JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1931 of 2158

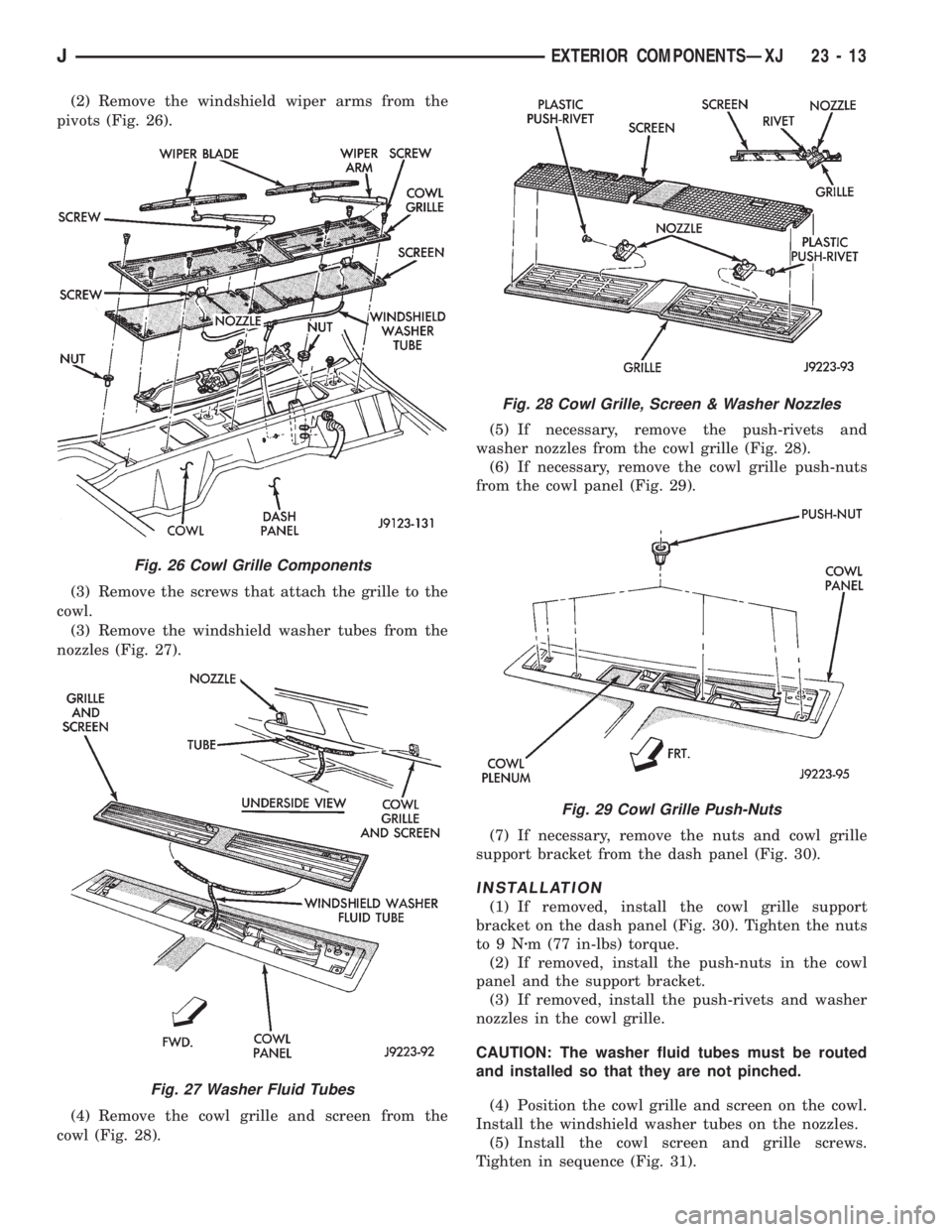

(2) Remove the windshield wiper arms from the

pivots (Fig. 26).

(3) Remove the screws that attach the grille to the

cowl.

(3) Remove the windshield washer tubes from the

nozzles (Fig. 27).

(4) Remove the cowl grille and screen from the

cowl (Fig. 28).(5) If necessary, remove the push-rivets and

washer nozzles from the cowl grille (Fig. 28).

(6) If necessary, remove the cowl grille push-nuts

from the cowl panel (Fig. 29).

(7) If necessary, remove the nuts and cowl grille

support bracket from the dash panel (Fig. 30).

INSTALLATION

(1) If removed, install the cowl grille support

bracket on the dash panel (Fig. 30). Tighten the nuts

to9Nzm (77 in-lbs) torque.

(2) If removed, install the push-nuts in the cowl

panel and the support bracket.

(3) If removed, install the push-rivets and washer

nozzles in the cowl grille.

CAUTION: The washer fluid tubes must be routed

and installed so that they are not pinched.

(4) Position the cowl grille and screen on the cowl.

Install the windshield washer tubes on the nozzles.

(5) Install the cowl screen and grille screws.

Tighten in sequence (Fig. 31).

Fig. 26 Cowl Grille Components

Fig. 27 Washer Fluid Tubes

Fig. 28 Cowl Grille, Screen & Washer Nozzles

Fig. 29 Cowl Grille Push-Nuts

JEXTERIOR COMPONENTSÐXJ 23 - 13

Page 1932 of 2158

Force the cowl grille rearward while tighten-

ing the screws.

(6) Install the windshield wiper arms on the piv-

ots.

