JEEP YJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 461 of 2158

LAMPS

CONTENTS

page page

BULB APPLICATIONÐXJ VEHICLES......... 18

GENERAL INFORMATION.................. 1INTERIOR LAMPS....................... 16

SERVICE PROCEDURES................... 6

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

DIAGNOSTIC PROCEDURESÐXJ

When a vehicle experiences problems with the

headlamp system, verify the condition of the batteryconnections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

JLAMPS 8L - 1

Page 462 of 2158

HEADLAMP DIAGNOSIS

8L - 2 LAMPSÐXJ VEHICLESJ

Page 463 of 2158

FOG LAMP DIAGNOSIS

JLAMPSÐXJ VEHICLES 8L - 3

Page 464 of 2158

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ

The multi-function switch contains electrical cir-

cuitry for:

²Headlamp Dimmer Switch.

²Passing Lights.

²Turn Signals.

²Hazard Warning.

²Windshield Wiper.

²Pulse Wiper.

²Windshield Washer.

This integrated switch is mounted to the left hand

side of the steering column. Should any function of

the switch fail, the entire switch must be replaced.

The multi-function switch also serves as a fog lamp

lock-out circuit. The circuit to the fog lamp switch is

completed only when the dimmer switch is in the low

beam position.

SWITCH TEST

(1) Disconnect battery negative cable.

