connector JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1830 of 2199

POSITION SENSOR

DESCRIPTION

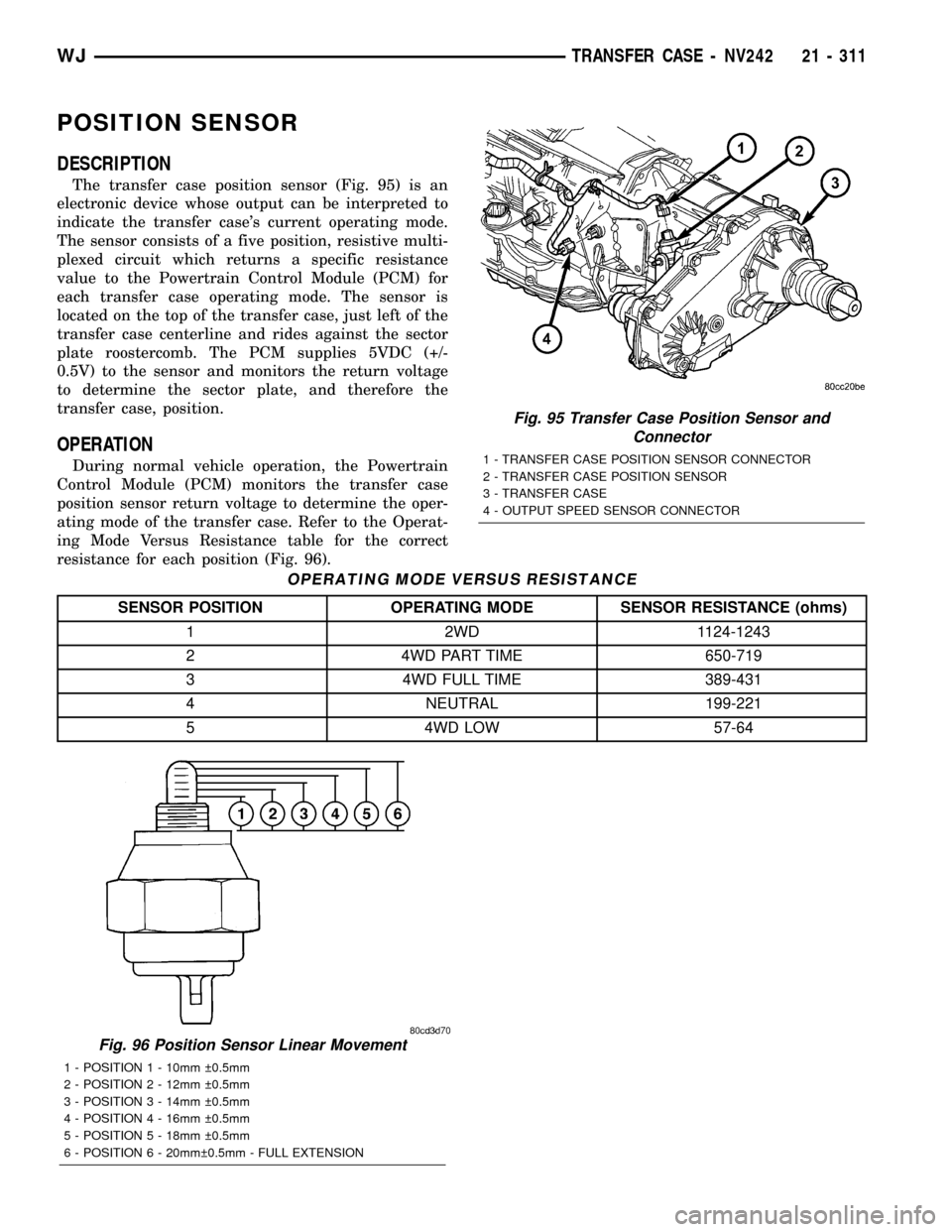

The transfer case position sensor (Fig. 95) is an

electronic device whose output can be interpreted to

indicate the transfer case's current operating mode.

The sensor consists of a five position, resistive multi-

plexed circuit which returns a specific resistance

value to the Powertrain Control Module (PCM) for

each transfer case operating mode. The sensor is

located on the top of the transfer case, just left of the

transfer case centerline and rides against the sector

plate roostercomb. The PCM supplies 5VDC (+/-

0.5V) to the sensor and monitors the return voltage

to determine the sector plate, and therefore the

transfer case, position.

