lock JEEP GRAND CHEROKEE 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2020Pages: 378, PDF Size: 6.88 MB

Page 211 of 378

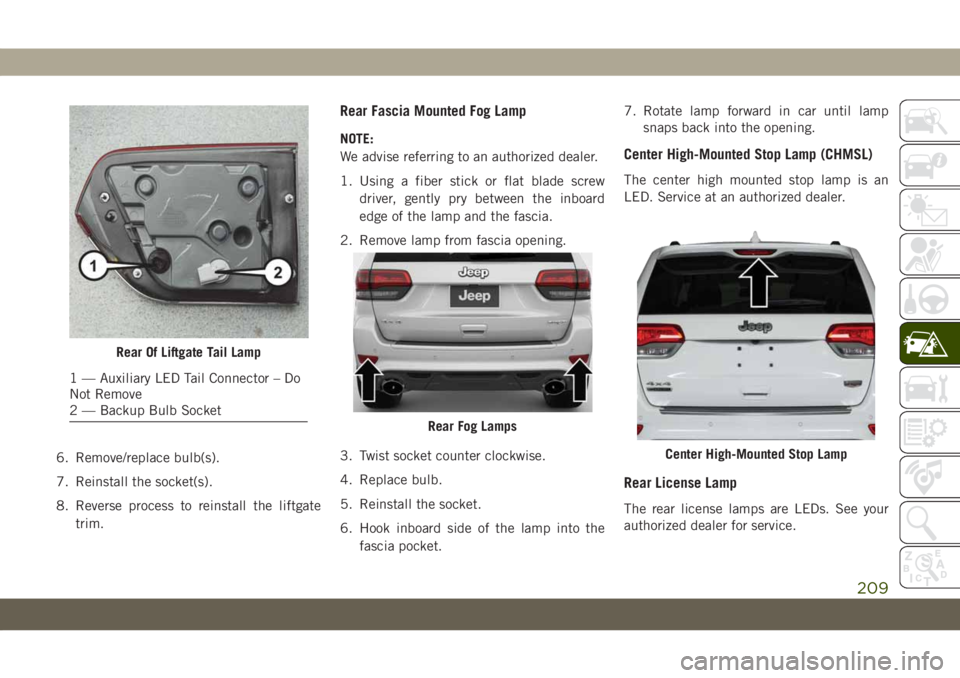

6. Remove/replace bulb(s).

7. Reinstall the socket(s).

8. Reverse process to reinstall the liftgate

trim.

Rear Fascia Mounted Fog Lamp

NOTE:

We advise referring to an authorized dealer.

1. Using a fiber stick or flat blade screw

driver, gently pry between the inboard

edge of the lamp and the fascia.

2. Remove lamp from fascia opening.

3. Twist socket counter clockwise.

4. Replace bulb.

5. Reinstall the socket.

6. Hook inboard side of the lamp into the

fascia pocket.7. Rotate lamp forward in car until lamp

snaps back into the opening.Center High-Mounted Stop Lamp (CHMSL)

The center high mounted stop lamp is an

LED. Service at an authorized dealer.

Rear License Lamp

The rear license lamps are LEDs. See your

authorized dealer for service.

