frame JEEP YJ 1995 Service And Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1599 of 2158

(6) Install and tighten clutch housing-to-engine

bolts to 38 Nzm (28 ft. lbs.) torque.Be sure housing

is properly seated on engine before tightening

bolts.

(7) Lower transmission no more than 7.6 cm (3 in.)

for access to the shift tower.

(8) Reach up and around the transmission and in-

sert shift lever in shift tower. Press lever retainer

downward and turn it clockwise to lock it in place.

Then install lever dust boot on shift tower.

(9) Install and connect crankshaft position sensor.

(10) Align and install transfer case on transmis-

sion. Tighten transfer case attaching nuts to 35 Nzm

(26 ft. lbs.) torque.

(11) Connect transfer case vacuum and vent hoses.

(12) Install and connect transfer case shift linkage.

Check and adjust linkage if necessary.

(13) Secure wire harnesses to clips/tie straps on

transmission and transfer case.

(14) Connect backup light switch wires.

(15) Install clutch slave cylinder.

(16) Connect vehicle speed sensor wires.

(17) On XJ, install rear crossmember and attach

cushion and bracket. Tighten crossmember-to-frame

bolts to 41 Nzm (30 ft. lbs.) torque. Tighten transmis-

sion-to-rear cushion and bracket bolts/nuts to 45 Nzm

(33 ft. lbs.) torque.

(18) On YJ, install rear cushion and bracket and

skid plate. Tighten attaching bolts/nuts to indicated

torque (Fig. 1).

(19) Align and install front/rear propeller shafts.

Tighten shaft U-joint clamp bolts to 19 Nzm (170 in.

lbs.) torque.

(20) On XJ, install skid plate if removed. Tighten

bolts to 42 Nzm (31 ft. lbs.) torque. Tighten stud nuts

to 17 Nzm (150 in. lbs.) torque.

(21) Top off transmission and transfer lubricant

levels.

(22) Remove supports and lower vehicle.

TRANSMISSION DISASSEMBLY AND OVERHAUL

ADAPTER HOUSING REMOVAL

(1) Remove release bearing, release lever and re-

lease fork from clutch housing. Then remove clutch

housing from transmission.

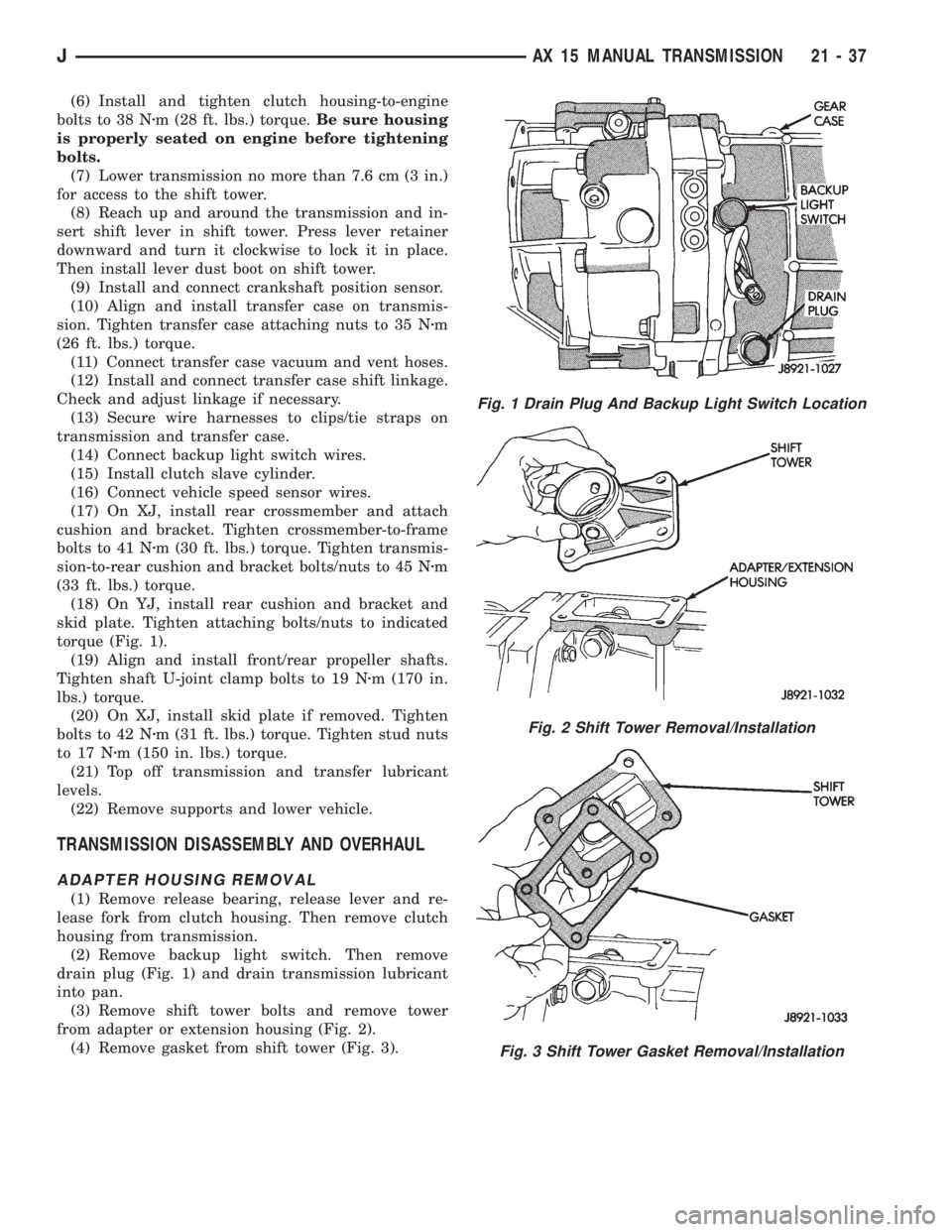

(2) Remove backup light switch. Then remove

drain plug (Fig. 1) and drain transmission lubricant

into pan.

(3) Remove shift tower bolts and remove tower

from adapter or extension housing (Fig. 2).

(4) Remove gasket from shift tower (Fig. 3).

Fig. 1 Drain Plug And Backup Light Switch Location

Fig. 2 Shift Tower Removal/Installation

Fig. 3 Shift Tower Gasket Removal/Installation

JAX 15 MANUAL TRANSMISSION 21 - 37

Page 1677 of 2158

30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

ConverterÐPump SealÐDrive Plate Service.... 116

Transmission and Converter Installation........ 117Transmission and Converter Removal......... 115

TRANSMISSION AND CONVERTER REMOVAL

(1) Remove fan shroud attaching bolts.

(2) Disconnect transmission fill tube at upper

bracket.

(3) Raise vehicle.

(4) Remove inspection cover from converter hous-

ing and remove skid plate for access, if necessary.

(5) Remove transmission fill tube and fill tube O-

ring.

(6) Remove starter motor.

(7) Mark propeller shafts and axle yokes for align-

ment reference.

(8) Disconnect propeller shafts at yokes. Secure

shafts to frame rails with wire.

