warning JEEP YJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 48 of 2158

hose unless the caliper must also be removed

for maintenance.Support the caliper with a

hanger to prevent brake fluid hose damage.

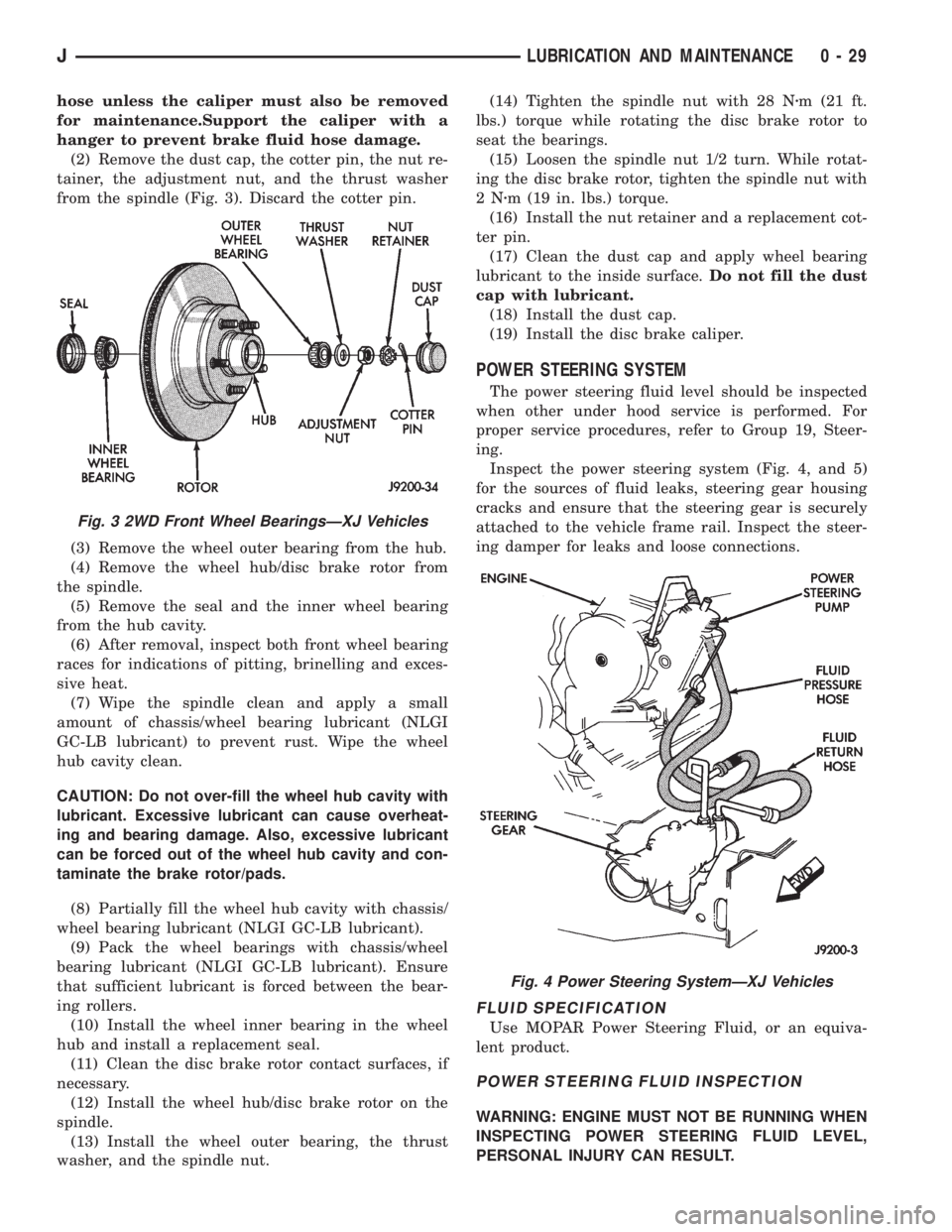

(2) Remove the dust cap, the cotter pin, the nut re-

tainer, the adjustment nut, and the thrust washer

from the spindle (Fig. 3). Discard the cotter pin.

(3) Remove the wheel outer bearing from the hub.

(4) Remove the wheel hub/disc brake rotor from

the spindle.

(5) Remove the seal and the inner wheel bearing

from the hub cavity.

(6) After removal, inspect both front wheel bearing

races for indications of pitting, brinelling and exces-

sive heat.

(7) Wipe the spindle clean and apply a small

amount of chassis/wheel bearing lubricant (NLGI

GC-LB lubricant) to prevent rust. Wipe the wheel

hub cavity clean.

CAUTION: Do not over-fill the wheel hub cavity with

lubricant. Excessive lubricant can cause overheat-

ing and bearing damage. Also, excessive lubricant

can be forced out of the wheel hub cavity and con-

taminate the brake rotor/pads.

(8) Partially fill the wheel hub cavity with chassis/

wheel bearing lubricant (NLGI GC-LB lubricant).

(9) Pack the wheel bearings with chassis/wheel

bearing lubricant (NLGI GC-LB lubricant). Ensure

that sufficient lubricant is forced between the bear-

ing rollers.

(10) Install the wheel inner bearing in the wheel

hub and install a replacement seal.

(11) Clean the disc brake rotor contact surfaces, if

necessary.

(12) Install the wheel hub/disc brake rotor on the

spindle.

(13) Install the wheel outer bearing, the thrust

washer, and the spindle nut.(14) Tighten the spindle nut with 28 Nzm (21 ft.

lbs.) torque while rotating the disc brake rotor to

seat the bearings.

(15) Loosen the spindle nut 1/2 turn. While rotat-

ing the disc brake rotor, tighten the spindle nut with

2Nzm (19 in. lbs.) torque.

(16) Install the nut retainer and a replacement cot-

ter pin.

