light JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 94 of 376

Dl

DAUNTLESS

V-6

ENGINE

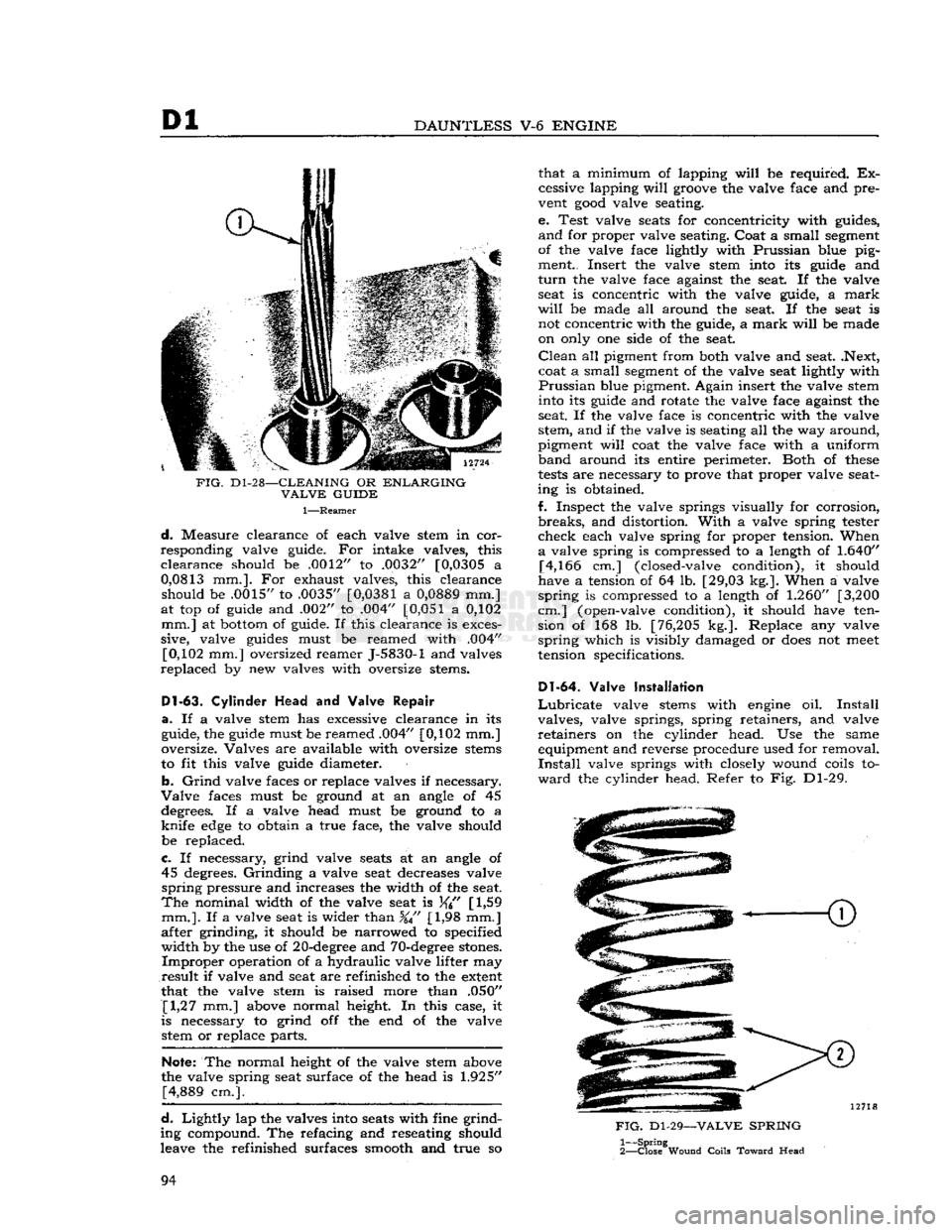

FIG.

D1-28—CLEANING

OR

ENLARGING

VALVE

GUIDE

1—Reamer

d.

Measure clearance of each valve stem in cor

responding valve guide. For intake valves, this

clearance

should be .0012" to .0032" [0,0305 a

0,0813

mm.]. For exhaust valves, this clearance should be .0015" to .0035"

[0,0381

a

0,0889

mm.]

at top of guide and .002" to .004"

[0,051

a 0,102 mm.] at bottom of guide. If this clearance is exces

sive, valve guides must be reamed with .004" [0,102 mm.] oversized reamer J-5830-1 and valves

replaced

by new valves with oversize stems.

Dl-63.

Cylinder

Head

and Valve

Repair

a.

If a valve stem has excessive clearance in its

guide, the guide must be reamed .004" [0,102 mm.]

oversize. Valves are available with oversize stems

to fit this valve guide diameter.

b.

Grind

valve faces or replace valves if necessary.

Valve

faces must be ground at an angle of 45 degrees. If a valve head must be ground to a

knife

edge

to obtain a true face, the valve should

be replaced.

c.

If necessary, grind valve seats at an angle of 45 degrees.

Grinding

a valve seat decreases valve

spring

pressure and increases the width of the seat.

The

nominal width of the valve seat is

[

1,59

mm.].

If a valve seat is wider than %" [1,98 mm.]

after grinding, it should be narrowed to specified

width

by the use of 20-degree and 70-degree stones.

Improper

operation of a hydraulic valve lifter may

result

if valve and seat are refinished to the extent

that the valve stem is raised more than .050" [1,27 mm.] above normal height. In this case, it

is necessary to grind off the end of the valve stetti or replace parts.

Note:

The normal height of the valve stem above

the valve spring seat surface of the head is

1.925"

[4,889 cm.].

d.

Lightly

lap the valves into seats with fine grind

ing compound. The refacing and reseating should

leave the refinished surfaces smooth and true so that a minimum of lapping

will

be required. Ex

cessive lapping

will

groove the valve face and pre

vent

good

valve seating.

e. Test valve seats for concentricity with guides,

and

for proper valve seating. Coat a small segment

of the valve face lightly with Prussian blue pig ment.. Insert the valve stem into its guide and

turn

the valve face against the seat. If the valve seat is concentric with the valve guide, a

mark

will

be made all around the seat. If the seat is not concentric with the guide, a

mark

will

be made

on only one side of the seat.

Clean

all pigment from both valve and seat. .Next,

coat a small segment of the valve seat lightly with

Prussian

blue pigment. Again insert the valve stem into its guide and rotate the valve face against the

seat. If the valve face is concentric with the valve

stem, and if the valve is seating all the way around,

pigment

will

coat the valve face with a uniform

band

around its entire perimeter. Both of

these

tests

are necessary to prove that proper valve seat

ing is obtained.

f. Inspect the valve springs visually for corrosion,

breaks,

and distortion.

With

a valve spring tester

check

each valve spring for proper tension. When

a

valve spring is compressed to a length of

1.640"

[4,166 cm.] (closed-valve condition), it should

have a tension of 64 lb. [29,03 kg.]. When a valve

spring

is compressed to a length of

1.260"

[3,200

cm.] (open-valve condition), it should have ten sion of 168 lb. [76,205 kg.]. Replace any valve

spring

which is visibly damaged or

does

not

meet

tension specifications.