(9) Disconnect exhaust pipes at exhaust manifolds,

if necessary.

(10) Drain transfer case lubricant, if transfer case

will also be serviced.

(11) Disconnect vehicle speed sensor wires.

(12) Disconnect transfer case shift linkage.

(13) Disconnect gearshift cable/linkage and throttle

valve cable at transmission levers.

(14) Disconnect transfer case vent hose. Then dis-

connect indicator switch wires on XJ, or vacuum

switch harness on YJ.

(15) Remove wire harness from clips on transfer

case.

(16) Remove transfer case attaching nuts and re-

move transfer case. Use transmission jack or helper

to support and remove transfer case.

(17) Disconnect park/neutral position switch wires.

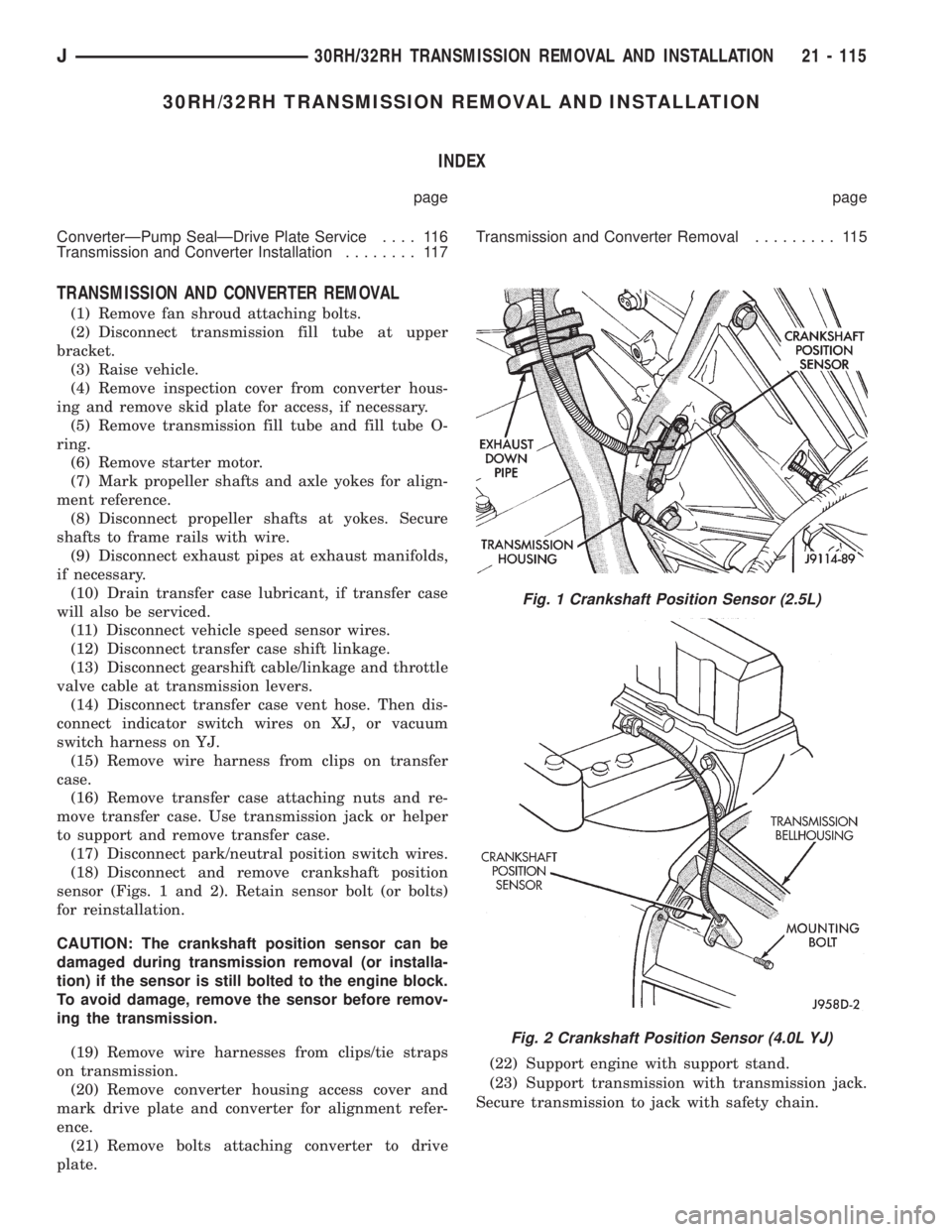

(18) Disconnect and remove crankshaft position

sensor (Figs. 1 and 2). Retain sensor bolt (or bolts)

for reinstallation.

CAUTION: The crankshaft position sensor can be

damaged during transmission removal (or installa-

tion) if the sensor is still bolted to the engine block.

To avoid damage, remove the sensor before remov-

ing the transmission.

(19) Remove wire harnesses from clips/tie straps

on transmission.

(20) Remove converter housing access cover and

mark drive plate and converter for alignment refer-

ence.

(21) Remove bolts attaching converter to drive

plate.(22) Support engine with support stand.

(23) Support transmission with transmission jack.

Secure transmission to jack with safety chain.

Fig. 1 Crankshaft Position Sensor (2.5L)

Fig. 2 Crankshaft Position Sensor (4.0L YJ)

J30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION 21 - 115

Page 1944 of 2158

(3) Pull downward and remove the grille from ex-

haust port in the door opening panel.

INSTALLATION

(1) Position the slot located in the upper end of re-

placement grille at the exhaust port and insert edge

in the slot.

(2) Push inward and seat the grille in the exhaust

port.

(3) Install the screw to attach the grille to the door

opening panel.

