fuse panel fuse 23 JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 363 of 2199

INSPECTION

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. Before removing any unit from the starting

system for repair or diagnosis, perform the following

inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer toBatteryin the

proper section of Group 8A - Battery for complete ser-

vice information for the battery.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinderin the proper

section of Group 8D - Ignition System for complete

service information for the ignition switch.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections. Refer toPark/Neutral Posi-

tion Switchin the proper section of Group 21 -

Transmission for complete service information for the

park/neutral position switch.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to the proper section ofGroup 8W -

Wiring Diagramsfor complete service information

and circuit diagrams for the starting system wiring

components.TESTING

COLD CRANKING TEST

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. The battery must be fully-charged and load-

tested before proceeding. Refer toBatteryin the

Diagnosis and Testing section of Group 8A - Battery

for the procedures.

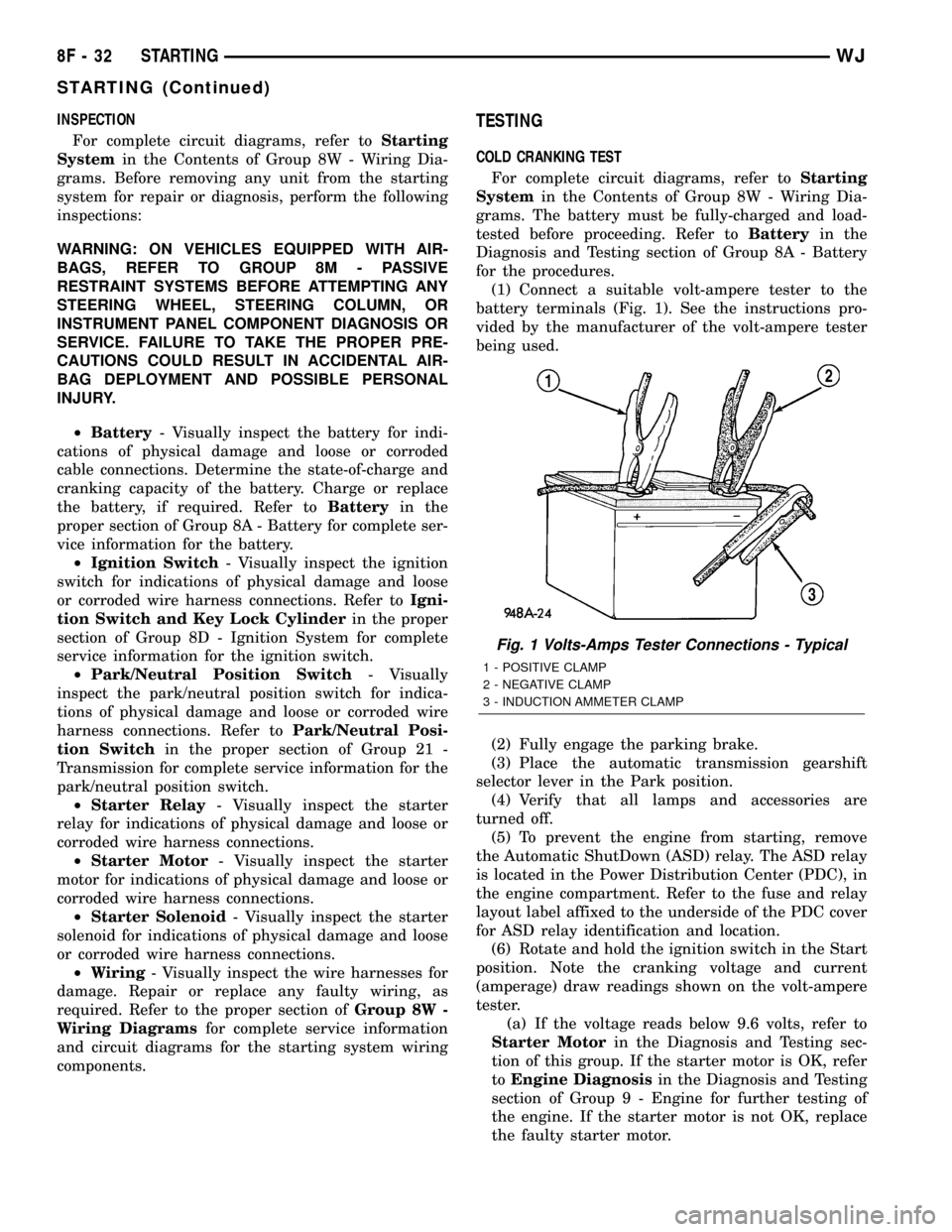

(1) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). See the instructions pro-

vided by the manufacturer of the volt-ampere tester

being used.

(2) Fully engage the parking brake.

(3) Place the automatic transmission gearshift

selector lever in the Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent the engine from starting, remove

the Automatic ShutDown (ASD) relay. The ASD relay

is located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

(6) Rotate and hold the ignition switch in the Start

position. Note the cranking voltage and current

(amperage) draw readings shown on the volt-ampere

tester.

(a) If the voltage reads below 9.6 volts, refer to

Starter Motorin the Diagnosis and Testing sec-

tion of this group. If the starter motor is OK, refer

toEngine Diagnosisin the Diagnosis and Testing

section of Group 9 - Engine for further testing of

the engine. If the starter motor is not OK, replace

the faulty starter motor.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 32 STARTINGWJ

STARTING (Continued)

Page 376 of 2199

not attach the wire harness connectors until the cur-

ing process is complete.

(11) Check the operation of the rear glass heating

grid.

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

The rear window defogger relay is an electrome-

chanical device that switches fused battery current to

the rear glass heating grid and the Light-Emitting

Diode (LED) indicator of the rear window defogger

switch, when the Body Control Module (BCM) rear

window defogger timer and logic circuitry grounds

the relay coil. The rear window defogger relay is

located in the junction block, under the left end of

the instrument panel in the passenger compartment.

