connector JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1891 of 2199

WINDOW REGULATOR

REMOVAL

(1) Remove front door glass, refer to (Refer to 23 -

BODY/DOOR - FRONT/DOOR GLASS - REMOVAL).

(2) Loosen bolts attaching regulator to inner door

panel (Fig. 16).

(3) Remove bolt attaching regulator to inner door

panel (Fig. 17).

(4) Lift regulator upward to disengage bolts from

door inner panel.

(5) Disengage power window regulator harness

connector, if equipped.

(6) Remove regulator through access hole in door.

INSTALLATION

(1) Position regulator in door through access hole.

(2) Engage power window regulator harness con-

nector, if equipped.

(3) Lift regulator upward and engage bolts in door

inner panel key hole slots.

(4) Install bolt attaching regulator to inner door

panel.

(5) Tighten bolts attaching regulator to inner door

panel.

(6) Install front door glass, refer to (Refer to 23 -

BODY/DOOR - FRONT/GLASS RUN CHANNEL -

INSTALLATION).

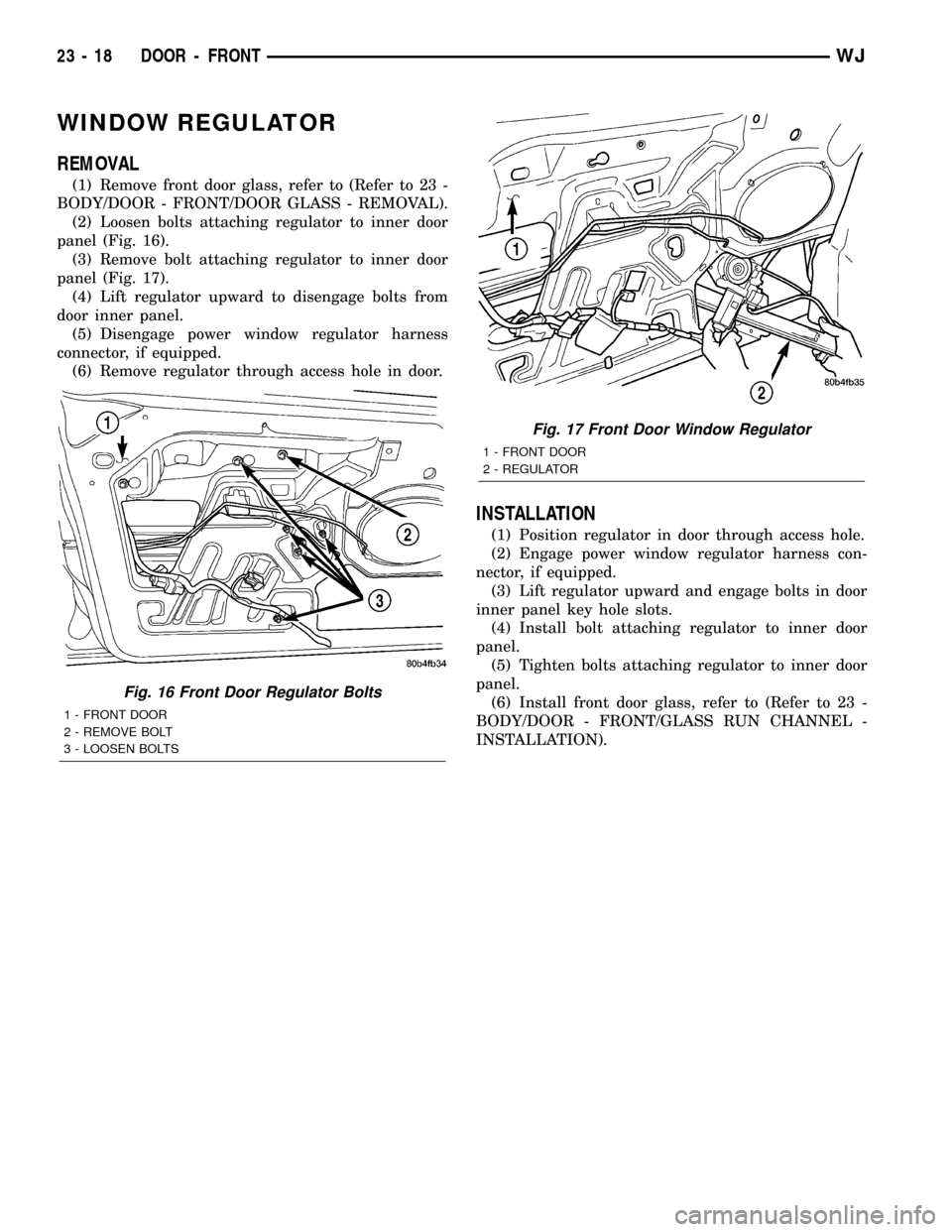

Fig. 16 Front Door Regulator Bolts

1 - FRONT DOOR

2 - REMOVE BOLT

3 - LOOSEN BOLTS

Fig. 17 Front Door Window Regulator

1 - FRONT DOOR

2 - REGULATOR

23 - 18 DOOR - FRONTWJ

Page 1893 of 2199

DOOR

REMOVAL

(1) Disconnect rear door harness connector (Fig. 2).

(2) Support door with padded floor jack.

(3) Remove retaining clips from hinge pins.

(4) Tap out hinge pins.

(5) Separate door from vehicle.

INSTALLATION

(1) Position door at vehicle and align hinges.

(2) Install hinge pins.

(3) Install retaining clips for hinge pins.

(4) Connect rear door harness connector (Fig. 2).

DOOR GLASS

REMOVAL

(1) Remove waterdam, refer to (Refer to 23 -

BODY/DOORS - REAR/WATERDAM - REMOVAL).

(2) Remove inner belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/RDR INNER

BELT WEATHERSTRIP - REMOVAL).

(3) Remove stationary glass, refer to (Refer to 23 -

BODY/STATIONARY GLASS/DOOR GLASS -

REMOVAL).

(4) Disengage clips attaching window glass to lift

plate.

(5) Press studs out of lift plate.

(6) Lift window glass from door (Fig. 3).

INSTALLATION

(1) Position window glass in door (Fig. 3).

(2) Engage studs into lift plate.

(3) Engage clips attaching window glass to lift

plate.

(4) Install stationary glass, refer to (Refer to 23 -

BODY/STATIONARY GLASS/DOOR GLASS -

INSTALLATION).

(5) Install inner belt weatherstrip, refer to (Refer

to 23 - BODY/WEATHERSTRIP/SEALS/RDR INNER

BELT WEATHERSTRIP - INSTALLATION).

(6) Install waterdam, refer to (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION).

EXTERIOR HANDLE

REMOVAL

(1) Remove waterdam, refer to (Refer to 23 -

BODY/DOORS - REAR/WATERDAM - REMOVAL).

(2) Locate glass to full up position.

(3) Disconnect lock knob to latch rod.

(4) Disconnect outside handle to latch rod.

(5) Remove fasteners attaching outside handle to

door (Fig. 4).

(6) Remove outside handle from door.

(7) Separate outside handle from vehicle.