EXTERIOR NAMEPLATESÐXJ

SERVICE INFORMATION

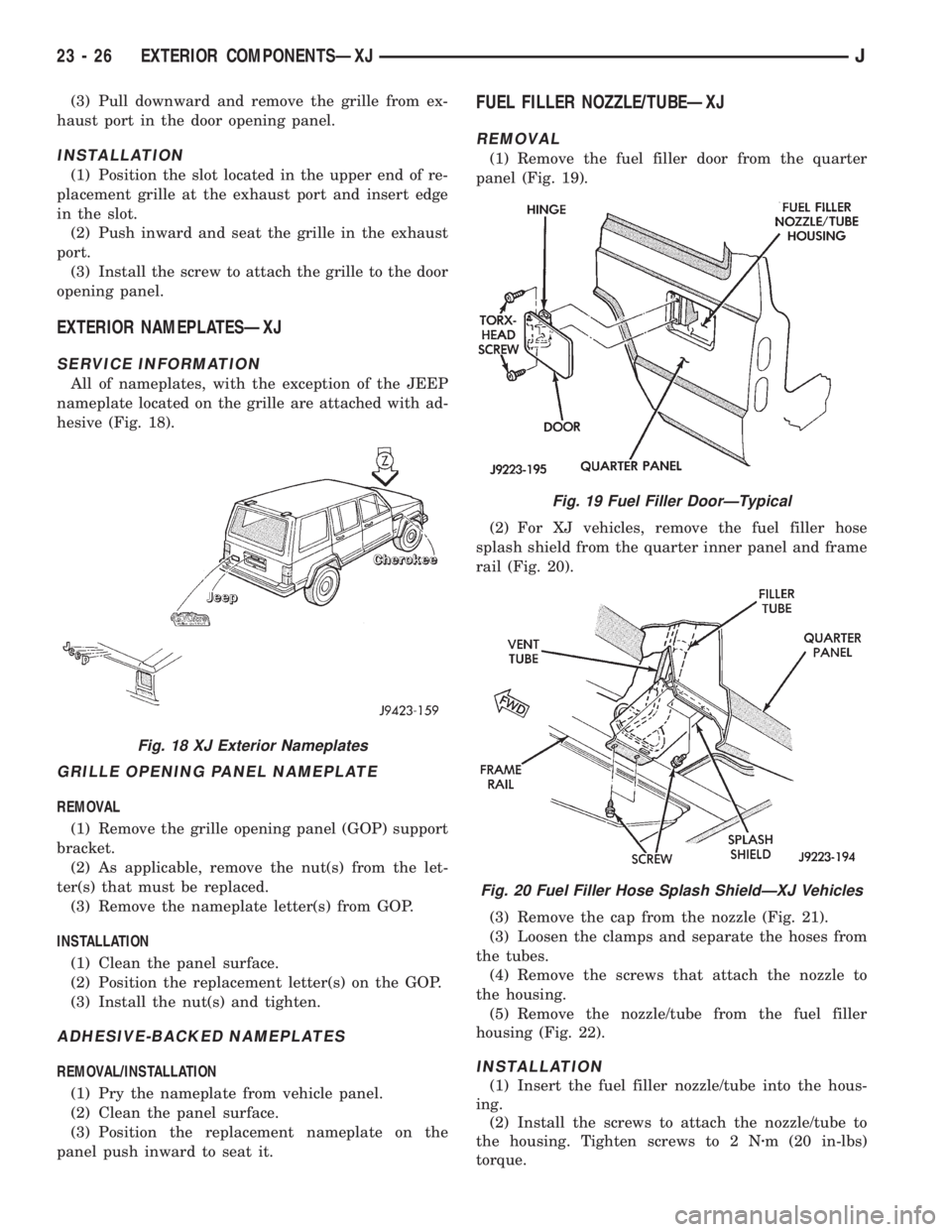

All of nameplates, with the exception of the JEEP

nameplate located on the grille are attached with ad-

hesive (Fig. 18).

GRILLE OPENING PANEL NAMEPLATE

REMOVAL

(1) Remove the grille opening panel (GOP) support

bracket.

(2) As applicable, remove the nut(s) from the let-

ter(s) that must be replaced.

(3) Remove the nameplate letter(s) from GOP.

INSTALLATION

(1) Clean the panel surface.

(2) Position the replacement letter(s) on the GOP.

(3) Install the nut(s) and tighten.

ADHESIVE-BACKED NAMEPLATES

REMOVAL/INSTALLATION

(1) Pry the nameplate from vehicle panel.

(2) Clean the panel surface.

(3) Position the replacement nameplate on the

panel push inward to seat it.

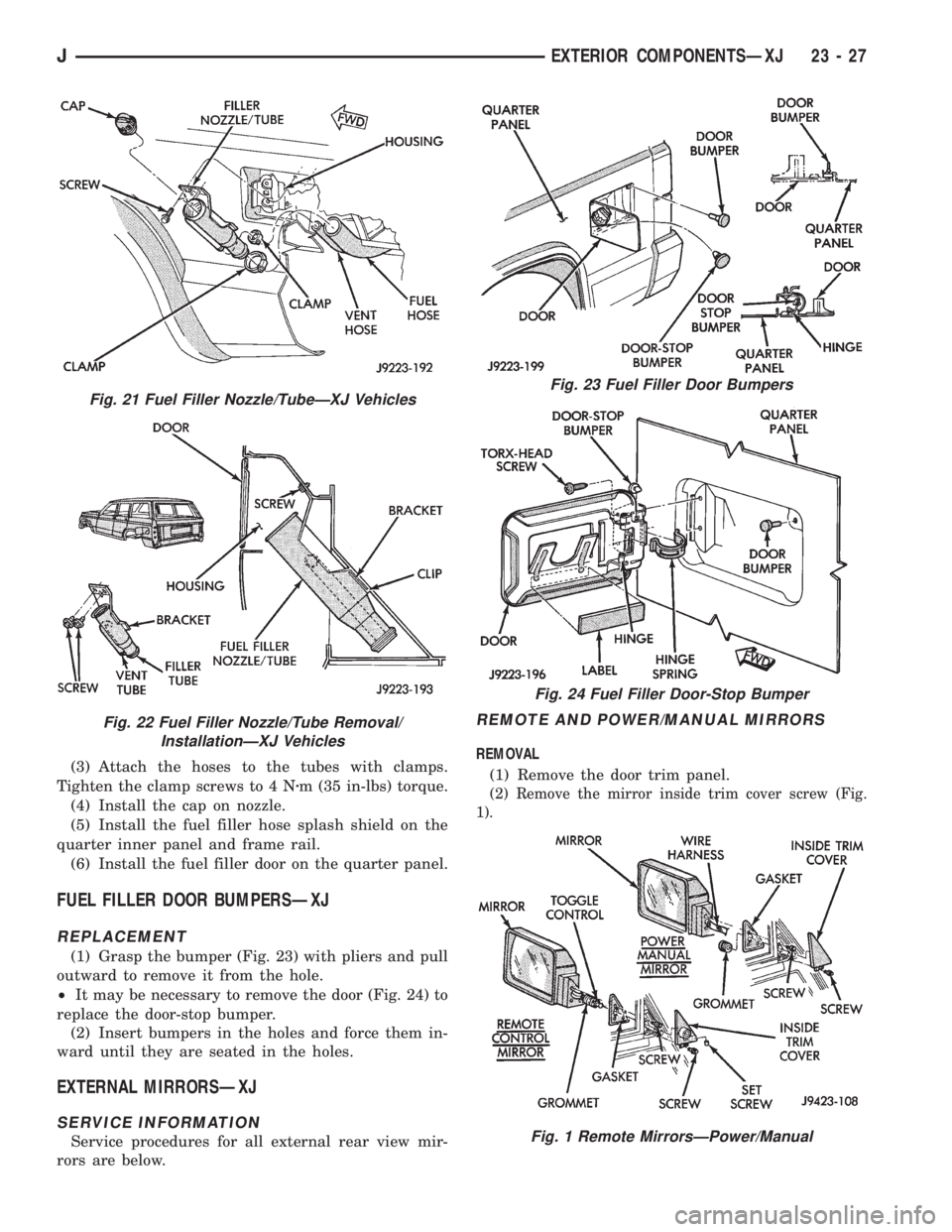

FUEL FILLER NOZZLE/TUBEÐXJ

REMOVAL

(1) Remove the fuel filler door from the quarter

panel (Fig. 19).

(2) For XJ vehicles, remove the fuel filler hose

splash shield from the quarter inner panel and frame

rail (Fig. 20).

(3) Remove the cap from the nozzle (Fig. 21).

