battery JEEP RENEGADE 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: RENEGADE, Model: JEEP RENEGADE 2018Pages: 356, PDF Size: 6.11 MB

Page 223 of 356

fully depress the brake pedal and hold

it down;

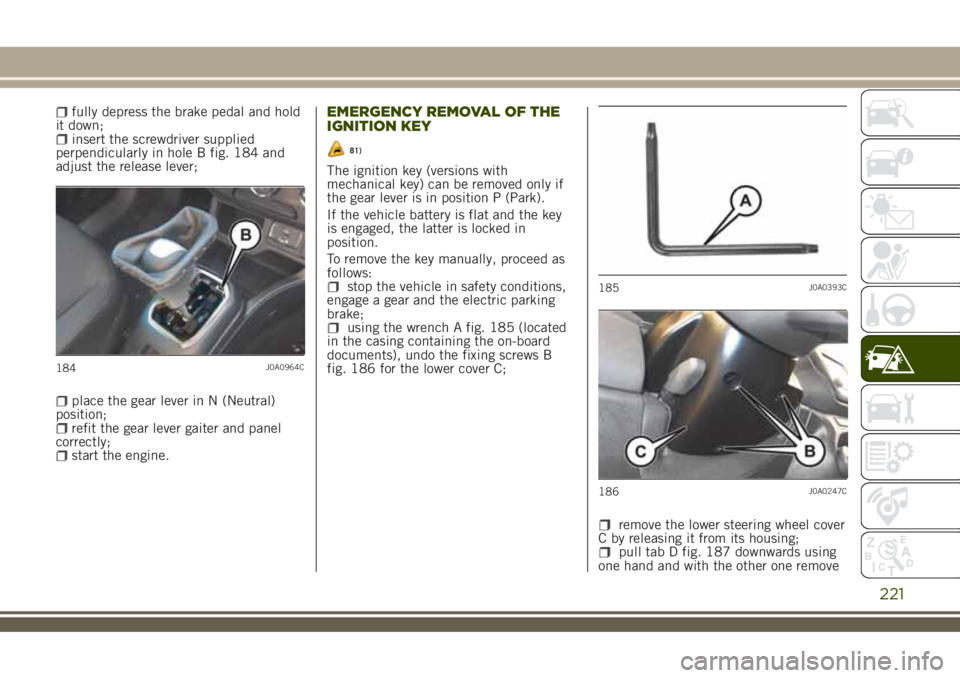

insert the screwdriver supplied

perpendicularly in hole B fig. 184 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and panel

correctly;

start the engine.

EMERGENCY REMOVAL OF THE

IGNITION KEY

81)

The ignition key (versions with

mechanical key) can be removed only if

the gear lever is in position P (Park).

If the vehicle battery is flat and the key

is engaged, the latter is locked in

position.

To remove the key manually, proceed as

follows:

stop the vehicle in safety conditions,

engage a gear and the electric parking

brake;