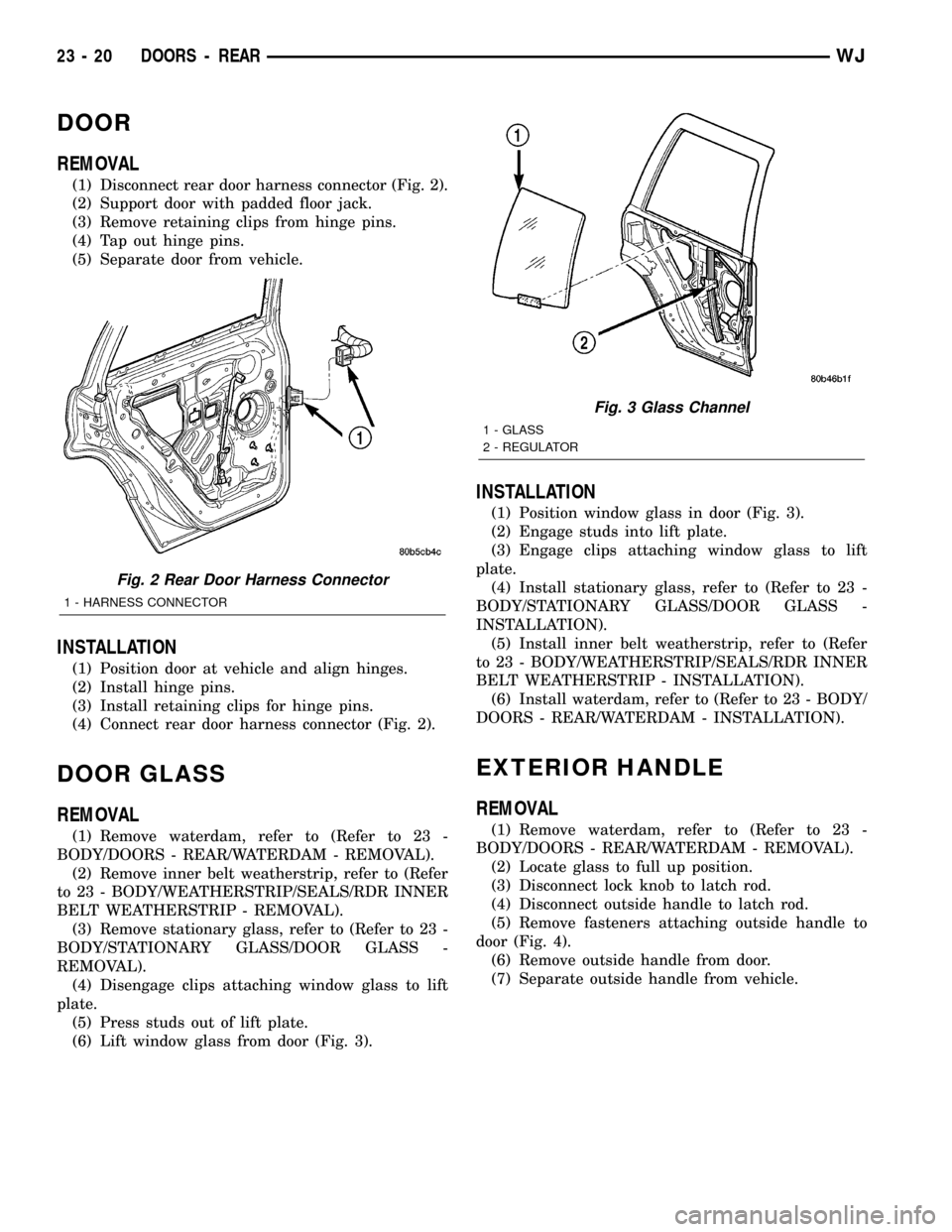

Fig. 2 Rear Door Harness Connector

1 - HARNESS CONNECTOR

Fig. 3 Glass Channel

1 - GLASS

2 - REGULATOR

23 - 20 DOORS - REARWJ

Page 1896 of 2199

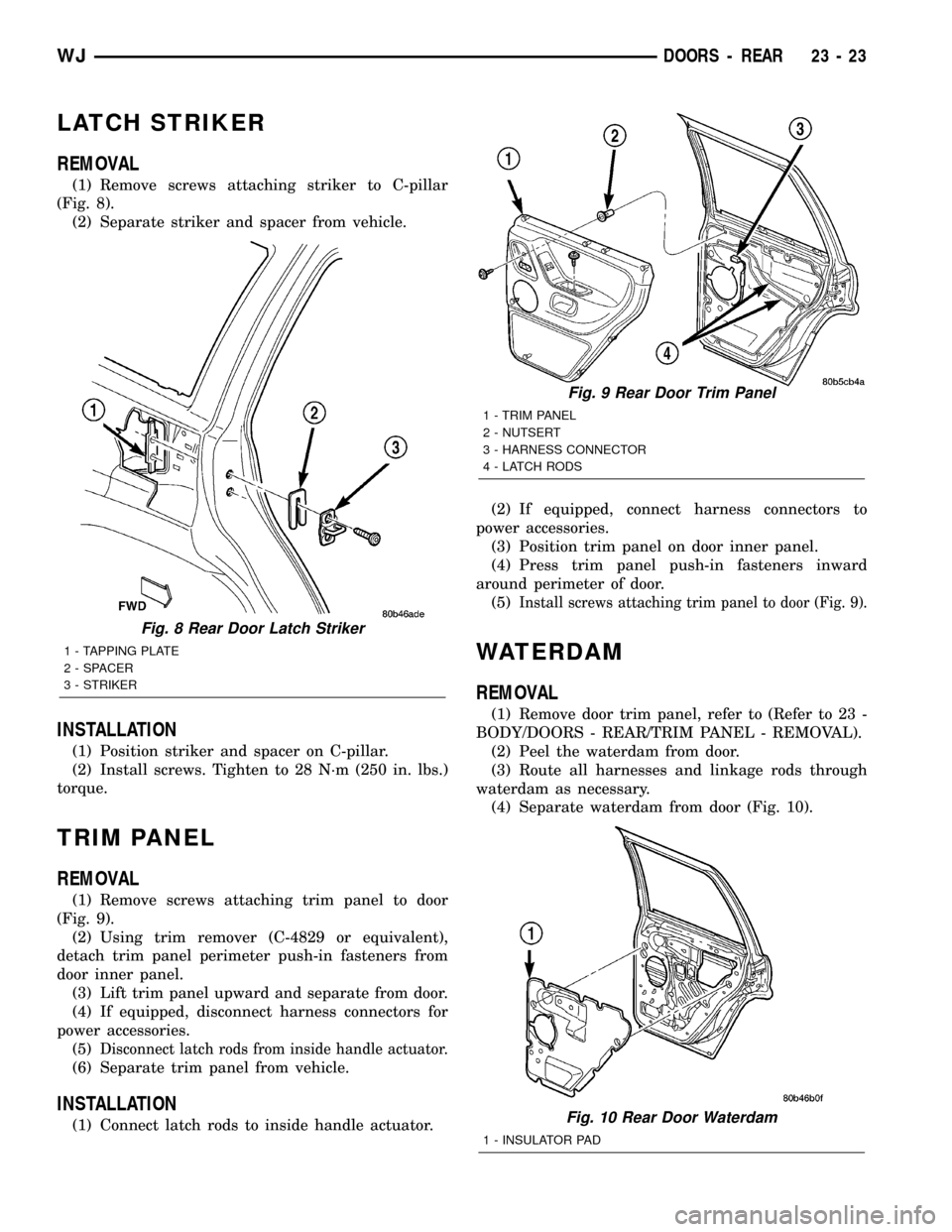

LATCH STRIKER

REMOVAL

(1) Remove screws attaching striker to C-pillar

(Fig. 8).

