cooling JEEP GLADIATOR 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 347 of 448

IN CASE OF EMERGENCY345

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cable’s reach, apply the parking brake and

make sure the ignition is OFF.

JUMP STARTING PROCEDURE

NOTE:Make sure at all times that unused ends of jumper

cables are not contacting each other or either

vehicle while making connections.

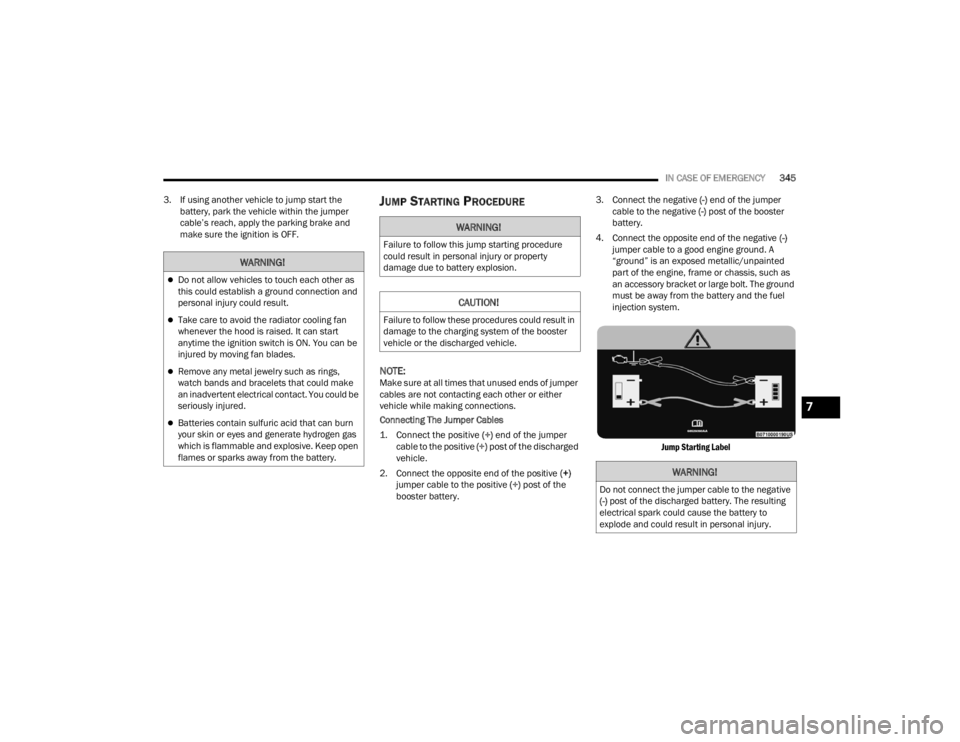

Connecting The Jumper Cables

1. Connect the positive

(+) end of the jumper

cable to the positive (+)

post of the discharged

vehicle.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery. 3. Connect the negative

(-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to a good engine ground. A

“ground” is an exposed metallic/unpainted

part of the engine, frame or chassis, such as

an accessory bracket or large bolt. The ground

must be away from the battery and the fuel

injection system.

Jump Starting Label

WARNING!

Do not allow vehicles to touch each other as

this could establish a ground connection and

personal injury could result.

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

7

23_JT_OM_EN_USC_t.book Page 345

Page 350 of 448

348IN CASE OF EMERGENCY

In the event it is observed that the temperature

gauge is moving towards or close to the HOT (H)

position, you can reduce the potential for

overheating by taking the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL (N), but do not increase the

engine idle speed while preventing vehicle

motion with the brakes.

If your Air Conditioner (A/C) is on, turn it off. The

A/C system adds heat to the engine cooling

system and turning the A/C off can help remove

this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the heater

core to act as a supplement to the radiator and

aids in removing heat from the engine cooling

system.