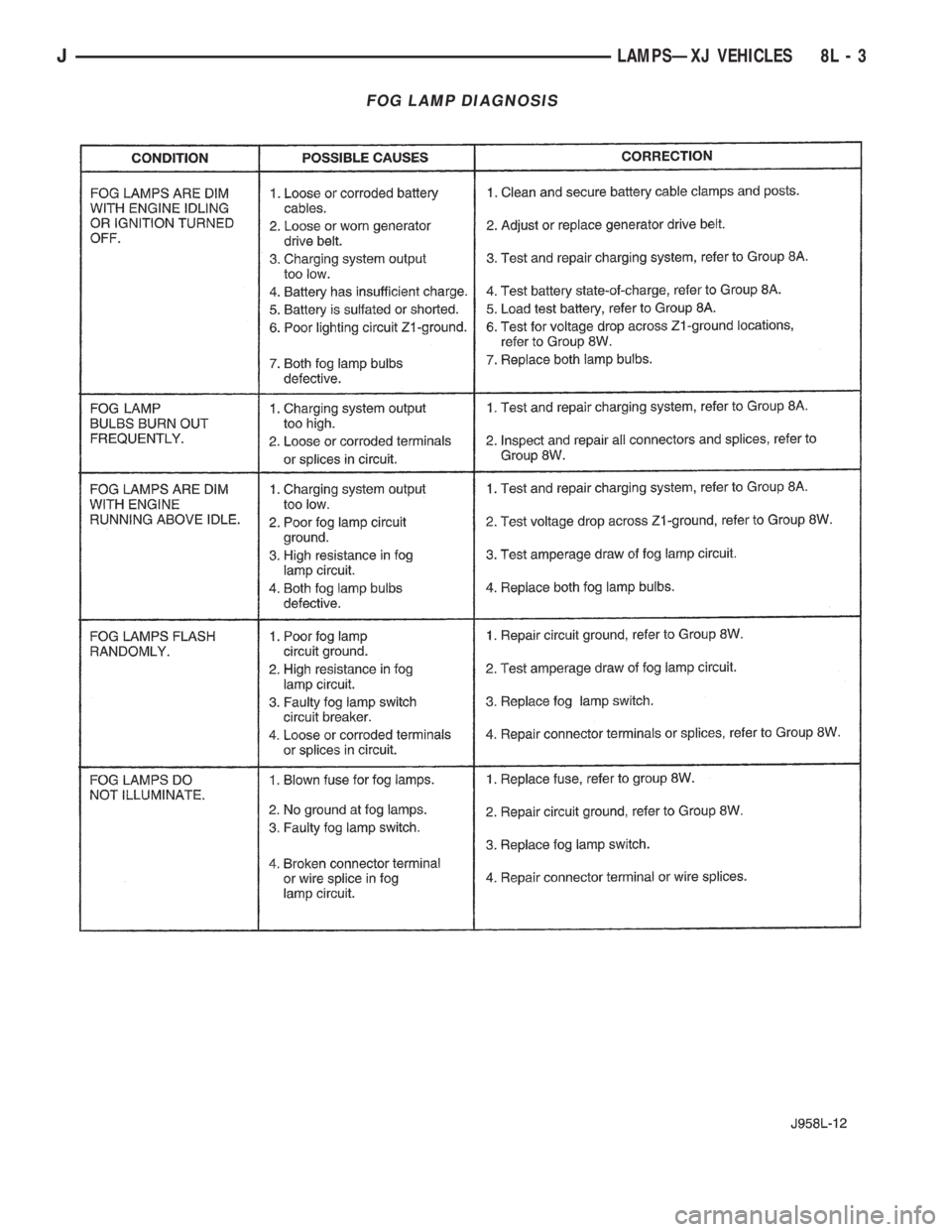

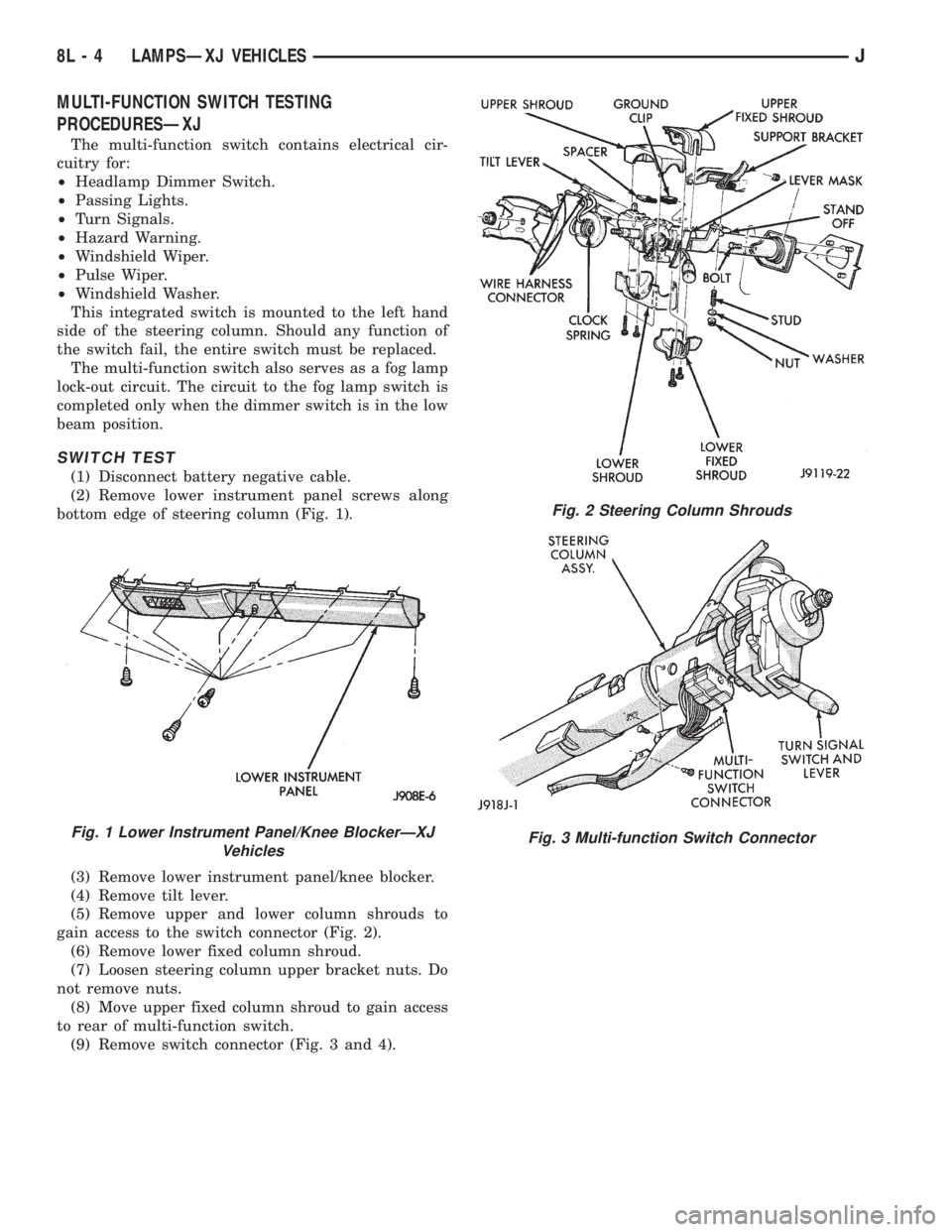

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 1).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 2).

(6) Remove lower fixed column shroud.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

