lock JEEP RENEGADE 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: RENEGADE, Model: JEEP RENEGADE 2023Pages: 364, PDF Size: 18.65 MB

Page 276 of 364

274 IN CASE OF EMERGENCY

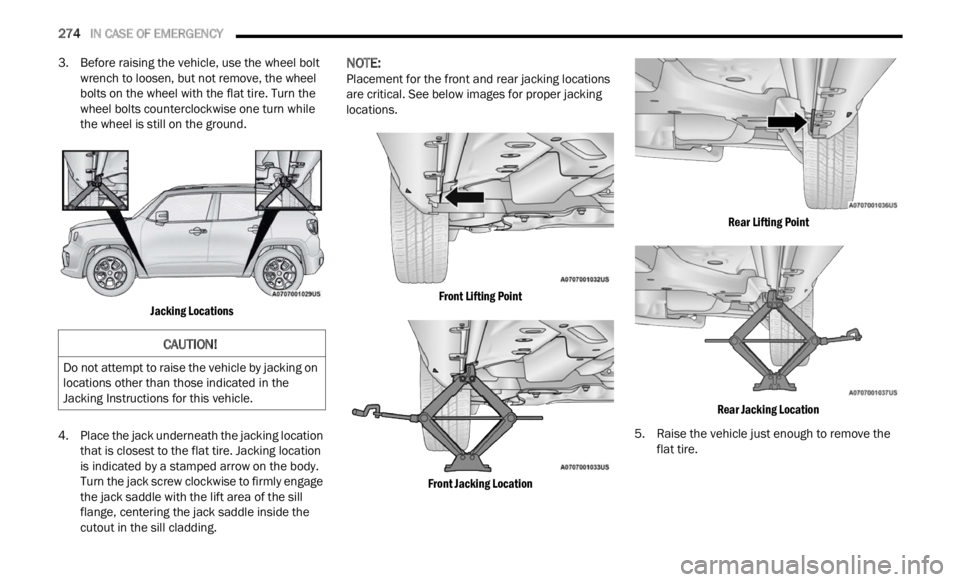

3. Before raising the vehicle, use the wheel bolt

wrench to loosen, but not remove, the wheel

bolts on the wheel with the flat tire. Turn the

wheel bolts counterclockwise one turn while

the wheel is still on the ground.

Jacking Locations

4. Place the jack underneath the jacking location that

is closest to the flat tire. Jacking location

is indicated by a stamped arrow on the body.

Turn the jack screw clockwise to firmly engage

the jack saddle with the lift area of the sill

flange, centering the jack saddle inside the

cutout in the sill cladding.

NOTE:

Placement for the front and rear jacking locations

are c r

itical. See below images for proper jacking

locations.