The rear window defogger relay is a International

Standards Organization (ISO) relay. Relays conform-

ing to the ISO specifications have common physical

dimensions, current capacities, terminal patterns,

and terminal functions.

The rear window defogger relay cannot be repaired

or adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

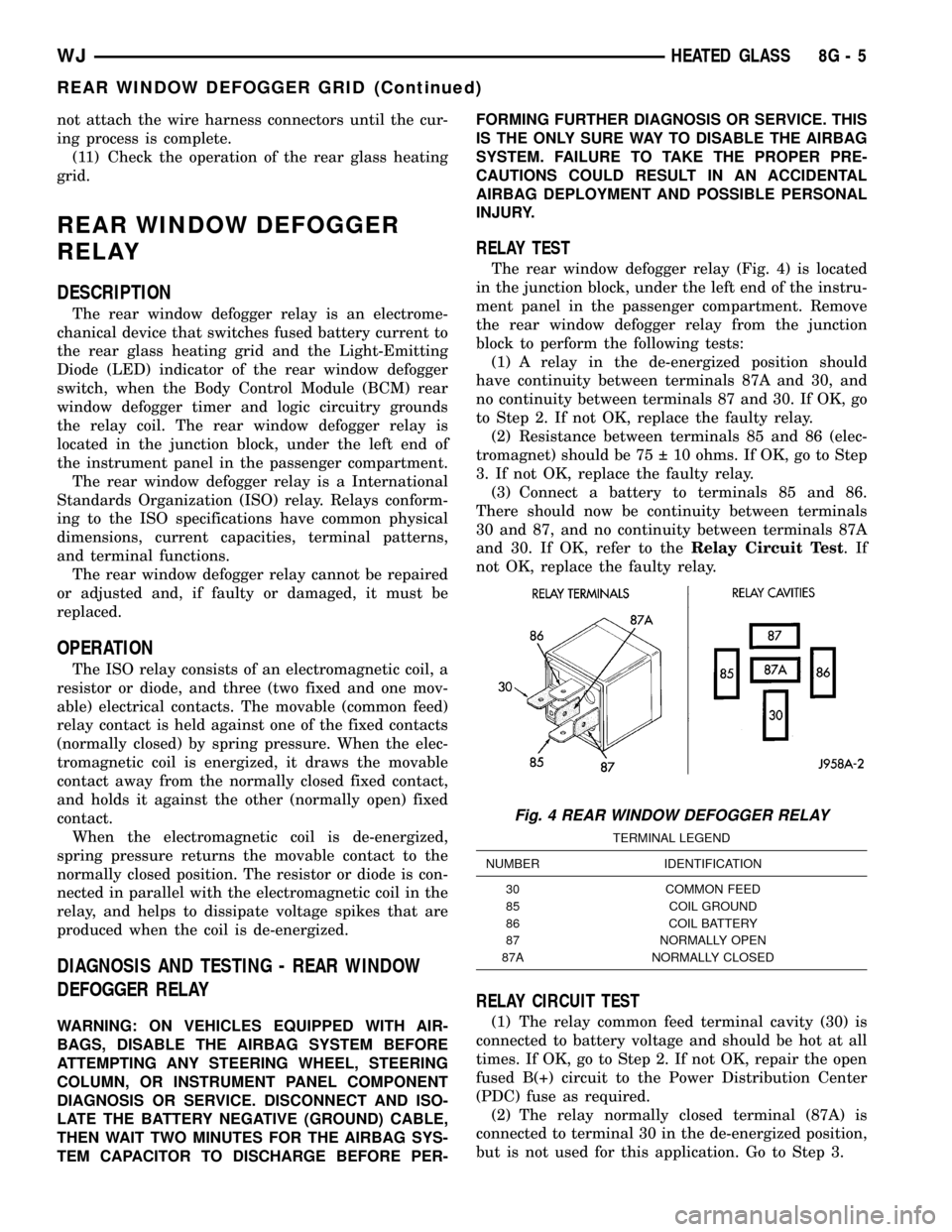

RELAY TEST

The rear window defogger relay (Fig. 4) is located

in the junction block, under the left end of the instru-

ment panel in the passenger compartment. Remove

the rear window defogger relay from the junction

block to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 10 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, refer to theRelay Circuit Test.If

not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

fused B(+) circuit to the Power Distribution Center

(PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

Fig. 4 REAR WINDOW DEFOGGER RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

WJHEATED GLASS 8G - 5

REAR WINDOW DEFOGGER GRID (Continued)

Page 377 of 2199

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the rear glass heating grid and to the fuse in the

junction block that feeds the rear window defogger

switch LED indicator. There should be continuity

between the cavity for relay terminal 87 and the rear

glass heating grid and the rear window defogger

switch LED indicator at all times. If OK, go to Step

4. If not OK, repair the open rear window defogger

relay output circuit as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open fused

B(+) circuit to the PDC fuse as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. This terminal is pro-

vided with ground by the Body Control Module

(BCM) rear window defogger timer and logic circuitry

to energize the defogger relay. There should be conti-

nuity to the rear window defogger relay control cir-

cuit cavity of the 22-way instrument panel wire

harness connector for the BCM. If OK, use a DRB

scan tool and refer to the Appropriate Diagnostic

Information to test the BCM. If not OK, repair the

open rear window defogger relay control circuit as

required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. Refer to Instrument

Panel System for the procedures.

