frame JEEP YJ 1995 Service And Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 2002 of 2158

REAR SEATBACK LATCH STRIKER AND BUMPERÐ

XJ

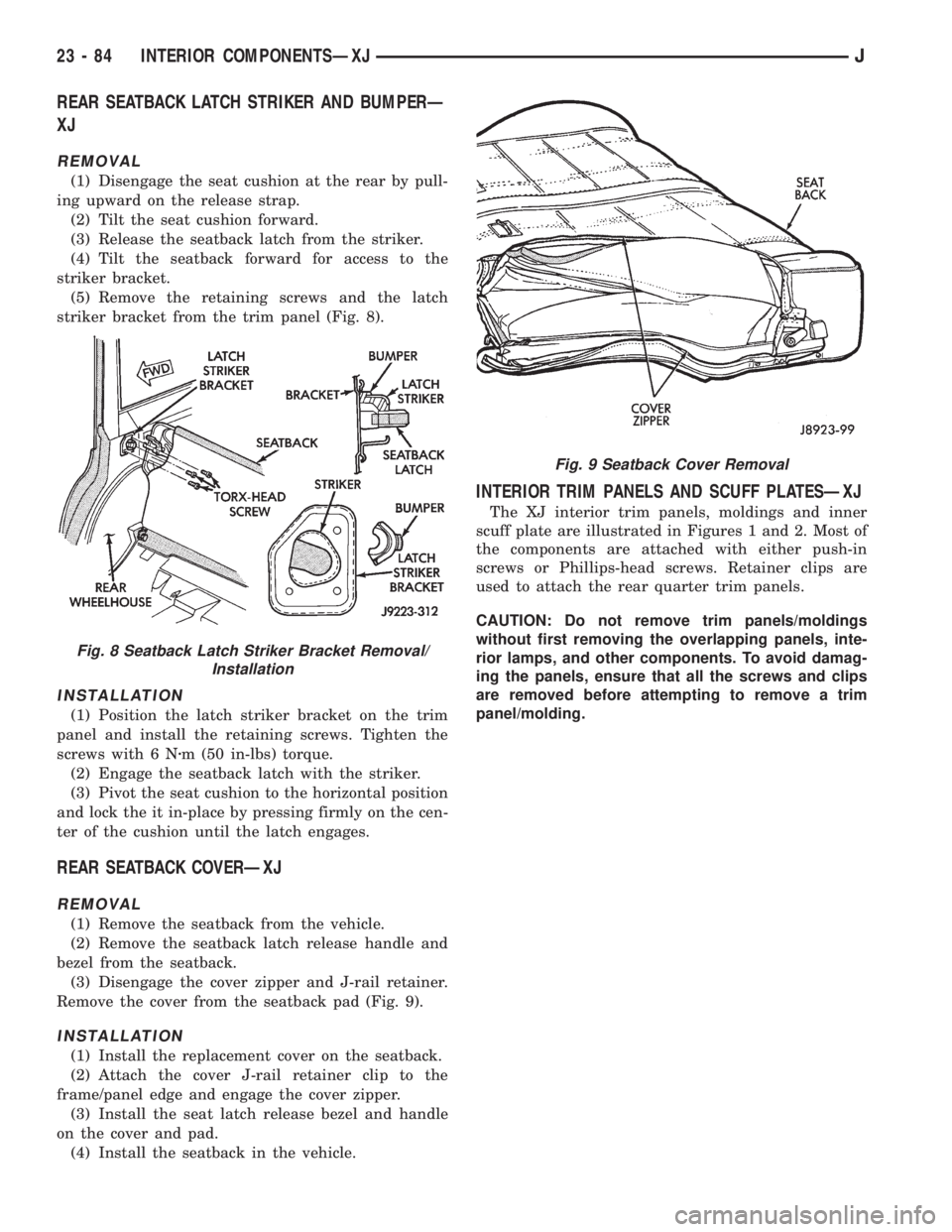

REMOVAL

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap.

(2) Tilt the seat cushion forward.

(3) Release the seatback latch from the striker.

(4) Tilt the seatback forward for access to the

striker bracket.

(5) Remove the retaining screws and the latch

striker bracket from the trim panel (Fig. 8).

INSTALLATION

(1) Position the latch striker bracket on the trim

panel and install the retaining screws. Tighten the

screws with 6 Nzm (50 in-lbs) torque.

(2) Engage the seatback latch with the striker.

(3) Pivot the seat cushion to the horizontal position

and lock the it in-place by pressing firmly on the cen-

ter of the cushion until the latch engages.

REAR SEATBACK COVERÐXJ

REMOVAL

(1) Remove the seatback from the vehicle.

(2) Remove the seatback latch release handle and

bezel from the seatback.

(3) Disengage the cover zipper and J-rail retainer.

Remove the cover from the seatback pad (Fig. 9).

INSTALLATION

(1) Install the replacement cover on the seatback.

(2) Attach the cover J-rail retainer clip to the

frame/panel edge and engage the cover zipper.

(3) Install the seat latch release bezel and handle

on the cover and pad.

(4) Install the seatback in the vehicle.

INTERIOR TRIM PANELS AND SCUFF PLATESÐXJ

The XJ interior trim panels, moldings and inner

scuff plate are illustrated in Figures 1 and 2. Most of

the components are attached with either push-in

screws or Phillips-head screws. Retainer clips are

used to attach the rear quarter trim panels.

CAUTION: Do not remove trim panels/moldings

without first removing the overlapping panels, inte-

rior lamps, and other components. To avoid damag-

ing the panels, ensure that all the screws and clips

are removed before attempting to remove a trim

panel/molding.

Fig. 8 Seatback Latch Striker Bracket Removal/

Installation

Fig. 9 Seatback Cover Removal

23 - 84 INTERIOR COMPONENTSÐXJJ

Page 2044 of 2158

(4) Apply weatherstrip adhesive to the hard top

weatherstrip seal (Fig. 4).

(5) Carefully position the weatherstrip seal on the

rear panels and the hard top.

(6) Press the seal onto the hard top flange and en-

sure that it is correctly seated on the flange.

(7) Install the seal retaining screws in the rear

panels and tighten them securely.

