lock JEEP GRAND CHEROKEE 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2020Pages: 378, PDF Size: 6.88 MB

Page 194 of 378

• If containers which can be screwed to the

filler are used, the reservoir is full when the

AdBlue

®level in the container stops pour-

ing out. Do not proceed further.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Operations After Refilling

Proceed as follows:

• Fit the cap back on the AdBlue

®filler by

turning it clockwise and screwing it com-

pletely.

• Cycle the ignition to RUN (it is not neces-

sary to start the engine).

• Wait for the indication on the instrument

panel to switch off before moving the car.

The indication may stay on for a few sec-

onds to approximately half a minute. If the

engine is started and the car is moved, the

indication will remain on for longer. This

will not compromise engine operation.• If the AdBlue

®was topped up when the

tank was empty, wait for 2 minutes before

starting the engine.

NOTE:

• If AdBlue

®is spilled out of the filler neck,

clean up well the area and proceed to filling

up again. If the liquid crystallizes, elimi-

nate it with a sponge and warm water.

• DO NOT EXCEED THE MAXIMUM LEVEL:

this could cause damage to the reservoir.

AdBlue

®freezes at under 12° F (-11° C).

Although the system is designed to operate

below the freezing point of the AdBlue

®,it

is advisable not to fill the tank beyond the

maximum level because if the AdBlue

®

freezes the system can be damaged. Follow

the instructions in this section.

• If the AdBlue

®is spilled on painted sur-

faces or aluminium, immediately clean the

area with water and use absorbent material

to collect the fluid that has been spilled on

the ground.

• Do not try to start the engine if AdBlue

®

was accidentally added to the diesel fuel

tank, this can result in serious engine dam-

age, contact an authorized dealer.• Do not add additives or other fluids to

AdBlue

®, doing so could damage the

system.

• The use of non-conforming or degraded

AdBlue

®may lead to indications appearing

on the instrument panel display refer to

“Warning Lights And Messages" in the

“Getting To Know Your Instrument Panel”

for further information.

• Never pour AdBlue

®into another con-

tainer: it could be contaminated.

• If the AdBlue

®runs out, see refer to “Warn-

ing Lights And Messages" in the “Getting To

Know Your Instrument Panel” for further

information to continue using the car

normally.

TRAILER TOWING

Trailer Towing Weights (Maximum Trailer

Weight Ratings) — Non SRT

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain.