Rear Of Liftgate Tail Lamp

1 — Auxiliary LED Tail Connector – Do

Not Remove

2 — Backup Bulb Socket

Rear Fog Lamps

Center High-Mounted Stop Lamp

209

Page 213 of 378

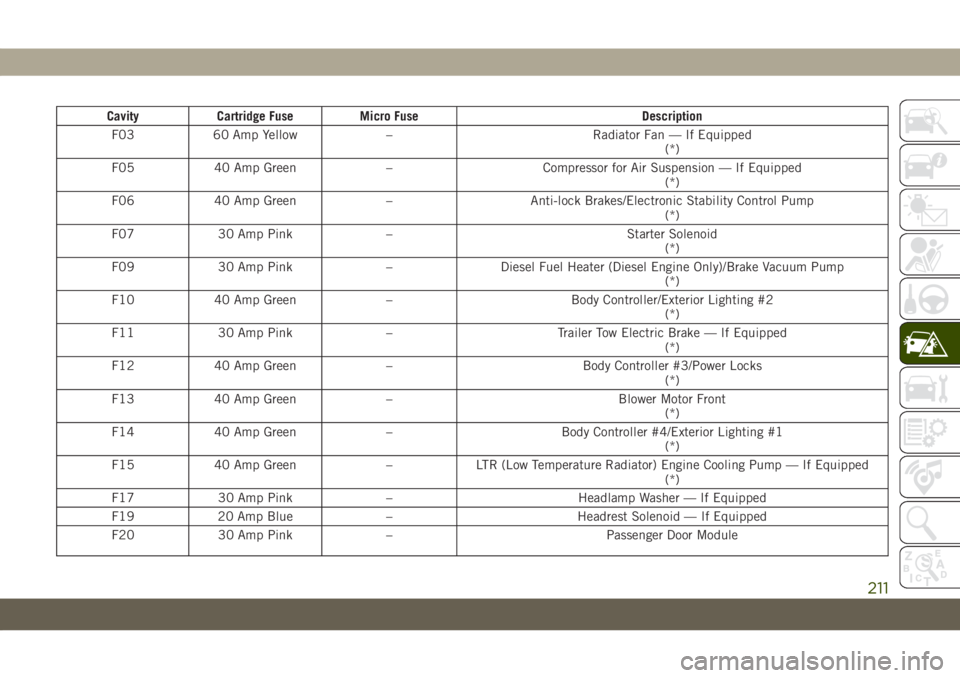

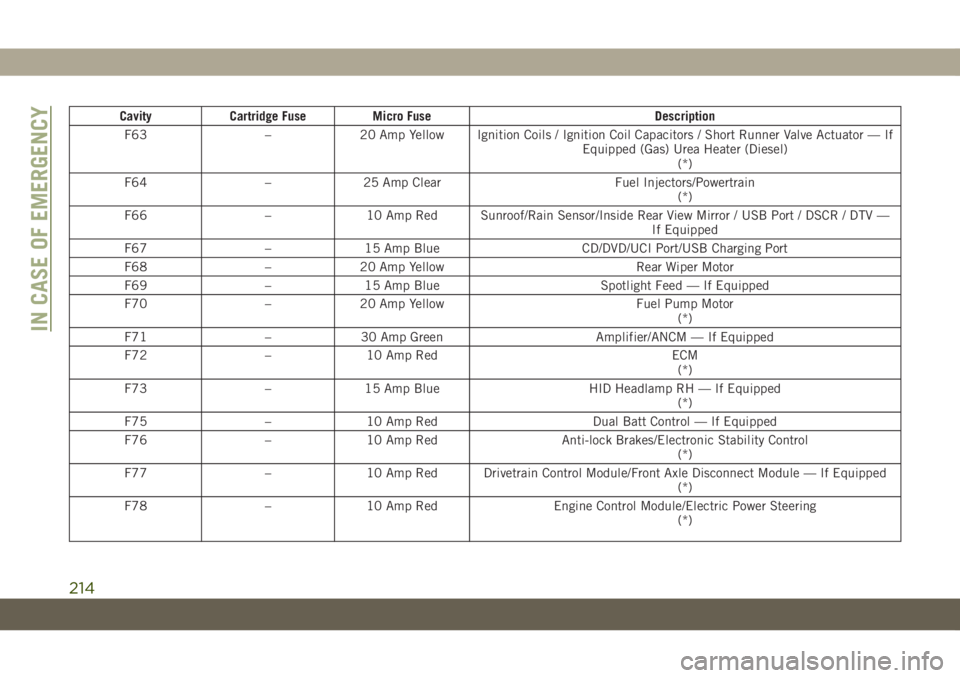

Cavity Cartridge Fuse Micro Fuse Description

F03 60 Amp Yellow – Radiator Fan — If Equipped

(*)

F05 40 Amp Green – Compressor for Air Suspension — If Equipped

(*)

F06 40 Amp Green – Anti-lock Brakes/Electronic Stability Control Pump

(*)

F07 30 Amp Pink – Starter Solenoid

(*)

F09 30 Amp Pink – Diesel Fuel Heater (Diesel Engine Only)/Brake Vacuum Pump

(*)

F10 40 Amp Green – Body Controller/Exterior Lighting #2

(*)

F11 30 Amp Pink – Trailer Tow Electric Brake — If Equipped

(*)

F12 40 Amp Green – Body Controller #3/Power Locks

(*)

F13 40 Amp Green – Blower Motor Front

(*)

F14 40 Amp Green – Body Controller #4/Exterior Lighting #1

(*)