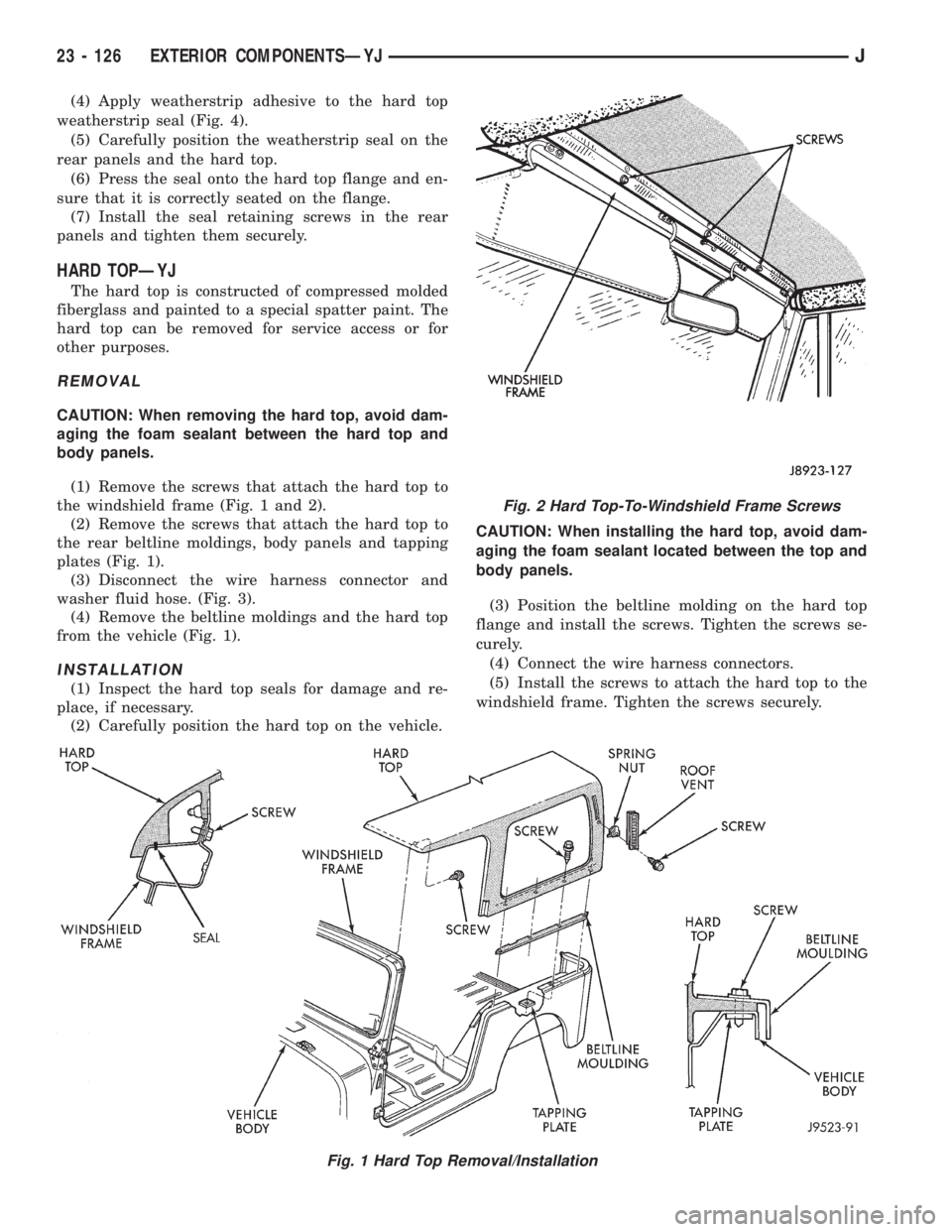

HARD TOPÐYJ

The hard top is constructed of compressed molded

fiberglass and painted to a special spatter paint. The

hard top can be removed for service access or for

other purposes.

REMOVAL

CAUTION: When removing the hard top, avoid dam-

aging the foam sealant between the hard top and

body panels.

(1) Remove the screws that attach the hard top to

the windshield frame (Fig. 1 and 2).

(2) Remove the screws that attach the hard top to

the rear beltline moldings, body panels and tapping

plates (Fig. 1).

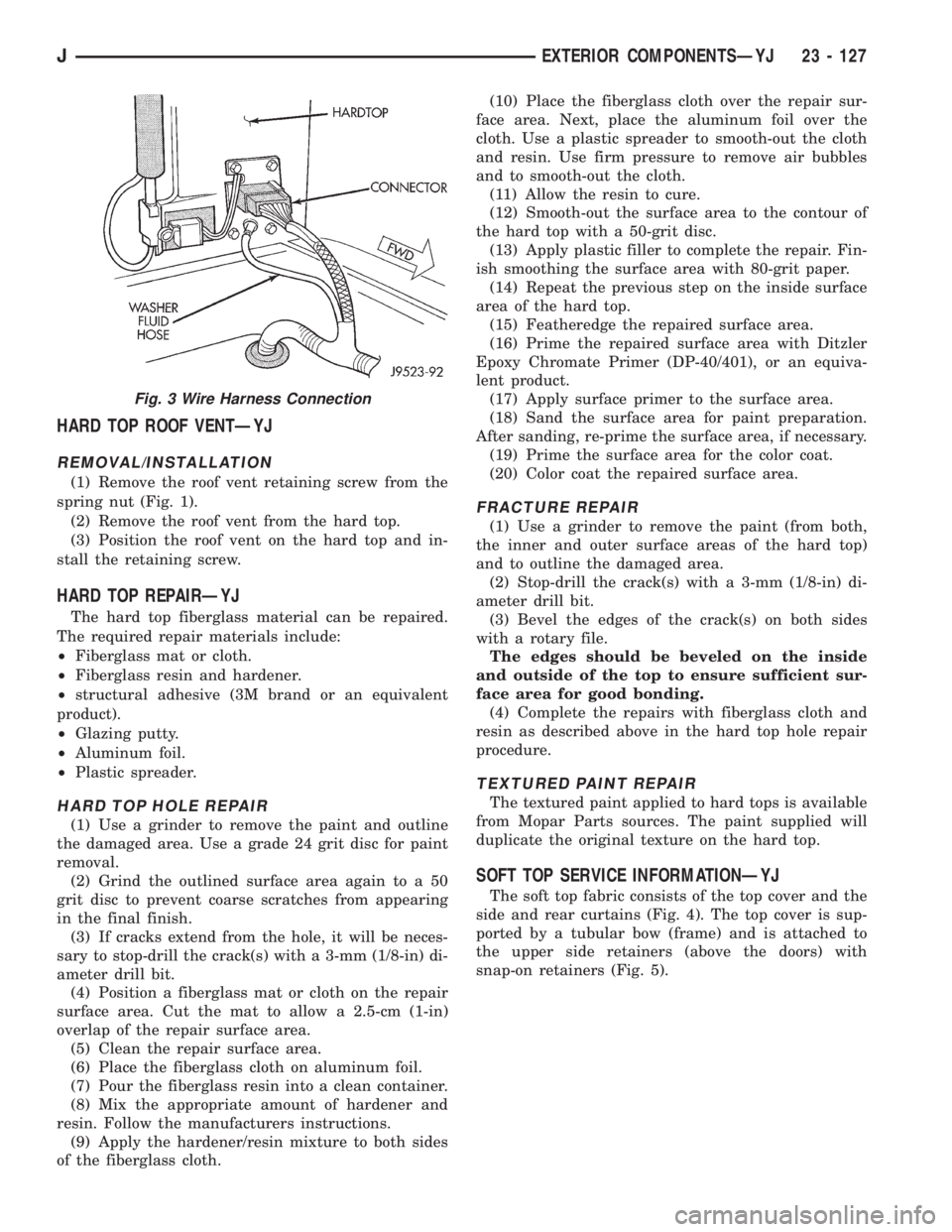

(3) Disconnect the wire harness connector and

washer fluid hose. (Fig. 3).

(4) Remove the beltline moldings and the hard top

from the vehicle (Fig. 1).

INSTALLATION

(1) Inspect the hard top seals for damage and re-

place, if necessary.

(2) Carefully position the hard top on the vehicle.CAUTION: When installing the hard top, avoid dam-

aging the foam sealant located between the top and

body panels.

(3) Position the beltline molding on the hard top

flange and install the screws. Tighten the screws se-

curely.

(4) Connect the wire harness connectors.

(5) Install the screws to attach the hard top to the

windshield frame. Tighten the screws securely.

Fig. 1 Hard Top Removal/Installation

Fig. 2 Hard Top-To-Windshield Frame Screws

23 - 126 EXTERIOR COMPONENTSÐYJJ

Page 2045 of 2158

HARD TOP ROOF VENTÐYJ

REMOVAL/INSTALLATION

(1) Remove the roof vent retaining screw from the

spring nut (Fig. 1).

(2) Remove the roof vent from the hard top.

(3) Position the roof vent on the hard top and in-

stall the retaining screw.

HARD TOP REPAIRÐYJ

The hard top fiberglass material can be repaired.