(17) Clean the dust cap and apply wheel bearing

lubricant to the inside surface.Do not fill the dust

cap with lubricant.

(18) Install the dust cap.

(19) Install the disc brake caliper.

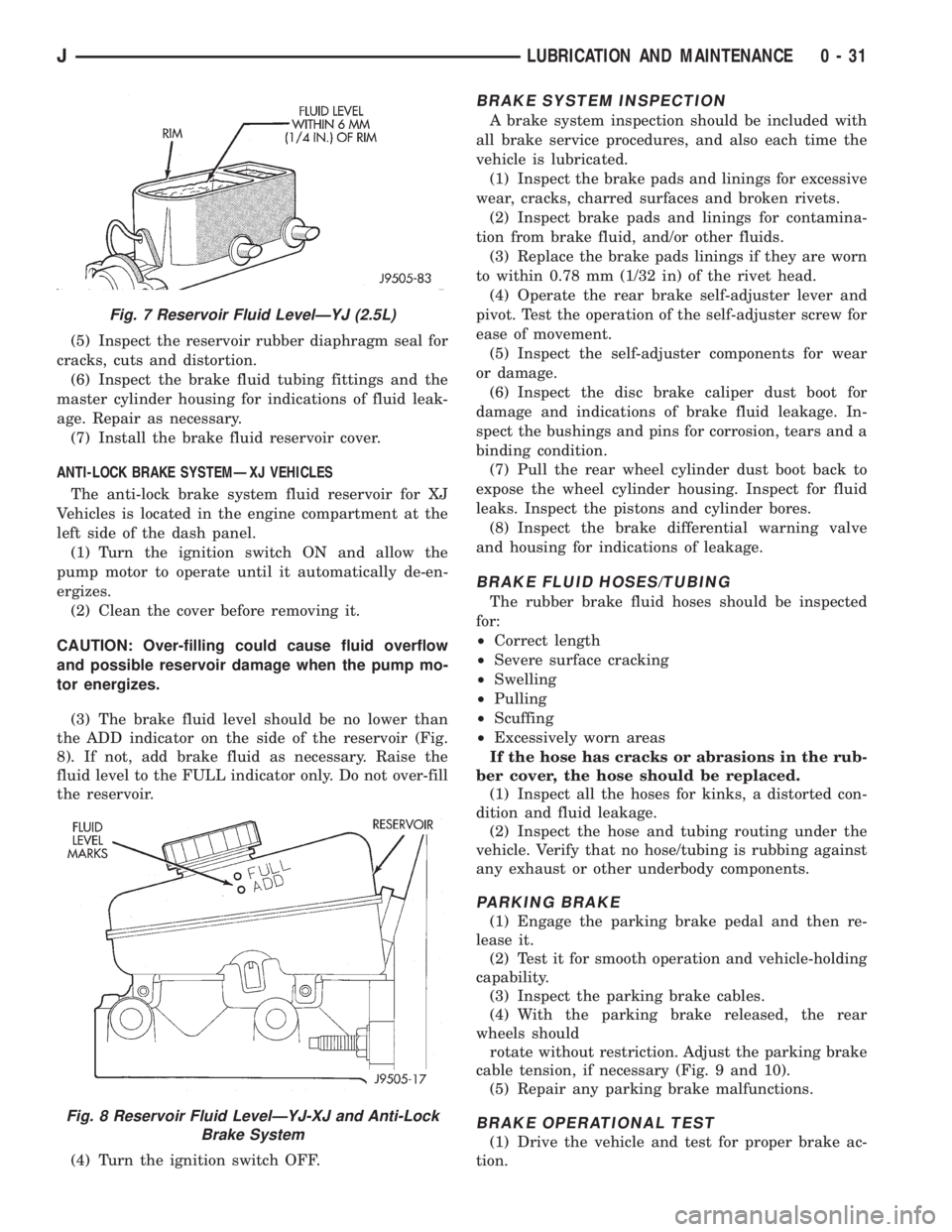

POWER STEERING SYSTEM

The power steering fluid level should be inspected

when other under hood service is performed. For

proper service procedures, refer to Group 19, Steer-

ing.

Inspect the power steering system (Fig. 4, and 5)

for the sources of fluid leaks, steering gear housing

cracks and ensure that the steering gear is securely

attached to the vehicle frame rail. Inspect the steer-

ing damper for leaks and loose connections.

FLUID SPECIFICATION

Use MOPAR Power Steering Fluid, or an equiva-

lent product.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

Fig. 3 2WD Front Wheel BearingsÐXJ Vehicles

Fig. 4 Power Steering SystemÐXJ Vehicles

JLUBRICATION AND MAINTENANCE 0 - 29

Page 50 of 2158

(5) Inspect the reservoir rubber diaphragm seal for

cracks, cuts and distortion.

(6) Inspect the brake fluid tubing fittings and the

master cylinder housing for indications of fluid leak-

age. Repair as necessary.

(7) Install the brake fluid reservoir cover.

