length JEEP CJ 1953 Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 192 of 376

H

ELECTRICAL

SYSTEM

Regulator

ground screw to battery ground post

—.03-volt maximum.

Generator

frame to battery ground post—.03-volt

maximum.

H-47.

Test Procedure

a.

Circuit

Breaker—Connect

an ammeter in series between the regulator B-terminal and the lead

wire

removed from that terminal. Connect a

voltmeter between the regulator

A-terminal

and the regulator mounting base. Disconnect the field lead

from

the regulator

F-terminal

and insert a variable resistance (3 amp., 50 ohm capacity) between the

lead

and the regulator terminal. Run the generator

at about 1000 generator rpm. Insert all the re

sistance in the field

circuit,

then slowly reduce the

resistance noting the voltage reading just before the change caused by the closing of the circuit

breaker.

Increase the charging rate to the figure

specified for the regulator being tested then reduce

the charging rate by inserting resistance in the

field

circuit.

Note

the voltmeter and ammeter

reading

just before the circuit breaker

opens

and

the ammeter reading drops to zero. The closing voltage and the opening voltage or current should

be within the limits specified. An accurate method

for noting the exact instant of the opening or closing

of the circuit breaker is to connect a headphone (2000 ohms or higher) to the battery and armature

terminals

of the regulator. When the contacts

open or close a

click

will

be

heard

in the headphones.

To

adjust the closing voltage change the armature

spring

tension by bending the hanger at the lower end of the spring. Increase the spring tension to

raise

the closing voltage or decrease the tension

to lower the closing voltage. To adjust the opening voltage raise or lower the stationary contact

keeping the contacts perfectly aligned. Increasing

the contact gap lowers the opening

'

voltage.

Change

the contact gap by expanding or contract

ing the stationary contact bracket, keeping the

contacts aligned. Do not adjust the gap between

the contacts to less than the specified minimum.

b.

Voltage Regulator—Connect the ammeter as in

step

a. Connect the voltmeter between the regulator

B-terminal

and the regulator base. Remove the

variable

resistance from the field

circuit.

Run the

generator at

half

output for 15 minutes to bring

the regulator to normal operating temperature.

Keep

the cover on the regulator during the

warm-

up period and also when taking readings.

Stop the engine then bring it up to approximately 2500 generator rpm. Adjust the amperage to

half

maximum

output by turning on lights or accessor

ies and then

note

the voltmeter reading.

This

read

ing should be within the limits specified for the voltage regulator operation. To adjust the oper

ating voltage change the

armature

spring tension by

bending the hanger at the lower end of the

arma

ture

spring. After each adjustment

stop

the engine then restart it.

Bring

it up to speed and adjust the

current

before taking a reading. In order to obtain

an

accurate indication of the operation of the volt

age regulator unit connect a headphone (2000 ohm

or

higher) between the

F-terminal

and ground to

pick

up the sound of the opening and closing of the

contacts. The clicks should be regular and clear without irregularities or missing. If the

tone

is not

clear

and regular remove the regulator cover and

inspect the contacts. The contacts should be flat

and

not burned excessively and should be aligned

to make

full

face contact. If the contacts need

cleaning refer to paragraph d for the method.

c.

Current

Regulator—Connect the regulator and the

test

equipment as in

step

b. Running the generator at approximately 3000 generator rpm.,

turn

on lights and accessories so that the generator must charge at maximum rate. The ammeter should give a reading within the limits specified.

To

adjust opening amperage, change the armature

spring

tension by bending the hanger at the lower

end of the armature spring. After each adjustment,

stop

the engine, then restart it.

Bring

the engine up to speed and take an ammeter reading. Keep

the cover on the regulator when taking

these

readings.

Connect

a headphone (2000 ohms or higher) be

tween the regulator

F-terminal

and ground to pick

up the sound of opening and closing of the contacts.

Clear,

regular clicks should be heard over the

headphones; they should not be

irregular

or missing.

If

the

tone

is not clear and regular remove the

regulator cover and inspect the contacts. The

contacts should be flat and not burned excessively

and

should be aligned to make

full

face contact. If

the contacts need cleaning refer to paragraph d.

below for the method.

d.

Contacts—Inspect the contacts on all three

units.

In normal use the contacts

will

become

grayed.

If the contacts are burned or dirty or if they are not smooth, file the contacts with a #6

American,

Swiss cut, equalling file. Move the file

parallel

and lengthwise to the armature.

File

just

enough so that the contacts present a smooth

sur

face toward each other. It is not necessary to remove every trace of pitting. After filing, dampen

a

piece of linen or lintless bond tape in refined

carbon

tetrachloride and draw the tape between

the contacts. Repeat with a dry piece of tape. Use

clean

tape for each set of contacts.

e. Recheck—Operate the unit at

half

maximum

output for five minutes with the cover on the regu

lator.

Repeat the testing procedure for all units as described in a, b, c above. Be sure cover is on regu

lator

when taking readings.

H-48.

Quick

Checks

H-49.

Low Charging Rate with a

Fully

Charged

Battery

A

fully charged battery and a low charging rate

indicates normal regulator operation.

A

further check of the regulator operation can be

made by using the starting motor for 5 to 10

seconds with the ignition switch in the "off" posi tion.

Then

start the engine and operate at a genera

tor speed of 2500 to 3000 rpm. The charging rate should rise to its maximum value then taper off to

a

minimum charge as the battery becomes charged.

H-50.

High Charging Rate with a

Fully

Charged

Battery

This

is usually an indication that the voltage regu

lator

is not operating correctly. The high voltage 192

Page 193 of 376

'Jeep1

UNIVERSAL

SERIES SERVICE

MANUAL

H

will

cause the battery to gas excessively and

will

shorten the life of the ignition contacts and, in

general,

will

have a detrimental

effect

on all con

nected load.

Connect

an ammeter in series with the regulator

"B"

terminal and the lead removed from the termi

nal.

Run the generator at a medium speed and per

form

the following operation. After each

test

is

completed reconnect whatever leads have been opened.

H-51.

Test One

Disconnect the field lead at the generator.

a.

Output drops to zero—shorted field circuit in regulator or in wiring harness. See

test

2.

b.

Output

does

not drop—shorted field circuit in

generator. Inspect generator.

H-52.

Test Two

Disconnect the field lead at the regulator.

a.

Output drops to zero—shorted field in regulator.

See

test

3.

b.

Output

does

not drop—shorted wiring harness.

Repair

or replace wiring harness.

H-53.

Test

Three

Remove the regulator cover and hold the

voltage

regulator contacts open.

a.

Output drops to zero—regulator contacts stick

ing,

regulator out of adjustment, or regulator in operative.

Check

operation

(test

5), check for high

resistance

(test

4), and clean contacts per instruc

tions in Par. H-56.

b.

Output

does

not drop—shorted field circuit in

the regulator.

Clean

the regulator contacts and in spect the regulator visually for incorrect wiring be

tween units and shorted leads.

H-54.

Test

Four

Operate

the units at 10 amperes output and meas

ure

the

voltage

drop from the regulator base to

the generator frame.

a.

Voltage reading below .03 volts—ground

cir

cuit

is satisfactory. See

test

5.

b.

Voltage reading above .03 volts—Inspect ground

circuit

for poor connections and eliminate the high

resistance. See

test

5.

H-56.

Test

Five

Connect

a headphone from the regulator field ter

minal

to the base and hold the current regulator

contacts closed.

a.

A steady beat is heard—voltage regulator oper

ating.

Reset regulator as in the operation

test,

Par.

H-47.

b.

An unsteady beat is heard—dirty or sticking

contacts.

Clean

contacts per instructions in Par.

H-56.

c.

No beat is heard—inoperative

voltage

regulator

unit.

Adjust regulator operation as in the operation

test.

If the regulator cannot be adjusted within

limits,

remove for overhaul.

H-56.

Cleaning of Contacts

Clean

the

voltage

regulator contacts with a #6

American

Swiss cut equalling file.

File

lengthwise

and

parallel to the armature and then clean the

contacts with clean linen tape.

First

draw a piece

of tape that has been wet with carbon tetrachlor

ide

between

the contacts then follow with dry tape. Reset the regulator operation as in the oper

ation

test,

Par. H-47.

H-57.

Low Battery and a Low or No Charging Rate

Check

all wiring for

loose

connections, frayed in

sulation and high resistance connections and cor

rect

any fault.

