sensor JEEP YJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 155 of 2158

ABS BRAKE DIAGNOSIS

INDEX

page page

ABS Diagnostic Connector................... 3

ABS Warning Light Display................... 3

Antilock ECU and Hcu Diagnosis............... 3

DRB Scan Tool............................ 3General Information........................ 3

Normal Operating Conditions.................. 3

Wheel/Tire Size and Input Signals.............. 3

GENERAL INFORMATION

The DRB scan tool is required for ABS diagnosis.

The scan tool is used to identify ABS circuit faults.

Once a faulty circuit has been identified, refer to

the appropriate chassis/body diagnostic manual for

individual component testing.

ABS WARNING LIGHT DISPLAY

The amber antilock light illuminates at startup as

part of the system self check feature. The light illu-

minates for 2-3 seconds then goes off as part of the

normal check routine.

An ABS circuit fault is indicated when the amber

light remains on after startup, or illuminates during

vehicle operation.

Verify that a fault is actually related to the ABS

system before making repairs. For example, if the

red warning illuminates but the ABS light does not,

the problem is related to a service brake component

and not the ABS system. Or, if neither light illumi-

nates but a brake problem is noted, again, the prob-

lem is with a service brake component and not with

the ABS system.

ABS DIAGNOSTIC CONNECTOR

The ABS diagnostic connector is inside the vehicle.

The connector is the access point for the DRB scan tool.

On XJ models, the connector is located under the

instrument panel to the right of the steering column.

On some models, the connecter may be tucked under

the carpeting on the transmission tunnel. The con-

necter is a black, 6-way type.

On YJ models, the connector is under the instru-

ment panel by the the driver side kick panel. The

connecter is a black, 6 or 8-way type.

The DRB scan tool kit contains adapter cords for

both types of connecter. Use the appropriate cord for

test hookup.

DRB SCAN TOOL

ABS diagnosis is performed with the DRB scan tool.

Refer to the DRB scan tool manual for test hookup and

procedures. Diagnosis information is provided in the ap-

propriate chassis/body diagnostic manual.

WHEEL/TIRE SIZE AND INPUT SIGNALS

Antilock system operation is dependant on accurate

signals from the wheel speed sensors. Ideally, the ve-

hicle wheels and tires should all be the same size

and type. However, the Jeep ABS system is designed

to operate with a compact spare tire installed.

NORMAL OPERATING CONDITIONS

Sound Levels

The hydraulic control unit pump and solenoid valves

may produce some sound as they cycle on and off. This

is a normal condition and should not be mistaken for

faulty operation. Under most conditions, pump and so-

lenoid valve operating sounds will not be audible.

Vehicle Response In Antilock Mode

During antilock braking, the hydraulic control unit

solenoid valves cycle rapidly in response to antilock

electronic control unit signals.

The driver will experience a pulsing sensation

within the vehicle as the solenoids decrease, hold, or

increase pressure as needed. Brake pedal pulsing will

also be noted and is anormal condition.

Steering Response

A modest amount of steering input is required dur-

ing extremely high deceleration braking, or when

braking on differing traction surfaces. An example of

differing traction surfaces would be when the left

side wheels are on ice and the right side wheels are

on dry pavement.

Owner Induced Faults

Driving away with the parking brakes still applied

will cause warning light illumination. Pumping the

brake pedal will also generate a system fault and in-

terfere with ABS system operation.

ANTILOCK ECU AND HCU DIAGNOSIS

An ECU or HCU fault can only be determined

through testing with the DRB scan tool. Do not re-

place either component unless a fault is actually in-

dicated.

JABS BRAKE DIAGNOSIS 5 - 3

Page 164 of 2158

connect scan tool and proceed to next step.

(7)Repeatconventional bleed procedure described

in steps (4) and (5).

(8) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

BRAKELINES AND HOSES

Metal brakelines and rubber brake hoses should be

inspected periodically and replaced if damaged.

Rubber brake hoses should be replaced if cut,

cracked, swollen, or leaking. Rubber hoses must be

replaced as they are not repairable.

Steel brakelines should be inspected any time the

vehicle is in for normal maintenance. This is impor-

tant on high mileage vehicles. It is especially impor-

tant when the vehicle is operated on roads that are

salted during winter months.

Heavily rusted/corroded brake rotors, drums,

support plates, and brakelines should be

cleaned and carefully inspected. Heavy rust

buildup can hide severe damage to a compo-

nent. Severely rusted parts should be replaced

if condition is suspect.

