engine JEEP RENEGADE 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: RENEGADE, Model: JEEP RENEGADE 2018Pages: 356, PDF Size: 6.11 MB

Page 211 of 356

WARNING

154)If the replaced fuse blows again,

contact a Jeep Dealership.

155)Never replace a fuse with another

with a higher amp rating; DANGER OF

FIRE.

156)If a general fuse (MAXI-FUSE,

MEGA-FUSE, MIDI-FUSE) cuts in, do not

attempt any repair and contact a Jeep

Dealership.

157)Before replacing a fuse, make sure

that the ignition device is at STOP, that

the key, if mechanical, has been removed

and that all devices are switched off

and/or disconnected.

158)If a general protection fuse for safety

systems (airbag system, braking system),

power unit systems (engine system,

transmission system) or steering system

blows, contact a Jeep Dealership.

IMPORTANT

77)Never replace a fuse with metal wires

or anything else.

78)If it is necessary to wash the engine

compartment, take care not to directly hit

the fuse box and the window wiper motors

with the water jet.

CHANGING A WHEEL

159) 160) 161) 162) 163) 166) 167)

JACK

164) 165)

Please note that:the weight of the jack is 2.8 kg;the jack requires no adjustment;the jack cannot be repaired and in the

event of a fault it must be replaced by

another genuine one;

no tool other than its cranking device

may be fitted on the jack.

Maintenance

prevent any dirt from depositing on

the "worm screw";

keep the "worm screw" lubricated;never modify the jack.

Conditions for non-use

temperatures below −40°C;on sandy or muddy ground;on uneven ground;on steep roads;in extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc...

in direct contact with the engine or for

repairs under the car;

on boats.

209

Page 212 of 356

CHANGING PROCEDURE

Proceed as follows:stop the car in a position that does

not cause any danger to traffic and lets

you change the tire in safety, as far as

possible from the edge of the driving

lane. The ground must be flat and

sufficiently compact;

engage the hazard warning lights and

the electric parking brake;

engage first gear or reverse or, for

versions with automatic transmission,

move the lever to position P (Park);

stop the engine and put on the

reflective safety jacket (for your own

safety and in compliance with national

laws) before getting out of the vehicle.

The motor must be kept off as long as

the car is lifted off the ground.