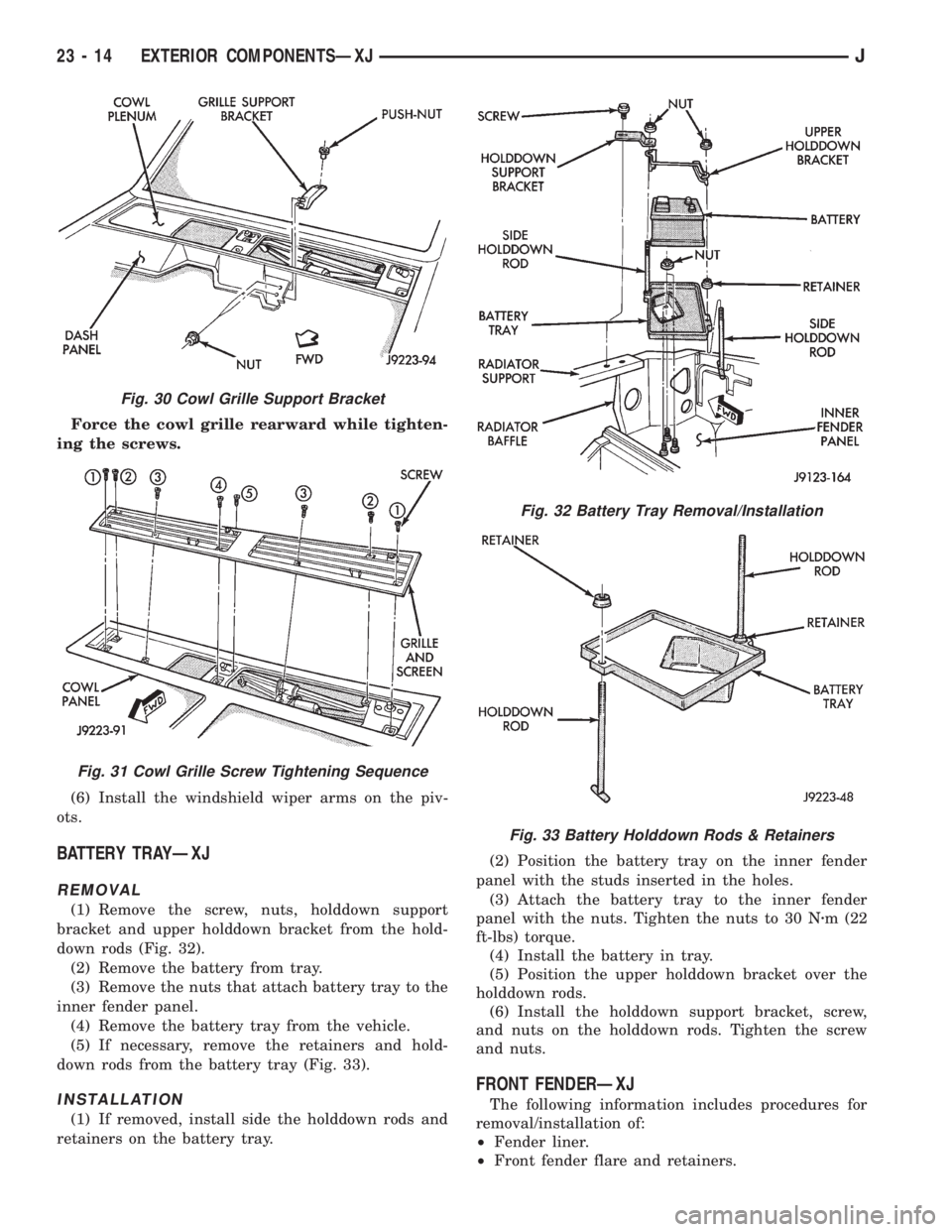

BATTERY TRAYÐXJ

REMOVAL

(1) Remove the screw, nuts, holddown support

bracket and upper holddown bracket from the hold-

down rods (Fig. 32).

(2) Remove the battery from tray.

(3) Remove the nuts that attach battery tray to the

inner fender panel.

(4) Remove the battery tray from the vehicle.

(5) If necessary, remove the retainers and hold-

down rods from the battery tray (Fig. 33).

INSTALLATION

(1) If removed, install side the holddown rods and

retainers on the battery tray.(2) Position the battery tray on the inner fender

panel with the studs inserted in the holes.

(3) Attach the battery tray to the inner fender

panel with the nuts. Tighten the nuts to 30 Nzm (22

ft-lbs) torque.

(4) Install the battery in tray.

(5) Position the upper holddown bracket over the

holddown rods.

(6) Install the holddown support bracket, screw,

and nuts on the holddown rods. Tighten the screw

and nuts.

FRONT FENDERÐXJ

The following information includes procedures for

removal/installation of:

²Fender liner.

²Front fender flare and retainers.