The required repair materials include:

²Fiberglass mat or cloth.

²Fiberglass resin and hardener.

²structural adhesive (3M brand or an equivalent

product).

²Glazing putty.

²Aluminum foil.

²Plastic spreader.

HARD TOP HOLE REPAIR

(1) Use a grinder to remove the paint and outline

the damaged area. Use a grade 24 grit disc for paint

removal.

(2) Grind the outlined surface area again to a 50

grit disc to prevent coarse scratches from appearing

in the final finish.

(3) If cracks extend from the hole, it will be neces-

sary to stop-drill the crack(s) with a 3-mm (1/8-in) di-

ameter drill bit.

(4) Position a fiberglass mat or cloth on the repair

surface area. Cut the mat to allow a 2.5-cm (1-in)

overlap of the repair surface area.

(5) Clean the repair surface area.

(6) Place the fiberglass cloth on aluminum foil.

(7) Pour the fiberglass resin into a clean container.

(8) Mix the appropriate amount of hardener and

resin. Follow the manufacturers instructions.

(9) Apply the hardener/resin mixture to both sides

of the fiberglass cloth.(10) Place the fiberglass cloth over the repair sur-

face area. Next, place the aluminum foil over the

cloth. Use a plastic spreader to smooth-out the cloth

and resin. Use firm pressure to remove air bubbles

and to smooth-out the cloth.

(11) Allow the resin to cure.

(12) Smooth-out the surface area to the contour of

the hard top with a 50-grit disc.

(13) Apply plastic filler to complete the repair. Fin-

ish smoothing the surface area with 80-grit paper.

(14) Repeat the previous step on the inside surface

area of the hard top.

(15) Featheredge the repaired surface area.

(16) Prime the repaired surface area with Ditzler

Epoxy Chromate Primer (DP-40/401), or an equiva-

lent product.

(17) Apply surface primer to the surface area.

(18) Sand the surface area for paint preparation.

After sanding, re-prime the surface area, if necessary.

(19) Prime the surface area for the color coat.

(20) Color coat the repaired surface area.

FRACTURE REPAIR

(1) Use a grinder to remove the paint (from both,

the inner and outer surface areas of the hard top)

and to outline the damaged area.

(2) Stop-drill the crack(s) with a 3-mm (1/8-in) di-

ameter drill bit.

(3) Bevel the edges of the crack(s) on both sides

with a rotary file.

The edges should be beveled on the inside

and outside of the top to ensure sufficient sur-

face area for good bonding.

(4) Complete the repairs with fiberglass cloth and

resin as described above in the hard top hole repair

procedure.

TEXTURED PAINT REPAIR

The textured paint applied to hard tops is available

from Mopar Parts sources. The paint supplied will

duplicate the original texture on the hard top.

SOFT TOP SERVICE INFORMATIONÐYJ

The soft top fabric consists of the top cover and the

side and rear curtains (Fig. 4). The top cover is sup-

ported by a tubular bow (frame) and is attached to

the upper side retainers (above the doors) with

snap-on retainers (Fig. 5).

Fig. 3 Wire Harness Connection

JEXTERIOR COMPONENTSÐYJ 23 - 127

Page 2047 of 2158

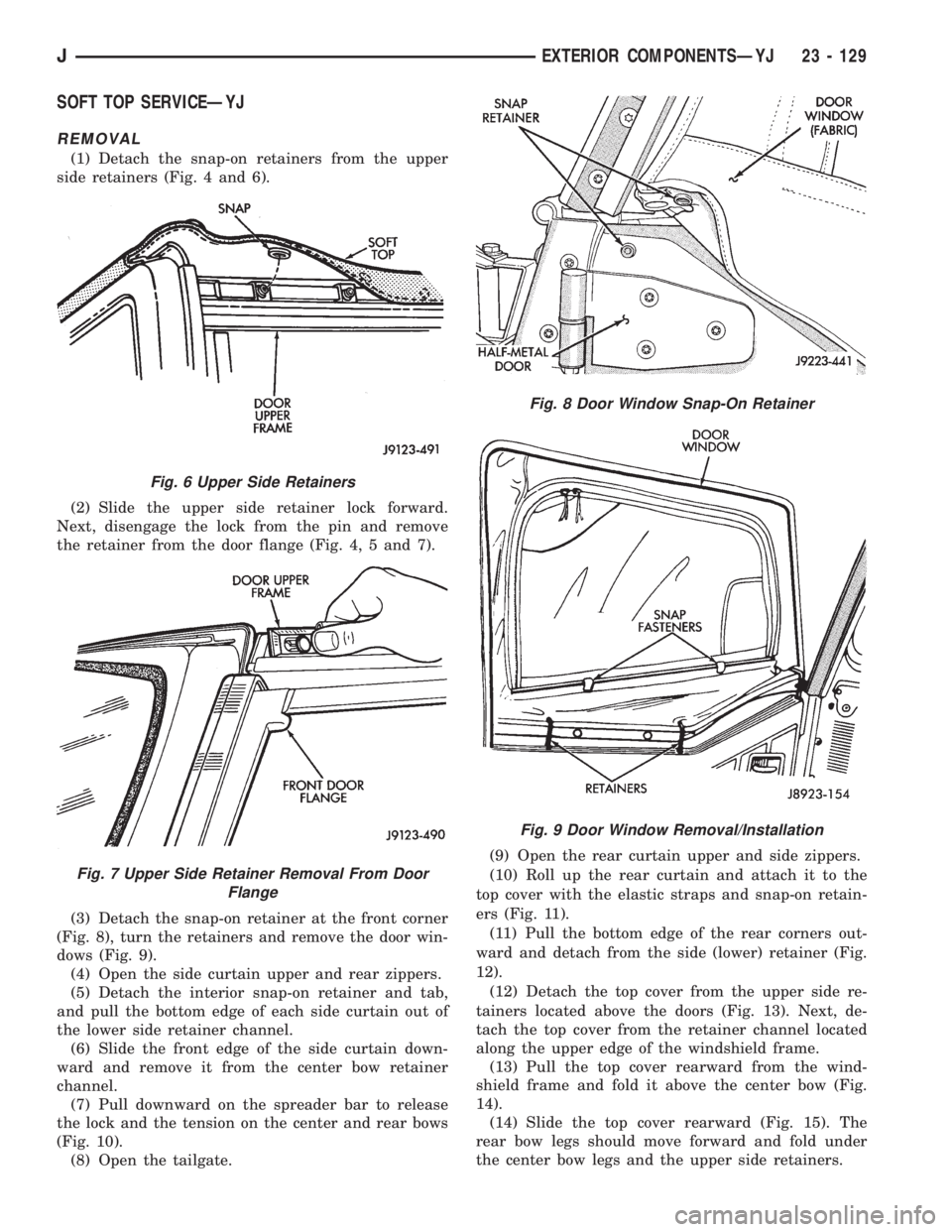

SOFT TOP SERVICEÐYJ

REMOVAL

(1) Detach the snap-on retainers from the upper

side retainers (Fig. 4 and 6).

(2) Slide the upper side retainer lock forward.

Next, disengage the lock from the pin and remove

the retainer from the door flange (Fig. 4, 5 and 7).

(3) Detach the snap-on retainer at the front corner

(Fig. 8), turn the retainers and remove the door win-

dows (Fig. 9).

(4) Open the side curtain upper and rear zippers.

(5) Detach the interior snap-on retainer and tab,

and pull the bottom edge of each side curtain out of

the lower side retainer channel.

(6) Slide the front edge of the side curtain down-

ward and remove it from the center bow retainer

channel.

(7) Pull downward on the spreader bar to release

the lock and the tension on the center and rear bows

(Fig. 10).