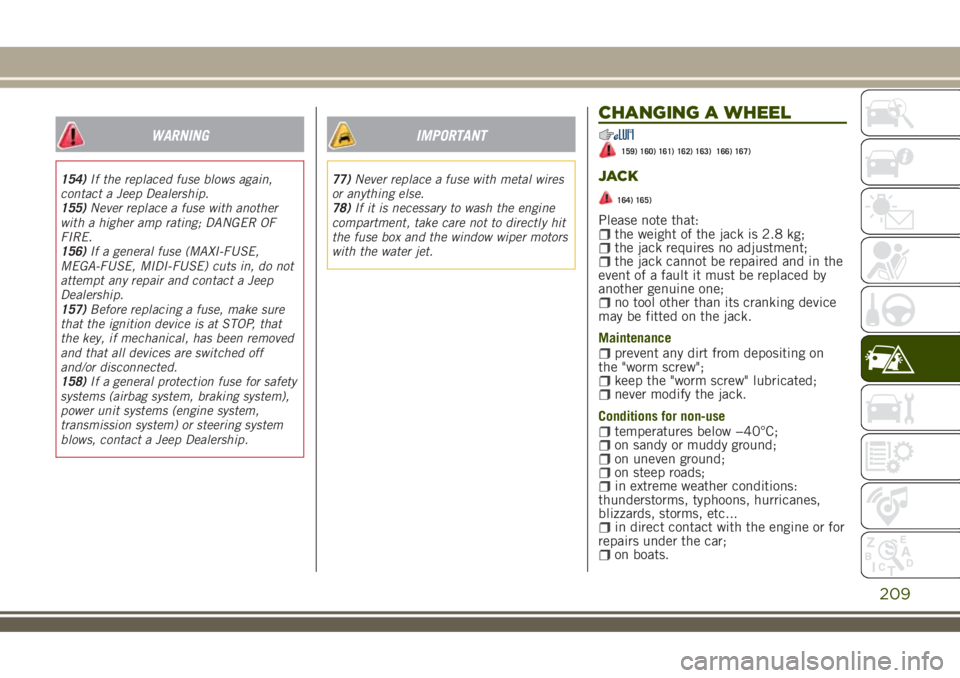

The spare tire, or depending on the

version, the temporary spare tire, are

located under the covering carpet in the

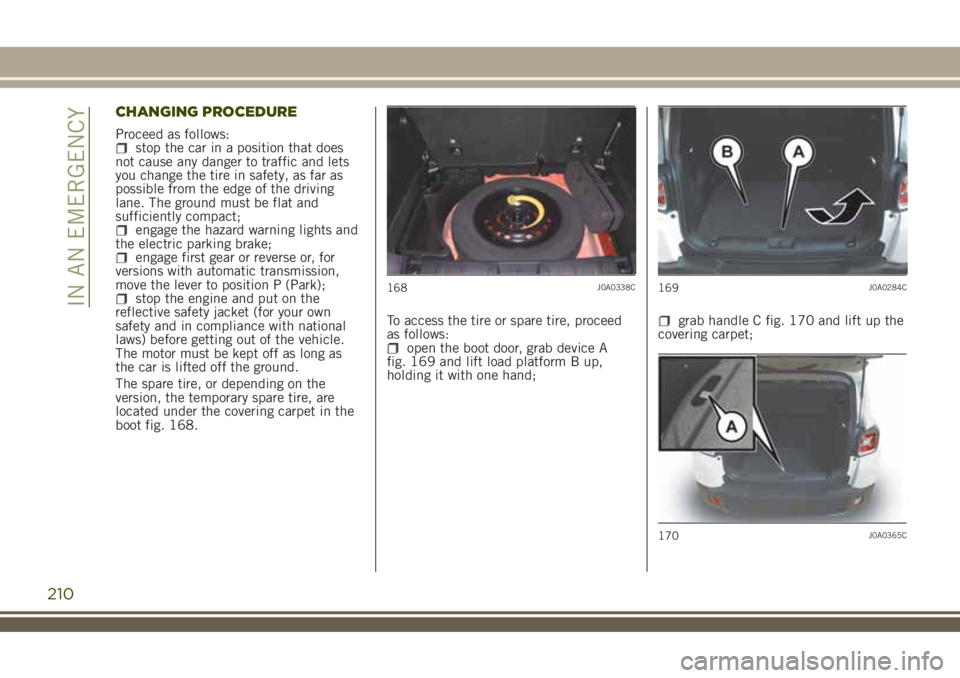

boot fig. 168.To access the tire or spare tire, proceed

as follows:

open the boot door, grab device A

fig. 169 and lift load platform B up,

holding it with one hand;

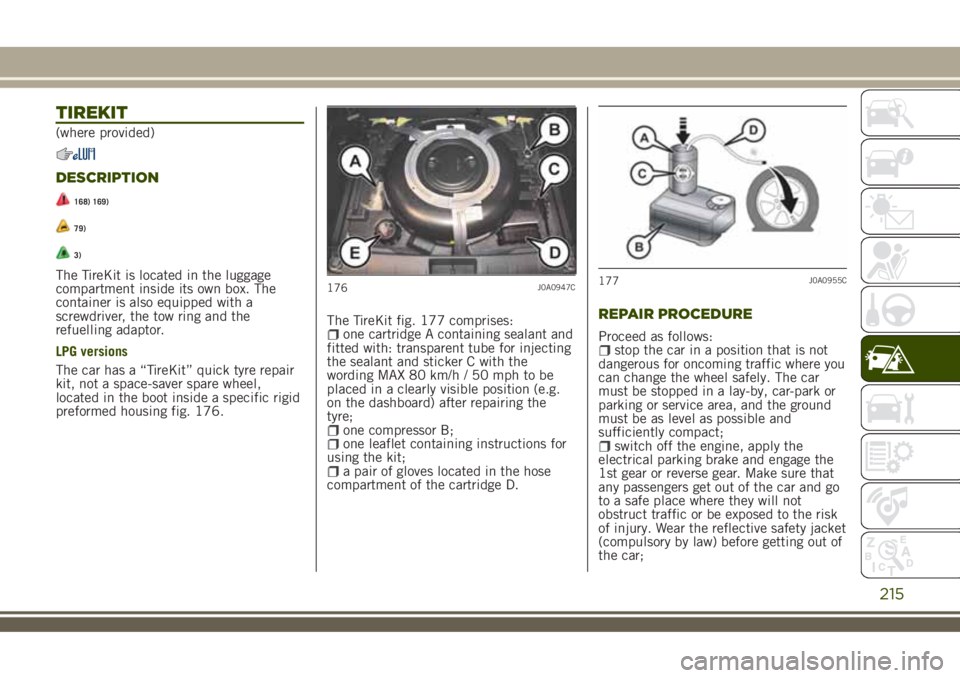

grab handle C fig. 170 and lift up the

covering carpet;

168J0A0338C169J0A0284C

170J0A0365C

210

IN AN EMERGENCY

Page 216 of 356

214

IN AN EMERGENCY

162)The vehicle's driving characteristics

will be modified with the space-saver

wheel fitted. Avoid violent acceleration

and braking, abrupt steering and fast

cornering. The overall duration of the

space-saver wheel is about 3000 km, after

which the relevant tyre must be replaced

with another one of the same type. Never

install a standard tyre on a rim that is

designed for use with a space-saver wheel.