Front Lifting Point

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat

tire.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

Page 277 of 364

IN CASE OF EMERGENCY 275

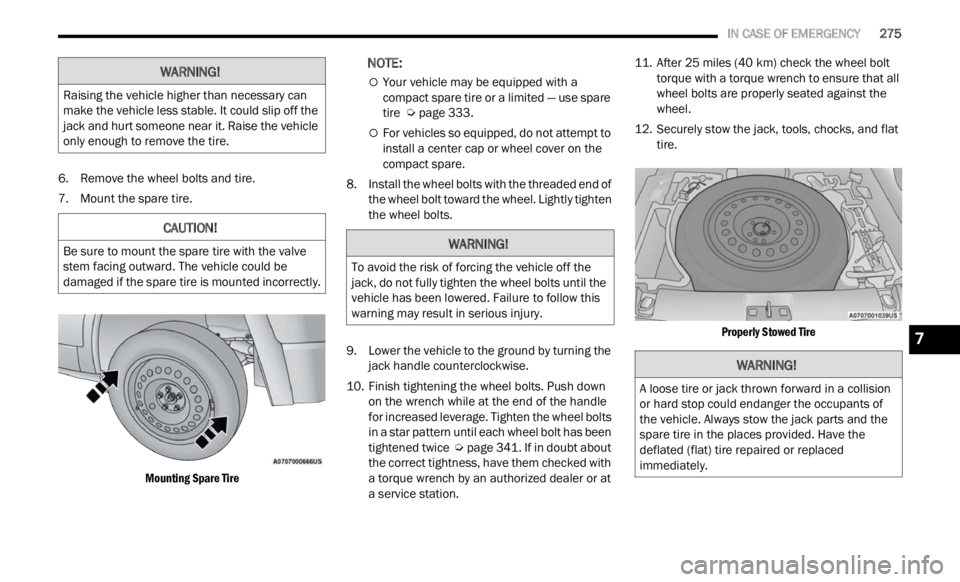

6. Remove the wheel bolts and tire.

7. M

ount the spare tire.

Mo

un

t

ing Spare Tire

NOTE:

Your vehicle may be equipped with a

compact spare tire or a limited — use spare

tire Ú page 333.

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

8. Install the wheel bolts with the threaded end of the w

heel bolt toward the wheel. Lightly tighten

the wheel bolts.

9. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the

wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice Ú page 341. If in doubt about

the correct tightness, have them checked with

a torq u

e wrench by an authorized dealer or at

a service station. 11. After 25

mile

s (40 km) check the wheel bolt

torque

with a torque wrench to ensure that all

wheel bolts are properly seated against the

wheel.

12. Securely stow the jack, tools, chocks, and flat tire.

P

roperly Stowed Tire

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not fully tighten the wheel bolts until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

Page 284 of 364

282 IN CASE OF EMERGENCY

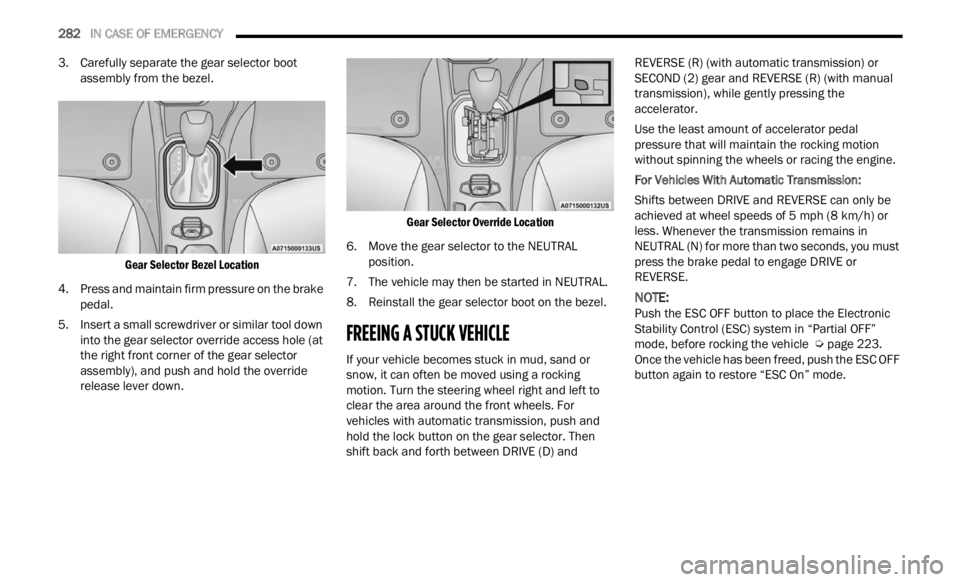

3. Carefully separate the gear selector boot

assembly from the bezel.

Gear Selector Bezel Location

4. Press and maintain firm pressure on the brake peda l

.

5. Insert a small screwdriver or similar tool down into t

he gear selector override access hole (at

the right front corner of the gear selector

assembly), and push and hold the override

release lever down.

Gear Selector Override Location

6. Move the gear selector to the NEUTRAL posit i

on.