(2) Separate striker and spacer from vehicle.

INSTALLATION

(1) Position striker and spacer on C-pillar.

(2) Install screws. Tighten to 28 N´m (250 in. lbs.)

torque.

TRIM PANEL

REMOVAL

(1) Remove screws attaching trim panel to door

(Fig. 9).

(2) Using trim remover (C-4829 or equivalent),

detach trim panel perimeter push-in fasteners from

door inner panel.

(3) Lift trim panel upward and separate from door.

(4) If equipped, disconnect harness connectors for

power accessories.

(5)

Disconnect latch rods from inside handle actuator.

(6) Separate trim panel from vehicle.

INSTALLATION

(1) Connect latch rods to inside handle actuator.(2) If equipped, connect harness connectors to

power accessories.

(3) Position trim panel on door inner panel.

(4) Press trim panel push-in fasteners inward

around perimeter of door.

(5)

Install screws attaching trim panel to door (Fig. 9).

WATERDAM

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOORS - REAR/TRIM PANEL - REMOVAL).

(2) Peel the waterdam from door.

(3) Route all harnesses and linkage rods through

waterdam as necessary.

(4) Separate waterdam from door (Fig. 10).

Fig. 8 Rear Door Latch Striker

1 - TAPPING PLATE

2 - SPACER

3 - STRIKER

Fig. 9 Rear Door Trim Panel

1 - TRIM PANEL

2 - NUTSERT

3 - HARNESS CONNECTOR

4 - LATCH RODS

Fig. 10 Rear Door Waterdam

1 - INSULATOR PAD

WJDOORS - REAR 23 - 23

Page 1900 of 2199

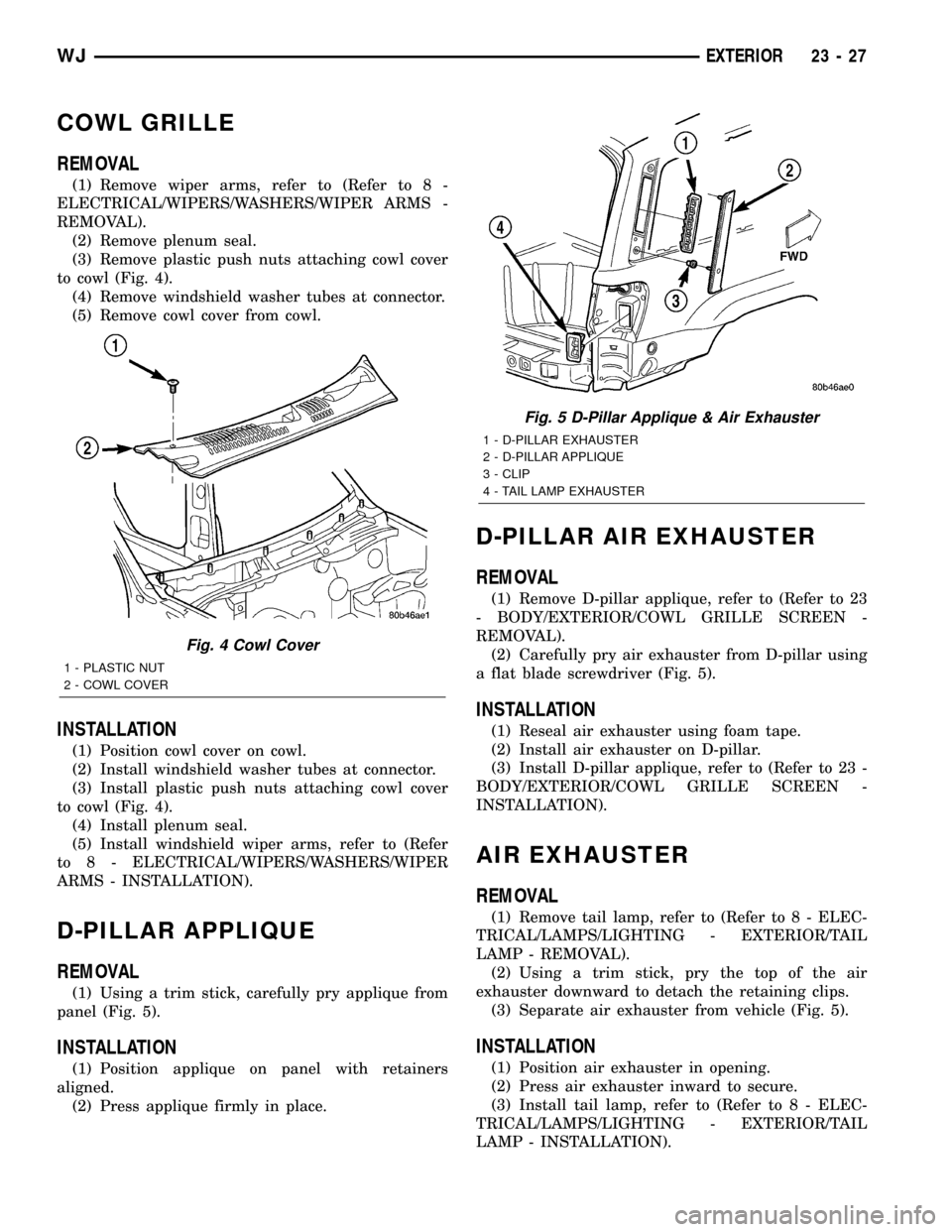

COWL GRILLE

REMOVAL

(1) Remove wiper arms, refer to (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL).

(2) Remove plenum seal.

(3) Remove plastic push nuts attaching cowl cover

to cowl (Fig. 4).

(4) Remove windshield washer tubes at connector.

(5) Remove cowl cover from cowl.

INSTALLATION

(1) Position cowl cover on cowl.

(2) Install windshield washer tubes at connector.

(3) Install plastic push nuts attaching cowl cover

to cowl (Fig. 4).

(4) Install plenum seal.

(5) Install windshield wiper arms, refer to (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WIPER

ARMS - INSTALLATION).

D-PILLAR APPLIQUE

REMOVAL

(1) Using a trim stick, carefully pry applique from

panel (Fig. 5).

INSTALLATION

(1) Position applique on panel with retainers

aligned.

(2) Press applique firmly in place.