OPERATION

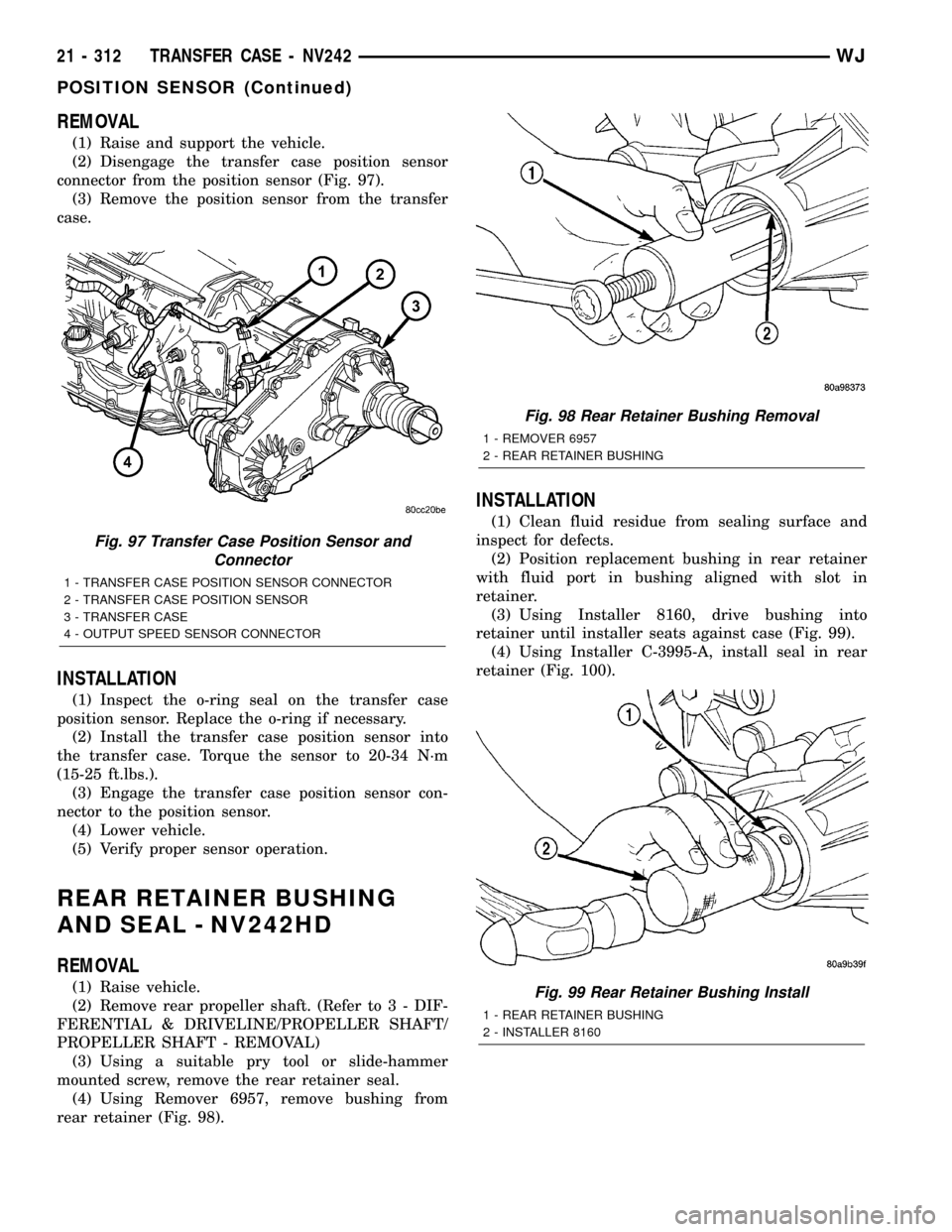

During normal vehicle operation, the Powertrain

Control Module (PCM) monitors the transfer case

position sensor return voltage to determine the oper-

ating mode of the transfer case. Refer to the Operat-

ing Mode Versus Resistance table for the correct

resistance for each position (Fig. 96).

OPERATING MODE VERSUS RESISTANCE

SENSOR POSITION OPERATING MODE SENSOR RESISTANCE (ohms)

1 2WD 1124-1243

2 4WD PART TIME 650-719

3 4WD FULL TIME 389-431

4 NEUTRAL 199-221

5 4WD LOW 57-64

Fig. 96 Position Sensor Linear Movement

1 - POSITION 1 - 10mm 0.5mm

2 - POSITION 2 - 12mm 0.5mm

3 - POSITION 3 - 14mm 0.5mm

4 - POSITION 4 - 16mm 0.5mm

5 - POSITION 5 - 18mm 0.5mm

6 - POSITION 6 - 20mm 0.5mm - FULL EXTENSION

Fig. 95 Transfer Case Position Sensor and

Connector

1 - TRANSFER CASE POSITION SENSOR CONNECTOR

2 - TRANSFER CASE POSITION SENSOR

3 - TRANSFER CASE

4 - OUTPUT SPEED SENSOR CONNECTOR

WJTRANSFER CASE - NV242 21 - 311

Page 1831 of 2199

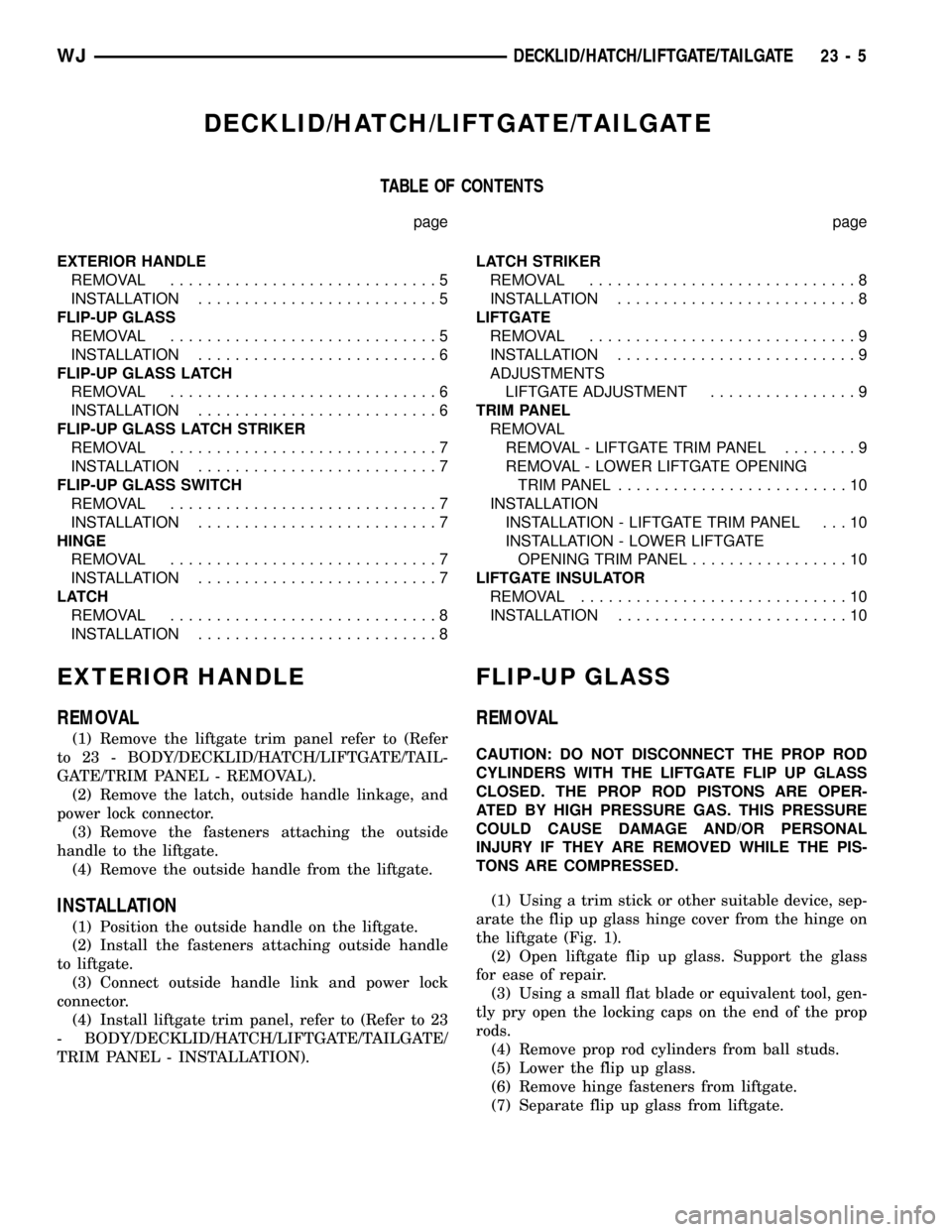

REMOVAL

(1) Raise and support the vehicle.

(2) Disengage the transfer case position sensor

connector from the position sensor (Fig. 97).

(3) Remove the position sensor from the transfer

case.

INSTALLATION

(1) Inspect the o-ring seal on the transfer case

position sensor. Replace the o-ring if necessary.

(2) Install the transfer case position sensor into

the transfer case. Torque the sensor to 20-34 N´m

(15-25 ft.lbs.).

(3) Engage the transfer case position sensor con-

nector to the position sensor.

(4) Lower vehicle.

(5) Verify proper sensor operation.

REAR RETAINER BUSHING

AND SEAL - NV242HD

REMOVAL

(1) Raise vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the rear retainer seal.

(4) Using Remover 6957, remove bushing from

rear retainer (Fig. 98).

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Position replacement bushing in rear retainer

with fluid port in bushing aligned with slot in

retainer.

(3) Using Installer 8160, drive bushing into

retainer until installer seats against case (Fig. 99).

(4) Using Installer C-3995-A, install seal in rear

retainer (Fig. 100).