7. The vehicle may then be started in NEUTRAL.

8. R ein

stall the gear selector boot on the bezel.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. For

vehicles with automatic transmission, push and

hold the lock button on the gear selector. Then

shift back and forth between DRIVE (D) and REVERSE (R) (with automatic transmission) or

SECOND (2) gear and REVERSE (R) (with manual

transmission), while gently pressing the

accelerator.

Use the least amount of accelerator pedal

pressu

re that will maintain the rocking motion

without spinning the wheels or racing the engine.

For Vehicles With Automatic Transmission:

Shifts between DRIVE and REVERSE can only be

a chiev

ed at wheel speeds of 5 mph (8 km/h) or

less.

Whenever the transmission remains in

NEUTRAL (N) for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

NOTE:

Push the ESC OFF button to place the Electronic

Stabi l

ity Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 223.

Once the vehicle has been freed, push the ESC OFF

button

again to restore “ESC On” mode.

Page 299 of 364

SERVICING AND MAINTENANCE 297

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. The manufacturer

recommends that air conditioning service be

performed by an authorized dealer using recovery

and recycling equipment.

NOTE:

Use only the manufacturer approved A/C system

PAG c om

pressor oil, and refrigerants.

Cabin Air Cleaner

See an authorized dealer for service.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice

a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods

may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from th

e windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies depending

on geog r

aphical area and frequency of use. Poor

performance of blades may be present with chat -tering, marks, water lines or wet spots. If any of

these

conditions are present, clean the wiper

blades or replace as necessary.

Service Position Strategy

The service position allows the wiper blades to be

placed in a position that allows the wiper blades to

be easily changed.

To enable the Service Position Strategy, the wipers

must b

e in the Park position before placing the

ignition in the STOP/OFF position.

Service mode must be activated within two

minut e

s after the ignition is placed in the STOP/

OFF position.

To have a correct activation of strategy, the Service

Positi on

command (antipanic) must be active for at

least half a second.

At every valid activation of Service Position

comman d

, the wiper blades are activated for

250 ms.

The Service Position command can be repeated

sever a

l times to bring the blades into the desired

position, up to a maximum of three times.

After three subsequent activations the strategy is

disab l

ed.

8

Page 308 of 364

306 SERVICING AND MAINTENANCE

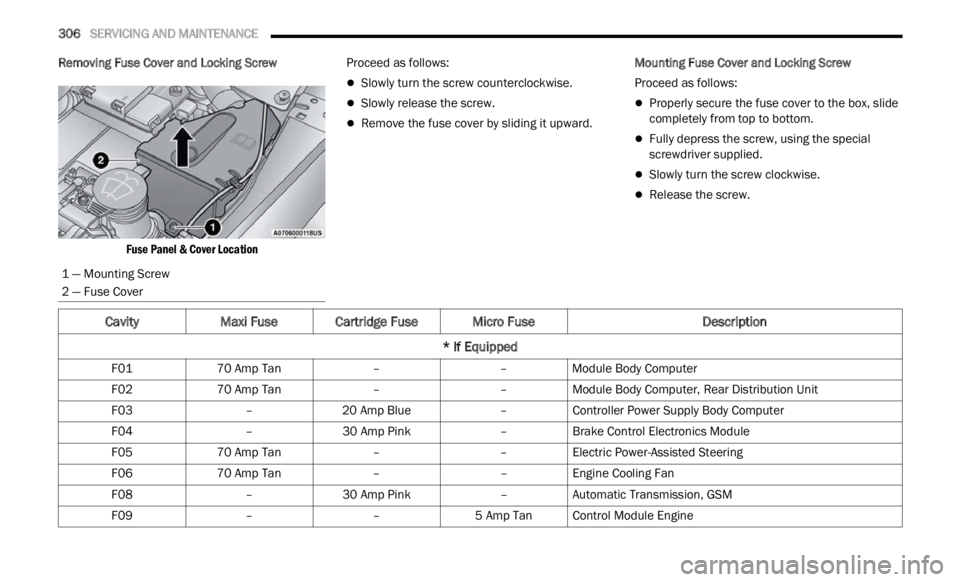

Removing Fuse Cover and Locking Screw

Fuse Panel & Cover Location

Proceed as follows:

Slowly turn the screw counterclockwise.