D-PILLAR AIR EXHAUSTER

REMOVAL

(1) Remove D-pillar applique, refer to (Refer to 23

- BODY/EXTERIOR/COWL GRILLE SCREEN -

REMOVAL).

(2) Carefully pry air exhauster from D-pillar using

a flat blade screwdriver (Fig. 5).

INSTALLATION

(1) Reseal air exhauster using foam tape.

(2) Install air exhauster on D-pillar.

(3) Install D-pillar applique, refer to (Refer to 23 -

BODY/EXTERIOR/COWL GRILLE SCREEN -

INSTALLATION).

AIR EXHAUSTER

REMOVAL

(1) Remove tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - REMOVAL).

(2) Using a trim stick, pry the top of the air

exhauster downward to detach the retaining clips.

(3) Separate air exhauster from vehicle (Fig. 5).

INSTALLATION

(1) Position air exhauster in opening.

(2) Press air exhauster inward to secure.

(3) Install tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - INSTALLATION).

Fig. 4 Cowl Cover

1 - PLASTIC NUT

2 - COWL COVER

Fig. 5 D-Pillar Applique & Air Exhauster

1 - D-PILLAR EXHAUSTER

2 - D-PILLAR APPLIQUE

3 - CLIP

4 - TAIL LAMP EXHAUSTER

WJEXTERIOR 23 - 27

Page 1903 of 2199

(3) Install fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION).

HEADLAMP MOUNTING

MODULE

REMOVAL

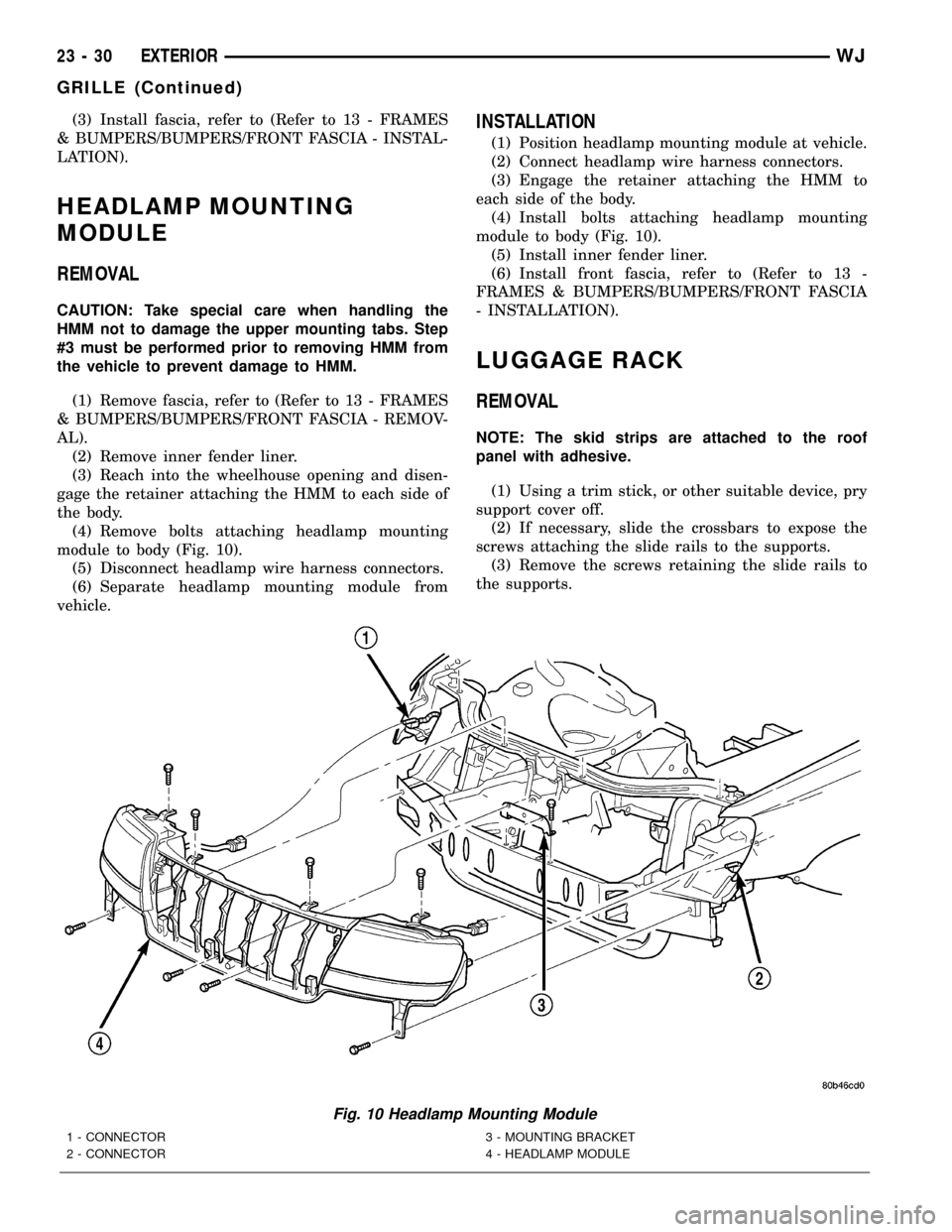

CAUTION: Take special care when handling the

HMM not to damage the upper mounting tabs. Step

#3 must be performed prior to removing HMM from

the vehicle to prevent damage to HMM.

(1) Remove fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - REMOV-

AL).

(2) Remove inner fender liner.

(3) Reach into the wheelhouse opening and disen-

gage the retainer attaching the HMM to each side of

the body.

(4) Remove bolts attaching headlamp mounting

module to body (Fig. 10).

(5) Disconnect headlamp wire harness connectors.

(6) Separate headlamp mounting module from

vehicle.

INSTALLATION

(1) Position headlamp mounting module at vehicle.

(2) Connect headlamp wire harness connectors.

(3) Engage the retainer attaching the HMM to

each side of the body.

(4) Install bolts attaching headlamp mounting

module to body (Fig. 10).

(5) Install inner fender liner.

(6) Install front fascia, refer to (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT FASCIA

- INSTALLATION).

LUGGAGE RACK

REMOVAL

NOTE: The skid strips are attached to the roof

panel with adhesive.

(1) Using a trim stick, or other suitable device, pry

support cover off.

(2) If necessary, slide the crossbars to expose the

screws attaching the slide rails to the supports.

(3) Remove the screws retaining the slide rails to

the supports.

Fig. 10 Headlamp Mounting Module

1 - CONNECTOR

2 - CONNECTOR3 - MOUNTING BRACKET

4 - HEADLAMP MODULE

23 - 30 EXTERIORWJ

GRILLE (Continued)

Page 1904 of 2199

(4) Remove the screws attaching the supports to

the roof panel.

(5) Separate the supports from the roof panel.

NOTE: If a crossbar needs to be serviced, the for-

ward or rearward supports will have to be removed.

INSTALLATION

(1) Position the supports on the roof panel and

install the screw. Be sure that the gasket is properly

seated.

(2) Position the luggage rack on the supports.

(3) Install the screws attaching the side rails to

the supports.