Fig. 97 Transfer Case Position Sensor and

Connector

1 - TRANSFER CASE POSITION SENSOR CONNECTOR

2 - TRANSFER CASE POSITION SENSOR

3 - TRANSFER CASE

4 - OUTPUT SPEED SENSOR CONNECTOR

Fig. 98 Rear Retainer Bushing Removal

1 - REMOVER 6957

2 - REAR RETAINER BUSHING

Fig. 99 Rear Retainer Bushing Install

1 - REAR RETAINER BUSHING

2 - INSTALLER 8160

21 - 312 TRANSFER CASE - NV242WJ

POSITION SENSOR (Continued)

Page 1878 of 2199

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

EXTERIOR HANDLE

REMOVAL.............................5

INSTALLATION..........................5

FLIP-UP GLASS

REMOVAL.............................5

INSTALLATION..........................6

FLIP-UP GLASS LATCH

REMOVAL.............................6

INSTALLATION..........................6

FLIP-UP GLASS LATCH STRIKER

REMOVAL.............................7

INSTALLATION..........................7

FLIP-UP GLASS SWITCH

REMOVAL.............................7

INSTALLATION..........................7

HINGE

REMOVAL.............................7

INSTALLATION..........................7

LATCH

REMOVAL.............................8

INSTALLATION..........................8LATCH STRIKER

REMOVAL.............................8

INSTALLATION..........................8

LIFTGATE

REMOVAL.............................9

INSTALLATION..........................9

ADJUSTMENTS

LIFTGATE ADJUSTMENT................9

TRIM PANEL

REMOVAL

REMOVAL - LIFTGATE TRIM PANEL........9

REMOVAL - LOWER LIFTGATE OPENING

TRIM PANEL.........................10

INSTALLATION

INSTALLATION - LIFTGATE TRIM PANEL . . . 10

INSTALLATION - LOWER LIFTGATE

OPENING TRIM PANEL.................10

LIFTGATE INSULATOR

REMOVAL.............................10

INSTALLATION.........................10

EXTERIOR HANDLE

REMOVAL

(1) Remove the liftgate trim panel refer to (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/TRIM PANEL - REMOVAL).

(2) Remove the latch, outside handle linkage, and

power lock connector.

(3) Remove the fasteners attaching the outside

handle to the liftgate.

(4) Remove the outside handle from the liftgate.

INSTALLATION

(1) Position the outside handle on the liftgate.

(2) Install the fasteners attaching outside handle

to liftgate.

(3) Connect outside handle link and power lock

connector.

(4) Install liftgate trim panel, refer to (Refer to 23

- BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

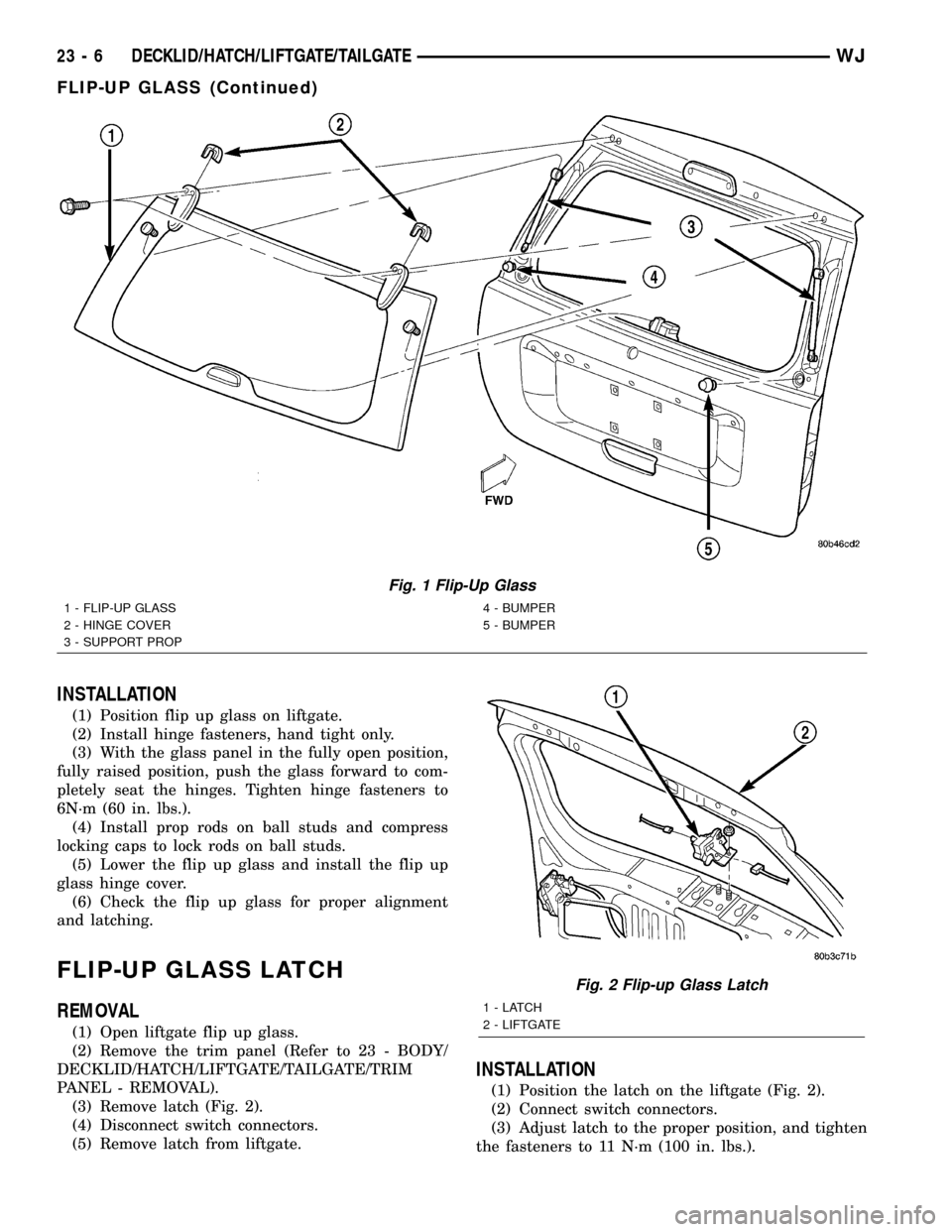

FLIP-UP GLASS

REMOVAL

CAUTION: DO NOT DISCONNECT THE PROP ROD

CYLINDERS WITH THE LIFTGATE FLIP UP GLASS

CLOSED. THE PROP ROD PISTONS ARE OPER-

ATED BY HIGH PRESSURE GAS. THIS PRESSURE

COULD CAUSE DAMAGE AND/OR PERSONAL

INJURY IF THEY ARE REMOVED WHILE THE PIS-

TONS ARE COMPRESSED.

(1) Using a trim stick or other suitable device, sep-

arate the flip up glass hinge cover from the hinge on

the liftgate (Fig. 1).

(2) Open liftgate flip up glass. Support the glass

for ease of repair.

(3) Using a small flat blade or equivalent tool, gen-

tly pry open the locking caps on the end of the prop

rods.

(4) Remove prop rod cylinders from ball studs.

(5) Lower the flip up glass.