(3) Loosen the clamps and separate the hoses from

the tubes.

(4) Remove the screws that attach the nozzle to

the housing.

(5) Remove the nozzle/tube from the fuel filler

housing (Fig. 22).

INSTALLATION

(1) Insert the fuel filler nozzle/tube into the hous-

ing.

(2) Install the screws to attach the nozzle/tube to

the housing. Tighten screws to 2 Nzm (20 in-lbs)

torque.

Fig. 18 XJ Exterior Nameplates

Fig. 19 Fuel Filler DoorÐTypical

Fig. 20 Fuel Filler Hose Splash ShieldÐXJ Vehicles

23 - 26 EXTERIOR COMPONENTSÐXJJ

Page 1945 of 2158

(3) Attach the hoses to the tubes with clamps.

Tighten the clamp screws to 4 Nzm (35 in-lbs) torque.

(4) Install the cap on nozzle.

(5) Install the fuel filler hose splash shield on the

quarter inner panel and frame rail.

(6) Install the fuel filler door on the quarter panel.

FUEL FILLER DOOR BUMPERSÐXJ

REPLACEMENT

(1) Grasp the bumper (Fig. 23) with pliers and pull

outward to remove it from the hole.

²It may be necessary to remove the door (Fig. 24) to

replace the door-stop bumper.

(2) Insert bumpers in the holes and force them in-

ward until they are seated in the holes.

EXTERNAL MIRRORSÐXJ

SERVICE INFORMATION

Service procedures for all external rear view mir-

rors are below.

REMOTE AND POWER/MANUAL MIRRORS

REMOVAL

(1) Remove the door trim panel.

(2) Remove the mirror inside trim cover screw (Fig.

1).

Fig. 21 Fuel Filler Nozzle/TubeÐXJ Vehicles

Fig. 22 Fuel Filler Nozzle/Tube Removal/

InstallationÐXJ Vehicles

Fig. 23 Fuel Filler Door Bumpers

Fig. 24 Fuel Filler Door-Stop Bumper

Fig. 1 Remote MirrorsÐPower/Manual

JEXTERIOR COMPONENTSÐXJ 23 - 27

Page 1971 of 2158

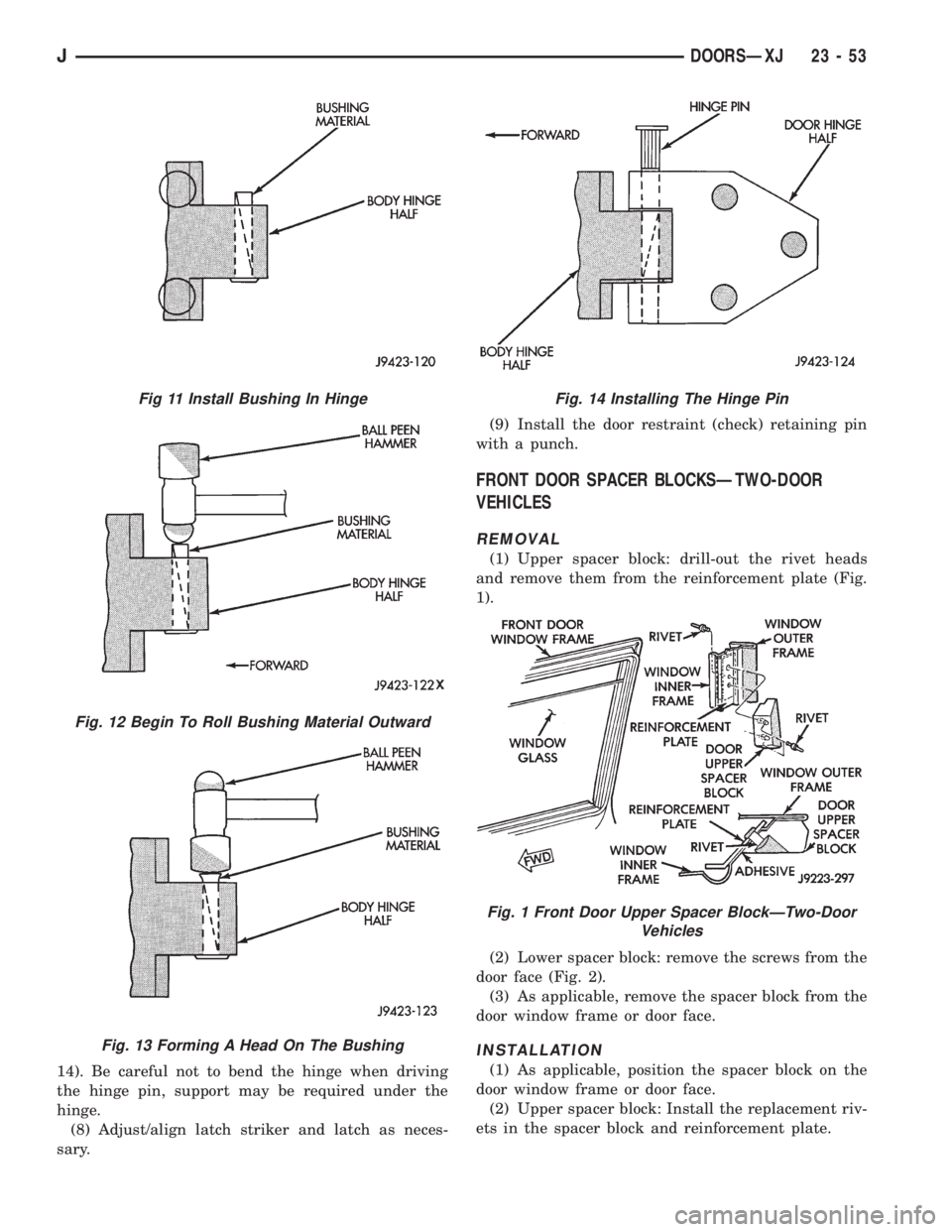

14). Be careful not to bend the hinge when driving

the hinge pin, support may be required under the

hinge.

(8) Adjust/align latch striker and latch as neces-

sary.(9) Install the door restraint (check) retaining pin

with a punch.

FRONT DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES

REMOVAL

(1) Upper spacer block: drill-out the rivet heads

and remove them from the reinforcement plate (Fig.

1).

(2) Lower spacer block: remove the screws from the

door face (Fig. 2).

(3) As applicable, remove the spacer block from the

door window frame or door face.

INSTALLATION

(1) As applicable, position the spacer block on the

door window frame or door face.

(2) Upper spacer block: Install the replacement riv-

ets in the spacer block and reinforcement plate.