STARTING AND OPERATING

192

Page 196 of 378

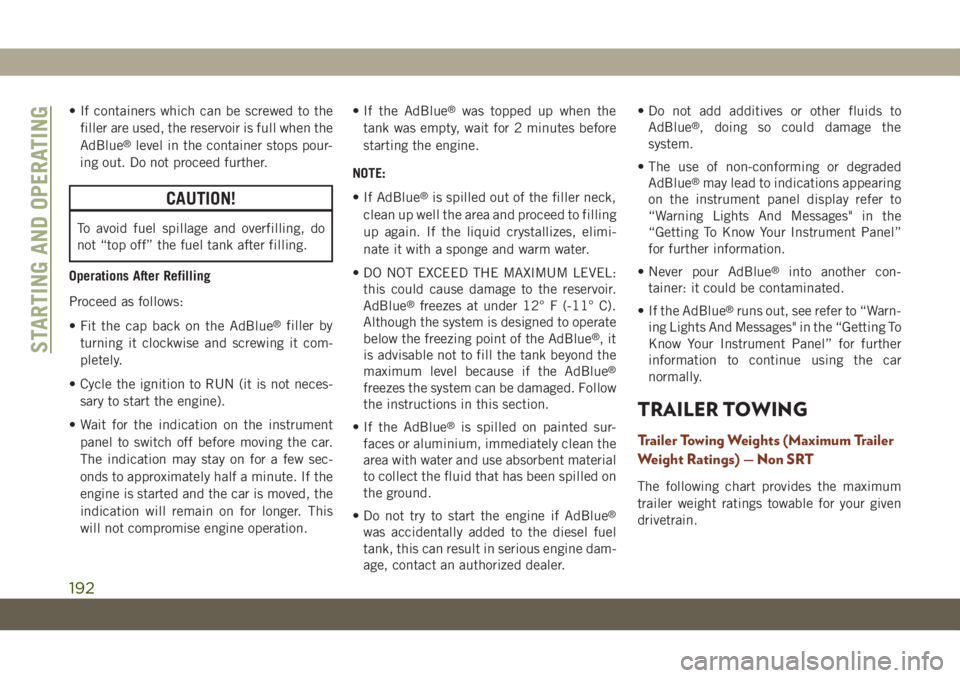

Trailer Towing Weights (Maximum Trailer

Weight Ratings) — SRT

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain.

Engine/Transmission GCWR (Gross Combined

Wt. Rating)Frontal Area Max. GTW (Gross Trailer

Wt.)Max. Trailer Tongue Wt.

(See Note)

6.2L Supercharged Automatic 13,099 lbs (5,942 kg) 55 sq ft (5.11 sq m) 6,500 lbs (2,949 kg) 324 lbs (147 kg)

6.4L Automatic 13,002 lbs (5,898 kg) 55 sq ft (5.11 sq m) 6,500 lbs (2,949 kg) 324 lbs (147 kg)

When towing a trailer the technically permissible laden weight may be exceeded by not more than 10% or 220 lbs (100 kg), whichever is lower

provided that the operating speed is restricted to 62 mph (100 km/h) or less.

Refer to local laws for maximum trailer towing speeds.

NOTE:

The trailer tongue weight must be considered

as part of the combined weight of occupants

and cargo, and should never exceed the

weight referenced on the Tire and Loading

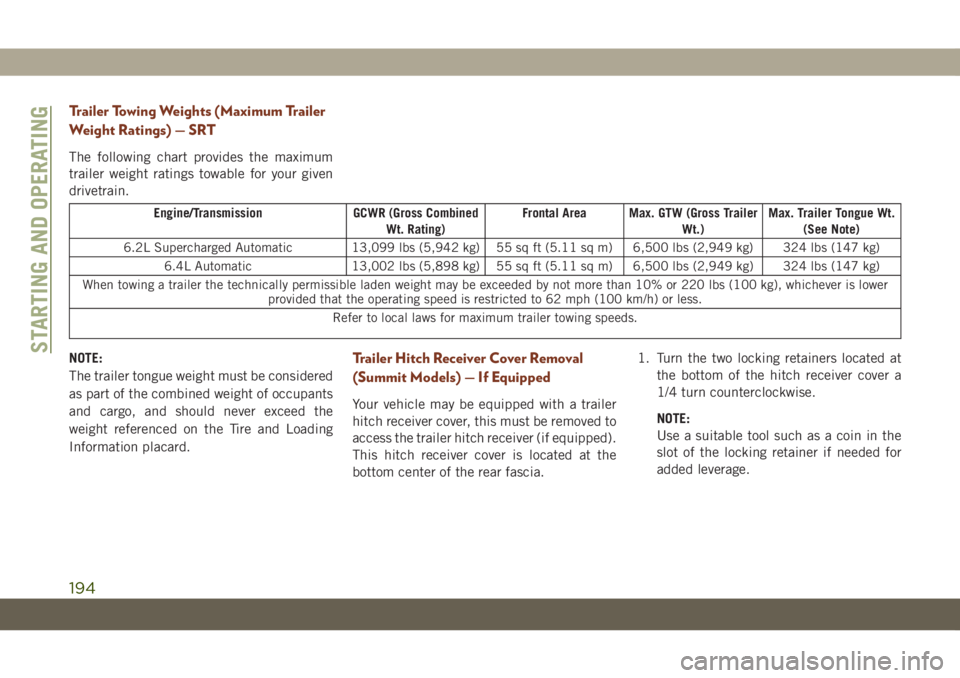

Information placard.Trailer Hitch Receiver Cover Removal

(Summit Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

added leverage.