Have the wheel repaired and refitted as

soon as possible. Using two or more

space-saver wheels at the same time is

forbidden. Do not grease the threads of

the stud bolts before fitting them: they

might slip out when driving!

163)The space-saver wheel (where

provided) is specific to your vehicle: do

not use it on other models, or use the

space-saver wheel of other models on your

vehicle. The space-saver wheel must only

be used in the event of an emergency.

Never use it for more than strictly

necessary and never exceed 80 km/h. On

the space-saver wheel there is an orange

label, summarising the main warnings

regarding space-saver wheel usage

restrictions. Never remove or cover the

label. Never apply a wheel cap on a

space-saver wheel.164)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on

other vehicles of the same model. Any

other use, e.g. to jack up other vehicle

models or different things, is strictly

prohibited. Never use it to carry out

servicing or repairs under the vehicle or to

change summer/winter wheels and vice

versa: we advise you to contact a Jeep

Dealership. Never go under the raised

vehicle: use it only in the positions

indicated. Do not use the jack for loads

higher than the one shown on its label.

Never start the engine with car raised. If

the vehicle is raised more than necessary,

everything can become more unstable,

with the risk of the vehicle dropping

violently. Thus, lift the car only as needed

in order to access the space-saver spare

wheel.

165)When turning the jack handle make

sure that it can turn freely without

scraping your hand against the ground.

The moving components of the jack

("worm screw" and joints) can also cause

injuries: do not touch them. If you come

into contact with lubricating grease, clean

yourself thoroughly.166)The space-saver wheel cannot be

fitted with snow chains. If a front (drive)

tyre is punctured and chains are needed,

use a standard wheel from the rear axle

and install the space-saver wheel on the

rear axle. In this way, with two normal

drive wheels at the front axle, it is

possible to use snow chains.

167)Incorrect hub cap assembly, if

present, may cause it to come off when

the vehicle is moving. Never tamper with

the inflation valve. Never introduce tools

of any kind between the rim and the tyre.

Check tyre and space-saver wheel

pressures regularly, complying with the

values given in the "Technical

specifications" chapter.

Page 217 of 356

TIREKIT

(where provided)

DESCRIPTION

168) 169)

79)

3)

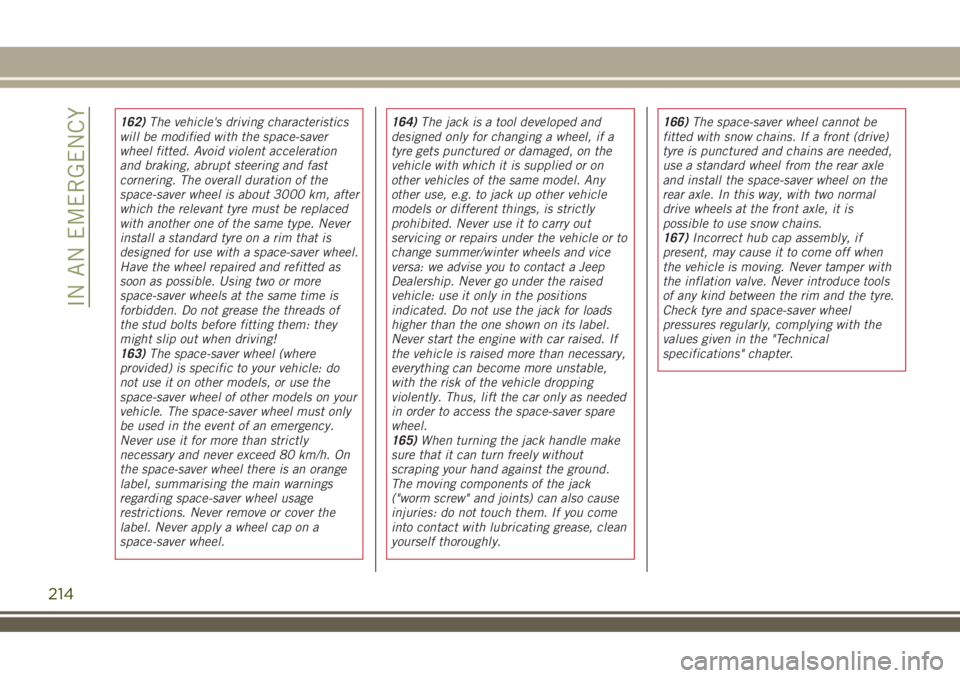

The TireKit is located in the luggage

compartment inside its own box. The

container is also equipped with a

screwdriver, the tow ring and the

refuelling adaptor.