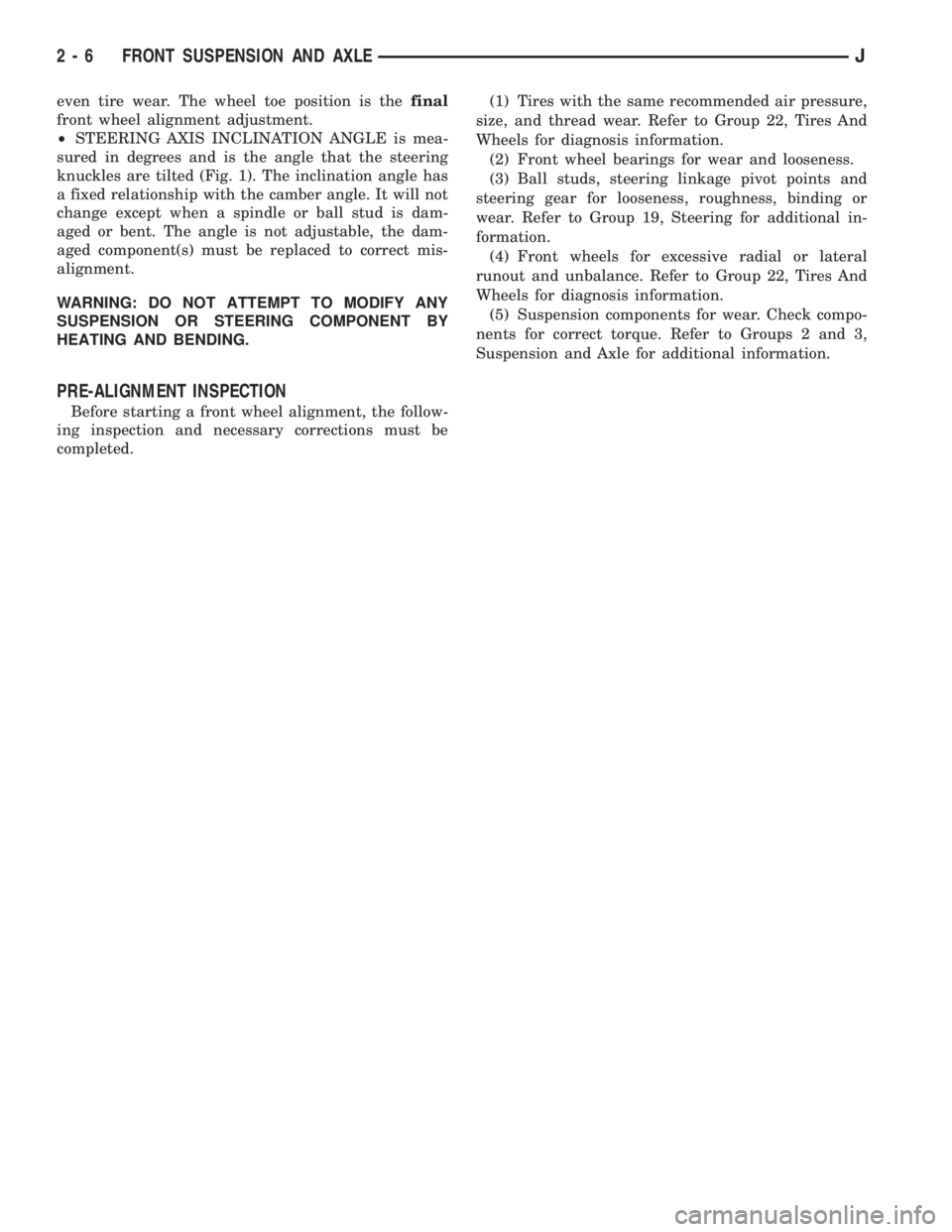

ANTI-LOCK BRAKE SYSTEMÐXJ VEHICLES

The anti-lock brake system fluid reservoir for XJ

Vehicles is located in the engine compartment at the

left side of the dash panel.

(1) Turn the ignition switch ON and allow the

pump motor to operate until it automatically de-en-

ergizes.

(2) Clean the cover before removing it.

CAUTION: Over-filling could cause fluid overflow

and possible reservoir damage when the pump mo-

tor energizes.

(3) The brake fluid level should be no lower than

the ADD indicator on the side of the reservoir (Fig.

8). If not, add brake fluid as necessary. Raise the

fluid level to the FULL indicator only. Do not over-fill

the reservoir.

(4) Turn the ignition switch OFF.

BRAKE SYSTEM INSPECTION

A brake system inspection should be included with

all brake service procedures, and also each time the

vehicle is lubricated.

(1) Inspect the brake pads and linings for excessive

wear, cracks, charred surfaces and broken rivets.

(2) Inspect brake pads and linings for contamina-

tion from brake fluid, and/or other fluids.

(3) Replace the brake pads linings if they are worn

to within 0.78 mm (1/32 in) of the rivet head.

(4) Operate the rear brake self-adjuster lever and

pivot. Test the operation of the self-adjuster screw for

ease of movement.

(5) Inspect the self-adjuster components for wear

or damage.

(6) Inspect the disc brake caliper dust boot for

damage and indications of brake fluid leakage. In-

spect the bushings and pins for corrosion, tears and a

binding condition.

(7) Pull the rear wheel cylinder dust boot back to

expose the wheel cylinder housing. Inspect for fluid

leaks. Inspect the pistons and cylinder bores.

(8) Inspect the brake differential warning valve

and housing for indications of leakage.

BRAKE FLUID HOSES/TUBING

The rubber brake fluid hoses should be inspected

for:

²Correct length

²Severe surface cracking

²Swelling

²Pulling

²Scuffing

²Excessively worn areas

If the hose has cracks or abrasions in the rub-

ber cover, the hose should be replaced.

(1) Inspect all the hoses for kinks, a distorted con-

dition and fluid leakage.

(2) Inspect the hose and tubing routing under the

vehicle. Verify that no hose/tubing is rubbing against

any exhaust or other underbody components.

PARKING BRAKE

(1) Engage the parking brake pedal and then re-

lease it.

(2) Test it for smooth operation and vehicle-holding

capability.

(3) Inspect the parking brake cables.

(4) With the parking brake released, the rear

wheels should

rotate without restriction. Adjust the parking brake

cable tension, if necessary (Fig. 9 and 10).

(5) Repair any parking brake malfunctions.

BRAKE OPERATIONAL TEST

(1) Drive the vehicle and test for proper brake ac-

tion.

Fig. 7 Reservoir Fluid LevelÐYJ (2.5L)

Fig. 8 Reservoir Fluid LevelÐYJ-XJ and Anti-Lock

Brake System

JLUBRICATION AND MAINTENANCE 0 - 31

Page 58 of 2158

even tire wear. The wheel toe position is thefinal

front wheel alignment adjustment.