(6) Remove hinge fasteners from liftgate.

(7) Separate flip up glass from liftgate.

WJDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 5

Page 1879 of 2199

INSTALLATION

(1) Position flip up glass on liftgate.

(2) Install hinge fasteners, hand tight only.

(3) With the glass panel in the fully open position,

fully raised position, push the glass forward to com-

pletely seat the hinges. Tighten hinge fasteners to

6N´m (60 in. lbs.).

(4) Install prop rods on ball studs and compress

locking caps to lock rods on ball studs.

(5) Lower the flip up glass and install the flip up

glass hinge cover.

(6) Check the flip up glass for proper alignment

and latching.

FLIP-UP GLASS LATCH

REMOVAL

(1) Open liftgate flip up glass.

(2) Remove the trim panel (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - REMOVAL).

(3) Remove latch (Fig. 2).

(4) Disconnect switch connectors.

(5) Remove latch from liftgate.

INSTALLATION

(1) Position the latch on the liftgate (Fig. 2).

(2) Connect switch connectors.

(3) Adjust latch to the proper position, and tighten

the fasteners to 11 N´m (100 in. lbs.).

Fig. 1 Flip-Up Glass

1 - FLIP-UP GLASS

2 - HINGE COVER

3 - SUPPORT PROP4 - BUMPER

5 - BUMPER

Fig. 2 Flip-up Glass Latch

1-LATCH

2 - LIFTGATE

23 - 6 DECKLID/HATCH/LIFTGATE/TAILGATEWJ

FLIP-UP GLASS (Continued)

Page 1880 of 2199

(4) Close flip up glass panel and verify proper

operation.

(5)

Install liftgate trim panel, refer to (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION).

FLIP-UP GLASS LATCH

STRIKER

REMOVAL

(1) Raise flip up glass panel.

(2) Mark the position of the handle/striker on the

glass panel.

(3) Remove the screws attaching the handle/striker

to the glass.

INSTALLATION

(1) Position the handle/striker on the glass panel

and align the reference marks.

(2) Install the screws attaching the handle/striker

to the glass panel. Tighten the fasteners to 6 N´m (60

in. lbs.).

FLIP-UP GLASS SWITCH

REMOVAL

(1) Remove license plate lamp housing/trim panel

from liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - REMOVAL).

(2) Squeeze the locking tabs inward to release the

switch from the housing.

(3) Disconnect the switch harness connector,

remove the switch from the housing.

INSTALLATION

(1) Install switch harness connector.(2) Position switch in housing, snap switch into

place.

(3) Install license plate lamp housing/trim panel

onto liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - INSTALLATION).

HINGE

REMOVAL

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Open the liftgate. Support the liftgate for ease

of repair.

(2) Remove the liftgate header trim panel.

(3) Mark the hinge location with a grease pencil or

other suitable device.

(4) Remove the hinge screws (Fig. 5).

(5) Remove hinge.

INSTALLATION

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Position the hinge on the roof panel and on the

liftgate. (Use 3MŸ Fast and Firm or equivalent on

the hinge to body mating surfaces as a sealant.

(2) Install and tighten hinge screws at roof panel

to 28N´m (21 ft. lbs.).

(3) Install hinge screws at liftgate. Tighten screws

to 28N´m (21 ft. lbs.).

(4) Install liftgate header trim panel.

(5) Check the liftgate for proper alignment and

operation.

WJDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 7

FLIP-UP GLASS LATCH (Continued)

Page 1881 of 2199

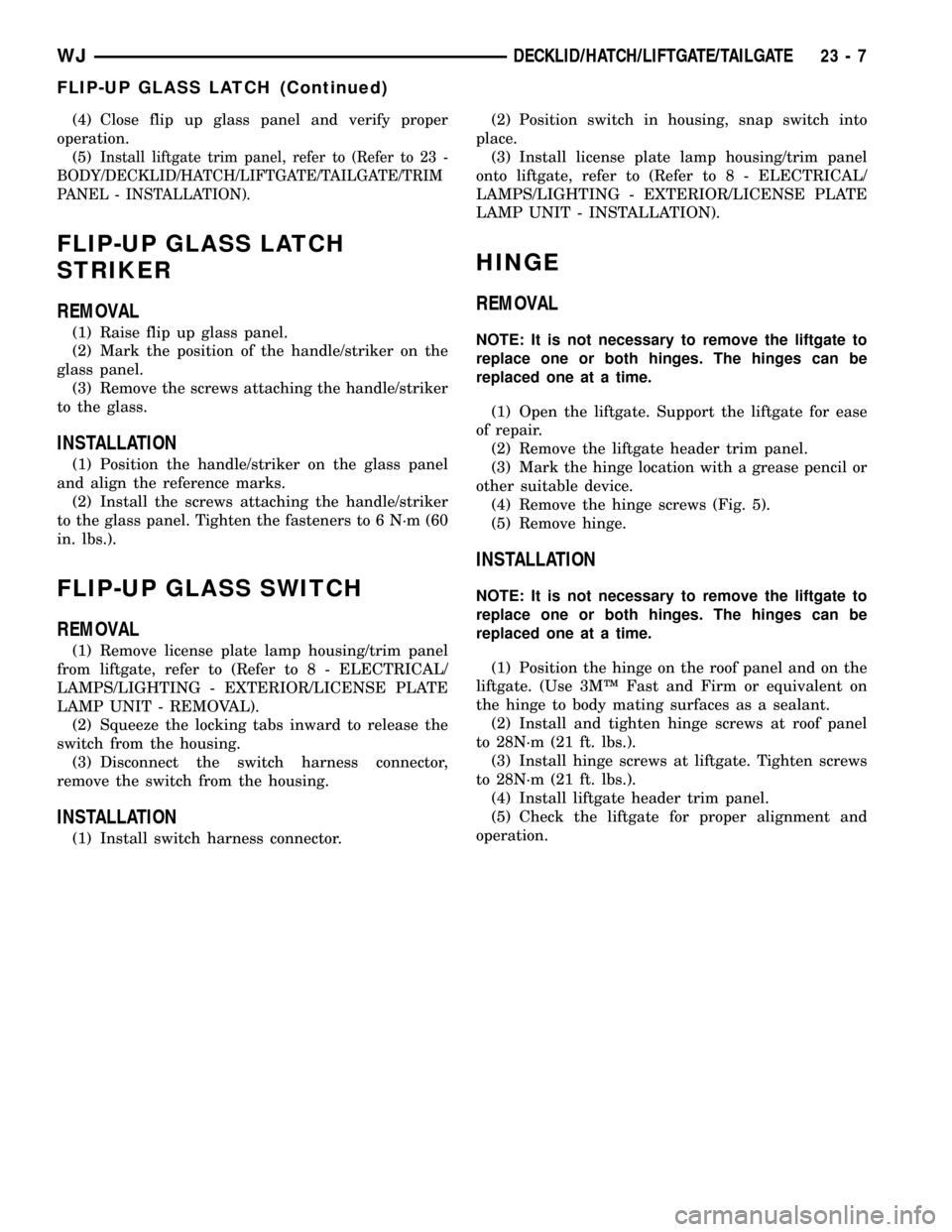

LATCH

REMOVAL

(1) Raise the liftgate.