(4) Position the supports covers on the supports

and press into place.

SIDE VIEW MIRROR GLASS

REMOVAL

(1) With damaged mirror still on vehicle, position

mirror glass down and centered.

(2) Position a wide leverage device between the

bottom edge of the glass and the mirror shell.

(3) Firmly apply pressure in an upward direction

until glass assembly disengages from adapter plate.

(4) Disconnect the heater wire terminal, if

equipped, or the EC plug, if equipped.

INSTALLATION

(1) Connect the heater wire terminal or the EC

plug, if equipped.

(2) Position the replacement glass in the mirror

shell and align the four snap tabs with the four cav-

ities in the shell.

(3) Apply firm pressure inward until the replace-

ment glass assembly engages with the adapter plate.

Correct assembly will result in a firm click. Glass

assembly should exhibit even gaps to the shell when

complete.

(4) Pull lightly on corners of glass assembly to

ensure all four snaps are engaged and there is no

free play.

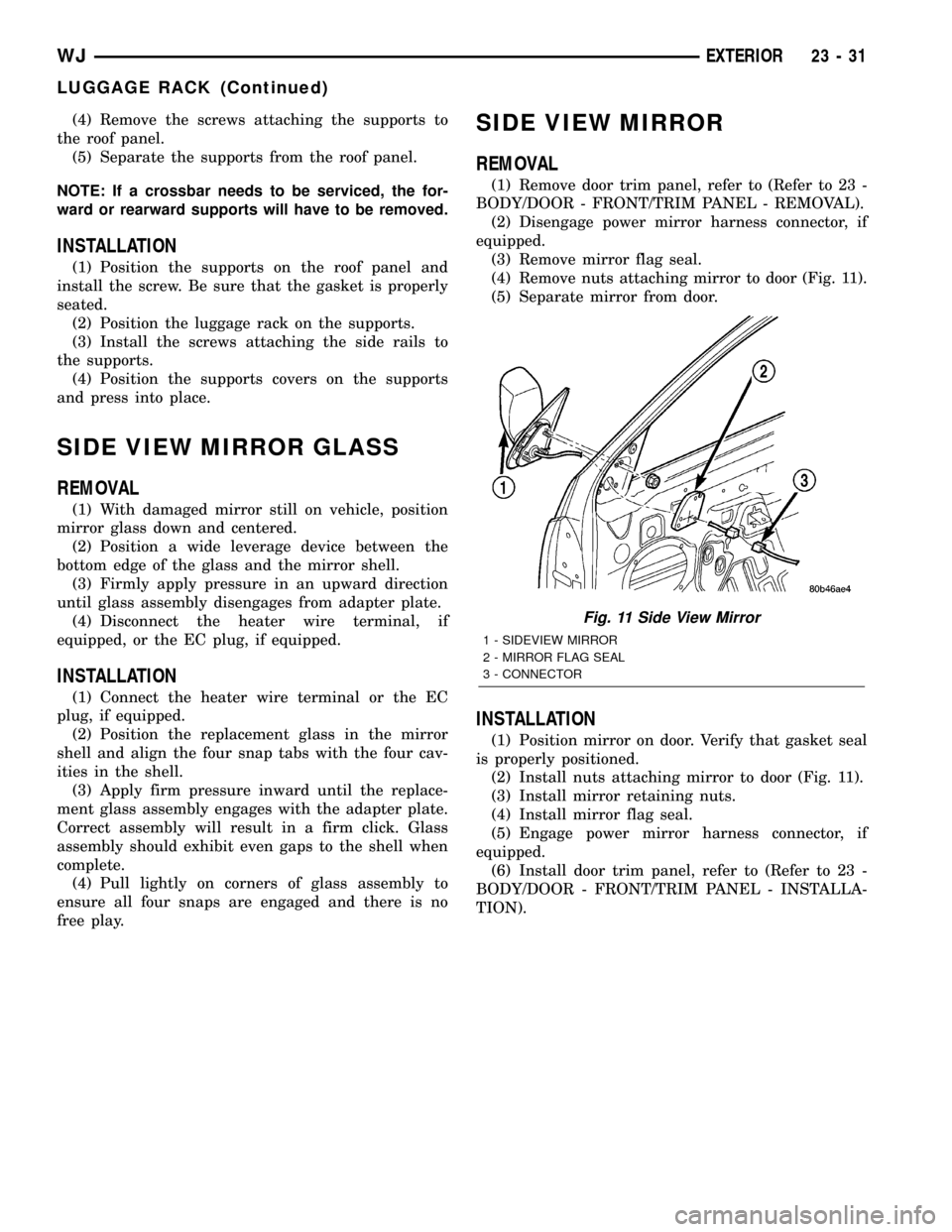

SIDE VIEW MIRROR

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Disengage power mirror harness connector, if

equipped.

(3) Remove mirror flag seal.

(4) Remove nuts attaching mirror to door (Fig. 11).

(5) Separate mirror from door.

INSTALLATION

(1) Position mirror on door. Verify that gasket seal

is properly positioned.

(2) Install nuts attaching mirror to door (Fig. 11).

(3) Install mirror retaining nuts.

(4) Install mirror flag seal.

(5) Engage power mirror harness connector, if

equipped.

(6) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

Fig. 11 Side View Mirror

1 - SIDEVIEW MIRROR

2 - MIRROR FLAG SEAL

3 - CONNECTOR

WJEXTERIOR 23 - 31

LUGGAGE RACK (Continued)