Make

sure the generator operates correctly with

out the regulator in the

circuit.

Remove the "A"

and

"B" leads from the regulator and connect an

ammeter

between

them. Remove the field lead from

the regulator and while operating at idle speed

touch the field lead to the regulator base. Increase

the speed slowly noting the charging rate. Do not

increase

the output above the rated output of the generator. If the generator output

will

not build

up,

inspect the wiring harness for shorts and

opens

and

remove the generator for an overhaul.

Connect

an ammeter

between

the battery lead and

the regulator

"B"

terminal. Connect the field lead to the regulator "F" terminal and connect the

armature

lead to the regulator

"A"

terminal.

Con

nect a voltmeter from the regulator

"A"

terminal to

the regulator base. Operate the generator at a medium speed and perform the following

tests:

H-58.

Test Six

Read

the voltmeter.

a.

Voltage builds up—open series

circuit.

See

test

7.

b.

Voltage

does

not build up—regulator out of ad

justment, field circuit open, grounded series

circuit.

See

test

8.

H-59.

Test Seven

Remove the regulator cover and with the generator

operating at a medium speed hold the circuit

breaker

contacts closed.

a.

Ammeter shows no charge—open

circuit

breaker

shunt winding, incorrect setting of circuit breaker,

or

dirty contacts.

Clean

contacts and reset circuit

breaker

as in

Par.

H-47d. If the circuit breaker

can

not be set, the shunt coil is open and the regulator

should be removed for overhaul.

b.

No generator output—clean the circuit breaker

contacts and try the

test

again. If there is

still

no

charge the series windings are open and the regu

lator

should be removed for overhaul.

H-60.

Test

Eight

Run

the generator at idle speed and momentarily

connect a jumper from the

F-terminal

to the regu

lator

base.

a.

Voltage builds up—open field circuit or regula

tor out of adjustment. See

test

9.

b.

Voltage

does

not build up—grounded series

cir

cuit.

Remove regulator for overhaul. 193

Page 206 of 376

H

ELECTRICAL

SYSTEM

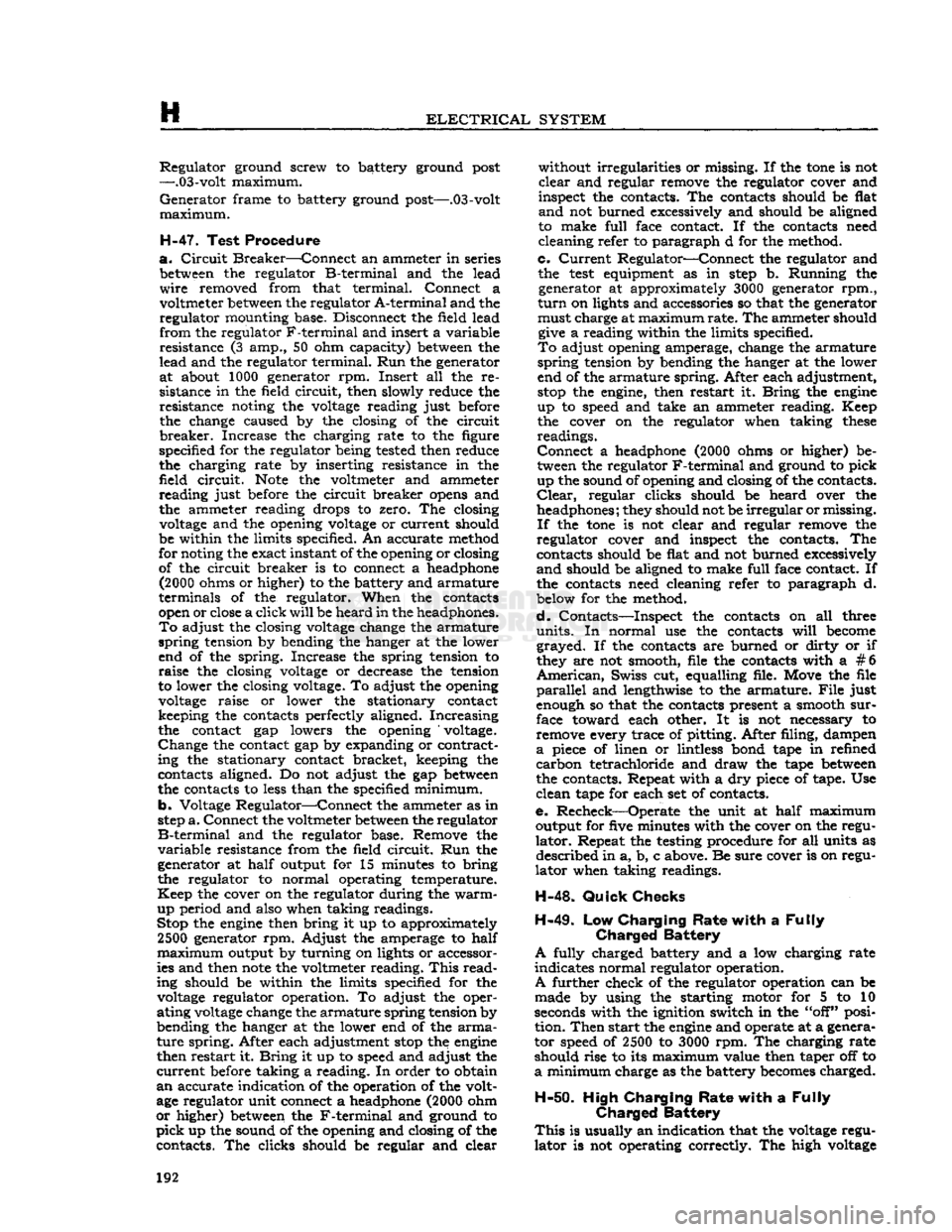

FIG.

H-42—GROWLER

d.

Install

the armature in starter motor frame,

using care to align the four brushes and brush

springs on the commutator so that they are free to

move

and are square on the commutator.

e.

Install

the thrust washer on the shaft.

Lubricate

the plug and bearing in the end plate.

Install

the

end plate.

Install

the two through

bolts

and tighten securely.

f.

On Prestolite V6 starting motors, check pinion position by measuring from the centerline of the

pinion housing mounting bolt

holes

to the outside

edge

of the pinion.

Correct

measurement with the

Bendix

drive retracted is [19,05 mm.] to

%"

[22,23 mm.]; with drive extended, 1%"

[34,93

mm.] to 1^" [38,10]. Adjust by installing

thrust

washers just inside the commutator end

head or intermediate bearing as required. The

Bendix

drive retaining pin must not project

beyond the outside diameter of the pinion

sleeve.

H-104.

Bench Test

The

motor should first be checked to see that the

free running

voltage

and current are within specifi cations. To

test,

connect the motor to a battery,

ammeter and voltmeter. If the current is too high

check

the bearing alignment and end play to make

sure

there is no binding or interference. Using a

spring

scale and torque arm check the stall torque to see that the motor is producing its rated

crank

ing power. The stall torque

will

be product of the

spring

scale reading and the length of the arm

in

feet.

If the torque is not up to specifications

check

the seating of the brushes on the commutator

and

the internal connection of the motor for high

resistance. The Bendix

Folo-Thru-Drive

should be checked for correct operation. The Bendix pinion

should be checked to see that it shifts when the motor is operated under no load.

H-105.

Bendix Folo-Thru Drive (Prestolite)

The

Bendix

Folo-Thru

Drive is designed to over

come

premature demeshing of the drive pinion

from

the flywheel ring gear until a predetermined

engine

speed is reached. See Fig. H-43. No repairs or adjustments are possible on this

drive

and a

complete

new unit must be installed

if

trouble develops.

H-106.

Lubrication

of

Folo-Thru Drive

A

periodic cleaning and relubrication of the drive is advisable, the frequency of which

will

depend on

the type of service to which the vehicle is sub

jected and the locale of operation.

a.

Remove the starting motor from the

engine

and take off the outboard housing. The pinion and

barrel

assembly

will

be in the demeshed position

on the screwshaft. Do not

move

it forward

until

after

that portion of the armature shaft ahead

of the pinion has been cleaned. If accidentally ro

tated to the outer end of the screwshaft it

will

lock

in that position and cannot be forced back.

b.