Fig. 30 Cowl Grille Support Bracket

Fig. 31 Cowl Grille Screw Tightening Sequence

Fig. 32 Battery Tray Removal/Installation

Fig. 33 Battery Holddown Rods & Retainers

23 - 14 EXTERIOR COMPONENTSÐXJJ

Page 1933 of 2158

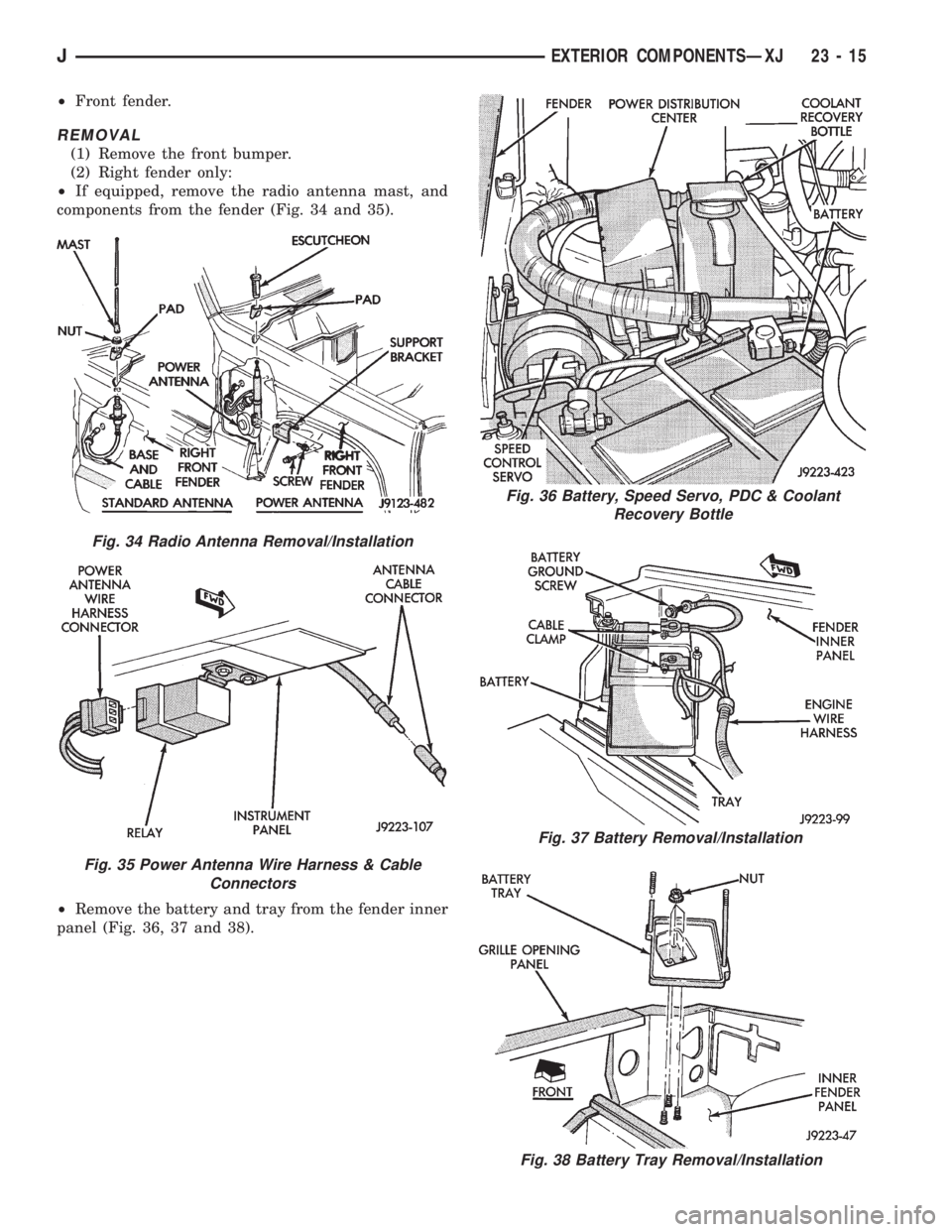

²Front fender.

REMOVAL

(1) Remove the front bumper.

(2) Right fender only:

²If equipped, remove the radio antenna mast, and

components from the fender (Fig. 34 and 35).

²Remove the battery and tray from the fender inner

panel (Fig. 36, 37 and 38).

Fig. 36 Battery, Speed Servo, PDC & Coolant

Recovery Bottle

Fig. 37 Battery Removal/Installation

Fig. 38 Battery Tray Removal/Installation

Fig. 34 Radio Antenna Removal/Installation

Fig. 35 Power Antenna Wire Harness & Cable

Connectors

JEXTERIOR COMPONENTSÐXJ 23 - 15

Page 1934 of 2158

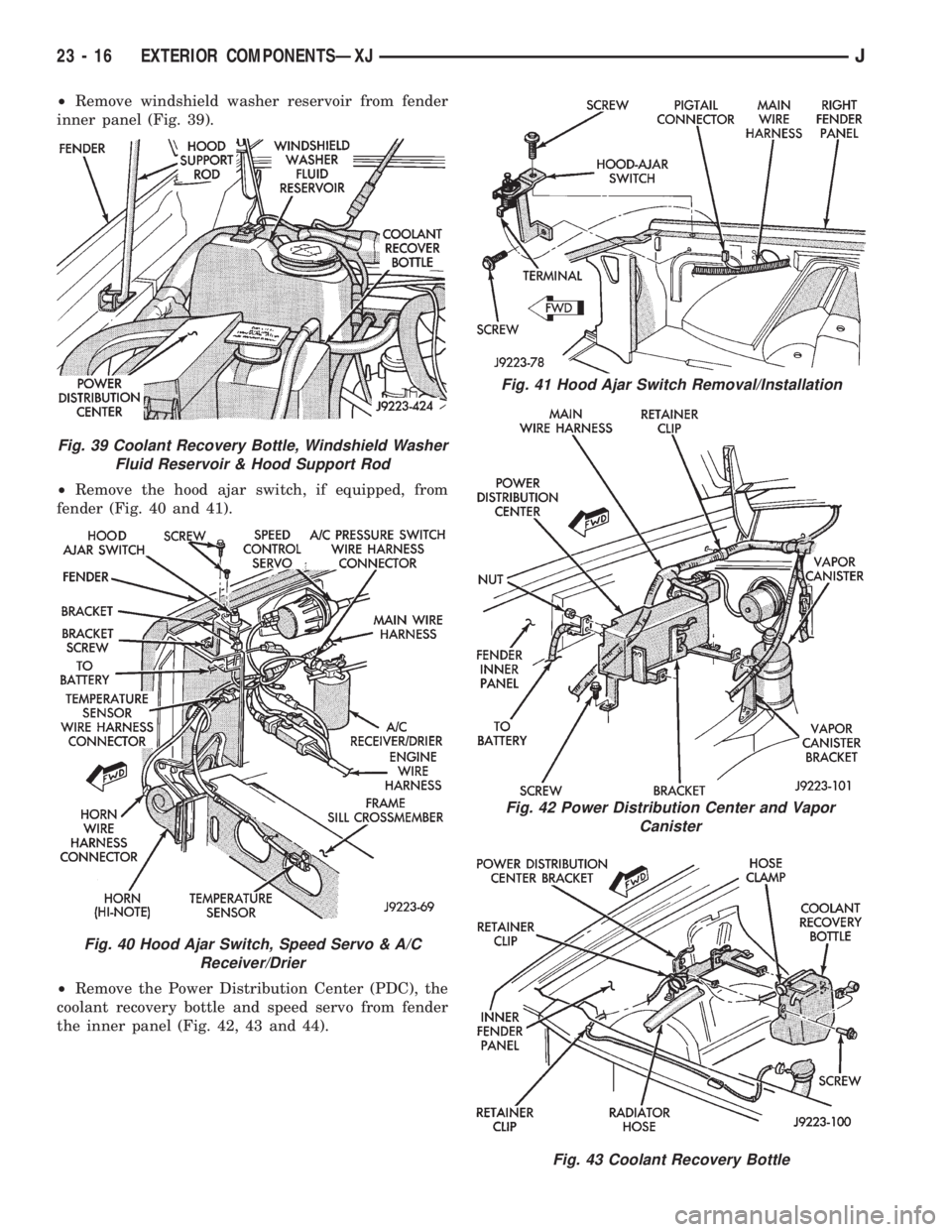

²Remove windshield washer reservoir from fender

inner panel (Fig. 39).

²Remove the hood ajar switch, if equipped, from

fender (Fig. 40 and 41).

²Remove the Power Distribution Center (PDC), the

coolant recovery bottle and speed servo from fender

the inner panel (Fig. 42, 43 and 44).