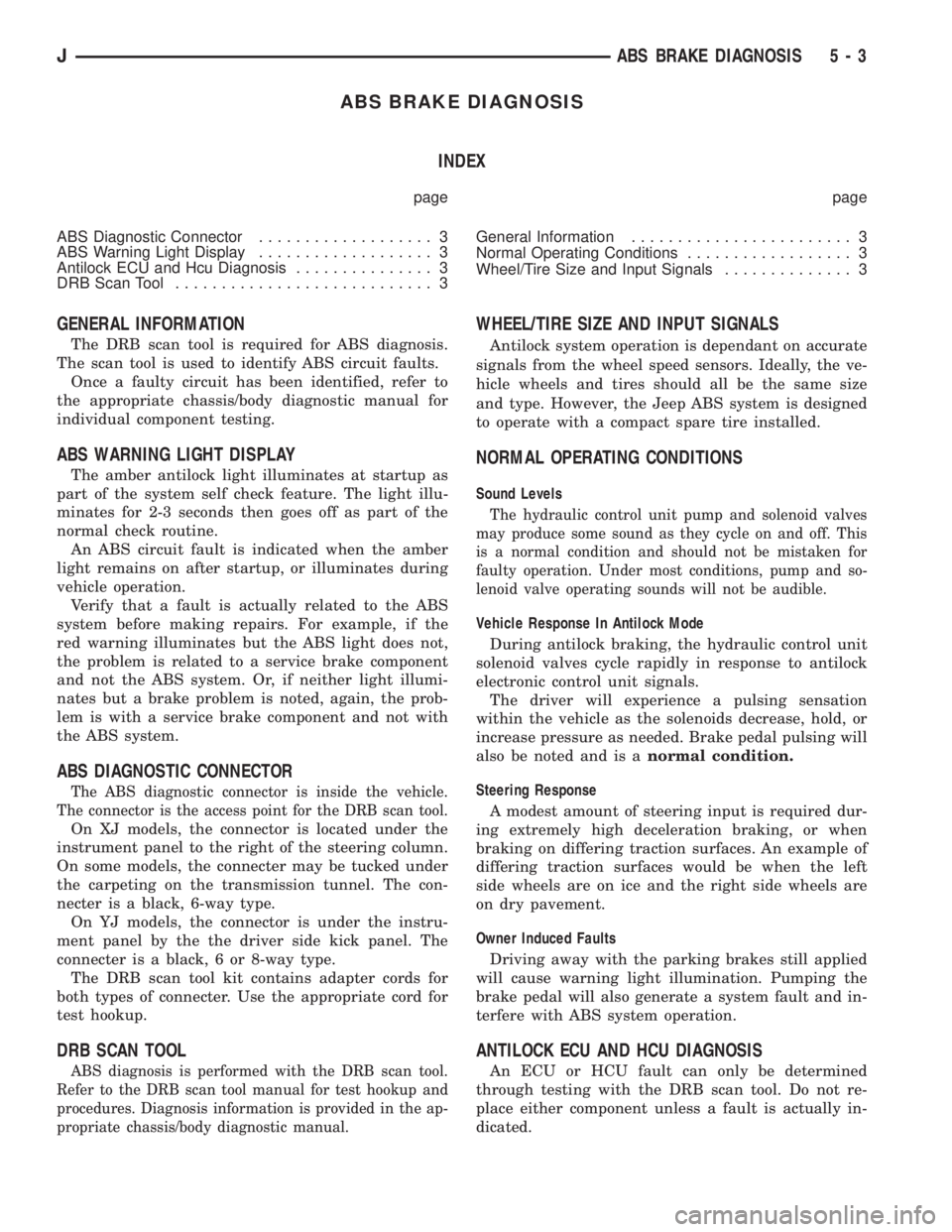

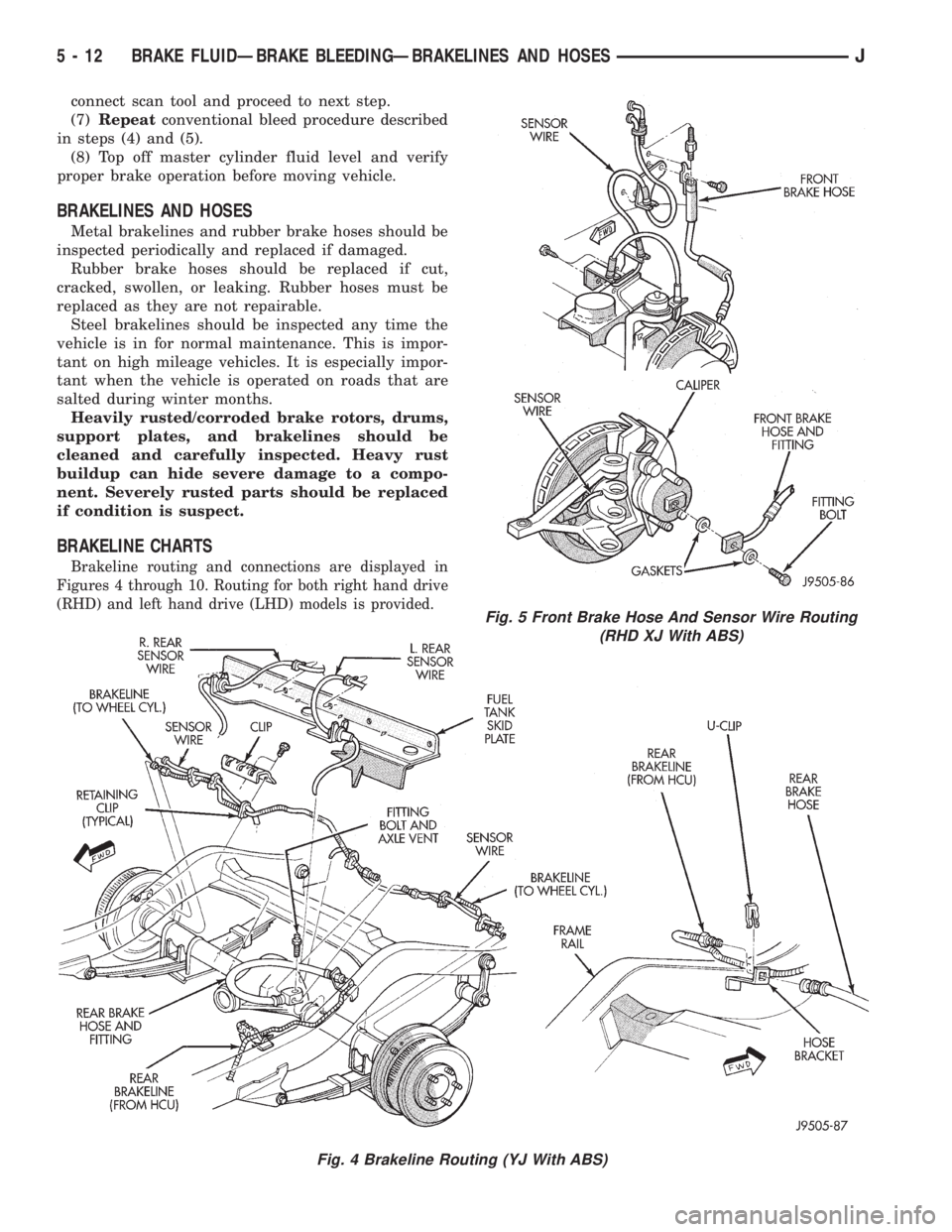

BRAKELINE CHARTS

Brakeline routing and connections are displayed in

Figures 4 through 10. Routing for both right hand drive

(RHD) and left hand drive (LHD) models is provided.

Fig. 4 Brakeline Routing (YJ With ABS)

Fig. 5 Front Brake Hose And Sensor Wire Routing

(RHD XJ With ABS)

5 - 12 BRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSESJ

Page 185 of 2158

ABS OPERATION AND SERVICE

INDEX

page page

ABS Component Serviceability............... 37

ABS Diagnostic Connector.................. 35

ABS Operation in Antilock Braking Mode........ 36

ABS Operation in Normal Braking Mode........ 35

ABS System Power-Up and Initialization........ 35

Acceleration Switch........................ 35

Acceleration Switch Installation............... 39

Acceleration Switch Operation................ 37

Acceleration Switch Removal................ 39

Combination Valve........................ 34

ECU Installation (XJ Models)................. 40

ECU Operation........................... 37

ECU Removal (XJ Models).................. 40

ECU Removal/Installation (YJ Models).......... 41

Electronic Control Unit (ECU)................ 34

Front Wheel Sensor Installation............... 38

Front Wheel Sensor Removal................ 38HCU Installation (XJ)....................... 43