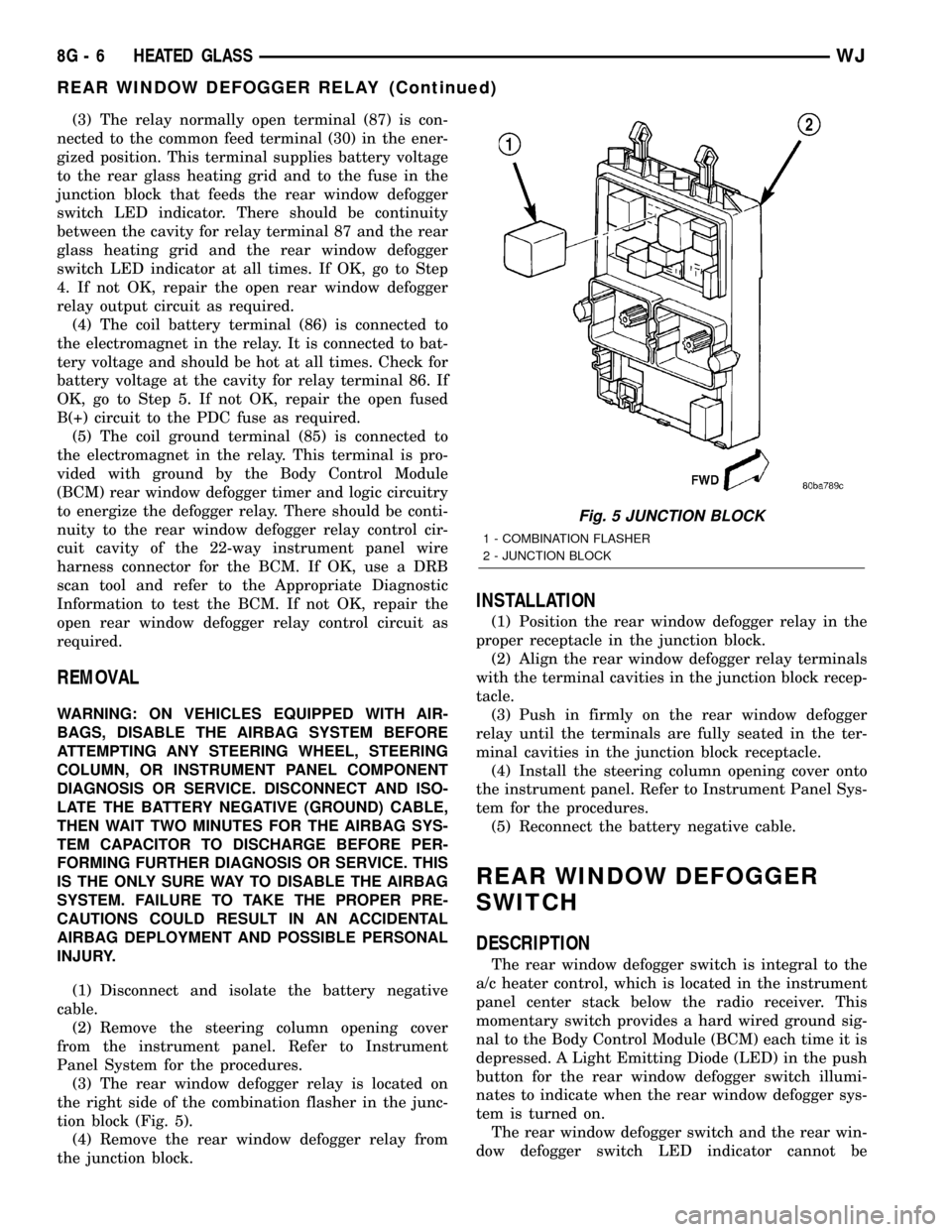

(3) The rear window defogger relay is located on

the right side of the combination flasher in the junc-

tion block (Fig. 5).

(4) Remove the rear window defogger relay from

the junction block.

INSTALLATION

(1) Position the rear window defogger relay in the

proper receptacle in the junction block.

(2) Align the rear window defogger relay terminals

with the terminal cavities in the junction block recep-

tacle.

(3) Push in firmly on the rear window defogger

relay until the terminals are fully seated in the ter-

minal cavities in the junction block receptacle.

(4) Install the steering column opening cover onto

the instrument panel. Refer to Instrument Panel Sys-

tem for the procedures.

(5) Reconnect the battery negative cable.

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is integral to the

a/c heater control, which is located in the instrument

panel center stack below the radio receiver. This

momentary switch provides a hard wired ground sig-

nal to the Body Control Module (BCM) each time it is

depressed. A Light Emitting Diode (LED) in the push

button for the rear window defogger switch illumi-

nates to indicate when the rear window defogger sys-

tem is turned on.

The rear window defogger switch and the rear win-

dow defogger switch LED indicator cannot be

Fig. 5 JUNCTION BLOCK

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

8G - 6 HEATED GLASSWJ

REAR WINDOW DEFOGGER RELAY (Continued)

Page 378 of 2199

repaired and, if faulty or damaged, the entire a/c

heater control must be replaced. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

OPERATION

When the rear window defogger switch push but-

ton is depressed, it momentarily closes the rear win-

dow defogger switch sense circuit for the BCM to

ground. The BCM monitors the rear window defogger

switch sense circuit. Each time the BCM rear win-

dow defogger timer and logic circuitry sees another

input from the switch, it toggles a control output to

the rear window defogger relay. Energizing the rear

window defogger relay provides electrical current to

the rear window defogger grid and to the LED indi-

cator in the switch, which lights to indicate when the

defogger system is turned on. A dedicated fuse in the

junction block protects the rear window defogger

relay output circuit to the LED indicator.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SWITCH

For complete circuit diagrams, refer to the Appro-

priate Wiring Information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the a/c heater control from the instru-

ment panel and disconnect the 11-way (manual tem-

perature control) or 16-way (automatic zone control)

instrument panel wire harness connector from the a/c

heater control receptacle.

(2) Check for continuity between the ground cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be continuity. If OK, go

to Step 3. If not OK, repair the open ground circuit to

ground as required.