Fig. 41 Hood Ajar Switch Removal/Installation

Fig. 42 Power Distribution Center and Vapor

Canister

Fig. 43 Coolant Recovery Bottle

Fig. 39 Coolant Recovery Bottle, Windshield Washer

Fluid Reservoir & Hood Support Rod

Fig. 40 Hood Ajar Switch, Speed Servo & A/C

Receiver/Drier

23 - 16 EXTERIOR COMPONENTSÐXJJ

Page 1935 of 2158

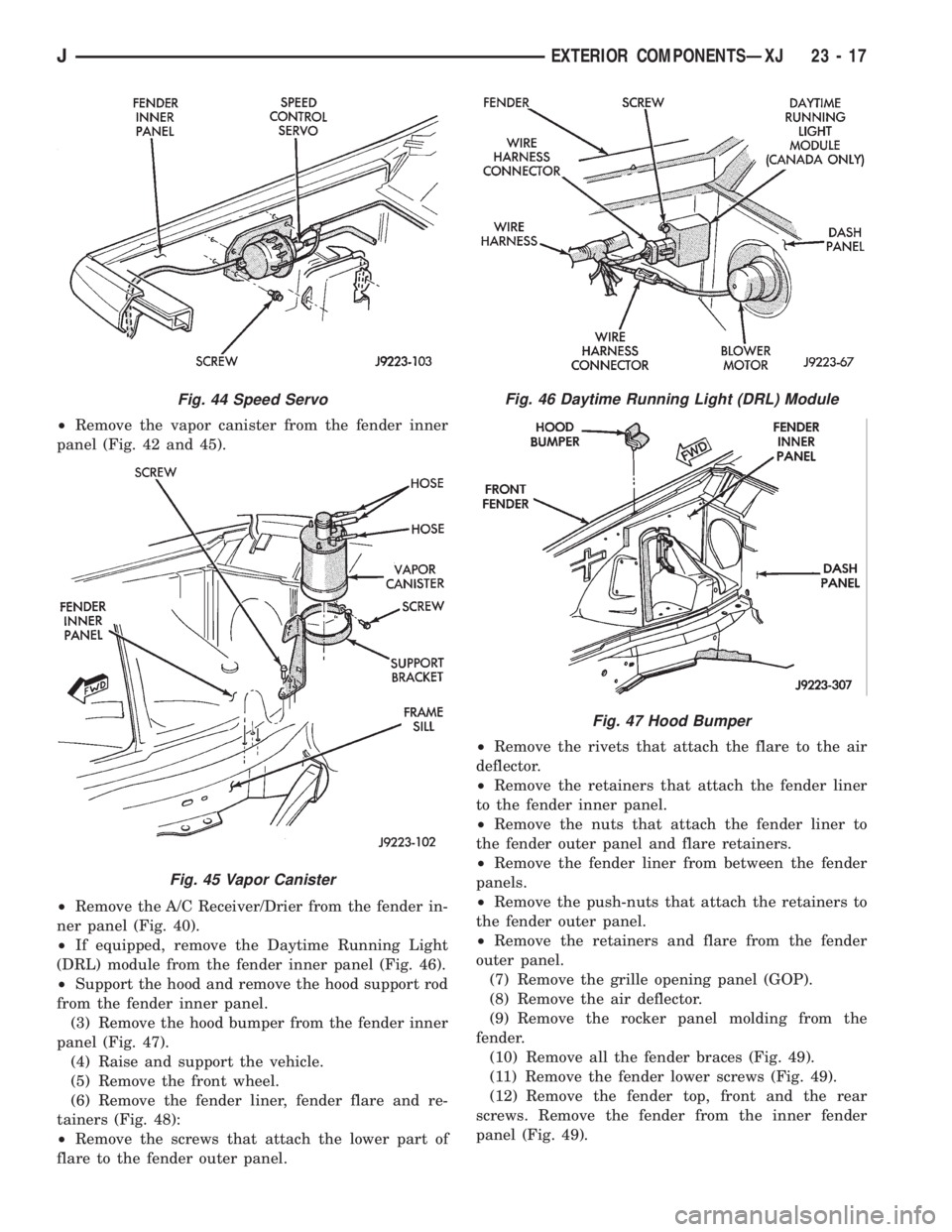

²Remove the vapor canister from the fender inner

panel (Fig. 42 and 45).

²Remove the A/C Receiver/Drier from the fender in-

ner panel (Fig. 40).

²If equipped, remove the Daytime Running Light

(DRL) module from the fender inner panel (Fig. 46).

²Support the hood and remove the hood support rod

from the fender inner panel.

(3) Remove the hood bumper from the fender inner

panel (Fig. 47).

(4) Raise and support the vehicle.

(5) Remove the front wheel.

(6) Remove the fender liner, fender flare and re-

tainers (Fig. 48):

²Remove the screws that attach the lower part of

flare to the fender outer panel.²Remove the rivets that attach the flare to the air

deflector.

²Remove the retainers that attach the fender liner

to the fender inner panel.

²Remove the nuts that attach the fender liner to

the fender outer panel and flare retainers.

²Remove the fender liner from between the fender

panels.

²Remove the push-nuts that attach the retainers to

the fender outer panel.

²Remove the retainers and flare from the fender

outer panel.

(7) Remove the grille opening panel (GOP).

(8) Remove the air deflector.

(9) Remove the rocker panel molding from the

fender.