HCU Installation (YJ)....................... 44

HCU Operation........................... 36

HCU Removal (XJ)........................ 41

HCU Removal (YJ)........................ 44

Hydraulic Control Unit (HCU)................. 33

Ignition Switch........................... 35

Master Cylinder/Power Brake Booster.......... 34

Rear Wheel Sensor Installation and Adjustment . . . 38

Rear Wheel Sensor Removal................ 38

Speed Sensor Air Gap..................... 37

System Description........................ 33

System Relays........................... 35

System Warning Light...................... 35

Wheel Speed Sensor Operation.............. 37

Wheel Speed Sensors..................... 34

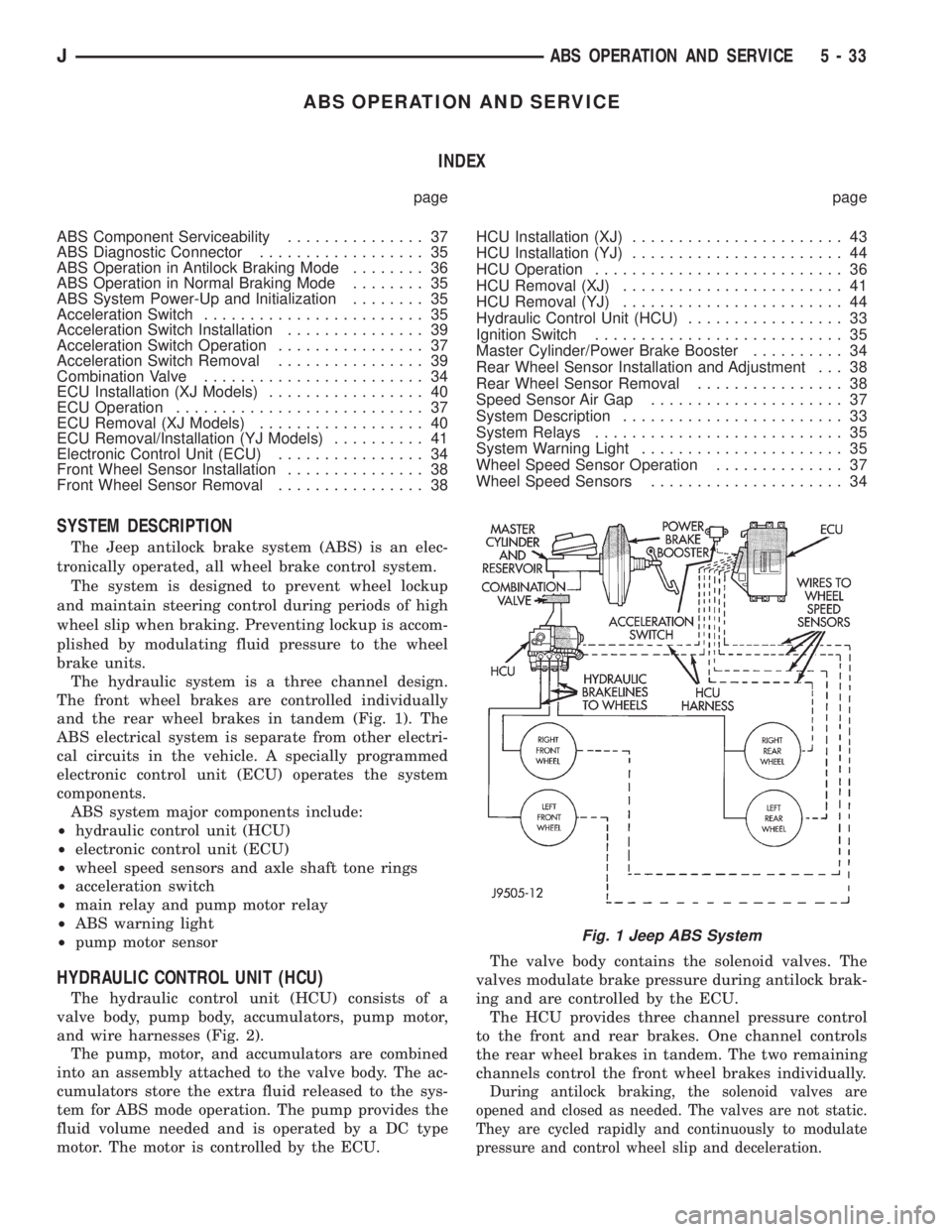

SYSTEM DESCRIPTION

The Jeep antilock brake system (ABS) is an elec-

tronically operated, all wheel brake control system.

The system is designed to prevent wheel lockup

and maintain steering control during periods of high

wheel slip when braking. Preventing lockup is accom-

plished by modulating fluid pressure to the wheel

brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 1). The

ABS electrical system is separate from other electri-

cal circuits in the vehicle. A specially programmed

electronic control unit (ECU) operates the system

components.

ABS system major components include:

²hydraulic control unit (HCU)

²electronic control unit (ECU)

²wheel speed sensors and axle shaft tone rings

²acceleration switch

²main relay and pump motor relay

²ABS warning light

²pump motor sensor

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) consists of a

valve body, pump body, accumulators, pump motor,

and wire harnesses (Fig. 2).

The pump, motor, and accumulators are combined

into an assembly attached to the valve body. The ac-

cumulators store the extra fluid released to the sys-

tem for ABS mode operation. The pump provides the

fluid volume needed and is operated by a DC type

motor. The motor is controlled by the ECU.The valve body contains the solenoid valves. The

valves modulate brake pressure during antilock brak-

ing and are controlled by the ECU.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed. The valves are not static.

They are cycled rapidly and continuously to modulate

pressure and control wheel slip and deceleration.

Fig. 1 Jeep ABS System

JABS OPERATION AND SERVICE 5 - 33

Page 186 of 2158

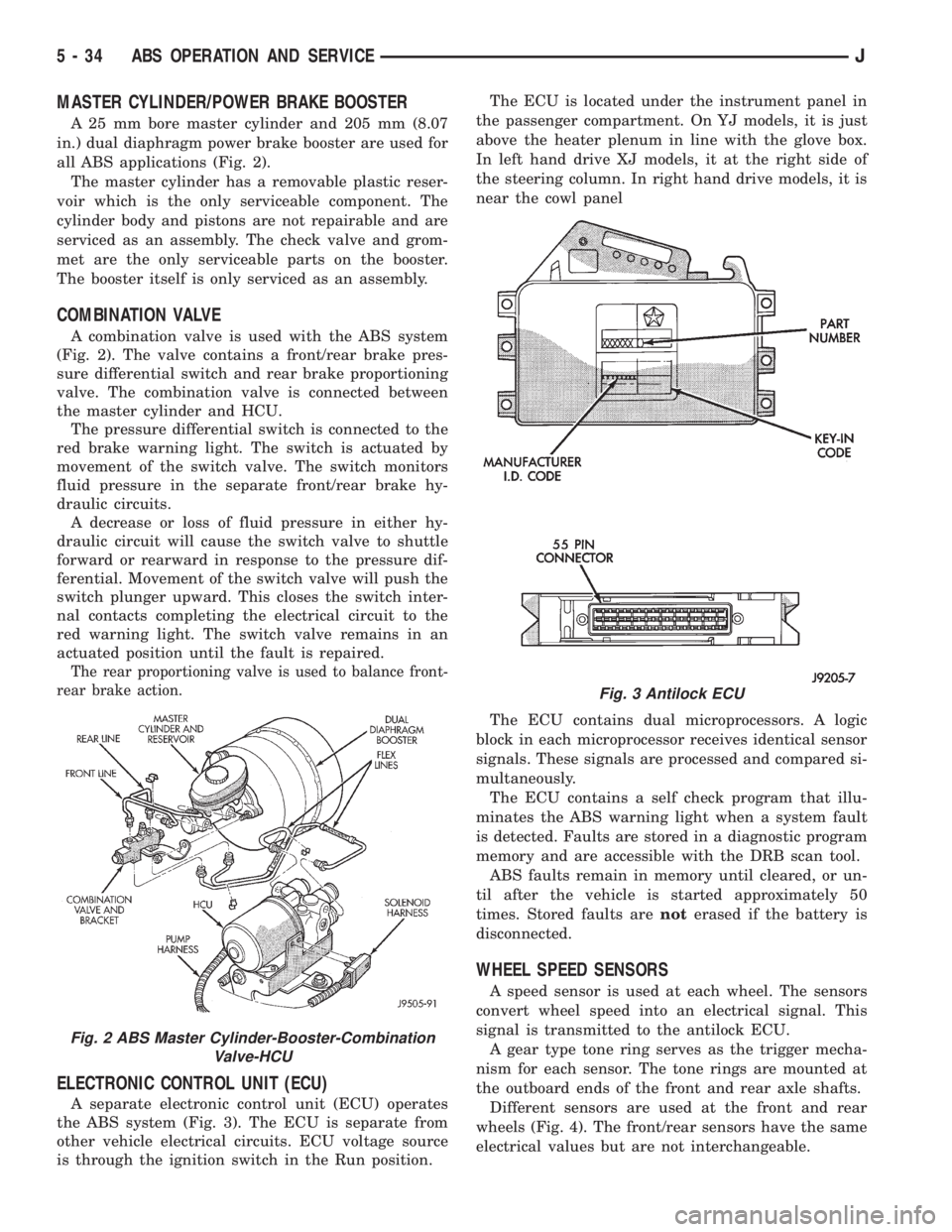

MASTER CYLINDER/POWER BRAKE BOOSTER

A 25 mm bore master cylinder and 205 mm (8.07

in.) dual diaphragm power brake booster are used for

all ABS applications (Fig. 2).

The master cylinder has a removable plastic reser-

voir which is the only serviceable component. The

cylinder body and pistons are not repairable and are

serviced as an assembly. The check valve and grom-

met are the only serviceable parts on the booster.

The booster itself is only serviced as an assembly.

COMBINATION VALVE

A combination valve is used with the ABS system

(Fig. 2). The valve contains a front/rear brake pres-

sure differential switch and rear brake proportioning

valve. The combination valve is connected between

the master cylinder and HCU.

The pressure differential switch is connected to the

red brake warning light. The switch is actuated by

movement of the switch valve. The switch monitors

fluid pressure in the separate front/rear brake hy-

draulic circuits.

