Brake light JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 203 of 1803

BRAKES

TABLE OF CONTENTS

page page

POWER BRAKE BOOSTER

REMOVAL - RHD........................1INSTALLATION - RHD.....................1

POWER BRAKE BOOSTER

REMOVAL - RHD

(1) Remove the air box (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

REMOVAL).

(2) Relocate the cruise control servo to gain access

to the booster for removal.

(3) Remove the brake lines from the master cylin-

der.

(4) Remove the master cylinder (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - REMOVAL).

(5) Disconnect vacuum hose from booster check

valve.

(6) Remove knee blocker under the steering colum-

n,(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(7) Remove the brake light switch.(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL)

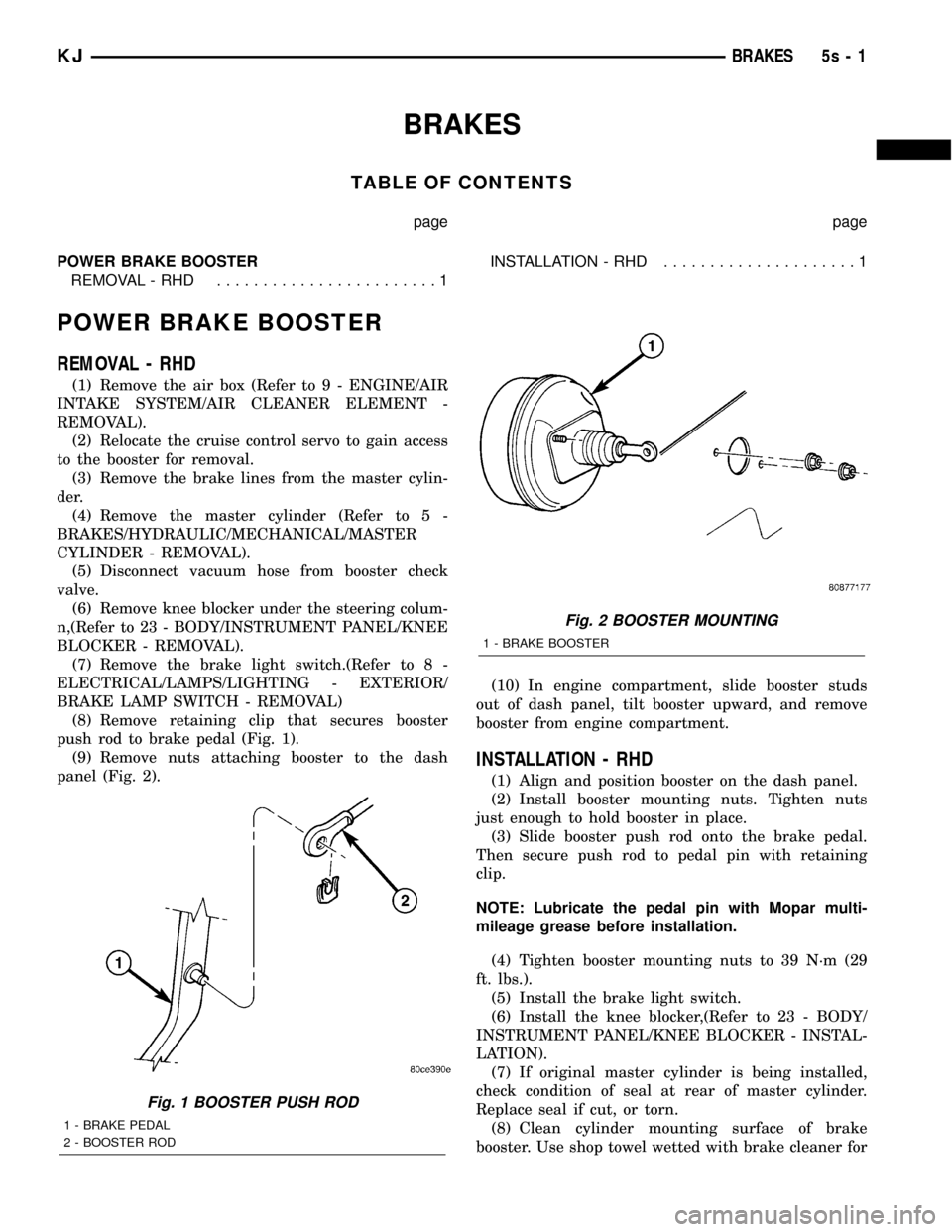

(8) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 1).

(9) Remove nuts attaching booster to the dash

panel (Fig. 2).(10) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

INSTALLATION - RHD

(1) Align and position booster on the dash panel.

(2) Install booster mounting nuts. Tighten nuts

just enough to hold booster in place.

(3) Slide booster push rod onto the brake pedal.

Then secure push rod to pedal pin with retaining

clip.

NOTE: Lubricate the pedal pin with Mopar multi-

mileage grease before installation.

(4) Tighten booster mounting nuts to 39 N´m (29

ft. lbs.).

(5) Install the brake light switch.

(6) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

(7) If original master cylinder is being installed,

check condition of seal at rear of master cylinder.

Replace seal if cut, or torn.