STARTING AND OPERATING

194

Page 197 of 378

2. Pull the bottom of the cover outward (to-

wards you), pull downwards to disengage

the tabs located at the top of the hitch

receiver cover.To reinstall the hitch receiver cover after

towing repeat the procedure in reverse order.NOTE:

Be sure to engage all tabs of the hitch re-

ceiver cover in the bumper fascia prior to

installation.

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

Hitch Receiver Cover

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

195

Page 198 of 378

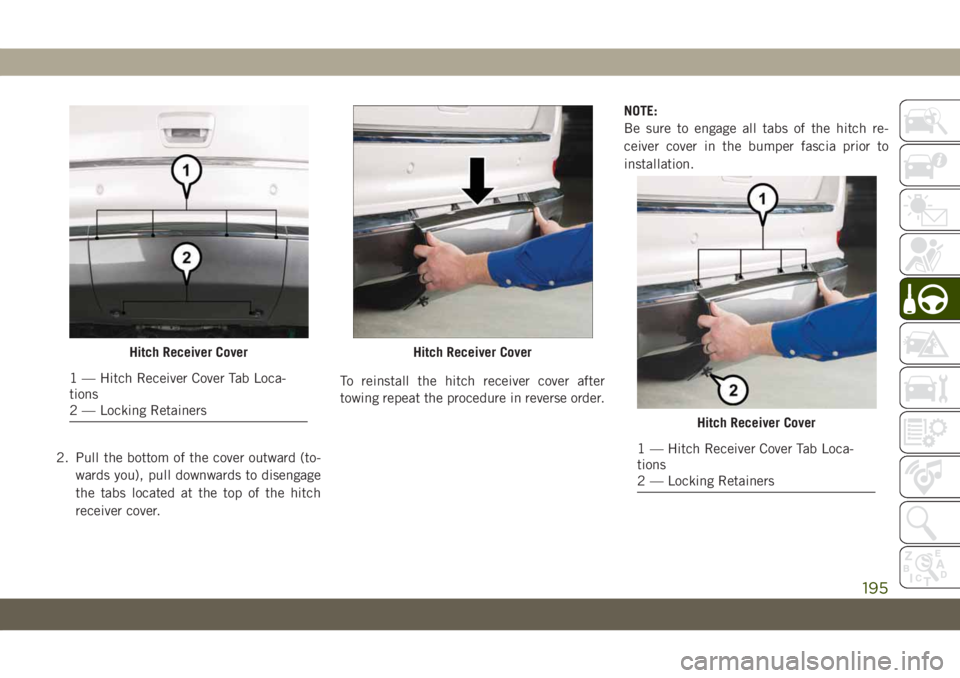

Trailer Hitch Receiver Cover Removal

(SRT Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.