A decrease or loss of fluid pressure in either hy-

draulic circuit will cause the switch valve to shuttle

forward or rearward in response to the pressure dif-

ferential. Movement of the switch valve will push the

switch plunger upward. This closes the switch inter-

nal contacts completing the electrical circuit to the

red warning light. The switch valve remains in an

actuated position until the fault is repaired.

The rear proportioning valve is used to balance front-

rear brake action.

ELECTRONIC CONTROL UNIT (ECU)

A separate electronic control unit (ECU) operates

the ABS system (Fig. 3). The ECU is separate from

other vehicle electrical circuits. ECU voltage source

is through the ignition switch in the Run position.The ECU is located under the instrument panel in

the passenger compartment. On YJ models, it is just

above the heater plenum in line with the glove box.

In left hand drive XJ models, it at the right side of

the steering column. In right hand drive models, it is

near the cowl panel

The ECU contains dual microprocessors. A logic

block in each microprocessor receives identical sensor

signals. These signals are processed and compared si-

multaneously.

The ECU contains a self check program that illu-

minates the ABS warning light when a system fault

is detected. Faults are stored in a diagnostic program

memory and are accessible with the DRB scan tool.

ABS faults remain in memory until cleared, or un-

til after the vehicle is started approximately 50

times. Stored faults arenoterased if the battery is

disconnected.

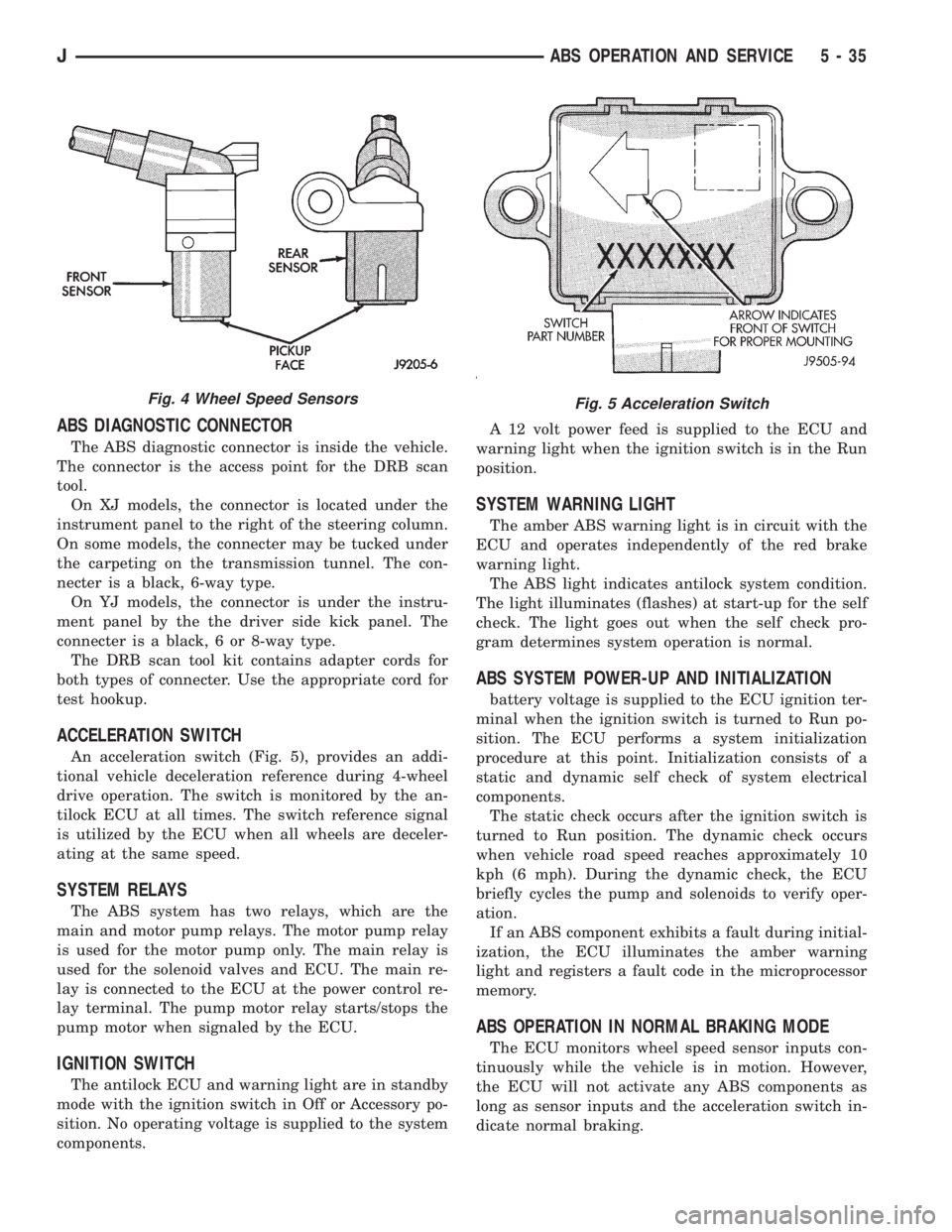

WHEEL SPEED SENSORS

A speed sensor is used at each wheel. The sensors

convert wheel speed into an electrical signal. This

signal is transmitted to the antilock ECU.

A gear type tone ring serves as the trigger mecha-

nism for each sensor. The tone rings are mounted at

the outboard ends of the front and rear axle shafts.

Different sensors are used at the front and rear

wheels (Fig. 4). The front/rear sensors have the same

electrical values but are not interchangeable.

Fig. 2 ABS Master Cylinder-Booster-Combination

Valve-HCU

Fig. 3 Antilock ECU

5 - 34 ABS OPERATION AND SERVICEJ

Page 187 of 2158

ABS DIAGNOSTIC CONNECTOR

The ABS diagnostic connector is inside the vehicle.

The connector is the access point for the DRB scan

tool.

On XJ models, the connector is located under the

instrument panel to the right of the steering column.

On some models, the connecter may be tucked under

the carpeting on the transmission tunnel. The con-

necter is a black, 6-way type.

On YJ models, the connector is under the instru-

ment panel by the the driver side kick panel. The

connecter is a black, 6 or 8-way type.

The DRB scan tool kit contains adapter cords for

both types of connecter. Use the appropriate cord for

test hookup.