Do not disassemble the drive for any reason.

c.

Do not dip or wash the drive in any cleaning solution.

d.

Do not remove the drive from the armature

shaft. Remove

excess

oil, grease or foreign matter

from

the armature shaft by wiping it with a clean cloth.

3

10859

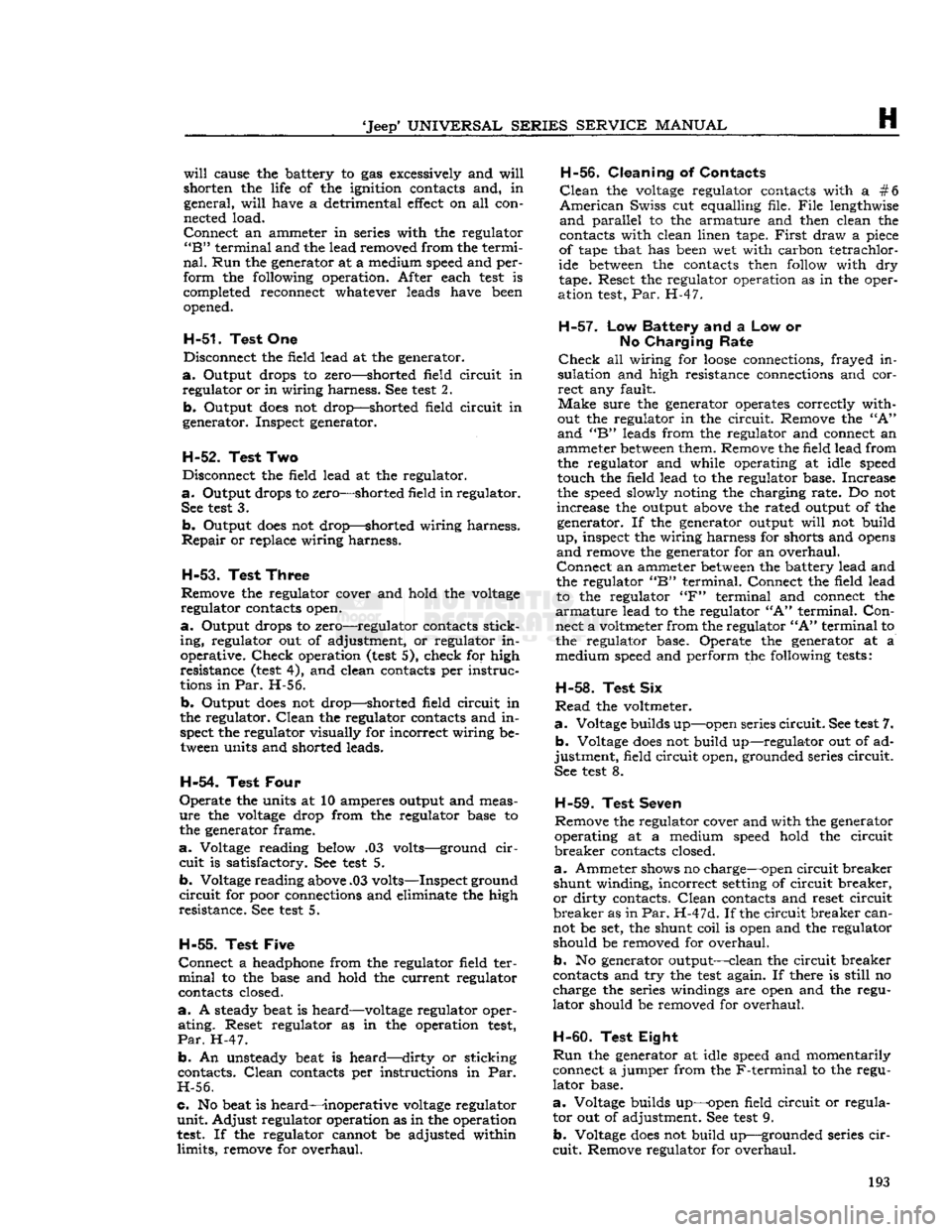

FIG.

H-43—BENDIX

FOLO-THRU DRIVE

Dampen

the cloth with kerosene if necessary. A

light film of

SAE

10 oil may then be applied to the shaft.

e.

Now rotate the pinion and

barrel

assembly to the

fully

extended position, thereby exposing the screw shaft triple threads. Use a cloth dampened with

kerosene to wipe them clean. Do not use

gaso

line

or any

commercial cleaner.

If the dirt is

thick

and gummy, apply the kerosene with a small

brush.

Tilt

the starting motor so that a small

amount

will

run under the control nut. Relubricate

with

a thin film of

SAE

10 oil. Use SAE 5 at ex tremely low temperatures.

f.

Reassemble the starting motor to the

engine

with the drive in the extended position.

Carefully

mesh the pinion with the flywheel ring gear before

tightening the starter motor mounting bolts. It may 206

Page 209 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

H-111.

Brushes

Check

brush length. If brushes are worn to one-

half

their original length, replace them. Also check

for

cracks,

chips, damaged mounting holes, oil

saturation,

or other damage; replace brushes.

H-112.

Commutator

Check

the commutator for wear and discoloration.

If

the commutator is rough or worn the armature

should be removed and the commutator turned

down in a lathe. A discolored commutator should

be cleaned with carbon tetrachloride and inspected.

Scratches

on the commutator may be removed

with

sand paper. Use compressed air to remove

sand

particles after cleaning.

H-113.

Armature

Visually

inspect the armature for mechanical

defects

before checking for shorted or grounded

coils. Use a set of

test

probes for testing armature

circuits.

To

test

the armature for grounds, touch

one point of the

test

probes to a commutator

seg

ment and touch the other point to the core or shaft.

Do not touch the points to the bearing surface or

to the brush surface as the arc formed

will

burn

the smooth finish. If the lamp lights, the coil con

nected to the commutator

segment

is grounded.

H-114.

Field

Coils

Using

test

probes, check the field coils for both ground and open circuits. To

test

for ground, place

one probe on the motor frame or

pole

piece and

touch the other probe to the field coil terminals.

If

a ground is present, the lamp

will

light.

To

test

for open circuits, place the probes on the

field coil terminal and on an insulated

brush.

If

the light

does

not light, the coil is open circuited.

H-115.

Brush

Holder Inspection

Inspect

brush

holders for distortion, wear, and other

damage.

Check

that brush holders pivot freely on

their

pivot pins.

Check

brush spring tension with

a

spring scale. Hook the spring scale under the

brush

holder at the brush and

pull

on a line

paral

lel

to the side of the

brush.

Note

scale reading just

as brush leaves commutator. Tension must be 35 oz. [9,925 kg.] minimum. Replace brush springs

if

tension is insufficient.

H-116.

Solenoid

Coils

Check

solenoid coil as follows:

a.

Remove screw from motor terminal of solenoid

and

bend field coil leads away from terminal.

Con

nect terminal to ground with a heavy jumper wire.

See

Fig.

H-48.

b.

Connect a 12-volt battery, a high-current

vari

able resistance, and an ammeter of 100 amperes

capacity

in series

between

S terminal of solenoid

and

ground; battery negative is to be connected

to ground. Connect a heavy jumper wire from

solenoid base to ground terminal of battery.

Con

nect a voltmeter

between

base of solenoid and

small

S terminal of solenoid. Refer to Fig. H-48.

