frame JEEP YJ 1995 Service And Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1386 of 2158

FRAME AND BUMPERS

CONTENTS

page page

BUMPERS.............................. 5

BUMPERS............................. 16FRAME................................. 1

FRAME................................ 10

FRAME

INDEX

page page

Frame Dimensions......................... 1

Front Skid Plate........................... 1

Fuel Filler Hose Splash ShieldÐXJ Vehicles...... 4

Fuel Tank Skid Plate........................ 3Fuel Tank Support Strap..................... 4

General Information........................ 1

Transfer Case Skid Plate.................... 3

GENERAL INFORMATION

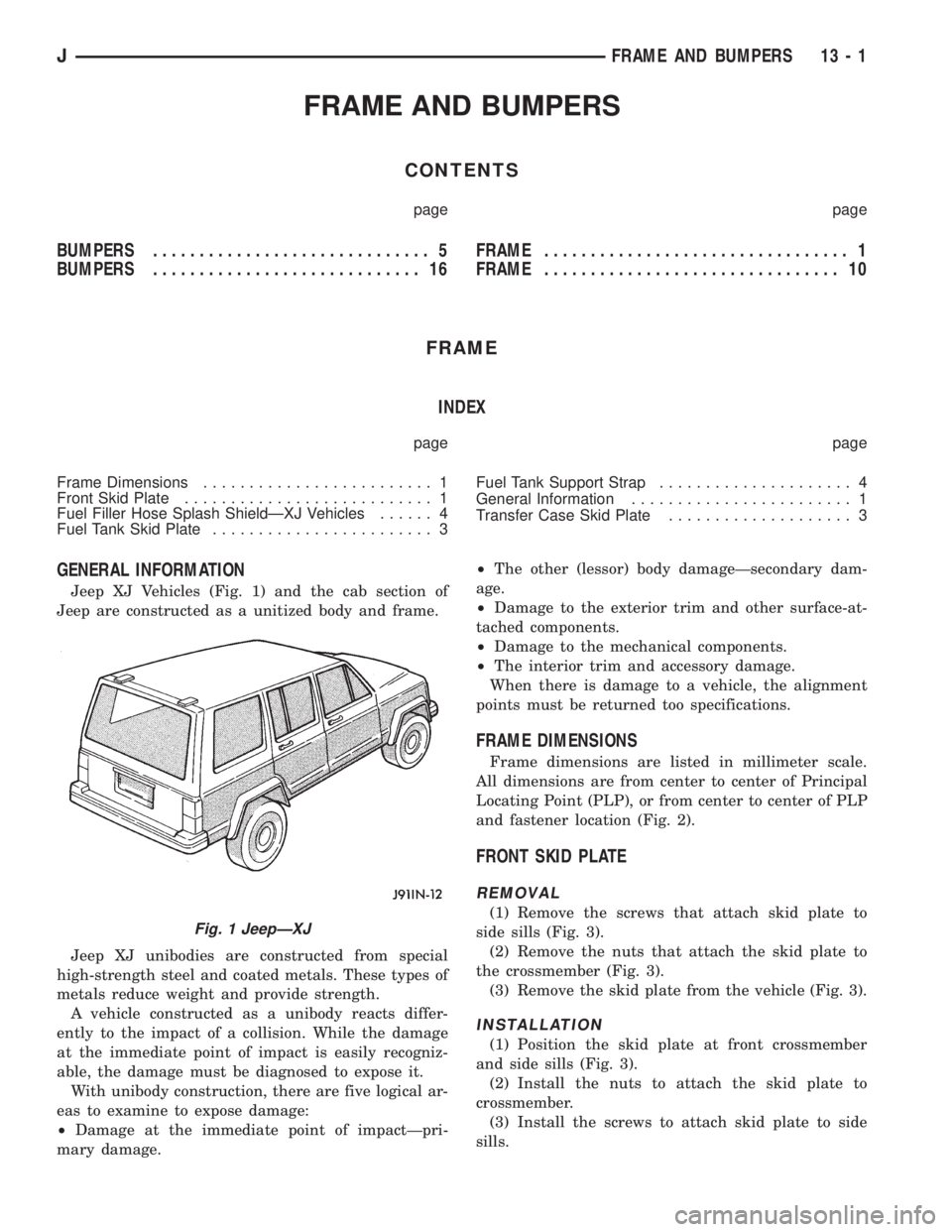

Jeep XJ Vehicles (Fig. 1) and the cab section of

Jeep are constructed as a unitized body and frame.

Jeep XJ unibodies are constructed from special

high-strength steel and coated metals. These types of

metals reduce weight and provide strength.

A vehicle constructed as a unibody reacts differ-

ently to the impact of a collision. While the damage

at the immediate point of impact is easily recogniz-

able, the damage must be diagnosed to expose it.

With unibody construction, there are five logical ar-

eas to examine to expose damage:

²Damage at the immediate point of impactÐpri-

mary damage.²The other (lessor) body damageÐsecondary dam-

age.

²Damage to the exterior trim and other surface-at-

tached components.

²Damage to the mechanical components.

²The interior trim and accessory damage.

When there is damage to a vehicle, the alignment

points must be returned too specifications.