F15 40 Amp Green – LTR (Low Temperature Radiator) Engine Cooling Pump — If Equipped

(*)

F17 30 Amp Pink – Headlamp Washer — If Equipped

F19 20 Amp Blue – Headrest Solenoid — If Equipped

F20 30 Amp Pink – Passenger Door Module

211

Page 214 of 378

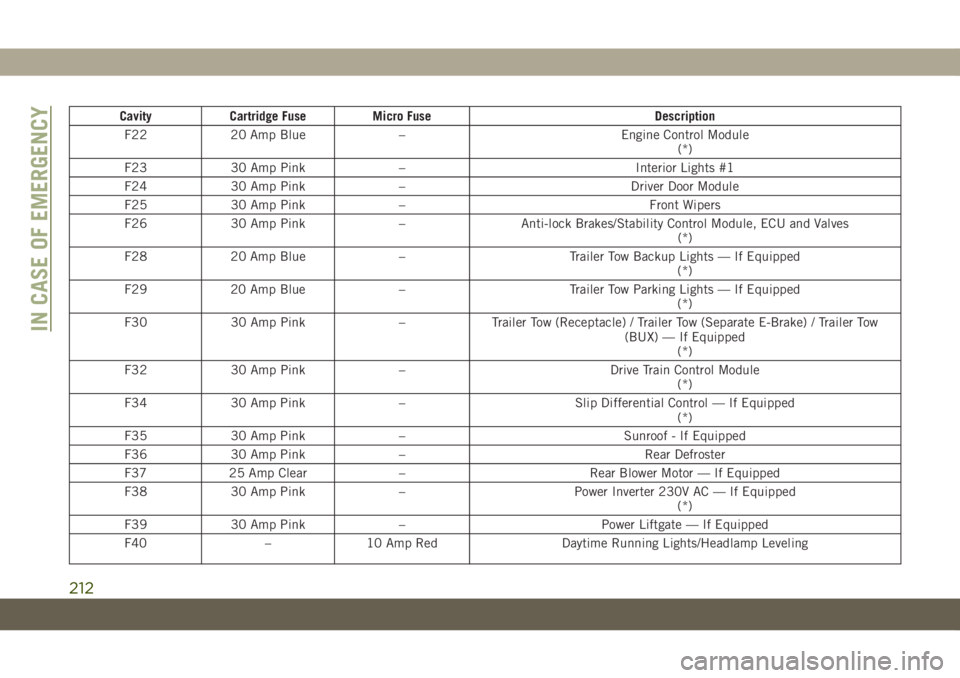

Cavity Cartridge Fuse Micro Fuse Description

F22 20 Amp Blue – Engine Control Module

(*)

F23 30 Amp Pink – Interior Lights #1

F24 30 Amp Pink – Driver Door Module

F25 30 Amp Pink – Front Wipers

F26 30 Amp Pink – Anti-lock Brakes/Stability Control Module, ECU and Valves

(*)

F28 20 Amp Blue – Trailer Tow Backup Lights — If Equipped

(*)

F29 20 Amp Blue – Trailer Tow Parking Lights — If Equipped

(*)

F30 30 Amp Pink – Trailer Tow (Receptacle) / Trailer Tow (Separate E-Brake) / Trailer Tow

(BUX) — If Equipped

(*)

F32 30 Amp Pink – Drive Train Control Module

(*)

F34 30 Amp Pink – Slip Differential Control — If Equipped

(*)

F35 30 Amp Pink – Sunroof - If Equipped

F36 30 Amp Pink – Rear Defroster

F37 25 Amp Clear – Rear Blower Motor — If Equipped

F38 30 Amp Pink – Power Inverter 230V AC — If Equipped

(*)