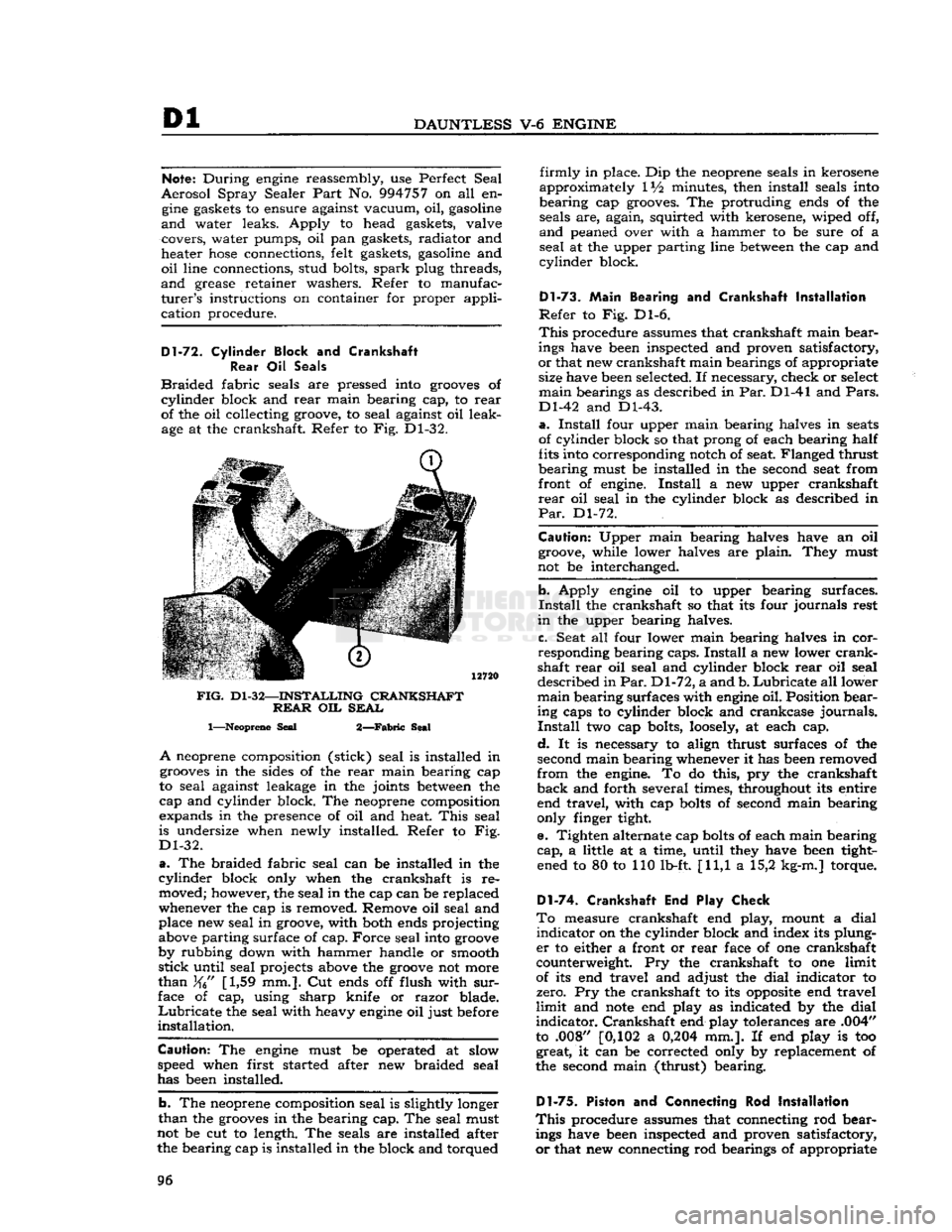

Dl-64.

Valve Installation

Lubricate

valve stems with engine oil.

Install

valves, valve springs, spring retainers, and valve

retainers

on the cylinder head. Use the same equipment and reverse procedure used for removal.

Install

valve springs with closely wound coils to

ward

the cylinder head. Refer to Fig. Dl-29.

FIG.

Dl-29—VALVE

SPRING

1—

Spring

2—

Close

Wound

Coils

Toward

Head

94

Page 96 of 376

Dl

DAUNTLESS

V-6

ENGINE

Note:

During

engine

reassembly, use Perfect Seal

Aerosol

Spray Sealer

Part

No.

994757

on all en

gine

gaskets to ensure against vacuum, oil, gasoline

and

water leaks. Apply to head gaskets, valve covers, water pumps, oil pan gaskets, radiator and

heater

hose

connections, felt gaskets, gasoline and

oil

line connections, stud bolts, spark plug threads,

and

grease retainer washers. Refer to manufac

turer's

instructions on container for proper appli

cation procedure.

Dl-72.

Cylinder

Block

and Crankshaft

Rear

Oil Seals

Braided

fabric seals are pressed into

grooves

of

cylinder

block and

rear

main bearing cap, to

rear

of the oil collecting groove, to seal against oil leak age at the crankshaft. Refer to Fig. Dl-32.

FIG.

Dl-32—INSTALLING

CRANKSHAFT REAR

OIL

SEAL

1—Neoprene

Seal

2—Fabric

Seal

A

neoprene composition (stick) seal is installed in

grooves

in the sides of the

rear

main bearing cap

to seal against leakage in the joints

between

the

cap and cylinder block. The neoprene composition

expands in the presence of oil and heat.

This

seal

is undersize when newly installed. Refer to Fig.

Dl-32.

a.

The braided fabric seal can be installed in the

cylinder

block only when the crankshaft is re moved; however, the seal in the cap can be replaced

whenever the cap is removed. Remove oil seal and place new seal in groove, with both ends projecting

above parting surface of cap. Force seal into

groove

by rubbing down with hammer handle or smooth

stick

until seal projects above the

groove

not more

than

[1,59 mm.]. Cut ends off flush with

sur

face of cap, using sharp knife or razor blade.

Lubricate

the seal with heavy

engine

oil just before

installation.

Caution:

The

engine

must be operated at slow

speed when first started after new braided seal

has been installed.

b. The neoprene composition seal is slightly longer

than

the

grooves

in the bearing cap. The seal must

not be cut to length. The seals are installed after the bearing cap is installed in the block and torqued

firmly

in place. Dip the neoprene seals in kerosene

approximately IV2 minutes, then install seals into

bearing cap grooves. The protruding ends of the seals are, again, squirted with kerosene, wiped off,

and

peaned over with a hammer to be sure of a

seal

at the upper parting line

between

the cap and

cylinder

block.

Dl-73.

Main

Bearing and Crankshaft

Installation

Refer

to Fig. Dl-6.

This

procedure assumes that crankshaft main bear

ings have been inspected and proven satisfactory,

or

that new crankshaft main bearings of appropriate size have been selected. If necessary, check or select

main

bearings as described in Par. Dl-41 and

Pars.

Dl-42 and Dl-43.

a.

Install

four upper main bearing halves in

seats

of cylinder block so that prong of each bearing half

fits into corresponding notch of seat. Flanged thrust

bearing must be installed in the second seat from

front of engine.

Install

a new upper crankshaft

rear

oil seal in the cylinder block as described in

Par.

Dl-72.

Caution:

Upper main bearing halves have an oil groove, while lower halves are plain. They must

not be interchanged.

b. Apply

engine

oil to upper bearing surfaces.

Install

the crankshaft so that its four journals rest

in

the upper bearing halves.

c. Seat all four lower main bearing halves in cor

responding bearing caps.

Install

a new lower

crank

shaft

rear

oil seal and cylinder block

rear

oil seal

described in

Par.

Dl-72, a and b.

Lubricate

all lower

main

bearing surfaces with

engine

oil. Position bear ing caps to cylinder block and crankcase journals.

Install

two cap bolts,

loosely,

at each cap.

d.

It is necessary to align thrust surfaces of the

second main bearing whenever it has been removed

from

the engine. To do this, pry the crankshaft

back

and forth several times, throughout its entire end travel, with cap

bolts

of second main bearing

only finger tight.

e. Tighten alternate cap

bolts

of each main bearing

cap,

a little at a time, until they have been tight ened to 80 to 110 lb-ft. [11,1 a 15,2 kg-m.] torque.

D1-74. Crankshaft End Play Check

To

measure crankshaft end play, mount a dial

indicator

on the cylinder block and index its plung

er

to either a front or

rear

face of one crankshaft

counterweight. Pry the crankshaft to one limit

of its end travel and adjust the dial indicator to

zero. Pry the crankshaft to its

opposite

end travel

limit

and

note

end play as indicated by the dial

indicator.

Crankshaft end play tolerances are .004"

to .008" [0,102 a

0,204

mm.]. If end play is too great, it can be corrected only by replacement of

the second main (thrust) bearing.

Dl-75.

Piston and Connecting Rod

Installation

This

procedure assumes that connecting rod bear ings have been inspected and proven satisfactory,