LPG versions

The car has a “TireKit” quick tyre repair

kit, not a space-saver spare wheel,

located in the boot inside a specific rigid

preformed housing fig. 176.The TireKit fig. 177 comprises:

one cartridge A containing sealant and

fitted with: transparent tube for injecting

the sealant and sticker C with the

wording MAX 80 km/h / 50 mph to be

placed in a clearly visible position (e.g.

on the dashboard) after repairing the

tyre;

one compressor B;one leaflet containing instructions for

using the kit;

a pair of gloves located in the hose

compartment of the cartridge D.

REPAIR PROCEDURE

Proceed as follows:stop the car in a position that is not

dangerous for oncoming traffic where you

can change the wheel safely. The car

must be stopped in a lay-by, car-park or

parking or service area, and the ground

must be as level as possible and

sufficiently compact;

switch off the engine, apply the

electrical parking brake and engage the

1st gear or reverse gear. Make sure that

any passengers get out of the car and go

to a safe place where they will not

obstruct traffic or be exposed to the risk

of injury. Wear the reflective safety jacket

(compulsory by law) before getting out of

the car;

176J0A0947C177J0A0955C

215

Page 218 of 356

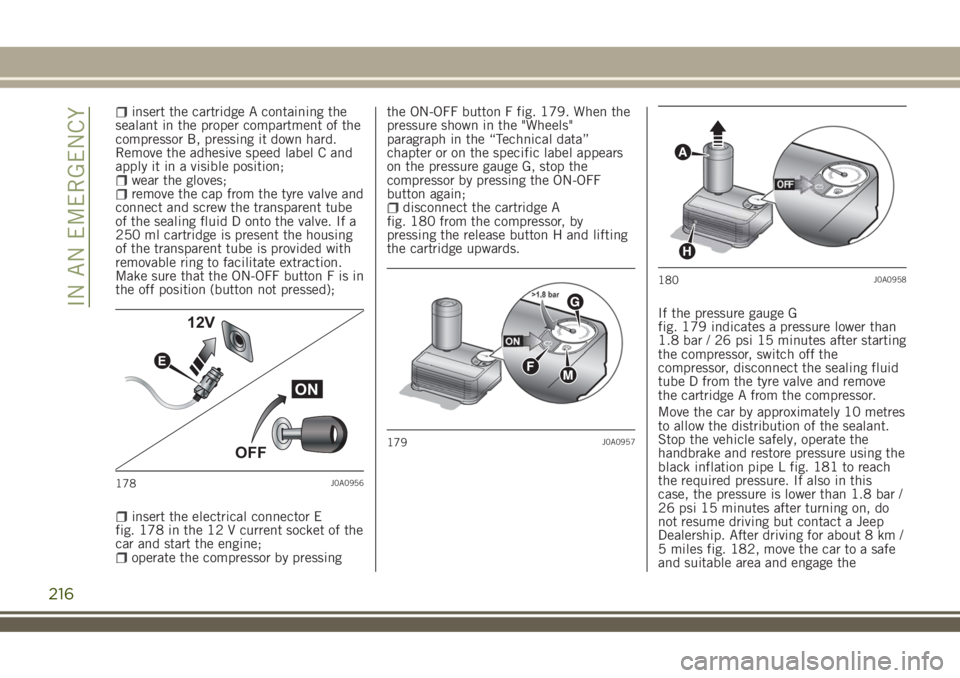

insert the cartridge A containing the

sealant in the proper compartment of the

compressor B, pressing it down hard.

Remove the adhesive speed label C and

apply it in a visible position;

wear the gloves;remove the cap from the tyre valve and

connect and screw the transparent tube

of the sealing fluid D onto the valve. If a

250 ml cartridge is present the housing

of the transparent tube is provided with

removable ring to facilitate extraction.