(3) Connect two jumper wires to the a/c heater

control 11-way or 16-way connector receptacle. Con-

nect one jumper from the ground circuit terminal inthe 11-way or 16-way a/c heater control connector

receptacle to a good ground. Connect the other

jumper from the fused rear window defogger relay

output circuit terminal of the 11-way or 16-way con-

nector receptacle to a 12-volt battery feed. The rear

window defogger switch LED indicator should light.

If OK, go to Step 4. If not OK, replace the faulty a/c

heater control.

(4) Check for continuity between the ground cir-

cuit and rear window defogger switch sense circuit

terminals of the 11-way or 16-way a/c heater control

connector receptacle. There should be momentary

continuity as the rear window defogger switch push

button is depressed, and then no continuity. If OK, go

to Step 5. If not OK, replace the faulty a/c heater

control.

(5) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the rear window defogger switch sense cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be no continuity. If OK,

go to Step 6. If not OK, repair the shorted rear win-

dow defogger switch sense circuit as required.

(6) Check for continuity between the rear window

defogger switch sense circuit cavities of the 11-way or

16-way instrument panel wire harness connector for

the a/c heater control and the 22-way instrument

panel wire harness connector for the BCM. There

should be continuity. If OK, refer to (Refer to 8 -

ELECTRICAL/HEATED GLASS/REAR WINDOW

DEFOGGER RELAY - DIAGNOSIS AND TESTING).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/A/C HEATER CONTROL - REMOVAL)

WJHEATED GLASS 8G - 7

REAR WINDOW DEFOGGER SWITCH (Continued)

Page 380 of 2199

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................9

OPERATION...........................10

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM............................10

DRIVER HEATED SEAT SWITCH

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH........................11

REMOVAL.............................12

INSTALLATION.........................13

HEATED SEAT ELEMENT

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT...........................14REMOVAL.............................14

INSTALLATION.........................14

HEATED SEAT SENSOR

DESCRIPTION.........................15

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................15

REMOVAL.............................15

PASSENGER HEATED SEAT SWITCH

DESCRIPTION.........................15

OPERATION...........................16

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH.................16

REMOVAL.............................17

INSTALLATION.........................17

HEATED SEAT SYSTEM

DESCRIPTION

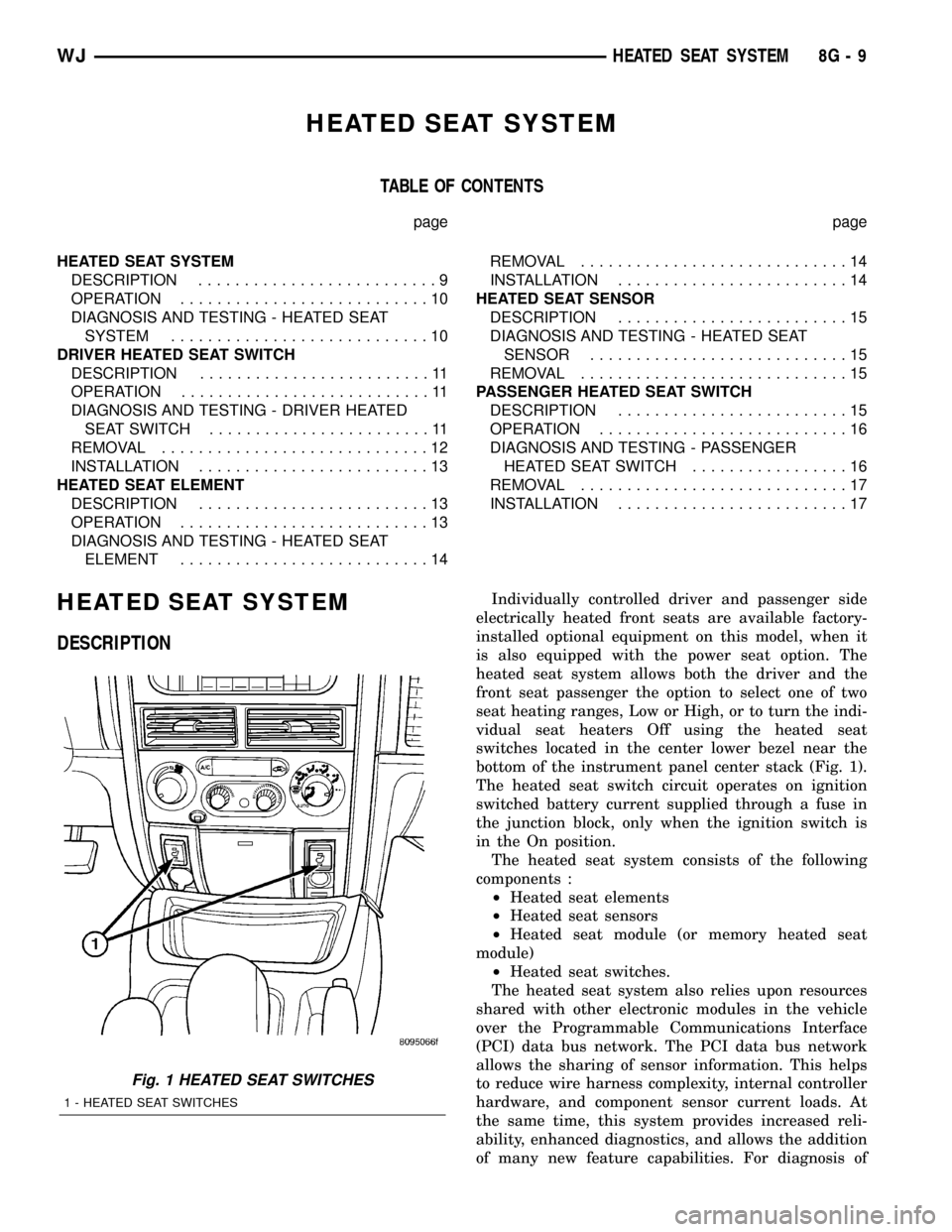

Individually controlled driver and passenger side

electrically heated front seats are available factory-

installed optional equipment on this model, when it

is also equipped with the power seat option. The

heated seat system allows both the driver and the

front seat passenger the option to select one of two

seat heating ranges, Low or High, or to turn the indi-

vidual seat heaters Off using the heated seat

switches located in the center lower bezel near the

bottom of the instrument panel center stack (Fig. 1).

