 341 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

R

FRAME

Contents

SUBJECT

PAR.

Draw

Bar

R-6

Frame

Alignment

.R-2

Frame

Dimensions

.R-3

Front

Axle Alignment.

R-5

Straightening

Frame

R-4

R-1.

GENERAL

equipped with V6 engines, refer

to

measurements

The

frame

is the

structural center

of

the vehicle,

B£?wn

in

FiB-

R"f

, _ , r' .

for in addition

to

carrying

the load,

it

provides and The inost convenient method

of

making this check,

maintains

correct relationship

between

other units

Particularly

when

the

body

is on the

chassis,

is by

to assure their normal functioning. marking

on the

floor

all

dimensional points from

Of

rugged design, the frame

is

constructed of heavy

fhlch

measurements should

be

taken.

This

is

channel

steel side

rails

and cross-members.

Brack-

known

a\

Plumb-bobbing

the

frame Select

a

ets and diagonal braces

are

used

to

maintain

the

?Pace

on the

floof

^hlch

»

extr«nely

level If

work-

proper

longitudinal position

of the

side

rails

rela-

ing Pn

a.,fPen^

c*ean

* s°

that

the fha*k

tive

to

each other, and

at the

same time provide

*****

Jl!*

be

vJs.lble

underneath

the

frame

to be

additional

resistance

to

torsional strains. Fig. R-1, checked

If

workmg

on a

wooden

floor

it is ad-

R-2,

and R-3 illustrate

the

subject models. disable

la^

f f * V

Underneath

*he ve"

Vehicles

that have been

in an

accident

of any

hide

and

carefully tack them

m

place. Drop

a

nature,

which

may

result

in a

swayed

or

sprung gumb-bob from each point indicated

in

Figures

frame,

should always

be

carefully checked

for ^

an?

L'maJkl?g the uflo?r

Meetly underneath

proper

frame alignment, steering geometry,

and the

point. Satisfactory checking depends entirely

axle alignment.

on the

accuracy

of the

marks

in

relation

to the

frame.

To

check points that have been marked, carefully

move

the vehicle away from the layout on the floor,

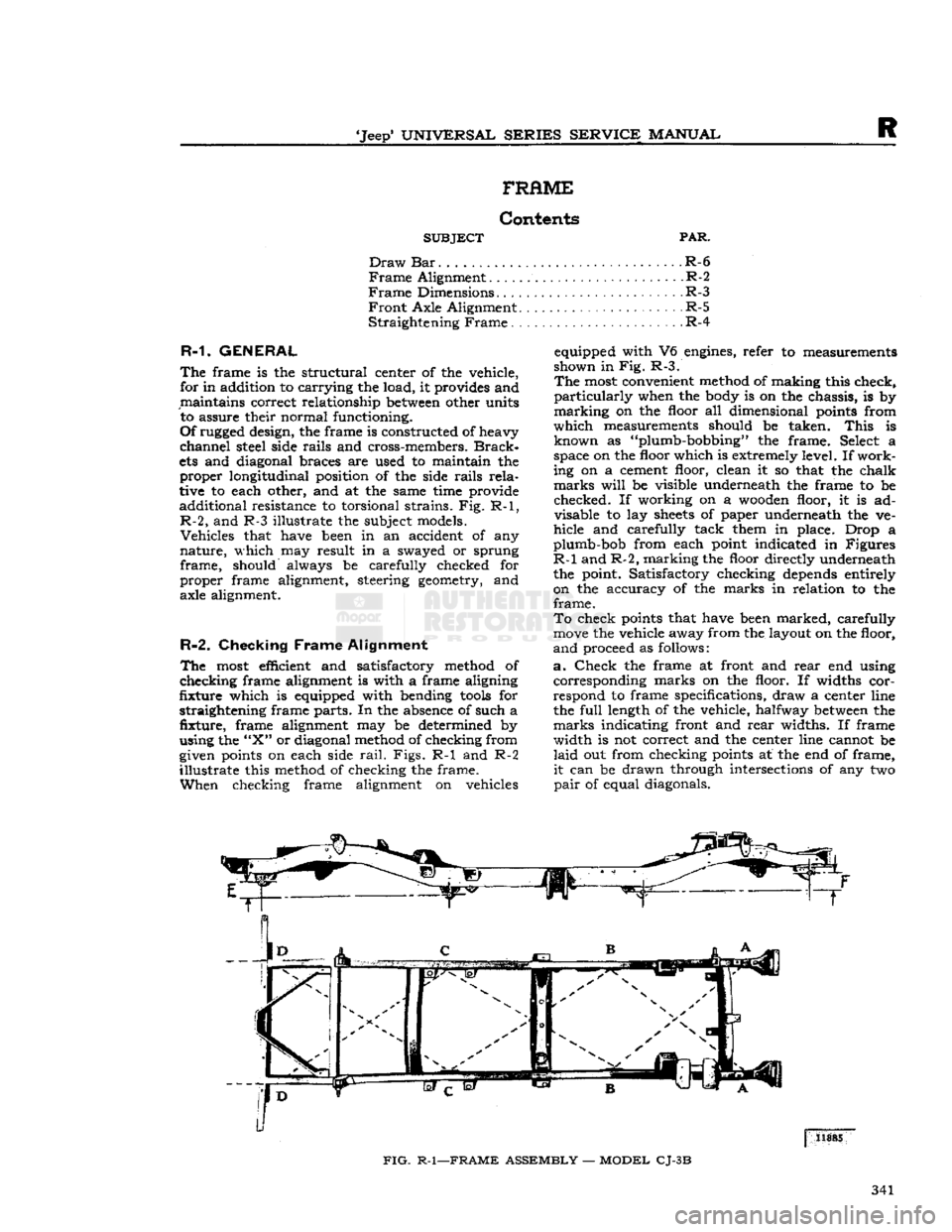

R-2.

Checking

Frame

Alignment

anci

proceed

as

follows:

The

most efficient

and

satisfactory method

of a.

Check

the

frame

at

front

and

rear

end

using

checking

frame alignment

is

with

a

frame aligning corresponding marks

on the

floor.

If

widths

cor-

fixture

which

is

equipped with bending

tools

for

respond

to

frame specifications, draw

a

center line

straightening frame parts. In the absence

of

such

a the

full

length

of

the vehicle, halfway

between

the

fixture,

frame

alignment

may be

determined

by

marks indicating front and

rear

widths.

If

frame

using the

"X"

or diagonal method of checking from width

is not

correct and

the

center line cannot

be

given points

on

each side

rail.

Figs.

R-1 and R-2

laid

out

from checking points

at the

end

of

frame,

illustrate

this method

of

checking

the

frame.

it

can

be

drawn through intersections

of

any

two

When

checking frame alignment

on

vehicles

pair

of

equal diagonals.

FIG.

R-1—FRAME

ASSEMBLY

—

MODEL

CJ-3B

341