²STEERING AXIS INCLINATION ANGLE is mea-

sured in degrees and is the angle that the steering

knuckles are tilted (Fig. 1). The inclination angle has

a fixed relationship with the camber angle. It will not

change except when a spindle or ball stud is dam-

aged or bent. The angle is not adjustable, the dam-

aged component(s) must be replaced to correct mis-

alignment.

WARNING: DO NOT ATTEMPT TO MODIFY ANY

SUSPENSION OR STEERING COMPONENT BY

HEATING AND BENDING.

PRE-ALIGNMENT INSPECTION

Before starting a front wheel alignment, the follow-

ing inspection and necessary corrections must be

completed.(1) Tires with the same recommended air pressure,

size, and thread wear. Refer to Group 22, Tires And

Wheels for diagnosis information.

(2) Front wheel bearings for wear and looseness.

(3) Ball studs, steering linkage pivot points and

steering gear for looseness, roughness, binding or

wear. Refer to Group 19, Steering for additional in-

formation.

(4) Front wheels for excessive radial or lateral

runout and unbalance. Refer to Group 22, Tires And

Wheels for diagnosis information.

(5) Suspension components for wear. Check compo-

nents for correct torque. Refer to Groups 2 and 3,

Suspension and Axle for additional information.

2 - 6 FRONT SUSPENSION AND AXLEJ

Page 146 of 2158

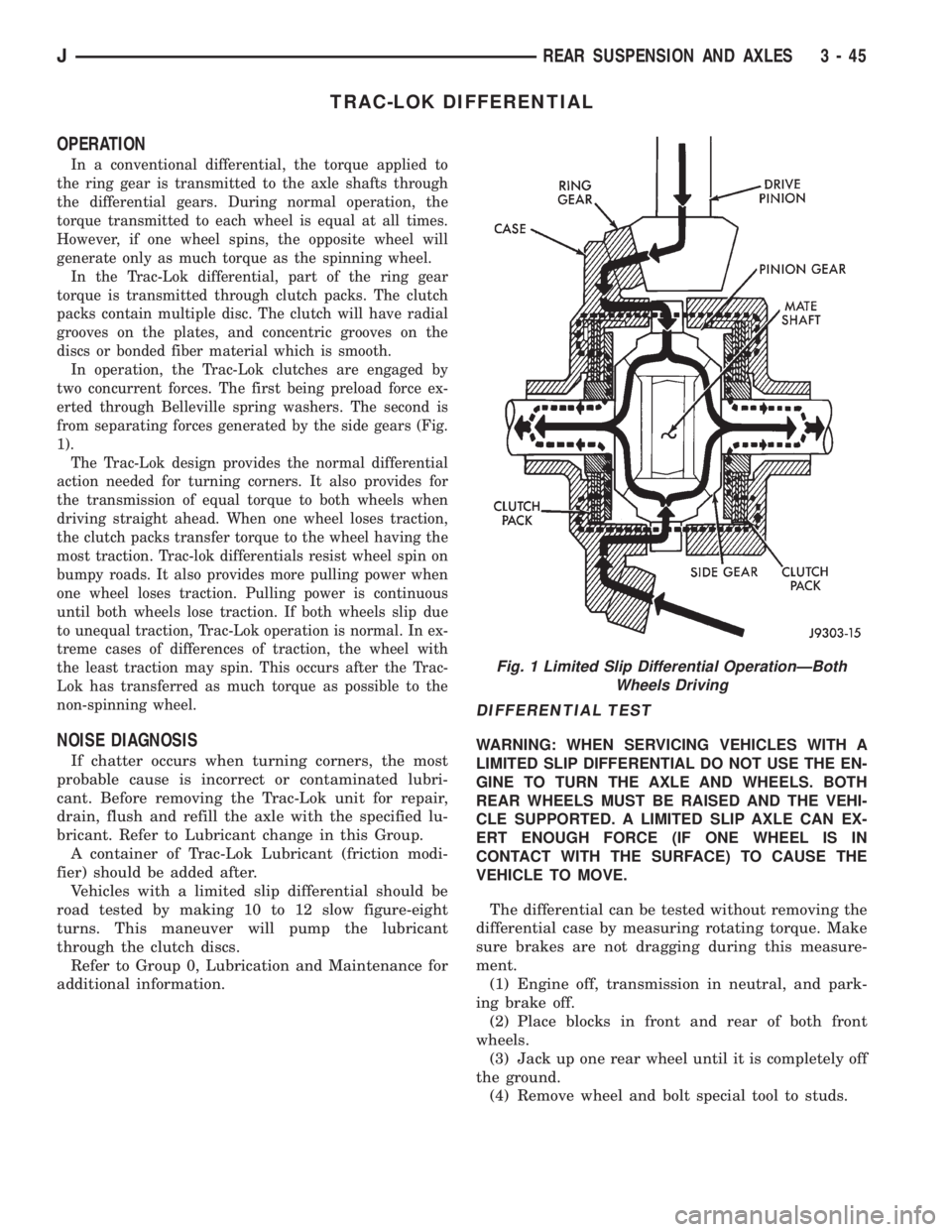

TRAC-LOK DIFFERENTIAL

OPERATION

In a conventional differential, the torque applied to

the ring gear is transmitted to the axle shafts through

the differential gears. During normal operation, the

torque transmitted to each wheel is equal at all times.

However, if one wheel spins, the opposite wheel will

generate only as much torque as the spinning wheel.

In the Trac-Lok differential, part of the ring gear

torque is transmitted through clutch packs. The clutch

packs contain multiple disc. The clutch will have radial

grooves on the plates, and concentric grooves on the

discs or bonded fiber material which is smooth.

