JEEP RENEGADE 2017 1.G Owners Manual

Manufacturer: JEEP, Model Year: 2017, Model line: RENEGADE, Model: JEEP RENEGADE 2017 1.GPages: 516, PDF Size: 5.73 MB

Page 351 of 516

CavityMini FuseDescription

F5 30 Amp GreenPower Seat (Driver Side)

F6 7.5 Amp BrownPower Seat (Driver Side And Passen-

ger Side)

F7 30 Amp GreenLumbar Adjustment Front Seats

(Driver Side And Passenger Side)

F8 20 Amp YellowHeating Front Seats

On the controller there is also a 20 amp fuse for the sun

visor of the retractable roof.

Fuse Holder No. 2

Cavity Mini FuseDescription

F1 10 Amp RedController Exterior Lighting On

Trailer

F5 15 Amp BlueController Exterior Lighting Lights

(Drivers Side)

F6 15 Amp BlueController Exterior Lighting Lights

(Passenger Side)

7

IN CASE OF EMERGENCY 349

Page 352 of 516

JACKING AND TIRE CHANGING

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

• Never start or run the engine while the vehicle is on

a jack.

• The jack is designed to be used as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should be

jacked on a firm level surface only. Avoid ice or

slippery areas.

Jack Location/Spare Tire Stowage

The jack and tools are located in the rear storage compart-

ment if equipped, inside a special container. 1. Open the liftgate.

2. Lift the access cover using the load floor pull strap.

Jack And Tools

1 — Wheel Bolt Wrench

2 — Jack

3 — Emergency Funnel

4 — Wheel Chocks

5 — Screwdriver

6 — Emergency Allen Key

350 IN CASE OF EMERGENCY

Page 353 of 516

3. Remove the fastener securing the spare tire.

4. Removethe chocks.

5. Remove the jack and wheel bolt wrench.

6. Remove the spare tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

(Continued)

WARNING!(Continued)

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from the

edge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the Electric Park Brake.

4. Place the gear selector into PARK (automatic transmis- sion) or REVERSE (manual transmission).

5. Turn the ignition off to the OFF position.Load Floor Pull Strap

7

IN CASE OF EMERGENCY 351

Page 354 of 516

6. Chock both the front and rear of the wheel diagonallyopposite of the jacking position. For

example, if changing the right front

tire, chock the left rear wheel.

NOTE: Passengers should not remain in the vehicle when

the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•

Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the wheel to be

raised.

• Apply the parking brake and place an automatic

transmission in PARK.

• Never start or run the engine with the vehicle on a

jack.

(Continued)

WARNING! (Continued)

•Do not let anyone sit in the vehicle when it is on a

jack.

• Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely

careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

352 IN CASE OF EMERGENCY

Page 355 of 516

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with wheels where the center cap covers the wheel bolts, use the wheel bolt wrench to pry the center

cap off carefully before raising the vehicle. 3. Before raising the vehicle, use the wheel bolt wrench to

loosen, but not remove, the wheel bolts on the wheel

with the flat tire. Turn the wheel bolts counterclockwise

one turn while the wheel is still on the ground.