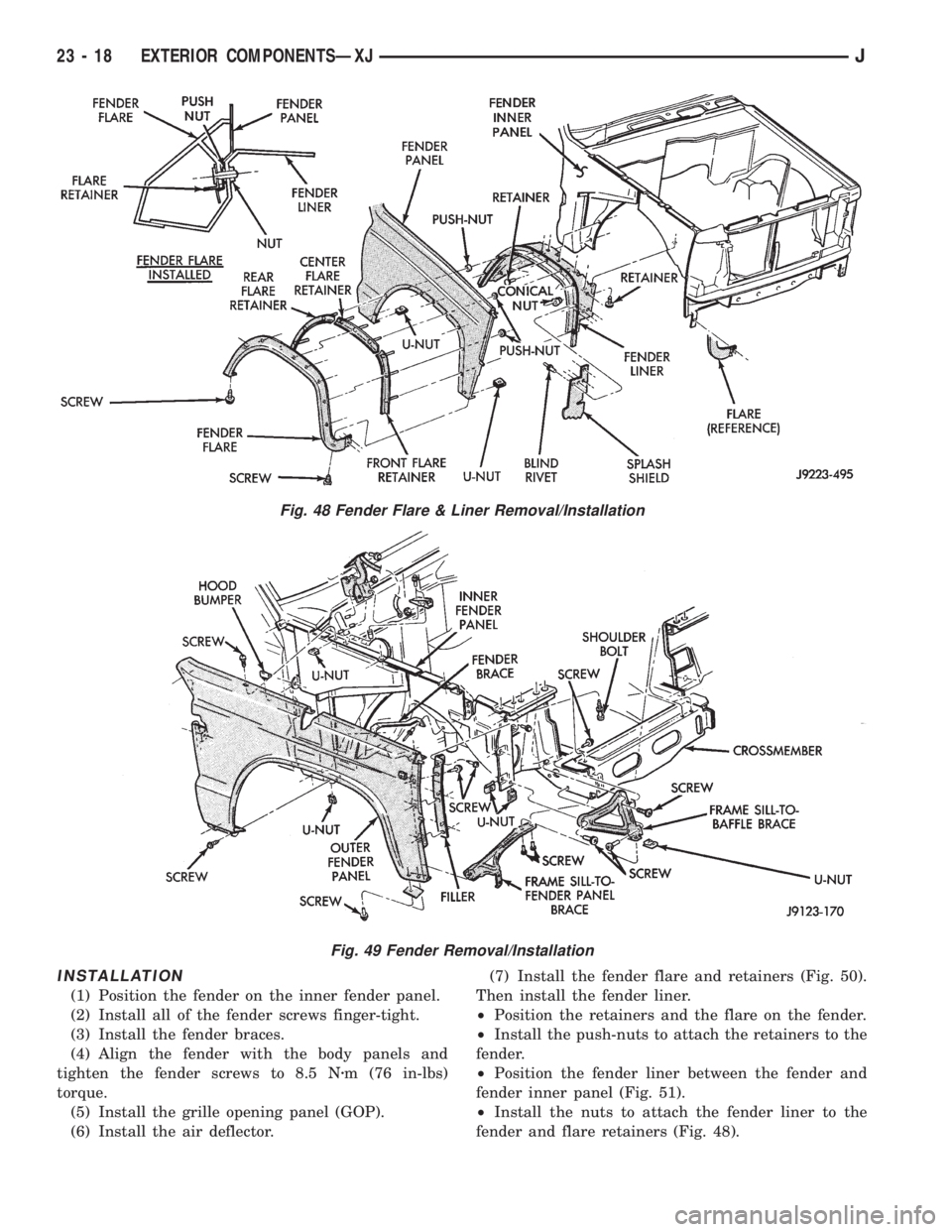

(10) Remove all the fender braces (Fig. 49).

(11) Remove the fender lower screws (Fig. 49).

(12) Remove the fender top, front and the rear

screws. Remove the fender from the inner fender

panel (Fig. 49).

Fig. 44 Speed Servo

Fig. 45 Vapor Canister

Fig. 46 Daytime Running Light (DRL) Module

Fig. 47 Hood Bumper

JEXTERIOR COMPONENTSÐXJ 23 - 17

Page 1936 of 2158

INSTALLATION

(1) Position the fender on the inner fender panel.

(2) Install all of the fender screws finger-tight.

(3) Install the fender braces.

(4) Align the fender with the body panels and

tighten the fender screws to 8.5 Nzm (76 in-lbs)

torque.

(5) Install the grille opening panel (GOP).

(6) Install the air deflector.(7) Install the fender flare and retainers (Fig. 50).

Then install the fender liner.

²Position the retainers and the flare on the fender.

²Install the push-nuts to attach the retainers to the

fender.

²Position the fender liner between the fender and

fender inner panel (Fig. 51).

²Install the nuts to attach the fender liner to the

fender and flare retainers (Fig. 48).