The heated seat switch circuit operates on ignition

switched battery current supplied through a fuse in

the junction block, only when the ignition switch is

in the On position.

The heated seat system consists of the following

components :

²Heated seat elements

²Heated seat sensors

²Heated seat module (or memory heated seat

module)

²Heated seat switches.

The heated seat system also relies upon resources

shared with other electronic modules in the vehicle

over the Programmable Communications Interface

(PCI) data bus network. The PCI data bus network

allows the sharing of sensor information. This helps

to reduce wire harness complexity, internal controller

hardware, and component sensor current loads. At

the same time, this system provides increased reli-

ability, enhanced diagnostics, and allows the addition

of many new feature capabilities. For diagnosis of

Fig. 1 HEATED SEAT SWITCHES

1 - HEATED SEAT SWITCHES

WJHEATED SEAT SYSTEM 8G - 9

Page 382 of 2199

PRELIMINARY TEST

Before testing the individual components in the

heated seat system, check the following:

²If the heated seat switch LED indicators do not

light with the ignition switch in the On position and

the heated seat switch in the Low or High position,

check the fused ignition switch output (run) fuse in

the junction block. If OK, refer toHeated Seat

Switch Diagnosis and Testingin this section. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

²If the heated seat switch LED indicators light,

but the heating elements do not heat, check the

power seat circuit breaker in the junction block. If

OK, refer toHeated Seat Element Diagnosis and

Testingin this section of the manual. If not OK,

replace the faulty power seat circuit breaker.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

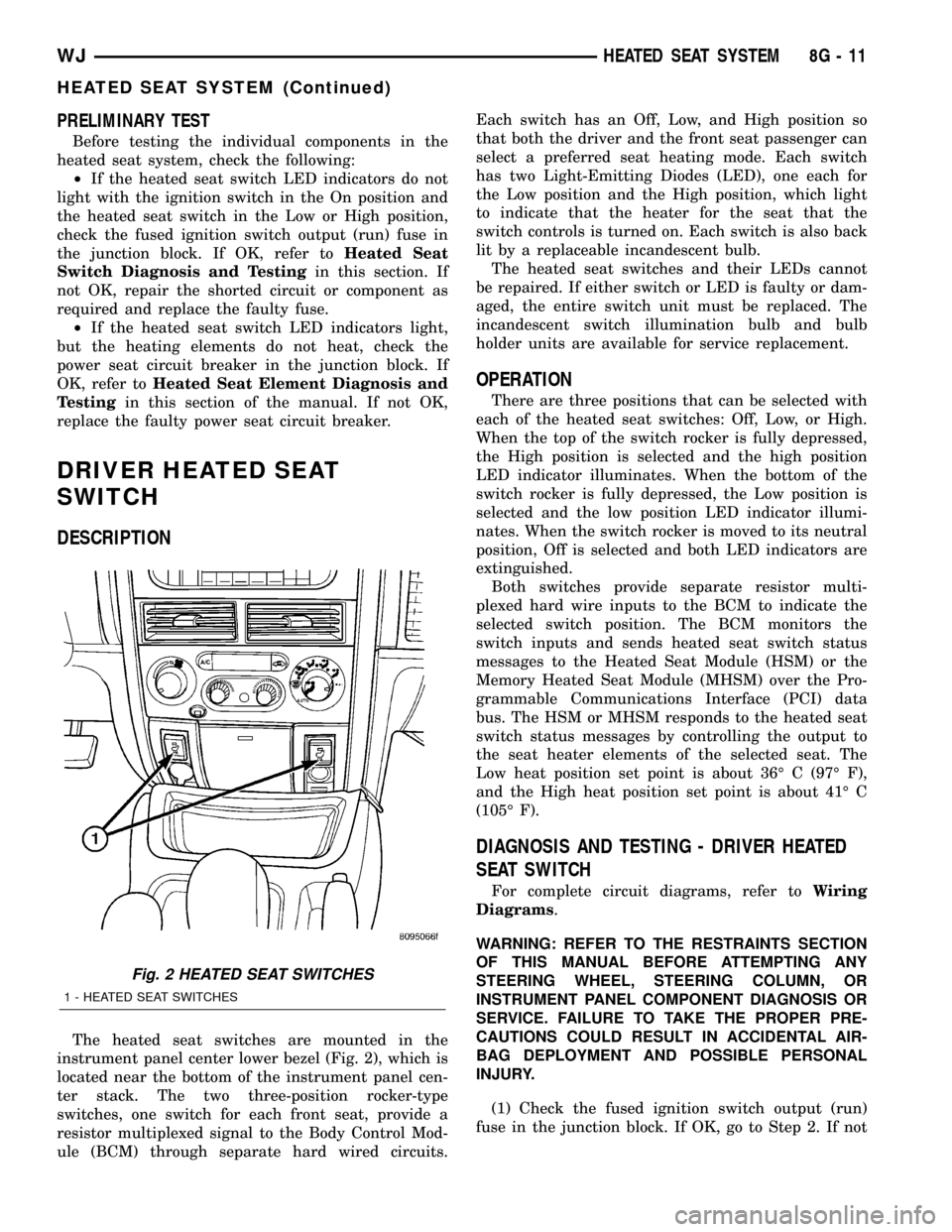

The heated seat switches are mounted in the

instrument panel center lower bezel (Fig. 2), which is

located near the bottom of the instrument panel cen-

ter stack. The two three-position rocker-type

switches, one switch for each front seat, provide a

resistor multiplexed signal to the Body Control Mod-

ule (BCM) through separate hard wired circuits.Each switch has an Off, Low, and High position so