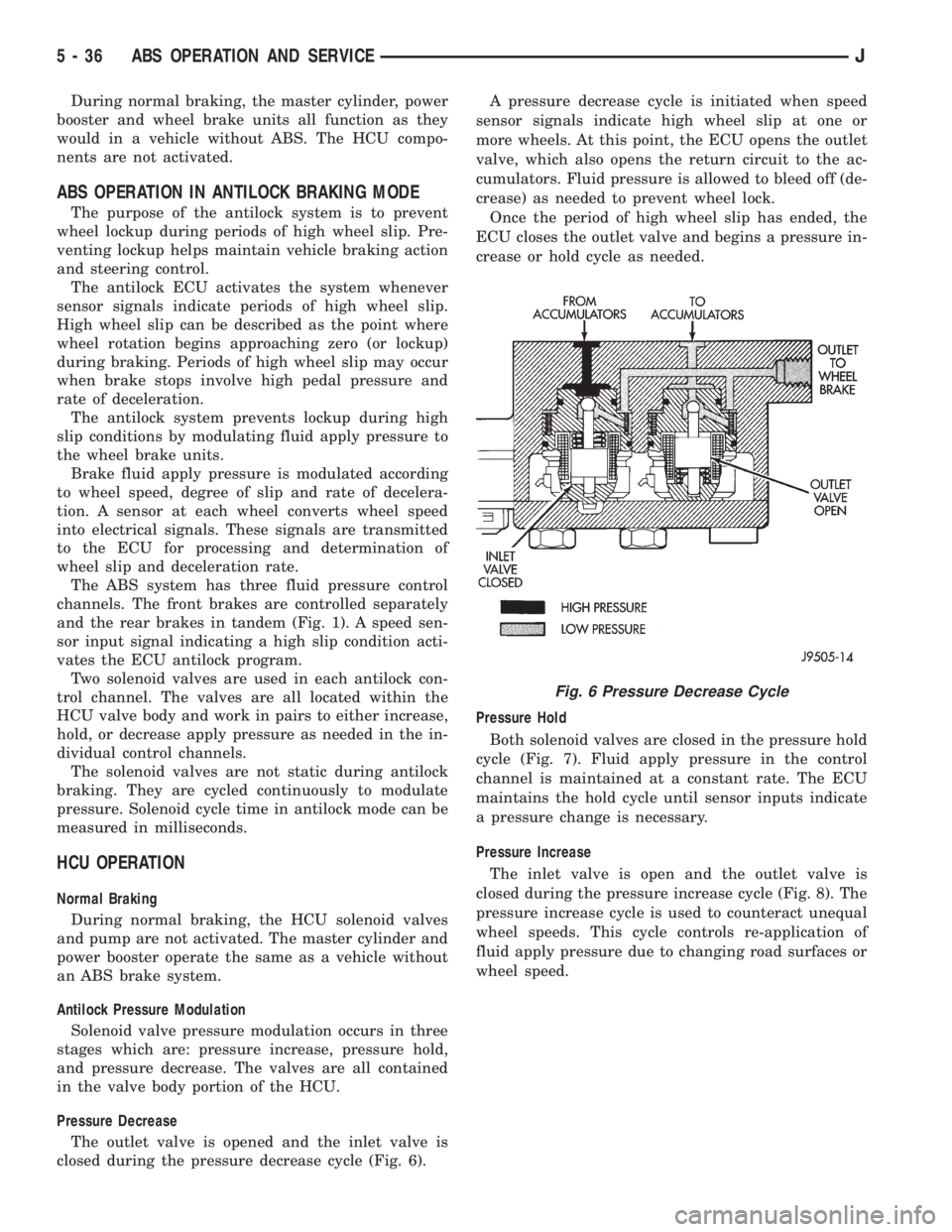

ACCELERATION SWITCH

An acceleration switch (Fig. 5), provides an addi-

tional vehicle deceleration reference during 4-wheel

drive operation. The switch is monitored by the an-

tilock ECU at all times. The switch reference signal

is utilized by the ECU when all wheels are deceler-

ating at the same speed.

SYSTEM RELAYS

The ABS system has two relays, which are the

main and motor pump relays. The motor pump relay

is used for the motor pump only. The main relay is

used for the solenoid valves and ECU. The main re-

lay is connected to the ECU at the power control re-

lay terminal. The pump motor relay starts/stops the

pump motor when signaled by the ECU.

IGNITION SWITCH

The antilock ECU and warning light are in standby

mode with the ignition switch in Off or Accessory po-

sition. No operating voltage is supplied to the system

components.A 12 volt power feed is supplied to the ECU and

warning light when the ignition switch is in the Run

position.

SYSTEM WARNING LIGHT

The amber ABS warning light is in circuit with the

ECU and operates independently of the red brake

warning light.

The ABS light indicates antilock system condition.

The light illuminates (flashes) at start-up for the self

check. The light goes out when the self check pro-

gram determines system operation is normal.

ABS SYSTEM POWER-UP AND INITIALIZATION

battery voltage is supplied to the ECU ignition ter-

minal when the ignition switch is turned to Run po-

sition. The ECU performs a system initialization

procedure at this point. Initialization consists of a

static and dynamic self check of system electrical

components.

The static check occurs after the ignition switch is

turned to Run position. The dynamic check occurs

when vehicle road speed reaches approximately 10

kph (6 mph). During the dynamic check, the ECU

briefly cycles the pump and solenoids to verify oper-

ation.

If an ABS component exhibits a fault during initial-

ization, the ECU illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ABS OPERATION IN NORMAL BRAKING MODE

The ECU monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the ECU will not activate any ABS components as

long as sensor inputs and the acceleration switch in-

dicate normal braking.

Fig. 4 Wheel Speed SensorsFig. 5 Acceleration Switch

JABS OPERATION AND SERVICE 5 - 35

Page 188 of 2158

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

ABS OPERATION IN ANTILOCK BRAKING MODE

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock ECU activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching zero (or lockup)

during braking. Periods of high wheel slip may occur

when brake stops involve high pedal pressure and

rate of deceleration.

The antilock system prevents lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the ECU for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem (Fig. 1). A speed sen-

sor input signal indicating a high slip condition acti-

vates the ECU antilock program.

Two solenoid valves are used in each antilock con-

trol channel. The valves are all located within the

HCU valve body and work in pairs to either increase,

hold, or decrease apply pressure as needed in the in-

dividual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

HCU OPERATION

Normal Braking

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

Antilock Pressure Modulation

Solenoid valve pressure modulation occurs in three

stages which are: pressure increase, pressure hold,

and pressure decrease. The valves are all contained

in the valve body portion of the HCU.

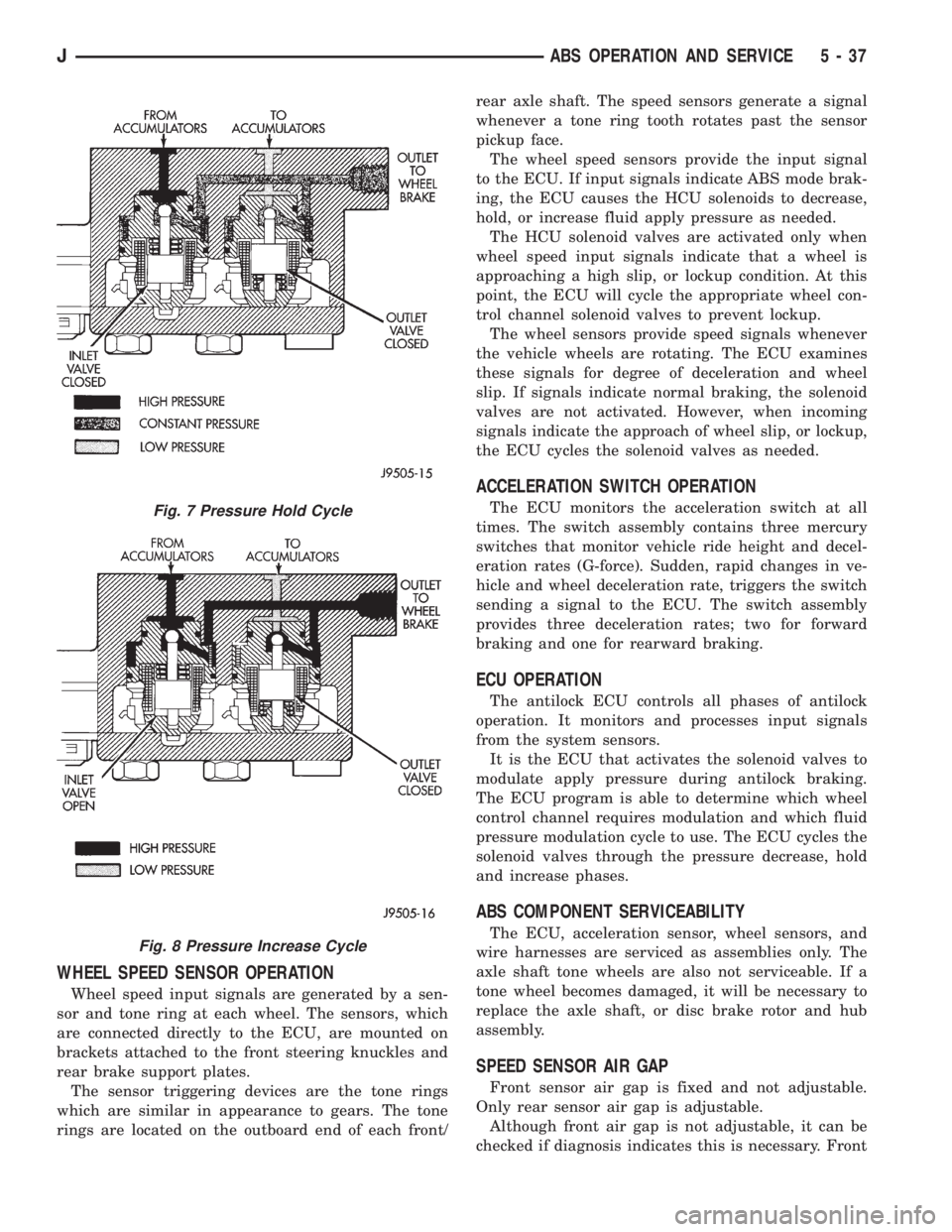

Pressure Decrease

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle (Fig. 6).A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the ECU opens the outlet

valve, which also opens the return circuit to the ac-

cumulators. Fluid pressure is allowed to bleed off (de-

crease) as needed to prevent wheel lock.