F39 30 Amp Pink – Power Liftgate — If Equipped

F40 – 10 Amp Red Daytime Running Lights/Headlamp Leveling

IN CASE OF EMERGENCY

212

Page 215 of 378

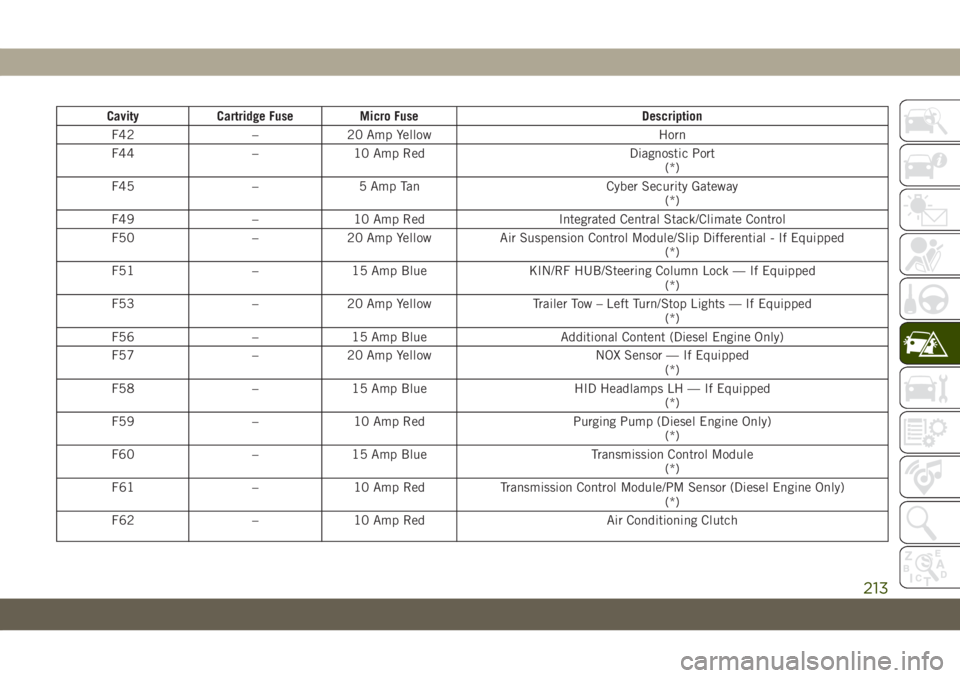

Cavity Cartridge Fuse Micro Fuse Description

F42 – 20 Amp Yellow Horn

F44 – 10 Amp Red Diagnostic Port

(*)

F45 – 5 Amp Tan Cyber Security Gateway

(*)

F49 – 10 Amp Red Integrated Central Stack/Climate Control

F50 – 20 Amp Yellow Air Suspension Control Module/Slip Differential - If Equipped

(*)

F51 – 15 Amp Blue KIN/RF HUB/Steering Column Lock — If Equipped

(*)

F53 – 20 Amp Yellow Trailer Tow – Left Turn/Stop Lights — If Equipped

(*)

F56 – 15 Amp Blue Additional Content (Diesel Engine Only)

F57 – 20 Amp Yellow NOX Sensor — If Equipped

(*)

F58 – 15 Amp Blue HID Headlamps LH — If Equipped

(*)

F59 – 10 Amp Red Purging Pump (Diesel Engine Only)

(*)

F60 – 15 Amp Blue Transmission Control Module

(*)

F61 – 10 Amp Red Transmission Control Module/PM Sensor (Diesel Engine Only)

(*)

F62 – 10 Amp Red Air Conditioning Clutch

213

Page 216 of 378

Cavity Cartridge Fuse Micro Fuse Description

F63 – 20 Amp Yellow Ignition Coils / Ignition Coil Capacitors / Short Runner Valve Actuator — If

Equipped (Gas) Urea Heater (Diesel)

(*)

F64 – 25 Amp Clear Fuel Injectors/Powertrain

(*)

F66 – 10 Amp Red Sunroof/Rain Sensor/Inside Rear View Mirror / USB Port / DSCR / DTV —

If Equipped

F67 – 15 Amp Blue CD/DVD/UCI Port/USB Charging Port

F68 – 20 Amp Yellow Rear Wiper Motor

F69 – 15 Amp Blue Spotlight Feed — If Equipped

F70 – 20 Amp Yellow Fuel Pump Motor

(*)

F71 – 30 Amp Green Amplifier/ANCM — If Equipped

F72 – 10 Amp Red ECM

(*)

F73 – 15 Amp Blue HID Headlamp RH — If Equipped

(*)

F75 – 10 Amp Red Dual Batt Control — If Equipped

F76 – 10 Amp Red Anti-lock Brakes/Electronic Stability Control

(*)

F77 – 10 Amp Red Drivetrain Control Module/Front Axle Disconnect Module — If Equipped

(*)

F78 – 10 Amp Red Engine Control Module/Electric Power Steering

(*)

IN CASE OF EMERGENCY

214

Page 220 of 378

Preparations For Jacking

CAUTION!