In operation, the Trac-Lok clutches are engaged by

two concurrent forces. The first being preload force ex-

erted through Belleville spring washers. The second is

from separating forces generated by the side gears (Fig.

1).

The Trac-Lok design provides the normal differential

action needed for turning corners. It also provides for

the transmission of equal torque to both wheels when

driving straight ahead. When one wheel loses traction,

the clutch packs transfer torque to the wheel having the

most traction. Trac-lok differentials resist wheel spin on

bumpy roads. It also provides more pulling power when

one wheel loses traction. Pulling power is continuous

until both wheels lose traction. If both wheels slip due

to unequal traction, Trac-Lok operation is normal. In ex-

treme cases of differences of traction, the wheel with

the least traction may spin. This occurs after the Trac-

Lok has transferred as much torque as possible to the

non-spinning wheel.

NOISE DIAGNOSIS

If chatter occurs when turning corners, the most

probable cause is incorrect or contaminated lubri-

cant. Before removing the Trac-Lok unit for repair,

drain, flush and refill the axle with the specified lu-

bricant. Refer to Lubricant change in this Group.

A container of Trac-Lok Lubricant (friction modi-

fier) should be added after.

Vehicles with a limited slip differential should be

road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs.

Refer to Group 0, Lubrication and Maintenance for

additional information.

DIFFERENTIAL TEST

WARNING: WHEN SERVICING VEHICLES WITH A

LIMITED SLIP DIFFERENTIAL DO NOT USE THE EN-

GINE TO TURN THE AXLE AND WHEELS. BOTH

REAR WHEELS MUST BE RAISED AND THE VEHI-

CLE SUPPORTED. A LIMITED SLIP AXLE CAN EX-

ERT ENOUGH FORCE (IF ONE WHEEL IS IN

CONTACT WITH THE SURFACE) TO CAUSE THE

VEHICLE TO MOVE.

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Engine off, transmission in neutral, and park-

ing brake off.

(2) Place blocks in front and rear of both front

wheels.

(3) Jack up one rear wheel until it is completely off

the ground.

(4) Remove wheel and bolt special tool to studs.

Fig. 1 Limited Slip Differential OperationÐBoth

Wheels Driving

JREAR SUSPENSION AND AXLES 3 - 45

Page 153 of 2158

BRAKES

CONTENTS

page page

ABS BRAKE DIAGNOSIS................... 3

ABS OPERATION AND SERVICE............ 33

BRAKE FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES............... 10

DISC BRAKES.......................... 45

DRUM BRAKES......................... 55

GENERAL INFORMATION.................. 1MASTER CYLINDERÐCOMBINATION VALVE . . 15

PARKING BRAKES....................... 60

POWER BRAKE BOOSTERÐBRAKE PEDALÐ

BRAKELIGHT SWITCH.................. 22

SERVICE BRAKE DIAGNOSIS............... 4

SPECIFICATIONS........................ 70

GENERAL INFORMATION

INDEX

page page

Antilock Brakes (ABS)....................... 1

Brake Components......................... 1

Brake Fluid/Lubricants/Cleaning Solvents......... 2

Brake Safety Precautions.................... 2Brake Warning Lights....................... 1

Brakelining Material........................ 1

Jeep Body Code Letters..................... 2

BRAKE COMPONENTS

Power assist front disc and rear drum brakes are

standard on Cherokee/Wrangler models. Disc brake

components consist of single piston calipers and ven-

tilated rotors. Rear drum brakes are dual shoe units

with cast brake drums.

The parking brake mechanism is lever and cable

operated. The cables are attached to levers on the

rear drum brake secondary shoes. The parking

brakes are operated by a foot pedal on YJ models and

a hand lever on XJ models.

A 205 mm dual diaphragm vacuum power brake

booster is used for all applications. Two master cylin-

ders are used; 4-cylinder YJ models have a one-piece

master cylinder. All other models have a two-piece

master cylinder with plastic reservoir.

All models are equipped with a combination valve.

The valve contains a pressure differential valve and

switch and a fixed rate rear proportioning valve.

BRAKELINING MATERIAL

Factory brakelining on all models consists of an or-

ganic base material combined with metallic particles.

The lining does not contain asbestos.

BRAKE WARNING LIGHTS

Cherokee/Wrangler models are equipped with one

or two brake warning lights. A red warning light is

standard on all models. An amber light is added on

models with ABS brakes. Both lights are located in

the instrument panel.

The red light is in circuit with the pressure differ-

ential switch (in the combination valve), and with the

parking brake switch. The light alerts the driver

when the parking brakes are applied, or when a

pressure differential exists between the front and

rear hydraulic systems. The light also illuminates for

a few seconds at start up as part of a bulb check.

The ABS warning light is amber in color and is lo-

cated in the same side of the instrument cluster as

the red warning light. The amber light only illumi-

nates when an ABS circuit fault occurs.

ANTILOCK BRAKES (ABS)

An antilock brake system (ABS) is available on

Cherokee/Wrangler models as an option. The system

is an electronically operated, all-wheel brake control

system. The ABS system is designed to prevent

wheel lockup during periods of high wheel slip brak-

ing. Refer to the antilock brake section for operation

and service information.

JBRAKES 5 - 1

Page 154 of 2158

ABS SYSTEM CHANGES

A different master cylinder, power brake booster,

and HCU are used in the 1995 Jeep ABS system.

The master cylinder reservoir has a single filler cap

and is no longer interconnected with the HCU. The

new HCU has built-in accumulators. The pedal travel

sensor has been eliminated and a new dual dia-

phragm power brake booster is used.

BRAKE FLUID/LUBRICANTS/CLEANING SOLVENTS

Recommended fluid for all Jeep vehicles is Mopar

DOT 3 brake fluid, or an equivalent meeting SAE

J1703 and DOT 3 standards.