Page 1906 of 2199

HOOD

TABLE OF CONTENTS

page page

GAS PROP

REMOVAL.............................33

INSTALLATION.........................33

HINGE

REMOVAL.............................33

INSTALLATION.........................33

HOOD

REMOVAL.............................33

INSTALLATION.........................34

ADJUSTMENTS

HOOD ADJUSTMENT..................34INSULATION

REMOVAL.............................34

INSTALLATION.........................34

LATCH

REMOVAL.............................34

INSTALLATION.........................34

LATCH RELEASE CABLE

REMOVAL.............................35

INSTALLATION.........................35

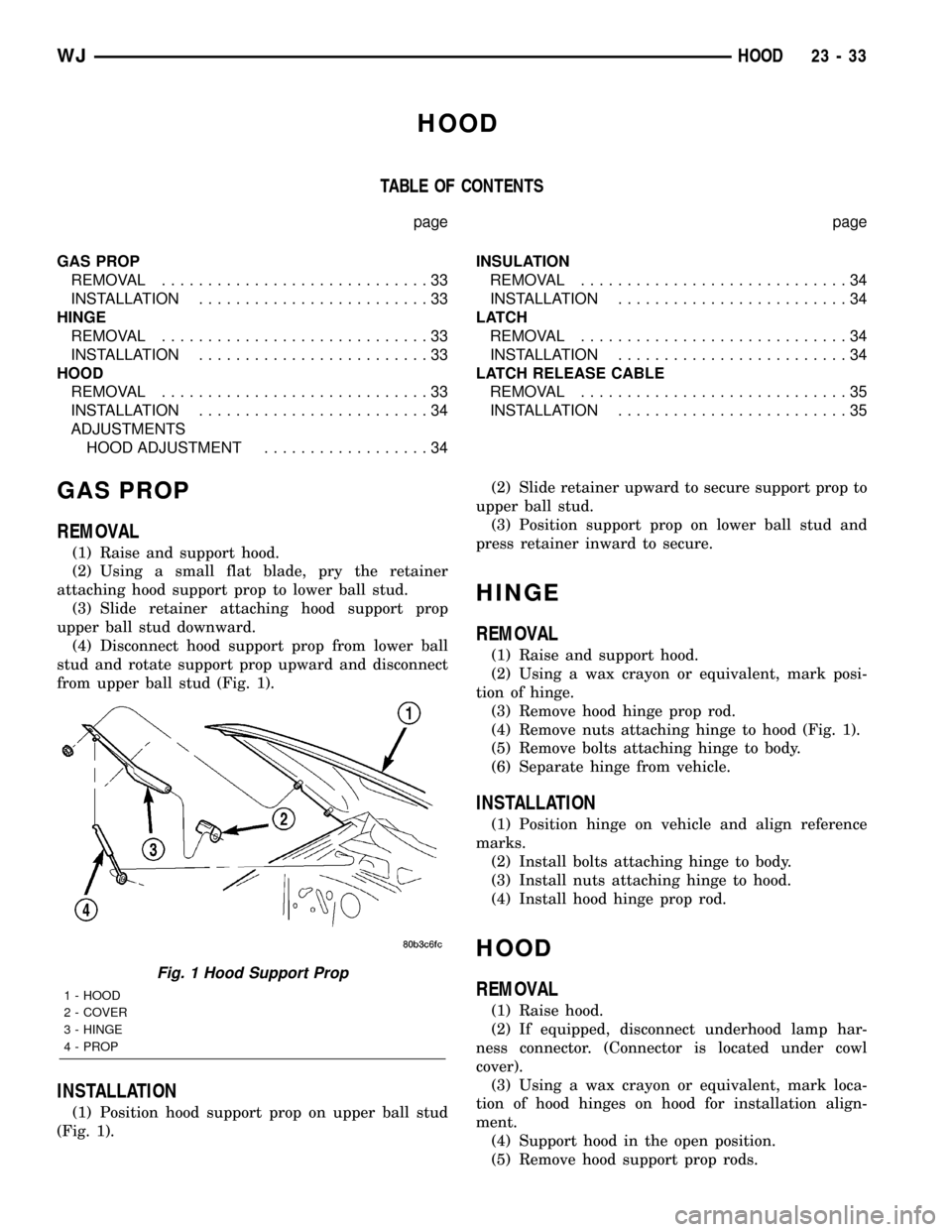

GAS PROP

REMOVAL

(1) Raise and support hood.

(2) Using a small flat blade, pry the retainer

attaching hood support prop to lower ball stud.

(3) Slide retainer attaching hood support prop

upper ball stud downward.

(4) Disconnect hood support prop from lower ball

stud and rotate support prop upward and disconnect

from upper ball stud (Fig. 1).

INSTALLATION

(1) Position hood support prop on upper ball stud

(Fig. 1).(2) Slide retainer upward to secure support prop to

upper ball stud.

(3) Position support prop on lower ball stud and

press retainer inward to secure.

HINGE

REMOVAL

(1) Raise and support hood.

(2) Using a wax crayon or equivalent, mark posi-

tion of hinge.

(3) Remove hood hinge prop rod.

(4) Remove nuts attaching hinge to hood (Fig. 1).

(5) Remove bolts attaching hinge to body.

(6) Separate hinge from vehicle.

INSTALLATION

(1) Position hinge on vehicle and align reference

marks.

(2) Install bolts attaching hinge to body.

(3) Install nuts attaching hinge to hood.

(4) Install hood hinge prop rod.

HOOD

REMOVAL

(1) Raise hood.

(2) If equipped, disconnect underhood lamp har-

ness connector. (Connector is located under cowl

cover).

(3) Using a wax crayon or equivalent, mark loca-

tion of hood hinges on hood for installation align-

ment.

(4) Support hood in the open position.

(5) Remove hood support prop rods.

Fig. 1 Hood Support Prop

1 - HOOD

2 - COVER

3 - HINGE

4 - PROP

WJHOOD 23 - 33

Page 1907 of 2199

(6) Remove bolts attaching hinges to hood.

(7) With the aid of a helper, remove hood from

vehicle.

INSTALLATION

(1) Position hood on hinges.

(2) Install bolts finger-tight.

(3) Align hinges with installation reference marks

and tighten bolts.

(4) Install hood support prop rods.

(5) Connect underhood lamp connector.

(6) Inspect hood for proper alignment and adjust

as necessary.

ADJUSTMENTS

HOOD ADJUSTMENT

The hood attaching holes are enlarged to aid front,

back and side to side adjustment.

(1) If hood is low in relation to cowl panel, insert

shims between hinge and hood.

(2) Adjust hood bumper in or out to adjust hood-

to-fender height alignment.

(3) Adjust the hood latch as necessary. Tighten the

nuts to 11N´m (8 ft. lbs.).

(4) Align the latch striker so that striker enters

the latch squarely and without binding.

INSULATION

REMOVAL

(1) Raise the hood.

(2) Remove the insulation panel fasteners.

(3) Remove the hood insulation panel.

INSTALLATION

(1) Position the insulation panel on the underside

of the hood.

(2) Install the insulation panel fasteners.

(3) Close the hood.