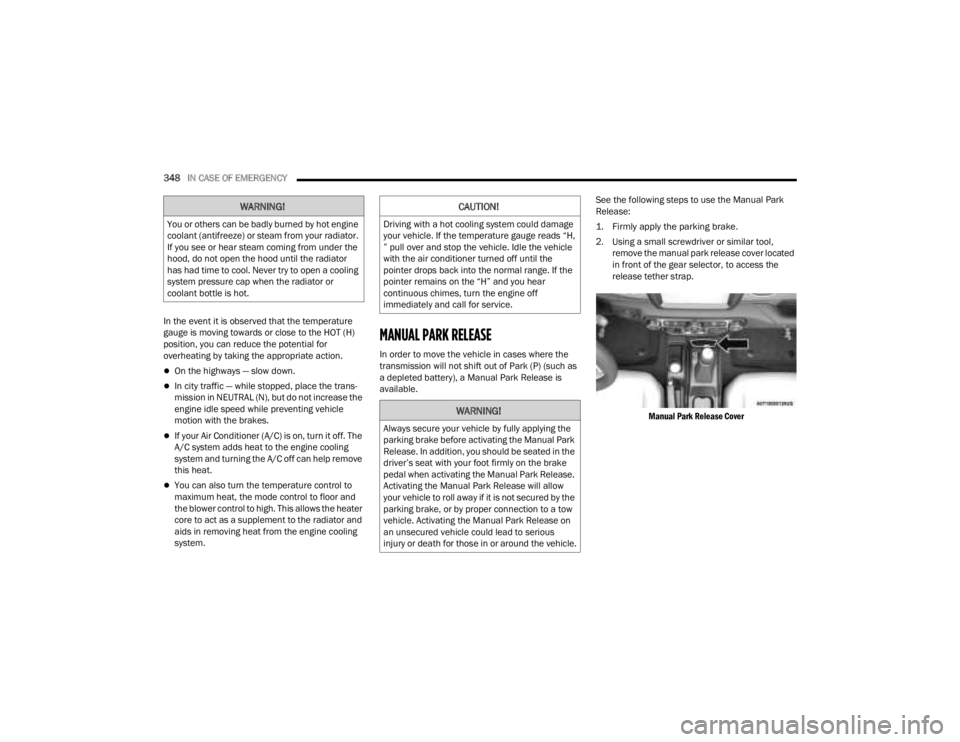

MANUAL PARK RELEASE

In order to move the vehicle in cases where the

transmission will not shift out of Park (P) (such as

a depleted battery), a Manual Park Release is

available. See the following steps to use the Manual Park

Release:

1. Firmly apply the parking brake.

2. Using a small screwdriver or similar tool,

remove the manual park release cover located

in front of the gear selector, to access the

release tether strap.

Manual Park Release Cover

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or

coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads “H,

” pull over and stop the vehicle. Idle the vehicle

with the air conditioner turned off until the

pointer drops back into the normal range. If the

pointer remains on the “H” and you hear

continuous chimes, turn the engine off

immediately and call for service.

WARNING!

Always secure your vehicle by fully applying the

parking brake before activating the Manual Park

Release. In addition, you should be seated in the

driver’s seat with your foot firmly on the brake

pedal when activating the Manual Park Release.

Activating the Manual Park Release will allow

your vehicle to roll away if it is not secured by the

parking brake, or by proper connection to a tow

vehicle. Activating the Manual Park Release on

an unsecured vehicle could lead to serious

injury or death for those in or around the vehicle.