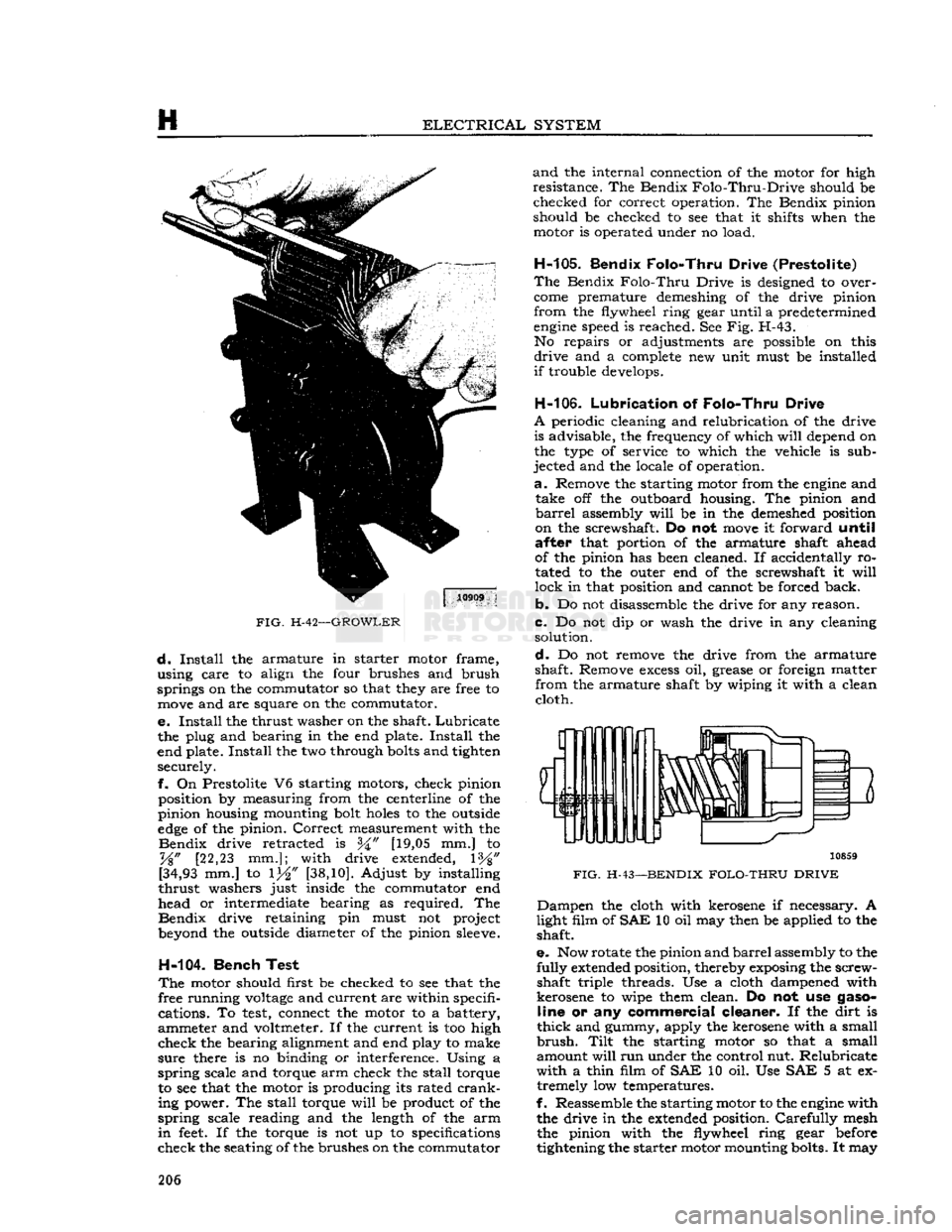

12455

FIG.

H-48—TEST CONNECTIONS,

STARTER

SOLENOID

COIL

1— S

Terminal

2—

Solenoid

3—

Ground

Connection 4—Voltmeter 5—Ammeter

6—

12-Volt

Battery

7—

Ground

Connection*

c.

Slowly decrease resistance until voltmeter

read

ing increases to 10 volts.

Note

ammeter reading.

This

is current drawn by both windings in

parallel

;

it

should be 42 to 49 amperes at 10 volts, with solenoid at room temperature.

d.

Disconnect jumper wire from motor terminal

of solenoid. Increase resistance until voltmeter

reads

10 volts;

note

ammeter reading.

This

is

cur

rent

drawn by hold-in winding only; it should be 10.5 to 12.5 amperes at 10 volts, with solenoid at

room temperature.

e. If solenoid windings do not rest within specifi cations given, replace solenoid switch assembly.

H-117.

Starting Motor Reassembly

a.

Lubricate

shift lever linkage and fasten in drive housing with lever stud.

Caution:

Do not lubricate solenoid plunger or solenoid cylinder.

b.

Install

return spring on solenoid plunger and

insert

plunger into solenoid cylinder. Apply sealing

compound on both sides of solenoid flange where it

extends

between

drive housing and field frame.

Attach

plunger to shift lever with fulcrum pin.

Fasten

solenoid to drive housing with two mount

ing screws.

c.

Lubricate

armature shaft with silicone grease.

Install

assist spring and drive assembly on shaft

with

pinion outward.

d.

Install

pinion

stop

retainer on armature shaft

with

recessed side outward. Place a new snap ring on drive end of shaft and hold it in place with a

hard

wood block. Strike block with hammer to

force snap ring over end of shaft; slide the ring

down into

groove

in shaft. See Fig. H-49, left hand view. 209

Page 226 of 376

![JEEP CJ 1953 Owners Guide

I

CLUTCH 1-1.

GENERAL

The

clutch on current Jeep vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single JEEP CJ 1953 Owners Guide

I

CLUTCH 1-1.

GENERAL

The

clutch on current Jeep vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single](/img/16/57040/w960_57040-225.png)

I

CLUTCH 1-1.

GENERAL

The

clutch on current 'Jeep' vehicles is either

Auburn

or Borg and Beck manufactured. Vehicles

equipped with F4-134

engines

have an

Auburn

9.25" [23,4 cm.] single plate dry-disc clutch. The

pressure plate has three coil pressure springs and

three levers or fingers.

The

V6-225

engine

is equipped with a 10.4" [26,4

cm.] Borg and Beck single plate dry-disc clutch.

The

pressure plate utilizes either a finger-type

diaphragm spring, or a coil

type

spring pressure plate for clutch release.

The

driven plates of all

models

are built with

vibra

tion damper springs and have two flexible facings

which

provide

smooth

engagement

of the

engine

power.

Early

'Jeep' vehicles equipped with a Dauntless

V-6

engine

use a 10.4" [26,4 cm.] single plate, dry-

disc clutch, incorporating a diaphram-type spring assembly.

The

clutch is of the centrifugal single dry disc

type

and

consists of the clutch disc, pressure plate and

the clutch release bearing.

The

clutch is actuated by a clutch pedal and a

series of mechanical linkage.

When

the clutch pedal is in the

engaged

position,

the clutch disc facings are clamped

between

the

friction surface of the

engine

flywheel and the face of the clutch pressure plate, thereby connect

ing

engine

power to the transmission. Depressing

the clutch pedal actuates the clutch release shaft

fork

which

moves

the clutch release bearing against

the clutch fingers.

This,

in

turn,

moves

the pressure

plate away from the clutch disc. Since the disc is splined to the transmission input shaft, the clutch

disc and transmission input shaft

will

stop

when

the clutch is disengaged, thereby disconnecting

engine

power from the transmission.

1-2.

Clutch

Maintenance

To

obtain normal life and satisfactory performance

from any clutch it must be correctly operated and

properly maintained. Two conditions which shorten

clutch life are continuous operation of the clutch

release bearing and clutch slippage.

The

clutch release bearing is

designed

for inter

mittent use. If run continuously the bearing

lubri

cant

will

become

exhausted causing the bearing to

become

dry, noisy, or

will

seize, resulting in clutch

finger or diaphragm wear. The clutch must be properly adjusted so that the release bearing is

free of the clutch fingers or diaphragm at all times,

except

when the clutch pedal is depressed.

Excessive

clutch slippage

often

occurs when the

vehicle is overloaded, the vehicle load is applied

too quickly, or when the pressure of the clutch fingers or diaphragm is only partially applied to the clutch plate.

Friction

between

the clutch facing

and

flywheel produces

excessive

heat causing

burned,

glazed and worn linings, resulting in shortened clutch life. Avoid clutch slippage under

heavy loads by using a lower gear or reducing the load.

1-3.

Clutch

Pedal

Linkage

and Adjustment

Adjust

the clutch pedal free travel whenever the clutch

does

not

disengage

properly, or when new

clutch parts are installed. Improper adjustment of

the clutch pedal free travel is one of the

most

fre

quent causes of clutch failure and can be a con tributing factor in

some

transmission failures.

As

the clutch facings wear the free travel of the clutch pedal diminishes. When sufficient wear oc

curs

the pedal clearance must be adjusted.

Two

types

of clutch linkage have

been

used on Jeep vehicles, a cross shaft

tube

and lever

type

shown in Fig. 1-1, and a clutch control cable

type

shown in Fig. 1-2. The clutch pedal adjustment

procedures for both

type

linkages are as follows.