FRAME DIMENSIONS

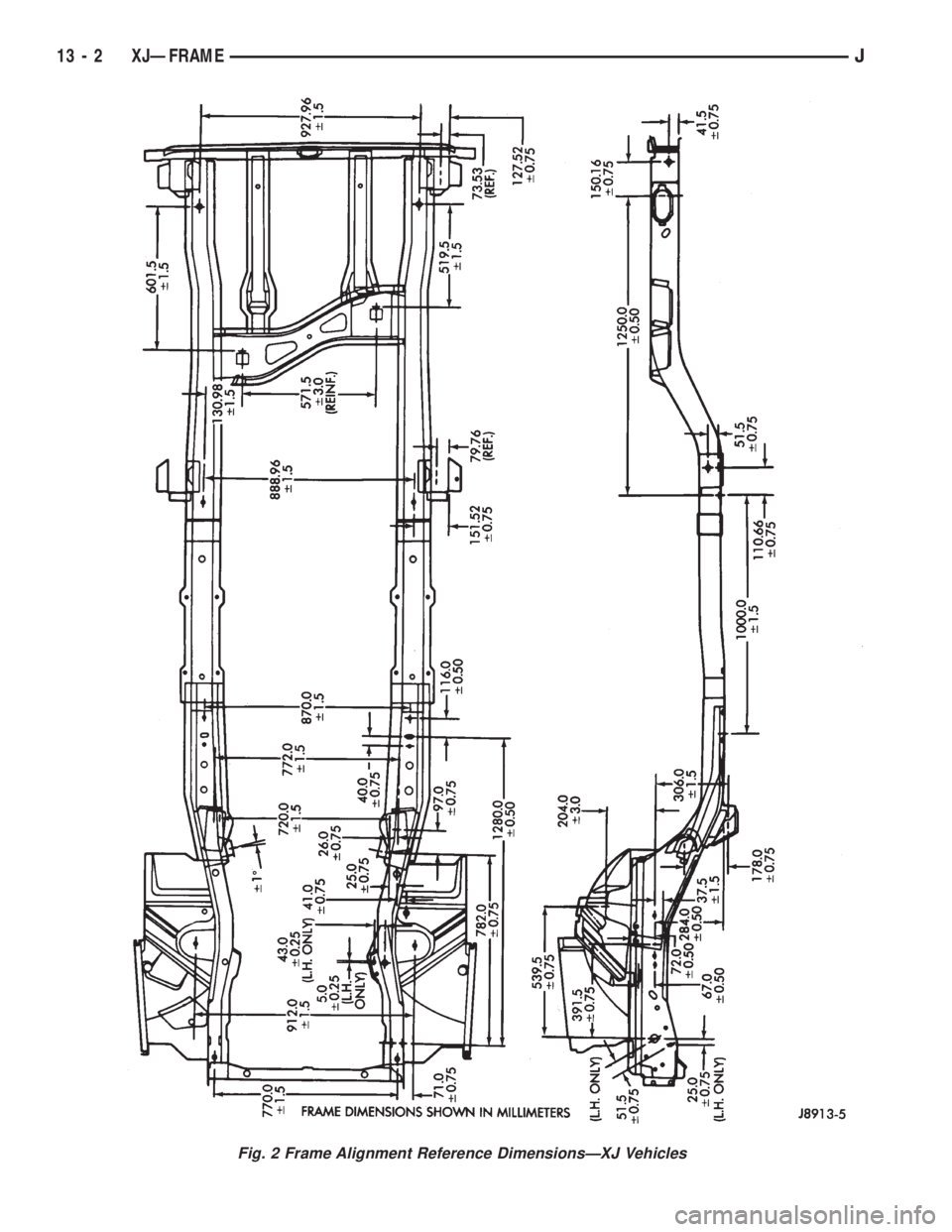

Frame dimensions are listed in millimeter scale.

All dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location (Fig. 2).

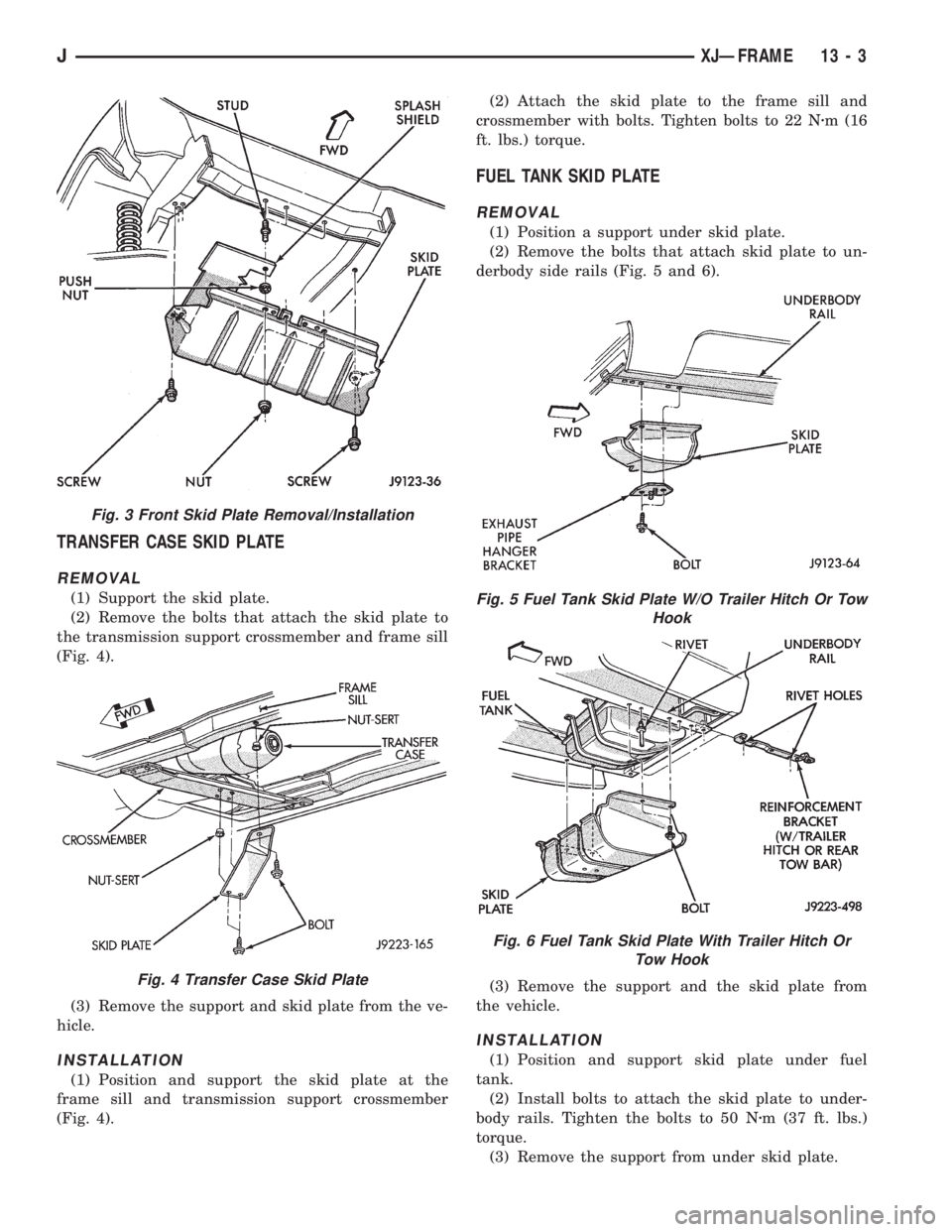

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 3).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 3).