(2) Remove the liftgate trim panel (Fig. 3).

(3) Disconnect the power connector.

(4)

Disconnect the outside handle link from the latch.

(5) Remove the latch screws and remove latch.

INSTALLATION

(1) Install the latch into the liftgate and tighten

the screws to 7N´m (5 ft. lbs.).

(2)

Connect the outside handle to the liftgate latch.

(3) Plug in the connector for the power.

(4) Install the liftgate trim panel.

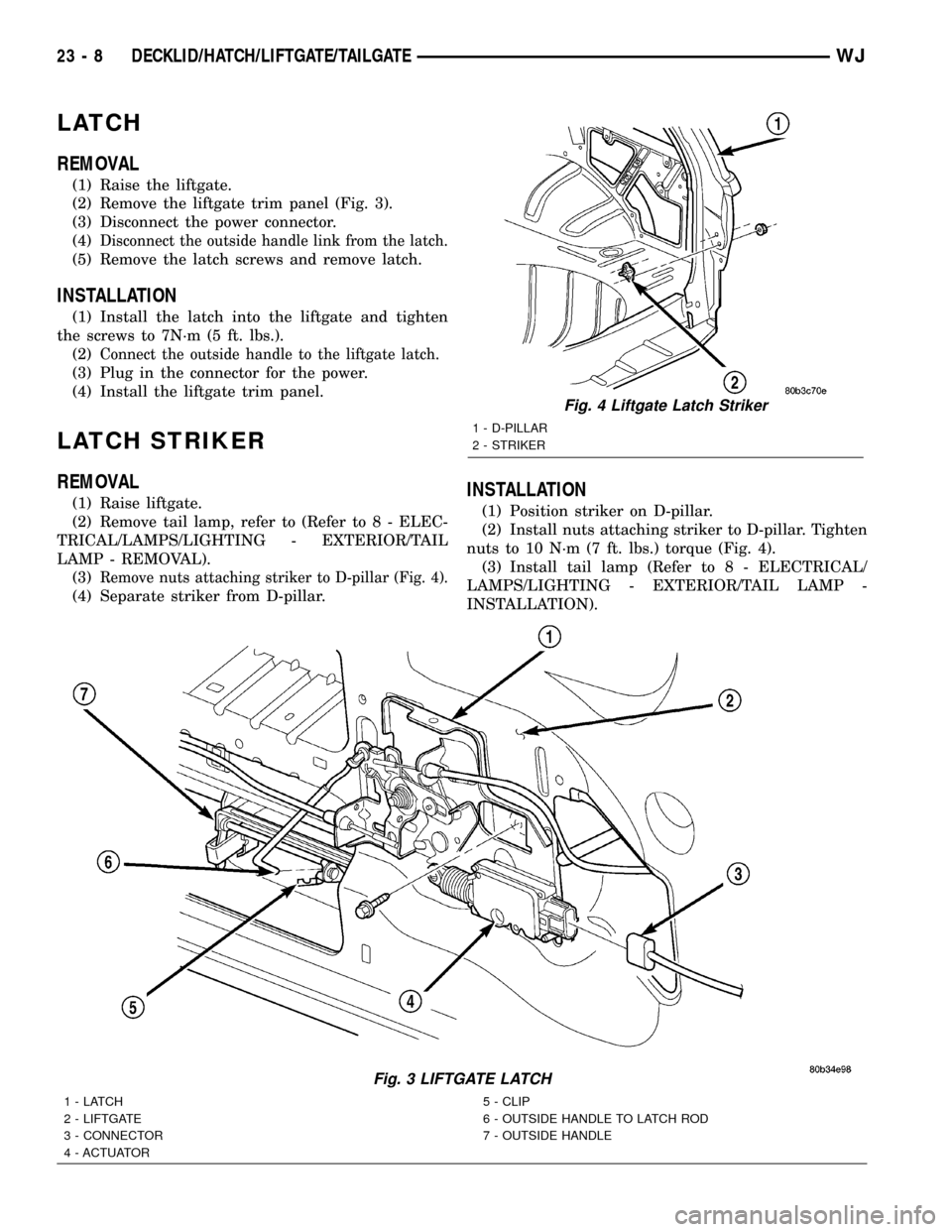

LATCH STRIKER

REMOVAL

(1) Raise liftgate.

(2) Remove tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - REMOVAL).

(3)

Remove nuts attaching striker to D-pillar (Fig. 4).

(4) Separate striker from D-pillar.

INSTALLATION

(1) Position striker on D-pillar.

(2) Install nuts attaching striker to D-pillar. Tighten

nuts to 10 N´m (7 ft. lbs.) torque (Fig. 4).

(3) Install tail lamp (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/TAIL LAMP -

INSTALLATION).