•

Cross

Shaft

Lever

and Tube Type

Refer

to Fig. 1-1.

Note:

Two different

Clutch

Control

Lever

and

Tube

Assemblies have

been

installed on 'Jeep*

Universal

vehicles equipped with a V-6

engine

and

T14A

transmission.

Should difficulty in shifting the transmission be

noted, check the length of the clutch release pedal

rod,

item (16) in Fig. 1-1. Measure the distance

between

the centerlines of the cotter key holes.

FIG.

1-2—CLUTCH

LINKAGE AND

ADJUSTMENT,

CONTROL

CABLE TYPE

A—Top

View,

Cable

to

Clutch

Fork

1—

Retracting

Spring

(Clutch

Fork)

2—

Clutch

Fork

3—

Ball

Adjusting Nut

4—

Lock

Nut 5—

Clutch

Cable

B—Side

View,

Cable

to

Clutch

Pedal 6—

Clutch

Cable

Support

Bracket

7—

Clutch

Cable

Housing

8—

Anchor

Bracket-to-Frame Side

Rail

9—

Retracting

Spring

(Clutch

Pedal)

10—Clutch

Pedal Assembly

*

© © ©

1437S

226

Page 227 of 376

![JEEP CJ 1953 Owners Guide

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq JEEP CJ 1953 Owners Guide

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is eq](/img/16/57040/w960_57040-226.png)

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

The

correct distance should be 10%"

[26,04

cm.].

If

the length of the clutch release pedal rod is

other than

10

W

[26,04

cm.], the vheicle is equipped with the early

type

Clutch

Control

Lever

and

Tube Assembly, which should be removed, and^trie latest

designed

parts should be installed.

The

free pedal clearance is adjusted by lengthening

or shortening the" clutch fork cable. To make this adjustment,

loosen

the jam nut on the cable clevis

and

lengthen or shorten the cable to obtain %"

[19,05

mm.] free travel at the pedal pad, then

tighten the jam unit.

•

Clutch

Control Cable Type

Refer

to Fig. 1-2.

a.

With the clutch pedal pad against the floor

panel, (pedal up, clutch

engaged)

adjust ball ad

justing nut until slack is removed from the cable

and

the clutch throwout bearing contacts the clutch

pressure plate, release levers or diaphragm plate.

b. Back-off ball adjusting nut 2

V2

turns to obtain

approximately %"

[19,05

mm.] free travel.

Lock

hex nut.

FIG.

1-3—AUBURN

CLUTCH

ASSEMBLY —

HURRICANE F4 ENGINE 1—

Driven

Plate and Hub

2—

Pressure

Plate

3—

Pivot Pin

4—

Bracket

5—

Spring

Cup 6—

Pressure

Spring 7— Release

Lever

8—

Return

Spring

9—

Adjusting

Screw

10—

Jam

Nut 11—

Washer

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One way to

compensate

for this wear is to install a pedal

slack

adjuster kit 1-4.

CLUTCH

—

HURRICANE

F4

ENGINE

•

Auburn

Vehicles equipped with the Hurricane F4

engine

have a 9.25" [23,4 cm.] driven plate. The auburn clutch driving (pressure) plate assembly (Fig. 1-3)

has three pressure springs and three levers or

fingers.

1-5.

Clutch

Removal

When

necessary to remove the clutch,

follow

the procedures outlined in Section J for the removal

of the transmission and transfer case from the vehicle. Then remove the flywheel housing and use

the following procedures for removing the clutch assembly.

Note:

The F4

engine

may be removed from the

vehicle when inspecting or replacing the clutch.

Refer

to Section D for Hurricane F4

engine

removal and then

follow

the instructions given

below

to remove the clutch assembly.

a.

Mark

the clutch pressure plate and

engine

fly

wheel with a center punch so the clutch assembly

may be installed in the same position after adjust

ments

or replacement are completed.

b. Remove the clutch pressure plate bracket

bolts

equally, a little at a time, to prevent distortion and

to relieve the clutch springs evenly.

c. Remove the pressure plate assembly and driven

plate from the flywheel.

1-6.

Clutch

Pressure Plate and Disc Inspection

Inspect the pressure plate face for

cracks,

chips,

and

warpage.

Check

the pressure plate levers for

excessive

wear and the springs for breaks. If any of the

above

conditions exist, the

complete

pressure

plate must be replaced.

Check

the clutch disc for

excessive

wear,

loose

or damaged facings, broken

vibration damper springs and evidence of grease

or oil. If any of the

above

conditions exist, replace

the clutch disc.

1-7.

Clutch

Pressure Plate Adjustment —

Auburn

The

clutch pressure plate must be checked

before

installing a new or reconditioned clutch. The proper 11339

FIG.

1-4—CHECKING

AUBURN

CLUTCH

LEVER

ADJUSTMENT

1— Adjustment Gauge

2—

Fixture

Mounting Bolt

3—

Clutch

Fixture

227

Page 228 of 376

CLUTCH

©—*

11378

FIG.

1-5—ADJUSTING

AUBURN

CLUTCH

LEVERS

1—

Gauge

5—Mounting Bolt

2—

Clutch

Lever

6—Clutch

Pressure

Plate

3—

Adjusting

Screw

7—Thickness

Spacer

4—

Locknut

8—Clutch

Adjusting

Fixture

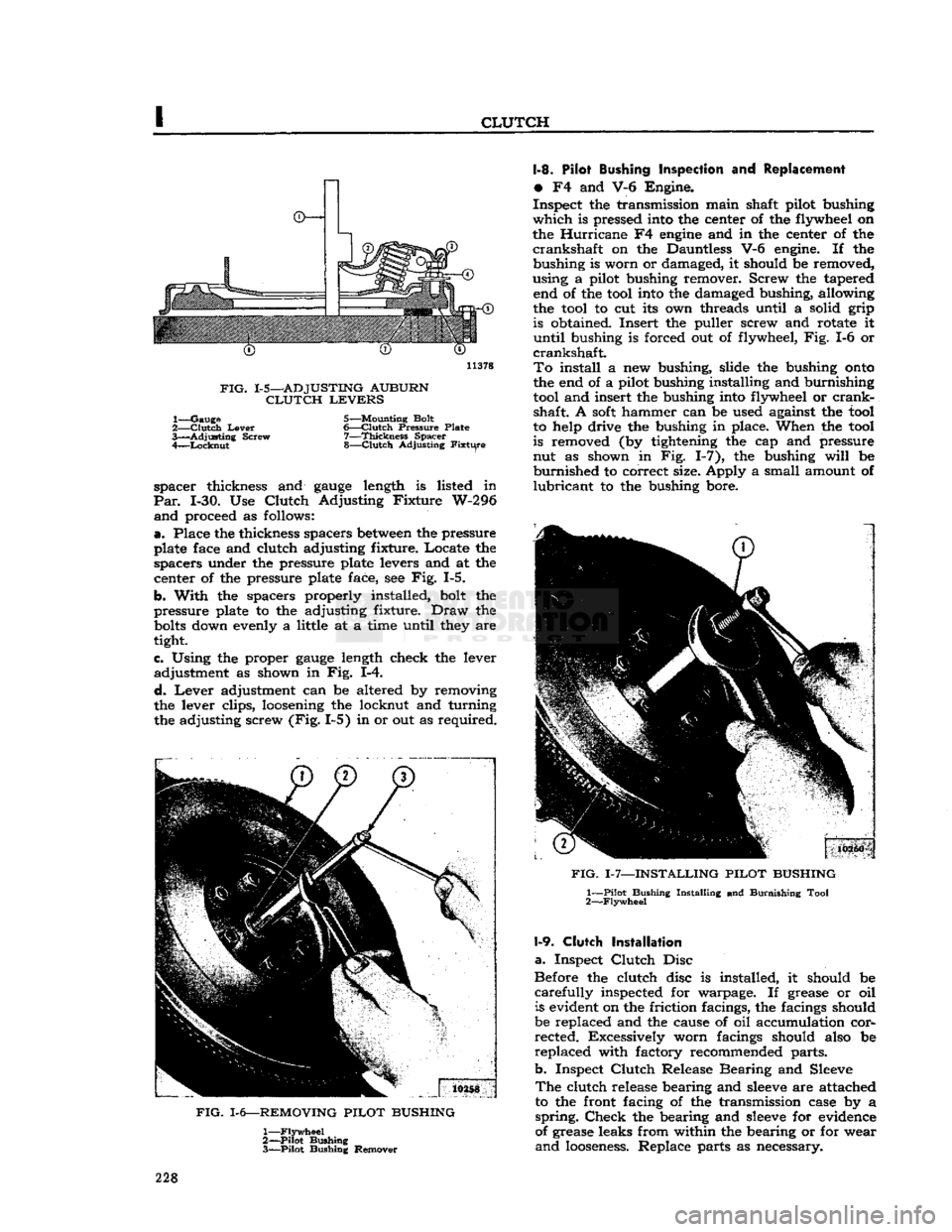

spacer thickness and

gauge

length is listed in

Par.