or

that new connecting rod bearings of appropriate 96

Page 103 of 376

'Jeep1

UNIVERSAL

SERIES

SERVICE

MANUAL

Dl

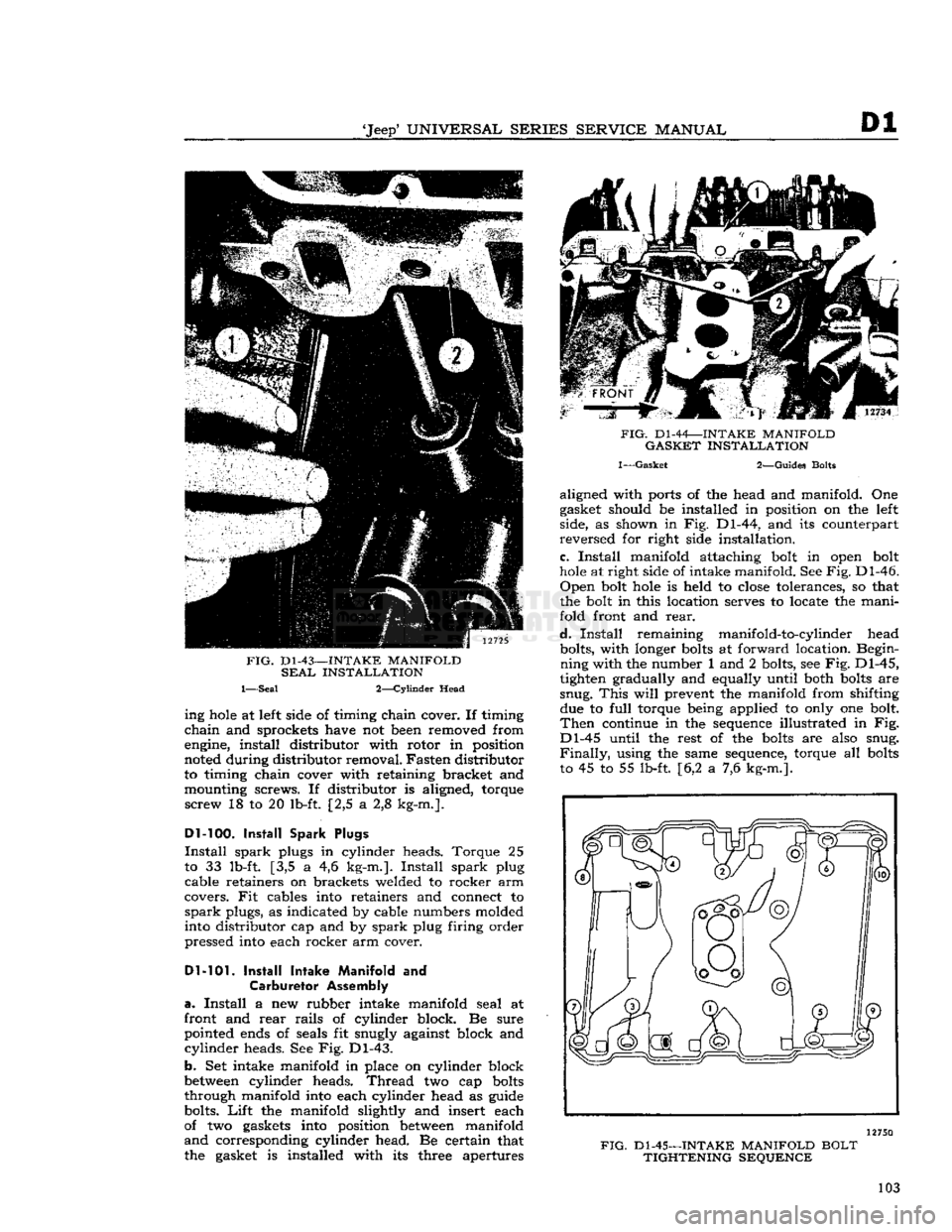

FIG.

D1-43—INTAKE

MANIFOLD

SEAL

INSTALLATION

1—Seal 2—Cylinder Head ing

hole

at left side of timing chain cover. If timing

chain

and sprockets have not been removed from

engine, install distributor with rotor in position

noted during distributor removal. Fasten distributor

to timing chain cover with retaining bracket and

mounting screws. If distributor is aligned, torque

screw

18 to 20 lb-ft. [2,5 a 2,8 kg-m.].

Dl-100.

Install Spark Plugs

Install

spark

plugs in cylinder heads. Torque 25

to 33 lb-ft. [3,5 a 4,6 kg-m.].

Install

spark

plug cable retainers on brackets welded to rocker arm

covers. Fit cables into retainers and connect to

spark

plugs, as indicated by cable numbers molded

into distributor cap and by

spark

plug firing order

pressed into each rocker arm cover.

Dl-101.

Install Intake Manifold

and

Carburetor

Assembly

a.

Install

a new rubber intake manifold seal at

front and

rear

rails

of cylinder block. Be sure

pointed ends of seals fit snugly against block and

cylinder

heads. See Fig. Dl-43.

b.

Set intake manifold in place on cylinder block

between

cylinder heads.

Thread

two cap

bolts

through manifold into each cylinder head as guide

bolts.

Lift

the manifold slightly and insert each

of two gaskets into position

between

manifold

and

corresponding cylinder head. Be certain that

the gasket is installed with its three apertures

FIG.

Dl-44—INTAKE

MANIFOLD

GASKET

INSTALLATION

1—Gasket

2—Guides Bolts aligned with ports of the head and manifold. One

gasket should be installed in position on the left

side, as shown in Fig. Dl-44, and its counterpart

reversed

for right side installation.

c.

Install

manifold attaching bolt in open bolt

hole

at right side of intake manifold. See

Fig.

Dl-46.

Open

bolt

hole

is held to

close

tolerances, so that

the bolt in this location serves to locate the mani

fold front and

rear.

d.

Install

remaining manifold-to-cylinder head bolts, with longer

bolts

at forward location. Begin

ning

with the number 1 and 2 bolts, see

Fig.

Dl-45,

tighten gradually and equally until both

bolts

are

snug.

This

will

prevent the manifold from shifting due to

full

torque being applied to only one bolt.

Then

continue in the sequence illustrated in Fig.

Dl-45

until the rest of the

bolts

are also snug.

Finally,

using the same sequence, torque all

bolts

to 45 to 55 lb-ft. [6,2 a 7,6 kg-m.].

12750

FIG.

Dl-45—INTAKE

MANIFOLD

BOLT

TIGHTENING

SEQUENCE

103

Page 117 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

Note:

The

Carter

YF-6115S Carburetor has a

throttle

return spring

attached

from the carburetor

main

body

to the carburetor

throttle

shaft. The

purpose

of

this

spring is to return the

throttle

to

idle

speed

position

should a linkage failure occur.

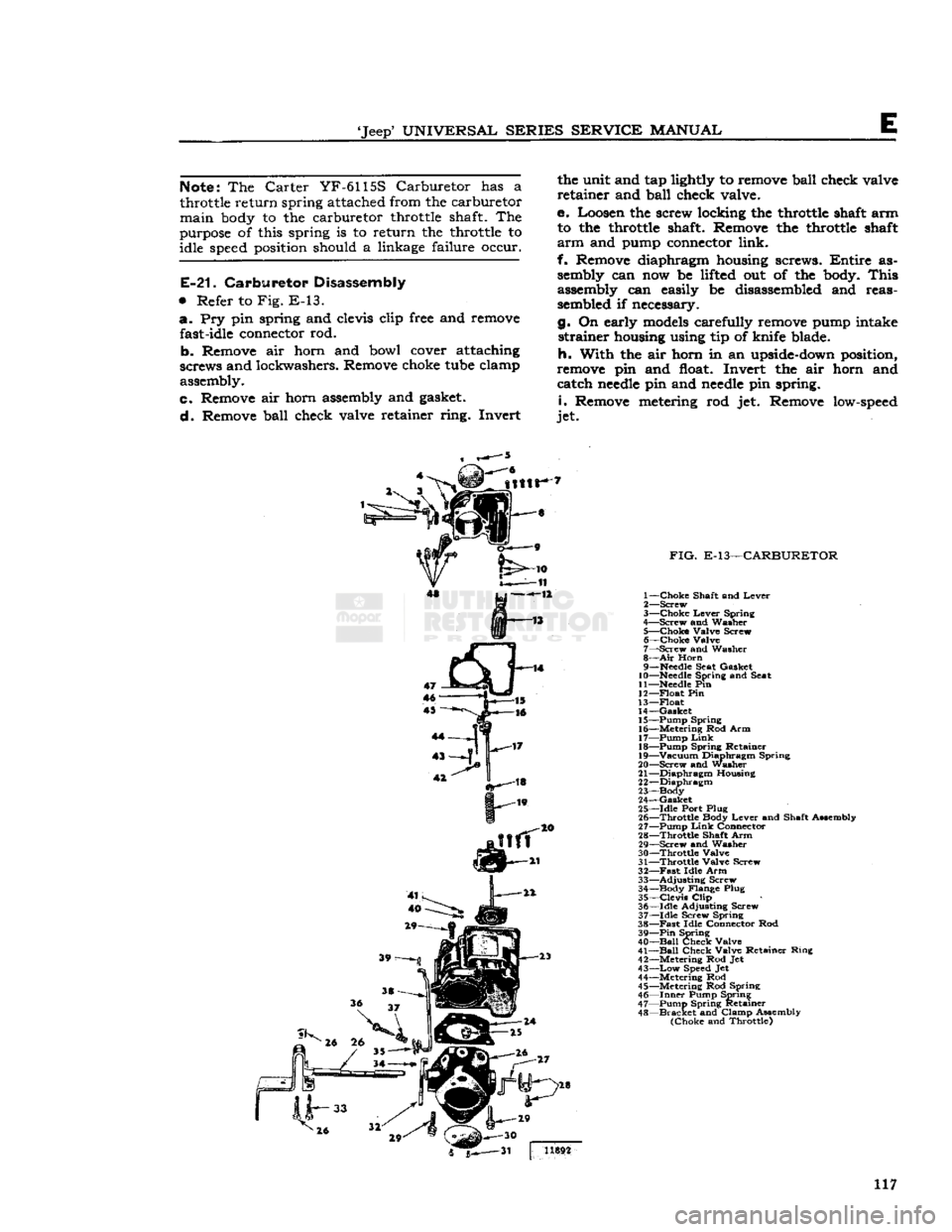

E-21.