23_JT_OM_EN_USC_t.book Page 348

Page 356 of 448

354SERVICING AND MAINTENANCE

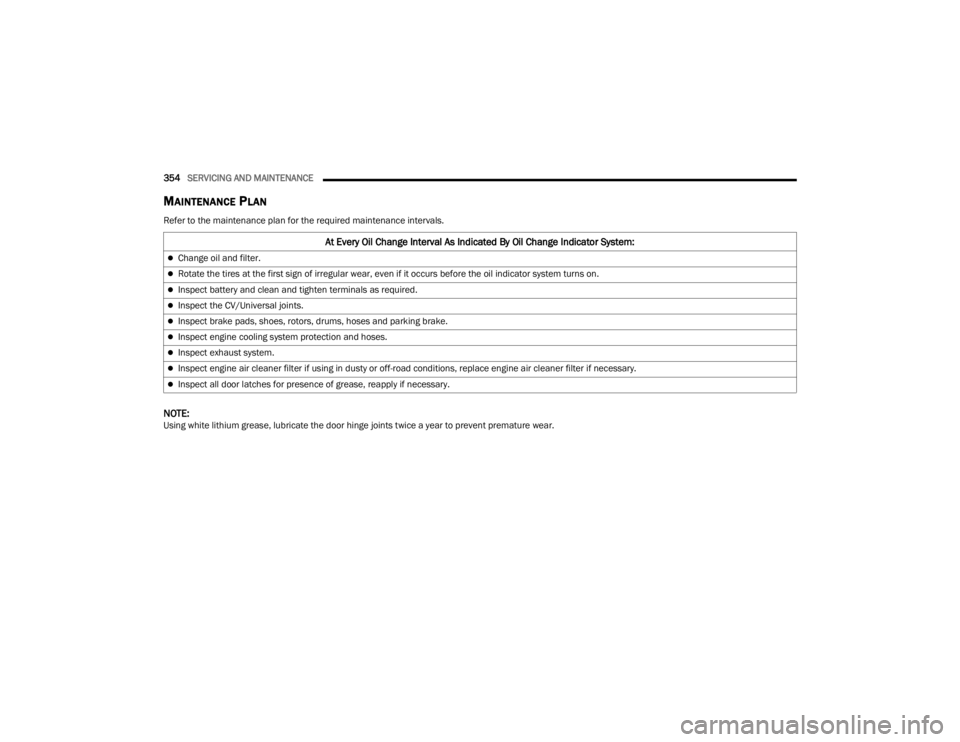

MAINTENANCE PLAN

Refer to the maintenance plan for the required maintenance intervals.

NOTE:Using white lithium grease, lubricate the door hinge joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Rotate the tires at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions, replace engine air cleaner filter if necessary.

Inspect all door latches for presence of grease, reapply if necessary.