(3) Remove the skid plate from the vehicle (Fig. 3).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 3).

(2) Install the nuts to attach the skid plate to

crossmember.

(3) Install the screws to attach skid plate to side

sills.

Fig. 1 JeepÐXJ

JFRAME AND BUMPERS 13 - 1

Page 1387 of 2158

Fig. 2 Frame Alignment Reference DimensionsÐXJ Vehicles

13 - 2 XJÐFRAMEJ

Page 1388 of 2158

TRANSFER CASE SKID PLATE

REMOVAL

(1) Support the skid plate.

(2) Remove the bolts that attach the skid plate to

the transmission support crossmember and frame sill

(Fig. 4).

(3) Remove the support and skid plate from the ve-

hicle.

INSTALLATION

(1) Position and support the skid plate at the

frame sill and transmission support crossmember

(Fig. 4).(2) Attach the skid plate to the frame sill and

crossmember with bolts. Tighten bolts to 22 Nzm (16

ft. lbs.) torque.

FUEL TANK SKID PLATE

REMOVAL

(1) Position a support under skid plate.

(2) Remove the bolts that attach skid plate to un-

derbody side rails (Fig. 5 and 6).

(3) Remove the support and the skid plate from

the vehicle.

INSTALLATION

(1) Position and support skid plate under fuel

tank.

(2) Install bolts to attach the skid plate to under-

body rails. Tighten the bolts to 50 Nzm (37 ft. lbs.)

torque.

(3) Remove the support from under skid plate.

Fig. 3 Front Skid Plate Removal/Installation

Fig. 4 Transfer Case Skid Plate

Fig. 5 Fuel Tank Skid Plate W/O Trailer Hitch Or Tow

Hook

Fig. 6 Fuel Tank Skid Plate With Trailer Hitch Or

Tow Hook

JXJÐFRAME 13 - 3

Page 1389 of 2158

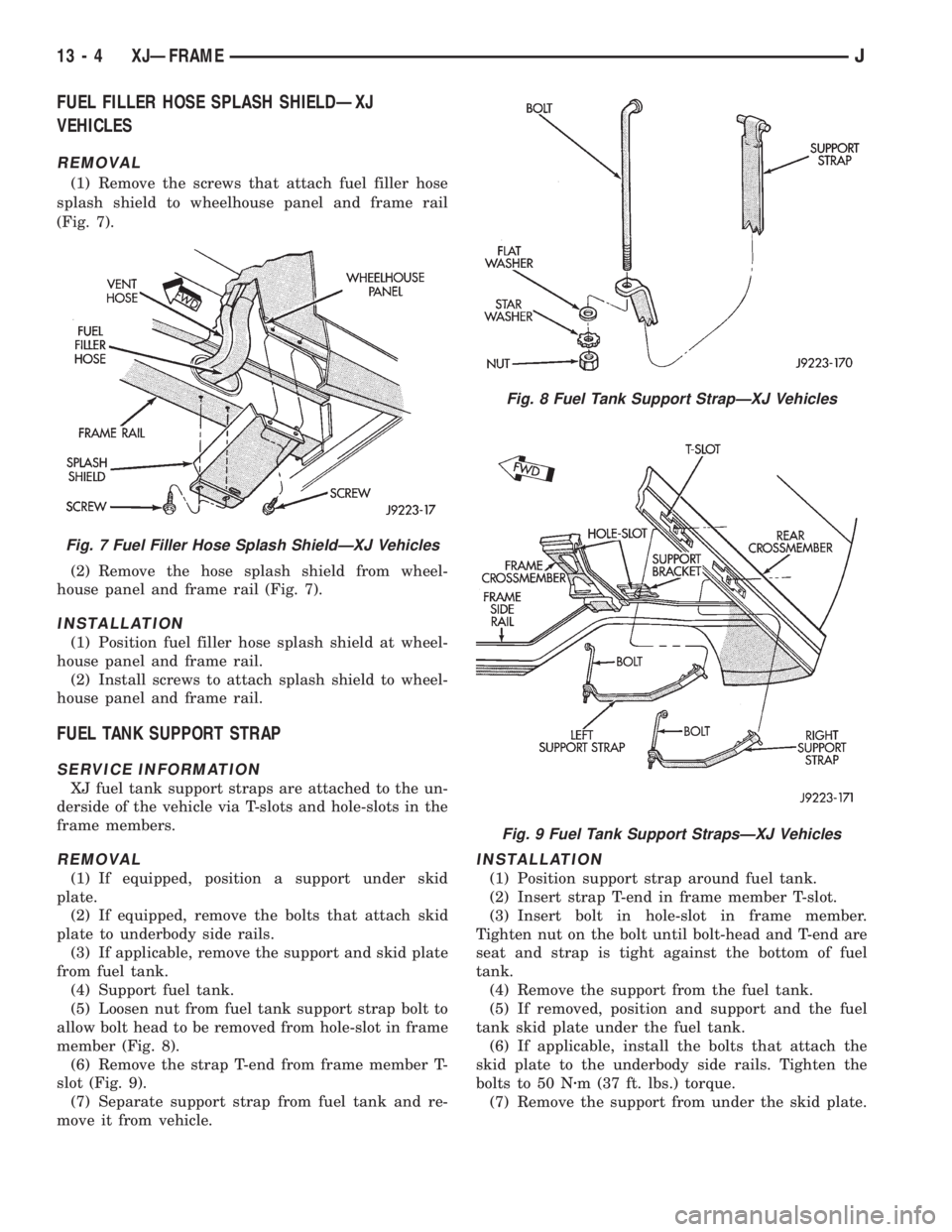

FUEL FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES

REMOVAL

(1) Remove the screws that attach fuel filler hose

splash shield to wheelhouse panel and frame rail

(Fig. 7).