Fig 11 Install Bushing In Hinge

Fig. 12 Begin To Roll Bushing Material Outward

Fig. 13 Forming A Head On The Bushing

Fig. 14 Installing The Hinge Pin

Fig. 1 Front Door Upper Spacer BlockÐTwo-Door

Vehicles

JDOORSÐXJ 23 - 53

Page 1996 of 2158

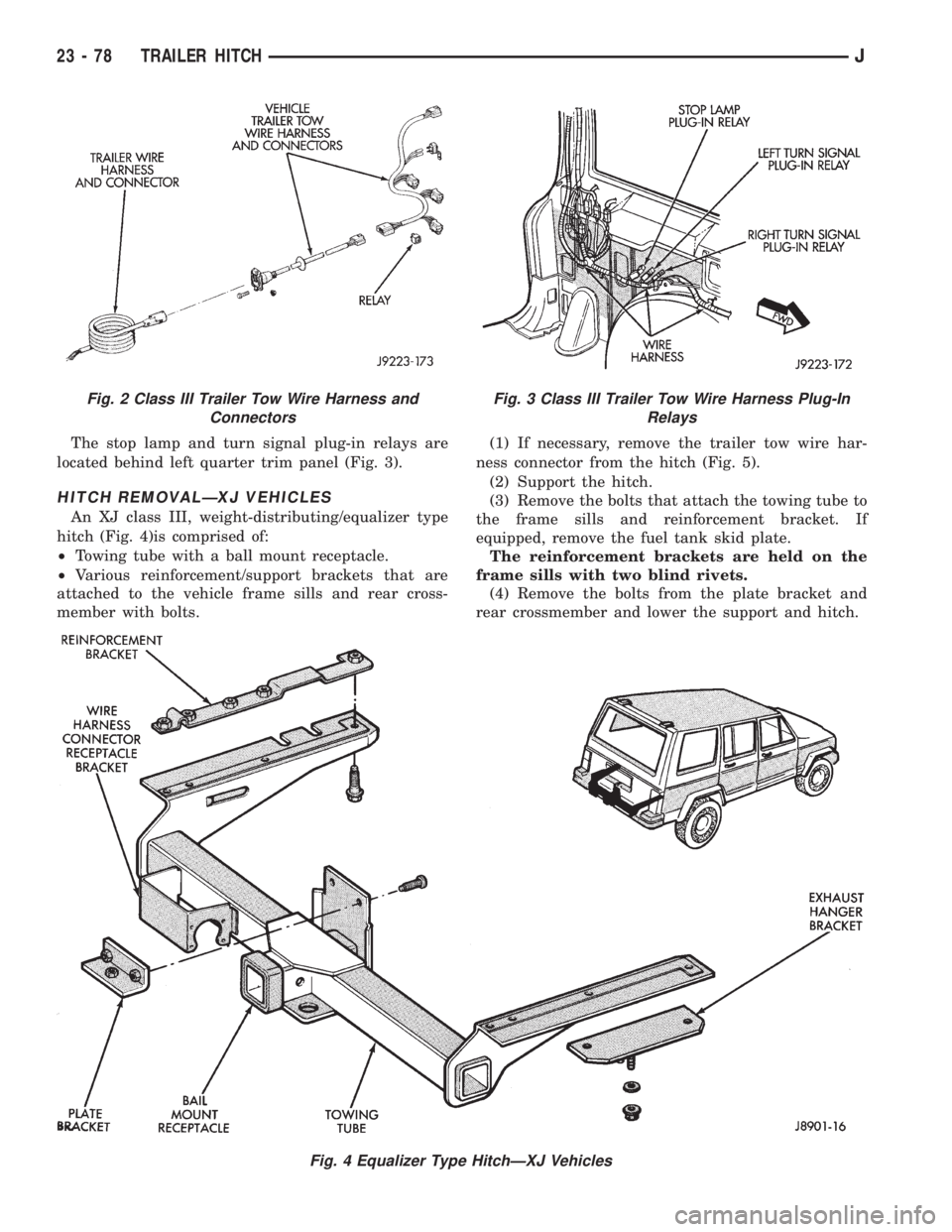

The stop lamp and turn signal plug-in relays are

located behind left quarter trim panel (Fig. 3).

HITCH REMOVALÐXJ VEHICLES

An XJ class III, weight-distributing/equalizer type

hitch (Fig. 4)is comprised of:

²Towing tube with a ball mount receptacle.

²Various reinforcement/support brackets that are

attached to the vehicle frame sills and rear cross-

member with bolts.(1) If necessary, remove the trailer tow wire har-

ness connector from the hitch (Fig. 5).

(2) Support the hitch.

(3) Remove the bolts that attach the towing tube to

the frame sills and reinforcement bracket. If

equipped, remove the fuel tank skid plate.

The reinforcement brackets are held on the

frame sills with two blind rivets.

(4) Remove the bolts from the plate bracket and

rear crossmember and lower the support and hitch.