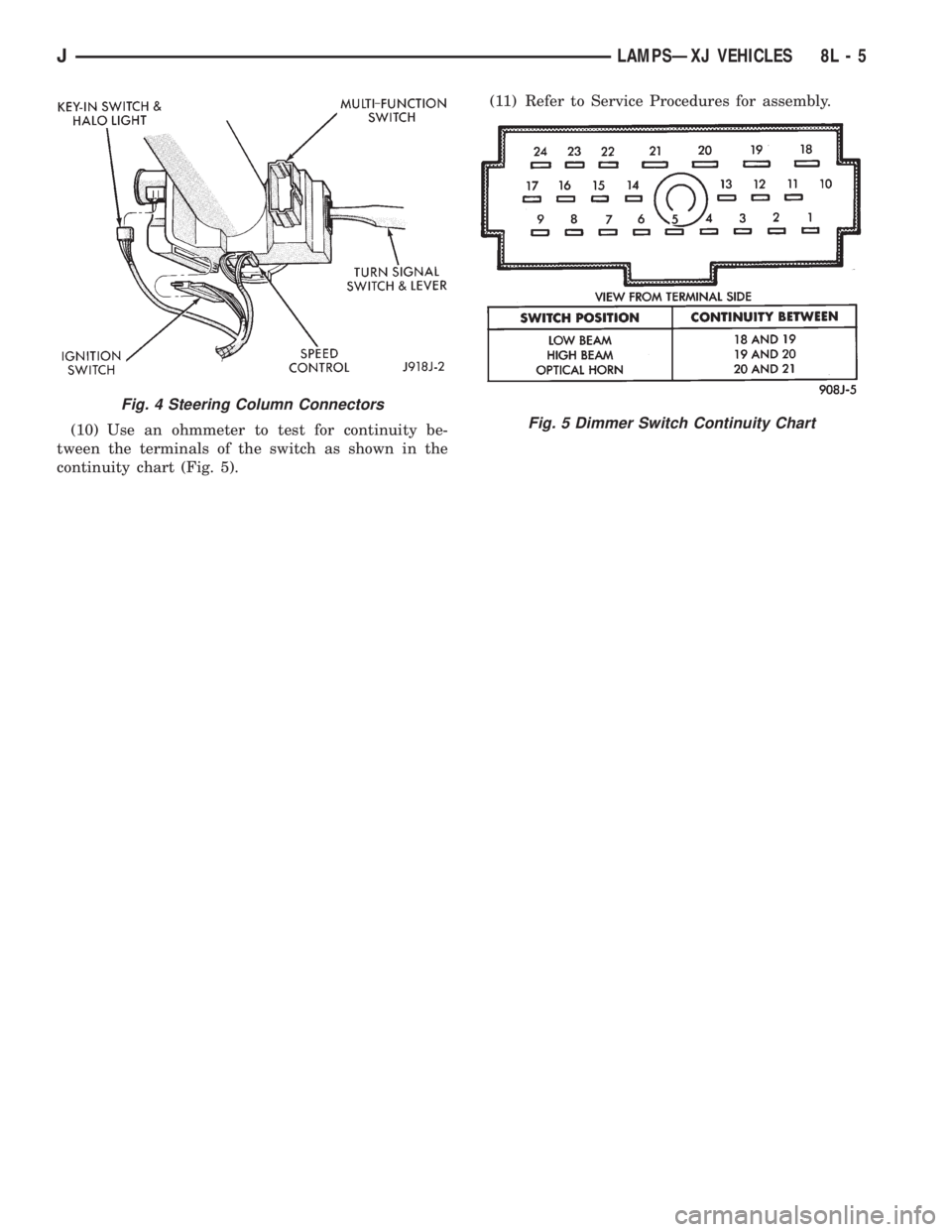

(9) Remove switch connector (Fig. 3 and 4).