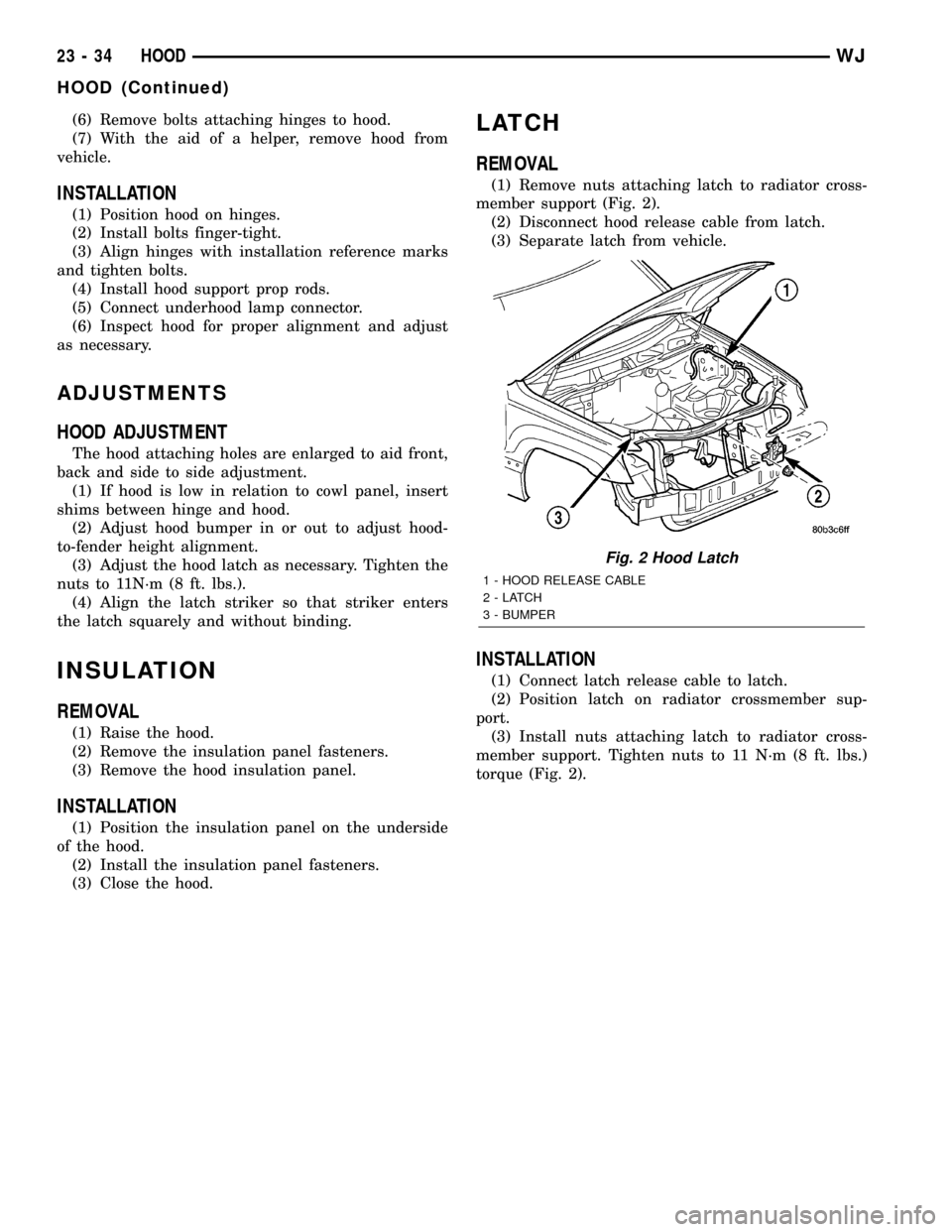

LATCH

REMOVAL

(1) Remove nuts attaching latch to radiator cross-

member support (Fig. 2).

(2) Disconnect hood release cable from latch.

(3) Separate latch from vehicle.

INSTALLATION

(1) Connect latch release cable to latch.

(2) Position latch on radiator crossmember sup-

port.

(3) Install nuts attaching latch to radiator cross-

member support. Tighten nuts to 11 N´m (8 ft. lbs.)

torque (Fig. 2).

Fig. 2 Hood Latch

1 - HOOD RELEASE CABLE

2-LATCH

3 - BUMPER

23 - 34 HOODWJ

HOOD (Continued)

Page 1911 of 2199

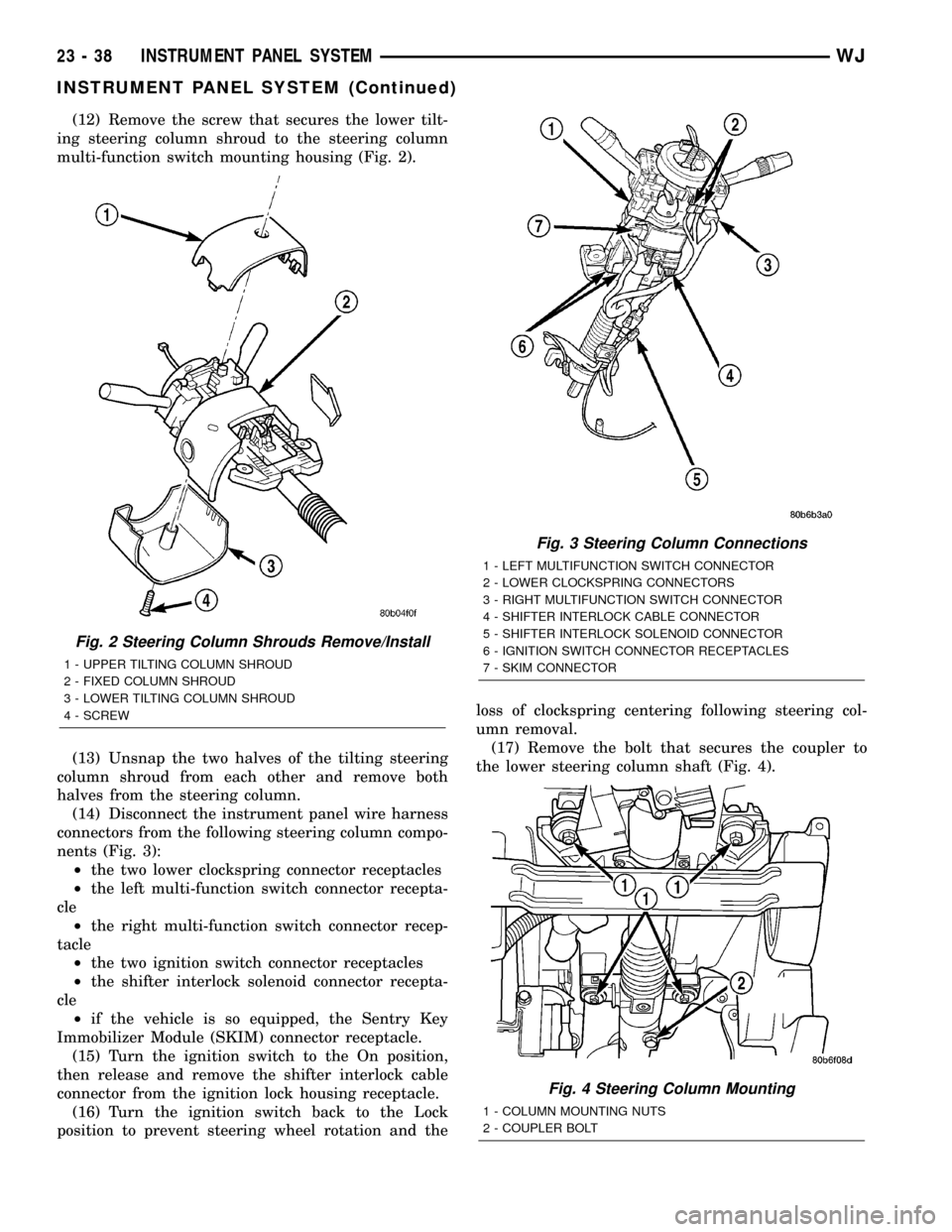

(12) Remove the screw that secures the lower tilt-

ing steering column shroud to the steering column

multi-function switch mounting housing (Fig. 2).

(13) Unsnap the two halves of the tilting steering

column shroud from each other and remove both

halves from the steering column.

(14) Disconnect the instrument panel wire harness

connectors from the following steering column compo-

nents (Fig. 3):

²the two lower clockspring connector receptacles

²the left multi-function switch connector recepta-

cle

²the right multi-function switch connector recep-

tacle

²the two ignition switch connector receptacles

²the shifter interlock solenoid connector recepta-

cle

²if the vehicle is so equipped, the Sentry Key

Immobilizer Module (SKIM) connector receptacle.