1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

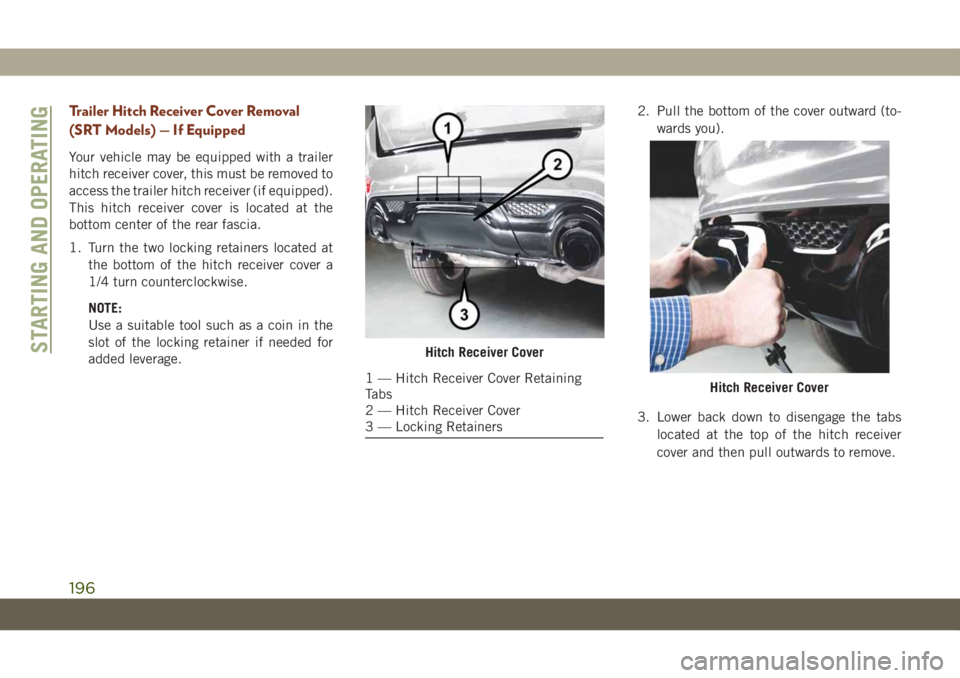

added leverage.2. Pull the bottom of the cover outward (to-

wards you).

3. Lower back down to disengage the tabs

located at the top of the hitch receiver

cover and then pull outwards to remove.

Hitch Receiver Cover

1 — Hitch Receiver Cover Retaining

Tabs

2 — Hitch Receiver Cover

3 — Locking RetainersHitch Receiver Cover

STARTING AND OPERATING

196

Page 199 of 378

To reinstall the hitch receiver cover after

towing repeat the procedure in reverse order.NOTE:

Be sure to engage all tabs of the hitch re-

ceiver cover in the bumper fascia prior to

installation.

Hitch Receiver Cover

1 — Hitch Receiver Cover Retaining

Tabs

2 — Hitch Receiver Cover

3 — Locking Retainer

197

Page 201 of 378

Recreational Towing — Two Wheel Drive

Models

DO NOT flat tow this vehicle. Damage to the

drivetrain will result.

Recreational towing (for two-wheel drive

models) is allowed ONLY if the rear wheels

are OFF the ground. This may be accom-

plished using a tow dolly or vehicle trailer. If

using a tow dolly, follow this procedure:

1. Properly secure the dolly to the tow ve-

hicle, following the dolly manufacturer's

instructions.

NOTE:

If vehicle is equipped with Quadra-Lift air

suspension, ensure the vehicle is set to

Normal Ride Height.

2. Drive the rear wheels onto the tow dolly.

3. Firmly apply the parking brake. Shift the

transmission into PARK.

4. Turn the ignition OFF.

5. Properly secure the rear wheels to the

dolly, following the dolly manufacturer’s

instructions.6. Turn the ignition to the ON/RUN mode,

but do not start the engine.

7. Confirm that the steering column is

unlocked.

8. Install a suitable clamping device, de-

signed for towing, to secure the front

wheels in the straight position.

9. Disconnect the negative battery cable,

and secure it away from the battery post.

NOTE:

Disconnecting your vehicle battery will

erase radio presets and may affect other

vehicle settings. It may also trigger vari-

ous fault codes, causing MIL illumination

when the battery is reconnected.

CAUTION!

Towing with the rear wheels on the ground

will cause severe transmission damage.

Damage from improper towing is not cov-

ered under the New Vehicle Limited

Warranty.

Recreational Towing — Quadra-Trac I

(Single-Speed Transfer Case) Four-Wheel

Drive Models

Recreational towing is not allowed.These

models do not have a NEUTRAL (N) position

in the transfer case.

NOTE:

This vehicle may be towed on a flatbed or

vehicle trailer provided all four wheels areOFF

the ground.

CAUTION!

Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or transfer case damage.

Damage from improper towing is not cov-

ered under the New Vehicle Limited

Warranty.

199

Page 203 of 378

5. Using a ballpoint pen or similar object,

push and hold the recessed transfer case

NEUTRAL (N) button (located by the se-

lector switch) for four seconds. The light

behind the N symbol will blink, indicating

shift in progress. The light will stop blink-

ing (stay on solid) when the shift to NEU-

TRAL (N) is complete. A “FOUR WHEEL

DRIVE SYSTEM IN NEUTRAL” message

will appear in the instrument cluster.