(8) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

Fig. 1 BOOSTER PUSH ROD

1 - BRAKE PEDAL

2 - BOOSTER ROD

Fig. 2 BOOSTER MOUNTING

1 - BRAKE BOOSTER

KJBRAKES 5s - 1

Page 218 of 1803

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

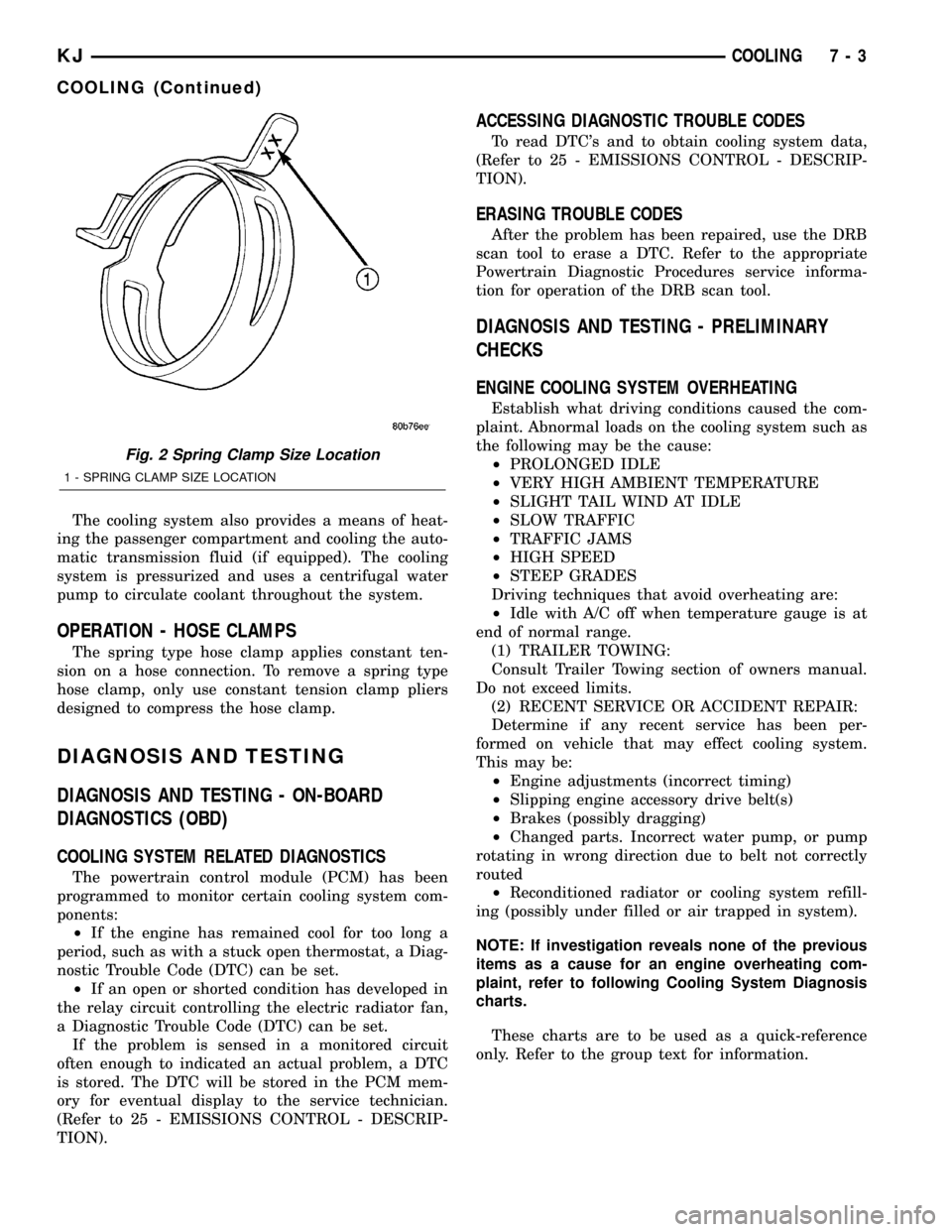

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED

²STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

(1) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(2) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump, or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

Fig. 2 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

KJCOOLING 7 - 3

COOLING (Continued)

Page 249 of 1803

OPERATION

OPERATION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED

²STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

(1) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(2) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump, or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

7s - 2 COOLING - 2.4LKJ

COOLING - 2.4L (Continued)

Page 303 of 1803

²Fog Lamp Control- The premium BCM pro-

vides fog lamp control for front fog lamps (optional),

and rear fog lamps (in required markets only).

²Front Wiper System Status- The BCM moni-

tors the status of the front wiper motor park switch.

²Fuel Economy and Distance to Empty Cal-

culations- The BCM calculates and transmits the

fuel economy and Distance To Empty (DTE) data.

²Headlamp Time Delay- The BCM provides a

headlamp time delay feature with the ignition switch

in the Off position.

²Heated Rear Glass Control- The BCM pro-

vides control and timer functions for the heated rear

glass feature and transmits the system status.

²Ignition On/Off Timer- The BCM monitors

and transmits the elapsed ignition On timer data

and monitors the ignition Off time.

²Ignition Switch Position Status- The BCM

monitors and transmits the status of the ignition

switch.

²Instrument Panel Dimming- The BCM mon-

itors and transmits the selected illumination inten-

sity level of the panel lamps dimmer switch.

²Interior Lamp Load Shedding- The BCM

provides a battery saver feature which will automat-

ically turn off all interior lamps that remain on after

a timed interval.