(15) Turn the ignition switch to the On position,

then release and remove the shifter interlock cable

connector from the ignition lock housing receptacle.

(16) Turn the ignition switch back to the Lock

position to prevent steering wheel rotation and theloss of clockspring centering following steering col-

umn removal.

(17) Remove the bolt that secures the coupler to

the lower steering column shaft (Fig. 4).

Fig. 2 Steering Column Shrouds Remove/Install

1 - UPPER TILTING COLUMN SHROUD

2 - FIXED COLUMN SHROUD

3 - LOWER TILTING COLUMN SHROUD

4 - SCREW

Fig. 3 Steering Column Connections

1 - LEFT MULTIFUNCTION SWITCH CONNECTOR

2 - LOWER CLOCKSPRING CONNECTORS

3 - RIGHT MULTIFUNCTION SWITCH CONNECTOR

4 - SHIFTER INTERLOCK CABLE CONNECTOR

5 - SHIFTER INTERLOCK SOLENOID CONNECTOR

6 - IGNITION SWITCH CONNECTOR RECEPTACLES

7 - SKIM CONNECTOR

Fig. 4 Steering Column Mounting

1 - COLUMN MOUNTING NUTS

2 - COUPLER BOLT

23 - 38 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL SYSTEM (Continued)

Page 1912 of 2199

(18) Remove the four nuts that secure the steering

column to the studs on the instrument panel steering

column support bracket.

(19) Remove the steering column from the instru-

ment panel. Be certain that the steering wheel is

locked and secured from rotation to prevent the loss

of clockspring centering.

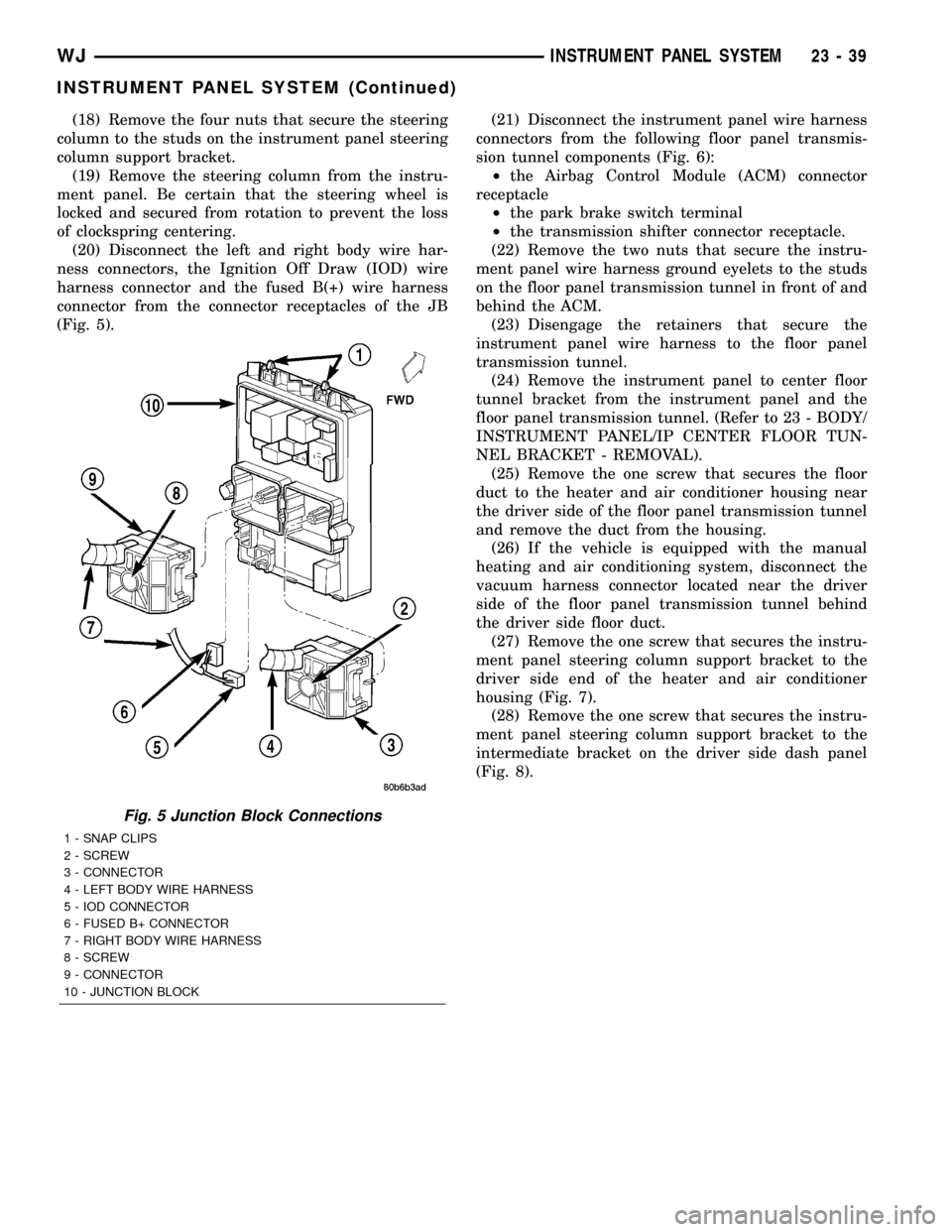

(20) Disconnect the left and right body wire har-

ness connectors, the Ignition Off Draw (IOD) wire

harness connector and the fused B(+) wire harness

connector from the connector receptacles of the JB

(Fig. 5).(21) Disconnect the instrument panel wire harness

connectors from the following floor panel transmis-

sion tunnel components (Fig. 6):

²the Airbag Control Module (ACM) connector

receptacle

²the park brake switch terminal

²the transmission shifter connector receptacle.

(22) Remove the two nuts that secure the instru-

ment panel wire harness ground eyelets to the studs

on the floor panel transmission tunnel in front of and

behind the ACM.

(23) Disengage the retainers that secure the

instrument panel wire harness to the floor panel

transmission tunnel.

(24) Remove the instrument panel to center floor

tunnel bracket from the instrument panel and the

floor panel transmission tunnel. (Refer to 23 - BODY/

INSTRUMENT PANEL/IP CENTER FLOOR TUN-

NEL BRACKET - REMOVAL).

(25) Remove the one screw that secures the floor

duct to the heater and air conditioner housing near

the driver side of the floor panel transmission tunnel

and remove the duct from the housing.

(26) If the vehicle is equipped with the manual

heating and air conditioning system, disconnect the

vacuum harness connector located near the driver

side of the floor panel transmission tunnel behind

the driver side floor duct.

(27) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

driver side end of the heater and air conditioner

housing (Fig. 7).

(28) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

intermediate bracket on the driver side dash panel

(Fig. 8).

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

WJINSTRUMENT PANEL SYSTEM 23 - 39

INSTRUMENT PANEL SYSTEM (Continued)