6. After the shift is completed and the NEU-

TRAL (N) light stays on, release the NEU-

TRAL (N) button.

7. Shift the transmission into REVERSE.8. Release the brake pedal for five seconds

and ensure that there is no vehicle

movement.

9. Press and hold the brake pedal. Shift the

transmission back into NEUTRAL.

10. Firmly apply the parking brake.

11. With the transmission and transfer case

in NEUTRAL, push and hold the EN-

GINE START/STOP button until the en-

gine turns off.

12. Place the transmission gear selector in

PARK. Release the brake pedal.

13. Push the ENGINE STOP/START button

twice (without pressing the brake pedal),

to turn the ignition to the OFF mode.

14. Attach the vehicle to the tow vehicle

using a suitable tow bar.

15. Release the parking brake.

16. Turn the ignition to the ON/RUN posi-

tion, but do not start the engine.

17. Confirm that the steering column is

unlocked.18. Disconnect the negative battery cable,

and secure it away from the negative

battery post.

NOTE:

Disconnecting your vehicle battery will

erase radio presets and may affect other

vehicle settings. It may also trigger vari-

ous fault codes, causing MIL illumination

when the battery is reconnected.

NOTE:

• Steps 1 through 4 are requirements that

must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, then the NEU-

TRAL (N) indicator light will flash continu-

ously until all requirements are met or until

the NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

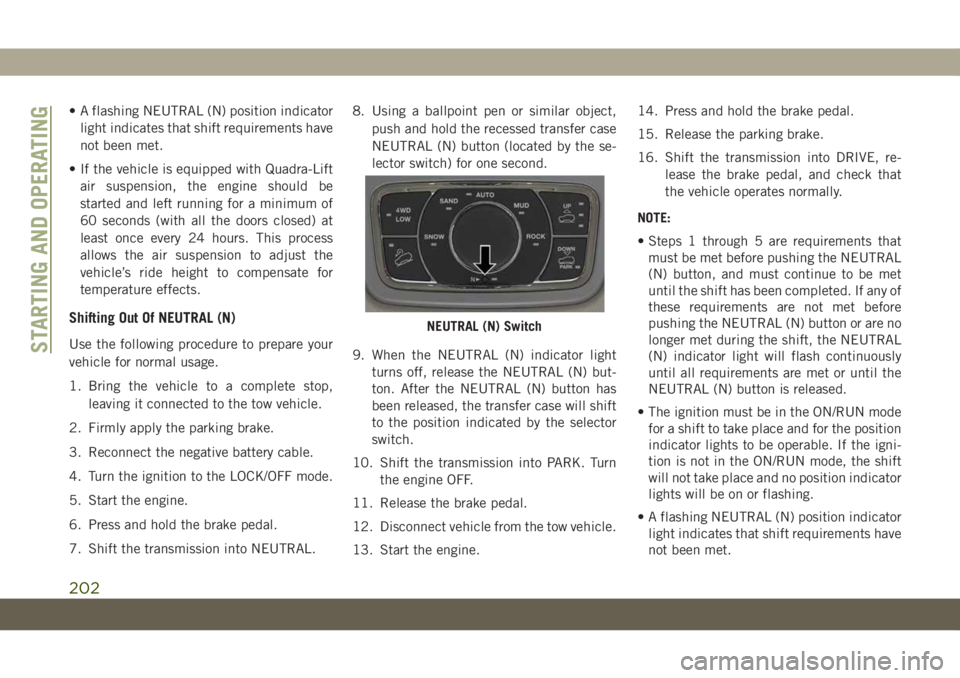

NEUTRAL (N) Switch

201

Page 204 of 378

• A flashing NEUTRAL (N) position indicator

light indicates that shift requirements have

not been met.