²Interior Lighting Control- The BCM moni-

tors inputs from the interior lighting switch, the door

ajar switches, the flip-up glass ajar switch, the tail-

gate ajar switch, the cargo lamp switch, the reading

lamp switches, and the Remote Keyless Entry (RKE)

module to provide courtesy lamp control. This

includes support for timed illuminated entry with

theater-style fade-to-off and courtesy illumination

defeat features.

²Intermittent Wipe and Front Wiper System

Control- The BCM monitors inputs from the front

wiper and washer switch and the front wiper motor

park switch to provide front wiper system control

through the wiper on/off and high/low relays. This

includes support for adjustable intermittent wipe,

mist wipe (also known as pulse wipe), and wipe-after-

wash features.

²Key-In-Ignition Switch Status- The BCM

monitors and transmits the status of the key-in-igni-

tion switch.

²Panic Mode- The BCM provides support for

the Remote Keyless Entry (RKE) system panic mode

feature.

²Parade Mode- The BCM provides a parade

mode (also known as funeral mode) that allows the

interior Vacuum Fluorescent Displays (VFD) to be

illuminated at full intensity while driving in daylight

with the exterior lamps On.²Power Locks- The BCM monitors inputs from

the power lock switches and the Remote Keyless

Entry (RKE) module (optional) to provide control of

the power lock motors through outputs to the lock,

unlock, and driver unlock (RKE only) relays. This

includes support for rolling door locks (also known as

automatic door locks) and a door lock inhibit mode.

²Programmable Features- The BCM provides

support for several standard and optional program-

mable features, including: rolling door locks, head-

lamp time delay interval, Remote Keyless Entry

(RKE) driver-door-only or unlock-all-doors, RKE opti-

cal chirp, and RKE audible chirp.

²Remote Keyless Entry- The premium BCM

provides the optional Remote Keyless Entry (RKE)

system features, including support for the RKE Lock,

Unlock (with optional driver-door-only unlock, and

unlock-all-doors), rear flip-up glass control, Panic,

audible chirp, optical chirp, and illuminated entry

modes, as well as the ability to be programmed to

recognize up to four RKE transmitters.

²Rolling Door Locks- The BCM provides sup-

port for the power lock system rolling door locks fea-

ture (also known as automatic door locks).

²Tailgate and Flip-Up Glass Ajar Status- The

BCM monitors and transmits the status of the tail-

gate and rear flip-up glass ajar switches.

²Remote Radio Switch Interface- The pre-

mium BCM monitors and transmits the status of the

optional remote radio switches.

²Self-Diagnostics- The BCM provides support

for diagnostics through communication with the

DRBIIItscan tool over the PCI data bus network.

Each analog and digital input can be verified, and

each output can be actuated through the use of this

diagnostic protocol. The BCM also stores Diagnostic

Trouble Codes (DTCs) to assist in troubleshooting

this unit.

²Vacuum Fluorescent Display Synchroniza-

tion- The BCM transmits panel lamp intensity data

which allows modules with Vacuum Fluorescent Dis-

plays (VFD) to coordinate their illumination inten-

sity.

²Vehicle Speed System- The BCM monitors a

vehicle speed input from the vehicle speed sensor

(without Antilock Brake System [ABS]) or from the

Controller Antilock Brake (CAB)(with ABS), calcu-

lates the vehicle speed based upon a programmed

axle ratio/tire size (electronic pinion factor), and

transmits the vehicle speed information to the Pow-

ertrain Control Module (PCM) on a hard wired out-

put circuit.

²Vehicle Theft Security System- The pre-

mium BCM monitors inputs from the door cylinder

lock switches, the tailgate cylinder lock switch, the

door ajar switches, the tailgate ajar switch, the

8E - 4 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 320 of 1803

Schedule Condition Expected Operation

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- 3rd gear FEMCC from 30-48 mph

- 3rd gear PEMCC above 35 mph

- Above 25 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

STANDARD PROCEDURE - TCM QUICK LEARN

The quick learn procedure requires the use of the

DRBtscan tool.

This program allows the electronic transmission

system to recalibrate itself. This will provide the

proper transmission operation. The quick learn pro-

cedure should be performed if any of the following

procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay in PARK until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBt

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

HEATED SEAT MODULE

DESCRIPTION

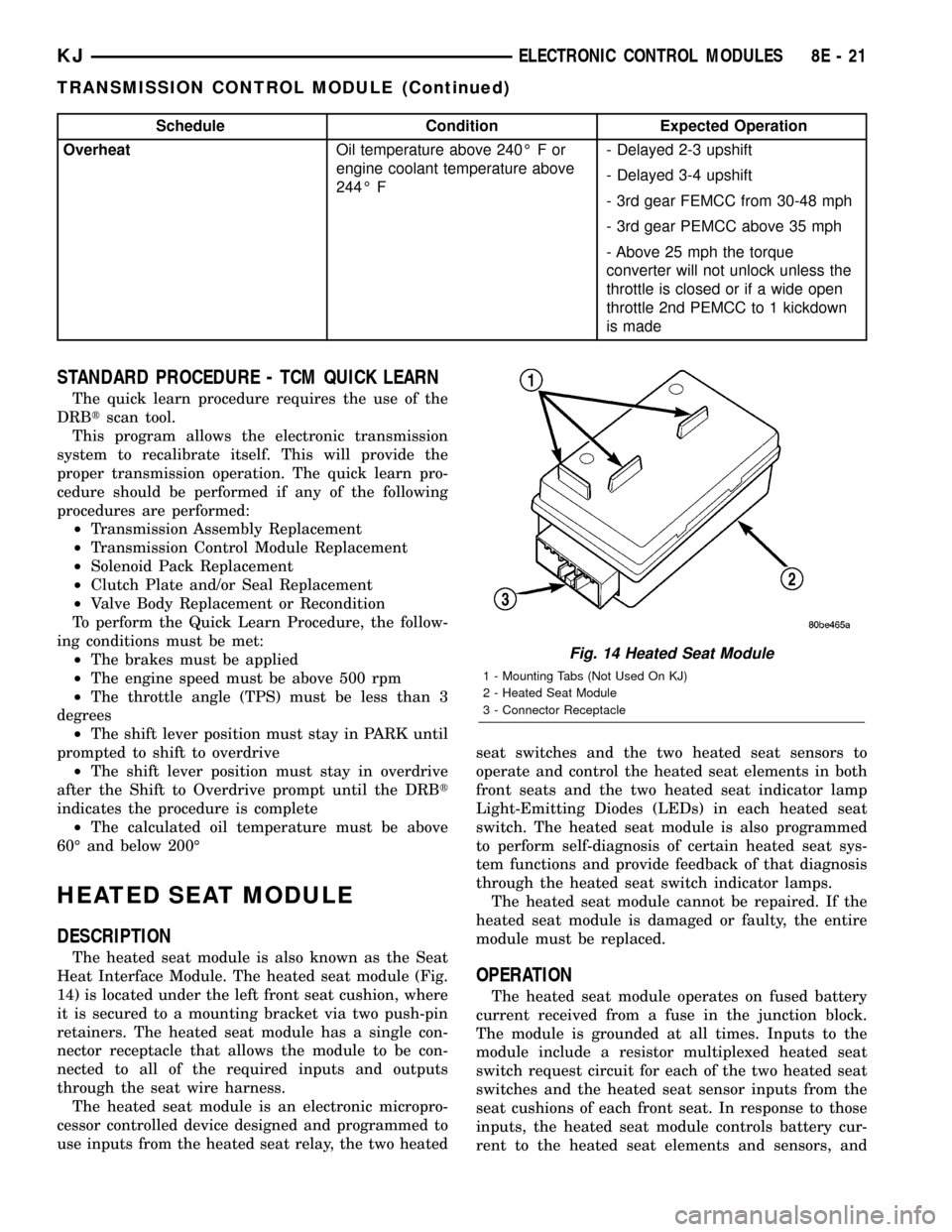

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

14) is located under the left front seat cushion, where

it is secured to a mounting bracket via two push-pin

retainers. The heated seat module has a single con-

nector receptacle that allows the module to be con-

nected to all of the required inputs and outputs

through the seat wire harness.

The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the heated seat relay, the two heatedseat switches and the two heated seat sensors to

operate and control the heated seat elements in both

front seats and the two heated seat indicator lamp

Light-Emitting Diodes (LEDs) in each heated seat

switch. The heated seat module is also programmed

to perform self-diagnosis of certain heated seat sys-

tem functions and provide feedback of that diagnosis

through the heated seat switch indicator lamps.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from a fuse in the junction block.

The module is grounded at all times. Inputs to the

module include a resistor multiplexed heated seat

switch request circuit for each of the two heated seat

switches and the heated seat sensor inputs from the

seat cushions of each front seat. In response to those

inputs, the heated seat module controls battery cur-

rent to the heated seat elements and sensors, and

Fig. 14 Heated Seat Module

1 - Mounting Tabs (Not Used On KJ)

2 - Heated Seat Module

3 - Connector Receptacle

KJELECTRONIC CONTROL MODULES 8E - 21

TRANSMISSION CONTROL MODULE (Continued)

Page 406 of 1803

perform its many functions. The EMIC module incor-

porates a blue-green digital Vacuum Fluorescent Dis-

play (VFD) for displaying odometer and trip

odometer information, as well as several warning

messages and certain diagnostic information. In addi-

tion to instrumentation and indicators, the EMIC has

the hardware and software needed to provide the fol-

lowing features:

²Chime Warning Service- A chime tone gener-

ator on the EMIC electronic circuit board provides

audible alerts to the vehicle operator and eliminates

the need for a separate chime module. (Refer to 8 -

ELECTRICAL/CHIME WARNING SYSTEM -

DESCRIPTION).

²Panel Lamps Dimming Service- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated

(PWM) output that synchronizes the dimming level

of the radio display, gear selector indicator, heater-air

conditioner control, and all other dimmable lighting

on the panel lamps dimmer circuit with that of the

cluster illumination lamps and VFD.