(2) Remove the hose splash shield from wheel-

house panel and frame rail (Fig. 7).

INSTALLATION

(1) Position fuel filler hose splash shield at wheel-

house panel and frame rail.

(2) Install screws to attach splash shield to wheel-

house panel and frame rail.

FUEL TANK SUPPORT STRAP

SERVICE INFORMATION

XJ fuel tank support straps are attached to the un-

derside of the vehicle via T-slots and hole-slots in the

frame members.

REMOVAL

(1) If equipped, position a support under skid

plate.

(2) If equipped, remove the bolts that attach skid

plate to underbody side rails.

(3) If applicable, remove the support and skid plate

from fuel tank.

(4) Support fuel tank.

(5) Loosen nut from fuel tank support strap bolt to

allow bolt head to be removed from hole-slot in frame

member (Fig. 8).

(6) Remove the strap T-end from frame member T-

slot (Fig. 9).

(7) Separate support strap from fuel tank and re-

move it from vehicle.

INSTALLATION

(1) Position support strap around fuel tank.

(2) Insert strap T-end in frame member T-slot.

(3) Insert bolt in hole-slot in frame member.

Tighten nut on the bolt until bolt-head and T-end are

seat and strap is tight against the bottom of fuel

tank.

(4) Remove the support from the fuel tank.

(5) If removed, position and support and the fuel

tank skid plate under the fuel tank.

(6) If applicable, install the bolts that attach the

skid plate to the underbody side rails. Tighten the

bolts to 50 Nzm (37 ft. lbs.) torque.

(7) Remove the support from under the skid plate.

Fig. 7 Fuel Filler Hose Splash ShieldÐXJ Vehicles

Fig. 8 Fuel Tank Support StrapÐXJ Vehicles

Fig. 9 Fuel Tank Support StrapsÐXJ Vehicles

13 - 4 XJÐFRAMEJ

Page 1394 of 2158

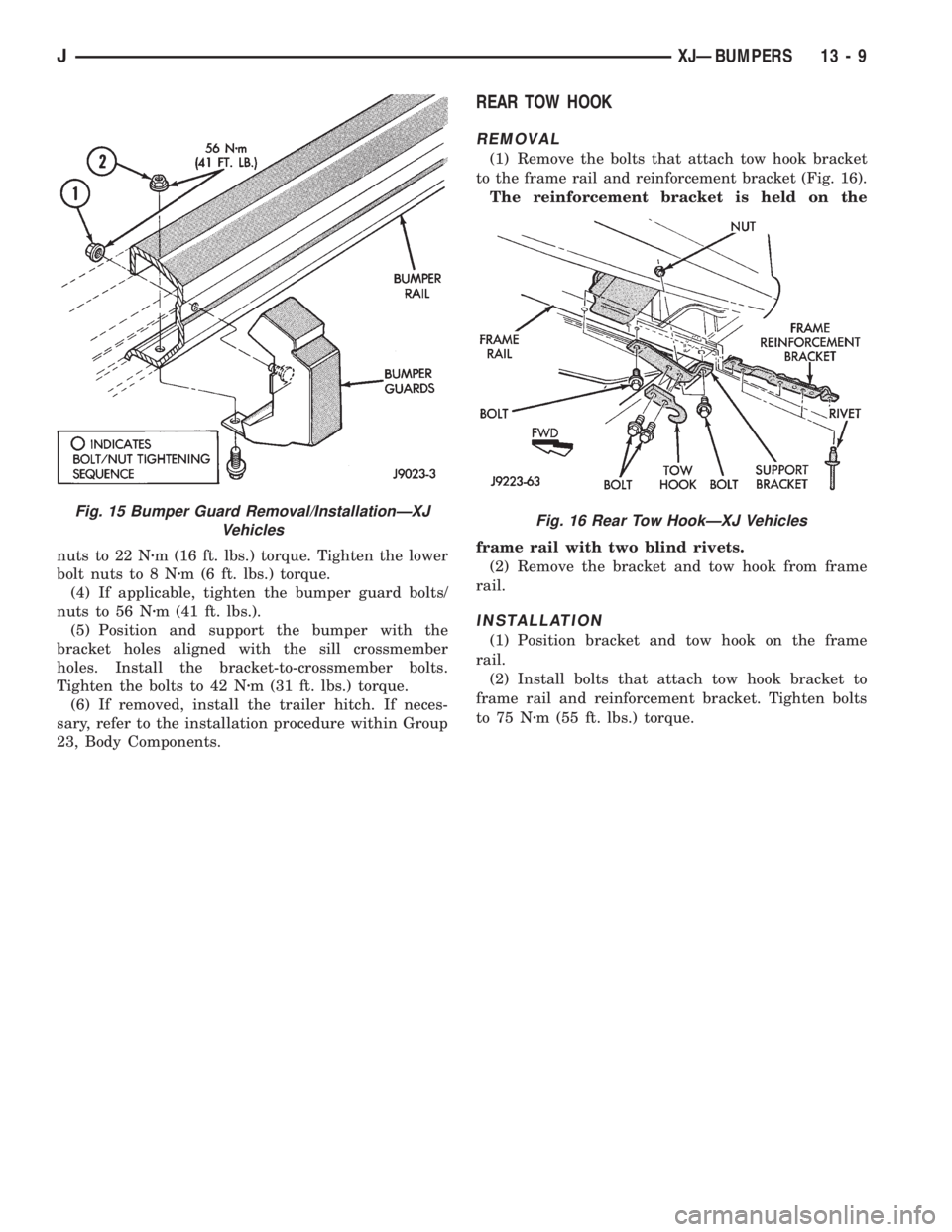

nuts to 22 Nzm (16 ft. lbs.) torque. Tighten the lower

bolt nuts to 8 Nzm (6 ft. lbs.) torque.

(4) If applicable, tighten the bumper guard bolts/

nuts to 56 Nzm (41 ft. lbs.).

(5) Position and support the bumper with the

bracket holes aligned with the sill crossmember

holes. Install the bracket-to-crossmember bolts.

Tighten the bolts to 42 Nzm (31 ft. lbs.) torque.

(6) If removed, install the trailer hitch. If neces-

sary, refer to the installation procedure within Group

23, Body Components.