Once the period of high wheel slip has ended, the

ECU closes the outlet valve and begins a pressure in-

crease or hold cycle as needed.

Pressure Hold

Both solenoid valves are closed in the pressure hold

cycle (Fig. 7). Fluid apply pressure in the control

channel is maintained at a constant rate. The ECU

maintains the hold cycle until sensor inputs indicate

a pressure change is necessary.

Pressure Increase

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle (Fig. 8). The

pressure increase cycle is used to counteract unequal

wheel speeds. This cycle controls re-application of

fluid apply pressure due to changing road surfaces or

wheel speed.

Fig. 6 Pressure Decrease Cycle

5 - 36 ABS OPERATION AND SERVICEJ

Page 189 of 2158

WHEEL SPEED SENSOR OPERATION

Wheel speed input signals are generated by a sen-

sor and tone ring at each wheel. The sensors, which

are connected directly to the ECU, are mounted on

brackets attached to the front steering knuckles and

rear brake support plates.

The sensor triggering devices are the tone rings

which are similar in appearance to gears. The tone

rings are located on the outboard end of each front/rear axle shaft. The speed sensors generate a signal

whenever a tone ring tooth rotates past the sensor

pickup face.

The wheel speed sensors provide the input signal

to the ECU. If input signals indicate ABS mode brak-

ing, the ECU causes the HCU solenoids to decrease,

hold, or increase fluid apply pressure as needed.

The HCU solenoid valves are activated only when

wheel speed input signals indicate that a wheel is

approaching a high slip, or lockup condition. At this

point, the ECU will cycle the appropriate wheel con-

trol channel solenoid valves to prevent lockup.

The wheel sensors provide speed signals whenever

the vehicle wheels are rotating. The ECU examines

these signals for degree of deceleration and wheel

slip. If signals indicate normal braking, the solenoid

valves are not activated. However, when incoming

signals indicate the approach of wheel slip, or lockup,

the ECU cycles the solenoid valves as needed.

ACCELERATION SWITCH OPERATION

The ECU monitors the acceleration switch at all

times. The switch assembly contains three mercury

switches that monitor vehicle ride height and decel-

eration rates (G-force). Sudden, rapid changes in ve-

hicle and wheel deceleration rate, triggers the switch

sending a signal to the ECU. The switch assembly

provides three deceleration rates; two for forward

braking and one for rearward braking.

ECU OPERATION

The antilock ECU controls all phases of antilock

operation. It monitors and processes input signals

from the system sensors.

It is the ECU that activates the solenoid valves to

modulate apply pressure during antilock braking.

The ECU program is able to determine which wheel

control channel requires modulation and which fluid

pressure modulation cycle to use. The ECU cycles the

solenoid valves through the pressure decrease, hold

and increase phases.

ABS COMPONENT SERVICEABILITY

The ECU, acceleration sensor, wheel sensors, and

wire harnesses are serviced as assemblies only. The

axle shaft tone wheels are also not serviceable. If a

tone wheel becomes damaged, it will be necessary to

replace the axle shaft, or disc brake rotor and hub

assembly.

SPEED SENSOR AIR GAP

Front sensor air gap is fixed and not adjustable.

Only rear sensor air gap is adjustable.

Although front air gap is not adjustable, it can be

checked if diagnosis indicates this is necessary. Front

Fig. 7 Pressure Hold Cycle

Fig. 8 Pressure Increase Cycle

JABS OPERATION AND SERVICE 5 - 37

Page 190 of 2158

air gap should be 0.40 to 1.3 mm (0.0157 to 0.051

in.). If gap is incorrect, the sensor is either loose, or

damaged.

A rear sensor air gap adjustment is only needed

when reinstalling an original sensor. Replacement

sensors have an air gap spacer attached to the sensor

pickup face. The spacer establishes correct air gap

when pressed against the tone ring during installa-

tion. As the tone ring rotates, it peels the spacer off

the sensor to create the required air gap. Rear sensor

air gap is 0.92-1.45 mm (0.036-0.057 in.).

Sensor air gap measurement, or adjustment proce-

dures are provided in this section. Refer to the front,

or rear sensor removal and installation procedures as

required.

FRONT WHEEL SENSOR REMOVAL

(1) Raise vehicle and turn wheel outward for easier

access to sensor.

(2) Remove sensor wire from mounting brackets.

(3) Clean sensor and surrounding area with shop

towel before removal.

(4) Remove bolt attaching sensor to steering

knuckle and remove sensor.

(5) remove sensor wire from brackets on body and

steering knuckle.

(6) Unseat sensor wire grommet in wheel house

panel.

(7) In engine compartment, disconnect sensor wire

connector at harness plug. Then remove sensor and

wire.

FRONT WHEEL SENSOR INSTALLATION

(1) Iforiginalsensor will be installed, wipe all

traces of old spacer material off sensor pickup face.

Use a dry shop towel for this purpose.

(2) Apply Mopar Lock N' Seal or Loctite 242 to bolt

that secures sensor in steering knuckle. Use new

sensor bolt if original bolt is worn or damaged.

(3) Position sensor on steering knuckle. Seat sen-

sor locating tab in hole in knuckle and install sensor

attaching bolt finger tight.

(4) Tighten sensor attaching bolt to 14 Nzm (11 ft.

lbs.) torque.

(5) If original sensor has been installed, check sen-

sor air gap. Air gap should be 0.40 to 1.3 mm (0.0157

to 0.051 in.). If gap is incorrect, sensor is either loose,

or damaged.

(6) Secure sensor wire to steering knuckle and

body brackets.

(7) Route sensor wire forward and behind shock

absorber. Then attach sensor wire to spring seat

bracket with grommets on sensor wire.

(8) Route sensor wire to outer sill bracket. Remove

all twists or kinks from wire.

(9) Attach sensor wire to sill bracket with grom-

met. Be sure wire is free of twists and kinks.(10) Verify sensor wire routing. Wire should loop

forward and above sill bracket. Loose end of wire

should be below sill bracket and towards brake hose.

(11) Seat sensor wire grommet in body panel and

clip wire to brake line at grommet location.

(12) Connect sensor wire to harness in engine com-

partment.