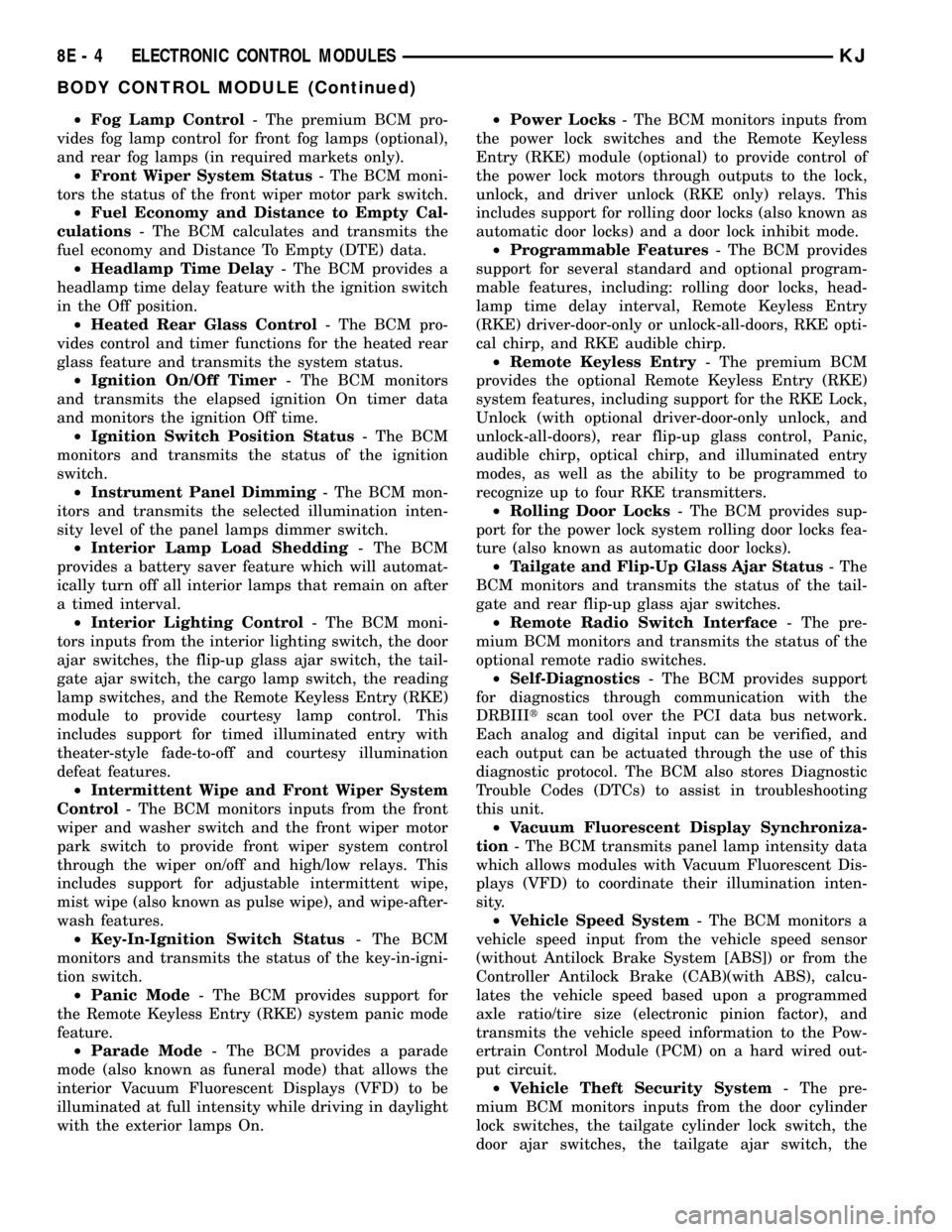

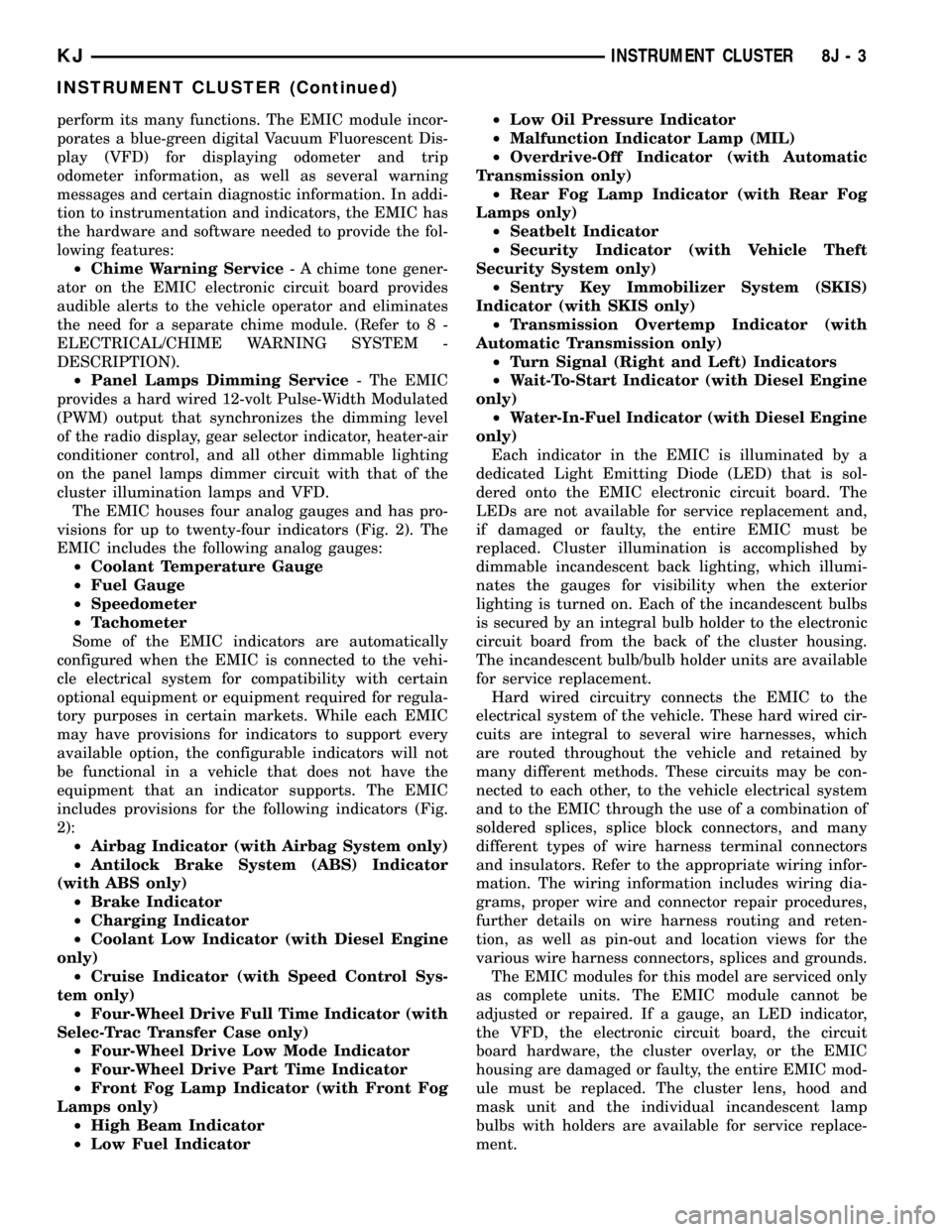

The EMIC houses four analog gauges and has pro-

visions for up to twenty-four indicators (Fig. 2). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Speedometer

²Tachometer

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

2):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS only)

²Brake Indicator

²Charging Indicator

²Coolant Low Indicator (with Diesel Engine

only)

²Cruise Indicator (with Speed Control Sys-

tem only)

²Four-Wheel Drive Full Time Indicator (with

Selec-Trac Transfer Case only)

²Four-Wheel Drive Low Mode Indicator

²Four-Wheel Drive Part Time Indicator

²Front Fog Lamp Indicator (with Front Fog

Lamps only)

²High Beam Indicator

²Low Fuel Indicator²Low Oil Pressure Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (with Automatic

Transmission only)

²Rear Fog Lamp Indicator (with Rear Fog

Lamps only)

²Seatbelt Indicator

²Security Indicator (with Vehicle Theft

Security System only)

²Sentry Key Immobilizer System (SKIS)

Indicator (with SKIS only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC is illuminated by a

dedicated Light Emitting Diode (LED) that is sol-

dered onto the EMIC electronic circuit board. The

LEDs are not available for service replacement and,

if damaged or faulty, the entire EMIC must be

replaced. Cluster illumination is accomplished by

dimmable incandescent back lighting, which illumi-

nates the gauges for visibility when the exterior

lighting is turned on. Each of the incandescent bulbs

is secured by an integral bulb holder to the electronic

circuit board from the back of the cluster housing.

The incandescent bulb/bulb holder units are available

for service replacement.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the VFD, the electronic circuit board, the circuit

board hardware, the cluster overlay, or the EMIC

housing are damaged or faulty, the entire EMIC mod-