(8) Open the tailgate.(9) Open the rear curtain upper and side zippers.

(10) Roll up the rear curtain and attach it to the

top cover with the elastic straps and snap-on retain-

ers (Fig. 11).

(11) Pull the bottom edge of the rear corners out-

ward and detach from the side (lower) retainer (Fig.

12).

(12) Detach the top cover from the upper side re-

tainers located above the doors (Fig. 13). Next, de-

tach the top cover from the retainer channel located

along the upper edge of the windshield frame.

(13) Pull the top cover rearward from the wind-

shield frame and fold it above the center bow (Fig.

14).

(14) Slide the top cover rearward (Fig. 15). The

rear bow legs should move forward and fold under

the center bow legs and the upper side retainers.

Fig. 6 Upper Side Retainers

Fig. 7 Upper Side Retainer Removal From Door

Flange

Fig. 8 Door Window Snap-On Retainer

Fig. 9 Door Window Removal/Installation

JEXTERIOR COMPONENTSÐYJ 23 - 129

Page 2049 of 2158

INSTALLATION

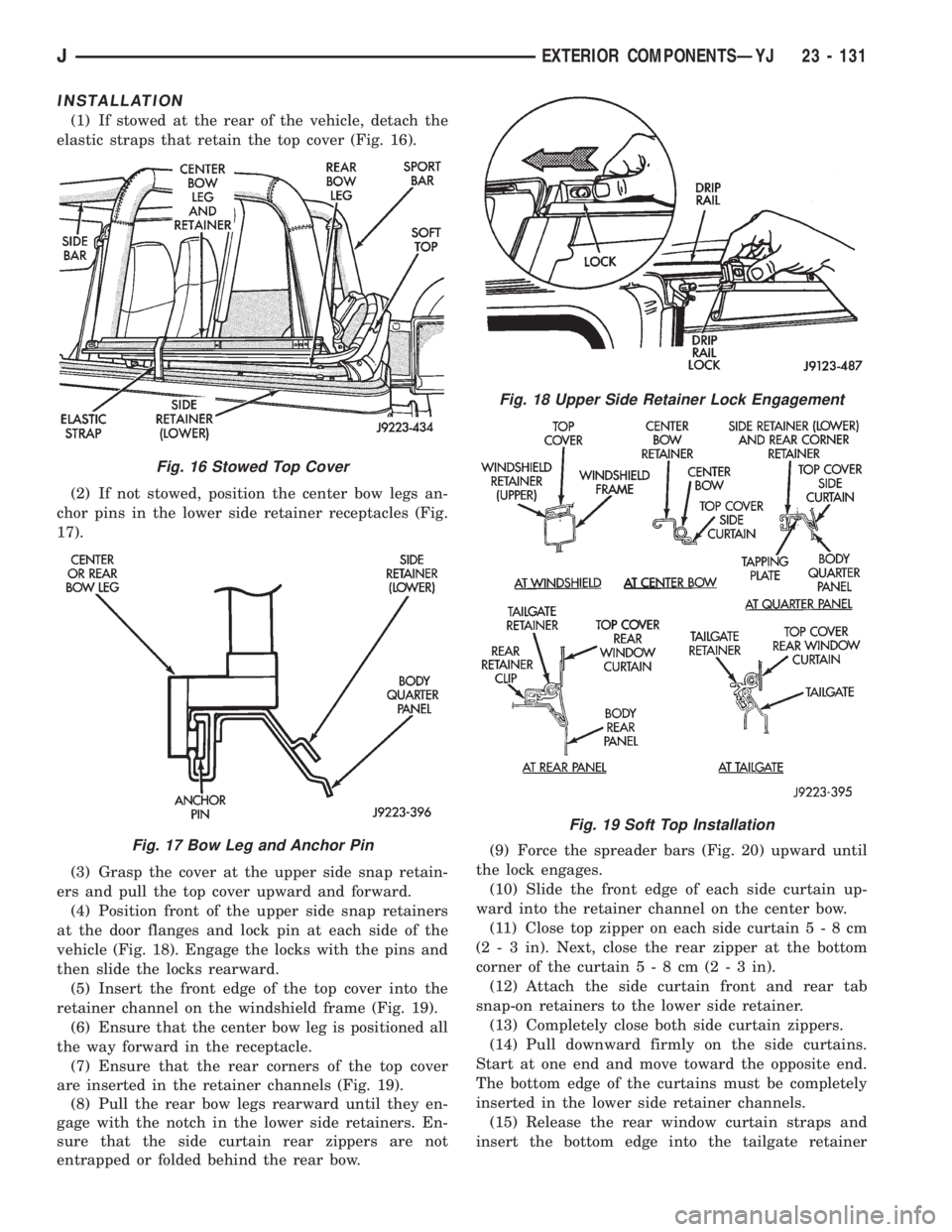

(1) If stowed at the rear of the vehicle, detach the

elastic straps that retain the top cover (Fig. 16).

(2) If not stowed, position the center bow legs an-

chor pins in the lower side retainer receptacles (Fig.

17).

(3) Grasp the cover at the upper side snap retain-

ers and pull the top cover upward and forward.

(4) Position front of the upper side snap retainers

at the door flanges and lock pin at each side of the

vehicle (Fig. 18). Engage the locks with the pins and

then slide the locks rearward.

(5) Insert the front edge of the top cover into the

retainer channel on the windshield frame (Fig. 19).

(6) Ensure that the center bow leg is positioned all

the way forward in the receptacle.

(7) Ensure that the rear corners of the top cover

are inserted in the retainer channels (Fig. 19).