Use Mopar Multi Mileage grease to lubricate drum

brake pivot pins and rear brakeshoe contact points

on the support plates. Use GE 661, or Dow 111 sili-

cone grease on caliper bushings and mounting bolts.

Use fresh brake fluid or Mopar brake cleaner to

clean or flush brake system components. These are

the only cleaning materials recommended.

CAUTION: Never use gasoline, kerosene, methyl or

isopropyl alcohol, paint thinner, or any fluid con-

taining mineral oil to clean brake parts. These fluids

damage rubber cups and seals. If system contami-

nation is suspected, check the fluid for dirt, discol-

oration, or separation into distinct layers. Drain and

flush the system with new brake fluid if contamina-

tion is suspected.

JEEP BODY CODE LETTERS

The body/model identification code letters for Jeep

vehicles are as follows:²Code letters XJ: Cherokee

²Code letters YJ: Wrangler/YJ

The code letters are used throughout this group to

simplify model identification and component applica-

tion.

BRAKE SAFETY PRECAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELINING ON JEEP VEHICLES IS MADE FROM

ASBESTOS FREE MATERIALS, SOME AFTER MAR-

KET BRAKELINING MAY CONTAIN ASBESTOS. THIS

SHOULD BE TAKEN INTO ACCOUNT WHEN RE-

PAIRING A VEHICLE WITH PRIOR BRAKE SERVICE.

WEAR A RESPIRATOR WHEN CLEANING BRAKE

COMPONENTS AS ASBESTOS FIBERS CAN BE A

HEALTH HAZARD. NEVER CLEAN WHEEL BRAKE

COMPONENTS WITH COMPRESSED AIR. USE A

VACUUM CLEANER SPECIFICALLY DESIGNED FOR

REMOVING BRAKE DUST. IF A VACUUM CLEANER

IS NOT AVAILABLE, CLEAN THE PARTS WITH WA-

TER DAMPENED SHOP RAGS. DO NOT CREATE

DUST BY SANDING BRAKELINING. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS IN SEALED BAGS OR CON-

TAINERS. FOLLOW ALL SAFETY PRACTICES REC-

OMMENDED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION (OSHA) AND THE ENVI-

RONMENTAL PROTECTION AGENCY (EPA), FOR

HANDLING AND DISPOSAL OF ASBESTOS.

5 - 2 BRAKESJ

Page 155 of 2158

ABS BRAKE DIAGNOSIS

INDEX

page page

ABS Diagnostic Connector................... 3

ABS Warning Light Display................... 3

Antilock ECU and Hcu Diagnosis............... 3

DRB Scan Tool............................ 3General Information........................ 3

Normal Operating Conditions.................. 3

Wheel/Tire Size and Input Signals.............. 3

GENERAL INFORMATION

The DRB scan tool is required for ABS diagnosis.

The scan tool is used to identify ABS circuit faults.

Once a faulty circuit has been identified, refer to

the appropriate chassis/body diagnostic manual for

individual component testing.

ABS WARNING LIGHT DISPLAY

The amber antilock light illuminates at startup as

part of the system self check feature. The light illu-

minates for 2-3 seconds then goes off as part of the

normal check routine.

An ABS circuit fault is indicated when the amber

light remains on after startup, or illuminates during

vehicle operation.

Verify that a fault is actually related to the ABS

system before making repairs. For example, if the

red warning illuminates but the ABS light does not,

the problem is related to a service brake component

and not the ABS system. Or, if neither light illumi-

nates but a brake problem is noted, again, the prob-

lem is with a service brake component and not with

the ABS system.

ABS DIAGNOSTIC CONNECTOR

The ABS diagnostic connector is inside the vehicle.

The connector is the access point for the DRB scan tool.

On XJ models, the connector is located under the

instrument panel to the right of the steering column.

On some models, the connecter may be tucked under

the carpeting on the transmission tunnel. The con-

necter is a black, 6-way type.

On YJ models, the connector is under the instru-

ment panel by the the driver side kick panel. The

connecter is a black, 6 or 8-way type.

The DRB scan tool kit contains adapter cords for

both types of connecter. Use the appropriate cord for

test hookup.

DRB SCAN TOOL

ABS diagnosis is performed with the DRB scan tool.

Refer to the DRB scan tool manual for test hookup and

procedures. Diagnosis information is provided in the ap-

propriate chassis/body diagnostic manual.

WHEEL/TIRE SIZE AND INPUT SIGNALS

Antilock system operation is dependant on accurate

signals from the wheel speed sensors. Ideally, the ve-

hicle wheels and tires should all be the same size

and type. However, the Jeep ABS system is designed

to operate with a compact spare tire installed.

NORMAL OPERATING CONDITIONS

Sound Levels

The hydraulic control unit pump and solenoid valves

may produce some sound as they cycle on and off. This

is a normal condition and should not be mistaken for

faulty operation. Under most conditions, pump and so-

lenoid valve operating sounds will not be audible.

Vehicle Response In Antilock Mode

During antilock braking, the hydraulic control unit

solenoid valves cycle rapidly in response to antilock

electronic control unit signals.

The driver will experience a pulsing sensation

within the vehicle as the solenoids decrease, hold, or

increase pressure as needed. Brake pedal pulsing will

also be noted and is anormal condition.

Steering Response

A modest amount of steering input is required dur-

ing extremely high deceleration braking, or when

braking on differing traction surfaces. An example of

differing traction surfaces would be when the left

side wheels are on ice and the right side wheels are

on dry pavement.

Owner Induced Faults

Driving away with the parking brakes still applied

will cause warning light illumination. Pumping the

brake pedal will also generate a system fault and in-

terfere with ABS system operation.

ANTILOCK ECU AND HCU DIAGNOSIS

An ECU or HCU fault can only be determined

through testing with the DRB scan tool. Do not re-

place either component unless a fault is actually in-

dicated.