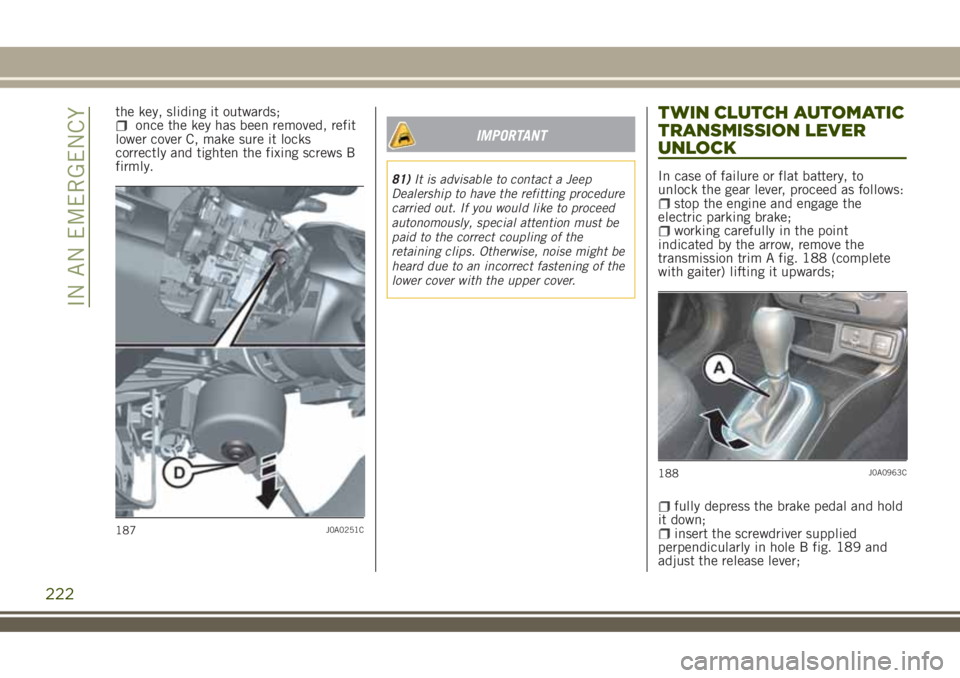

using the wrench A fig. 185 (located

in the casing containing the on-board

documents), undo the fixing screws B

fig. 186 for the lower cover C;

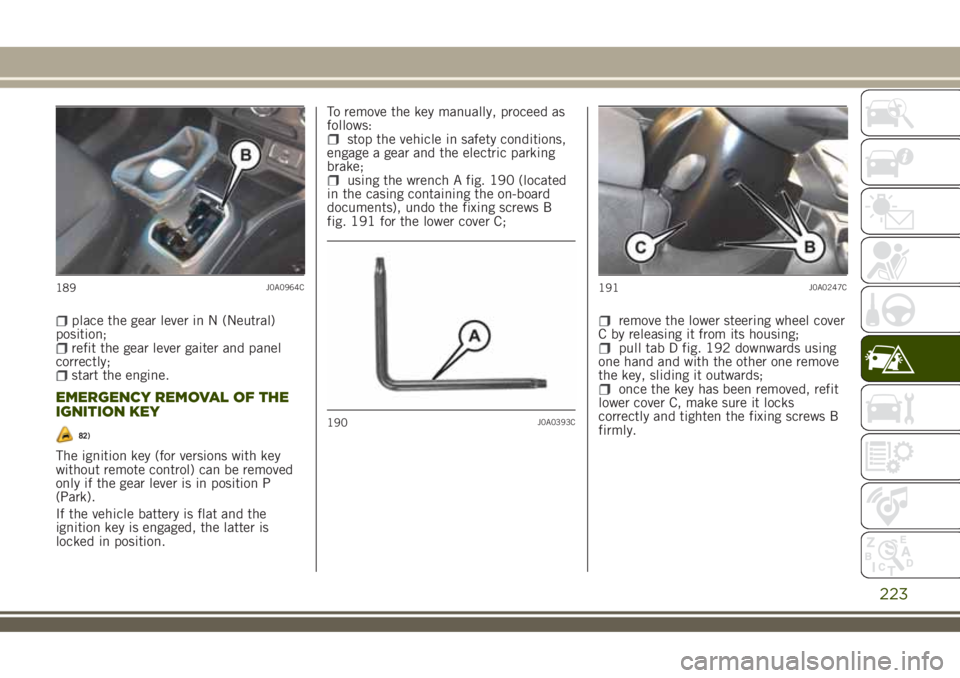

remove the lower steering wheel cover

C by releasing it from its housing;

pull tab D fig. 187 downwards using

one hand and with the other one remove

184J0A0964C

185J0A0393C

186J0A0247C

221

Page 224 of 356

the key, sliding it outwards;once the key has been removed, refit

lower cover C, make sure it locks

correctly and tighten the fixing screws B

firmly.IMPORTANT

81)It is advisable to contact a Jeep

Dealership to have the refitting procedure

carried out. If you would like to proceed

autonomously, special attention must be

paid to the correct coupling of the

retaining clips. Otherwise, noise might be

heard due to an incorrect fastening of the

lower cover with the upper cover.

TWIN CLUTCH AUTOMATIC

TRANSMISSION LEVER

UNLOCK

In case of failure or flat battery, to

unlock the gear lever, proceed as follows:

stop the engine and engage the

electric parking brake;

working carefully in the point

indicated by the arrow, remove the

transmission trim A fig. 188 (complete

with gaiter) lifting it upwards;

fully depress the brake pedal and hold

it down;

insert the screwdriver supplied

perpendicularly in hole B fig. 189 and

adjust the release lever;187J0A0251C

188J0A0963C

222

IN AN EMERGENCY

Page 225 of 356

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and panel

correctly;

start the engine.

EMERGENCY REMOVAL OF THE

IGNITION KEY

82)

The ignition key (for versions with key

without remote control) can be removed

only if the gear lever is in position P

(Park).