(8) Pull the rear bow legs rearward until they en-

gage with the notch in the lower side retainers. En-

sure that the side curtain rear zippers are not

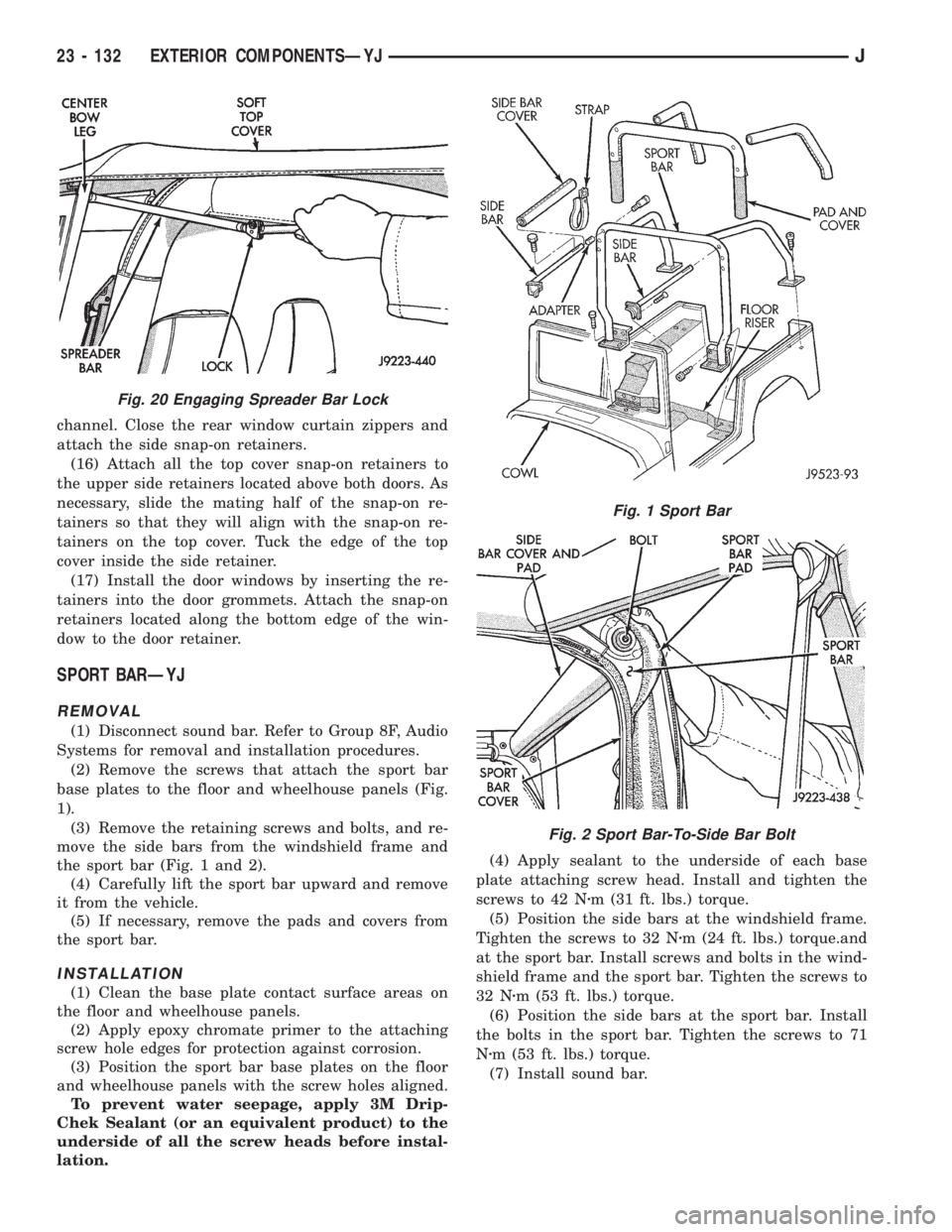

entrapped or folded behind the rear bow.(9) Force the spreader bars (Fig. 20) upward until

the lock engages.

(10) Slide the front edge of each side curtain up-

ward into the retainer channel on the center bow.

(11) Close top zipper on each side curtain5-8cm

(2 - 3 in). Next, close the rear zipper at the bottom

corner of the curtain5-8cm(2-3in).

(12) Attach the side curtain front and rear tab

snap-on retainers to the lower side retainer.

(13) Completely close both side curtain zippers.

(14) Pull downward firmly on the side curtains.

Start at one end and move toward the opposite end.

The bottom edge of the curtains must be completely

inserted in the lower side retainer channels.

(15) Release the rear window curtain straps and

insert the bottom edge into the tailgate retainer

Fig. 16 Stowed Top Cover

Fig. 17 Bow Leg and Anchor Pin

Fig. 18 Upper Side Retainer Lock Engagement

Fig. 19 Soft Top Installation

JEXTERIOR COMPONENTSÐYJ 23 - 131

Page 2050 of 2158

channel. Close the rear window curtain zippers and

attach the side snap-on retainers.

(16) Attach all the top cover snap-on retainers to

the upper side retainers located above both doors. As

necessary, slide the mating half of the snap-on re-

tainers so that they will align with the snap-on re-

tainers on the top cover. Tuck the edge of the top

cover inside the side retainer.

(17) Install the door windows by inserting the re-

tainers into the door grommets. Attach the snap-on

retainers located along the bottom edge of the win-

dow to the door retainer.

SPORT BARÐYJ

REMOVAL

(1) Disconnect sound bar. Refer to Group 8F, Audio

Systems for removal and installation procedures.

(2) Remove the screws that attach the sport bar

base plates to the floor and wheelhouse panels (Fig.

1).

(3) Remove the retaining screws and bolts, and re-

move the side bars from the windshield frame and

the sport bar (Fig. 1 and 2).

(4) Carefully lift the sport bar upward and remove

it from the vehicle.

(5) If necessary, remove the pads and covers from

the sport bar.

INSTALLATION

(1) Clean the base plate contact surface areas on

the floor and wheelhouse panels.

(2) Apply epoxy chromate primer to the attaching

screw hole edges for protection against corrosion.

(3) Position the sport bar base plates on the floor

and wheelhouse panels with the screw holes aligned.

To prevent water seepage, apply 3M Drip-

Chek Sealant (or an equivalent product) to the

underside of all the screw heads before instal-

lation.(4) Apply sealant to the underside of each base

plate attaching screw head. Install and tighten the

screws to 42 Nzm (31 ft. lbs.) torque.

(5) Position the side bars at the windshield frame.

Tighten the screws to 32 Nzm (24 ft. lbs.) torque.and

at the sport bar. Install screws and bolts in the wind-

shield frame and the sport bar. Tighten the screws to

32 Nzm (53 ft. lbs.) torque.

(6) Position the side bars at the sport bar. Install

the bolts in the sport bar. Tighten the screws to 71

Nzm (53 ft. lbs.) torque.

(7) Install sound bar.

Fig. 20 Engaging Spreader Bar Lock

Fig. 1 Sport Bar

Fig. 2 Sport Bar-To-Side Bar Bolt

23 - 132 EXTERIOR COMPONENTSÐYJJ

Page 2052 of 2158

DOORS

INDEX

page page

Beltline SealÐYJ........................ 142

Door Frame Glass Channel ReplacementÐYJ . . . 142

Door Weatherstrip Seal ReplacementÐYJ...... 142

Full-Metal Door Assist HandleÐYJ........... 136

Full-Metal Door HingesÐYJ................ 140

Full-Metal Door Key Lock CylinderÐYJ........ 139

Full-Metal Door Latch External Release

HandleÐYJ........................... 140

Full-Metal Door Latch Inside Release and Lock

HandleÐYJ........................... 137

Full-Metal Door LatchÐYJ.................. 140Full-Metal Door ServiceÐYJ................ 142