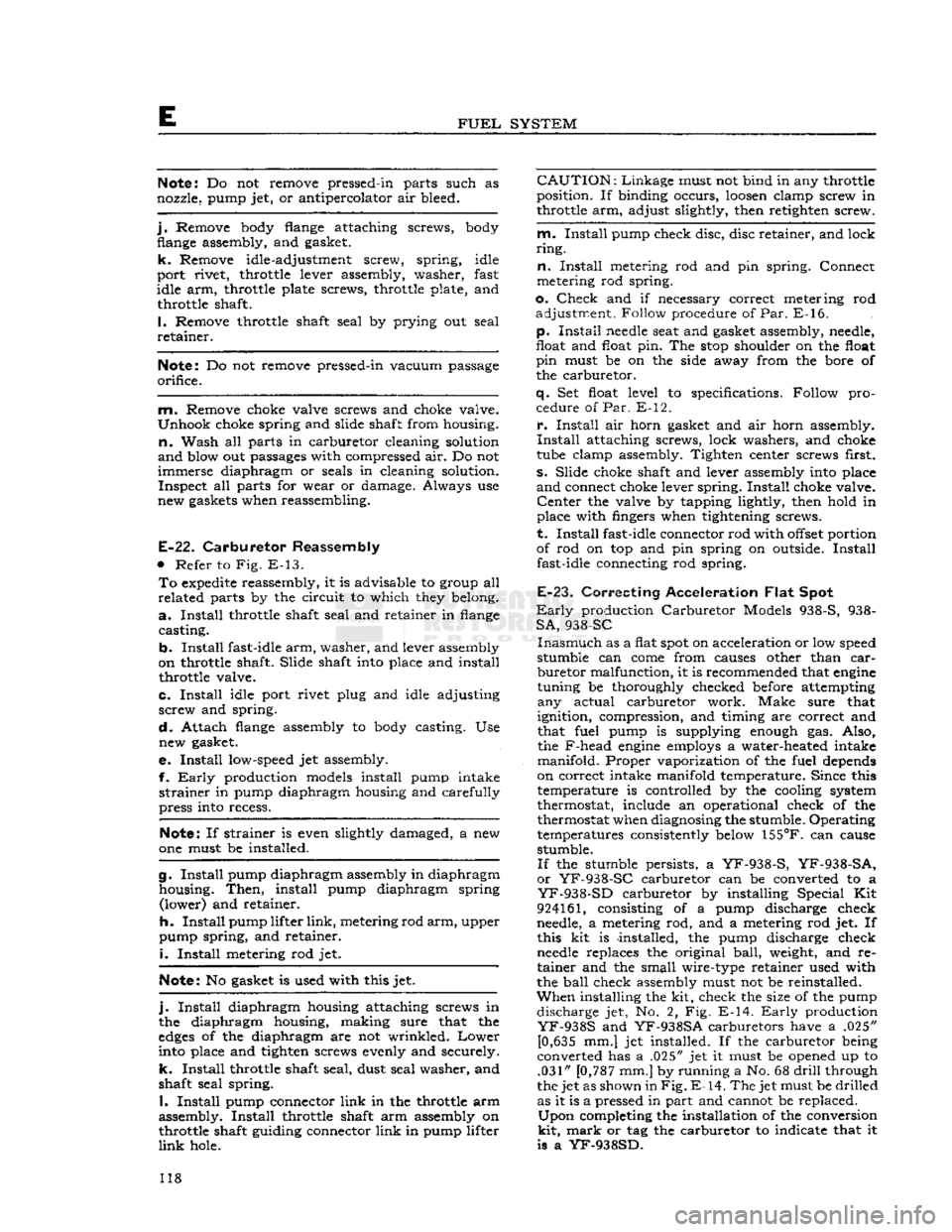

Carburetor Disassembly

•

Refer to Fig. E-13. a. Pry pin spring and

clevis

clip

free

and

remove

fast-idle

connector

rod.

b- Remove air horn and bowl

cover

attaching

screws and lockwashers. Remove

choke

tube

clamp

assembly.

c. Remove air horn

assembly

and

gasket.

d. Remove ball check valve retainer ring. Invert the unit and tap

lightly

to

remove

ball check valve

retainer and ball check valve.

e. Loosen the screw locking the

throttle

shaft

arm to the

throttle

shaft. Remove the

throttle

shaft

arm

and

pump

connector

link.

f. Remove diaphragm

housing

screws.

Entire

as

sembly

can now be

lifted

out of the

body.

This

assembly

can easily be

disassembled

and reas

sembled

if necessary.

g. On early

models

carefully

remove

pump

intake strainer

housing

using tip of knife blade.

h. With the air horn in an

upside-down

position,

remove

pin and

float.

Invert the air horn and catch

needle

pin and

needle

pin spring.

i.

Remove

metering

rod jet. Remove

low-speed

jet.

FIG.

E-13—CARBURETOR

1— Choke Shaft and Lever

2— Screw

3— Choke Lever Spring

4— Screw and Washer

5— Choke Valve Screw 6— Choke Valve

7— Screw and Washer

8—

Air

Horn

9—

Needle

Seat Gasket

10—

Needle

Spring and Seat

11—Needle

Pin

12— Float Pin

13— Float

14— Gasket 15— Pump Spring

16— Metering Rod Arm

17— Pump

Link

18— Pump Spring Retainer

19— Vacuum Diaphragm Spring

20— Screw and washer

21— Diaphragm Housing

22— Diaphragm

23—Body

24— Gasket

25— Idle Port Plug

26— Throttle Body Lever and Shaft Assembly

27— Pump

Link

Connector

28— Throttle Shaft Arm 29— Screw and Washer

30— Throttle Valve

31— Throttle Valve Screw

32—

Fast

Idle Arm 33— Adjusting Screw

34— Body Flange Plug

35— Clevis

Clip

36— Idle Adjusting Screw

37— Idle Screw Spring

38—

Fast

Idle Connector Rod 39—

Pin

Spring

40—

Ball

Check Valve

41—

Ball

Check Valve Retainer Ring

42— Metering Rod Jet

43—

Low

Speed

Jet

44— Metering Rod

45— Metering Rod Spring 46—

Inner

Pump Spring

47— Pump Spring Retainer

48—

Bracket

and Clamp Assembly (Choke and Throttle) 5^—31 | 1X892

117

Page 118 of 376

E

FUEL

SYSTEM

Note:

Do not remove pressed-in parts such as

nozzle, pump jet, or antipercolator air bleed.

j.

Remove body flange attaching screws, body flange assembly, and gasket.

k.

Remove idle-adjustment screw, spring, idle

port

rivet, throttle lever assembly, washer, fast

idle arm, throttle plate screws, throttle plate, and throttle shaft.

1. Remove throttle shaft seal by prying out seal

retainer.

Note:

Do not remove pressed-in vacuum passage

orifice.

m.

Remove choke valve screws and choke valve.

Unhook

choke spring and slide shaft from housing,

n.

Wash all parts in carburetor cleaning solution

and

blow out passages with compressed air. Do not immerse diaphragm or seals in cleaning solution.

Inspect

all parts for wear or damage. Always use

new gaskets when reassembling.

E-22.

Carburetor

Reassembly

•

Refer to Fig. E-13.

To

expedite

reassembly, it is advisable to group all

related

parts by the circuit to which they belong.

a.

Install

throttle shaft seal and retainer in flange casting.

b.

Install

fast-idle

arm,

washer, and lever assembly

on throttle shaft. Slide shaft into place and install throttle valve.

c.

Install

idle port rivet plug and idle adjusting

screw

and spring.

d.

Attach flange assembly to body casting. Use new gasket.

e.

Install

low-speed jet assembly.

f.

Early

production models install pump intake

strainer

in pump diaphragm housing and carefully

press into recess.

Note:

If strainer is even slightly damaged, a new

one must be installed.

g.

Install

pump diaphragm assembly in diaphragm housing.

Then,

install pump diaphragm spring

(lower)

and retainer.

h.

Install

pump lifter

link,

metering rod

arm,

upper

pump spring, and retainer.

I.

Install

metering rod jet.

Note:

No gasket is used with this jet.

j.

Install

diaphragm housing attaching screws in

the diaphragm housing, making sure that the

edges

of the diaphragm are not wrinkled.

Lower

into place and tighten screws evenly and securely,

k.

Install

throttle shaft seal, dust seal washer, and

shaft seal spring.

I.

Install

pump connector

link

in the throttle arm

assembly.

Install

throttle shaft arm assembly on

throttle shaft guiding connector

link

in pump lifter

link

hole.

CAUTION:

Linkage

must not bind in any throttle

position. If binding occurs,

loosen

clamp screw in

throttle arm, adjust slightly, then retighten screw.

m.

Install

pump check disc, disc retainer, and lock

ring.

n.

Install

metering rod and pin spring. Connect

metering rod spring.

o.

Check

and if necessary correct meter ing rod adjustment. Follow procedure of

Par.

E-16.

p.

Install

needle

seat and gasket assembly, needle,

float

and

float pin. The

stop

shoulder on the float

pin

must be on the side away from the bore of

the carburetor.

q.

Set float level to specifications. Follow pro cedure of

Par.

E-12.

r.

Install

air horn gasket and air horn assembly.

Install

attaching screws, lock washers, and choke

tube clamp assembly. Tighten center screws first,

s. Slide choke shaft and lever assembly into place

and

connect choke lever

spring.

Install

choke valve.

Center

the valve by tapping lightly, then hold in

place with fingers when tightening screws,

t.

Install

fast-idle connector rod with

offset

portion

of rod on top and pin spring on outside.

Install

fast-idle connecting rod spring.

E-23.

Correcting Acceleration

Flat

Spot

Early

production

Carburetor

Models 938-S, 938-

SA,

938-SC

Inasmuch

as a flat

spot

on acceleration or low speed

stumble can

come

from causes other than

car

buretor

malfunction, it is recommended that

engine

tuning be thoroughly checked before attempting

any

actual carburetor work. Make sure that

ignition, compression, and timing are correct and

that fuel pump is supplying enough gas. Also, the F-head

engine

employs a water-heated intake

manifold.