Fig. 1 Lower Instrument Panel/Knee BlockerÐXJ

Vehicles

Fig. 2 Steering Column Shrouds

Fig. 3 Multi-function Switch Connector

8L - 4 LAMPSÐXJ VEHICLESJ

Page 465 of 2158

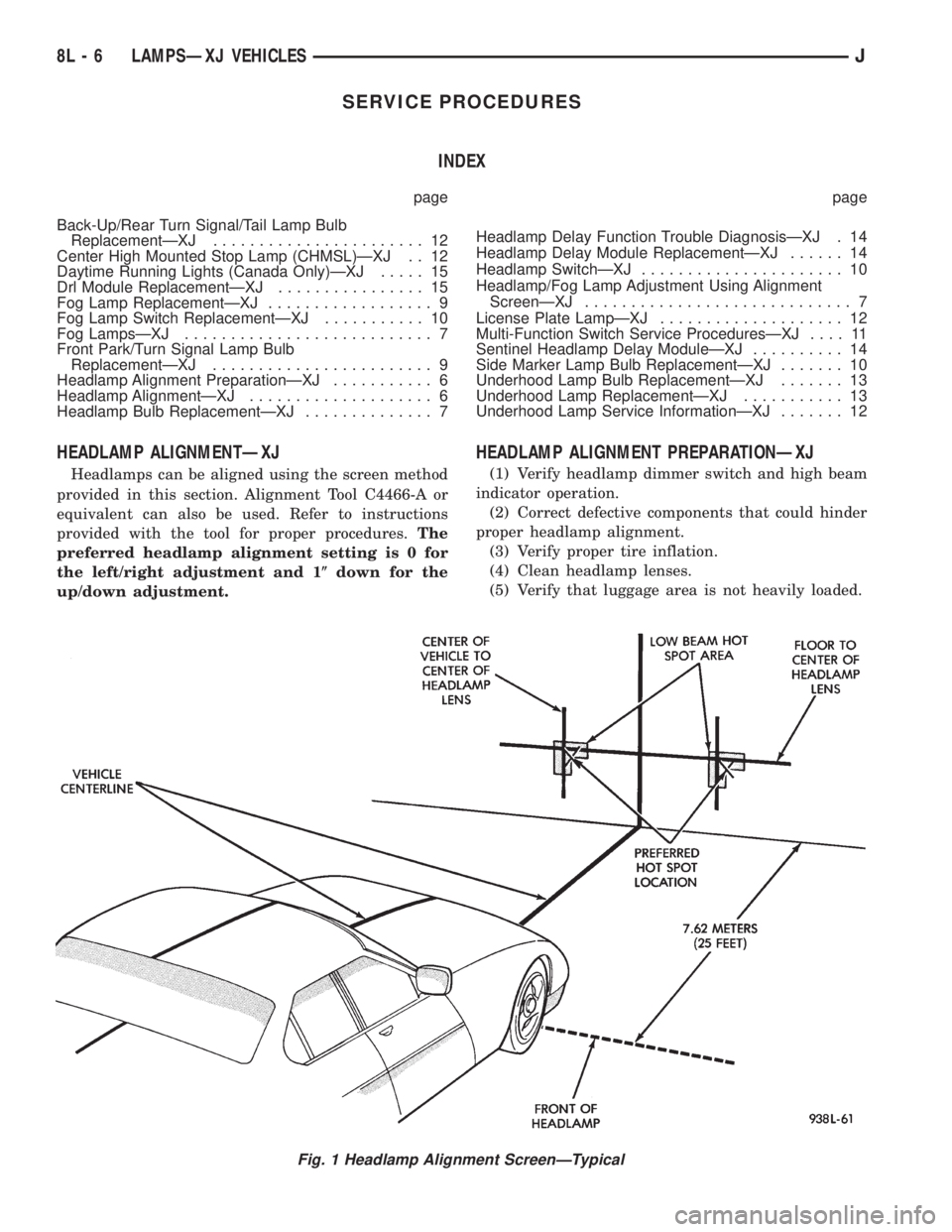

(10) Use an ohmmeter to test for continuity be-

tween the terminals of the switch as shown in the

continuity chart (Fig. 5).(11) Refer to Service Procedures for assembly.

Fig. 4 Steering Column Connectors

Fig. 5 Dimmer Switch Continuity Chart

JLAMPSÐXJ VEHICLES 8L - 5

Page 466 of 2158

SERVICE PROCEDURES

INDEX

page page

Back-Up/Rear Turn Signal/Tail Lamp Bulb

ReplacementÐXJ....................... 12

Center High Mounted Stop Lamp (CHMSL)ÐXJ . . 12

Daytime Running Lights (Canada Only)ÐXJ..... 15

Drl Module ReplacementÐXJ................ 15

Fog Lamp ReplacementÐXJ.................. 9

Fog Lamp Switch ReplacementÐXJ........... 10

Fog LampsÐXJ........................... 7

Front Park/Turn Signal Lamp Bulb

ReplacementÐXJ........................ 9

Headlamp Alignment PreparationÐXJ........... 6

Headlamp AlignmentÐXJ.................... 6

Headlamp Bulb ReplacementÐXJ.............. 7Headlamp Delay Function Trouble DiagnosisÐXJ . 14