23_JT_OM_EN_USC_t.book Page 354

Page 360 of 448

358SERVICING AND MAINTENANCE

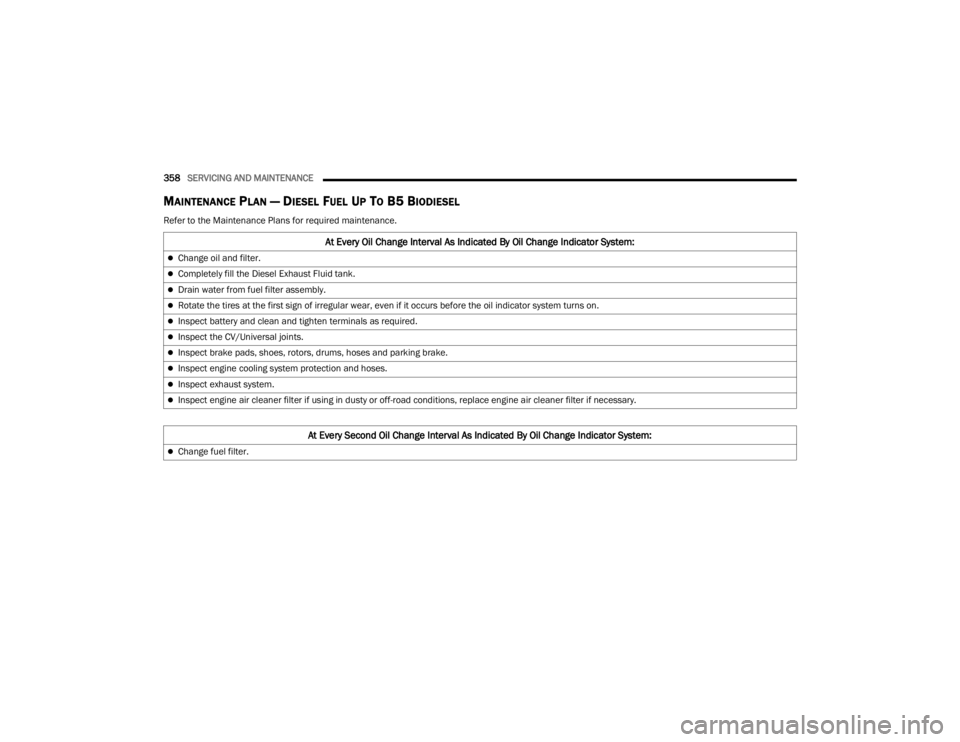

MAINTENANCE PLAN — DIESEL FUEL UP TO B5 BIODIESEL

Refer to the Maintenance Plans for required maintenance.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Completely fill the Diesel Exhaust Fluid tank.

Drain water from fuel filter assembly.

Rotate the tires at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions, replace engine air cleaner filter if necessary.

At Every Second Oil Change Interval As Indicated By Oil Change Indicator System:

Change fuel filter.

23_JT_OM_EN_USC_t.book Page 358

Page 374 of 448

372SERVICING AND MAINTENANCE

(Continued)

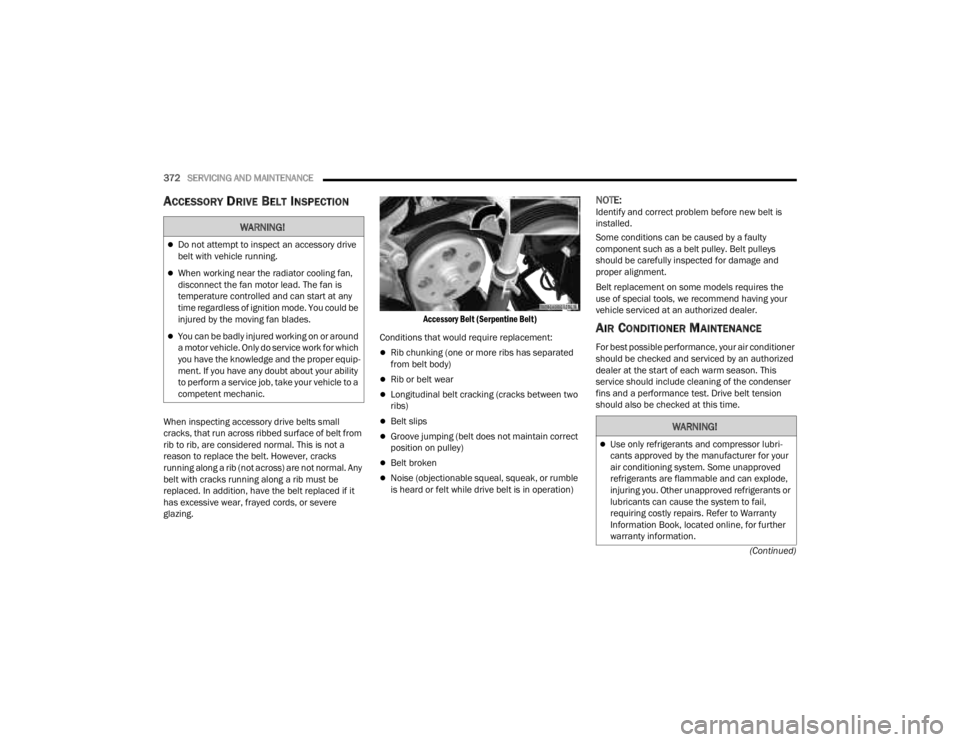

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts small

cracks, that run across ribbed surface of belt from

rib to rib, are considered normal. This is not a

reason to replace the belt. However, cracks

running along a rib (not across) are not normal. Any

belt with cracks running along a rib must be

replaced. In addition, have the belt replaced if it

has excessive wear, frayed cords, or severe

glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two

ribs)

Belt slips

Groove jumping (belt does not maintain correct

position on pulley)

Belt broken

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation)

NOTE:Identify and correct problem before new belt is

installed.

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This

service should include cleaning of the condenser

fins and a performance test. Drive belt tension

should also be checked at this time.

WARNING!

Do not attempt to inspect an accessory drive

belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could be

injured by the moving fan blades.