Full-Metal Door Trim PanelÐYJ.............. 137

Full-Metal Door Vent Window GlassÐYJ....... 137

Full-Metal Door WaterdamÐYJ.............. 137

Full-Metal Door Weatherstrip SealsÐYJ........ 141

Full-Metal Door Window Glass Regulator

HandleÐYJ........................... 136

Full-Metal Door Window Glass RegulatorÐYJ . . . 138

Full-Metal Door Window GlassÐYJ........... 139

Half-Metal Door Latch StrikerÐYJ............ 135

Half-Metal Soft Top DoorÐYJ............... 134

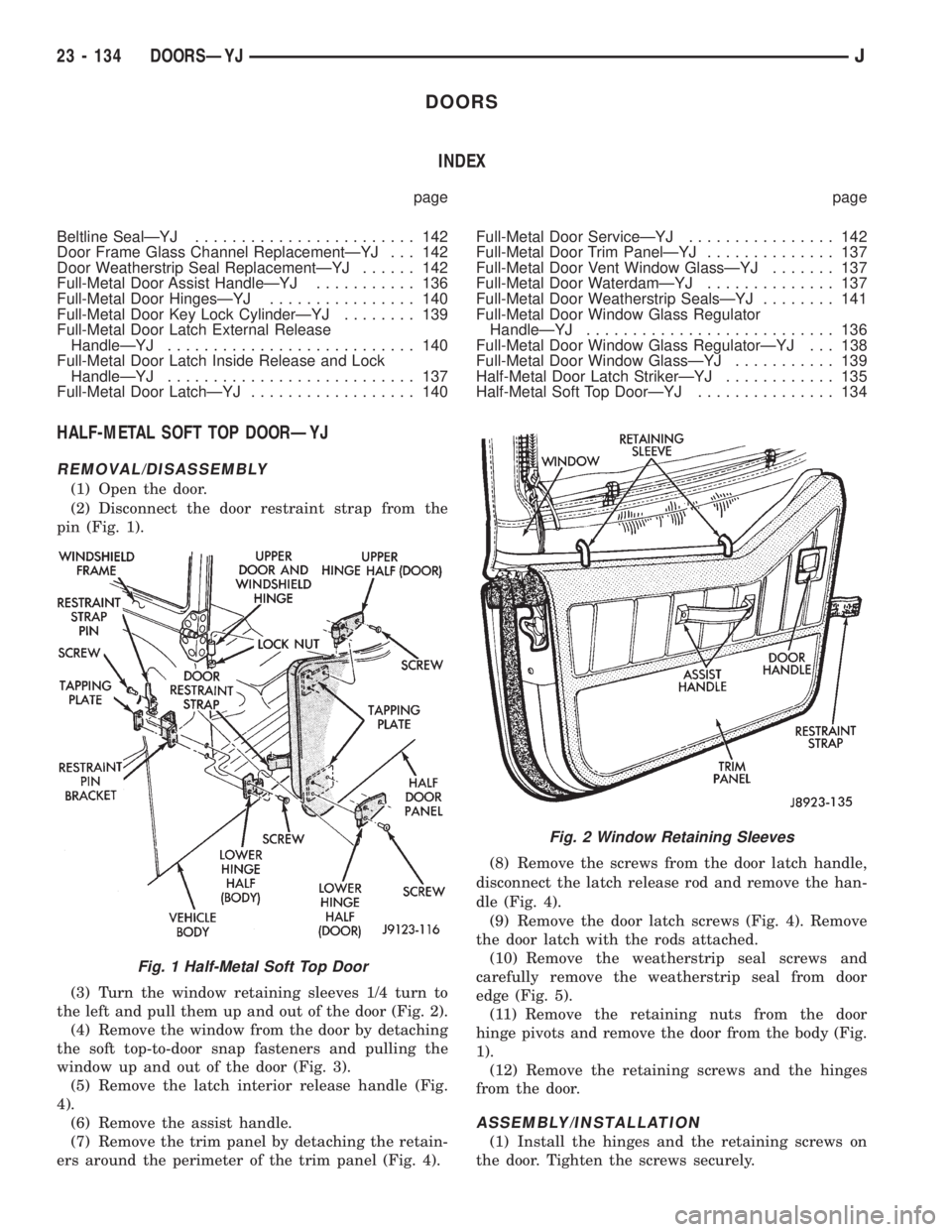

HALF-METAL SOFT TOP DOORÐYJ

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Disconnect the door restraint strap from the

pin (Fig. 1).

(3) Turn the window retaining sleeves 1/4 turn to

the left and pull them up and out of the door (Fig. 2).

(4) Remove the window from the door by detaching

the soft top-to-door snap fasteners and pulling the

window up and out of the door (Fig. 3).

(5) Remove the latch interior release handle (Fig.

4).

(6) Remove the assist handle.

(7) Remove the trim panel by detaching the retain-

ers around the perimeter of the trim panel (Fig. 4).(8) Remove the screws from the door latch handle,

disconnect the latch release rod and remove the han-

dle (Fig. 4).

(9) Remove the door latch screws (Fig. 4). Remove

the door latch with the rods attached.

(10) Remove the weatherstrip seal screws and

carefully remove the weatherstrip seal from door

edge (Fig. 5).

(11) Remove the retaining nuts from the door

hinge pivots and remove the door from the body (Fig.

1).

(12) Remove the retaining screws and the hinges

from the door.

ASSEMBLY/INSTALLATION

(1) Install the hinges and the retaining screws on

the door. Tighten the screws securely.

Fig. 1 Half-Metal Soft Top Door

Fig. 2 Window Retaining Sleeves

23 - 134 DOORSÐYJJ

Page 2056 of 2158

(4) Detach the front three inches of weatherstrip

seal from the door upper frame. Lower the division

channel and tilt it toward the rear of the door.

(5) Remove the vent window glass from the door

frame.

INSTALLATION

(1) Position the vent window glass in the door

frame.

(2) Install the division channel in the door and po-

sition the channel on the window glass.(3) Install the upper attaching screw and the lower

adjustment screw.

(4) Attach the weatherstrip seal to the door upper

frame.

(5) Water test the window and inspect for leaks.

(6) If water leakage is evident, apply windshield

sealant to seal the area or re-align the weatherstrip

seal.

(7) Test the operation and adjustment of the door

window glass.

(8) Install the door waterdam and the trim panel

(Fig. 8 and 10).

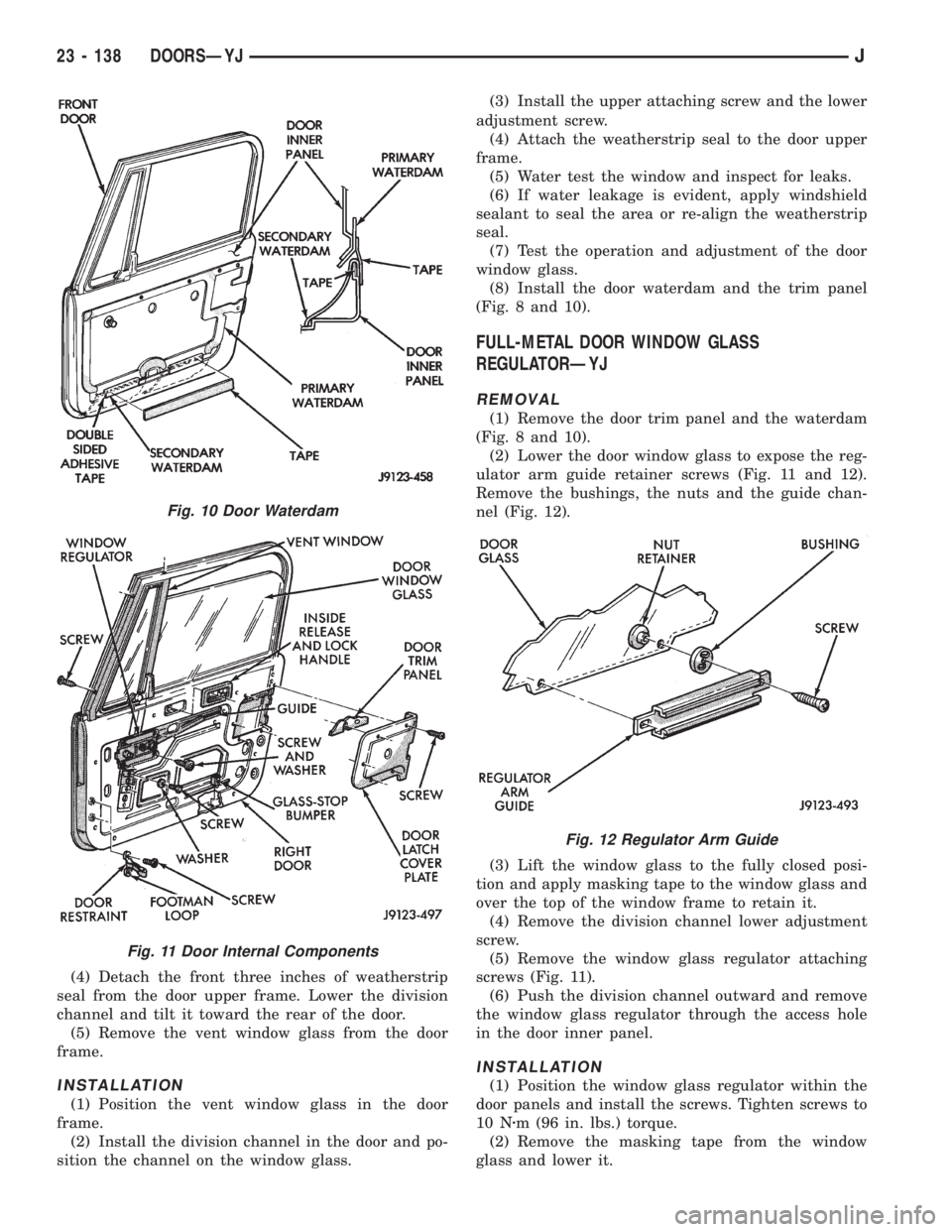

FULL-METAL DOOR WINDOW GLASS

REGULATORÐYJ

REMOVAL

(1) Remove the door trim panel and the waterdam

(Fig. 8 and 10).