Headlamp Delay Module ReplacementÐXJ...... 14

Headlamp SwitchÐXJ...................... 10

Headlamp/Fog Lamp Adjustment Using Alignment

ScreenÐXJ............................. 7

License Plate LampÐXJ.................... 12

Multi-Function Switch Service ProceduresÐXJ.... 11

Sentinel Headlamp Delay ModuleÐXJ.......... 14

Side Marker Lamp Bulb ReplacementÐXJ....... 10

Underhood Lamp Bulb ReplacementÐXJ....... 13

Underhood Lamp ReplacementÐXJ........... 13

Underhood Lamp Service InformationÐXJ....... 12

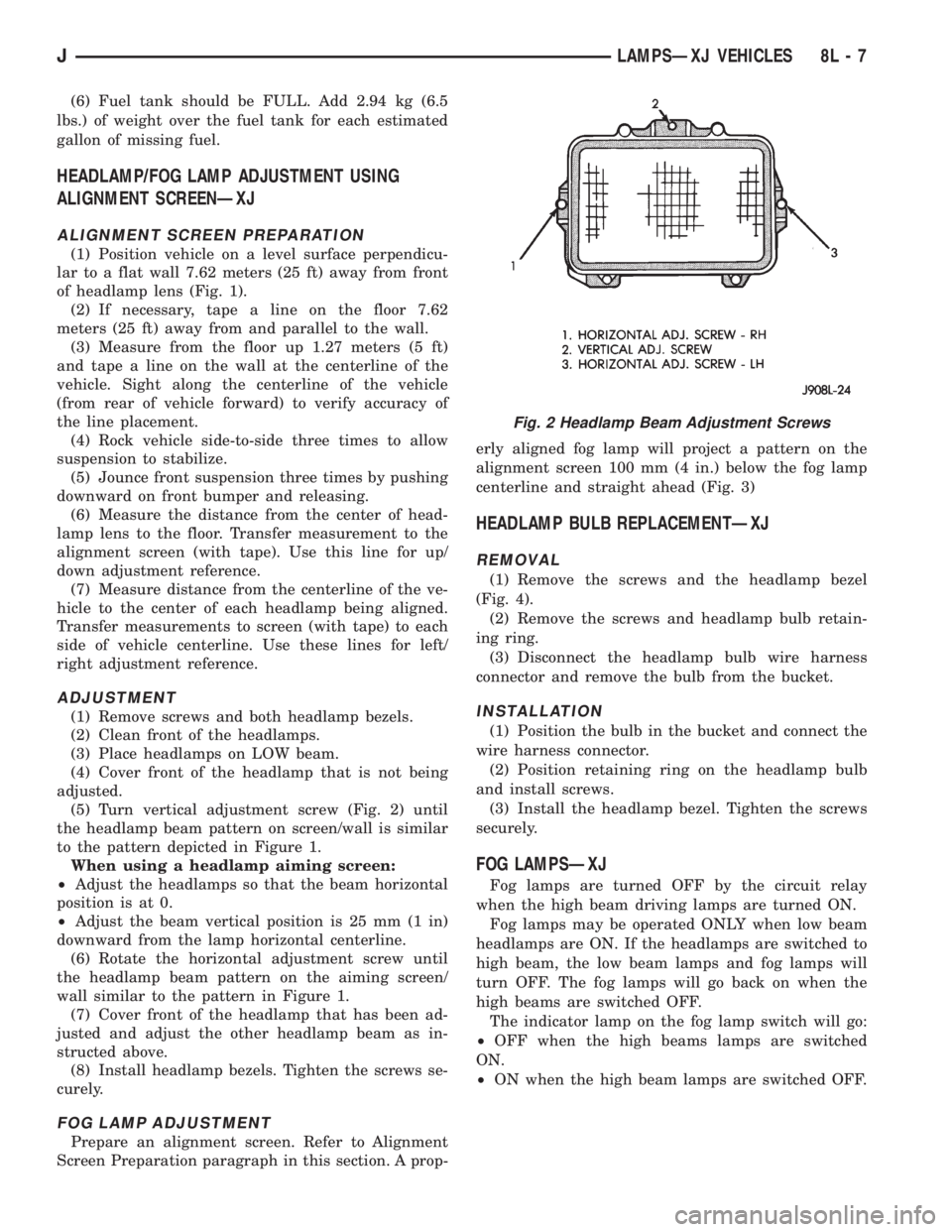

HEADLAMP ALIGNMENTÐXJ

Headlamps can be aligned using the screen method

provided in this section. Alignment Tool C4466-A or

equivalent can also be used. Refer to instructions

provided with the tool for proper procedures.The

preferred headlamp alignment setting is 0 for

the left/right adjustment and 1(down for the

up/down adjustment.

HEADLAMP ALIGNMENT PREPARATIONÐXJ

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Correct defective components that could hinder

proper headlamp alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

Fig. 1 Headlamp Alignment ScreenÐTypical

8L - 6 LAMPSÐXJ VEHICLESJ

Page 467 of 2158

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREENÐXJ

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft) away from front

of headlamp lens (Fig. 1).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft) away from and parallel to the wall.

(3) Measure from the floor up 1.27 meters (5 ft)

and tape a line on the wall at the centerline of the

vehicle. Sight along the centerline of the vehicle

(from rear of vehicle forward) to verify accuracy of

the line placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for up/

down adjustment reference.

(7) Measure distance from the centerline of the ve-

hicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle centerline. Use these lines for left/

right adjustment reference.

ADJUSTMENT

(1) Remove screws and both headlamp bezels.

(2) Clean front of the headlamps.

(3) Place headlamps on LOW beam.

(4) Cover front of the headlamp that is not being

adjusted.

(5) Turn vertical adjustment screw (Fig. 2) until

the headlamp beam pattern on screen/wall is similar

to the pattern depicted in Figure 1.

When using a headlamp aiming screen:

²Adjust the headlamps so that the beam horizontal

position is at 0.

²Adjust the beam vertical position is 25 mm (1 in)

downward from the lamp horizontal centerline.

(6) Rotate the horizontal adjustment screw until

the headlamp beam pattern on the aiming screen/

wall similar to the pattern in Figure 1.

(7) Cover front of the headlamp that has been ad-

justed and adjust the other headlamp beam as in-

structed above.

(8) Install headlamp bezels. Tighten the screws se-

curely.