Fig. 4 Equalizer Type HitchÐXJ Vehicles

Fig. 2 Class III Trailer Tow Wire Harness and

ConnectorsFig. 3 Class III Trailer Tow Wire Harness Plug-In

Relays

23 - 78 TRAILER HITCHJ

Page 1997 of 2158

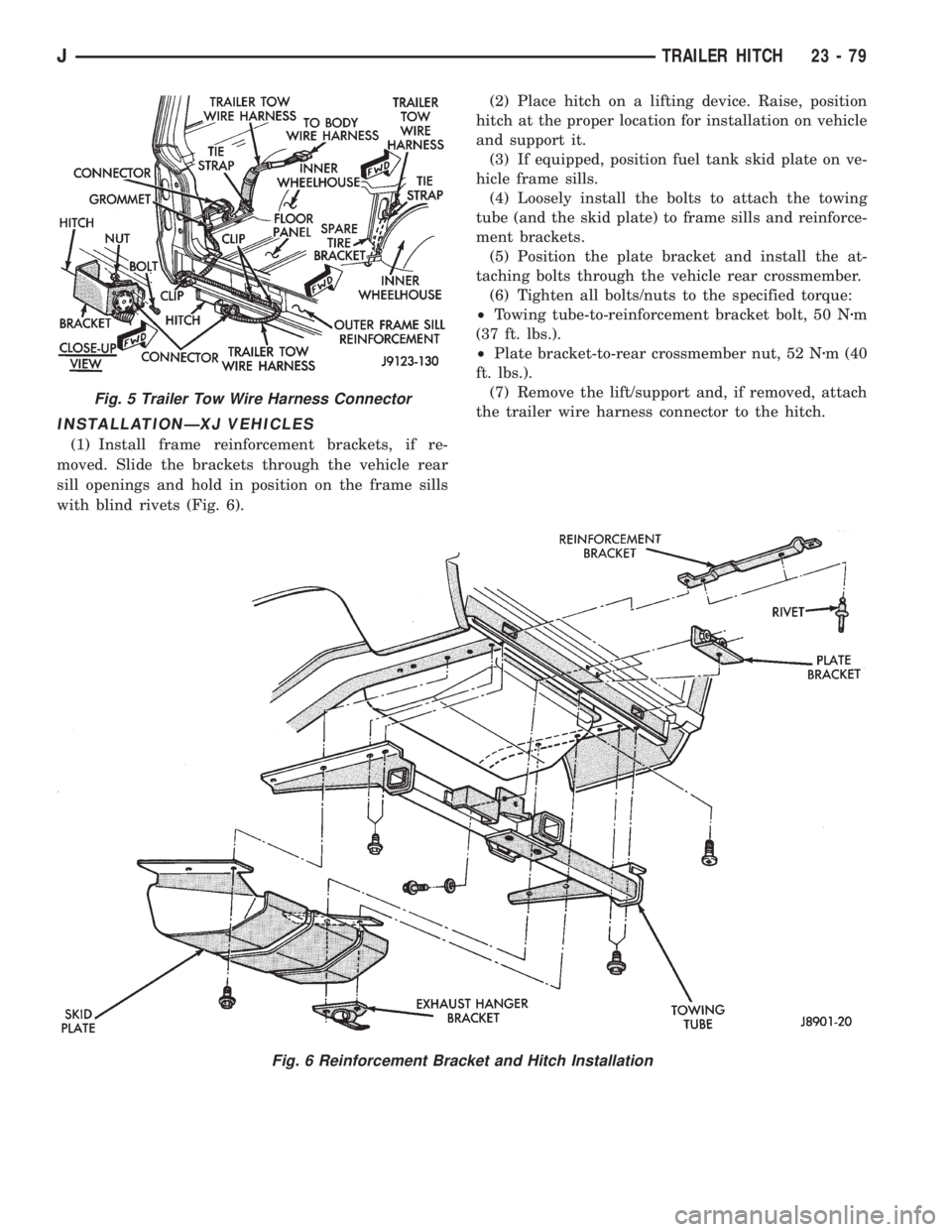

INSTALLATIONÐXJ VEHICLES

(1) Install frame reinforcement brackets, if re-

moved. Slide the brackets through the vehicle rear

sill openings and hold in position on the frame sills

with blind rivets (Fig. 6).(2) Place hitch on a lifting device. Raise, position

hitch at the proper location for installation on vehicle

and support it.

(3) If equipped, position fuel tank skid plate on ve-

hicle frame sills.

(4) Loosely install the bolts to attach the towing

tube (and the skid plate) to frame sills and reinforce-

ment brackets.

(5) Position the plate bracket and install the at-

taching bolts through the vehicle rear crossmember.

(6) Tighten all bolts/nuts to the specified torque:

²Towing tube-to-reinforcement bracket bolt, 50 Nzm

(37 ft. lbs.).

²Plate bracket-to-rear crossmember nut, 52 Nzm (40

ft. lbs.).

(7) Remove the lift/support and, if removed, attach

the trailer wire harness connector to the hitch.

Fig. 6 Reinforcement Bracket and Hitch Installation

Fig. 5 Trailer Tow Wire Harness Connector

JTRAILER HITCH 23 - 79

Page 1998 of 2158

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ........................ 89

B/C-Pillar and Liftgate Pillar Trim CoversÐXJ.... 88

Bucket Seat Cushion and CoverÐXJ........... 81

Bucket Seat PlatformÐXJ................... 82

Bucket Seatback Cover and FrameÐXJ........ 81

Cargo BarrierÐXJ........................ 101

Cargo LampÐXJ......................... 94

Carpets and Floor MatsÐXJ................. 99

Dome LampÐXJ......................... 93

Front Bucket SeatsÐXJ.................... 81

Front Carpet/MatÐXJ...................... 99

Front Inner Scuff Plate/Cowl Side Trim PanelÐXJ . 86

Front Shoulder Belt/BuckleÐXJ............... 90

Full Floor ConsoleÐXJ..................... 95

HeadlinerÐXJ............................ 92

I/P Ash Receiver Tray LampÐXJ.............. 80

Instrument Cluster BezelÐXJ................ 80

Interior Trim Panels and Scuff PlatesÐXJ....... 84

Jack StorageÐXJ......................... 97

Keyless Entry ReceiverÐXJ................. 93Mini-Console with Floor ShiftÐXJ............. 94