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for service replace-

ment.

KJINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 407 of 1803

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges and indicators in the

EMIC provide valuable information about the various

standard and optional powertrains, fuel and emis-

sions systems, cooling systems, lighting systems,

safety systems and many other convenience items.

The EMIC is installed in the instrument panel so

that all of these monitors can be easily viewed by the

vehicle operator when driving, while still allowing

relative ease of access for service. The microproces-sor-based EMIC hardware and software uses various

inputs to control the gauges and indicators visible on

the face of the cluster. Some of these inputs are hard

wired, but most are in the form of electronic mes-

sages that are transmitted by other electronic mod-

ules over the Programmable Communications

Interface (PCI) data bus network. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

Fig. 2 EMIC Gauges & Indicators

1 - SKIS INDICATOR 16 - REAR FOG LAMP INDICATOR

2 - AIRBAG INDICATOR 17 - ABS INDICATOR

3 - LOW FUEL INDICATOR 18 - CHARGING INDICATOR

4 - WAIT-TO-START INDICATOR 19 - WATER-IN-FUEL INDICATOR

5 - OVERDRIVE-OFF INDICATOR 20 - ENGINE TEMPERATURE GAUGE

6 - COOLANT LOW INDICATOR 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

7 - SEATBELT INDICATOR 22 - ODOMETER/TRIP ODOMETER DISPLAY

8 - TACHOMETER 23 - CRUISE INDICATOR

9 - LEFT TURN INDICATOR 24 - LOW OIL PRESSURE INDICATOR

10 - HIGH BEAM INDICATOR 25 - TRANSMISSION OVERTEMP INDICATOR

11 - RIGHT TURN INDICATOR 26 - PART TIME 4WD INDICATOR

12 - SPEEDOMETER 27 - BRAKE INDICATOR

13 - FRONT FOG LAMP INDICATOR 28 - FULL TIME 4WD INDICATOR

14 - 4WD LOW MODE INDICATOR 29 - SECURITY INDICATOR

15 - MALFUNCTION INDICATOR LAMP (MIL) 30 - FUEL GAUGE

8J - 4 INSTRUMENT CLUSTERKJ

INSTRUMENT CLUSTER (Continued)