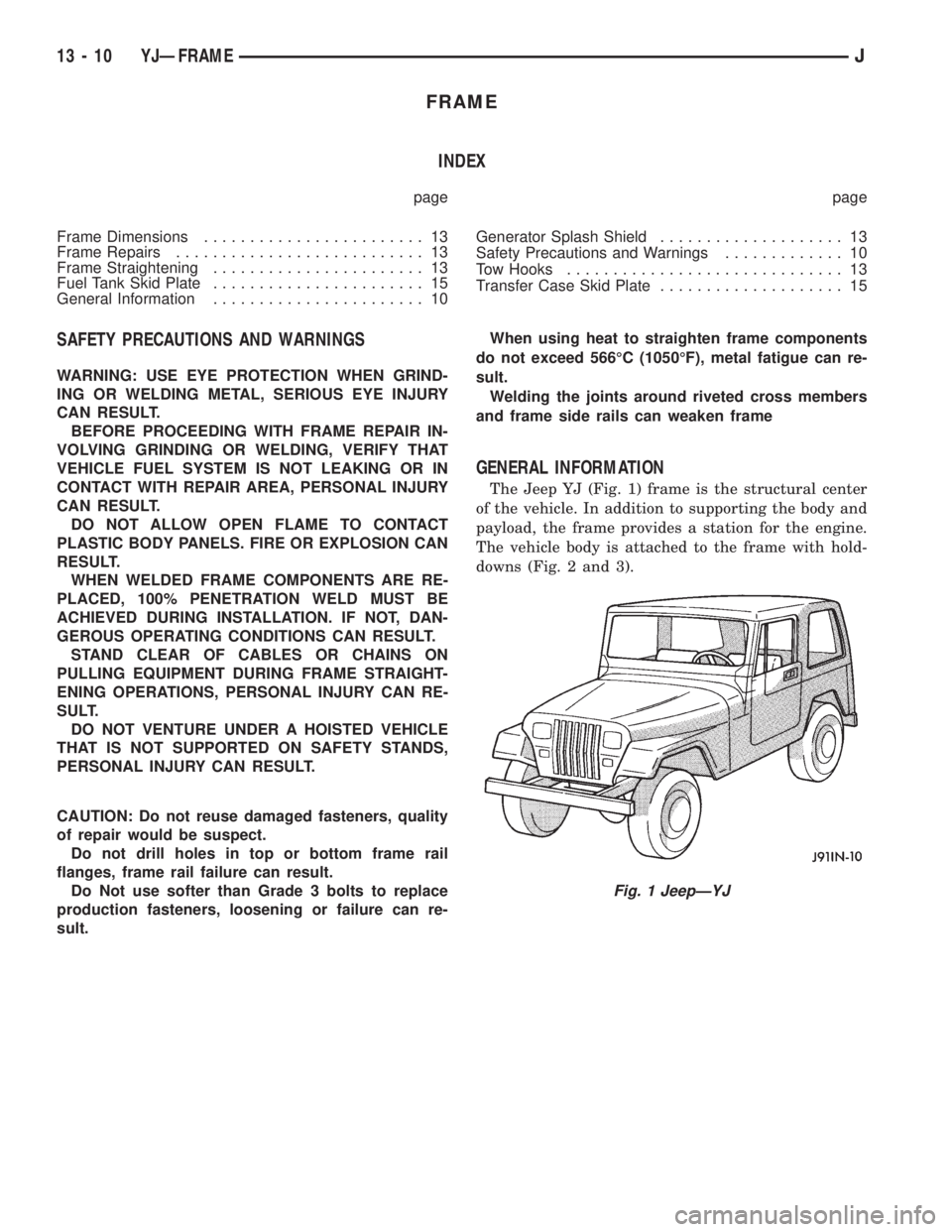

REAR TOW HOOK

REMOVAL

(1) Remove the bolts that attach tow hook bracket

to the frame rail and reinforcement bracket (Fig. 16).

The reinforcement bracket is held on the

frame rail with two blind rivets.

(2) Remove the bracket and tow hook from frame

rail.

INSTALLATION

(1) Position bracket and tow hook on the frame

rail.

(2) Install bolts that attach tow hook bracket to

frame rail and reinforcement bracket. Tighten bolts

to 75 Nzm (55 ft. lbs.) torque.

Fig. 15 Bumper Guard Removal/InstallationÐXJ

VehiclesFig. 16 Rear Tow HookÐXJ Vehicles

JXJÐBUMPERS 13 - 9

Page 1395 of 2158

FRAME

INDEX

page page

Frame Dimensions........................ 13

Frame Repairs........................... 13

Frame Straightening....................... 13

Fuel Tank Skid Plate....................... 15

General Information....................... 10Generator Splash Shield.................... 13

Safety Precautions and Warnings............. 10

Tow Hooks.............................. 13

Transfer Case Skid Plate.................... 15

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

BEFORE PROCEEDING WITH FRAME REPAIR IN-

VOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

DO NOT ALLOW OPEN FLAME TO CONTACT

PLASTIC BODY PANELS. FIRE OR EXPLOSION CAN

RESULT.

WHEN WELDED FRAME COMPONENTS ARE RE-

PLACED, 100% PENETRATION WELD MUST BE

ACHIEVED DURING INSTALLATION. IF NOT, DAN-

GEROUS OPERATING CONDITIONS CAN RESULT.

STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN RE-

SULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT SUPPORTED ON SAFETY STANDS,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect.

Do not drill holes in top or bottom frame rail

flanges, frame rail failure can result.

Do Not use softer than Grade 3 bolts to replace

production fasteners, loosening or failure can re-

sult.When using heat to straighten frame components

do not exceed 566ÉC (1050ÉF), metal fatigue can re-

sult.