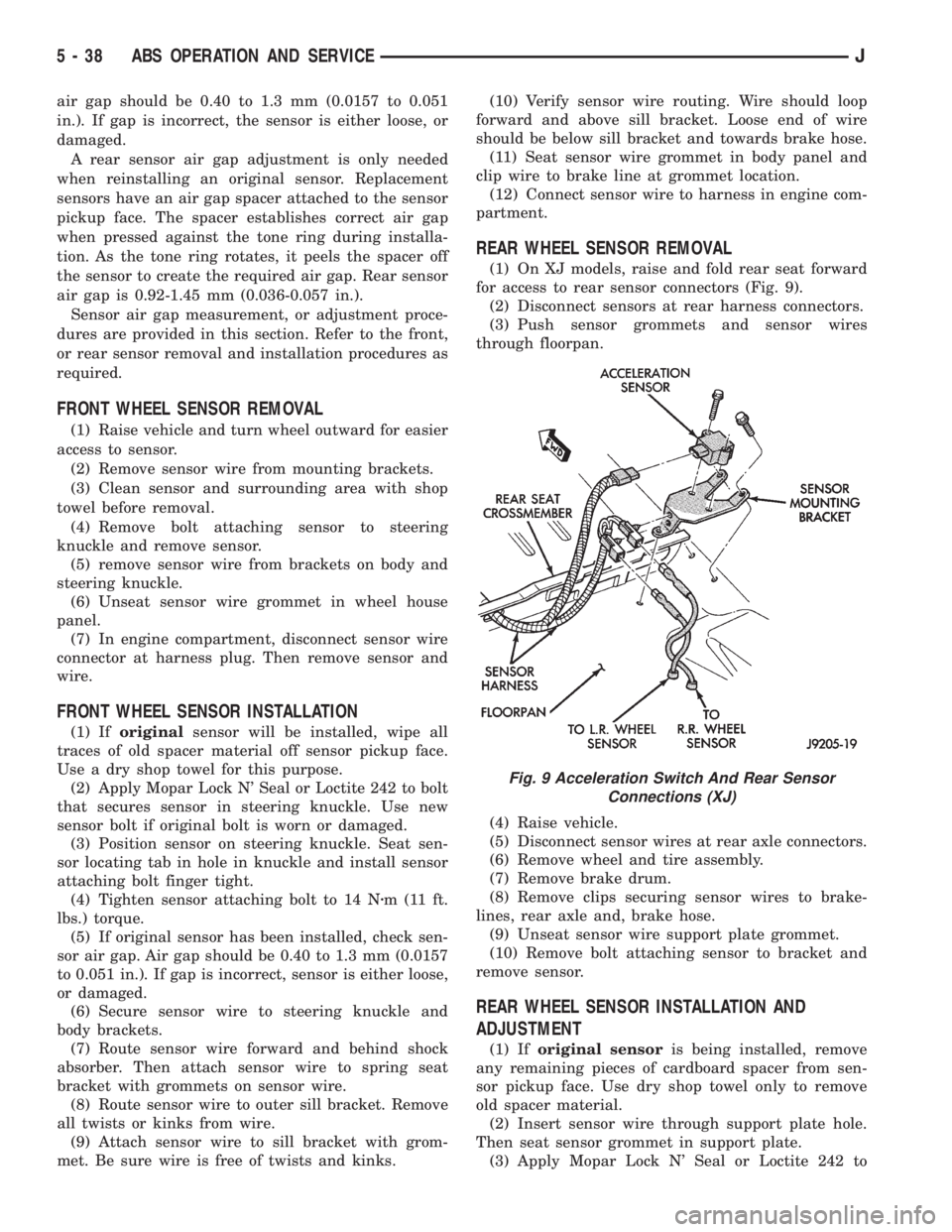

REAR WHEEL SENSOR REMOVAL

(1) On XJ models, raise and fold rear seat forward

for access to rear sensor connectors (Fig. 9).

(2) Disconnect sensors at rear harness connectors.

(3) Push sensor grommets and sensor wires

through floorpan.

(4) Raise vehicle.

(5) Disconnect sensor wires at rear axle connectors.

(6) Remove wheel and tire assembly.

(7) Remove brake drum.

(8) Remove clips securing sensor wires to brake-

lines, rear axle and, brake hose.

(9) Unseat sensor wire support plate grommet.

(10) Remove bolt attaching sensor to bracket and

remove sensor.

REAR WHEEL SENSOR INSTALLATION AND

ADJUSTMENT

(1) Iforiginal sensoris being installed, remove

any remaining pieces of cardboard spacer from sen-

sor pickup face. Use dry shop towel only to remove

old spacer material.

(2) Insert sensor wire through support plate hole.

Then seat sensor grommet in support plate.

(3) Apply Mopar Lock N' Seal or Loctite 242 to

Fig. 9 Acceleration Switch And Rear Sensor

Connections (XJ)

5 - 38 ABS OPERATION AND SERVICEJ

Page 191 of 2158

original sensor bolt. Use new bolt if original is worn

or damaged.

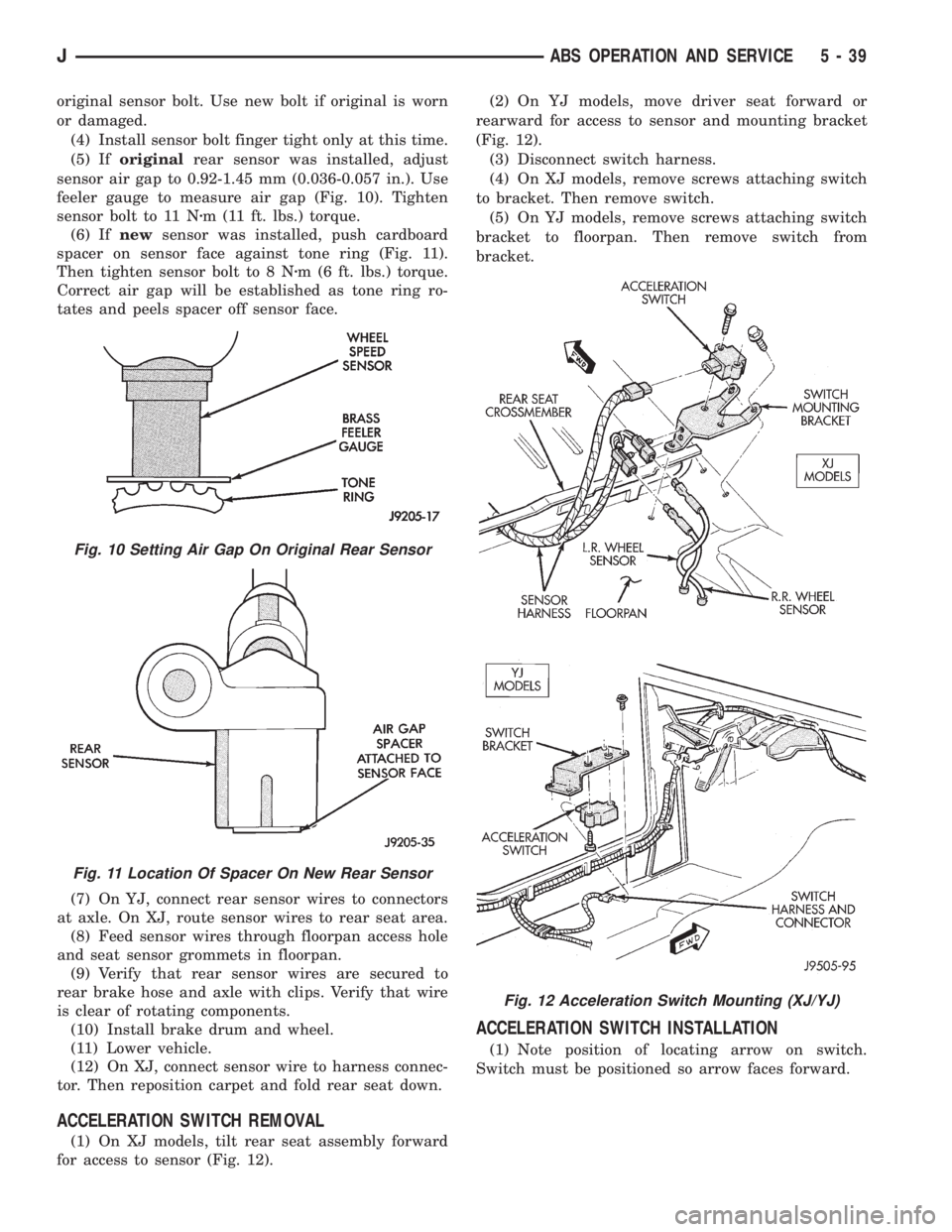

(4) Install sensor bolt finger tight only at this time.