Page 409 of 1803

eter/trip odometer switch button that extends

through the lower edge of the cluster lens, just right

of the speedometer. Actuating this switch momen-

tarily with the ignition switch in the On position will

toggle the VFD between the odometer and trip odom-

eter modes. Depressing the switch button for about

two seconds while the VFD is in the trip odometer

mode will reset the trip odometer value to zero. Hold-

ing this switch depressed while turning the ignition

switch from the Off position to the On position will

initiate the EMIC self-diagnostic actuator test. The

VFD will also display the cluster software version

level near the completion of the EMIC self-diagnostic

actuator test. Refer to the appropriate diagnostic

information for additional details on this VFD func-

tion.

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control some of the VFD functions requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information. Specific operation details for

the odometer, the trip odometer, and the various

warning message functions of the VFD may be found

elsewhere in this service information.

INDICATORS Indicators are located in various

positions within the EMIC and are all connected to

the EMIC circuit board. The turn signal indicators,

security indicator, washer fluid indicator, and coolant

low indicator (diesel engine only) use hard wired

inputs to the EMIC. The brake indicator is controlled

by PCI data bus messages from the Controller

Antilock Brake (CAB) as well as by hard wired park

brake switch and brake fluid level switch inputs to

the EMIC. The Malfunction Indicator Lamp (MIL) is

normally controlled by PCI data bus messages from

the Powertrain Control Module (PCM); however, if

the EMIC loses PCI data bus communication, the

EMIC circuitry will automatically turn the MIL on

until PCI data bus communication is restored. The

EMIC uses PCI data bus messages from the Body

Control Module (BCM), the PCM, the Airbag Control

Module (ACM), and the CAB to control all of the

remaining indicators.

The various indicators are controlled by different

strategies; some receive fused ignition switch output

from the EMIC circuitry and have a switched ground,

others are grounded through the EMIC circuitry and

have a switched battery feed, while still others are

completely controlled by the EMIC microprocessor

based upon various hard wired and electronic mes-

sage inputs. Some indicators are illuminated at a

fixed intensity, while the illumination intensity ofothers is synchronized with that of the EMIC general

illumination lamps.

In addition, certain indicators in this instrument

cluster are automatically configured or self-config-

ured. This feature allows the configurable indicators

to be enabled by the EMIC circuitry for compatibility

with certain optional equipment. The ABS indicator,

airbag indicator, SKIS indicator are automatically

configured by PCI data bus messages received by the

EMIC from the CAB, ACM, or Sentry Key Immobi-

lizer Module (SKIM) after the EMIC is installed in

the vehicle. Once these configuration settings are

learned by the EMIC, the DRBIIItscan tool must be

used to remove these settings from the EMIC non-

volatile memory. The self-configured indicators

remain latent in each EMIC at all times and will be

activated only when the EMIC receives the appropri-

ate PCI message inputs for the optional system or

equipment.

The hard wired indicators are diagnosed using con-

ventional diagnostic methods. The EMIC and PCI

bus message controlled indicators are diagnosed

using the EMIC self-diagnostic actuator test. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). Proper testing of the

PCI data bus and the electronic data bus message

inputs to the EMIC that control each indicator

require the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.

CLUSTER ILLUMINATION The EMIC has several

illumination lamps that are illuminated when the

exterior lighting is turned on with the headlamp

(multi-function) switch. The illumination intensity of

these lamps is adjusted by a 12-volt Pulse Width

Modulated (PWM) output of the EMIC when the

interior lighting control ring on the left control stalk

of the multi-function switch is rotated (down to dim,

up to brighten) to one of six available minor detent

positions. The BCM provides electronic dimming

level messages based upon internal programming

and inputs it receives from the control knob and con-

trol ring on the left (lighting) control stalk of the

multi-function switch on the steering column, then

provides a control output to energize or de-energize

the park lamp relay as appropriate. The energized

park lamp relay provides battery current to the

EMIC on the hard wired fused park lamp relay out-

put circuit, and the BCM provides the electronic dim-

ming level message to the EMIC over the PCI data

bus. The EMIC electronic circuitry provides the

proper PWM output to the cluster illumination lamps

and the VFD on the EMIC circuit board, then pro-

vides a synchronized PWM output on the hard wired

8J - 6 INSTRUMENT CLUSTERKJ

INSTRUMENT CLUSTER (Continued)

Page 414 of 1803

(2) With the bulb holder fully seated against the

cluster electronic circuit board, turn the bulb holder

clockwise about sixty degrees to lock it into place.

(3) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(4) Reconnect the battery negative cable.

CLUSTER LENS, HOOD, AND MASK

(1) Position the cluster lens, hood, and mask unit

over the face of the instrument cluster (Fig. 5). Be

certain that the odometer/trip odometer switch but-

ton is inserted through the proper clearance holes in

the mask and the lens.

(2) From the back of the instrument cluster, install

and tighten the six screws that secure the rear cover

and the lens, hood, and mask unit to the cluster

housing. Tighten the screws to 1 N´m (10 in. lbs.).