You can be badly injured working on or around

a motor vehicle. Only do service work for which

you have the knowledge and the proper equip -

ment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for your

air conditioning system. Some unapproved

refrigerants are flammable and can explode,

injuring you. Other unapproved refrigerants or

lubricants can cause the system to fail,

requiring costly repairs. Refer to Warranty

Information Book, located online, for further

warranty information.

23_JT_OM_EN_USC_t.book Page 372

Page 379 of 448

SERVICING AND MAINTENANCE377

COOLING SYSTEM

Coolant Checks

Check the engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

weather, where applicable). If the engine coolant is

dirty or rusty in appearance, the system should be

drained, flushed, and refilled with fresh Organic

Additive Technology (OAT) coolant (conforming to MS.90032) by an authorized dealer. Check the

front of the A/C condenser (if equipped) or radiator

for any accumulation of bugs, leaves, etc. If dirty,

clean by gently spraying water from a garden hose

vertically down the face of the A/C condenser (if

equipped) or the back of the radiator core.

Check the engine cooling system hoses for brittle

rubber, cracking, tears, cuts, and tightness of the

connection at the coolant recovery bottle and

radiator. Inspect the entire system for leaks. DO

NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush, And Refill

Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly

could lead to severe internal engine damage. If any

coolant is needed to be added to the system

please contact an authorized dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant

(conforming to MS.90032).

For the proper maintenance intervals see

Ú

page 354 for gas engines or Ú page 358 for

diesel engines.

Selection Of Coolant

For further information Ú page 424.

NOTE:

Mixing of engine coolant (antifreeze), other than

specified Organic Additive Technology (OAT)

engine coolant, may result in engine damage

and may decrease corrosion protection. OAT

engine coolant is different and should not be

mixed with Hybrid Organic Additive Technology

(HOAT) engine coolant or any “globally compat -

ible” coolant. If a non-OAT engine coolant is

introduced into the cooling system in an emer -

gency, the cooling system will need to be

drained, flushed, and refilled with fresh OAT

coolant (conforming to MS.90032), by an autho -

rized dealer as soon as possible.

Do not use water alone or alcohol-based engine

coolant products. Do not use additional rust

inhibitors or anti-rust products, as they may not

be compatible with the radiator engine coolant

and may clog the radiator.

This vehicle has not been designed for use with

propylene glycol-based engine coolant. Use of

propylene glycol-based engine coolant is not

recommended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized dealer.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radi -

ator or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry away

from the radiator cooling fan when the hood is

raised. The fan starts automatically and may

start at any time, whether the engine is

running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the igni -

tion to the OFF position. The fan is tempera -

ture controlled and can start at any time the

ignition is in the ON position.

8

23_JT_OM_EN_USC_t.book Page 377

Page 380 of 448

378SERVICING AND MAINTENANCE

Adding Coolant

Your vehicle has been built with an improved engine

coolant (OAT coolant conforming to MS.90032) that

allows extended maintenance intervals. This engine

coolant (antifreeze) can be used up to 10 years or

150,000 miles (240,000 km) before replacement.

To prevent reducing this extended maintenance

period, it is important to use the same engine

coolant (OAT coolant conforming to MS.90032)

throughout the life of your vehicle.

Please review these recommendations for using

Organic Additive Technology (OAT) engine coolant

that meets the requirements of the manufacturer

Material Standard MS.90032. When adding

engine coolant (antifreeze):

We recommend using Mopar® Antifreeze/

Coolant 10 Year/150,000 Mile (240,000 km)

Formula OAT (Organic Additive Technology) that

meets the requirements of the manufacturer

Material Standard MS.90032.

Mix a minimum solution of 50% OAT engine

coolant that meets the requirements of the

manufacturer Material Standard MS.90032

and distilled water. Use higher concentrations

(not to exceed 70%) if temperatures below

-34°F (-37°C) are anticipated. Please contact

an authorized dealer for assistance.

Use only high purity water, such as distilled or

deionized water, when mixing the water/engine coolant solution. The use of lower quality water

will reduce the amount of corrosion protection

in the engine cooling system.