(5) Iforiginalrear sensor was installed, adjust

sensor air gap to 0.92-1.45 mm (0.036-0.057 in.). Use

feeler gauge to measure air gap (Fig. 10). Tighten

sensor bolt to 11 Nzm (11 ft. lbs.) torque.

(6) Ifnewsensor was installed, push cardboard

spacer on sensor face against tone ring (Fig. 11).

Then tighten sensor bolt to 8 Nzm (6 ft. lbs.) torque.

Correct air gap will be established as tone ring ro-

tates and peels spacer off sensor face.

(7) On YJ, connect rear sensor wires to connectors

at axle. On XJ, route sensor wires to rear seat area.

(8) Feed sensor wires through floorpan access hole

and seat sensor grommets in floorpan.

(9) Verify that rear sensor wires are secured to

rear brake hose and axle with clips. Verify that wire

is clear of rotating components.

(10) Install brake drum and wheel.

(11) Lower vehicle.

(12) On XJ, connect sensor wire to harness connec-

tor. Then reposition carpet and fold rear seat down.

ACCELERATION SWITCH REMOVAL

(1) On XJ models, tilt rear seat assembly forward

for access to sensor (Fig. 12).(2) On YJ models, move driver seat forward or

rearward for access to sensor and mounting bracket

(Fig. 12).

(3) Disconnect switch harness.

(4) On XJ models, remove screws attaching switch

to bracket. Then remove switch.

(5) On YJ models, remove screws attaching switch

bracket to floorpan. Then remove switch from

bracket.

ACCELERATION SWITCH INSTALLATION

(1) Note position of locating arrow on switch.

Switch must be positioned so arrow faces forward.

Fig. 10 Setting Air Gap On Original Rear Sensor

Fig. 11 Location Of Spacer On New Rear Sensor

Fig. 12 Acceleration Switch Mounting (XJ/YJ)

JABS OPERATION AND SERVICE 5 - 39

Page 257 of 2158

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warmup and overall

temperature control.

An arrow plus the wordUPis stamped on the

front flange next to the air bleed. The wordsTO

RADare stamped on one arm of the thermostat.

They indicate the proper installed position.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

ON-BOARD DIAGNOSTICS

XJ and YJ models are equipped with On-Board Di-

agnostics for certain cooling system components. Re-

fer to On-Board Diagnostics (OBD) in the Diagnosis

section of this group for additional information. If the

powertrain control module (PCM) detects low engine

coolant temperature, it will record a Diagnostic Trou-

ble Code (DTC) in the PCM memory. The DTC num-

ber for low coolant temperature is 17. Do not change

a thermostat for lack of heat as indicated by the in-

strument panel gauge or heater performance unless a

DTC number 17 is present. Refer to the Diagnosis

section of this group for other probable causes. For

other DTC numbers, refer to On-Board Diagnostics

in the General Diagnosis section of Group 14, Fuel

Systems.

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Drain the coolant from the radiator until the

level is below the thermostat housing.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (FIG. 15). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS. AL-

WAYS WEAR SAFETY GLASSES WHEN SERVICING

CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 16). If re-

placement is necessary, use only an original equip-

ment clamp with matching number or letter.

(2) Remove radiator upper hose and heater hose at

thermostat housing.

(3) Disconnect wiring connector at engine coolant

temperature sensor.

(4) Remove thermostat housing mounting bolts,

thermostat housing, gasket and thermostat (Fig. 17).

Discard old gasket.

(5) Clean the gasket mating surfaces.

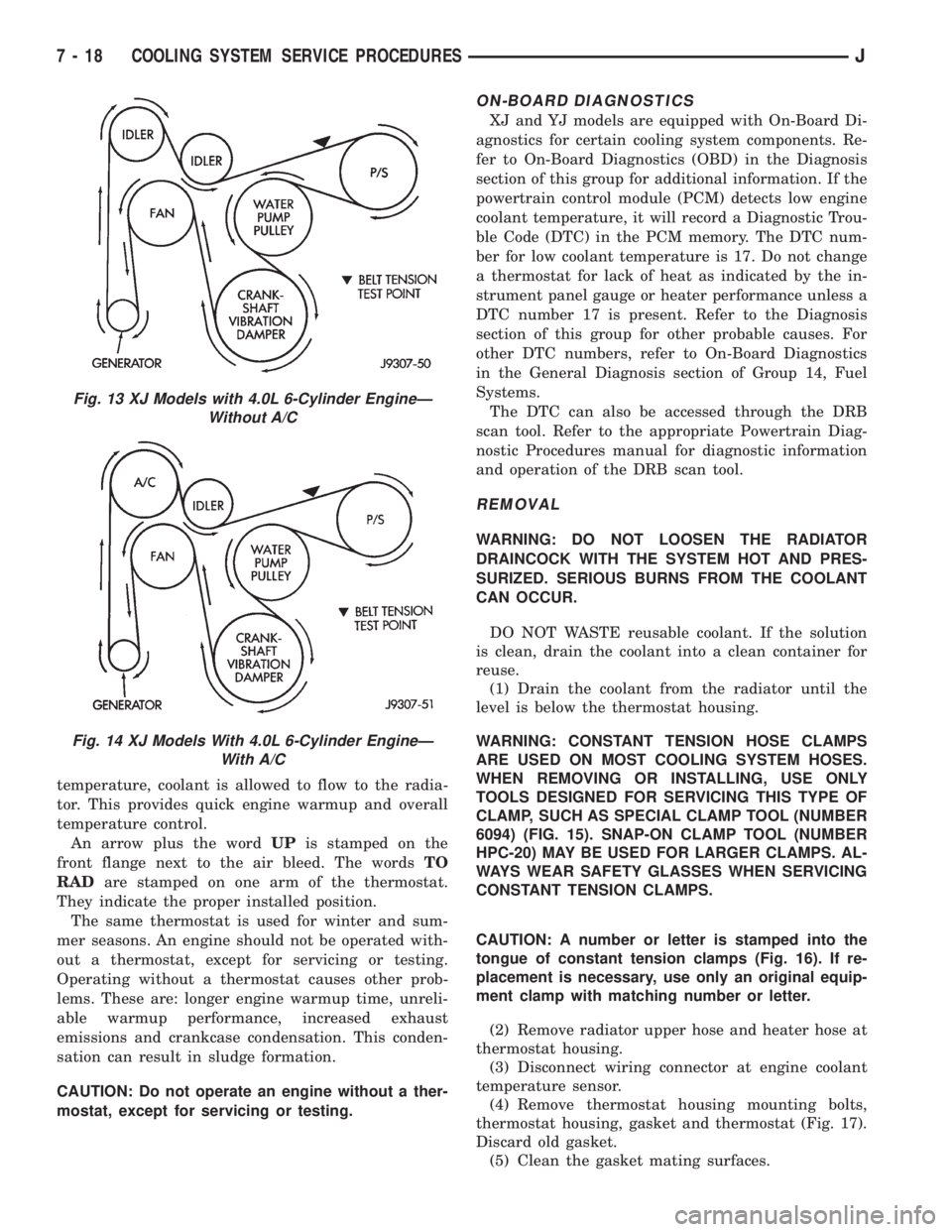

Fig. 13 XJ Models with 4.0L 6-Cylinder EngineÐ

Without A/C

Fig. 14 XJ Models With 4.0L 6-Cylinder EngineÐ

With A/C

7 - 18 COOLING SYSTEM SERVICE PROCEDURESJ