(2) Lower the door window glass to expose the reg-

ulator arm guide retainer screws (Fig. 11 and 12).

Remove the bushings, the nuts and the guide chan-

nel (Fig. 12).

(3) Lift the window glass to the fully closed posi-

tion and apply masking tape to the window glass and

over the top of the window frame to retain it.

(4) Remove the division channel lower adjustment

screw.

(5) Remove the window glass regulator attaching

screws (Fig. 11).

(6) Push the division channel outward and remove

the window glass regulator through the access hole

in the door inner panel.

INSTALLATION

(1) Position the window glass regulator within the

door panels and install the screws. Tighten screws to

10 Nzm (96 in. lbs.) torque.

(2) Remove the masking tape from the window

glass and lower it.

Fig. 10 Door Waterdam

Fig. 11 Door Internal Components

Fig. 12 Regulator Arm Guide

23 - 138 DOORSÐYJJ

Page 2057 of 2158

(3) Slide the regulator arm guide onto the regula-

tor arm and position the guide on the window glass

(Fig. 12). Install the nuts, bushings and screws.

(4) Install the division channel lower adjustment

screw.

(5) Test the window glass for proper operation.

(6) Install the door waterdam and the trim panel

(Fig. 8 and 10).

FULL-METAL DOOR WINDOW GLASSÐYJ

ADJUSTMENT

One adjustment location provides amount of effort

required to raise and lower the door window glass.

The door window glass division channel is adjustable

fore and aft at the lower attaching location.

(1) Remove the door trim panel and the waterdam

(Fig. 8 and 10).

(2) Loosen channel lower adjustment screw and

move the division channel fore or aft to obtain the

desired door window glass operation.

Movement of the division channel fore or aft

will decrease or increase the free-play between

the channels.

(3) Tighten the division channel lower adjustment

screw.

(4) Install the door waterdam and the trim panel

(Fig. 8 and 10).

REMOVAL

(1) Remove the door trim panel and the waterdam

(Fig. 8 and 10).

(2) Remove the window glass down-stop bumper

(Fig. 11).

(3) Remove the screws that attach the regulator

arm guide to the window glass. Remove the screws,

bushings, nuts and the guide from the glass (Fig. 11).

(4) Lower the window glass to the bottom of the

door.

(5) Remove the division channel upper attaching

screw and the lower adjustment screw. Detach the

front 3 inches of window glass weatherstrip seal from

the door upper frame.

(6) Separate the division channel from the front

window glass rubber seal. Pull the division channel

up and in toward the inside of vehicle.

(7) Raise and tilt the window glass toward the

hinge side of the door and disengage it from the rear

channel.

(8) Pull the window glass up and out of the door

panel.

INSTALLATION

(1) Lower the window glass into the door, while in-

serting the window glass into the front and rear

channels.

(2) Slide the window glass downward to the bottom

of the door panel.(3) Lower the division channel into the door and

position the window glass securely in the channel.

(4) Install the weatherstrip seal in the upper door

frame and install the upper attaching screw and the

lower adjustment screw.

(5) Slide the guide onto the regulator arm and po-

sition the guide on the window glass. Install the re-

taining nuts, bushings and screws (Fig. 12).

(6) Install the window glass down-stop bumper

(Fig. 11).

(7) Test the window operation for proper adjust-

ment.

(8) Install the door waterdam and the trim panel

(Fig. 8 and 10).

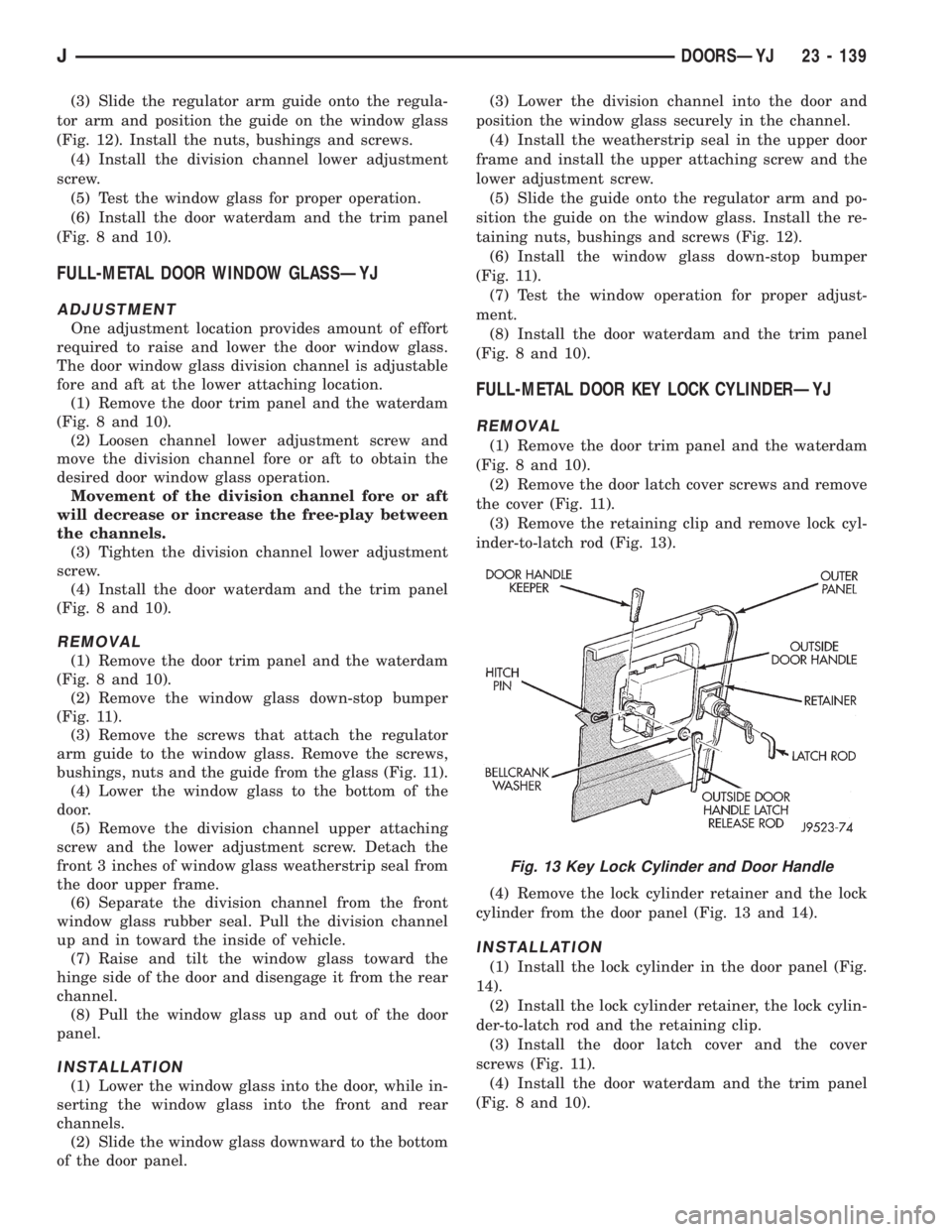

FULL-METAL DOOR KEY LOCK CYLINDERÐYJ

REMOVAL

(1) Remove the door trim panel and the waterdam

(Fig. 8 and 10).