JABS BRAKE DIAGNOSIS 5 - 3

Page 156 of 2158

SERVICE BRAKE DIAGNOSIS

INDEX

page page

Brake Drag............................... 6

Brake Fade.............................. 6

Brake Fluid Contamination................... 7

Brake Noise.............................. 7

Brake Pull............................... 6

Brake Warning Light Operation................ 5

Brakes Do Not Hold After Driving Through Deep

Water Puddles........................... 7

Component Inspection...................... 5

Contaminated Brakelining.................... 7

Diagnosing Parking Brake Malfunctions.......... 8

Diagnosis Procedures....................... 4

General Information........................ 4Hard Pedal or High Pedal Effort............... 6

Low Pedal............................... 5

Master Cylinder/Power Booster Test............ 8

Pedal Falls Away.......................... 5

Pedal Pulsation (Non-ABS Brakes Only)......... 6

Power Booster Check Valve Test............... 9

Power Booster Vacuum Test.................. 9

Preliminary Brake Check..................... 4

Rear Brake Grab.......................... 7

Road Testing............................. 5

Spongy Pedal............................. 5

Wheel and Tire Problems.................... 7

GENERAL INFORMATION

The diagnosis information in this section covers

service brake components which include:

²disc brake calipers

²disc brakeshoes

²drum brake wheel cylinders

²drum brakeshoes and brake drums

²drum brake support plates

²parking brake mechanism

²master cylinder/combination valve

²vacuum power brake booster

²brake pedal and brakelight switch

²brake warning light

DIAGNOSIS PROCEDURES

Service brake diagnosis involves determining if a

problem is related to a mechanical, hydraulic or vac-

uum operated component. A preliminary brake check,

followed by road testing and component inspection

are needed to determine a problem cause.

Road testing will either verify proper brake opera-

tion or confirm the existence of a problem. Compo-

nent inspection will, in most cases, identify the

actual part responsible for a problem.

The first diagnosis step is the preliminary brake

check. This involves inspecting fluid level, parking

brake action, wheel and tire condition, checking for

obvious leaks or component damage and testing

brake pedal response. A road test will confirm or

deny the existence of a problem. The final diagnosis

procedure involves road test analysis and a visual in-

spection of brake components.

PRELIMINARY BRAKE CHECK

(1) If amber ABS light is illuminated, refer to ABS

Brake System Diagnosis. If red warning light is illu-

minated, or if neither warning light is illuminated,

continue with brake check.(2) Inspect condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, tramp and a condition simi-

lar to grab.

(3) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn, or damaged suspension or steering

components.

(4) Inspect brake fluid level:

(a) If vehicle has one-piece master cylinder, fluid

level should be within 6 mm (1/4 in.) of reservoir

rim.

(b) If vehicle has nylon reservoir with single

filler cap, correct level is to FULL mark on side of

reservoir. Acceptable level is between FULL and

ADD marks.

(c) Remember that fluid level in the reservoir

compartments will decrease in proportion to nor-

mal lining wear. However, if fluid level is abnor-

mally low, look for leaks at calipers, wheel

cylinders, brakelines and master cylinder.

(5) Inspect brake fluid condition:

(a) Fluid should be free of foreign material.Note

that brake fluid tends to darken over time.

This is normal and should not be mistaken for

contamination. If fluid is clear of foreign ma-

terial, it is OK.

(b) If fluid is highly discolored, or appears to con-

tain foreign material, drain out a sample with a

clean suction gun. Pour sample in a glass container

and note condition described in step (c).

(c) If fluid separates into layers, obviously con-

tains oil, or a substance other than brake fluid,

system seals and cups will have to be replaced and

hydraulic system flushed.

(6) Check parking brake operation. Verify free

movement and full release of cables and foot pedal or

5 - 4 SERVICE BRAKE DIAGNOSISJ

Page 157 of 2158

hand lever. Also note if vehicle was being operated

with parking brake partially applied (this will cause

red light to remain on).

(7) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for be-

ing loose or for bind condition. Do not road test until

condition is corrected.

(8) If components inspected look OK, road test ve-

hicle.

ROAD TESTING

(1) If amber warning light is on, problem is with

antilock system component. Refer to antilock diagno-

sis section.

(2) If red warning light is not on, proceed to step

(4).

(3) If red warning light is on, proceed as follows:

(a) See if parking brakes are applied. If brakes

are applied, release them and proceed to step (4).

(b) Note if brake pedal is abnormally low. If

pedal is definitely low and red light is still on,

check front/rear hydraulic circuits for leak.Do not

road test. Inspect and repair as needed.

(4) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under steady foot pressure. If pedal falls away,

do not road test as problem is in master cylinder, or

HCU on ABS models. If pedal holds firm, proceed to

next step.

(5) During road test, make normal and firm brake

stops in 25-35 mph range. Note faulty brake opera-

tion such as hard pedal, pull, grab, drag, noise, fade,

etc.

(6) Return to shop and inspect brake components.

Refer to inspection and diagnosis information.

COMPONENT INSPECTION

Fluid leak points and dragging brake units can

usually be located without removing any components.

The area around a leak point will be wet with fluid.

The components at a dragging brake unit (wheel,

tire, rotor) will be quite warm or hot to the touch.

Other brake problem conditions will require compo-

nent removal for proper inspection. Raise the vehicle

and remove the necessary wheels for better visual ac-

cess.

During component inspection, pay particular atten-

tion to heavily rusted/corroded brake components

(e.g. rotors, caliper pistons, brake return/holddown

springs, support plates, etc.).

Heavy accumulations of rust may be covering se-

vere damage to a brake component. It is wise to re-

move surface rust in order to accurately determine

the depth of rust penetration and damage. Light sur-

face rust is fairly normal and not a major concern (as

long as it is removed). However, heavy rust buildup,especially on high mileage vehicles may cover struc-

tural damage to such important components as

brakelines, rotors, support plates, and brake boost-

ers. Refer to the wheel brake service procedures in

this group for more information.