Mini-Floor ConsoleÐXJ..................... 94

Outer Scuff PlatesÐXJ..................... 89

Overhead ConsoleÐXJ..................... 93

Parking Brake Handle CoverÐXJ............. 94

Quarter and Wheelhouse Trim PanelsÐXJ...... 87

Quarter Trim Panel ExtensionÐXJ............. 87

Rear Carpet/MatÐXJ..................... 100

Rear Seat Cushion CoverÐXJ............... 82

Rear Seat CushionÐXJ.................... 82

Rear Seatback CoverÐXJ................... 84

Rear Seatback Latch Striker and BumperÐXJ.... 84

Rear SeatbackÐXJ........................ 83

Rear Shoulder/Lap Belt/BuckleÐXJ............ 91

Sound BarÐXJ........................... 94

Spare Tire/Wheel Holddown and Floor

BracketsÐXJ........................... 98

SunvisorsÐXJ........................... 93

Windshield Side MoldingÐXJ................ 86

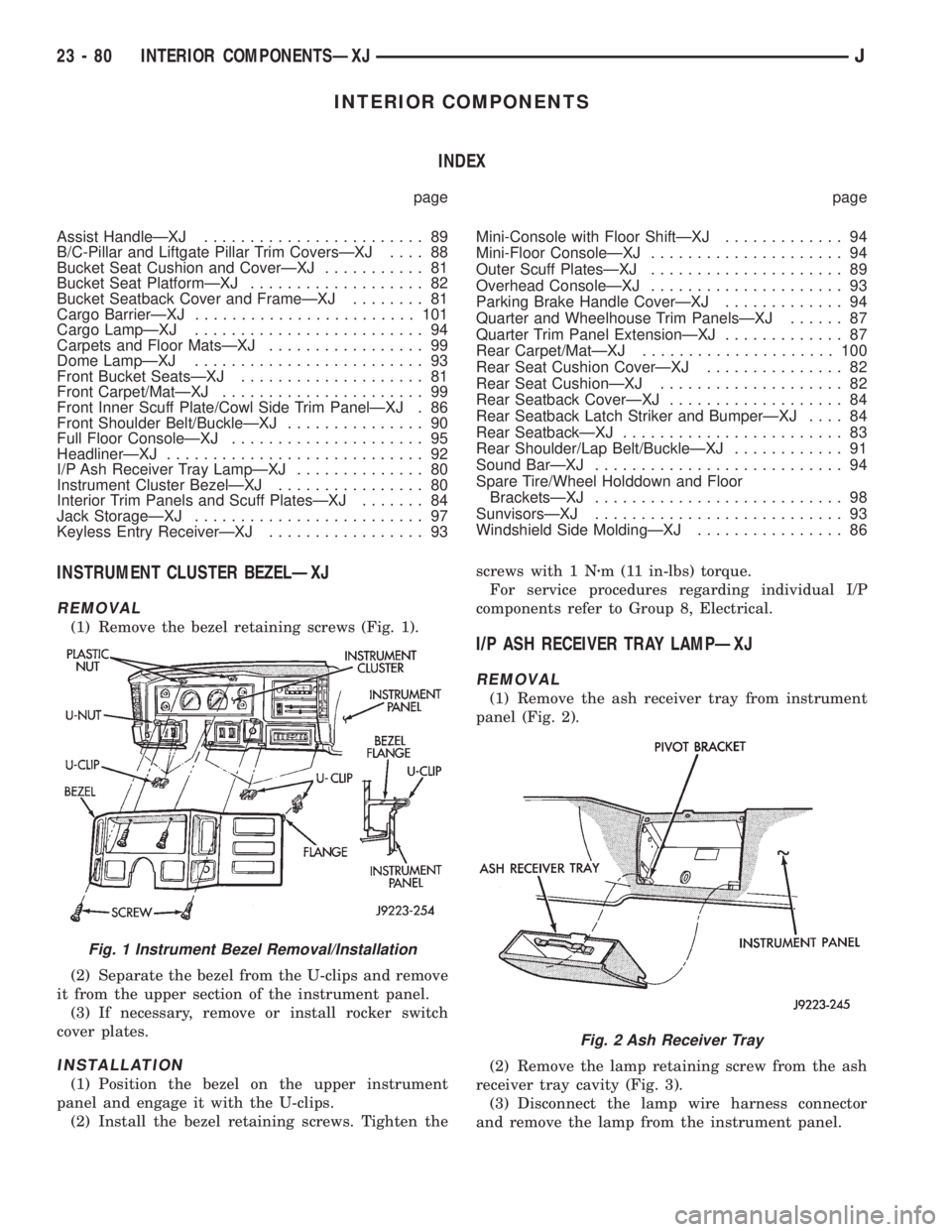

INSTRUMENT CLUSTER BEZELÐXJ

REMOVAL

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates.

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten thescrews with 1 Nzm (11 in-lbs) torque.

For service procedures regarding individual I/P

components refer to Group 8, Electrical.

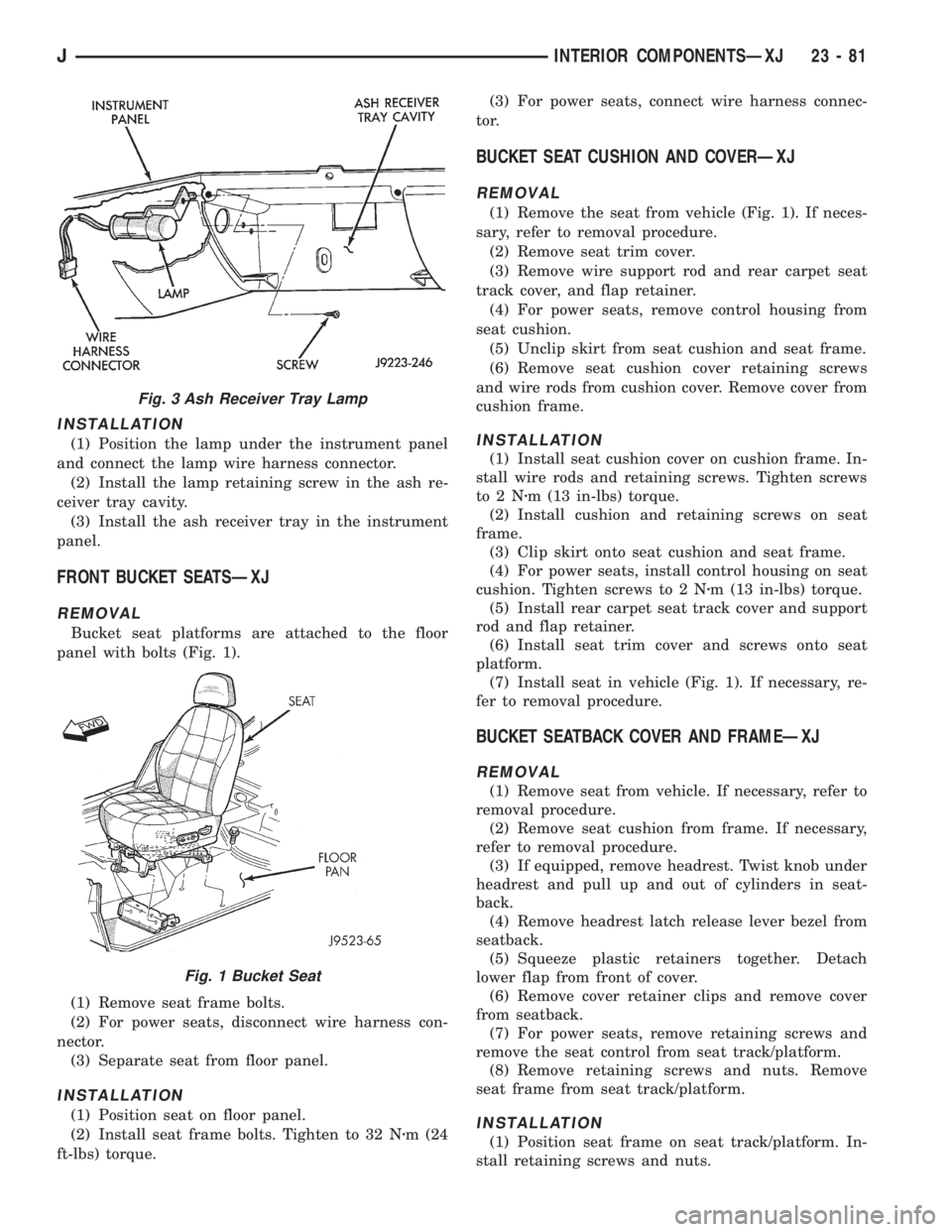

I/P ASH RECEIVER TRAY LAMPÐXJ

REMOVAL

(1) Remove the ash receiver tray from instrument

panel (Fig. 2).

(2) Remove the lamp retaining screw from the ash

receiver tray cavity (Fig. 3).

(3) Disconnect the lamp wire harness connector

and remove the lamp from the instrument panel.

Fig. 1 Instrument Bezel Removal/Installation

Fig. 2 Ash Receiver Tray

23 - 80 INTERIOR COMPONENTSÐXJJ

Page 1999 of 2158

INSTALLATION

(1) Position the lamp under the instrument panel

and connect the lamp wire harness connector.

(2) Install the lamp retaining screw in the ash re-

ceiver tray cavity.

(3) Install the ash receiver tray in the instrument

panel.