(2) Remove the door latch cover screws and remove

the cover (Fig. 11).

(3) Remove the retaining clip and remove lock cyl-

inder-to-latch rod (Fig. 13).

(4) Remove the lock cylinder retainer and the lock

cylinder from the door panel (Fig. 13 and 14).

INSTALLATION

(1) Install the lock cylinder in the door panel (Fig.

14).

(2) Install the lock cylinder retainer, the lock cylin-

der-to-latch rod and the retaining clip.

(3) Install the door latch cover and the cover

screws (Fig. 11).

(4) Install the door waterdam and the trim panel

(Fig. 8 and 10).

Fig. 13 Key Lock Cylinder and Door Handle

JDOORSÐYJ 23 - 139

Page 2059 of 2158

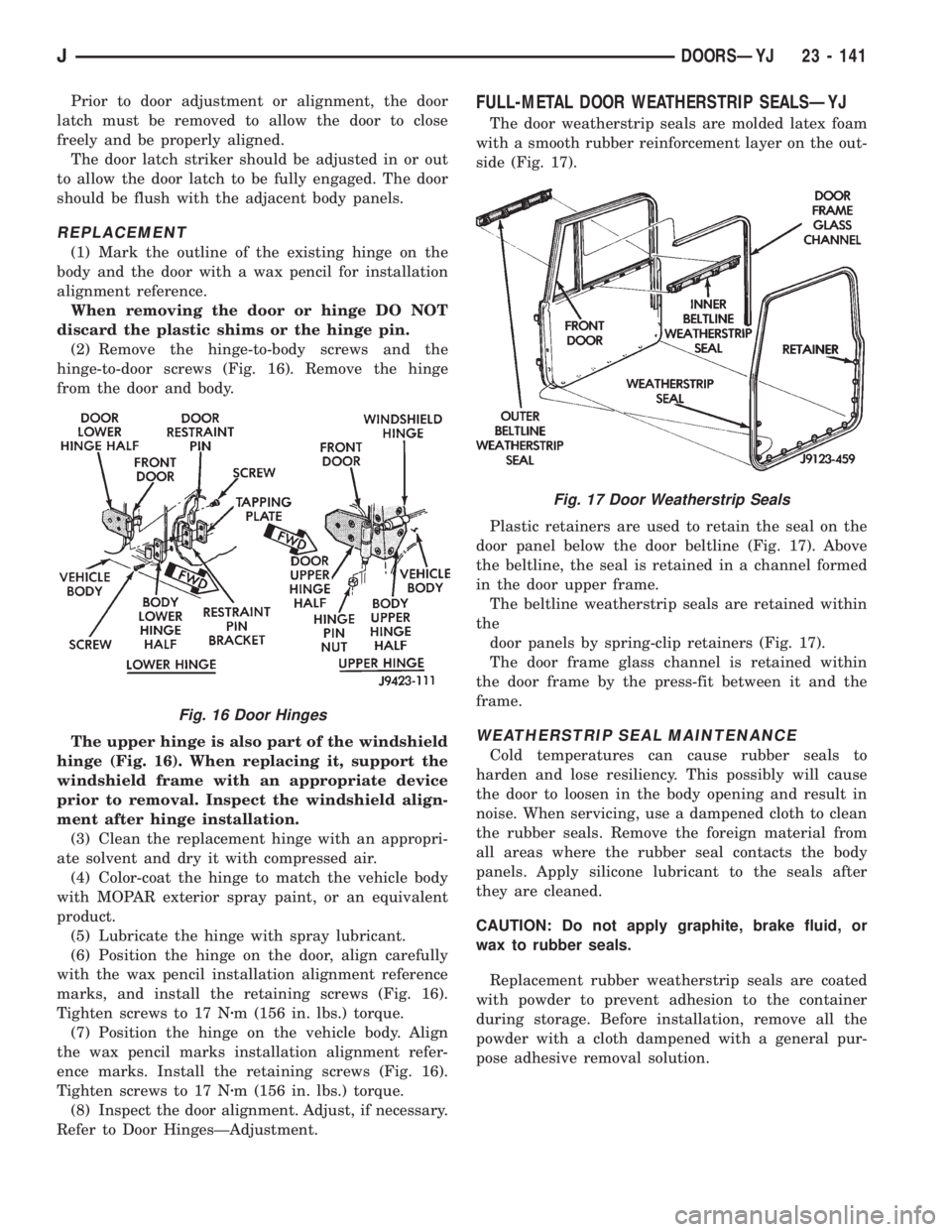

Prior to door adjustment or alignment, the door

latch must be removed to allow the door to close

freely and be properly aligned.

The door latch striker should be adjusted in or out

to allow the door latch to be fully engaged. The door

should be flush with the adjacent body panels.

REPLACEMENT

(1) Mark the outline of the existing hinge on the

body and the door with a wax pencil for installation

alignment reference.

When removing the door or hinge DO NOT

discard the plastic shims or the hinge pin.

(2) Remove the hinge-to-body screws and the

hinge-to-door screws (Fig. 16). Remove the hinge

from the door and body.

The upper hinge is also part of the windshield

hinge (Fig. 16). When replacing it, support the

windshield frame with an appropriate device

prior to removal. Inspect the windshield align-

ment after hinge installation.

(3) Clean the replacement hinge with an appropri-

ate solvent and dry it with compressed air.

(4) Color-coat the hinge to match the vehicle body

with MOPAR exterior spray paint, or an equivalent

product.

(5) Lubricate the hinge with spray lubricant.

(6) Position the hinge on the door, align carefully

with the wax pencil installation alignment reference

marks, and install the retaining screws (Fig. 16).

Tighten screws to 17 Nzm (156 in. lbs.) torque.

(7) Position the hinge on the vehicle body. Align

the wax pencil marks installation alignment refer-

ence marks. Install the retaining screws (Fig. 16).

Tighten screws to 17 Nzm (156 in. lbs.) torque.

(8) Inspect the door alignment. Adjust, if necessary.

Refer to Door HingesÐAdjustment.

FULL-METAL DOOR WEATHERSTRIP SEALSÐYJ

The door weatherstrip seals are molded latex foam

with a smooth rubber reinforcement layer on the out-

side (Fig. 17).

Plastic retainers are used to retain the seal on the

door panel below the door beltline (Fig. 17). Above

the beltline, the seal is retained in a channel formed

in the door upper frame.

The beltline weatherstrip seals are retained within

the

door panels by spring-clip retainers (Fig. 17).

The door frame glass channel is retained within

the door frame by the press-fit between it and the

frame.

WEATHERSTRIP SEAL MAINTENANCE

Cold temperatures can cause rubber seals to

harden and lose resiliency. This possibly will cause

the door to loosen in the body opening and result in

noise. When servicing, use a dampened cloth to clean

the rubber seals. Remove the foreign material from

all areas where the rubber seal contacts the body

panels. Apply silicone lubricant to the seals after

they are cleaned.

CAUTION: Do not apply graphite, brake fluid, or

wax to rubber seals.

Replacement rubber weatherstrip seals are coated

with powder to prevent adhesion to the container

during storage. Before installation, remove all the

powder with a cloth dampened with a general pur-

pose adhesive removal solution.

Fig. 16 Door Hinges

Fig. 17 Door Weatherstrip Seals

JDOORSÐYJ 23 - 141