NOTE:

It is the owner's responsibility to maintain the

proper level of protection against freezing

according to the temperatures occurring in the

area where the vehicle is operated.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system, please contact an authorized

dealer.

Mixing engine coolant types is not recom

-

mended and can result in cooling system

damage. If HOAT and OAT coolant are mixed in

an emergency, have an authorized dealer drain,

flush, and refill with OAT coolant (conforming to

MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

engine coolant (antifreeze), and to ensure that

engine coolant will return to the radiator from the

coolant expansion bottle/recovery tank if so

equipped.

The cap should be inspected and cleaned if there

is any accumulation of foreign material on the

sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze)

OAT or HOAT, is a regulated substance requiring

proper disposal. Check with your local authorities

to determine the disposal rules for your

community. To prevent ingestion by animals or

children, do not store ethylene glycol-based

coolant in open containers or allow it to remain in

puddles on the ground, clean up any ground spills

immediately. If ingested, seek emergency

assistance immediately.

WARNING!

Do not open hot engine cooling system. Never

add engine coolant (antifreeze) when the

engine is overheated. Do not loosen or

remove the cap to cool an overheated engine.

Heat causes pressure to build-up in the

cooling system. To prevent scalding or injury,

do not remove the pressure cap while the

system is hot or under pressure.

Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or

engine damage may result.

23_JT_OM_EN_USC_t.book Page 378

Page 381 of 448

SERVICING AND MAINTENANCE379

Coolant Level

The coolant bottle provides a quick visual method

for determining that the coolant level is adequate.

With the engine in the off and cold, the level of the

engine coolant (antifreeze) in the bottle should be

between the ranges indicated on the bottle.

The radiator normally remains completely full, so

there is no need to remove the radiator/coolant

pressure cap unless checking for engine coolant

freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant

only needs to be checked once a month.

When additional engine coolant is needed to

maintain the proper level, only OAT coolant that

meets the requirements of FCA Material Standard

MS.90032 should be added to the coolant bottle.

Do not overfill.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator. If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the freezing point of the coolant in the

radiator and in the coolant expansion bottle. If

determined that more engine coolant needs to

be added to the radiator, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro

-

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. With air

conditioning, keep the front of the condenser

clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat. Other designs may result in unsatisfactory

engine system performance, poor gas mileage,

and increased emissions.

CHARGE AIR COOLER — INTER-COOLER

(D

IESEL ENGINE)

The charge air cooler is positioned in front of the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly reaches

high temperature. The air is then directed through

a hose to the charge air cooler and through

another hose to the intake manifold of the engine.

This cooling process enables more efficient

burning of fuel resulting in fewer emissions.

To guarantee optimum performance of the system,

keep the surfaces of the charge air cooler,

condenser and radiator clean and free of debris.

Periodically check the hoses leading to and from

the charge air cooler for cracks or loose clamps

resulting in loss of pressure and reduced engine

performance.

8

23_JT_OM_EN_USC_t.book Page 379

Page 413 of 448

SERVICING AND MAINTENANCE411

STORING THE VEHICLE If you are storing your vehicle for more than 3

weeks, we recommend that you take the following

steps to minimize the drain on your vehicle's

battery:

Disconnect the negative cable from the battery.

If your vehicle is equipped with Stop/Start

system then disconnect both the main and

supplemental negative battery cables.

Any time you store your vehicle or keep it out of

service (i.e., vacation) for two weeks or more,

run the air conditioning system at idle for about

five minutes in the fresh air and high blower

setting. This will ensure adequate system lubri-

cation to minimize the possibility of compressor

damage when the system is started again.

If assistance is needed to disconnect the

battery system, see an authorized dealer.