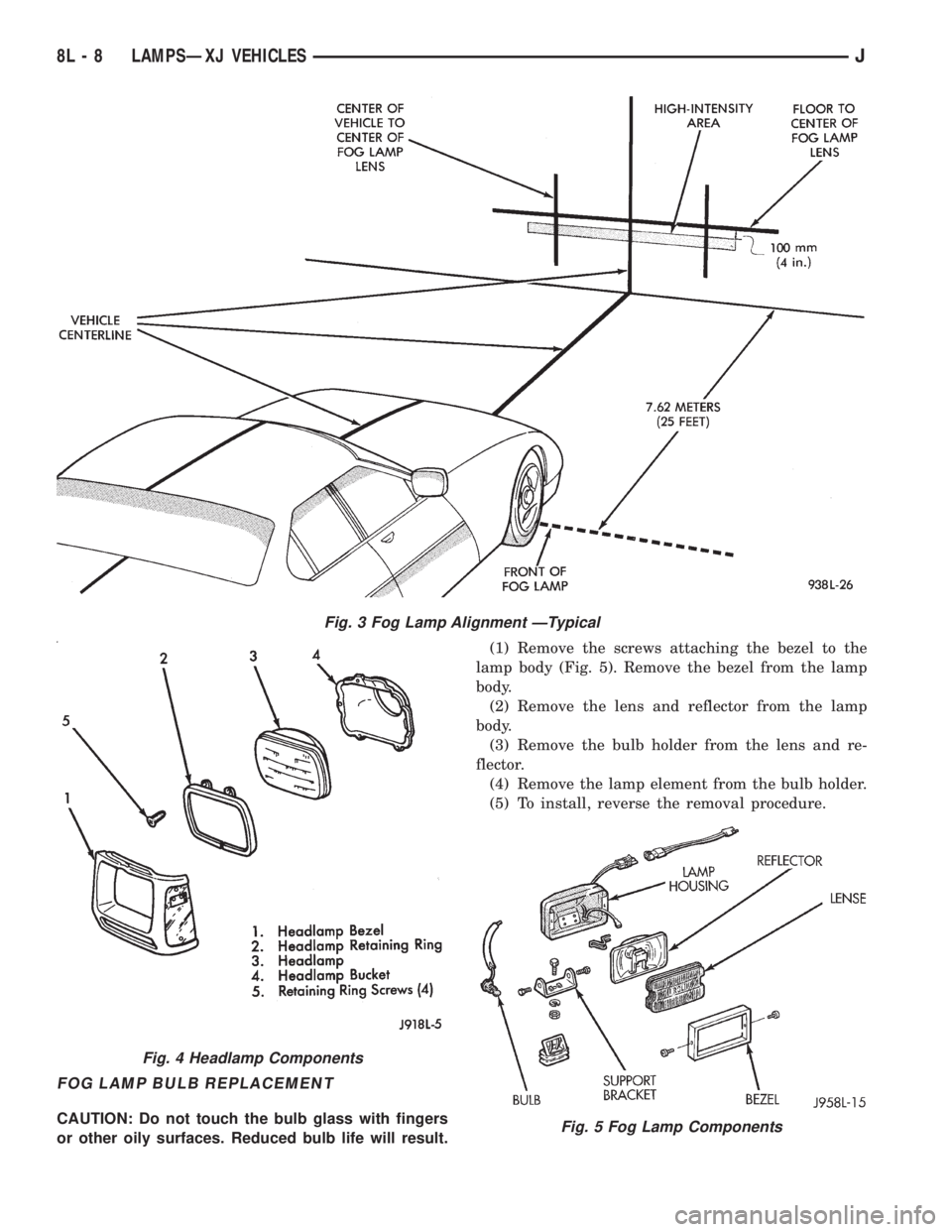

FOG LAMP ADJUSTMENT

Prepare an alignment screen. Refer to Alignment

Screen Preparation paragraph in this section. A prop-erly aligned fog lamp will project a pattern on the

alignment screen 100 mm (4 in.) below the fog lamp

centerline and straight ahead (Fig. 3)

HEADLAMP BULB REPLACEMENTÐXJ

REMOVAL

(1) Remove the screws and the headlamp bezel

(Fig. 4).

(2) Remove the screws and headlamp bulb retain-

ing ring.

(3) Disconnect the headlamp bulb wire harness

connector and remove the bulb from the bucket.

INSTALLATION

(1) Position the bulb in the bucket and connect the

wire harness connector.

(2) Position retaining ring on the headlamp bulb

and install screws.

(3) Install the headlamp bezel. Tighten the screws

securely.

FOG LAMPSÐXJ

Fog lamps are turned OFF by the circuit relay

when the high beam driving lamps are turned ON.

Fog lamps may be operated ONLY when low beam

headlamps are ON. If the headlamps are switched to

high beam, the low beam lamps and fog lamps will

turn OFF. The fog lamps will go back on when the

high beams are switched OFF.

The indicator lamp on the fog lamp switch will go:

²OFF when the high beams lamps are switched

ON.

²ON when the high beam lamps are switched OFF.

Fig. 2 Headlamp Beam Adjustment Screws

JLAMPSÐXJ VEHICLES 8L - 7

Page 468 of 2158

FOG LAMP BULB REPLACEMENT

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.(1) Remove the screws attaching the bezel to the

lamp body (Fig. 5). Remove the bezel from the lamp

body.

(2) Remove the lens and reflector from the lamp

body.

(3) Remove the bulb holder from the lens and re-

flector.

(4) Remove the lamp element from the bulb holder.

(5) To install, reverse the removal procedure.