Slowly release the screw.

Remove the fuse cover by sliding it upward.

Mounting Fuse Cover and Locking Screw

Proceed as follows:

Properly secure the fuse cover to the box, slide

completely from top to bottom.

Fully depress the screw, using the special

screwdriver supplied.

Slowly turn the screw clockwise.

Release the screw.

1 — Mounting Screw

2 — Fuse Cover

CavityMaxi Fuse Cartridge Fuse Micro Fuse Description

* If Equipped

F01 70 Amp Tan ––Module Body Computer

F02 70 Amp Tan ––Module Body Computer, Rear Distribution Unit

F03 –20 Amp Blue –Controller Power Supply Body Computer

F04 –30 Amp Pink –Brake Control Electronics Module

F05 70 Amp Tan ––Electric Power-Assisted Steering

F06 70 Amp Tan ––Engine Cooling Fan

F08 –30 Amp Pink –Automatic Transmission, GSM

F09 ––5 Amp TanControl Module Engine

Page 310 of 364

308 SERVICING AND MAINTENANCE

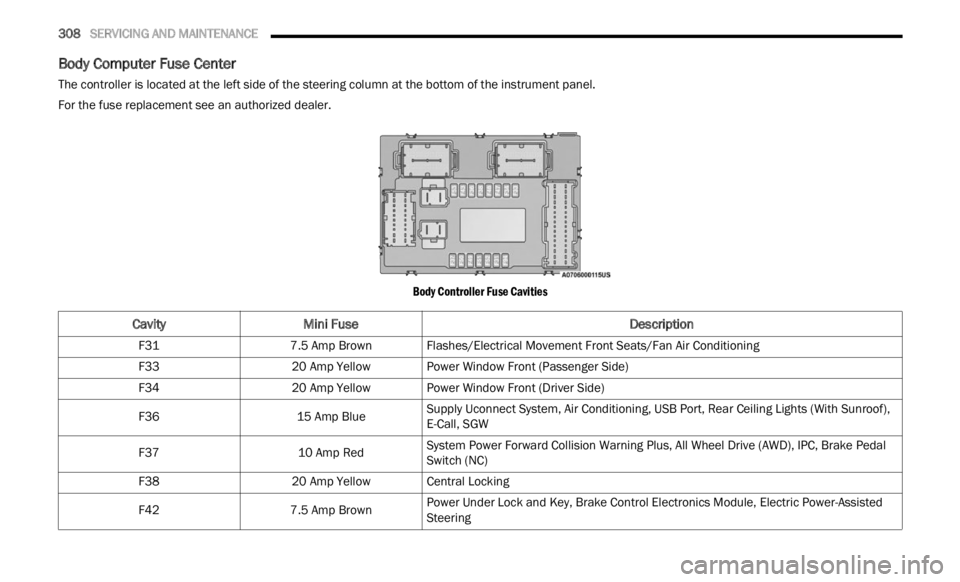

Body Computer Fuse Center

The controller is located at the left side of the steering column at the bottom of the instrument panel.

For the fuse replacement see an authorized dealer.

Body Controller Fuse Cavities

CavityMini Fuse Description

F317.5 Amp BrownFlashes/Electrical Movement Front Seats/Fan Air Conditioning

F33 20 Amp YellowPower Window Front (Passenger Side)

F34 20 Amp YellowPower Window Front (Driver Side)

F36 15 Amp BlueSupply Uconnect System, Air Conditioning, USB Port, Rear Ceiling Lights (With Sunroof),

E-Call

, SGW

F37 10 Amp RedSystem Power Forward Collision Warning Plus, All Wheel Drive (AWD), IPC, Brake Pedal

Switc

h

(NC)