Fig. 3 LIFTGATE LATCH

1-LATCH

2 - LIFTGATE

3 - CONNECTOR

4 - ACTUATOR5 - CLIP

6 - OUTSIDE HANDLE TO LATCH ROD

7 - OUTSIDE HANDLE

Fig. 4 Liftgate Latch Striker

1 - D-PILLAR

2 - STRIKER

23 - 8 DECKLID/HATCH/LIFTGATE/TAILGATEWJ

Page 1885 of 2199

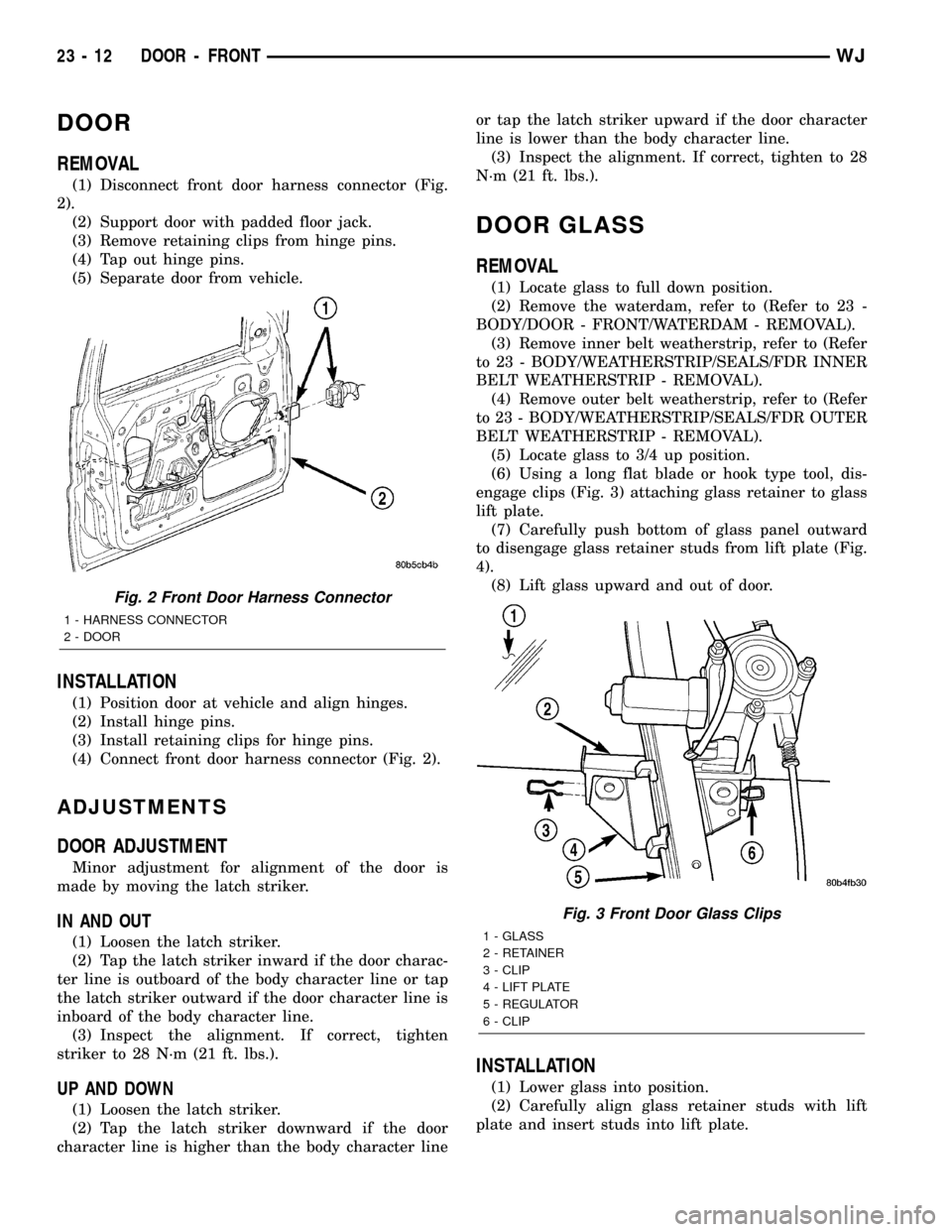

DOOR

REMOVAL

(1) Disconnect front door harness connector (Fig.

2).

(2) Support door with padded floor jack.

(3) Remove retaining clips from hinge pins.

(4) Tap out hinge pins.

(5) Separate door from vehicle.

INSTALLATION

(1) Position door at vehicle and align hinges.

(2) Install hinge pins.

(3) Install retaining clips for hinge pins.

(4) Connect front door harness connector (Fig. 2).

ADJUSTMENTS

DOOR ADJUSTMENT

Minor adjustment for alignment of the door is

made by moving the latch striker.

IN AND OUT

(1) Loosen the latch striker.

(2) Tap the latch striker inward if the door charac-

ter line is outboard of the body character line or tap

the latch striker outward if the door character line is

inboard of the body character line.

(3) Inspect the alignment. If correct, tighten

striker to 28 N´m (21 ft. lbs.).

UP AND DOWN

(1) Loosen the latch striker.

(2) Tap the latch striker downward if the door

character line is higher than the body character lineor tap the latch striker upward if the door character

line is lower than the body character line.

(3) Inspect the alignment. If correct, tighten to 28

N´m (21 ft. lbs.).

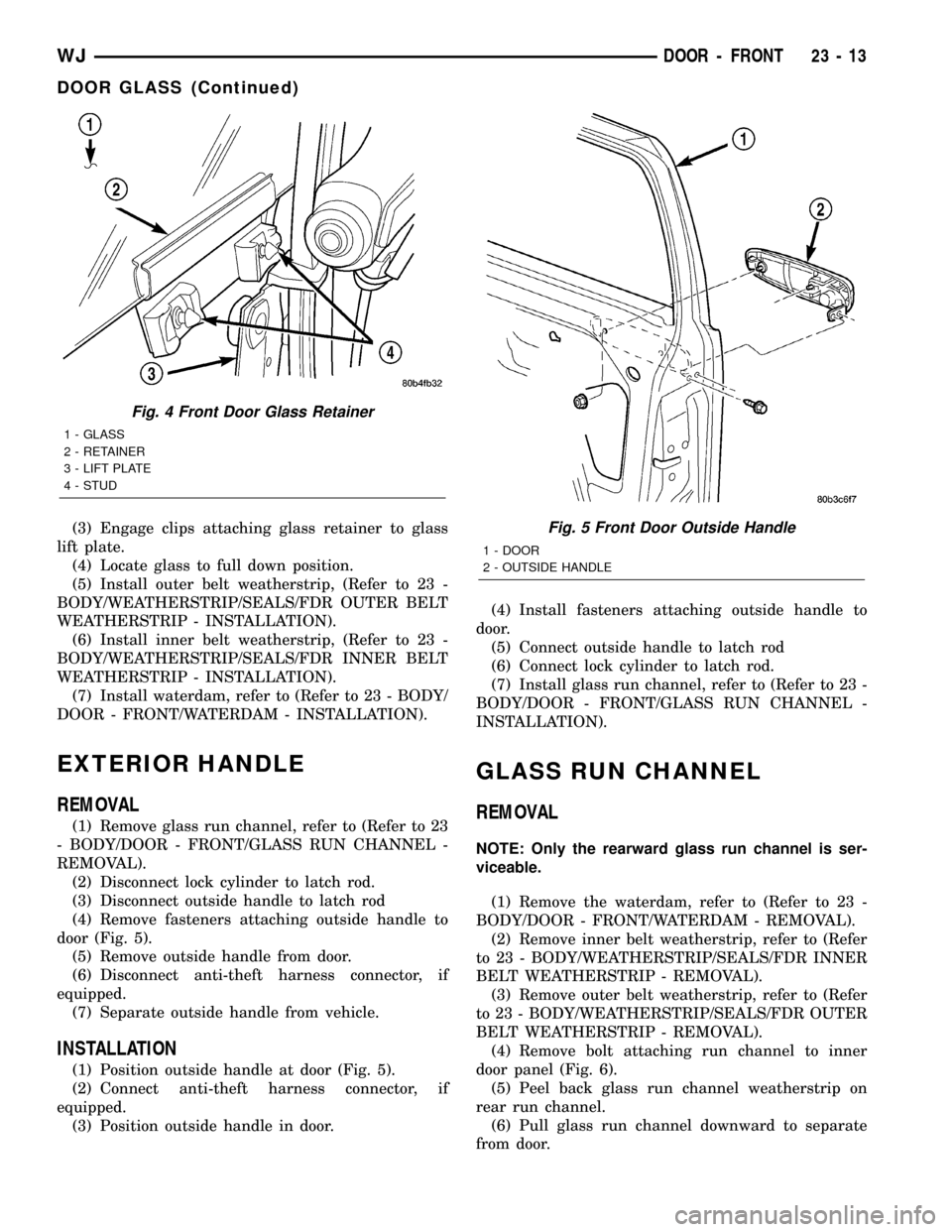

DOOR GLASS

REMOVAL

(1) Locate glass to full down position.

(2) Remove the waterdam, refer to (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(3) Remove inner belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - REMOVAL).

(4) Remove outer belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/FDR OUTER

BELT WEATHERSTRIP - REMOVAL).

(5) Locate glass to 3/4 up position.

(6) Using a long flat blade or hook type tool, dis-

engage clips (Fig. 3) attaching glass retainer to glass

lift plate.