that both the driver and the front seat passenger can

select a preferred seat heating mode. Each switch

has two Light-Emitting Diodes (LED), one each for

the Low position and the High position, which light

to indicate that the heater for the seat that the

switch controls is turned on. Each switch is also back

lit by a replaceable incandescent bulb.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch unit must be replaced. The

incandescent switch illumination bulb and bulb

holder units are available for service replacement.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the top of the switch rocker is fully depressed,

the High position is selected and the high position

LED indicator illuminates. When the bottom of the

switch rocker is fully depressed, the Low position is

selected and the low position LED indicator illumi-

nates. When the switch rocker is moved to its neutral

position, Off is selected and both LED indicators are

extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the junction block. If OK, go to Step 2. If not

Fig. 2 HEATED SEAT SWITCHES

1 - HEATED SEAT SWITCHES

WJHEATED SEAT SYSTEM 8G - 11

HEATED SEAT SYSTEM (Continued)

Page 383 of 2199

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

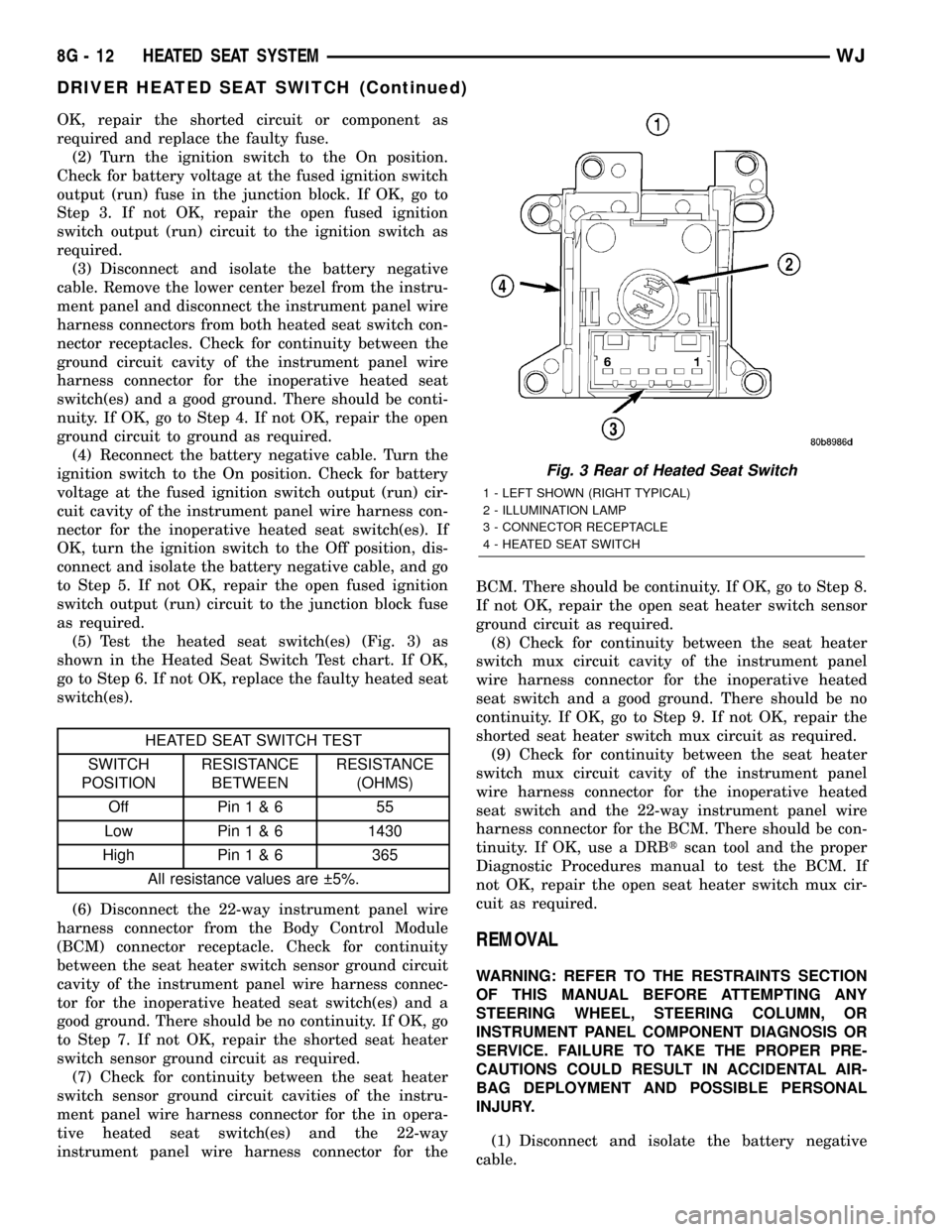

(5) Test the heated seat switch(es) (Fig. 3) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

(6) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the seat heater switch sensor ground circuit

cavity of the instrument panel wire harness connec-

tor for the inoperative heated seat switch(es) and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the shorted seat heater

switch sensor ground circuit as required.

(7) Check for continuity between the seat heater

switch sensor ground circuit cavities of the instru-

ment panel wire harness connector for the in opera-

tive heated seat switch(es) and the 22-way

instrument panel wire harness connector for theBCM. There should be continuity. If OK, go to Step 8.

If not OK, repair the open seat heater switch sensor

ground circuit as required.

(8) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted seat heater switch mux circuit as required.

(9) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and the 22-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRBtscan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open seat heater switch mux cir-

cuit as required.