F38 20 Amp YellowCentral Locking

F42 7.5 Amp BrownPower Under Lock and Key, Brake Control Electronics Module, Electric Power-Assisted

Steer

i

ng

Page 315 of 364

SERVICING AND MAINTENANCE 313

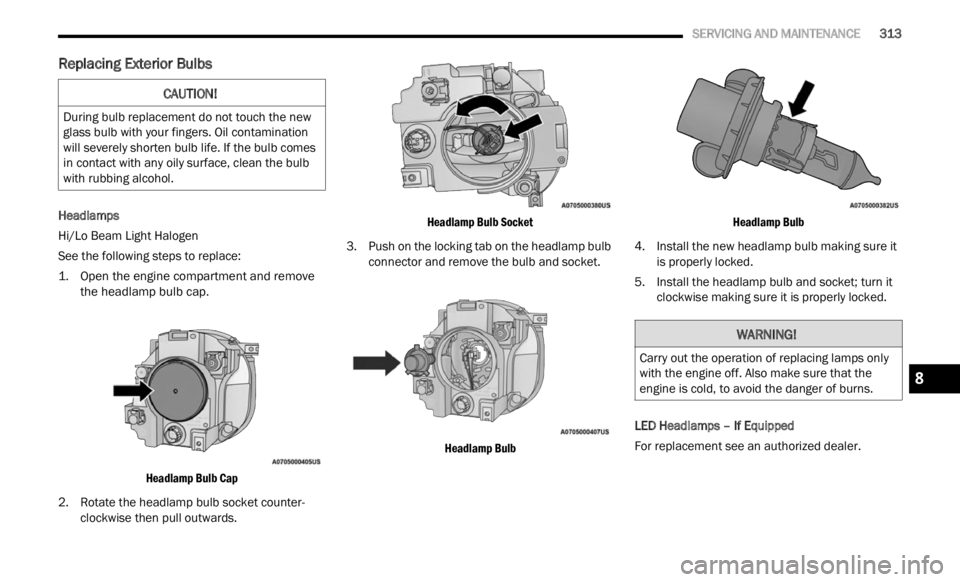

Replacing Exterior Bulbs

Headlamps

Hi/Lo Beam Light Halogen

See the following steps to replace:

1. O

pen the engine compartment and remove

the he a

dlamp bulb cap.

Headlamp Bulb Cap

2. Rotate the headlamp bulb socket counter -

clock w

ise then pull outwards.

Headlamp Bulb Socket

3. P ush on the locking tab on the headlamp bulb

conne c

tor and remove the bulb and socket.

Headlamp Bulb Headlamp Bulb

4. Install the new headlamp bulb making sure it is pr operly locked.

5. Install the headlamp bulb and socket; turn it clockw

ise making sure it is properly locked.

LED Headlamps – If Equipped

For replacement see an authorized dealer.

CAUTION!

During bulb replacement do not touch the new

glass bulb with your fingers. Oil contamination

will severely shorten bulb life. If the bulb comes

in contact with any oily surface, clean the bulb

with rubbing alcohol.

WARNING!

Carry out the operation of replacing lamps only

with the engine off. Also make sure that the

engine is cold, to avoid the danger of burns.