(7) Carefully push bottom of glass panel outward

to disengage glass retainer studs from lift plate (Fig.

4).

(8) Lift glass upward and out of door.

INSTALLATION

(1) Lower glass into position.

(2) Carefully align glass retainer studs with lift

plate and insert studs into lift plate.

Fig. 2 Front Door Harness Connector

1 - HARNESS CONNECTOR

2 - DOOR

Fig. 3 Front Door Glass Clips

1 - GLASS

2 - RETAINER

3 - CLIP

4 - LIFT PLATE

5 - REGULATOR

6 - CLIP

23 - 12 DOOR - FRONTWJ

Page 1886 of 2199

(3) Engage clips attaching glass retainer to glass

lift plate.

(4) Locate glass to full down position.

(5) Install outer belt weatherstrip, (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

WEATHERSTRIP - INSTALLATION).

(6) Install inner belt weatherstrip, (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - INSTALLATION).

(7) Install waterdam, refer to (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

EXTERIOR HANDLE

REMOVAL

(1) Remove glass run channel, refer to (Refer to 23

- BODY/DOOR - FRONT/GLASS RUN CHANNEL -

REMOVAL).

(2) Disconnect lock cylinder to latch rod.

(3) Disconnect outside handle to latch rod

(4) Remove fasteners attaching outside handle to

door (Fig. 5).

(5) Remove outside handle from door.

(6) Disconnect anti-theft harness connector, if

equipped.

(7) Separate outside handle from vehicle.

INSTALLATION

(1) Position outside handle at door (Fig. 5).

(2) Connect anti-theft harness connector, if

equipped.

(3) Position outside handle in door.(4) Install fasteners attaching outside handle to

door.

(5) Connect outside handle to latch rod

(6) Connect lock cylinder to latch rod.

(7) Install glass run channel, refer to (Refer to 23 -

BODY/DOOR - FRONT/GLASS RUN CHANNEL -

INSTALLATION).

GLASS RUN CHANNEL

REMOVAL

NOTE: Only the rearward glass run channel is ser-

viceable.

(1) Remove the waterdam, refer to (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Remove inner belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - REMOVAL).

(3) Remove outer belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/FDR OUTER

BELT WEATHERSTRIP - REMOVAL).

(4) Remove bolt attaching run channel to inner

door panel (Fig. 6).

(5) Peel back glass run channel weatherstrip on

rear run channel.

(6) Pull glass run channel downward to separate

from door.

Fig. 4 Front Door Glass Retainer

1 - GLASS

2 - RETAINER

3 - LIFT PLATE

4 - STUD

Fig. 5 Front Door Outside Handle

1 - DOOR

2 - OUTSIDE HANDLE

WJDOOR - FRONT 23 - 13

DOOR GLASS (Continued)

Page 1888 of 2199

INSTALLATION

(1) Position hinge on ªAº pillar. (Use 3MtFast and

Firm or equivalent on the hinge to body mating sur-

face as a sealant.)

(2) Install hinge to body bolts, but do not tighten.

(3) Align the hinge to the reference marks and

torque the bolts to 35N´m (26 ft. lbs.).

(4) Install the door on the hinge and align with the

reference marks.

(5) Tighten the door to hinge fasteners.

(6) For adjustment see door adjustment procedure.

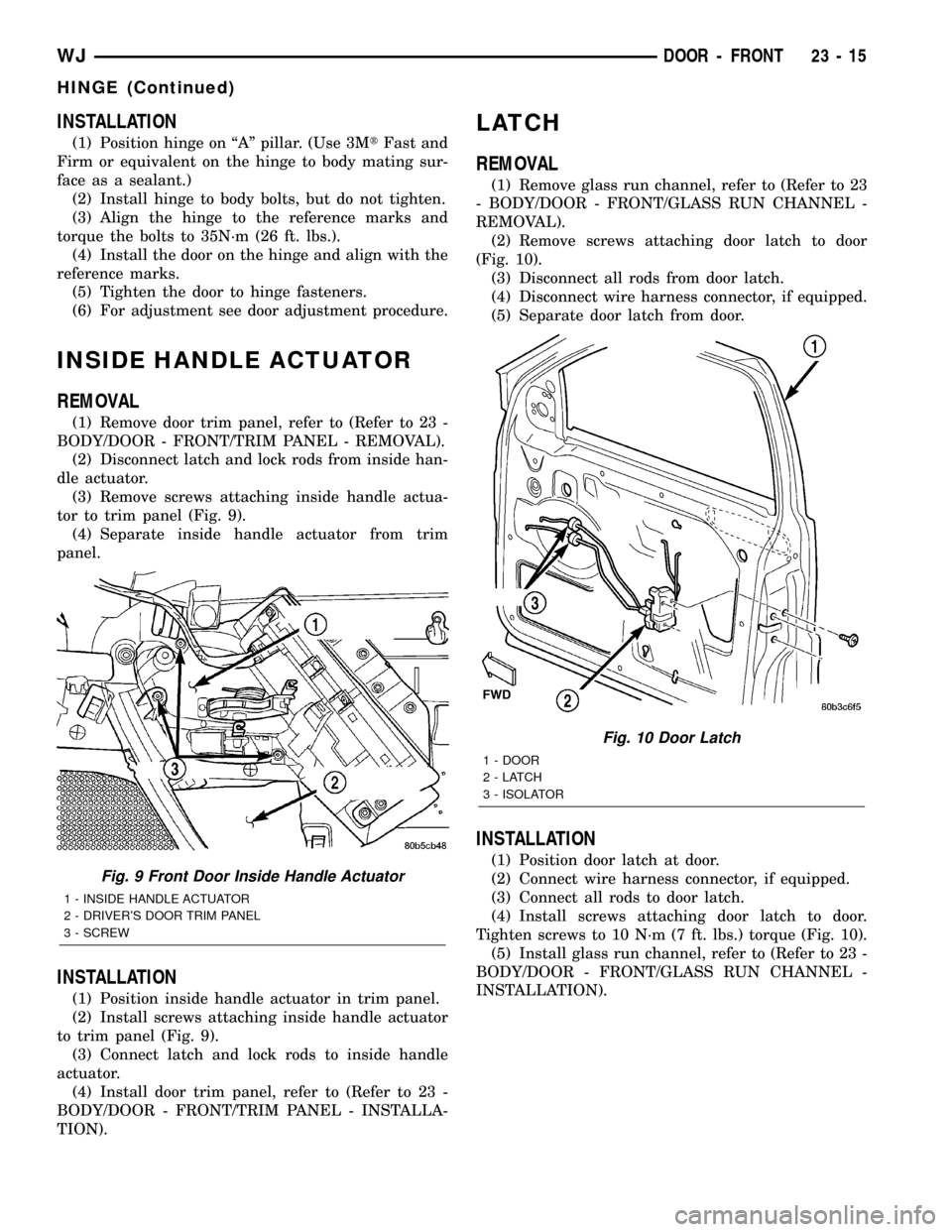

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Disconnect latch and lock rods from inside han-

dle actuator.

(3) Remove screws attaching inside handle actua-

tor to trim panel (Fig. 9).