Make sure that the ON-OFF button F is in

the off position (button not pressed);

insert the electrical connector E

fig. 178 in the 12 V current socket of the

car and start the engine;

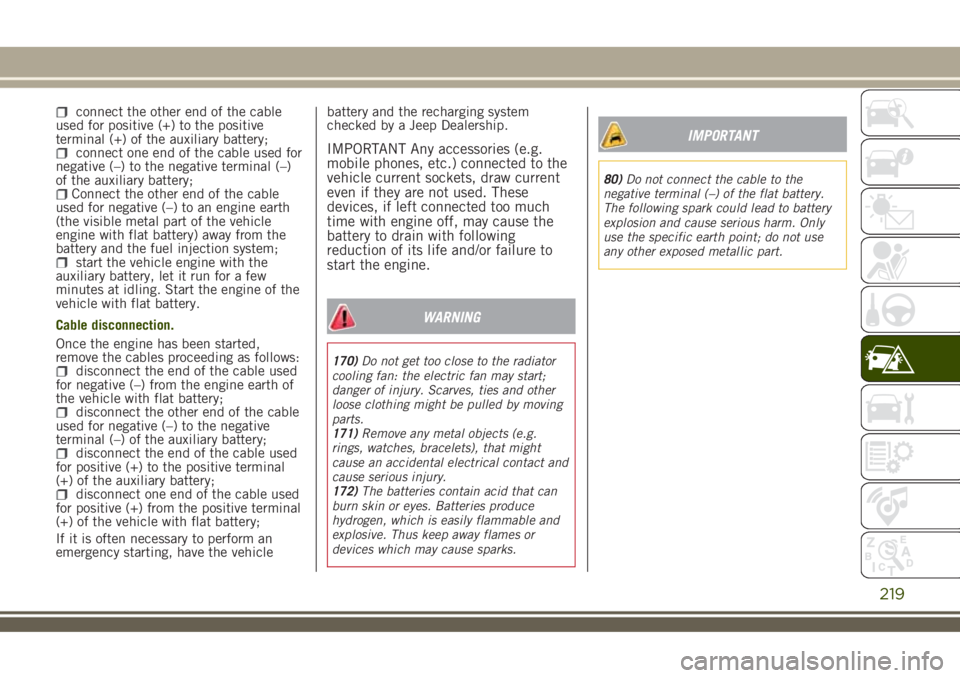

operate the compressor by pressingthe ON-OFF button F fig. 179. When the

pressure shown in the "Wheels"

paragraph in the “Technical data”

chapter or on the specific label appears

on the pressure gauge G, stop the

compressor by pressing the ON-OFF

button again;

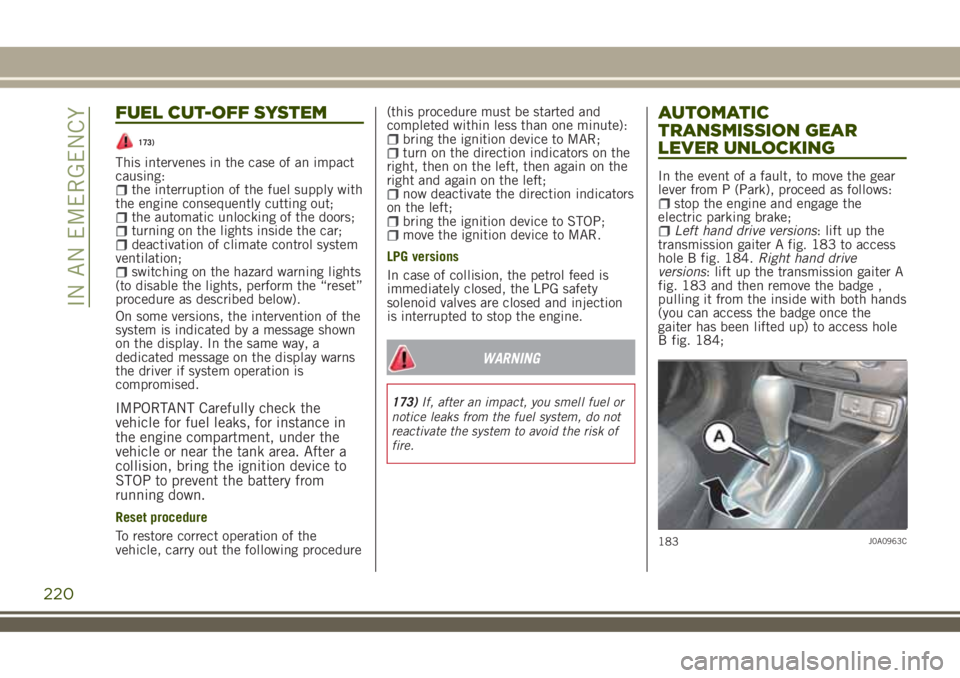

disconnect the cartridge A

fig. 180 from the compressor, by

pressing the release button H and lifting

the cartridge upwards.