BRAKE WARNING LIGHT OPERATION

The red brake warning light will illuminate under

the following conditions:

²for 2-3 seconds at startup as part of normal bulb

check

²when parking brakes are applied

²low pedal caused by leak in front/rear brake hy-

draulic circuit

If the red light remains on after startup, first ver-

ify that the parking brakes are fully released. Then

check pedal action and fluid level. A red light plus

low pedal indicates the pressure differential switch

and valve have been actuated due to a system leak.

On models with ABS brakes, the amber warning

light only illuminates when an ABS malfunction has

occurred. The ABS light operates independently of

the red warning light.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brakeline, fitting, hose,

wheel cylinder, or caliper. Internal leakage in the

master cylinder caused by worn or damaged piston

cups, may also be the problem cause.

If leakage is severe, fluid will be evident at or

around the leaking component. However internal

leakage in the master cylinder will not be physically

evident. Refer to the cylinder test procedure at the

end of this section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the most likely causes.

However, if the pedal remains low and the red warn-

ing light is on, the likely cause is a leak in the hy-

draulic system.

A decrease in master cylinder fluid level may only

be the result of normal lining wear. Fluid level will

drop somewhat as lining wear occurs. It is a result of

the outward movement of caliper and wheel cylinder

pistons to compensate for normal wear.

SPONGY PEDAL

Air in the system is the usual cause of a spongy

pedal. Brake drums machined way beyond allowable

limits (too thin), or substandard brake lines and

hoses can also cause a condition similar to a spongy

JSERVICE BRAKE DIAGNOSIS 5 - 5

Page 160 of 2158

produce a condition similar to grab as the tire loses

and recovers traction.

Flat-spotted tires can cause vibration and wheel

tramp and generate shudder during brake operation.

A tire with internal damage such as a severe bruise

or ply separation can cause vibration and pull. The

pull will be magnified when braking.

DIAGNOSING PARKING BRAKE MALFUNCTIONS

Adjustment Mechanism

Parking brake adjustment is controlled by a ca-

ble tensioner mechanism. The cable tensioner,

once adjusted at the factory, will not need further

attention under normal circumstances. There are

only two instances when adjustment is required.

The first is when a new tensioner, or cables have

been installed. And the second, is when the ten-

sioner and cables are disconnected for access to

other brake components.

Parking Brake Switch And Warning Light Illumination

The parking brake switch on the lever, or foot

pedal, is in circuit with the red warning light. The

switch will illuminate the red light only when the

parking brakes are applied. If the light remains on

after parking brake release, the switch or wires are

faulty, or cable tensioner adjustment is incorrect.

If the red light comes on while the vehicle is in mo-

tion and brake pedal height decreases, a fault has oc-

curred in the front or rear brake hydraulic system.

Parking Brake problem Causes

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/wont

hold), can be traced to a drum brake component.

The leading cause of improper parking brake

operation, is excessive clearance between the

brakeshoes and the drum surface. Excessive

clearance is a result of: lining and/or drum

wear; oversize drums; or inoperative shoe ad-

juster components.

Excessive parking brake lever travel (sometimes de-

scribed as a loose lever or too loose condition), is the re-

sult of worn brakeshoes/drums, improper brakeshoe

adjustment, or incorrectly assembled brake parts.

A ``too loose'' condition can also be caused by inop-

erative brakeshoe adjusters. If the adjusters are mis-

assembled, they will not function. In addition, since

the adjuster mechanism only works during reverse

stops, it is important that complete stops be made.

The adjuster mechanism does not operate when roll-

ing stops are made in reverse. The vehicle must be

brought to a complete halt before the adjuster lever

will turn the adjuster screw.

A condition where the parking brakes do not hold, will

most probably be due to a wheel brake component.

Items to look for when diagnosing a parking brake

problem, are:

²rear brakeshoe wear or adjuster problem

²rear brake drum wear

²brake drums machined beyond allowable diameter

(oversize)

²parking brake front cable not secured to lever

²parking brake rear cable seized

²parking brake strut reversed

²parking brake strut not seated in both shoes

²parking brake lever not seated in secondary shoe

²parking brake lever or brakeshoe bind on support

plate

²brakeshoes reversed

²adjuster screws seized

²adjuster screws reversed

²holddown or return springs misassembled or lack

tension

²wheel cylinder pistons seized

Brake drums that are machined oversize are diffi-

cult to identify without inspection. If oversize drums

are suspected, diameter of the braking surface will

have to be checked with an accurate drum gauge.

Oversize drums will cause low brake pedal and lack

of parking brake holding ability.

Improper parking brake strut and lever installation

will result in unsatisfactory parking brake operation.

Intermixing the adjuster screws will cause drag, bind

and pull along with poor parking brake operation.

Parking brake adjustment and parts replacement pro-

cedures are described in the Parking Brake section.

MASTER CYLINDER/POWER BOOSTER TEST

(1) Start engine and check booster vacuum hose

connections. Hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure.

(a) If pedal holds firm, proceed to step (5).

(b) If pedal does not hold firm and falls away,

master cylinder is faulty due to internal leakage.

Overhaul or replace cylinder.

(5) Start engine and note pedal action.

(a) If pedal falls away slightly under light foot

pressure then holds firm, proceed to step (6).

(b) If no pedal action is discernible, or hard pedal

is noted, power booster or vacuum check valve is

faulty. Install known good check valve and repeat

steps (2) through (5).

(6) Rebuild booster vacuum reserve as follows: Re-

lease brake pedal. Increase engine speed to 1500

rpm, close throttle and immediately turn off ignition.

5 - 8 SERVICE BRAKE DIAGNOSISJ