8

Page 316 of 364

314 SERVICING AND MAINTENANCE

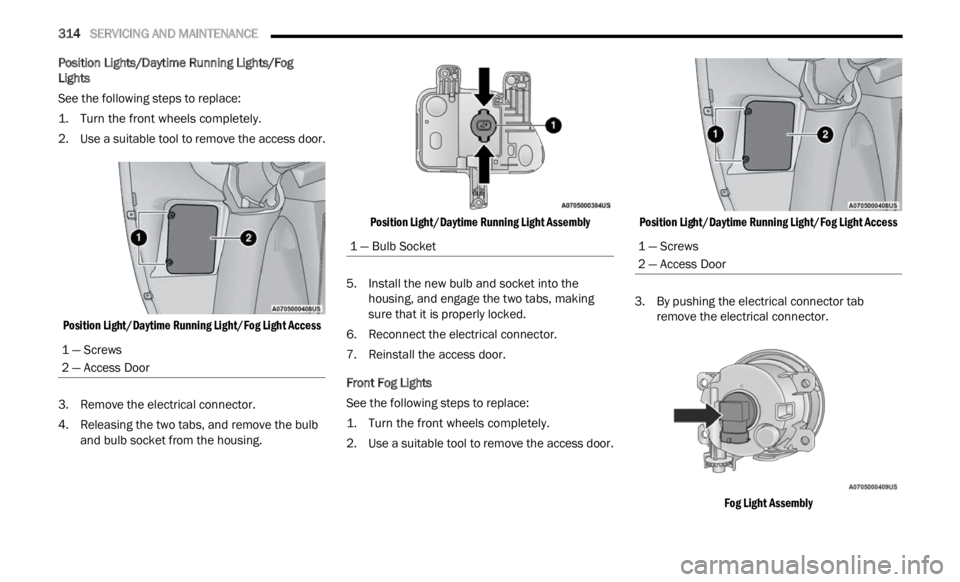

Position Lights/Daytime Running Lights/Fog

Lights

See the following steps to replace:

1. Turn the front wheels completely.

2. Us e

a suitable tool to remove the access door.

Posi t

ion Light/Daytime Running Light/Fog Light Access

3. Remove the electrical connector.

4. Re l

easing the two tabs, and remove the bulb

and b

ulb socket from the housing.

Position Light/Daytime Running Light Assembly

5. Install the new bulb and socket into the housi n

g, and engage the two tabs, making

sure that it is properly locked.

6. Reconnect the electrical connector.

7. Re i

nstall the access door.

Front

Fog Lights

See the following steps to replace:

1. T urn the front wheels completely.

2. Us e

a suitable tool to remove the access door.

Posi

t

ion Light/Daytime Running Light/Fog Light Access

3. By pushing the electrical connector tab remov e

the electrical connector.

Fog Light Assembly

1 — Screws

2 — Access Door

1 — Bulb Socket1 — Screws

2 — Access Door

Page 317 of 364

SERVICING AND MAINTENANCE 315

4. Rotate the bulb counterclockwise, and then

replace the bulb.

5. Insert the new bulb in the socket, making sure the b

ulb is locked into place.

6. Reconnect the electrical connector.

7. R ein

stall the access door.

LE D

F

r

ont Fog Lamps – If Equipped

For replacement see an authorized dealer.

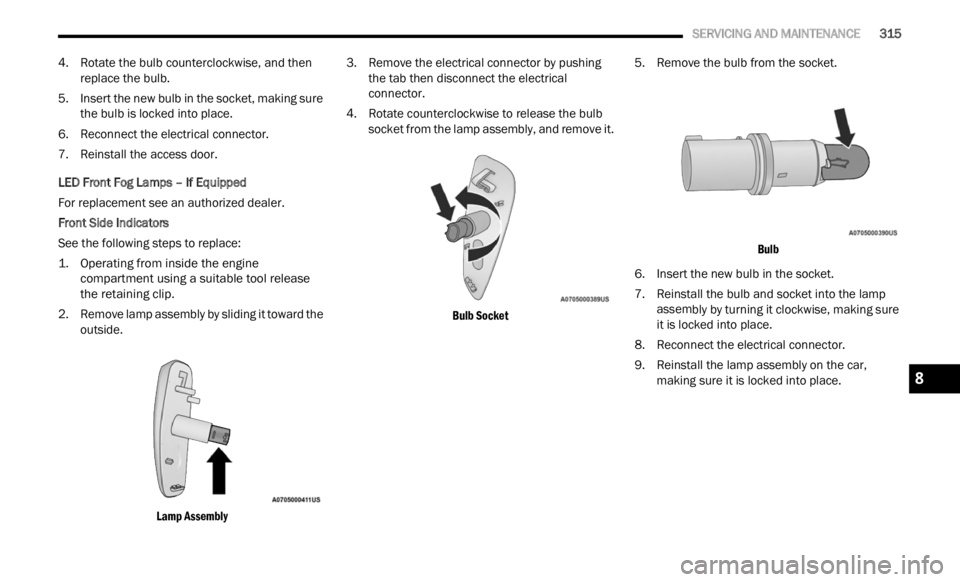

Front Side Indicators

See the following steps to replace:

1. O perating from inside the engine

comp a

rtment using a suitable tool release

the retaining clip.