• If the vehicle is equipped with Quadra-Lift

air suspension, the engine should be

started and left running for a minimum of

60 seconds (with all the doors closed) at

least once every 24 hours. This process

allows the air suspension to adjust the

vehicle’s ride height to compensate for

temperature effects.

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage.

1. Bring the vehicle to a complete stop,

leaving it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Reconnect the negative battery cable.

4. Turn the ignition to the LOCK/OFF mode.

5. Start the engine.

6. Press and hold the brake pedal.

7. Shift the transmission into NEUTRAL.8. Using a ballpoint pen or similar object,

push and hold the recessed transfer case

NEUTRAL (N) button (located by the se-

lector switch) for one second.

9. When the NEUTRAL (N) indicator light

turns off, release the NEUTRAL (N) but-

ton. After the NEUTRAL (N) button has

been released, the transfer case will shift

to the position indicated by the selector

switch.

10. Shift the transmission into PARK. Turn

the engine OFF.

11. Release the brake pedal.

12. Disconnect vehicle from the tow vehicle.

13. Start the engine.14. Press and hold the brake pedal.

15. Release the parking brake.

16. Shift the transmission into DRIVE, re-

lease the brake pedal, and check that

the vehicle operates normally.

NOTE:

• Steps 1 through 5 are requirements that

must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, the NEUTRAL

(N) indicator light will flash continuously

until all requirements are met or until the

NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator

light indicates that shift requirements have

not been met.

NEUTRAL (N) Switch

STARTING AND OPERATING

202

Page 209 of 378

CAUTION!

• Always use the correct bulb size and type

for replacement. An incorrect bulb size

or type may overheat and cause damage

to the lamp, the bulb socket, or the lamp

wiring.

4. Turn the low or high beam bulb one–

quarter turn counterclockwise to remove

from housing.

5. Disconnect the electrical connector and

replace the bulb.

Front Turn Signal Lamp

SRT vehicles are equipped with front turn

signal lamps are LEDs. See your authorized

dealer for service.

NOTE:

We advise referring to an authorized dealer.

1. Open the hood.

2. Access the back of the headlamp.NOTE:

• The air filter housing must be removed.

• The windshield washer reservoir may

need to be rotated out of the way by

removing the fastener.

• Coolant reservoir (if equipped) will

need to be repositioned by removing the

fasteners, and moving the unit out of

the way.

3. Turn the turn signal bulb one–quarter turn

counterclockwise to remove from housing.

4. Disconnect the electrical connector and

replace the bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

Please see your authorized dealer for service.