If the vehicle battery is flat and the

ignition key is engaged, the latter is

locked in position.To remove the key manually, proceed as

follows:

stop the vehicle in safety conditions,

engage a gear and the electric parking

brake;

using the wrench A fig. 190 (located

in the casing containing the on-board

documents), undo the fixing screws B

fig. 191 for the lower cover C;

remove the lower steering wheel cover

C by releasing it from its housing;

pull tab D fig. 192 downwards using

one hand and with the other one remove

the key, sliding it outwards;

once the key has been removed, refit

lower cover C, make sure it locks

correctly and tighten the fixing screws B

firmly.

189J0A0964C

190J0A0393C

191J0A0247C

223

Page 229 of 356

SERVICING AND MAINTENANCE

Correct maintenance permits the

performance of the vehicle to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SCHEDULED SERVICING.......228

ENGINE COMPARTMENT.......243

BATTERY RECHARGING........251

SERVICING PROCEDURES......252

LIFTING THE VEHICLE.........254

WHEELS AND TYRES..........255

BODYWORK................256

227

Page 230 of 356

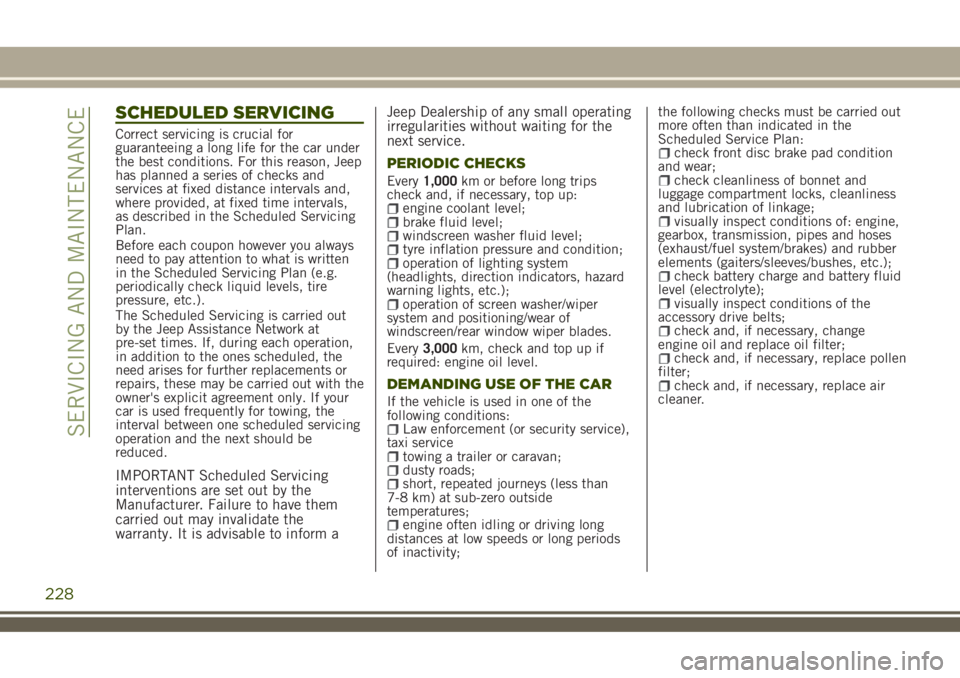

SCHEDULED SERVICING

Correct servicing is crucial for

guaranteeing a long life for the car under

the best conditions. For this reason, Jeep

has planned a series of checks and

services at fixed distance intervals and,

where provided, at fixed time intervals,

as described in the Scheduled Servicing

Plan.

Before each coupon however you always

need to pay attention to what is written

in the Scheduled Servicing Plan (e.g.

periodically check liquid levels, tire

pressure, etc.).

The Scheduled Servicing is carried out

by the Jeep Assistance Network at

pre-set times. If, during each operation,

in addition to the ones scheduled, the

need arises for further replacements or

repairs, these may be carried out with the

owner's explicit agreement only. If your

car is used frequently for towing, the

interval between one scheduled servicing

operation and the next should be

reduced.

IMPORTANT Scheduled Servicing

interventions are set out by the

Manufacturer. Failure to have them

carried out may invalidate the

warranty. It is advisable to inform aJeep Dealership of any small operating

irregularities without waiting for the

next service.