Always lift or jack the vehicle from the

correct jacking points. Failure to follow

this information could cause damage to

the vehicle or underbody components.

NOTE:

To assist with changing a spare tire, the air

suspension system (if equipped) has a fea-

ture which allows the automatic leveling to

be disabled.

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery surfaces.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.4. Place the gear selector into PARK.

5. Turn the ignition OFF.

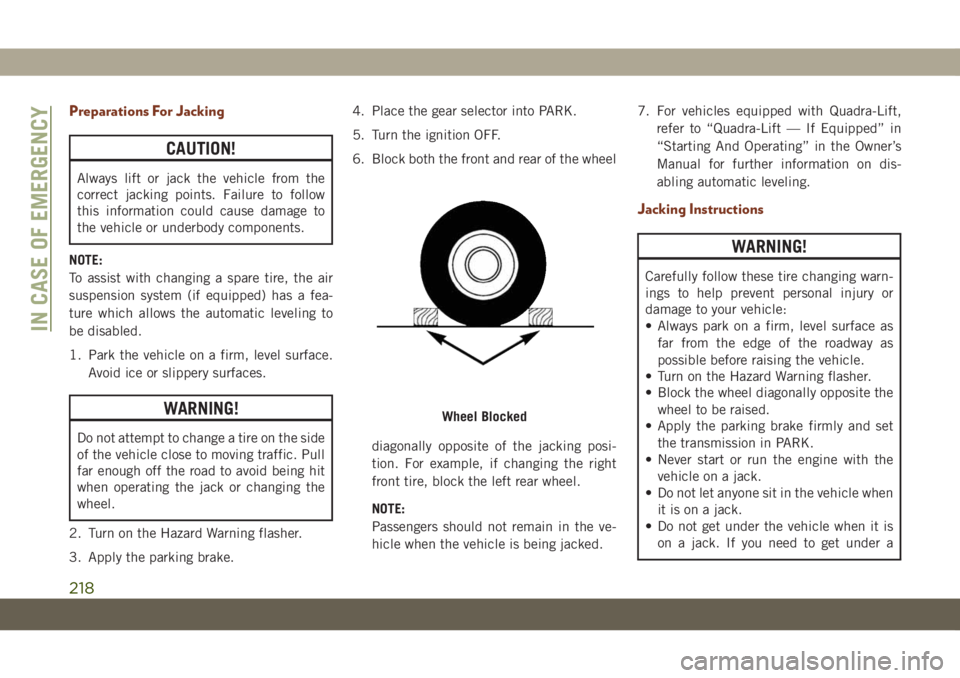

6. Block both the front and rear of the wheel

diagonally opposite of the jacking posi-

tion. For example, if changing the right

front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the ve-

hicle when the vehicle is being jacked.7. For vehicles equipped with Quadra-Lift,

refer to “Quadra-Lift — If Equipped” in

“Starting And Operating” in the Owner’s

Manual for further information on dis-

abling automatic leveling.

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Apply the parking brake firmly and set

the transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

Wheel Blocked

IN CASE OF EMERGENCY

218

Page 222 of 378

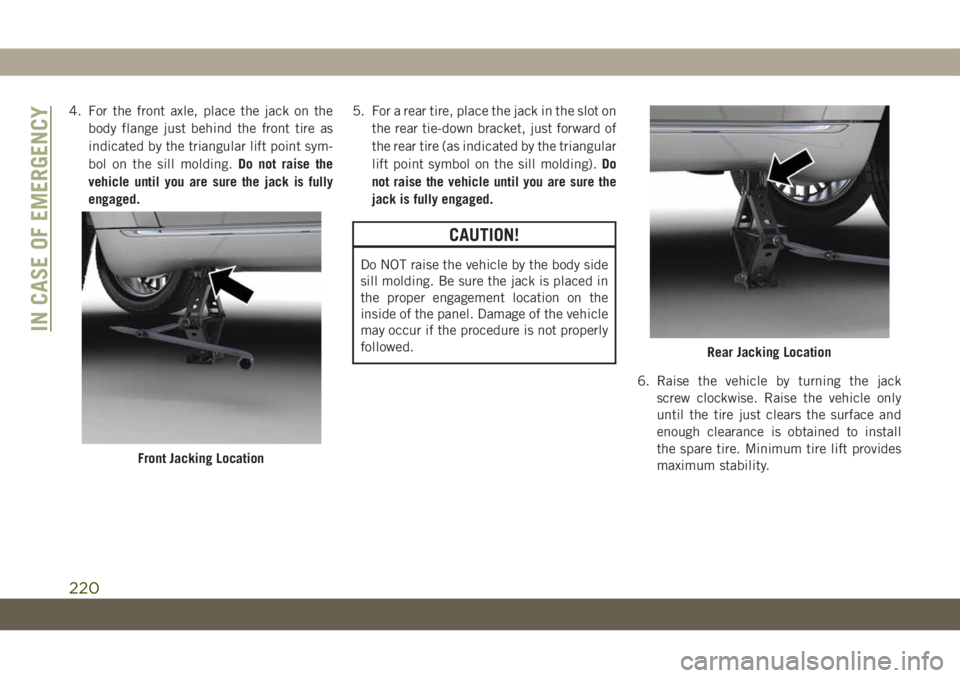

4. For the front axle, place the jack on the

body flange just behind the front tire as

indicated by the triangular lift point sym-

bol on the sill molding.Do not raise the

vehicle until you are sure the jack is fully

engaged.5. For a rear tire, place the jack in the slot on

the rear tie-down bracket, just forward of

the rear tire (as indicated by the triangular

lift point symbol on the sill molding).Do

not raise the vehicle until you are sure the

jack is fully engaged.

CAUTION!

Do NOT raise the vehicle by the body side

sill molding. Be sure the jack is placed in

the proper engagement location on the

inside of the panel. Damage of the vehicle

may occur if the procedure is not properly

followed.

6. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

Front Jacking Location

Rear Jacking Location

IN CASE OF EMERGENCY

220

Page 223 of 378

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the lug nuts and wheel.

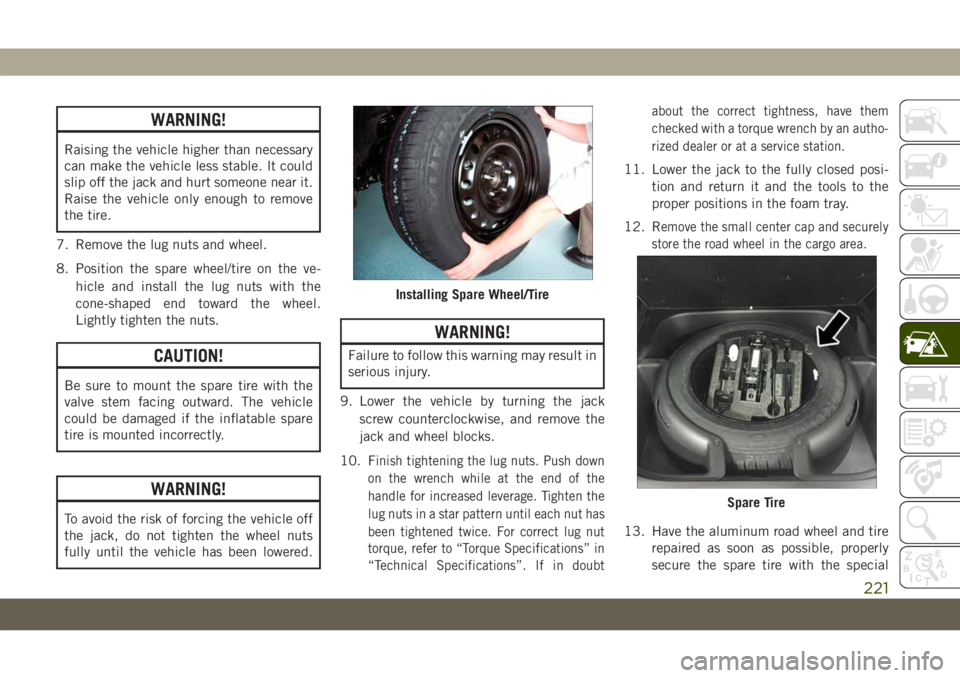

8. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the nuts.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the inflatable spare

tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

WARNING!

Failure to follow this warning may result in

serious injury.

9. Lower the vehicle by turning the jack

screw counterclockwise, and remove the

jack and wheel blocks.

10. F

inish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut has

been tightened twice. For correct lug nut

torque, refer to “Torque Specifications” in

“Technical Specifications”. If in doubtabout the correct tightness, have them

checked with a torque wrench by an autho-

rized dealer or at a service station.