Fig. 48 Fender Flare & Liner Removal/Installation

Fig. 49 Fender Removal/Installation

23 - 18 EXTERIOR COMPONENTSÐXJJ

Page 1937 of 2158

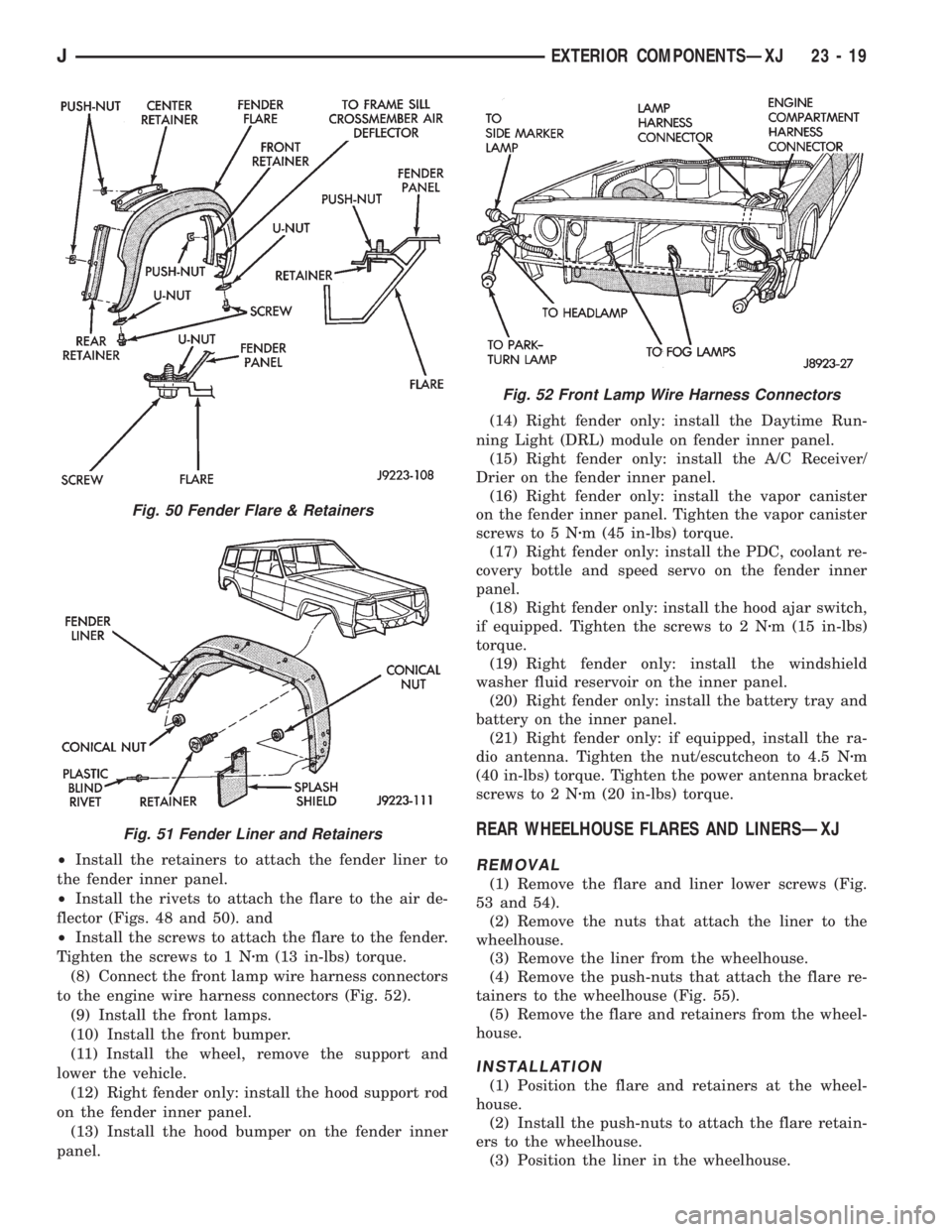

²Install the retainers to attach the fender liner to

the fender inner panel.

²Install the rivets to attach the flare to the air de-

flector (Figs. 48 and 50). and

²Install the screws to attach the flare to the fender.

Tighten the screws to 1 Nzm (13 in-lbs) torque.

(8) Connect the front lamp wire harness connectors

to the engine wire harness connectors (Fig. 52).

(9) Install the front lamps.

(10) Install the front bumper.

(11) Install the wheel, remove the support and

lower the vehicle.

(12) Right fender only: install the hood support rod

on the fender inner panel.

(13) Install the hood bumper on the fender inner

panel.(14) Right fender only: install the Daytime Run-

ning Light (DRL) module on fender inner panel.

(15) Right fender only: install the A/C Receiver/

Drier on the fender inner panel.

(16) Right fender only: install the vapor canister

on the fender inner panel. Tighten the vapor canister

screws to 5 Nzm (45 in-lbs) torque.

(17) Right fender only: install the PDC, coolant re-

covery bottle and speed servo on the fender inner

panel.

(18) Right fender only: install the hood ajar switch,

if equipped. Tighten the screws to 2 Nzm (15 in-lbs)

torque.

(19) Right fender only: install the windshield

washer fluid reservoir on the inner panel.

(20) Right fender only: install the battery tray and

battery on the inner panel.

(21) Right fender only: if equipped, install the ra-

dio antenna. Tighten the nut/escutcheon to 4.5 Nzm

(40 in-lbs) torque. Tighten the power antenna bracket

screws to 2 Nzm (20 in-lbs) torque.

REAR WHEELHOUSE FLARES AND LINERSÐXJ

REMOVAL

(1) Remove the flare and liner lower screws (Fig.

53 and 54).

(2) Remove the nuts that attach the liner to the

wheelhouse.

(3) Remove the liner from the wheelhouse.

(4) Remove the push-nuts that attach the flare re-

tainers to the wheelhouse (Fig. 55).

(5) Remove the flare and retainers from the wheel-

house.

INSTALLATION

(1) Position the flare and retainers at the wheel-

house.

(2) Install the push-nuts to attach the flare retain-

ers to the wheelhouse.

(3) Position the liner in the wheelhouse.

Fig. 50 Fender Flare & Retainers

Fig. 51 Fender Liner and Retainers

Fig. 52 Front Lamp Wire Harness Connectors

JEXTERIOR COMPONENTSÐXJ 23 - 19

Page 1938 of 2158

(4) Install the nuts to attach the liner to the

wheelhouse and flare retainers.

(5) Install the flare and liner lower screws. Tighten

the screws to 1 Nzm (13 in-lbs) torque.