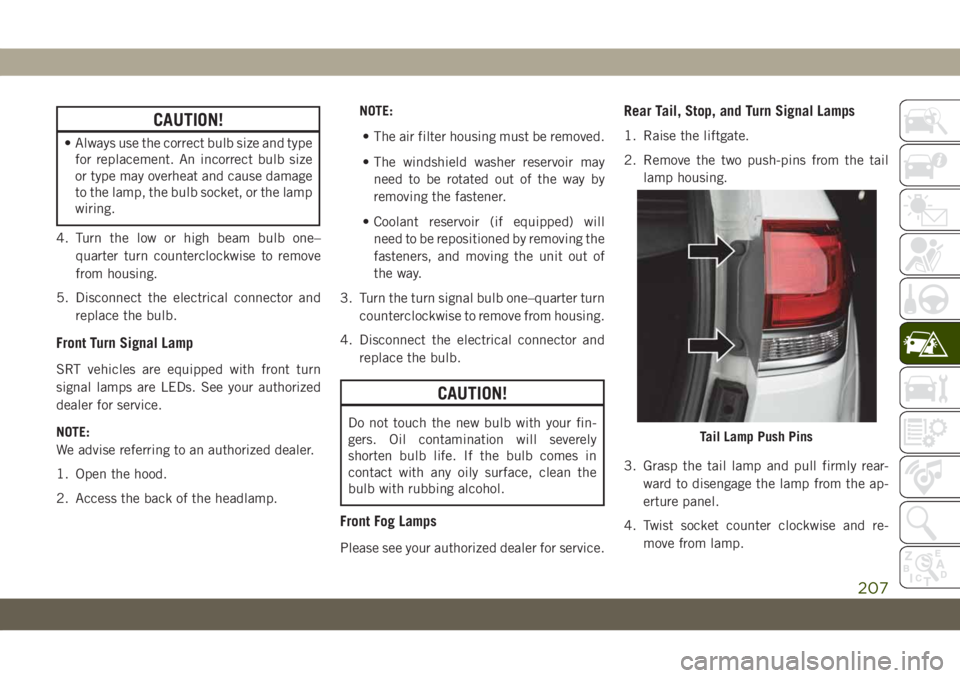

Rear Tail, Stop, and Turn Signal Lamps

1. Raise the liftgate.

2. Remove the two push-pins from the tail

lamp housing.

3. Grasp the tail lamp and pull firmly rear-

ward to disengage the lamp from the ap-

erture panel.

4. Twist socket counter clockwise and re-

move from lamp.

Tail Lamp Push Pins

207

Page 210 of 378

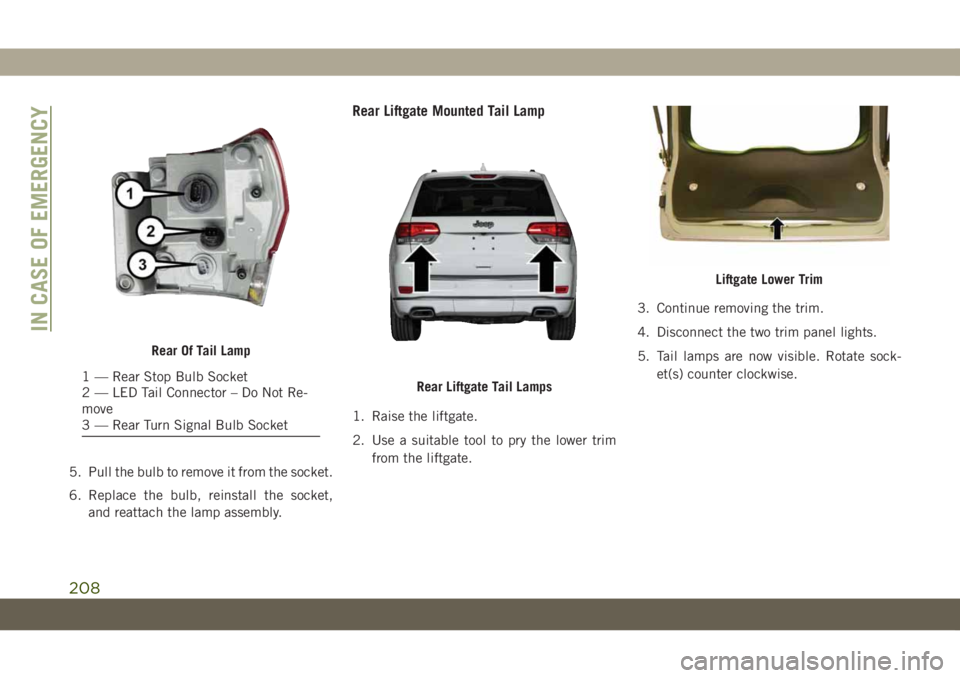

5. Pull the bulb to remove it from the socket.

6. Replace the bulb, reinstall the socket,

and reattach the lamp assembly.

Rear Liftgate Mounted Tail Lamp

1. Raise the liftgate.

2. Use a suitable tool to pry the lower trim

from the liftgate.3. Continue removing the trim.

4. Disconnect the two trim panel lights.

5. Tail lamps are now visible. Rotate sock-

et(s) counter clockwise.

Rear Of Tail Lamp

1 — Rear Stop Bulb Socket

2 — LED Tail Connector – Do Not Re-

move

3 — Rear Turn Signal Bulb SocketRear Liftgate Tail Lamps

Liftgate Lower Trim

IN CASE OF EMERGENCY

208