11. Lower the jack to the fully closed posi-

tion and return it and the tools to the

proper positions in the foam tray.

12. R

emove the small center cap and securely

store the road wheel in the cargo area.

13. Have the aluminum road wheel and tire

repaired as soon as possible, properly

secure the spare tire with the special

Installing Spare Wheel/Tire

Spare Tire

221

Page 224 of 378

wing nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit foam tray,

and latch the rear load floor cover.

NOTE:

Do not drive with the spare tire installed for

more than 50 miles (80 km) at a max speed

of 50 mph (80 km/h).

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Refer to “Torque Specifications” in

“Technical Specifications” for proper lug

nut torque.

5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

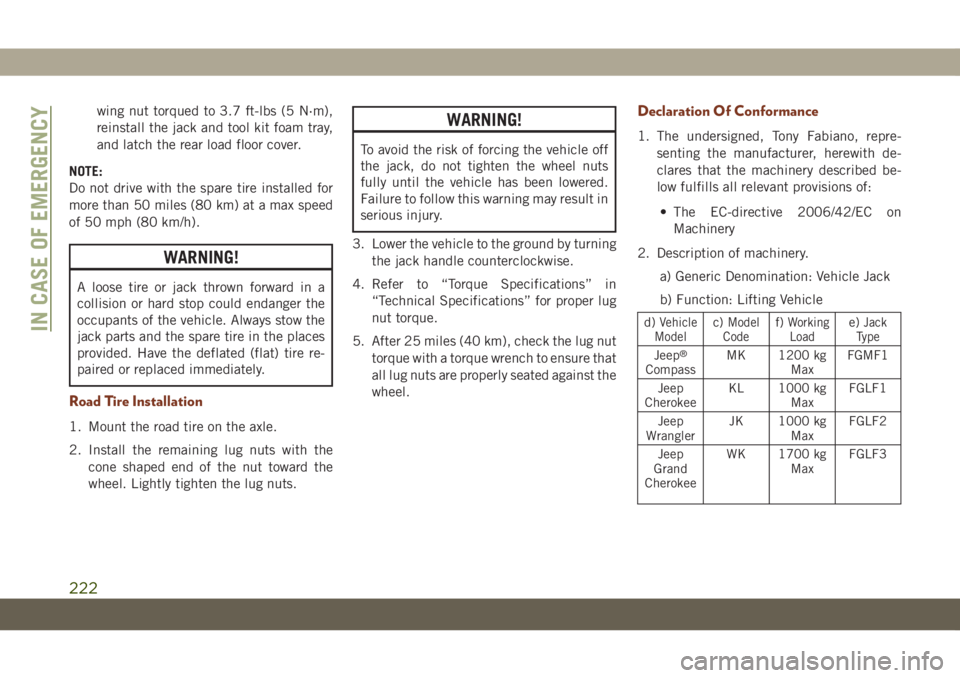

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described be-

low fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d)Vehicle

Modelc)Model

Codef)Working

Loade)Jack

Type

Jeep®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

IN CASE OF EMERGENCY

222

Page 232 of 378

CAUTION!

Closing the armrest while the Manual Park

Release is activated may damage the

Manual Park Release mechanism, the

transmission, and/or the armrest.

NOTE:

To prevent the vehicle from rolling uninten-

tionally, firmly apply the parking brake.To Disengage The Manual Park Release Le-

ver:

1. To disengage the Manual Park Release,

apply tension upward while pushing the

release latch towards the tether to unlock

the lever.

2. Once the tension has been released and

the lever has been unlocked, be sure it is

stowed properly and locks into position.

NOTE:

Be sure to replace the cover by snapping it

back in place.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Push and hold the lock button on the gear

selector. Then, shift back and forth between

DRIVE and REVERSE while gently pressing

the accelerator.NOTE:

Shifts between DRIVE and REVERSE can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL for more than two sec-

onds, you must press the brake pedal to

engage DRIVE or REVERSE.

Use the least amount of accelerator pedal

pressure that will maintain the rocking mo-

tion without spinning the wheels or racing the

engine.

NOTE:

Push the "ESC Off" switch, to place the Elec-

tronic Stability Control (ESC) system in "Par-

tial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control” in

“Safety” in your Owner’s Manual for further

information. Once the vehicle has been

freed, push the "ESC Off" switch again to

restore "ESC On" mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

Released Position

IN CASE OF EMERGENCY

230