Proper vaporization of the fuel depends

on correct intake manifold temperature. Since this

temperature is controlled by the cooling system

thermostat, include an operational check of the

thermostat when diagnosing the stumble. Operating

temperatures consistently below

155°F.

can cause stumble.

If

the stumble persists, a

YF-938-S,

YF-938-SA,

or

YF-938-SC

carburetor can be converted to a

YF-938-SD

carburetor by installing Special Kit

924161, consisting of a pump discharge check

needle, a metering rod, and a metering rod jet. If this kit is installed, the pump discharge check

needle

replaces the original

ball,

weight, and re

tainer

and the small wire-type retainer used with

the

ball

check assembly must not be reinstalled.

When

installing the kit, check the size of the pump discharge jet, No. 2, Fig. E-14.

Early

production

YF-938S

and

YF-938SA

carburetors have a .025" [0,635 mm.] jet installed. If the carburetor being

converted has a .025" jet it must be opened up to .031" [0,787 mm.] by running a No. 68

drill

through

the jet as shown in

Fig.

E-14.

The jet must be drilled

as it is a pressed in part and cannot be replaced.

Upon

completing the installation of the conversion

kit,

mark

or tag the carburetor to indicate that it

is a

YF-938SD.

118

Page 120 of 376

E

FUEL

SYSTEM

There

are six adjustments: curb idle speed, curb

idle mixture, float level, float drop, accelerator pump, and fast idle.

This

carburetor has six basic systems: float, low

speed, main metering, power, accelerator pump

and

choke.

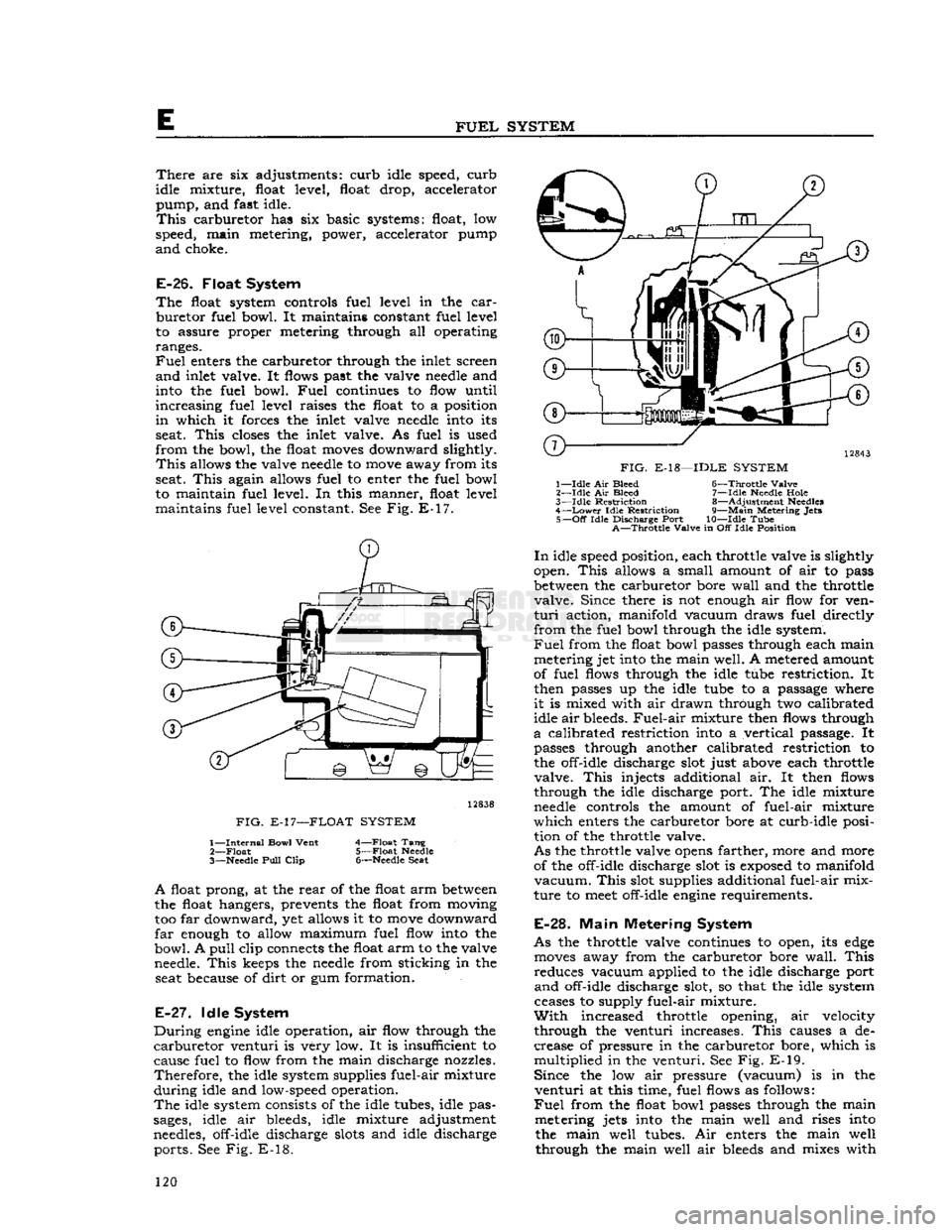

E-26.

Float System

The

float system controls fuel level in the

car

buretor fuel bowl. It maintains constant fuel level

to assure proper metering through all operating

ranges.

Fuel

enters the carburetor through the inlet screen

and

inlet valve. It flows past the valve

needle

and into the fuel bowl.

Fuel

continues to flow until

increasing

fuel level raises the float to a position

in

which it forces the inlet valve

needle

into its seat.

This

closes

the inlet valve. As fuel is used

from

the bowl, the float

moves

downward slightly.

This

allows the valve

needle

to

move

away from its

seat.

This

again allows fuel to enter the fuel bowl

to maintain fuel level. In this manner, float level maintains fuel level constant. See Fig. E-17. 12838

FIG.

E-17—FLOAT

SYSTEM

1—

Internal

Bowl

Vent

4—Float Tang

2—

Float

5—Float Needle

3— Needle

Pull

Clip

6—Needle

Seat

A

float prong, at the

rear

of the float arm

between

the float hangers, prevents the float from moving too far downward, yet allows it to

move

downward

far

enough to allow maximum fuel flow into the

bowl. A

pull

clip connects the float arm to the valve needle.

This

keeps the

needle

from sticking in the seat because of

dirt

or gum formation.

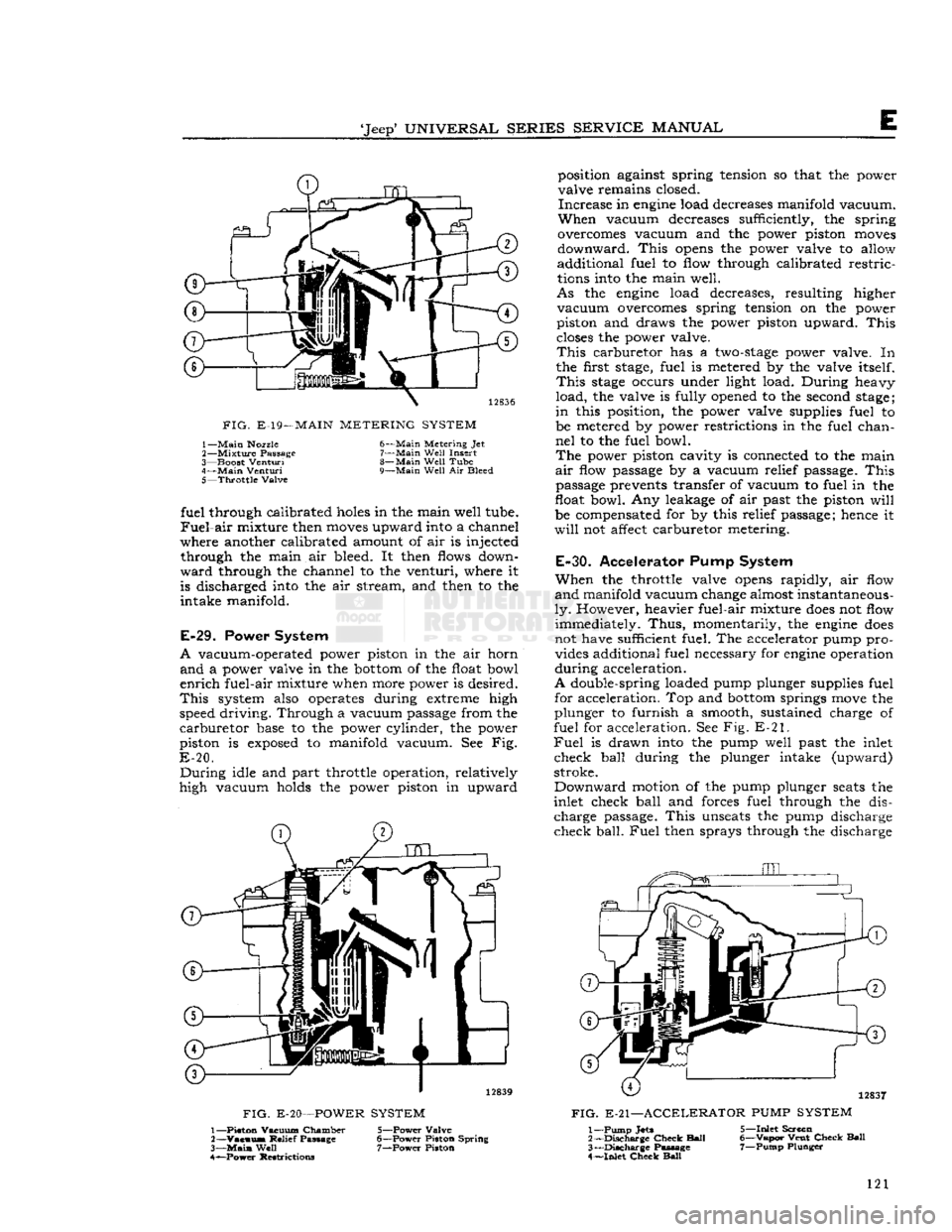

E-27.