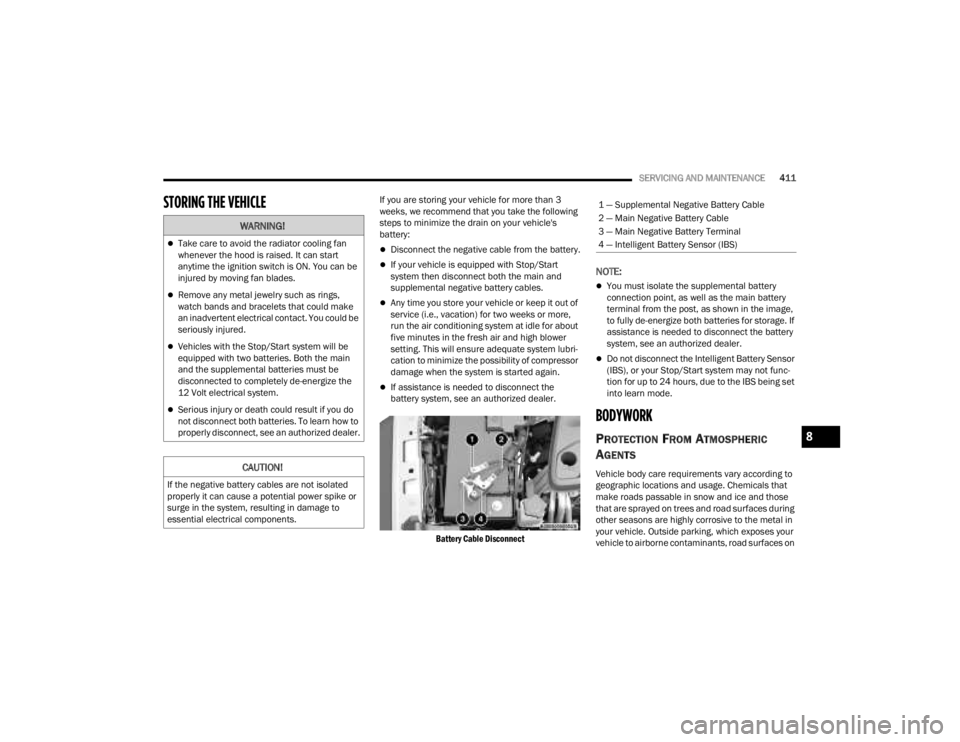

Battery Cable Disconnect

NOTE:

You must isolate the supplemental battery

connection point, as well as the main battery

terminal from the post, as shown in the image,

to fully de-energize both batteries for storage. If

assistance is needed to disconnect the battery

system, see an authorized dealer.

Do not disconnect the Intelligent Battery Sensor

(IBS), or your Stop/Start system may not func -

tion for up to 24 hours, due to the IBS being set

into learn mode.

BODYWORK

PROTECTION FROM ATMOSPHERIC

A

GENTS

Vehicle body care requirements vary according to

geographic locations and usage. Chemicals that

make roads passable in snow and ice and those

that are sprayed on trees and road surfaces during

other seasons are highly corrosive to the metal in

your vehicle. Outside parking, which exposes your

vehicle to airborne contaminants, road surfaces on

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Vehicles with the Stop/Start system will be

equipped with two batteries. Both the main

and the supplemental batteries must be

disconnected to completely de-energize the

12 Volt electrical system.

Serious injury or death could result if you do

not disconnect both batteries. To learn how to

properly disconnect, see an authorized dealer.

CAUTION!

If the negative battery cables are not isolated

properly it can cause a potential power spike or

surge in the system, resulting in damage to

essential electrical components.

1 — Supplemental Negative Battery Cable

2 — Main Negative Battery Cable

3 — Main Negative Battery Terminal

4 — Intelligent Battery Sensor (IBS)

8

23_JT_OM_EN_USC_t.book Page 411

Page 425 of 448

TECHNICAL SPECIFICATIONS423

Fuel Water Separation — Must Use

Mopar® Approved Fuel Filter Elements

Biodiesel fuel has a natural affinity to water and

water accelerates microbial growth. Your Mopar®

filtration system is designed to provide adequate

fuel water separation capabilities.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been observed

with the use of biodiesel fuel. Fuel in oil must not

exceed 5%. To ensure this limit is met your oil

change interval must be maintained within the

suggested schedule. The regular use of biodiesel

between 6% and 20% requires intervals shorter

than the outlined 10,000 miles (16,000 km) and must not exceed the suggested schedule. When

routinely operating on biodiesel between 6% and

20%, oil and filter replacement intervals must not

exceed 8,000 miles (13,000 km) or six months,

which ever comes first.