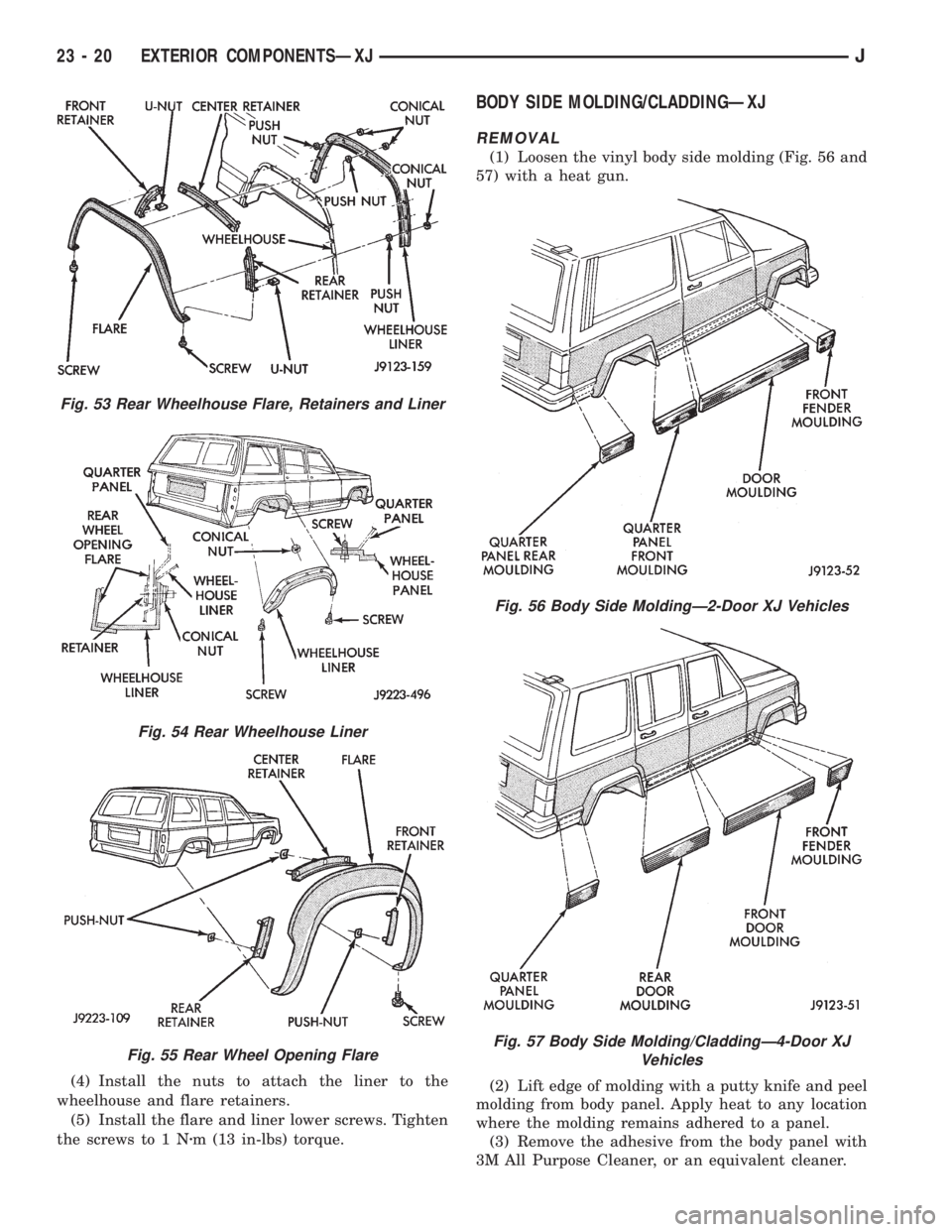

BODY SIDE MOLDING/CLADDINGÐXJ

REMOVAL

(1) Loosen the vinyl body side molding (Fig. 56 and

57) with a heat gun.

(2) Lift edge of molding with a putty knife and peel

molding from body panel. Apply heat to any location

where the molding remains adhered to a panel.

(3) Remove the adhesive from the body panel with

3M All Purpose Cleaner, or an equivalent cleaner.

Fig. 53 Rear Wheelhouse Flare, Retainers and Liner

Fig. 54 Rear Wheelhouse Liner

Fig. 55 Rear Wheel Opening Flare

Fig. 56 Body Side MoldingÐ2-Door XJ Vehicles

Fig. 57 Body Side Molding/CladdingÐ4-Door XJ

Vehicles

23 - 20 EXTERIOR COMPONENTSÐXJJ

Page 1939 of 2158

(4) If the original molding will be installed, also re-

move all adhesive from it.

INSTALLATION

(1) Install 3M 06379 double-sided tape on the

molding.

(2) For vertical alignment, use masking tape or a

string as reference.

(3) Remove the backing from the tape, align the

molding and position it on the body panel.

(4) Press the molding onto the body panel with a

roller or hand pressure.

BODY STRIPES/DECALSÐXJ

SERVICE INFORMATION

XJ body stripes and decals are weather resistant

tape with a adhesive backing.

REPAIR

Small nicks, scratches and other surface marks in

a body stripe/decal can be touched-up with paint.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin.

A heat gun can also be used to remove small wrin-

kles in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement requires that the

metal repair and paint refinish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²

Sharp knife, single edge razor blade or X-acto knife.

²Pair of scissors.

²Needle or pin.

The use of a wetting solution aids the installation of a

tape stripe/decal on a painted panel. Prepare the wet-

ting solution by mixing two or three teaspoons of dish

detergent with 1 gallon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

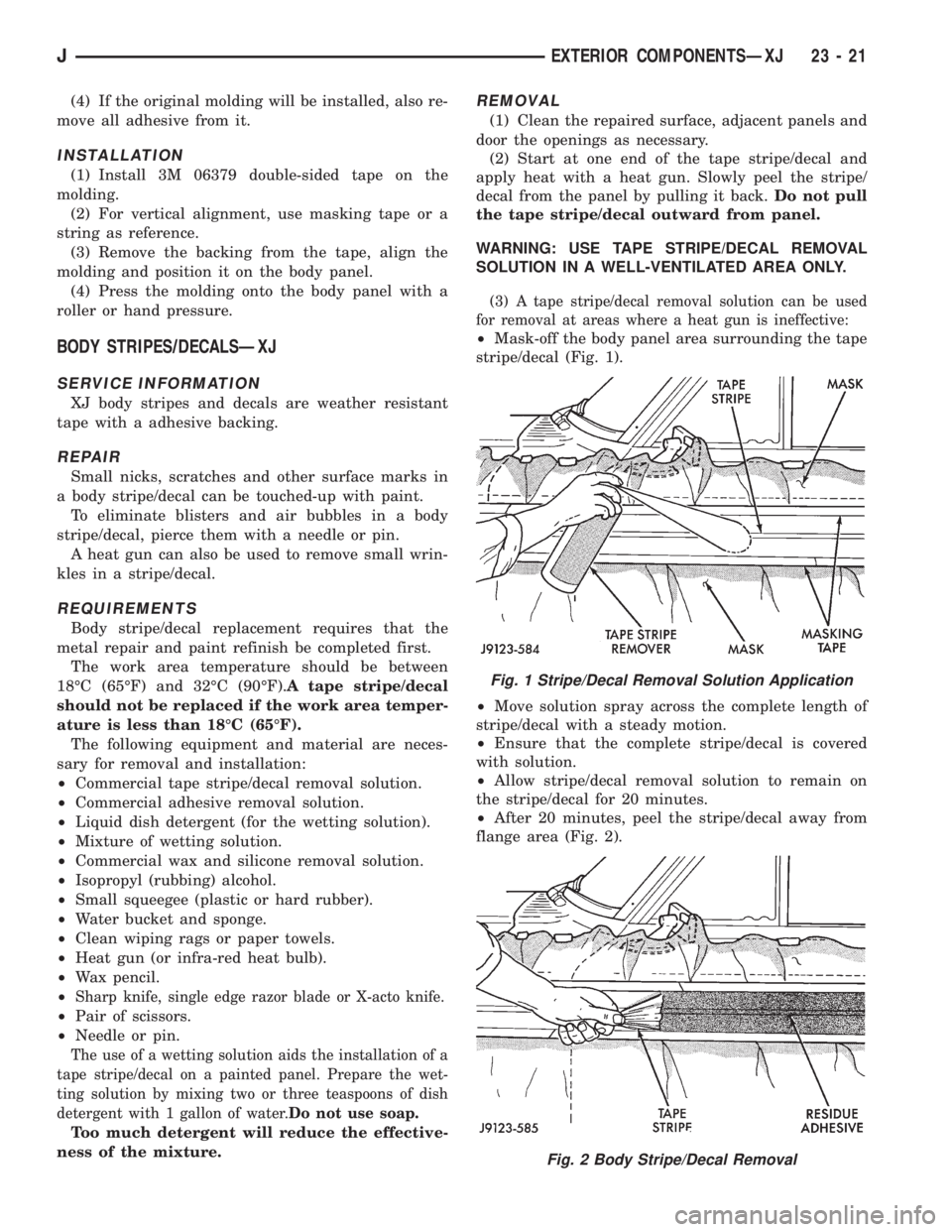

REMOVAL

(1) Clean the repaired surface, adjacent panels and

door the openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from panel.