PERIODIC CHECKS

Every1,000km or before long trips

check and, if necessary, top up:

engine coolant level;brake fluid level;windscreen washer fluid level;tyre inflation pressure and condition;operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of screen washer/wiper

system and positioning/wear of

windscreen/rear window wiper blades.

Every3,000km, check and top up if

required: engine oil level.

DEMANDING USE OF THE CAR

If the vehicle is used in one of the

following conditions:

Law enforcement (or security service),

taxi service

towing a trailer or caravan;dusty roads;short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;the following checks must be carried out

more often than indicated in the

Scheduled Service Plan:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks, cleanliness

and lubrication of linkage;

visually inspect conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and rubber

elements (gaiters/sleeves/bushes, etc.);

check battery charge and battery fluid

level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace pollen

filter;

check and, if necessary, replace air

cleaner.

228

SERVICING AND MAINTENANCE

Page 245 of 356

ENGINE COMPARTMENT

CHECKING LEVELS

177) 178)83)

1.4 Turbo MultiAir version

1. Engine oil dipstick 2. Engine oil cap/filler 3. Engine coolant 4. Windscreen/rear window washer fluid 5. Brake fluid

6. Battery

196J0A0138C

243

Page 246 of 356

1.4 T-Jet 120 HP LPG version

1. Engine oil dipstick 2. Engine oil cap / filler 3. Engine coolant 4. Washer fluid for windscreen/rear window 5. Brake fluid 6.