(3) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(4) Reconnect the battery negative cable.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the instrument cluster to the instru-

ment panel.

(2) Reconnect the instrument panel wire harness

connector for the cluster to the cluster connector

receptacle.

(3) Position the instrument cluster into the instru-

ment panel.

(4) Install and tighten the four screws that secure

the instrument cluster to the instrument panel (Fig.

3). Tighten the screws to 2 N´m (17 in. lbs.).

(5) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(6) Reconnect the battery negative cable.NOTE: Some of the indicators in this instrument

cluster are self configured or automatically config-

ured when the cluster is connected to the vehicle

electrical system. This feature allows those indica-

tors to be enabled for compatibility with certain

optional equipment. However, if an instrument clus-

ter was previously connected to another vehicle

with different equipment options than the current

vehicle, some of the automatically configured indi-

cator settings may have to be disabled using a

DRBIIITscan tool. Refer to the appropriate diagnos-

tic information.

ABS INDICATOR

DESCRIPTION

An Antilock Brake System (ABS) indicator is stan-

dard equipment on all instrument clusters. However,

the instrument cluster is programmed to automati-

cally enable this indicator only on vehicles equipped

with the optional antilock brake system. The ABS

indicator is located above the engine temperature

gauge and to the right of the speedometer in the

instrument cluster. The ABS indicator consists of a

stencil-like cutout of the International Control and

Display Symbol icon for ªFailure of Anti-lock Braking

Systemº in the opaque layer of the instrument clus-

ter overlay. The dark outer layer of the overlay pre-

vents the indicator from being clearly visible when it

is not illuminated. An amber Light Emitting Diode

(LED) behind the cutout in the opaque layer of the

overlay causes the icon to appear in amber through

the translucent outer layer of the overlay when it is

illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The ABS indicator is serviced as a unit with

the instrument cluster.

OPERATION

The ABS indicator gives an indication to the vehi-

cle operator when the ABS system is faulty or inop-

erative. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Controller Antilock Brake (CAB)

over the Programmable Communications Interface

(PCI) data bus. The ABS indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The LED only

KJINSTRUMENT CLUSTER 8J - 11

INSTRUMENT CLUSTER (Continued)

Page 415 of 1803

illuminates when it is provided a path to ground by

the instrument cluster transistor. The instrument

cluster will turn on the ABS indicator for the follow-

ing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ABS indicator is illu-

minated by the cluster for about three seconds as a

bulb test.

²ABS Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the CAB, the

ABS indicator will be illuminated. The indicator

remains illuminated until the cluster receives a

lamp-off message from the CAB, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Communication Error- If the cluster receives

no lamp-on or lamp-off messages from the CAB for

six consecutive seconds, the ABS indicator is illumi-

nated. The indicator remains illuminated until the

cluster receives a valid message from the CAB, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the ABS indica-

tor will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off by lamp-on and lamp-off messages

from the CAB during the performance of the ABS

diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a lamp-on message after the

bulb test, it indicates that the CAB has detected a

system malfunction and/or that the ABS system has

become inoperative. The CAB will each store a Diag-

nostic Trouble Code (DTC) for any malfunction it

detects. Each time the ABS indicator fails to light

due to an open or short in the cluster ABS indicator

circuit, the cluster sends a message notifying the

CAB of the condition, then the instrument cluster

and the CAB will each store a DTC. For proper diag-

nosis of the antilock brake system, the CAB, the PCI

data bus, or the message inputs to the instrument

cluster that control the ABS indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. However, the instrument cluster

is programmed to automatically enable this indicator

only on vehicles equipped with the airbag system,

which is not available in some markets. The airbag

indicator is located above the fuel gauge and to the

left of the tachometer in the instrument cluster. The

airbag indicator consists of a stencil-like cutout of the

words ªAIR BAGº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. A red Light Emitting

Diode (LED) behind the cutout in the opaque layer of

the overlay causes the ªAIR BAGº text to appear in

red through the translucent outer layer of the over-

lay when it is illuminated from behind by the LED,

which is soldered onto the instrument cluster elec-

tronic circuit board. The airbag indicator is serviced

as a unit with the instrument cluster.

OPERATION

The airbag indicator gives an indication to the

vehicle operator when the airbag system is faulty or

inoperative. The airbag indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Airbag Control

Module (ACM) over the Programmable Communica-

tions Interface (PCI) data bus. The airbag indicator

Light Emitting Diode (LED) is completely controlled

by the instrument cluster logic circuit, and that logic

will only allow this indicator to operate when the

instrument cluster receives a battery current input

on the fused ignition switch output (run-start) cir-

cuit. Therefore, the LED will always be off when the

ignition switch is in any position except On or Start.

The LED only illuminates when it is provided a path

to ground by the instrument cluster transistor. The

instrument cluster will turn on the airbag indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the airbag indicator is illu-

minated for about six seconds. The entire six second

bulb test is a function of the ACM.

²ACM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the ACM, the

airbag indicator will be illuminated. The indicator

remains illuminated for about twelve seconds or until

the cluster receives a lamp-off message from the

ACM, whichever is longer.

²Communication Error- If the cluster receives

no airbag messages for six consecutive seconds, the

airbag indicator is illuminated. The indicator

8J - 12 INSTRUMENT CLUSTERKJ

ABS INDICATOR (Continued)