1-30. Use

Clutch

Adjusting Fixture W-296

and

proceed as follows:

a.

Place the thickness spacers

between

the pressure

plate face and clutch adjusting fixture. Locate the spacers under the pressure plate levers and at the

center of the pressure plate face, see Fig. 1-5.

b. With the spacers properly installed, bolt the

pressure plate to the adjusting fixture.

Draw

the

bolts

down evenly a little at a time until they are

tight.

c. Using the proper

gauge

length check the lever adjustment as shown in Fig. 1-4.

d.

Lever

adjustment can be altered by removing

the lever clips, loosening the locknut and turning

the adjusting screw (Fig. 1-5) in or out as required.

FIG.

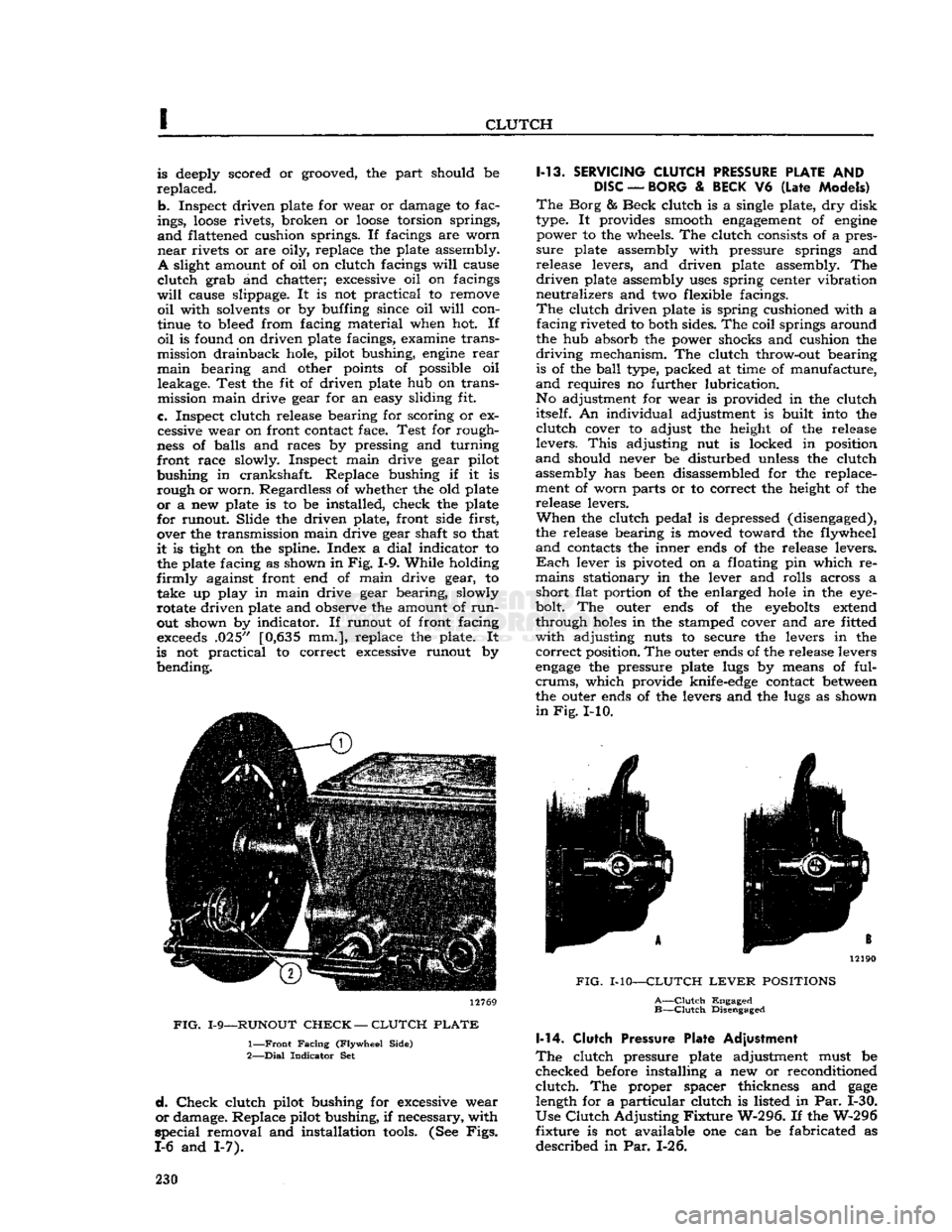

1-6—REMOVING

PILOT

BUSHING

1—

Flywheel

2—

Pilot

Bushing

3—

Pilot

Bushing Remover 1-8. Pilot Bushing Inspection and Replacement

•

F4 and V-6 Engine.

Inspect the transmission main shaft pilot bushing

which

is pressed into the center of the flywheel on

the Hurricane F4

engine

and in the center of the

crankshaft

on the Dauntless V-6 engine. If the bushing is worn or damaged, it should be removed,

using a pilot bushing remover. Screw the tapered end of the tool into the damaged bushing, allowing

the tool to cut its own threads until a solid grip is obtained. Insert the puller screw and rotate it

until

bushing is forced out of flywheel, Fig. 1-6 or

crankshaft.

To

install a new bushing, slide the bushing

onto

the end of a pilot bushing installing and burnishing tool and insert the bushing into flywheel or

crank

shaft. A

soft

hammer can be used against the tool

to help drive the bushing in place. When the tool

is removed (by tightening the cap and pressure

nut as shown in Fig. 1-7), the bushing

will

be

burnished

to correct size. Apply a small amount of

lubricant

to the bushing bore.

FIG.

1-7—INSTALLING

PILOT

BUSHING

1—

Pilot

Bushing

Installing

and

Burnishing

Tool

2—

Flywheel

1-9.

Clutch

Installation

a.

Inspect

Clutch

Disc

Before the clutch disc is installed, it should be

carefully

inspected for warpage. If grease or oil is evident on the friction facings, the facings should

be replaced and the cause of oil accumulation cor rected. Excessively worn facings should also be

replaced with factory recommended parts.

b. Inspect

Clutch

Release Bearing and Sleeve

The

clutch release bearing and

sleeve

are attached to the front facing of the transmission case by a

spring.

Check

the bearing and

sleeve

for evidence

of grease leaks from within the bearing or for wear

and

looseness.

Replace parts as necessary. 228

Page 230 of 376

CLUTCH

is deeply scored or grooved, the part should be

replaced.

b. Inspect driven plate for wear or damage to fac

ings,

loose

rivets, broken or

loose

torsion springs,

and

flattened cushion springs. If facings are worn

near

rivets or are oily, replace the plate assembly.

A

slight amount of oil on clutch facings

will

cause

clutch

grab and chatter; excessive oil on facings

will

cause slippage. It is not practical to remove

oil

with solvents or by buffing since oil

will

con

tinue to bleed from facing material when hot. If

oil

is found on driven plate facings, examine trans

mission drainback hole, pilot bushing,

engine

rear

main

bearing and other points of possible oil leakage. Test the fit of driven plate hub on trans

mission main drive gear for an easy sliding fit.

c. Inspect clutch release bearing for scoring or ex cessive wear on front contact face. Test for rough

ness

of balls and races by pressing and turning

front race slowly. Inspect main drive gear pilot

bushing in crankshaft. Replace bushing if it is rough or worn. Regardless of whether the old plate

or

a new plate is to be installed, check the plate

for runout. Slide the driven plate, front side first,

over the transmission main drive gear shaft so that

it

is tight on the spline. Index a

dial

indicator to the plate facing as shown in

Fig.