Fig. 3 Fog Lamp Alignment ÐTypical

Fig. 4 Headlamp Components

Fig. 5 Fog Lamp Components

8L - 8 LAMPSÐXJ VEHICLESJ

Page 469 of 2158

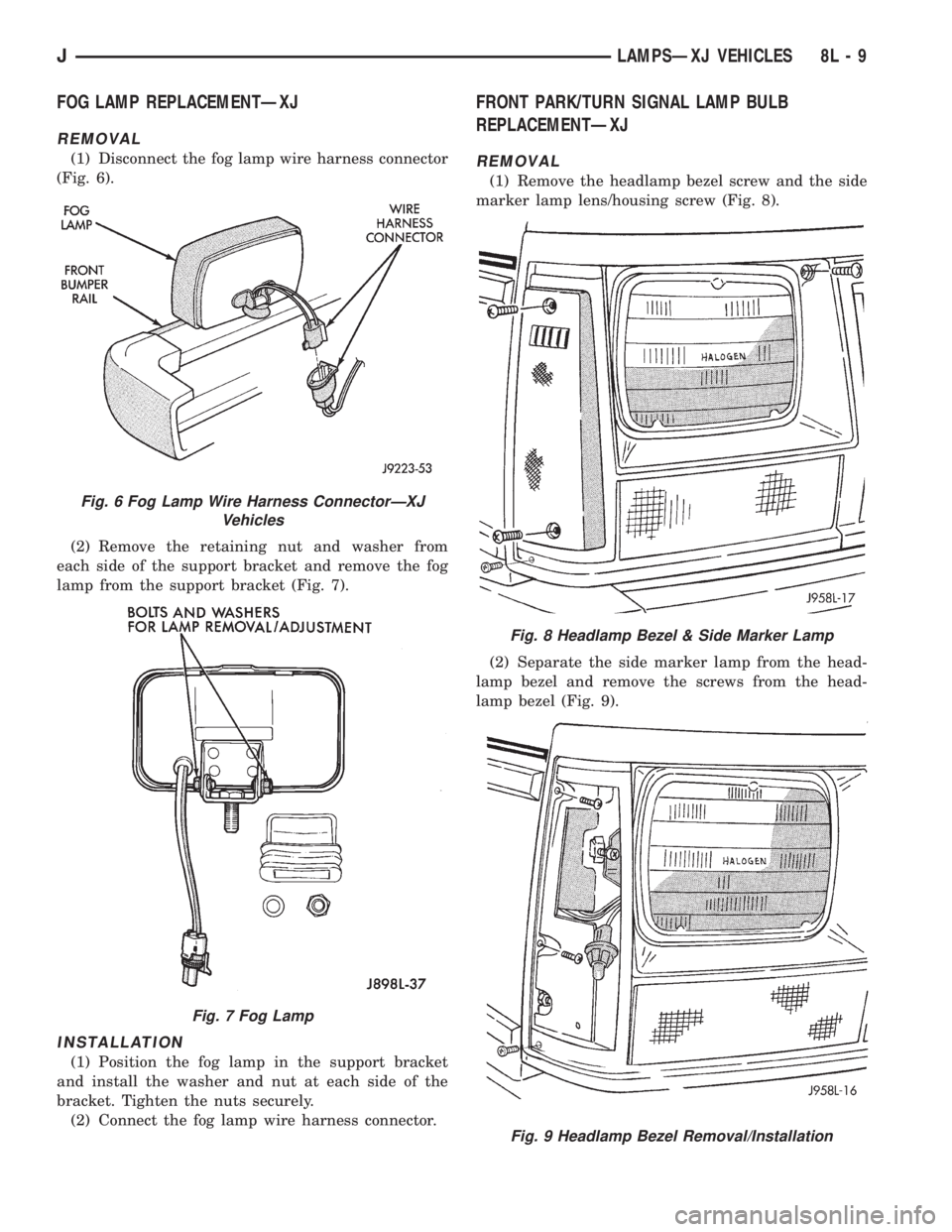

FOG LAMP REPLACEMENTÐXJ

REMOVAL

(1) Disconnect the fog lamp wire harness connector

(Fig. 6).

(2) Remove the retaining nut and washer from

each side of the support bracket and remove the fog

lamp from the support bracket (Fig. 7).

INSTALLATION

(1) Position the fog lamp in the support bracket

and install the washer and nut at each side of the

bracket. Tighten the nuts securely.

(2) Connect the fog lamp wire harness connector.

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ

REMOVAL

(1) Remove the headlamp bezel screw and the side

marker lamp lens/housing screw (Fig. 8).

(2) Separate the side marker lamp from the head-

lamp bezel and remove the screws from the head-

lamp bezel (Fig. 9).