Idle System

During

engine

idle operation, air flow through the

carburetor

venturi is very low. It is insufficient to

cause fuel to flow from the main discharge nozzles.

Therefore,

the idle system supplies fuel-air mixture

during

idle and low-speed operation.

The

idle system consists of the idle tubes, idle pas

sages,

idle air bleeds, idle mixture adjustment

needles, off-idle discharge

slots

and idle discharge ports. See Fig. E-18.

FIG.

E-18—IDLE

SYSTEM

1—

Idle

Air Bleed 6—Throttle

Valve

2—

Idle

Air Bleed 7—Idle Needle

Hole

3—

Idle

Restriction

8—Adjustment Needles

4—

Lower

Idle

Restriction

9—Main

Metering

Jets

5—

Off

Idle

Discharge Port 10—Idle Tube

A—Throttle

Valve

in Off

Idle

Position

In

idle speed position, each throttle valve is slightly

open.

This

allows a small amount of air to pass

between

the carburetor bore

wall

and the throttle valve. Since there is not enough air flow for ven

turi

action, manifold vacuum draws fuel directly

from

the fuel bowl through the idle system.

Fuel

from the float bowl passes through each main metering jet into the main well. A metered amount

of fuel flows through the idle tube restriction. It

then passes up the idle tube to a passage where

it

is mixed with air drawn through two calibrated

idle air bleeds.

Fuel-air

mixture then flows through

a

calibrated restriction into a vertical passage. It passes through another calibrated restriction to the off-idle discharge slot just above each throttle

valve.

This

injects additional air. It then flows

through the idle discharge port. The idle mixture

needle

controls the amount of fuel-air mixture

which

enters the carburetor bore at curb-idle posi tion of the throttle valve.

As

the throttle valve

opens

farther, more and more of the off-idle discharge slot is

exposed

to manifold

vacuum.

This

slot supplies additional fuel-air mix

ture to

meet

off-idle

engine

requirements.

E-28.

Main

Metering System

As

the throttle valve continues to open, its

edge

moves

away from the carburetor bore

wall.

This

reduces vacuum applied to the idle discharge port

and

off-idle discharge slot, so that the idle system

ceases

to supply fuel-air mixture.

With

increased throttle opening, air velocity through the venturi increases.

This

causes a de

crease of pressure in the carburetor bore, which is multiplied in the venturi. See Fig. E-19.

Since

the low air pressure (vacuum) is in the

venturi

at this time, fuel flows as follows:

Fuel

from the float bowl passes through the main metering jets into the main well and rises into the main well tubes. Air enters the main well through the main well air

bleeds

and mixes with 120

Page 121 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

FIG.

E-19—

MAIN

METERING SYSTEM

1—

Main

Nozzle

2—

Mixture

Passage

3—

Boost

Venturi

4—

Main

Venturi

5—

Throttle

Valve 6—

Main

Metering Jet

7—

Main

Well

Insert

8—

Main

Well

Tube

9—

Main

Well

Air Bleed fuel through calibrated

holes

in the main well tube.

Fuel-air

mixture then

moves

upward into a channel

where another calibrated amount of air is injected through the main air bleed. It then flows down

ward

through the channel to the venturi, where it is discharged into the air stream, and then to the

intake manifold.

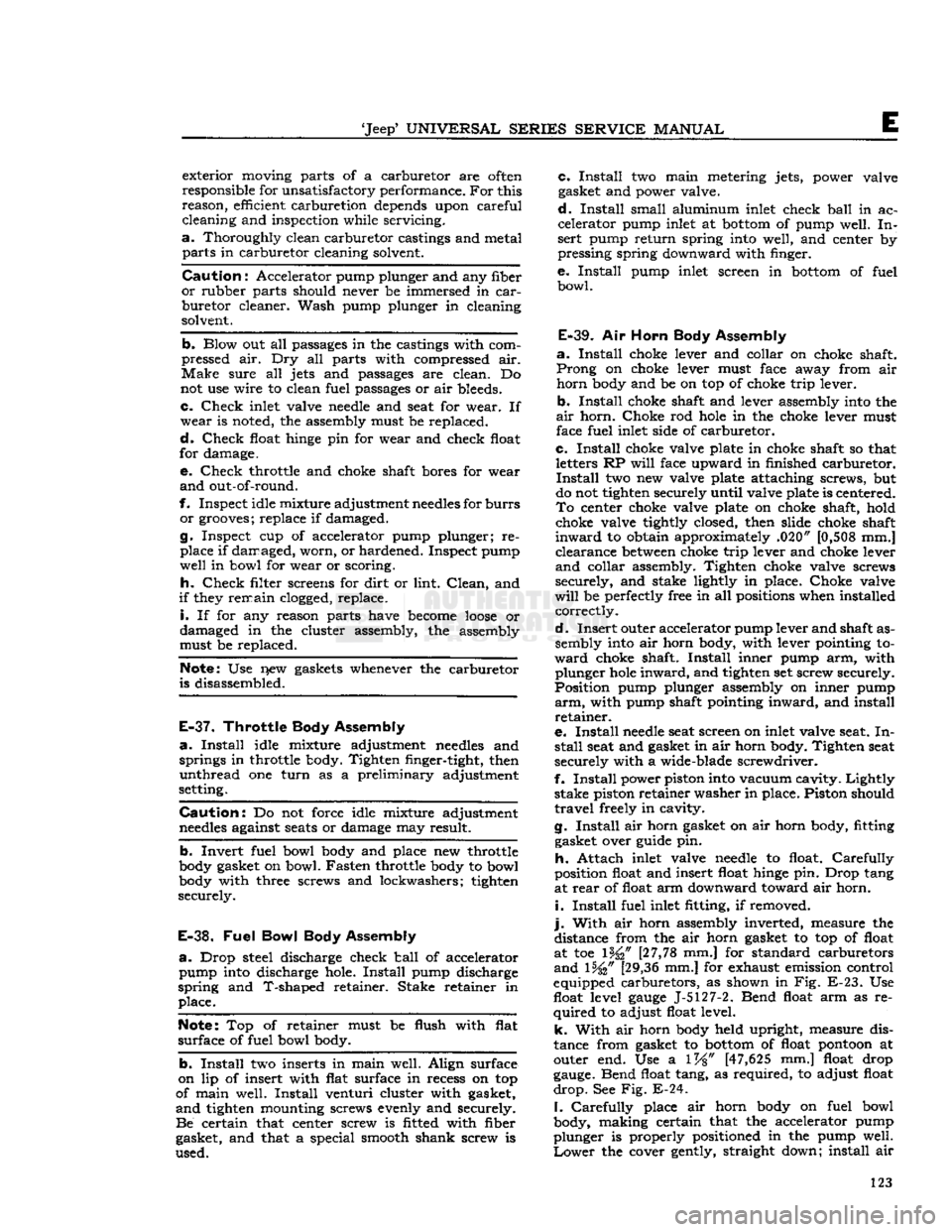

E-29.

Power System

A

vacuum-operated power piston in the air horn

and

a power valve in the

bottom

of the float bowl

enrich

fuel-air mixture when more power is desired.

This

system also operates during extreme high

speed driving. Through a vacuum passage from the

carburetor

base to the power cylinder, the power

piston is

exposed

to manifold vacuum. See Fig.

E-20.

During

idle and part throttle operation, relatively

high vacuum holds the power piston in upward

FIG.

E-20—POWER

SYSTEM

position against spring tension so that the power

valve remains closed.

Increase

in

engine

load decreases manifold vacuum.

When

vacuum decreases sufficiently, the spring

overcomes vacuum and the power piston

moves

downward.

This

opens

the power valve to allow

additional fuel to flow through calibrated restric

tions into the main well.

As

the

engine

load decreases, resulting higher

vacuum

overcomes spring tension on the power

piston and draws the power piston upward.

This

closes

the power valve.

This

carburetor has a

two-stage

power valve. In

the first

stage,

fuel is metered by the valve itself.