REMOVAL

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

Fig. 3 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 12 HEATED SEAT SYSTEMWJ

DRIVER HEATED SEAT SWITCH (Continued)

Page 387 of 2199

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the top of the switch rocker is fully depressed,

the High position is selected and the high position

LED indicator illuminates. When the bottom of the

switch rocker is fully depressed, the Low position is

selected and the low position LED indicator illumi-

nates. When the switch rocker is moved to its neutral

position, Off is selected and both LED indicators are

extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seatswitch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

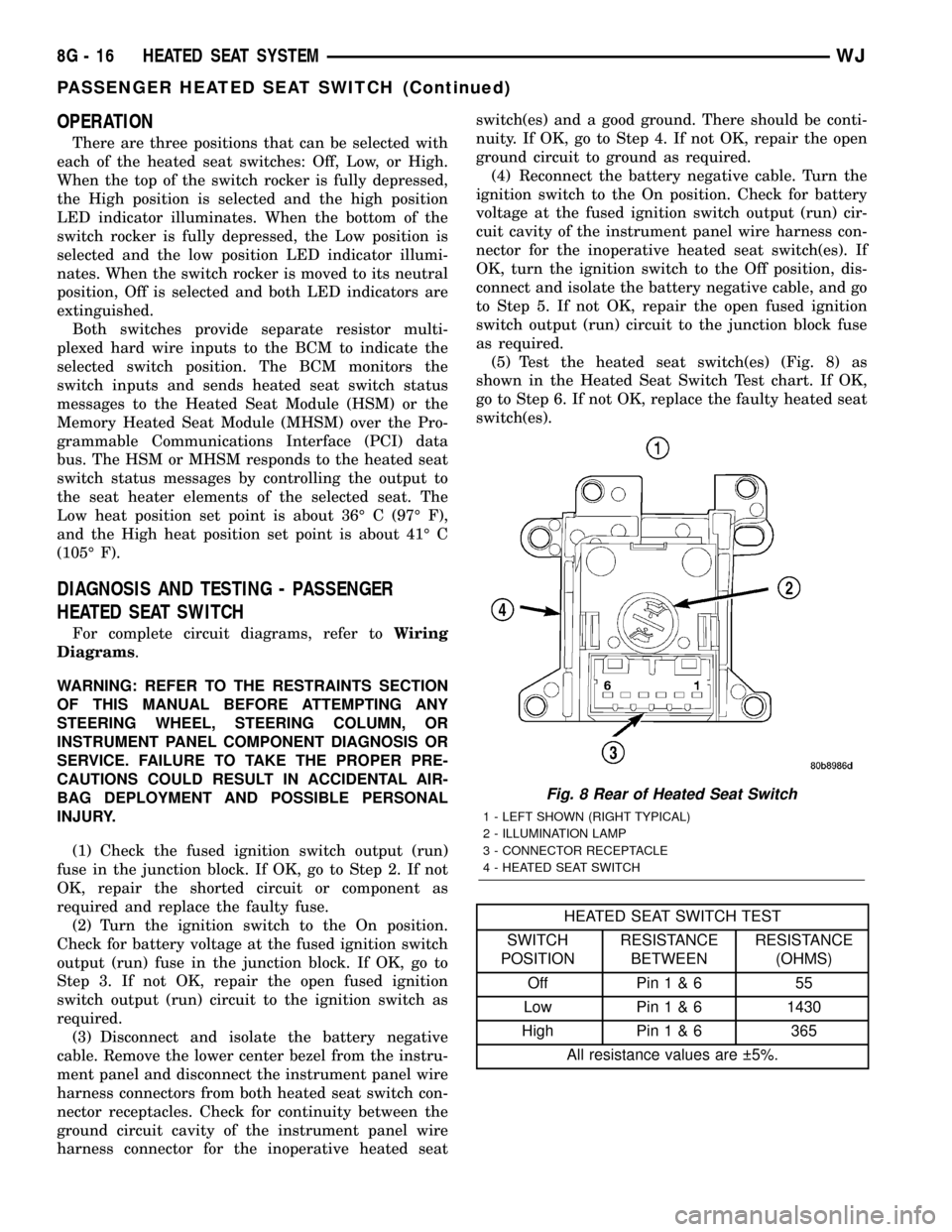

(5) Test the heated seat switch(es) (Fig. 8) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

Fig. 8 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 16 HEATED SEAT SYSTEMWJ

PASSENGER HEATED SEAT SWITCH (Continued)

Page 391 of 2199

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds. Following are general descriptions of the

remaining major components in the horn system.

OPERATION

The horn system is activated by a horn switch con-

cealed beneath the driver side airbag module trim

cover in the center of the steering wheel. Depressing

the center of the driver side airbag module trim cover

closes the horn switch. Closing the horn switch acti-

vates the horn relay. The activated horn relay then

switches the battery current needed to energize the

horns.

The BCM can also activate the horn system by

energizing the horn relay through a single hard

wired output circuit. The BCM energizes and de-en-

ergizes the horn relay in response to internal pro-

gramming as well as message inputs received over

the Programmable Communications Interface (PCI)

data bus network. The BCM can energize the horn

relay for a single chirp (RKE lock request), or for

extended operation (RKE panic mode and VTSS

alarm mode).

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the horn system.

DIAGNOSIS AND TESTING - HORN SYSTEM

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn relay from the Power Distribution Center

(PDC). Refer to Horn Relay for the proper removal

procedure. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

BOTH HORNS

INOPERATIVE1. Faulty fuse. 1. Check the fuses in the Power Distribution

Center (PDC) and the Junction Block (JB).

Replace the fuse and repair the shorted circuit or

component, if required.

2. Faulty horn relay. 2. Refer to Horn Relay for the proper horn relay

diagnosis and testing procedures. Replace the

horn relay or repair the open horn relay circuit, if

required.

3. Faulty horn switch. 3. Refer to Horn Switch for the proper horn switch

diagnosis and testing procedures. Replace the

horn switch or repair the open horn switch circuit,

if required.