Welding the joints around riveted cross members

and frame side rails can weaken frame

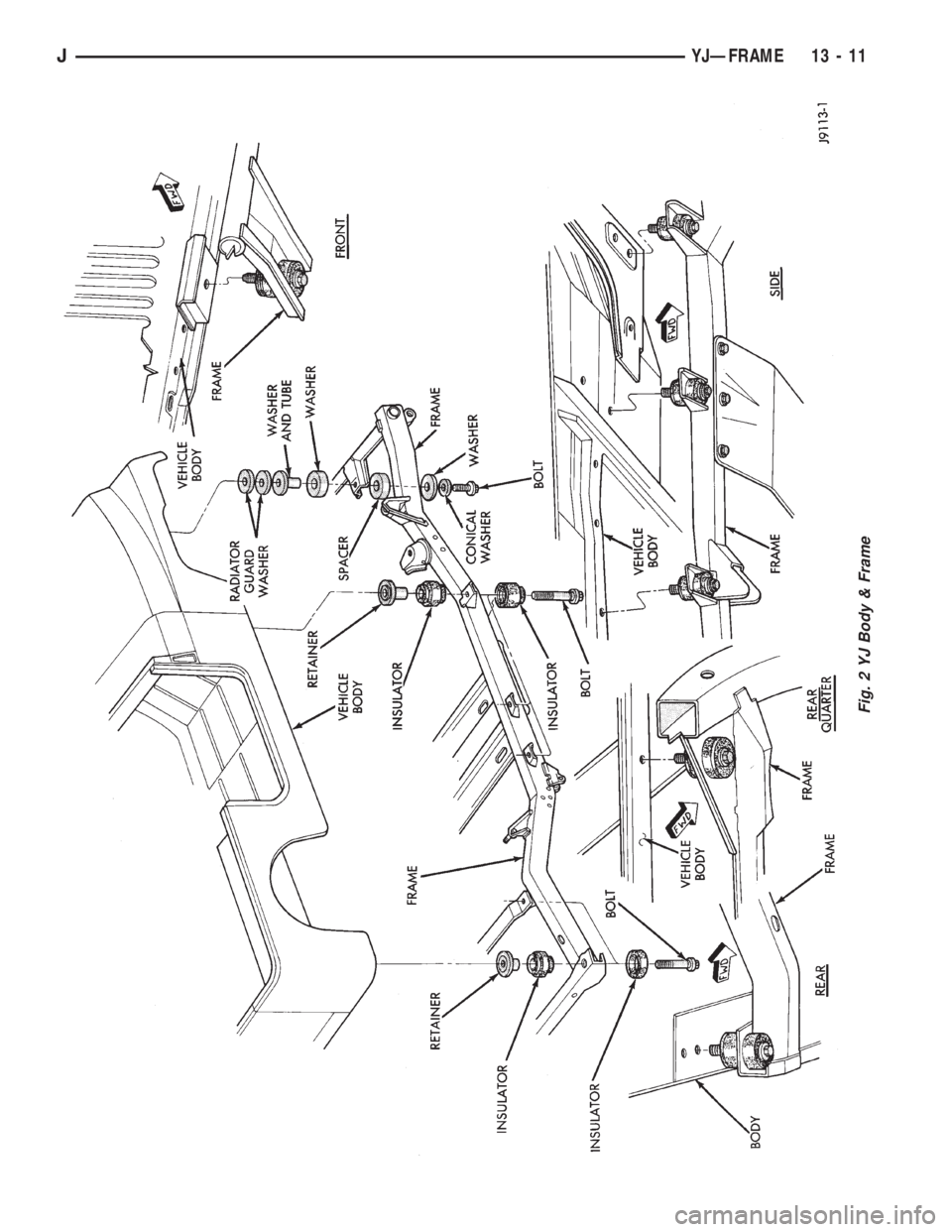

GENERAL INFORMATION

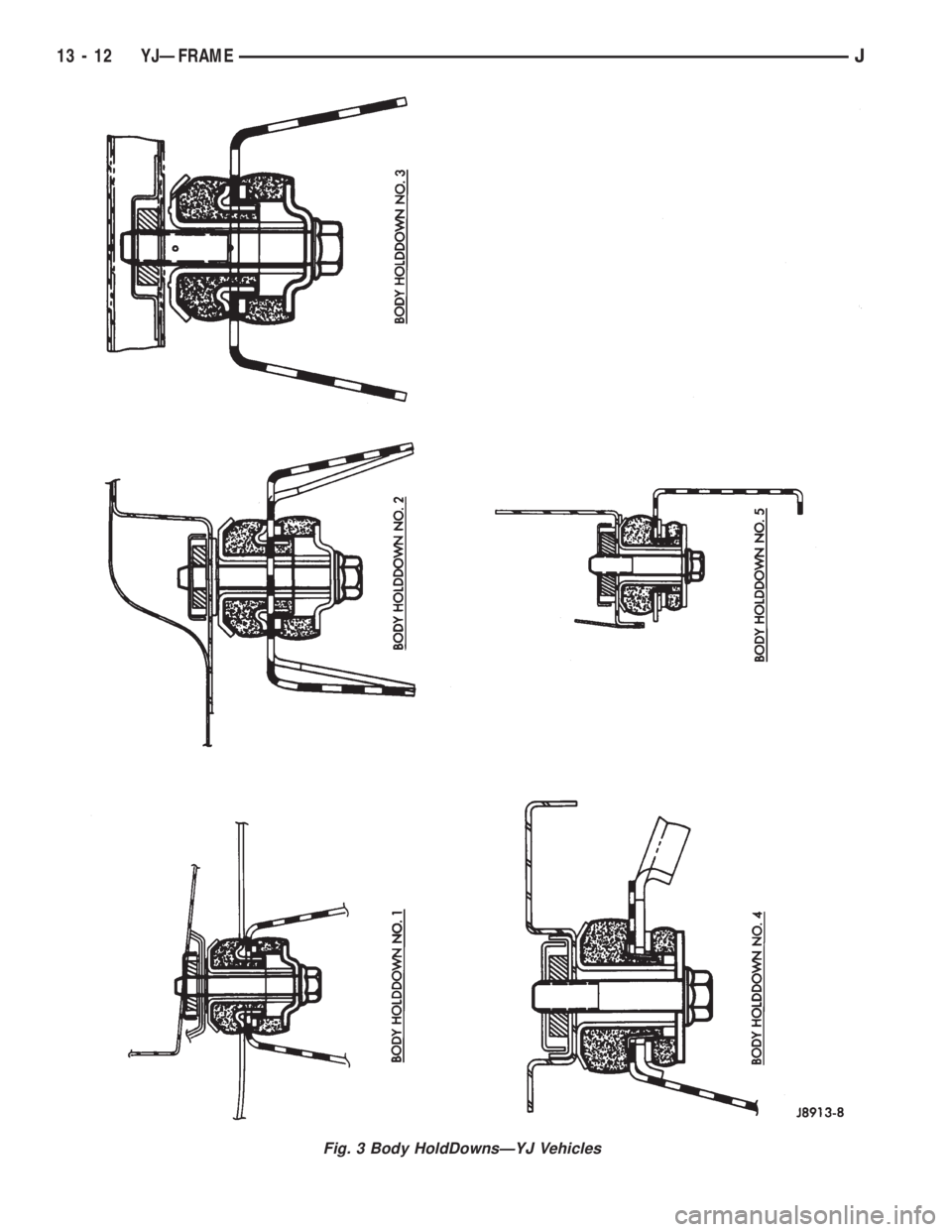

The Jeep YJ (Fig. 1) frame is the structural center

of the vehicle. In addition to supporting the body and

payload, the frame provides a station for the engine.

The vehicle body is attached to the frame with hold-

downs (Fig. 2 and 3).

Fig. 1 JeepÐYJ

13 - 10 YJÐFRAMEJ

Page 1396 of 2158

Fig. 2 YJ Body & Frame

JYJÐFRAME 13 - 11

Page 1397 of 2158

Fig. 3 Body HoldDownsÐYJ Vehicles

13 - 12 YJÐFRAMEJ

Page 1398 of 2158

The frame is constructed of high-strength channel

steel siderails and crossmembers. The crossmembers

join the siderails and retain them in alignment in re-

lation to each other. This provides resistance to

frame twists and strains.

FRAME STRAIGHTENING

When necessary, a conventional frame that is bent

or twisted can be straightened by application of heat.

The temperature must not exceed 566ÉC (1050ÉF).

The use of a specially designed heat crayon can de-

termine the desired temperature. Excessive heat will

decrease the strength of the metal and result in a

weakened frame.