This

stage

occurs under light load. During heavy

load,

the valve is fully opened to the second

stage;

in

this position, the power valve supplies fuel to

be metered by power restrictions in the fuel chan

nel

to the fuel bowl.

The

power piston cavity is connected to the main

air

flow passage by a vacuum relief passage.

This

passage prevents transfer of vacuum to fuel in the

float bowl. Any leakage of air past the piston

will

be compensated for by this relief passage; hence it

will

not affect carburetor metering.

E-30.

Accelerator Pump System

When

the throttle valve

opens

rapidly, air flow

and

manifold vacuum change almost instantaneous

ly.

However, heavier fuel-air mixture

does

not flow immediately.

Thus,

momentarily, the

engine

does

not have sufficient fuel. The accelerator pump pro vides additional fuel necessary for

engine

operation

during

acceleration.

A

double-spring loaded pump plunger supplies fuel for acceleration. Top and

bottom

springs

move

the

plunger to furnish a smooth, sustained charge of

fuel for acceleration. See Fig. E-21.

Fuel

is drawn into the pump well past the inlet

check ball during the plunger intake (upward)

stroke.

Downward

motion of the pump plunger

seats

the

inlet check ball and forces fuel through the dis charge

passage.

This

unseats

the pump discharge

check

ball.

Fuel

then sprays through the discharge

12837

FIG.

E-21—ACCELERATOR

PUMP

SYSTEM

1— Piston Vacuum Chamber

2—

Vacuus*

Relief Passage

3—

Main

Well

4— ^Power Restrictions 5— Power Valve

6— Power Piston Spring 7— Power Piston 1— Pump

Jets

2—

Discharge

Check

Ball

3—

Discharge

Passage

4—

Inlet

Check

Ball

5—

Inlet

Screen

6—

Vapor

Vent

Check

Ball

7—

Pump

Plunger

121

Page 123 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

E

exterior moving parts of a carburetor are

often

responsible for unsatisfactory performance.

For

this

reason,

efficient carburetion depends upon careful cleaning and inspection while servicing.

a.

Thoroughly clean carburetor castings and metal

parts

in carburetor cleaning solvent.

Caution:

Accelerator pump plunger and any fiber

or

rubber parts should never be immersed in

car

buretor

cleaner. Wash pump plunger in cleaning

solvent.

b.

Blow out all passages in the castings with com

pressed air. Dry all parts with compressed air.

Make

sure all jets and passages are clean. Do

not use wire to clean fuel passages or air bleeds.

c.

Check

inlet valve

needle

and seat for wear. If

wear

is noted, the assembly must be replaced.

d.

Check

float hinge pin for wear and check float

for damage.

e.

Check

throttle and choke shaft bores for wear

and

out-of-round.

f. Inspect idle mixture adjustment

needles

for

burrs

or

grooves; replace if damaged.

g. Inspect cup of accelerator pump plunger; re

place if damaged, worn, or hardened. Inspect pump

well

in bowl for wear or scoring.

h.

Check

filter screens for

dirt

or lint.

Clean,

and

if

they remain

clogged,

replace.

i.

If for any reason parts have

become

loose

or

damaged in the cluster assembly, the assembly

must be replaced.

Note:

Use ijew gaskets whenever the carburetor

is disassembled.

E-37.

Throttle Body Assembly

a.

Install

idle mixture adjustment

needles

and

springs in throttle body. Tighten finger-tight, then

unthread

one

turn

as a preliminary adjustment

setting.

Caution:

Do not force idle mixture adjustment

needles

against

seats

or damage may result.

b.

Invert

fuel bowl body and place new throttle

body gasket on bowl. Fasten throttle body to bowl

body with three screws and lockwashers; tighten

securely.

E-38.

Fuel

Bowl Body Assembly

a.

Drop steel discharge check

tall

of accelerator

pump into discharge hole.

Install

pump discharge

spring

and T-shaped retainer. Stake retainer in

place.

Note:

Top of retainer must be flush with flat

surface

of fuel bowl body.

b.

Install

two inserts in main well. Align surface

on lip of insert with flat surface in recess on top

of main well.

Install

venturi cluster with gasket,

and

tighten mounting screws evenly and securely.

Be

certain that center screw is fitted with fiber gasket, and that a special smooth shank screw is

used.

c.

Install

two main metering jets, power valve

gasket and power valve.

d.

Install

small aluminum inlet check

ball

in ac

celerator

pump inlet at

bottom

of pump well. In

sert

pump return spring into well, and center by

pressing spring downward with finger.

e.

Install

pump inlet screen in

bottom

of fuel

bowl.

E-39.

Air

Horn Body

Assembly

a.

Install

choke lever and collar on choke shaft.

Prong

on choke lever must face away from air

horn

body and be on top of choke trip lever.

b.

Install

choke shaft and lever assembly into the

air

horn. Choke rod

hole

in the choke lever must

face fuel inlet side of carburetor.

c.

Install

choke valve plate in choke shaft so that

letters RP

will

face upward in finished carburetor.

Install

two new valve plate attaching screws, but

do not tighten securely until valve plate is centered.

To

center choke valve plate on choke shaft, hold

choke valve tightly closed, then slide choke shaft

inward

to obtain approximately .020" [0,508 mm.]

clearance

between

choke trip lever and choke lever

and

collar assembly. Tighten choke valve screws

securely,

and stake lightly in place. Choke valve

will

be perfectly free in all positions when installed

correctly.

d.

Insert

outer accelerator pump lever and shaft as sembly into air horn body, with lever pointing to

ward

choke shaft.

Install

inner pump arm, with plunger

hole

inward,

and tighten set screw securely.

Position pump plunger assembly on inner pump

arm,

with pump shaft pointing

inward,

and install

retainer.

e.

Install

needle

seat screen on inlet valve seat. In

stall

seat and gasket in air horn body. Tighten seat

securely with a wide-blade screwdriver.

f.

Install

power piston into vacuum cavity.

Lightly

stake piston retainer washer in place. Piston should

travel

freely in cavity.

g.

Install

air horn gasket on air horn body, fitting

gasket over guide pin.

h.

Attach inlet valve

needle

to float.

Carefully

position float and insert float hinge pin. Drop tang

at

rear

of float arm downward toward air horn.

i.

Install

fuel inlet fitting, if removed.

j.

With

air horn assembly inverted, measure the distance from the air horn gasket to top of float

at toe \%£f [27,78 mm.] for standard carburetors

and

\%i [29,36 mm.] for exhaust emission control

equipped carburetors, as shown in Fig. E-23. Use

float level

gauge

J-5127-2. Bend float arm as re

quired

to adjust float level.

k.

With

air horn body held upright, measure dis

tance from gasket to

bottom

of float

pontoon

at outer end. Use a l7/s" [47,625 mm.] float drop

gauge.

Bend float tang, as required, to adjust float

drop.

See Fig. E-24.

I.

Carefully

place air horn body on fuel bowl

body, making certain that the accelerator pump

plunger is properly positioned in the pump well.

Lower

the cover gently, straight down; install air 123

Page 127 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

E-47.

Reassembly

•

Refer to Fig. E-29.

Install

the valve gaskets, valves, valve retainer and

secure them with the valve retainer screws. Make

sure that the inlet and

outlet

valves are in their proper positions. Place the diaphragm spring re

tainer in position on the diaphragm

pull

rod

and

install diaphragm spring. Position the

dia

phragm assembly in pump

body

and attach the

cover to pump body, with file marks aligned, with

the six attaching screws. Do not draw the screws

up tight.

Install

rocker arm spring, rocker arm

pin

washers, rocker arm and rocker arm pin.

With

rocker

arm positioned on the diaphragm rod, draw

the six pump

body

screws up evenly and securely.

Install

the filter screen, cork gasket and sediment

bowl and secure them firmly with the thumb screw

on the bowl clamp.

E-48.

Vacuum

Pump

The

double-action fuel pump resembles two single-

action pumps placed one

above

the other. A single

fuel pump rocker arm actuates the two separate diaphragms. One diaphragm is part of the fuel

delivery pump and operates as described in Par.

E-45.

The other diaphragm is part of the vacuum

pump and operates as described here.

As

the actuating lever forces the diaphragm upward against spring pressure, air is forced through the

outlet

port

into

the

engine's

intake manifold. On

the return stroke, spring pressure forces the

dia

phragm downward, creating a

partial

vacuum and

opening the inlet valve. In this manner, air is pumped out of the windshield wiper motor and

into

the intake manifold. When the wiper motor is shut off, manifold vacuum holds the diaphragm against its spring so that the

full

motion of the actuating

lever is not accompanied by a

complete

up-and-

down motion of the diaphragm.

When

the windshield wiper motor is turned on, but manifold vacuum is greater than the vacuum

created by the

booster

pump, air

flows

from the

wiper motor through both valves of the vacuum

booster.

As manifold vacuum drops off as a result

of the

engine

operating under low

speed

and high load, the vacuum created by the vacuum

booster

will

be greater than

engine

intake manifold vacuum

and

the pump

will

operate the wiper motor when the wiper control switch is turned on.