Biodiesel Fuel Filter Change Intervals

The use of biodiesel requires more frequent fuel

filter change intervals. When operating on

biodiesel between 6% and 20%, fuel filter

replacement intervals should be every second oil

change, and must not exceed 16,000 miles

(25,750 km).

NOTE:Under no circumstances should oil change

intervals exceed 8,000 miles (12,875 km) or six

months, if regular operation occurs with 6% - 20%

biodiesel blends. Under no circumstances should

fuel filter replacement intervals exceed every

second oil change and must not exceed

16,000 miles (25,750 km), if regular operation

occurs with 6% - 20% biodiesel blends. Failure to

comply with these Oil Change and fuel filter

requirements for vehicles operating on biodiesel

blends up to B20 may result in premature engine

wear. Such wear is not covered by the New Vehicle

Limited Warranty. The engine may suffer severe

damage if operated with concentrations of

biodiesel higher than 20%.

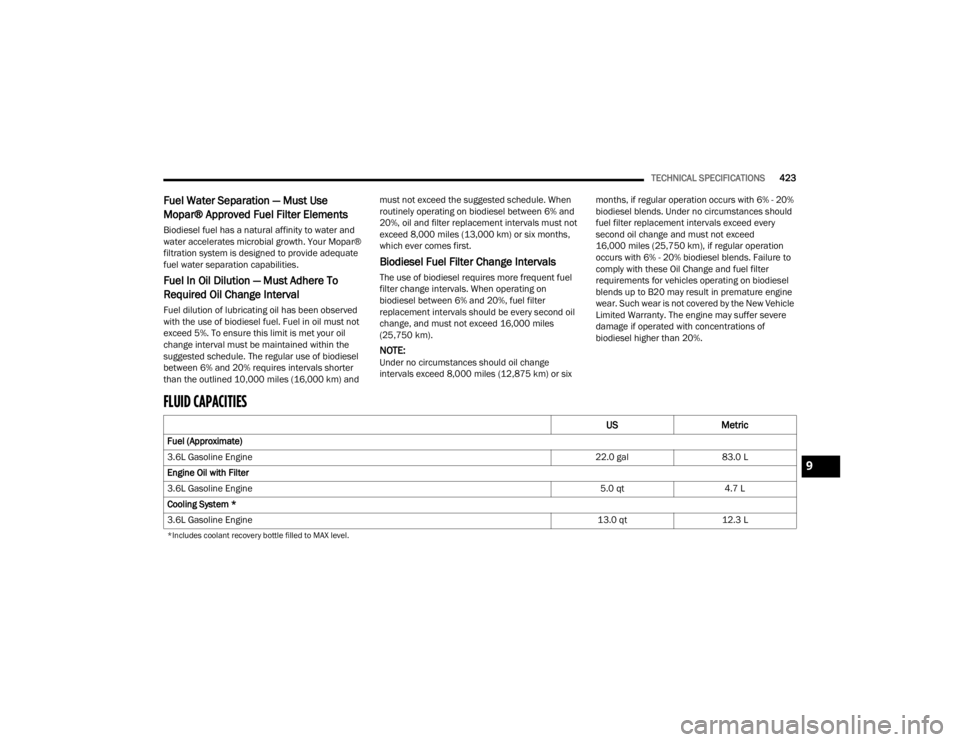

FLUID CAPACITIES

US

Metric

Fuel (Approximate)

3.6L Gasoline Engine 22.0 gal83.0 L

Engine Oil with Filter

3.6L Gasoline Engine 5.0 qt4.7 L

Cooling System *

3.6L Gasoline Engine 13.0 qt12.3 L

*Includes coolant recovery bottle filled to MAX level.

9

23_JT_OM_EN_USC_t.book Page 423