Welding the joints around riveted cross members

and frame side rails is not recommended.

A straightening repair process should be limited to

frame members that are not severely damaged.

FRAME REPAIRS

DRILLING HOLES

Do not drill holes in frame side rail top and bottom

flanges, metal fatigue can result causing frame fail-

ure. Holes drilled in the side of the frame rail must

be at least 38 mm (1.5 in.) from the top and bottom

flanges.

Additional drill holes should be located away from

existing holes.

WELDING

Use MIG, TIG or arc welding equipment to repair

welded frame components.

Frame components that have been damaged should

be inspected for cracks before returning the vehicle

to use. If cracks are found in accessible frame com-

ponents perform the following procedures.

(1) Drill a hole at each end of the crack with a 3

mm (O.125 in.) diameter drill bit.

(2) Using a suitable die grinder with 3 inch cut off

wheel, V-groove the crack to allow 100% weld pene-

tration.

(3) Weld the crack.

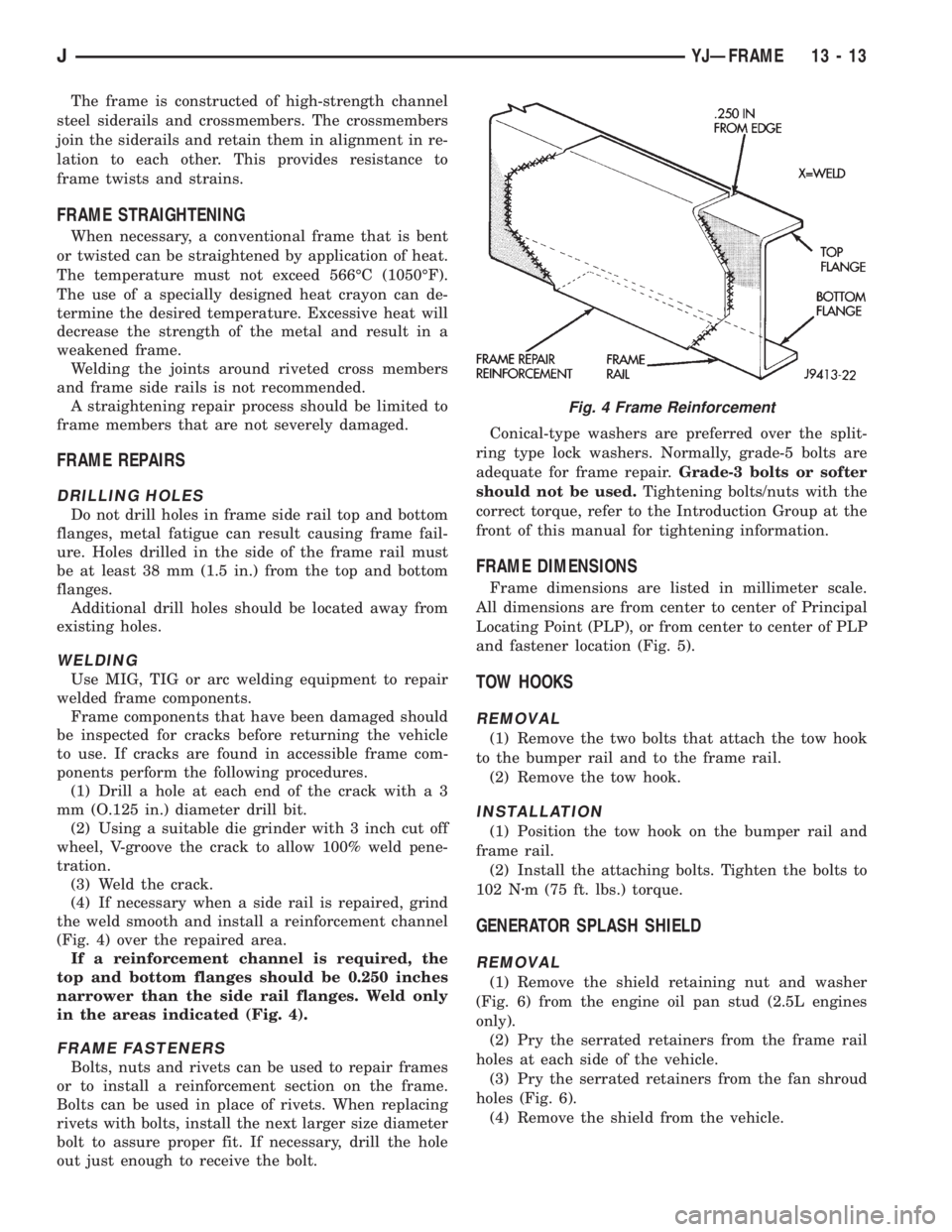

(4) If necessary when a side rail is repaired, grind

the weld smooth and install a reinforcement channel

(Fig. 4) over the repaired area.