4. Faulty horns. 4. Refer to Horn for the proper horn diagnosis

and testing procedures. Replace the horns or

repair the open horn circuit, if required.

ONE HORN INOPERATIVE 1. Faulty horn. 1. Refer to Horn for the proper horn diagnosis

and testing procedures. Replace the horn or

repair the open horn circuit, if required.

8H - 2 HORNWJ

HORN SYSTEM (Continued)

Page 394 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

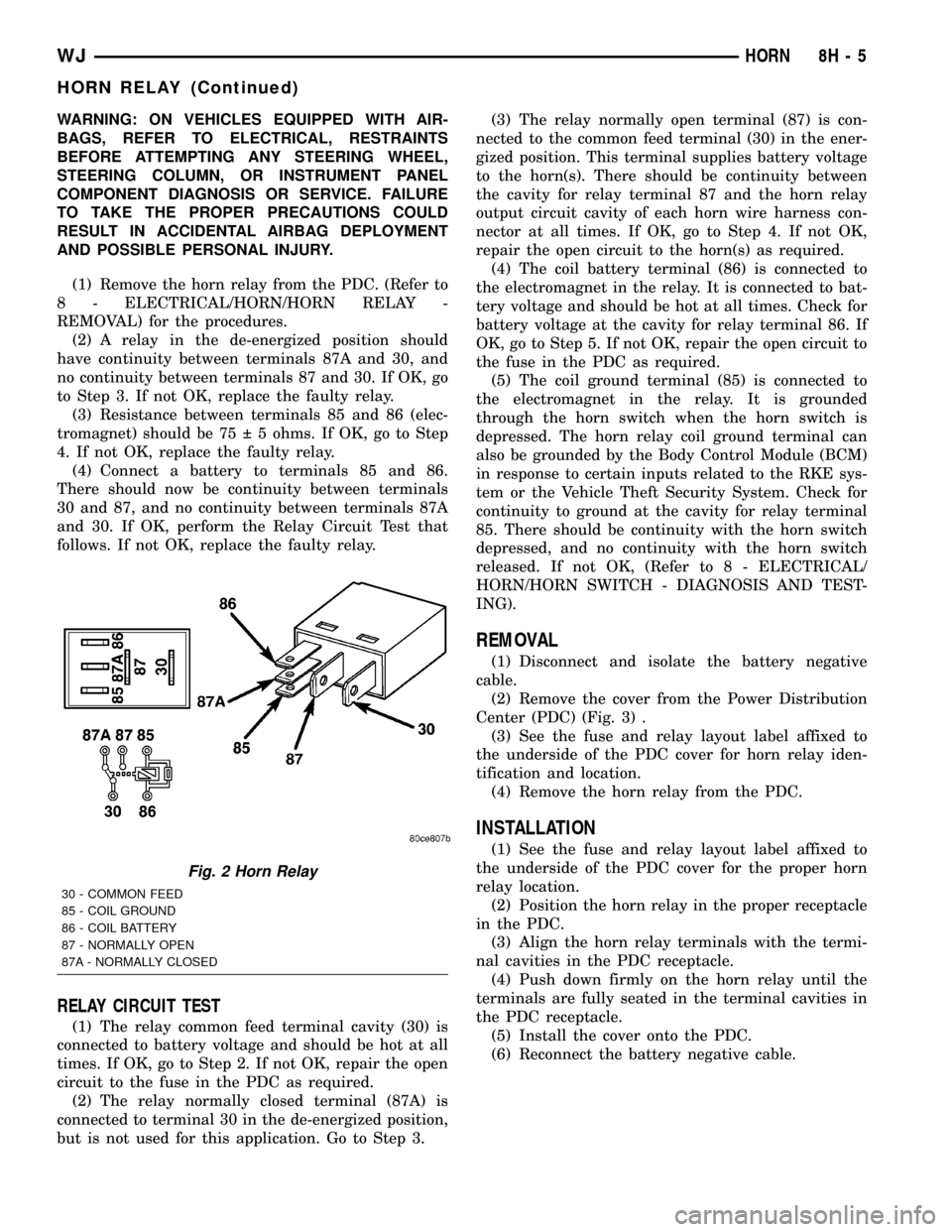

(1) Remove the horn relay from the PDC. (Refer to

8 - ELECTRICAL/HORN/HORN RELAY -

REMOVAL) for the procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the horn(s). There should be continuity between

the cavity for relay terminal 87 and the horn relay

output circuit cavity of each horn wire harness con-

nector at all times. If OK, go to Step 4. If not OK,

repair the open circuit to the horn(s) as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open circuit to

the fuse in the PDC as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the horn switch when the horn switch is

depressed. The horn relay coil ground terminal can

also be grounded by the Body Control Module (BCM)

in response to certain inputs related to the RKE sys-

tem or the Vehicle Theft Security System. Check for

continuity to ground at the cavity for relay terminal

85. There should be continuity with the horn switch

depressed, and no continuity with the horn switch

released. If not OK, (Refer to 8 - ELECTRICAL/

HORN/HORN SWITCH - DIAGNOSIS AND TEST-

ING).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 3) .

(3) See the fuse and relay layout label affixed to

the underside of the PDC cover for horn relay iden-

tification and location.

(4) Remove the horn relay from the PDC.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the PDC cover for the proper horn

relay location.

(2) Position the horn relay in the proper receptacle

in the PDC.

(3) Align the horn relay terminals with the termi-

nal cavities in the PDC receptacle.

(4) Push down firmly on the horn relay until the

terminals are fully seated in the terminal cavities in

the PDC receptacle.

(5) Install the cover onto the PDC.

(6) Reconnect the battery negative cable.

Fig. 2 Horn Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

WJHORN 8H - 5

HORN RELAY (Continued)