Battery

197J0A0395C

244

SERVICING AND MAINTENANCE

Page 247 of 356

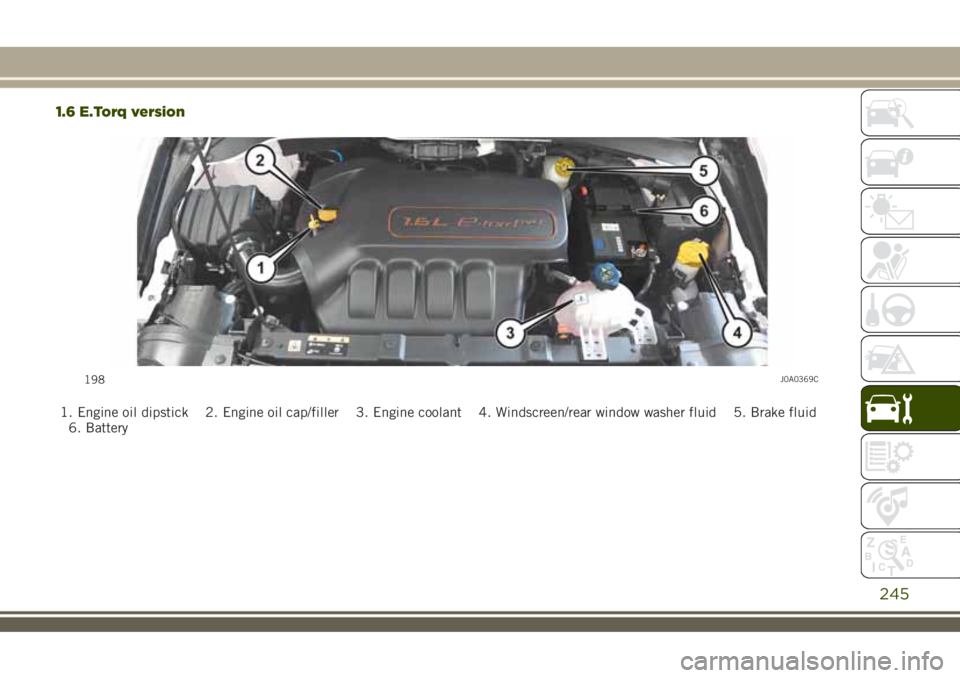

1.6 E.Torq version

1. Engine oil dipstick 2. Engine oil cap/filler 3. Engine coolant 4. Windscreen/rear window washer fluid 5. Brake fluid

6. Battery

198J0A0369C

245

Page 248 of 356

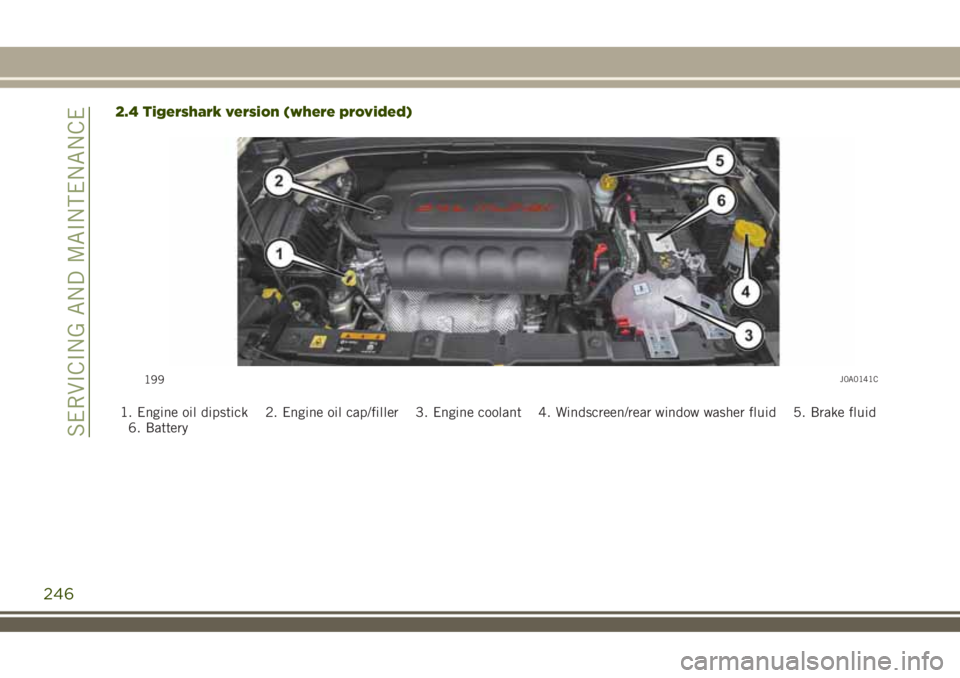

2.4 Tigershark version (where provided)

1. Engine oil dipstick 2. Engine oil cap/filler 3. Engine coolant 4. Windscreen/rear window washer fluid 5. Brake fluid

6. Battery

199J0A0141C

246

SERVICING AND MAINTENANCE

Page 249 of 356

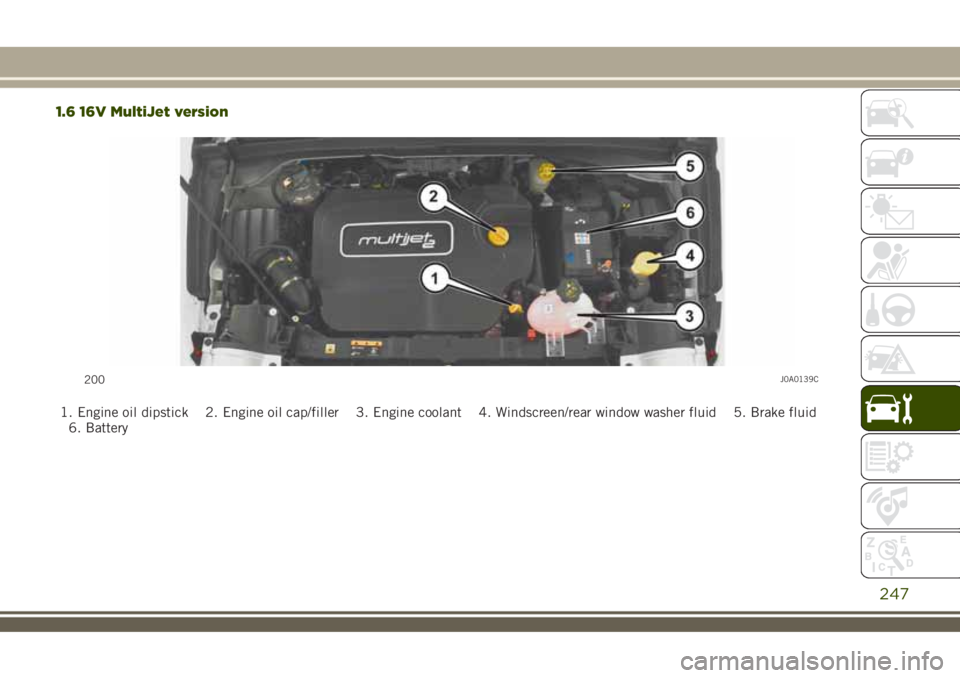

1.6 16V MultiJet version

1. Engine oil dipstick 2. Engine oil cap/filler 3. Engine coolant 4. Windscreen/rear window washer fluid 5. Brake fluid

6. Battery

200J0A0139C

247