1-9. While holding

firmly

against front end of main drive gear, to take up play in main drive gear bearing, slowly

rotate driven plate and observe the amount of

run

out shown by indicator. If runout of front facing

exceeds

.025" [0,635 mm.], replace the plate. It

is not practical to correct excessive runout by bending. 12769

FIG.

1-9—RUNOUT

CHECK

—

CLUTCH

PLATE

1—

Front

Facing

(Flywheel

Side)

2—

Dial

Indicator

Set

d.

Check

clutch pilot bushing for excessive wear

or

damage. Replace pilot bushing, if necessary, with

special

removal and installation

tools.

(See

Figs.

1-6 and 1-7). 1-13.

SERVICING

CLUTCH

PRESSURE

PLATE

AND

DISC

—

BORG

&

BECK

V6

(Late

Models)

The

Borg & Beck clutch is a single plate, dry disk

type. It provides smooth

engagement

of

engine

power to the wheels. The clutch consists of a pres

sure

plate assembly with pressure springs and

release levers, and driven plate assembly. The

driven

plate assembly

uses

spring center vibration

neutralizes and two flexible facings.

The

clutch driven plate is spring cushioned with a facing riveted to both sides. The coil springs around

the hub absorb the power shocks and cushion the

driving

mechanism. The clutch throw-out bearing is of the

ball

type, packed at time of manufacture,

and

requires no further lubrication.

No adjustment for wear is provided in the clutch itself. An individual adjustment is built into the

clutch

cover to adjust the height of the release

levers.

This

adjusting nut is locked in position

and

should never be disturbed unless the clutch assembly has been disassembled for the replace

ment of worn parts or to correct the height of the release levers.

When

the clutch pedal is depressed (disengaged),

the release bearing is moved toward the flywheel

and

contacts the inner ends of the release levers.

Each

lever is pivoted on a floating pin which re

mains stationary in the lever and rolls across a short flat portion of the enlarged

hole

in the eye-

bolt. The outer ends of the

eyebolts

extend

through

holes

in the stamped cover and are fitted

with

adjusting nuts to secure the levers in the

correct

position. The outer ends of the release levers

engage

the pressure plate lugs by means of ful-

crums,

which provide knife-edge contact

between

the outer ends of the levers and the lugs as shown

in

Fig.

I-10. 12190

FIG.

MO—CLUTCH

LEVER

POSITIONS

A—Clutch

Engaged

B—Clutch

Disengaged 1-14.

Clutch

Pressure Plate Adjustment

The

clutch pressure plate adjustment must be

checked before installing a new or reconditioned

clutch.

The proper spacer thickness and

gage

length for a particular clutch is listed in Par. 1-30.

Use

Clutch

Adjusting

Fixture

W-296. If the W-296

fixture is not available one can be fabricated as

described in Par. 1-26. 230

Page 231 of 376

'Jeep1

UNIVERSAL

SERIES SERVICE

MANUAL

I

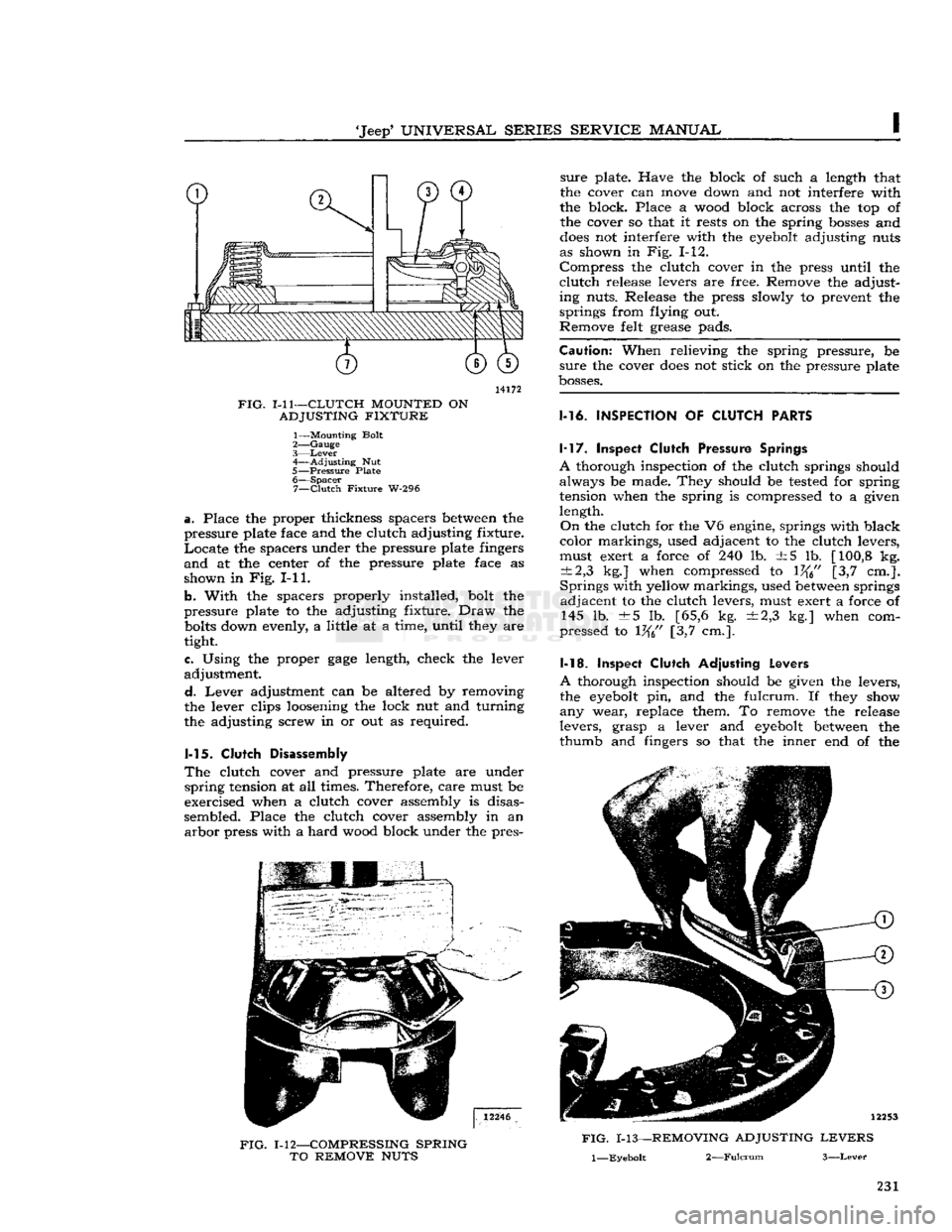

14172

FIG.

1-11—CLUTCH

MOUNTED

ON

ADJUSTING

FIXTURE

1— Mounting Bolt

2—

Gauge

3—

Lever

4—

Adjusting

Nut

5—

Pressure

Plate 6—

Spacer

7—

Clutch

Fixture

W-296

a.

Place the proper thickness

spacers

between the

pressure

plate face and the

clutch

adjusting

fixture.

Locate the

spacers

under the

pressure

plate fingers

and at the center of the

pressure

plate face as

shown

in Fig. I-11.

b.

With

the

spacers

properly installed,

bolt

the

pressure

plate to the adjusting

fixture.

Draw the

bolts

down evenly, a

little

at a

time,

until

they are

tight.

e. Using the proper

gage

length, check the lever

adjustment.

d.

Lever adjustment can be altered by removing

the lever clips loosening the

lock

nut and

turning

the adjusting screw in or out as required.

1-15.

Clutch

Disassembly

The

clutch

cover and

pressure

plate are under

spring

tension at all times. Therefore,

care

must be

exercised when a

clutch

cover assembly is disas

sembled. Place the

clutch

cover assembly in an arbor

press

with

a hard

wood

block under the pres-

FIG.

1-12—COMPRESSING

SPRING

TO

REMOVE

NUTS

sure

plate. Have the block of such a length that

the cover can move down and not interfere

with

the block. Place a

wood

block

across

the top of the cover so that it

rests

on the spring

bosses

and

does

not interfere

with

the eyebolt adjusting nuts

as shown in Fig. 1-12.

Compress the

clutch

cover in the

press

until

the

clutch

release

levers are free. Remove the adjust

ing

nuts.

Release

the

press

slowly

to prevent the

springs

from

flying

out.

Remove

felt

grease

pads.