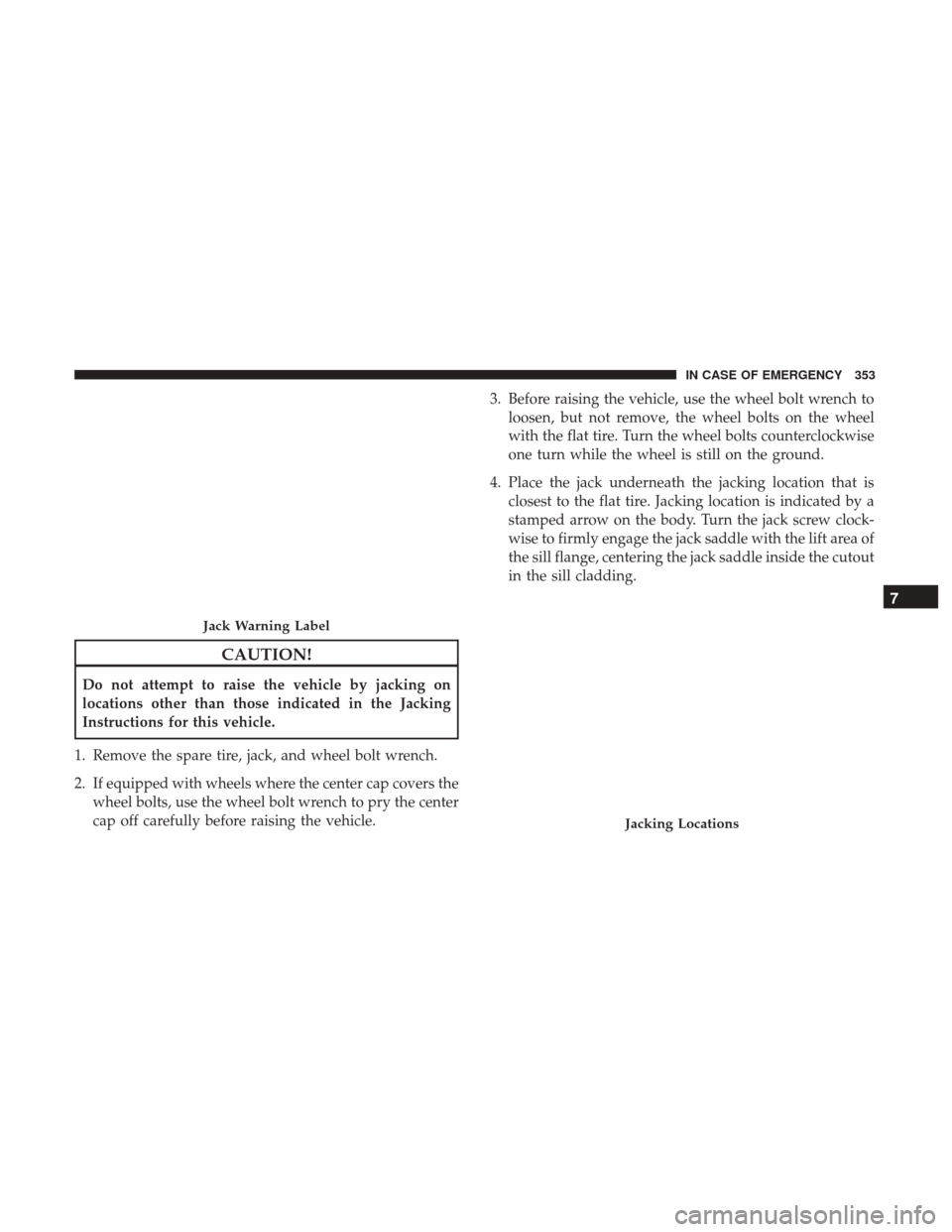

4. Place the jack underneath the jacking location that is closest to the flat tire. Jacking location is indicated by a

stamped arrow on the body. Turn the jack screw clock-

wise to firmly engage the jack saddle with the lift area of

the sill flange, centering the jack saddle inside the cutout

in the sill cladding.

Jack Warning Label

Jacking Locations

7

IN CASE OF EMERGENCY 353

Page 356 of 516

Front Jacking LocationFront Jacking Engagement Point

354 IN CASE OF EMERGENCY

Page 357 of 516

5. Raise the vehicle just enough to remove the flat tire.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

Rear Jacking LocationRear Jacking Engagement Point

7

IN CASE OF EMERGENCY 355

Page 358 of 516

6. Remove the wheel bolts and tire.

7. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.NOTE:

•Your vehicle may be equipped with a compact spare

tire or a limited — use spare tire. For further informa-

tion refer to “Tires — General Information” in “Servic-

ing And Maintenance”.

• For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

8. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the wheel

bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the wheel bolts until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

Mounting Spare Tire

356 IN CASE OF EMERGENCY

Page 359 of 516

“Torque Specifications” in “Technical Specifications”

for the proper lug bolt torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station.

11. Securely stow the jack, tools, chocks, and flat tire.WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the wheel bolts until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Properly Stowed Tire

7

IN CASE OF EMERGENCY 357

Page 360 of 516

3. Lower the vehicle to the ground by turning the jackhandle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in the “Technical Specifications”

section for the proper lug bolt torque. If in doubt about

the correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

5. Lower the jack until it is free. Remove the wheel chocks. Stow the jack and tools back in the proper storage

location. Release the Electric Park Brake before driving

the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

TIRE SERVICE KIT — IF EQUIPPED

Tire Service Kit Storage

The Tire Service Kit is located in the rear storage compartment

inside a storage container. Located inside the container are a screwdriver and the emergency fuel funnel. To access the Tire

Service Kit open the liftgate and remove the load floor.