If the pressure gauge G

fig. 179 indicates a pressure lower than

1.8 bar / 26 psi 15 minutes after starting

the compressor, switch off the

compressor, disconnect the sealing fluid

tube D from the tyre valve and remove

the cartridge A from the compressor.

Move the car by approximately 10 metres

to allow the distribution of the sealant.

Stop the vehicle safely, operate the

handbrake and restore pressure using the

black inflation pipe L fig. 181 to reach

the required pressure. If also in this

case, the pressure is lower than 1.8 bar /

26 psi 15 minutes after turning on, do

not resume driving but contact a Jeep

Dealership. After driving for about 8 km /

5 miles fig. 182, move the car to a safe

and suitable area and engage the

ON

OFF 12V

E

178J0A0956

179J0A0957

A

H

180J0A0958

216

IN AN EMERGENCY

Page 221 of 356

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used for

negative (–) to the negative terminal (–)

of the auxiliary battery;

Connect the other end of the cable

used for negative (–) to an engine earth

(the visible metal part of the vehicle

engine with flat battery) away from the

battery and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

vehicle with flat battery.

Cable disconnection.

Once the engine has been started,

remove the cables proceeding as follows:

disconnect the end of the cable used

for negative (–) from the engine earth of

the vehicle with flat battery;

disconnect the other end of the cable

used for negative (–) to the negative

terminal (–) of the auxiliary battery;

disconnect the end of the cable used

for positive (+) to the positive terminal

(+) of the auxiliary battery;

disconnect one end of the cable used

for positive (+) from the positive terminal

(+) of the vehicle with flat battery;

If it is often necessary to perform an

emergency starting, have the vehiclebattery and the recharging system

checked by a Jeep Dealership.

IMPORTANT Any accessories (e.g.

mobile phones, etc.) connected to the

vehicle current sockets, draw current

even if they are not used. These

devices, if left connected too much

time with engine off, may cause the

battery to drain with following

reduction of its life and/or failure to

start the engine.

WARNING

170)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.

171)Remove any metal objects (e.g.

rings, watches, bracelets), that might

cause an accidental electrical contact and

cause serious injury.

172)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Thus keep away flames or

devices which may cause sparks.

IMPORTANT

80)Do not connect the cable to the

negative terminal (–) of the flat battery.

The following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use

any other exposed metallic part.

219

Page 222 of 356

FUEL CUT-OFF SYSTEM

173)

This intervenes in the case of an impact

causing:

the interruption of the fuel supply with

the engine consequently cutting out;

the automatic unlocking of the doors;turning on the lights inside the car;deactivation of climate control system

ventilation;

switching on the hazard warning lights

(to disable the lights, perform the “reset”

procedure as described below).

On some versions, the intervention of the

system is indicated by a message shown

on the display. In the same way, a

dedicated message on the display warns

the driver if system operation is

compromised.

IMPORTANT Carefully check the

vehicle for fuel leaks, for instance in

the engine compartment, under the

vehicle or near the tank area. After a

collision, bring the ignition device to

STOP to prevent the battery from

running down.

Reset procedure

To restore correct operation of the

vehicle, carry out the following procedure(this procedure must be started and

completed within less than one minute):

bring the ignition device to MAR;turn on the direction indicators on the

right, then on the left, then again on the

right and again on the left;

now deactivate the direction indicators

on the left;

bring the ignition device to STOP;move the ignition device to MAR.

LPG versions

In case of collision, the petrol feed is

immediately closed, the LPG safety

solenoid valves are closed and injection

is interrupted to stop the engine.

WARNING

173)If, after an impact, you smell fuel or

notice leaks from the fuel system, do not

reactivate the system to avoid the risk of

fire.