2. Remove lamp assembly by sliding it toward the outsi d

e.

Lamp Assembly

3. Remove the electrical connector by pushing

the t

ab then disconnect the electrical

connector.

4. Rotate counterclockwise to release the bulb socke t

from the lamp assembly, and remove it.

Bulb Socket

5. Remove the bulb from the socket.

Bulb

6 .

Insert the new bulb in the socket.

7. Rei

nstall the bulb and socket into the lamp

asse m

bly by turning it clockwise, making sure

it is locked into place.

8. Reconnect the electrical connector.

9. R ein

stall the lamp assembly on the car,

m a

ki

n

g sure it is locked into place.8

Page 318 of 364

316 SERVICING AND MAINTENANCE

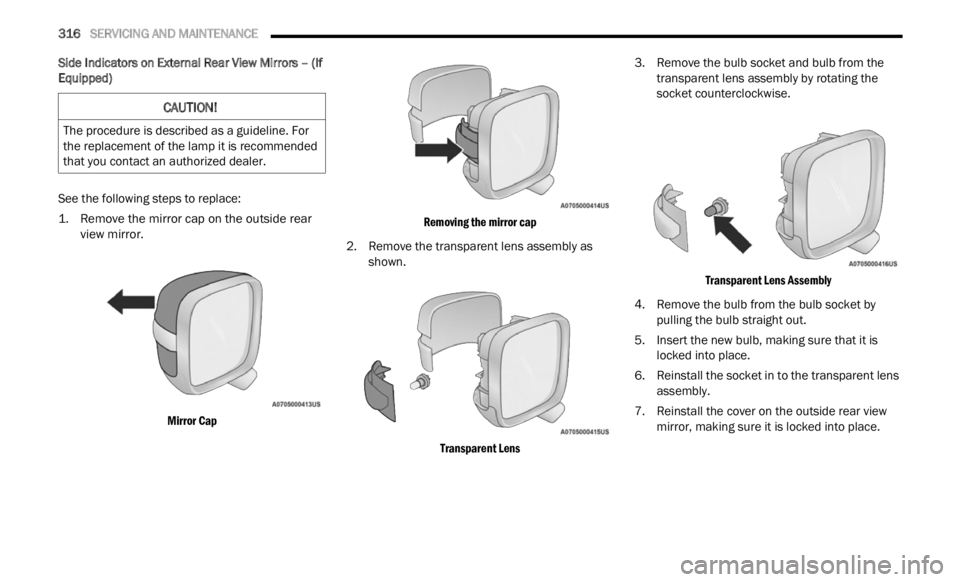

Side Indicators on External Rear View Mirrors – (If

Equipped)

See the following steps to replace:

1. Remove the mirror cap on the outside rear

view m

irror.

Mirror Cap Removing the mirror cap

2. Remove the transparent lens assembly as shown .

T

ransparent Lens

3. Remove the bulb socket and bulb from the

trans

parent lens assembly by rotating the

socket counterclockwise.

Transparent Lens Assembly

4. Remove the bulb from the bulb socket by pulli

ng the bulb straight out.

5. Insert the new bulb, making sure that it is locked

into place.

6. Reinstall the socket in to the transparent lens assem

bly.

7. Reinstall the cover on the outside rear view mirror

, making sure it is locked into place.

CAUTION!

The procedure is described as a guideline. For

the replacement of the lamp it is recommended

that you contact an authorized dealer.