WARNING: USE TAPE STRIPE/DECAL REMOVAL

SOLUTION IN A WELL-VENTILATED AREA ONLY.

(3) A tape stripe/decal removal solution can be used

for removal at areas where a heat gun is ineffective:

²Mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move solution spray across the complete length of

stripe/decal with a steady motion.

²Ensure that the complete stripe/decal is covered

with solution.

²Allow stripe/decal removal solution to remain on

the stripe/decal for 20 minutes.

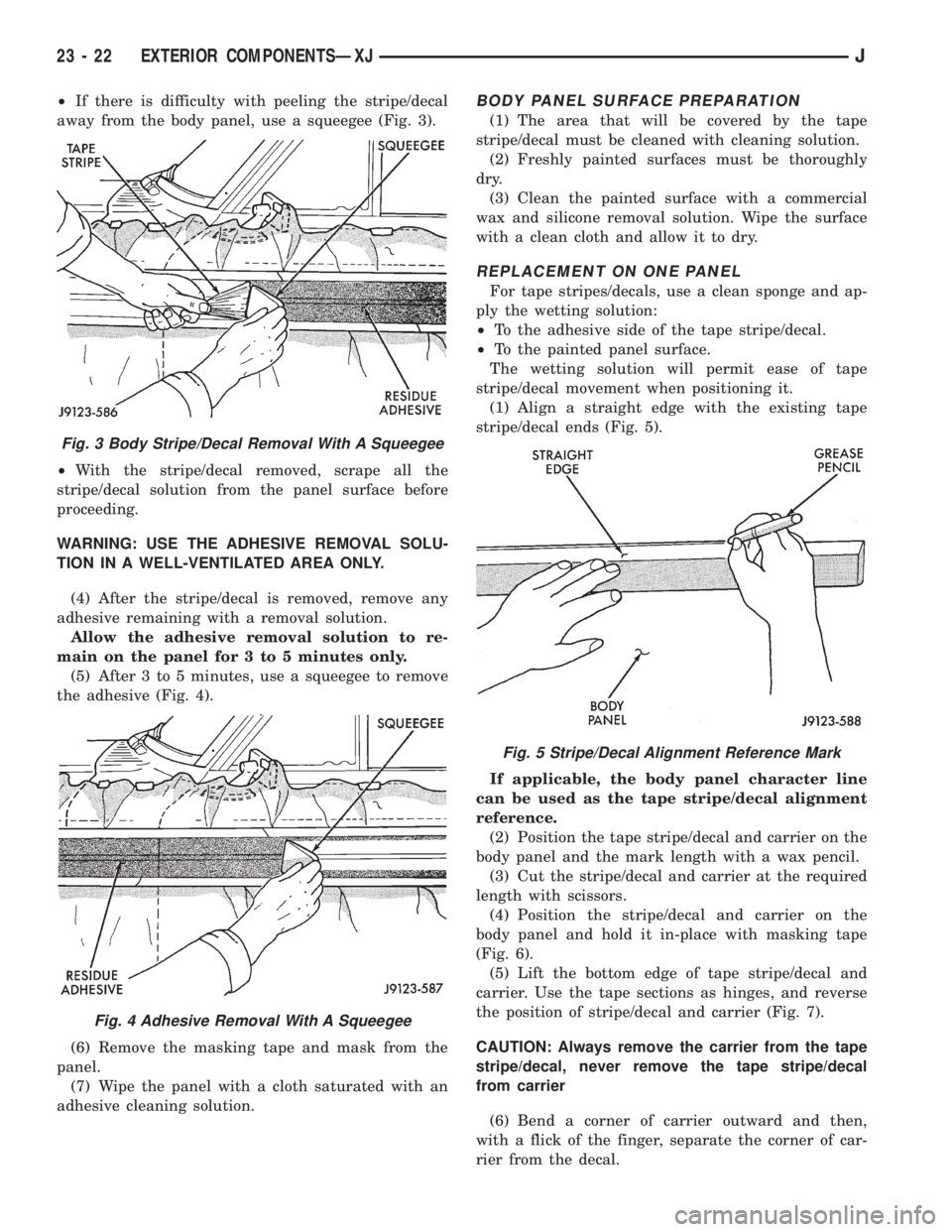

²After 20 minutes, peel the stripe/decal away from

flange area (Fig. 2).

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐXJ 23 - 21

Page 1940 of 2158

²If there is difficulty with peeling the stripe/decal

away from the body panel, use a squeegee (Fig. 3).

²With the stripe/decal removed, scrape all the

stripe/decal solution from the panel surface before

proceeding.

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining with a removal solution.

Allow the adhesive removal solution to re-

main on the panel for 3 to 5 minutes only.

(5) After 3 to 5 minutes, use a squeegee to remove

the adhesive (Fig. 4).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth saturated with an

adhesive cleaning solution.BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with cleaning solution.

(2) Freshly painted surfaces must be thoroughly

dry.

(3) Clean the painted surface with a commercial

wax and silicone removal solution. Wipe the surface

with a clean cloth and allow it to dry.

REPLACEMENT ON ONE PANEL

For tape stripes/decals, use a clean sponge and ap-

ply the wetting solution:

²To the adhesive side of the tape stripe/decal.

²To the painted panel surface.

The wetting solution will permit ease of tape

stripe/decal movement when positioning it.

(1) Align a straight edge with the existing tape

stripe/decal ends (Fig. 5).

If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position the tape stripe/decal and carrier on the

body panel and the mark length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position the stripe/decal and carrier on the

body panel and hold it in-place with masking tape

(Fig. 6).

(5) Lift the bottom edge of tape stripe/decal and

carrier. Use the tape sections as hinges, and reverse

the position of stripe/decal and carrier (Fig. 7).

CAUTION: Always remove the carrier from the tape

stripe/decal, never remove the tape stripe/decal

from carrier

(6) Bend a corner of carrier outward and then,

with a flick of the finger, separate the corner of car-

rier from the decal.

Fig. 3 Body Stripe/Decal Removal With A Squeegee

Fig. 4 Adhesive Removal With A Squeegee

Fig. 5 Stripe/Decal Alignment Reference Mark

23 - 22 EXTERIOR COMPONENTSÐXJJ