Fig. 6 Fog Lamp Wire Harness ConnectorÐXJ

Vehicles

Fig. 7 Fog Lamp

Fig. 8 Headlamp Bezel & Side Marker Lamp

Fig. 9 Headlamp Bezel Removal/Installation

JLAMPSÐXJ VEHICLES 8L - 9

Page 470 of 2158

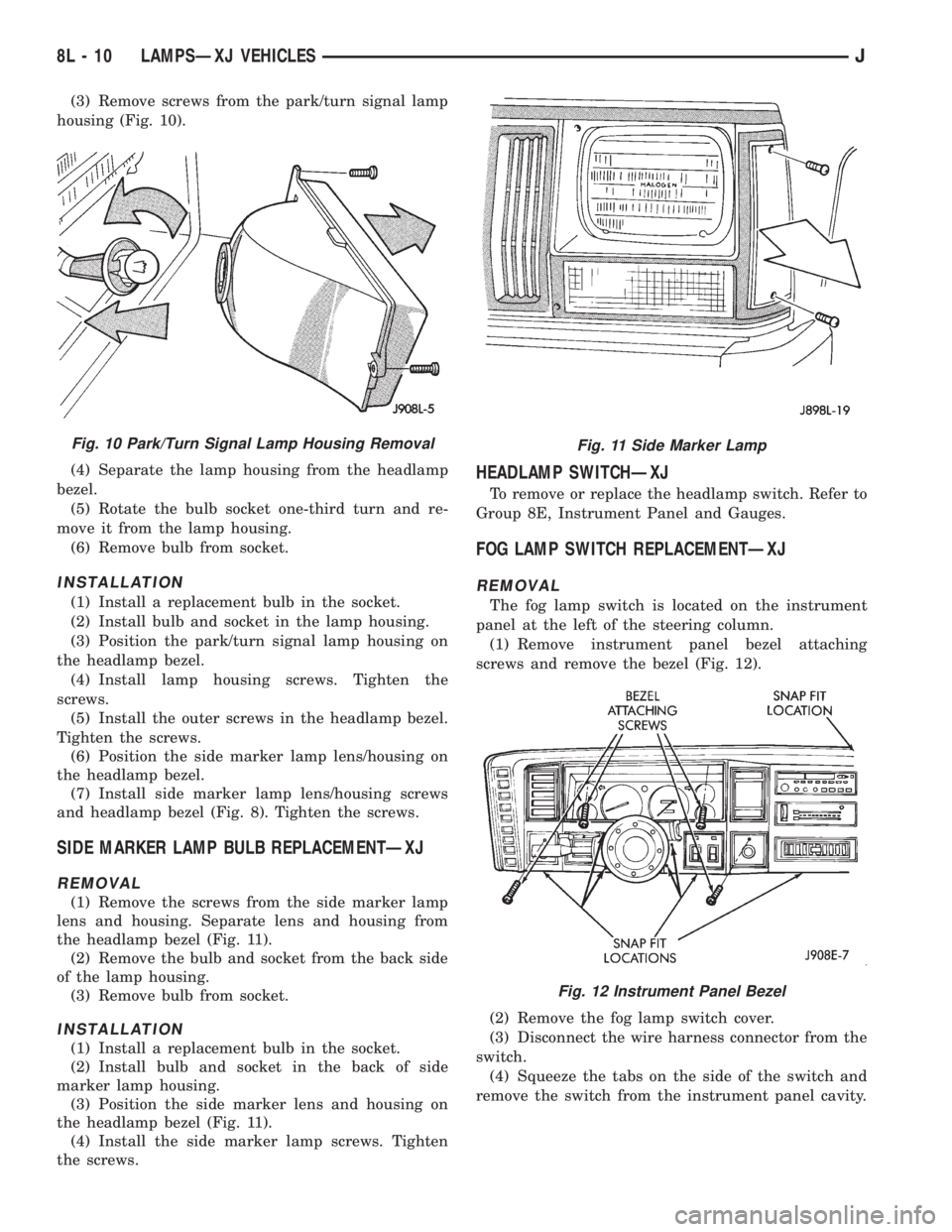

(3) Remove screws from the park/turn signal lamp

housing (Fig. 10).

(4) Separate the lamp housing from the headlamp

bezel.

(5) Rotate the bulb socket one-third turn and re-

move it from the lamp housing.

(6) Remove bulb from socket.

INSTALLATION

(1) Install a replacement bulb in the socket.

(2) Install bulb and socket in the lamp housing.

(3) Position the park/turn signal lamp housing on

the headlamp bezel.

(4) Install lamp housing screws. Tighten the

screws.

(5) Install the outer screws in the headlamp bezel.

Tighten the screws.

(6) Position the side marker lamp lens/housing on

the headlamp bezel.

(7) Install side marker lamp lens/housing screws

and headlamp bezel (Fig. 8). Tighten the screws.

SIDE MARKER LAMP BULB REPLACEMENTÐXJ

REMOVAL

(1) Remove the screws from the side marker lamp

lens and housing. Separate lens and housing from

the headlamp bezel (Fig. 11).

(2) Remove the bulb and socket from the back side

of the lamp housing.

(3) Remove bulb from socket.

INSTALLATION

(1) Install a replacement bulb in the socket.

(2) Install bulb and socket in the back of side

marker lamp housing.

(3) Position the side marker lens and housing on

the headlamp bezel (Fig. 11).

(4) Install the side marker lamp screws. Tighten

the screws.

HEADLAMP SWITCHÐXJ

To remove or replace the headlamp switch. Refer to

Group 8E, Instrument Panel and Gauges.

FOG LAMP SWITCH REPLACEMENTÐXJ

REMOVAL

The fog lamp switch is located on the instrument

panel at the left of the steering column.

(1) Remove instrument panel bezel attaching

screws and remove the bezel (Fig. 12).

(2) Remove the fog lamp switch cover.

(3) Disconnect the wire harness connector from the

switch.

(4) Squeeze the tabs on the side of the switch and

remove the switch from the instrument panel cavity.

Fig. 10 Park/Turn Signal Lamp Housing RemovalFig. 11 Side Marker Lamp

Fig. 12 Instrument Panel Bezel

8L - 10 LAMPSÐXJ VEHICLESJ