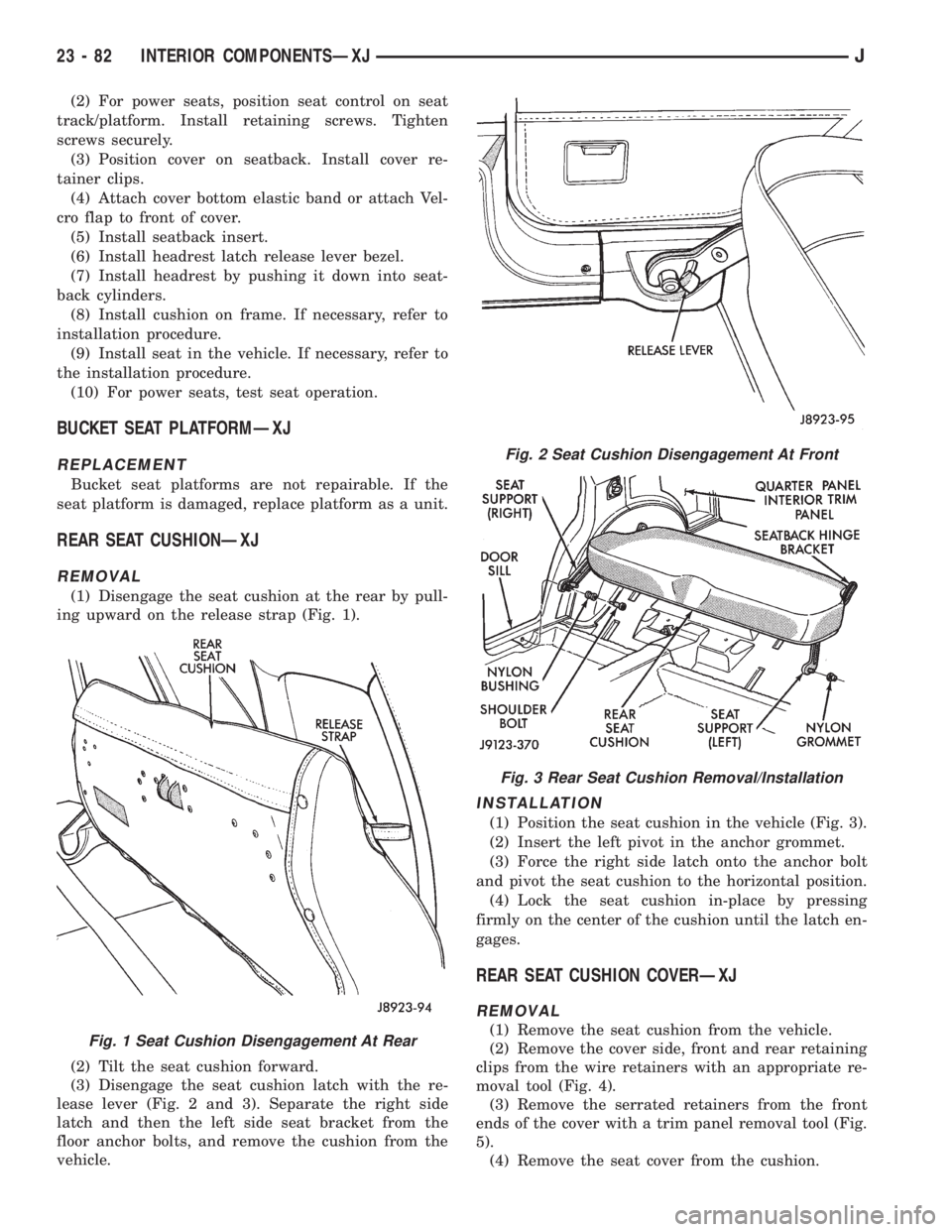

FRONT BUCKET SEATSÐXJ

REMOVAL

Bucket seat platforms are attached to the floor

panel with bolts (Fig. 1).

(1) Remove seat frame bolts.

(2) For power seats, disconnect wire harness con-

nector.

(3) Separate seat from floor panel.

INSTALLATION

(1) Position seat on floor panel.

(2) Install seat frame bolts. Tighten to 32 Nzm (24

ft-lbs) torque.(3) For power seats, connect wire harness connec-

tor.

BUCKET SEAT CUSHION AND COVERÐXJ

REMOVAL

(1) Remove the seat from vehicle (Fig. 1). If neces-

sary, refer to removal procedure.

(2) Remove seat trim cover.

(3) Remove wire support rod and rear carpet seat

track cover, and flap retainer.

(4) For power seats, remove control housing from

seat cushion.

(5) Unclip skirt from seat cushion and seat frame.

(6) Remove seat cushion cover retaining screws

and wire rods from cushion cover. Remove cover from

cushion frame.

INSTALLATION

(1) Install seat cushion cover on cushion frame. In-

stall wire rods and retaining screws. Tighten screws

to2Nzm (13 in-lbs) torque.

(2) Install cushion and retaining screws on seat

frame.

(3) Clip skirt onto seat cushion and seat frame.

(4) For power seats, install control housing on seat

cushion. Tighten screws to 2 Nzm (13 in-lbs) torque.

(5) Install rear carpet seat track cover and support

rod and flap retainer.

(6) Install seat trim cover and screws onto seat

platform.

(7) Install seat in vehicle (Fig. 1). If necessary, re-

fer to removal procedure.

BUCKET SEATBACK COVER AND FRAMEÐXJ

REMOVAL

(1) Remove seat from vehicle. If necessary, refer to

removal procedure.

(2) Remove seat cushion from frame. If necessary,

refer to removal procedure.

(3) If equipped, remove headrest. Twist knob under

headrest and pull up and out of cylinders in seat-

back.

(4) Remove headrest latch release lever bezel from

seatback.

(5) Squeeze plastic retainers together. Detach

lower flap from front of cover.

(6) Remove cover retainer clips and remove cover

from seatback.

(7) For power seats, remove retaining screws and

remove the seat control from seat track/platform.

(8) Remove retaining screws and nuts. Remove

seat frame from seat track/platform.

INSTALLATION

(1) Position seat frame on seat track/platform. In-

stall retaining screws and nuts.

Fig. 3 Ash Receiver Tray Lamp

Fig. 1 Bucket Seat

JINTERIOR COMPONENTSÐXJ 23 - 81

Page 2000 of 2158

(2) For power seats, position seat control on seat

track/platform. Install retaining screws. Tighten

screws securely.

(3) Position cover on seatback. Install cover re-

tainer clips.

(4) Attach cover bottom elastic band or attach Vel-

cro flap to front of cover.

(5) Install seatback insert.

(6) Install headrest latch release lever bezel.

(7) Install headrest by pushing it down into seat-

back cylinders.

(8) Install cushion on frame. If necessary, refer to

installation procedure.

(9) Install seat in the vehicle. If necessary, refer to

the installation procedure.

(10) For power seats, test seat operation.

BUCKET SEAT PLATFORMÐXJ

REPLACEMENT

Bucket seat platforms are not repairable. If the

seat platform is damaged, replace platform as a unit.

REAR SEAT CUSHIONÐXJ

REMOVAL

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap (Fig. 1).

(2) Tilt the seat cushion forward.

(3) Disengage the seat cushion latch with the re-

lease lever (Fig. 2 and 3). Separate the right side

latch and then the left side seat bracket from the

floor anchor bolts, and remove the cushion from the

vehicle.

INSTALLATION

(1) Position the seat cushion in the vehicle (Fig. 3).

(2) Insert the left pivot in the anchor grommet.

(3) Force the right side latch onto the anchor bolt

and pivot the seat cushion to the horizontal position.

(4) Lock the seat cushion in-place by pressing

firmly on the center of the cushion until the latch en-

gages.

REAR SEAT CUSHION COVERÐXJ

REMOVAL

(1) Remove the seat cushion from the vehicle.

(2) Remove the cover side, front and rear retaining

clips from the wire retainers with an appropriate re-

moval tool (Fig. 4).

(3) Remove the serrated retainers from the front

ends of the cover with a trim panel removal tool (Fig.

5).

(4) Remove the seat cover from the cushion.Fig. 1 Seat Cushion Disengagement At Rear

Fig. 2 Seat Cushion Disengagement At Front

Fig. 3 Rear Seat Cushion Removal/Installation

23 - 82 INTERIOR COMPONENTSÐXJJ