(4) Separate inside handle actuator from trim

panel.

INSTALLATION

(1) Position inside handle actuator in trim panel.

(2) Install screws attaching inside handle actuator

to trim panel (Fig. 9).

(3) Connect latch and lock rods to inside handle

actuator.

(4) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

LATCH

REMOVAL

(1) Remove glass run channel, refer to (Refer to 23

- BODY/DOOR - FRONT/GLASS RUN CHANNEL -

REMOVAL).

(2) Remove screws attaching door latch to door

(Fig. 10).

(3) Disconnect all rods from door latch.

(4) Disconnect wire harness connector, if equipped.

(5) Separate door latch from door.

INSTALLATION

(1) Position door latch at door.

(2) Connect wire harness connector, if equipped.

(3) Connect all rods to door latch.

(4) Install screws attaching door latch to door.

Tighten screws to 10 N´m (7 ft. lbs.) torque (Fig. 10).

(5) Install glass run channel, refer to (Refer to 23 -

BODY/DOOR - FRONT/GLASS RUN CHANNEL -

INSTALLATION).

Fig. 9 Front Door Inside Handle Actuator

1 - INSIDE HANDLE ACTUATOR

2 - DRIVER'S DOOR TRIM PANEL

3 - SCREW

Fig. 10 Door Latch

1 - DOOR

2-LATCH

3 - ISOLATOR

WJDOOR - FRONT 23 - 15

HINGE (Continued)

Page 1890 of 2199

INSTALLATION

(1) Connect lock cylinder switch, if equipped.

(2) Position lock cylinder in door handle.

(3) Position lock cylinder retainer and install

screw (Fig. 13).

(4) Install outside door handle, refer to (Refer to

23 - BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION).

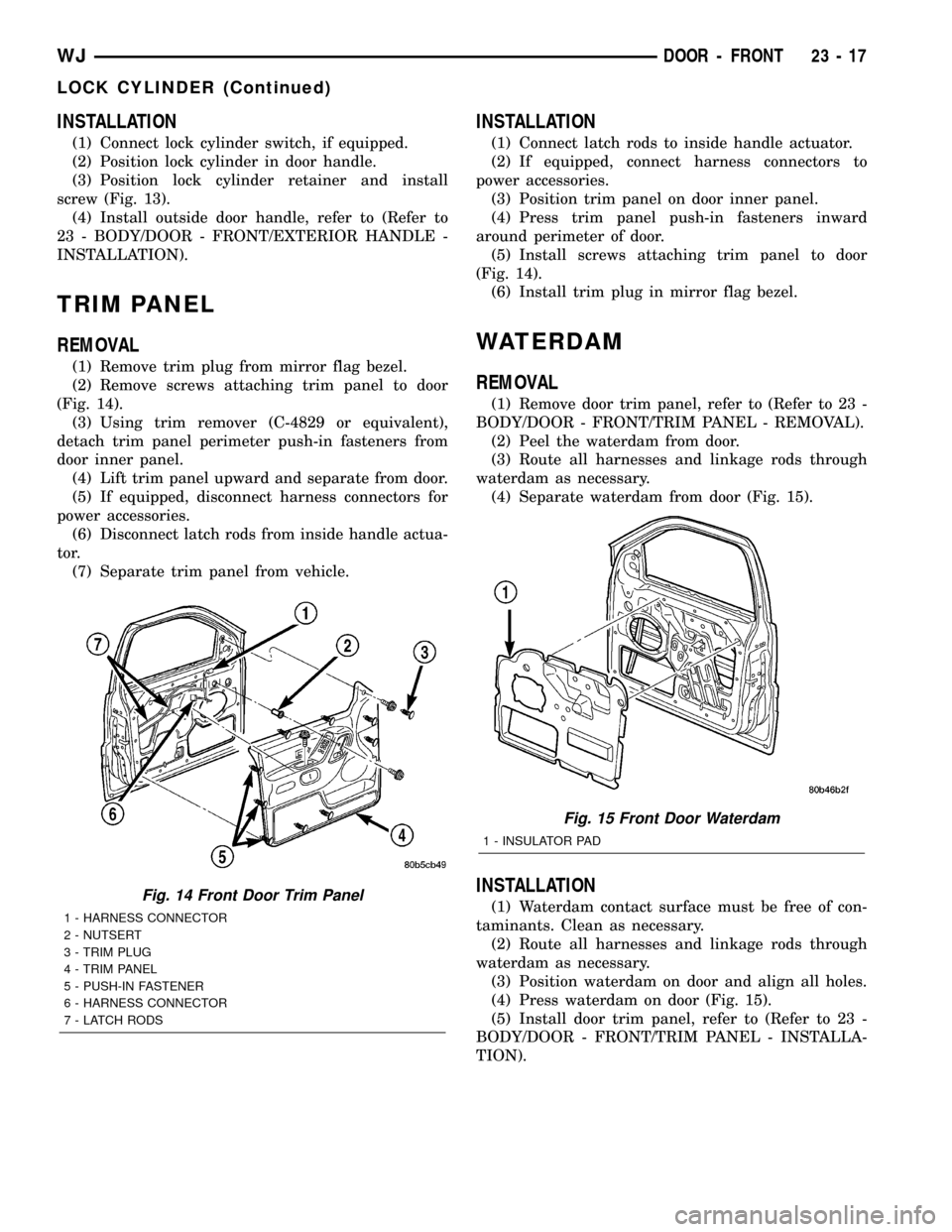

TRIM PANEL

REMOVAL

(1) Remove trim plug from mirror flag bezel.

(2) Remove screws attaching trim panel to door

(Fig. 14).

(3) Using trim remover (C-4829 or equivalent),

detach trim panel perimeter push-in fasteners from

door inner panel.

(4) Lift trim panel upward and separate from door.

(5) If equipped, disconnect harness connectors for

power accessories.

(6) Disconnect latch rods from inside handle actua-

tor.

(7) Separate trim panel from vehicle.

INSTALLATION

(1) Connect latch rods to inside handle actuator.

(2) If equipped, connect harness connectors to

power accessories.

(3) Position trim panel on door inner panel.

(4) Press trim panel push-in fasteners inward

around perimeter of door.

(5) Install screws attaching trim panel to door

(Fig. 14).

(6) Install trim plug in mirror flag bezel.

WATERDAM

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Peel the waterdam from door.

(3) Route all harnesses and linkage rods through

waterdam as necessary.

(4) Separate waterdam from door (Fig. 15).

INSTALLATION

(1) Waterdam contact surface must be free of con-

taminants. Clean as necessary.

(2) Route all harnesses and linkage rods through

waterdam as necessary.

(3) Position waterdam on door and align all holes.

(4) Press waterdam on door (Fig. 15).

(5) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).Fig. 14 Front Door Trim Panel

1 - HARNESS CONNECTOR

2 - NUTSERT

3 - TRIM PLUG

4 - TRIM PANEL

5 - PUSH-IN FASTENER

6 - HARNESS CONNECTOR

7 - LATCH RODS

Fig. 15 Front Door Waterdam

1 - INSULATOR PAD

WJDOOR - FRONT 23 - 17

LOCK CYLINDER (Continued)