AUTOMATIC

TRANSMISSION GEAR

LEVER UNLOCKING

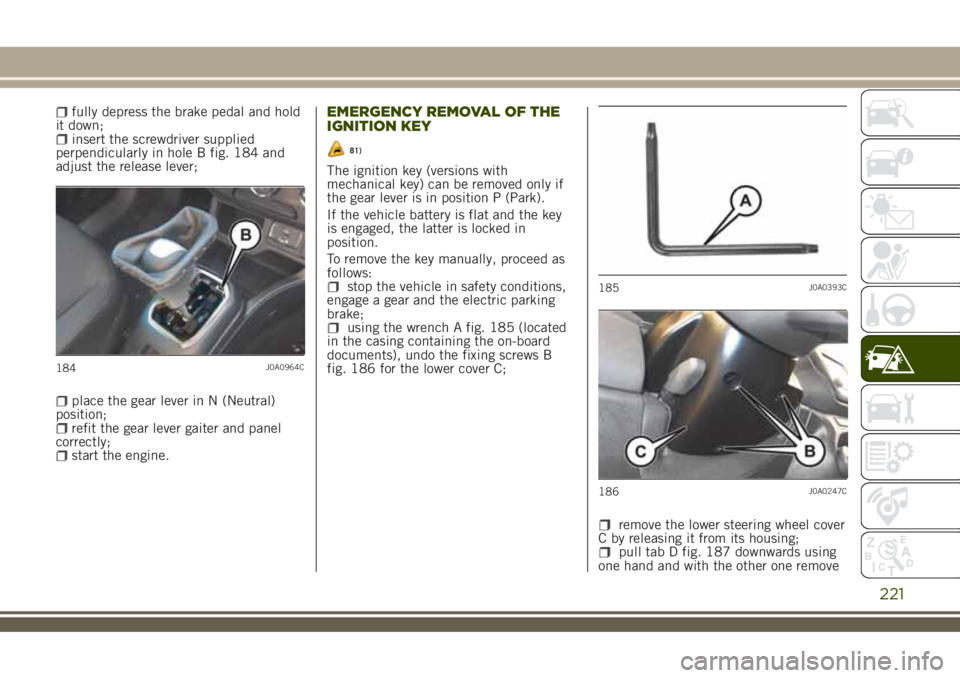

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

stop the engine and engage the

electric parking brake;

Left hand drive versions: lift up the

transmission gaiter A fig. 183 to access

hole B fig. 184.Right hand drive

versions: lift up the transmission gaiter A

fig. 183 and then remove the badge ,

pulling it from the inside with both hands

(you can access the badge once the

gaiter has been lifted up) to access hole

B fig. 184;

183J0A0963C

220

IN AN EMERGENCY

Page 223 of 356

fully depress the brake pedal and hold

it down;

insert the screwdriver supplied

perpendicularly in hole B fig. 184 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and panel

correctly;

start the engine.

EMERGENCY REMOVAL OF THE

IGNITION KEY

81)

The ignition key (versions with

mechanical key) can be removed only if

the gear lever is in position P (Park).

If the vehicle battery is flat and the key

is engaged, the latter is locked in

position.

To remove the key manually, proceed as

follows:

stop the vehicle in safety conditions,

engage a gear and the electric parking

brake;

using the wrench A fig. 185 (located

in the casing containing the on-board

documents), undo the fixing screws B

fig. 186 for the lower cover C;

remove the lower steering wheel cover

C by releasing it from its housing;

pull tab D fig. 187 downwards using

one hand and with the other one remove

184J0A0964C

185J0A0393C

186J0A0247C

221

Page 224 of 356

the key, sliding it outwards;once the key has been removed, refit

lower cover C, make sure it locks

correctly and tighten the fixing screws B

firmly.IMPORTANT

81)It is advisable to contact a Jeep

Dealership to have the refitting procedure

carried out. If you would like to proceed

autonomously, special attention must be

paid to the correct coupling of the

retaining clips. Otherwise, noise might be

heard due to an incorrect fastening of the

lower cover with the upper cover.