•

Refer to Fig. E-29. Remove the

eight

cover attaching screws and

lockwashers, and remove the cover, diaphragm

spring

and spring seat. Detach the diaphragm rod

from the rocker arm and remove the diaphragm.

The

valve assemblies are pressed

into

the cover

and

body

and lightly staked. They may be removed

with the point of a knife blade. If installing new valves be sure the inlet and

outlet

valves are

correctly positioned and stake them lightly with

a

small punch.

Assemble the vacuum pump in the reverse order

of disassembly, drawing the cover attaching screws up evenly and tightly.

E-49.

Fuel

Pump

Testing

Four

tests

are presented in following paragraphs to

test

for proper operation of the fuel pump. In addi

tion, check the following:

a.

Check

for secure mounting of the fuel pump.

The

rocker arm may be working the entire pump

up and down, rather than just the pump

dia

phragms.

b. Remove and clean the fuel sediment bowl.

c.

Check

all fuel lines.

E-50.

Volume

Check

To

measure fuel pump capacity (amount of fuel

delivered in a given time) disconnect the pump-to-

carburetor

line at the carburetor end. Place the

open

end of the line in a suitable container.

Start

the

engine

and operate at normal idle speed.

Delivery

should be one quart U.S. [1 ltr.] within

one minute.

E-51.

Pressure

Check

To

measure fuel pump pressure (force of fuel de

livery)

disconnect the pump-to-carburetor line

at the carburetor end. Plug a pressure

gauge

and T-fitting

into

the

open

end of this line and

into

the

carburetor.

Start

the

engine

and operate at normal

idle speed. Pressure should be 2J4 to 3% psi.

[0,716

a

0,264

kg-cm2] at 1800 rpm. and at 16"

[406 mm.]

above

the

outlet.

E-52.

Vacuum

Check

To

measure fuel pump vacuum (pull of. the pump

at the inlet side) disconnect the pump-to-fuel-tank

line at the fuel pump. Attach a vacuum

gauge

to the fuel pump inlet.

Start

the

engine,

accelerate to

specified speed, and hold this

engine

speed

while

taking a

gauge

reading. Permissible

gauge

reading

is 8* [203 mm.] of mercury [Hg] at 1200 rpm. and

10j^'

[267 mm.] at 1800 rpm.

E-53.

Vacuum

Booster

Check

To

test

the condition of the vacuum

booster

pump,

disconnect both inlet and

outlet

lines at the pump.

Attach

a vacuum

gauge

to the windshield wiper

connection at the pump.

Start

the

engine,

accelerate

to

2000

rpm., and hold this

engine

speed

while taking a

gauge

reading. Permissible

gauge

reading

is 10* to 14" [254 a 356 cm.] of mercury [Hg].

E-54.'

FUEL

PUMP

(SINGLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models.

Vehicles with electric windshield wiper motors are

equipped with a single-action fuel pump (Fig.

E-30).

The fuel pump cam lever is activated by an eccentric on the

engine

camshaft. When the

car

buretor float

needle

valve closes, accumulation of

fuel in the pump

extends

the diaphragm spring.

This

action causes the rocker arm linkage to be

come

inoperative until the pressure on the

dia

phragm and spring is reduced. The fuel pump dis

charge pressure is thus controlled by the diaphragm

spring.

This

provides a steady supply of fuel to the

carburetor

at a fairly constant pressure. 127

Page 132 of 376

FUEL

SYSTEM

14417

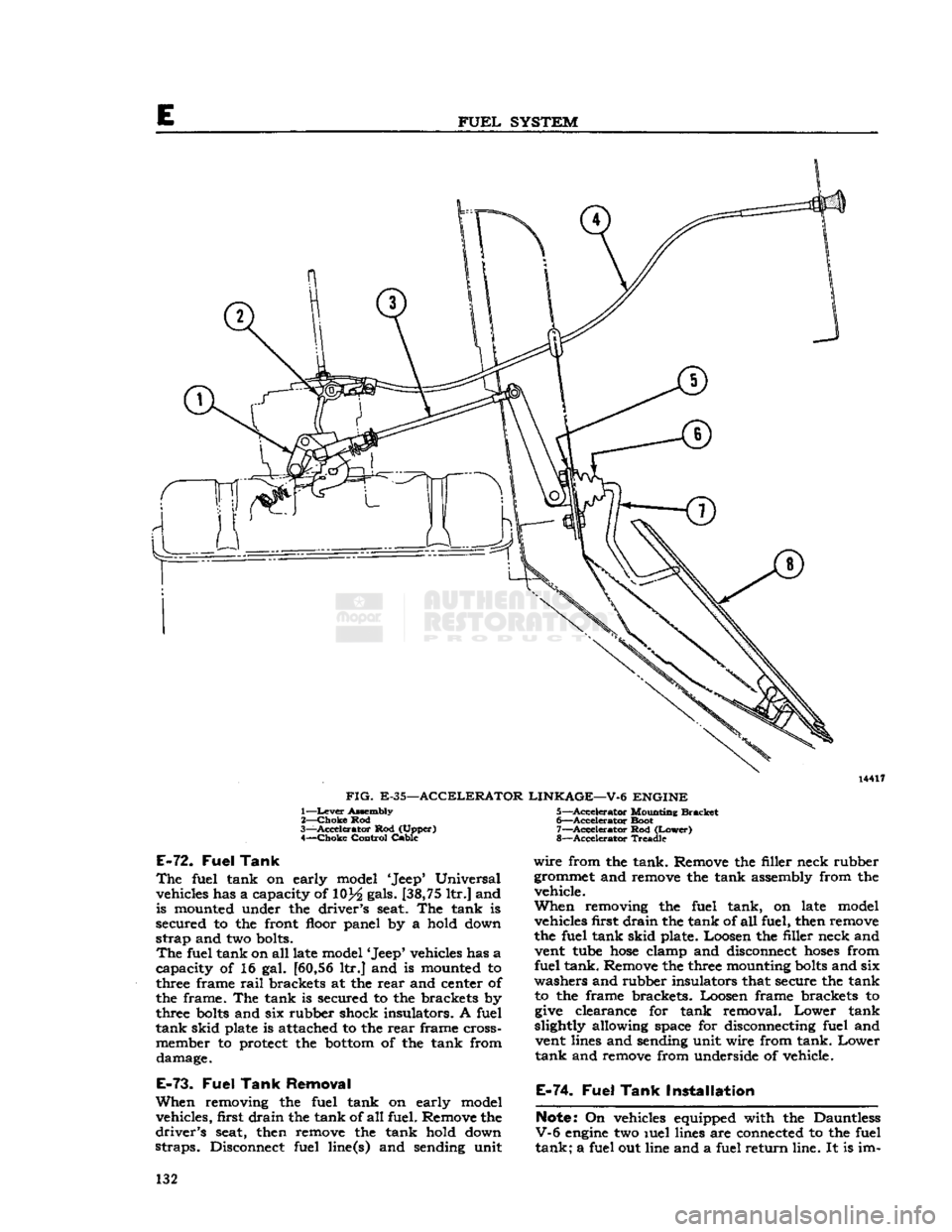

FIG.

E-35—ACCELERATOR LINKAGE—V-6 ENGINE

1— Lever

Assembly

2—

Choke

Rod

3—

-Accelerator

Rod (Upper) 4—

Choke

Control Cable

E-72.

Fuel

Tank

The

fuel tank on early model 'Jeep* Universal vehicles has a capacity of 10}4 gals. [38,75 ltr.] and

is mounted under the driver's seat. The tank is

secured to the front floor panel by a hold down

strap

and two bolts.

The

fuel tank on all late model 'Jeep* vehicles has a

capacity of 16 gal. [60,56 ltr.] and is mounted to

three frame

rail

brackets at the

rear

and center of

the frame. The tank is secured to the brackets by

three

bolts

and six rubber shock insulators. A fuel

tank

skid plate is attached to the

rear

frame cross- member to protect the

bottom

of the tank from damage.

E-73.

Fuel

Tank

Removal

When

removing the fuel tank on early model vehicles, first drain the tank of

all

fuel. Remove the

driver's

seat, then remove the tank hold down

straps.

Disconnect fuel line(s) and sending unit 5—

Accelerator

Mounting Bracket

6—

-Accelerator

Boot

7—

Accelerator

Rod

(Lower)

8—

Accelerator

Treadle

wire

from the tank. Remove the filler neck rubber

grommet and remove the tank assembly from the vehicle.

When

removing the fuel tank, on late model vehicles first

drain

the tank of

all

fuel, then remove

the fuel tank skid plate. Loosen the filler neck and vent tube

hose

clamp and disconnect

hoses

from fuel tank. Remove the three mounting

bolts

and six

washers and rubber insulators that secure the tank to the frame brackets. Loosen frame brackets to

give

clearance for tank removal.

Lower

tank

slightly allowing space for disconnecting fuel and vent lines and sending unit wire from tank.

Lower

tank

and remove from underside of vehicle.

E-74.

Fuel Tank Installation

Note:

On vehicles equipped with the Dauntless

V-6

engine

two luel lines are connected to the fuel

tank;

a fuel out line and a fuel return line. It is im- 132