Caution:

When

relieving

the spring

pressure,

be

sure

the cover

does

not stick on the

pressure

plate

bosses.

1-16.

INSPECTION

OF

CLUTCH

PARTS 1-17. Inspect

Clutch

Pressure

Springs

A

thorough inspection of the

clutch

springs should always be made. They should be tested for spring

tension when the spring is compressed to a given

length.

On

the

clutch

for the V6 engine, springs

with

black

color

markings, used adjacent to the

clutch

levers,

must exert a force of 240 lb. ±5 lb. [100,8 kg.

±2,3

kg.] when compressed to 1%" [3,7 cm.].

Springs

with

yellow

markings, used between springs adjacent to the

clutch

levers, must exert a force of 145 lb. ±5 lb. [65,6 kg. ±2,3 kg.] when com

pressed

to 1%" [3,7 cm.].

1-18. Inspect

Clutch

Adjusting

Levers

A

thorough inspection should be given the levers,

the eyebolt pin, and the

fulcrum.

If they show

any wear, replace them. To remove the

release

levers,

grasp

a lever and eyebolt between the

thumb

and fingers so that the inner end of the

FIG.

1-13—REMOVING

ADJUSTING

LEVERS

l—Eyebolt

2—Fulcrum

3—Lever

231

Page 237 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I

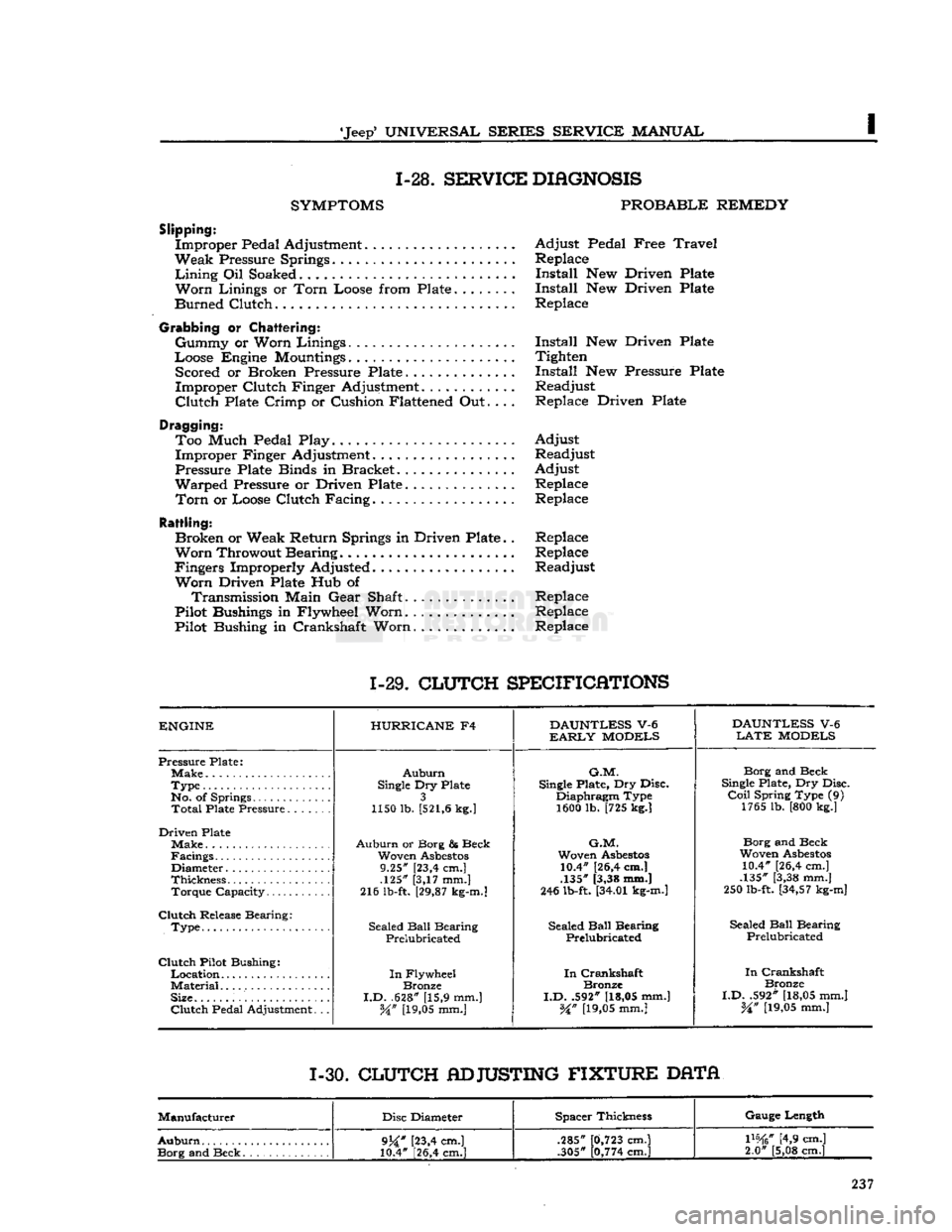

1-28.

SERVICE

DIAGNOSIS

SYMPTOMS

PROBABLE

REMEDY

Slipping:

Improper Pedal Adjustment Adjust Pedal Free

Travel

Weak Pressure Springs Replace

Lining

Oil Soaked Install New Driven Plate

Worn

Linings or

Torn

Loose from Plate Install New Driven Plate

Burned Clutch Replace

Grabbing

or

Chattering:

Gummy or Worn Linings Install New Driven Plate

Loose Engine

Mountings

Tighten Scored or Broken Pressure Plate Install New Pressure Plate

Improper Clutch Finger Adjustment............ Readjust

Clutch

Plate Crimp or Cushion Flattened Out.... Replace Driven Plate

Dragging: Too Much Pedal Play. Adjust Improper Finger Adjustment. Readjust

Pressure Plate Binds in Bracket Adjust

Warped Pressure or Driven Plate Replace

Torn

or Loose Clutch Facing. Replace

Rattling:

Broken or Weak Return Springs in Driven Plate.. Replace

Worn

Throwout Bearing Replace

Fingers Improperly Adjusted Readjust

Worn

Driven Plate Hub of Transmission Main Gear Shaft.............. Replace

Pilot Bushings in Flywheel Worn.

.............

Replace

Pilot Bushing in Crankshaft Worn Replace

1-29.

CLUTCH

SPECIFICATIONS

ENGINE

HURRICANE

F4

DAUNTLESS

V-6

DAUNTLESS

V-6

EARLY

MODELS

LATE

MODELS

Pressure Plate;

Auburn

G.M.

Borg and Beck

Type

Single

Dry Plate

Single

Plate, Dry Disc.

Single

Plate, Dry Disc.

No. of Springs 3 Diaphragm Type

Coil

Spring Type (9)

Total

Plate Pressure 1150 lb.

[521,6

kg.]

1600 lb. [725 kg.] 1765 lb. [800 kg.]

Driven Plate Make

Auburn

or Borg & Beck

G.M.

Borg and Beck

Facings Woven

Asbestos

Woven

Asbestos

Woven

Asbestos

Diameter 9.25" [23,4 cm.] 10.4" [26,4 cm.]

10.4" [26,4 cm.]

Thickness .125" [3,17 mm.] .135" [3,38 mm.]

.135" [3,38 mm.]

Torque Capacity 216 lb-ft.

[29,87

kg-m.]

246 lb-ft.

[34.01

kg-m.]

250 lb-ft.

[34,57

kg-m]

Clutch

Release Bearing: Sealed

Ball

Bearing

.

Type Sealed

Ball

Bearing Sealed

Ball

Bearing Sealed

Ball

Bearing

.

Type

Prelubricated Prelubricated

Prelubricated

Clutch

Pilot Bushing:

In

Crankshaft

In

Flywheel

In

Crankshaft

In

Crankshaft

Material

Bronze Bronze

Bronze

Size.

I.D.

.628" [15,9 mm.]

I.D.

.592"

[18,05

mm.]

I.D.

.592"

[18,05

mm.]

Clutch

Pedal Adjustment. .. W

[19,05

mm.]

%n

[19,05

mm.]

%n

[19,05

mm.]

1-30.

CLUTCH

ADJUSTING

FIXTURE

DATA

Manufacturer Disc Diameter Spacer Thickness Gauge Length

Auburn

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]