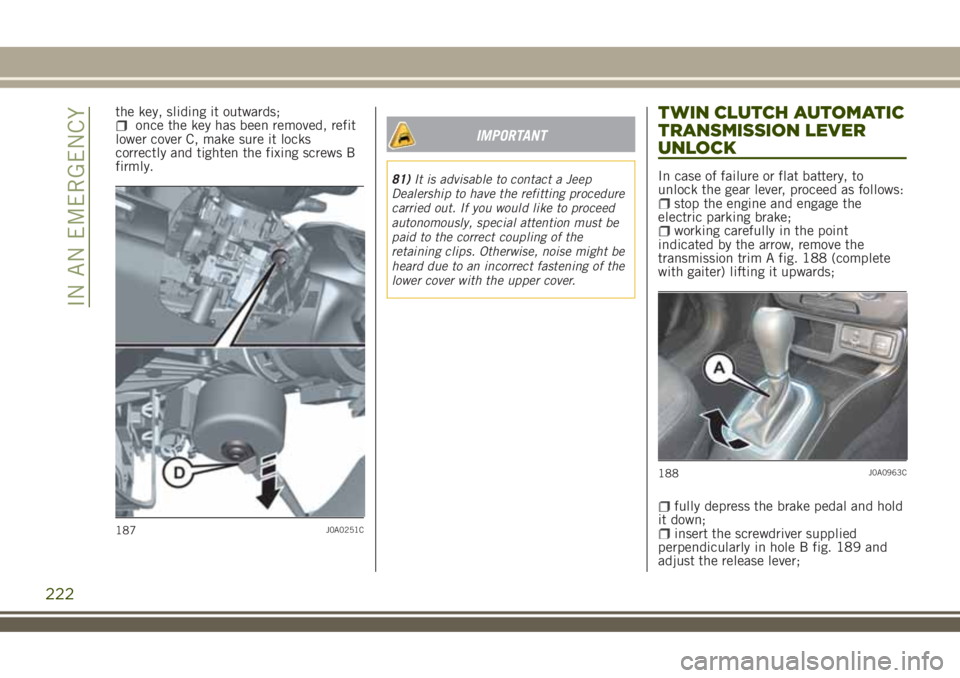

TWIN CLUTCH AUTOMATIC

TRANSMISSION LEVER

UNLOCK

In case of failure or flat battery, to

unlock the gear lever, proceed as follows:

stop the engine and engage the

electric parking brake;

working carefully in the point

indicated by the arrow, remove the

transmission trim A fig. 188 (complete

with gaiter) lifting it upwards;

fully depress the brake pedal and hold

it down;

insert the screwdriver supplied

perpendicularly in hole B fig. 189 and

adjust the release lever;187J0A0251C

188J0A0963C

222

IN AN EMERGENCY

Page 225 of 356

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and panel

correctly;

start the engine.

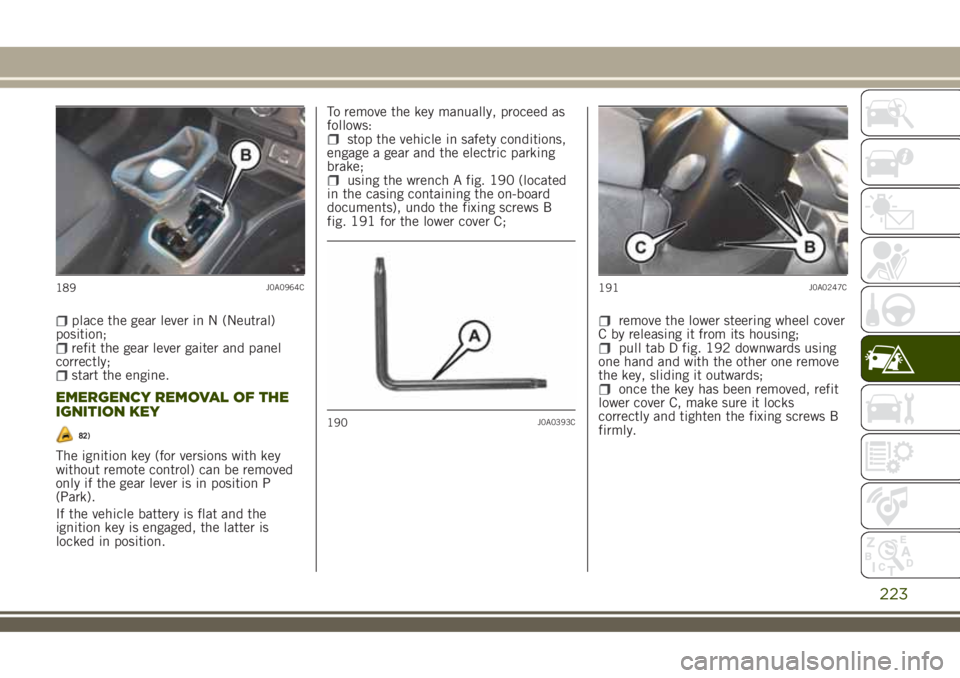

EMERGENCY REMOVAL OF THE

IGNITION KEY

82)

The ignition key (for versions with key

without remote control) can be removed

only if the gear lever is in position P

(Park).

If the vehicle battery is flat and the

ignition key is engaged, the latter is

locked in position.To remove the key manually, proceed as

follows:

stop the vehicle in safety conditions,

engage a gear and the electric parking

brake;

using the wrench A fig. 190 (located

in the casing containing the on-board

documents), undo the fixing screws B

fig. 191 for the lower cover C;

remove the lower steering wheel cover

C by releasing it from its housing;

pull tab D fig. 192 downwards using

one hand and with the other one remove

the key, sliding it outwards;

once the key has been removed, refit

lower cover C, make sure it locks

correctly and tighten the fixing screws B

firmly.

189J0A0964C

190J0A0393C

191J0A0247C

223