If a reinforcement channel is required, the

top and bottom flanges should be 0.250 inches

narrower than the side rail flanges. Weld only

in the areas indicated (Fig. 4).

FRAME FASTENERS

Bolts, nuts and rivets can be used to repair frames

or to install a reinforcement section on the frame.

Bolts can be used in place of rivets. When replacing

rivets with bolts, install the next larger size diameter

bolt to assure proper fit. If necessary, drill the hole

out just enough to receive the bolt.Conical-type washers are preferred over the split-

ring type lock washers. Normally, grade-5 bolts are

adequate for frame repair.Grade-3 bolts or softer

should not be used.Tightening bolts/nuts with the

correct torque, refer to the Introduction Group at the

front of this manual for tightening information.

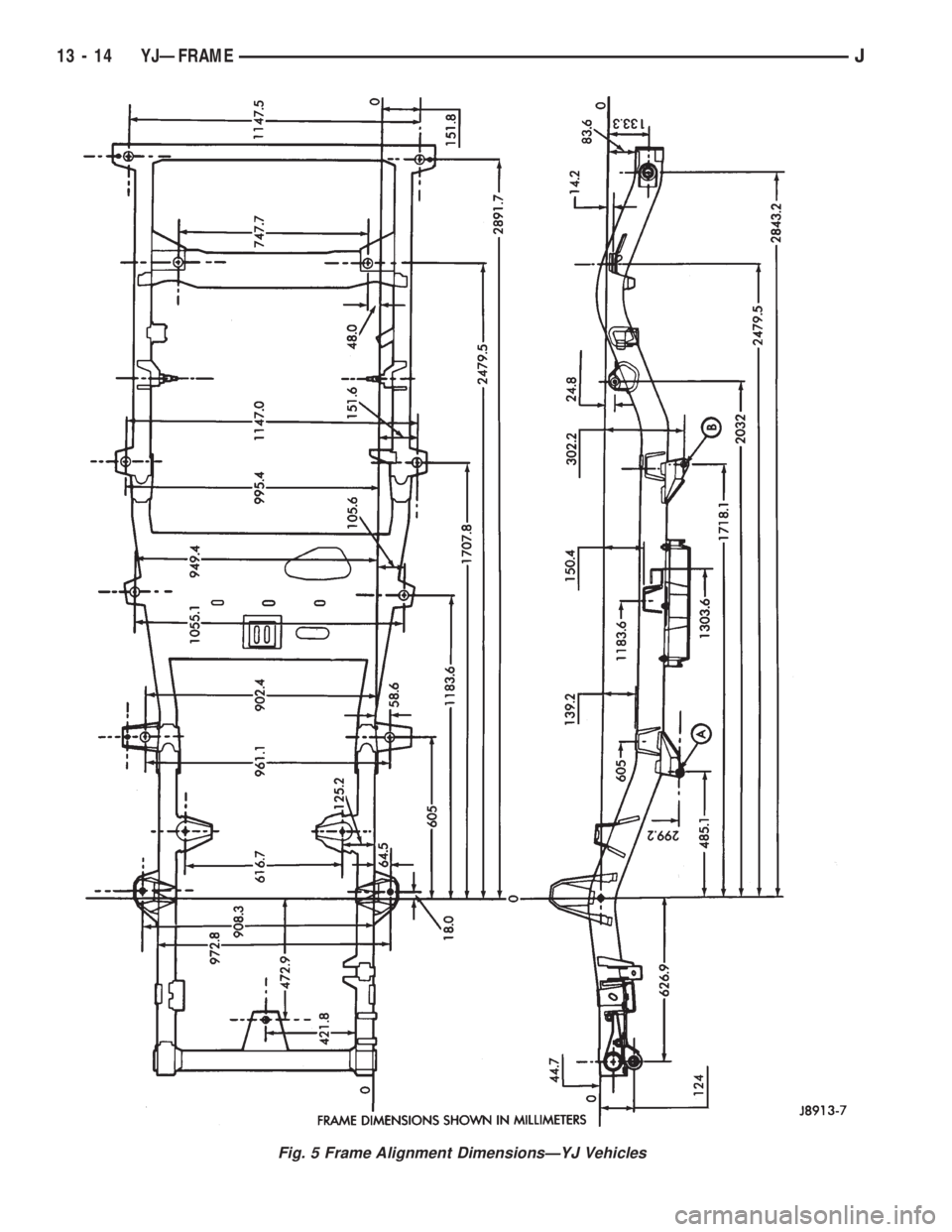

FRAME DIMENSIONS

Frame dimensions are listed in millimeter scale.

All dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location (Fig. 5).

TOW HOOKS

REMOVAL

(1) Remove the two bolts that attach the tow hook

to the bumper rail and to the frame rail.

(2) Remove the tow hook.

INSTALLATION

(1) Position the tow hook on the bumper rail and

frame rail.

(2) Install the attaching bolts. Tighten the bolts to

102 Nzm (75 ft. lbs.) torque.

GENERATOR SPLASH SHIELD

REMOVAL

(1) Remove the shield retaining nut and washer

(Fig. 6) from the engine oil pan stud (2.5L engines

only).

(2) Pry the serrated retainers from the frame rail

holes at each side of the vehicle.

(3) Pry the serrated retainers from the fan shroud

holes (Fig. 6).

(4) Remove the shield from the vehicle.

Fig. 4 Frame Reinforcement

JYJÐFRAME 13 - 13

Page 1399 of 2158

Fig. 5 Frame Alignment DimensionsÐYJ Vehicles

13 - 14 YJÐFRAMEJ