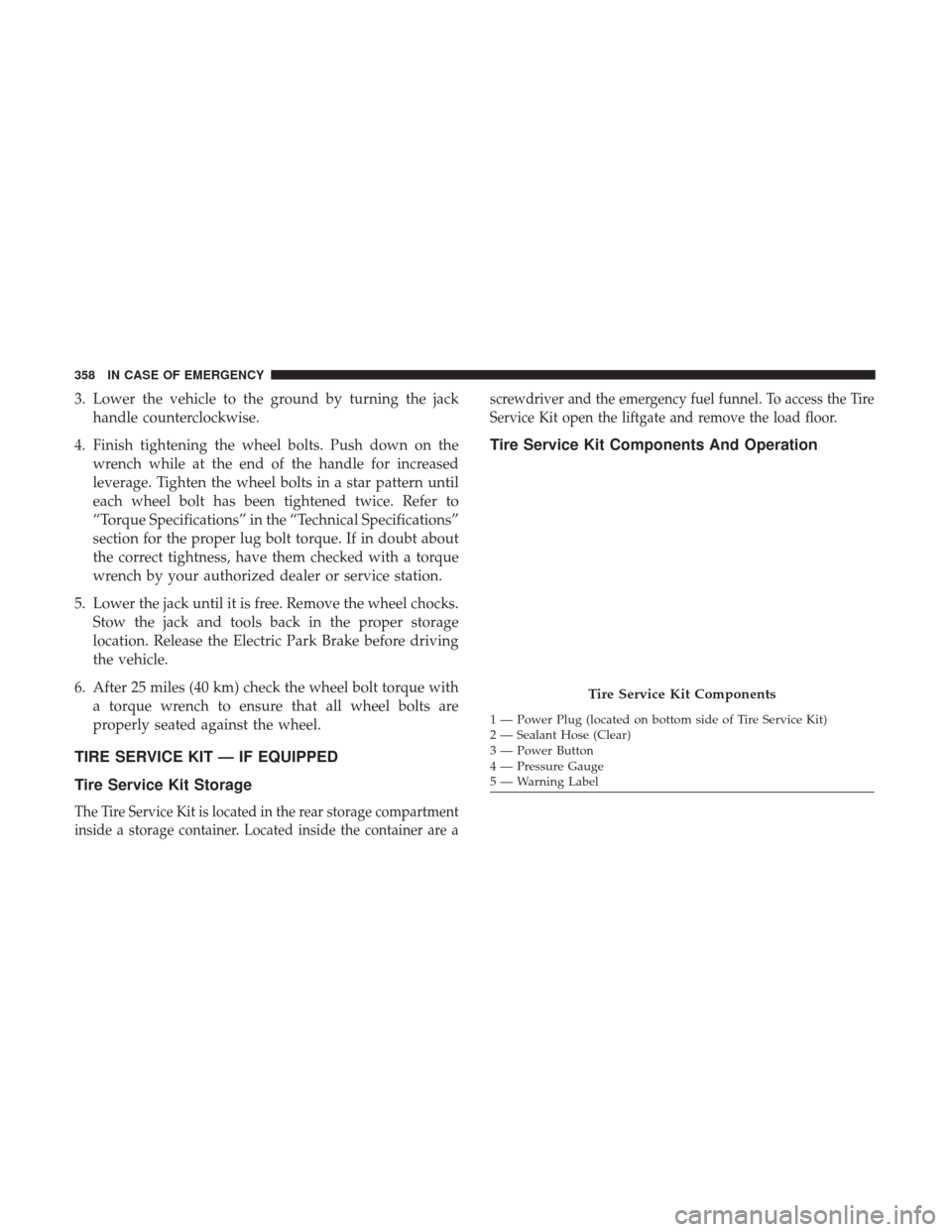

Tire Service Kit Components And Operation

Tire Service Kit Components

1 — Power Plug (located on bottom side of Tire Service Kit)

2 — Sealant Hose (Clear)

3 — Power Button

4 — Pressure Gauge

5 — Warning Label

358 IN CASE OF EMERGENCY