battery KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 966 of 1575

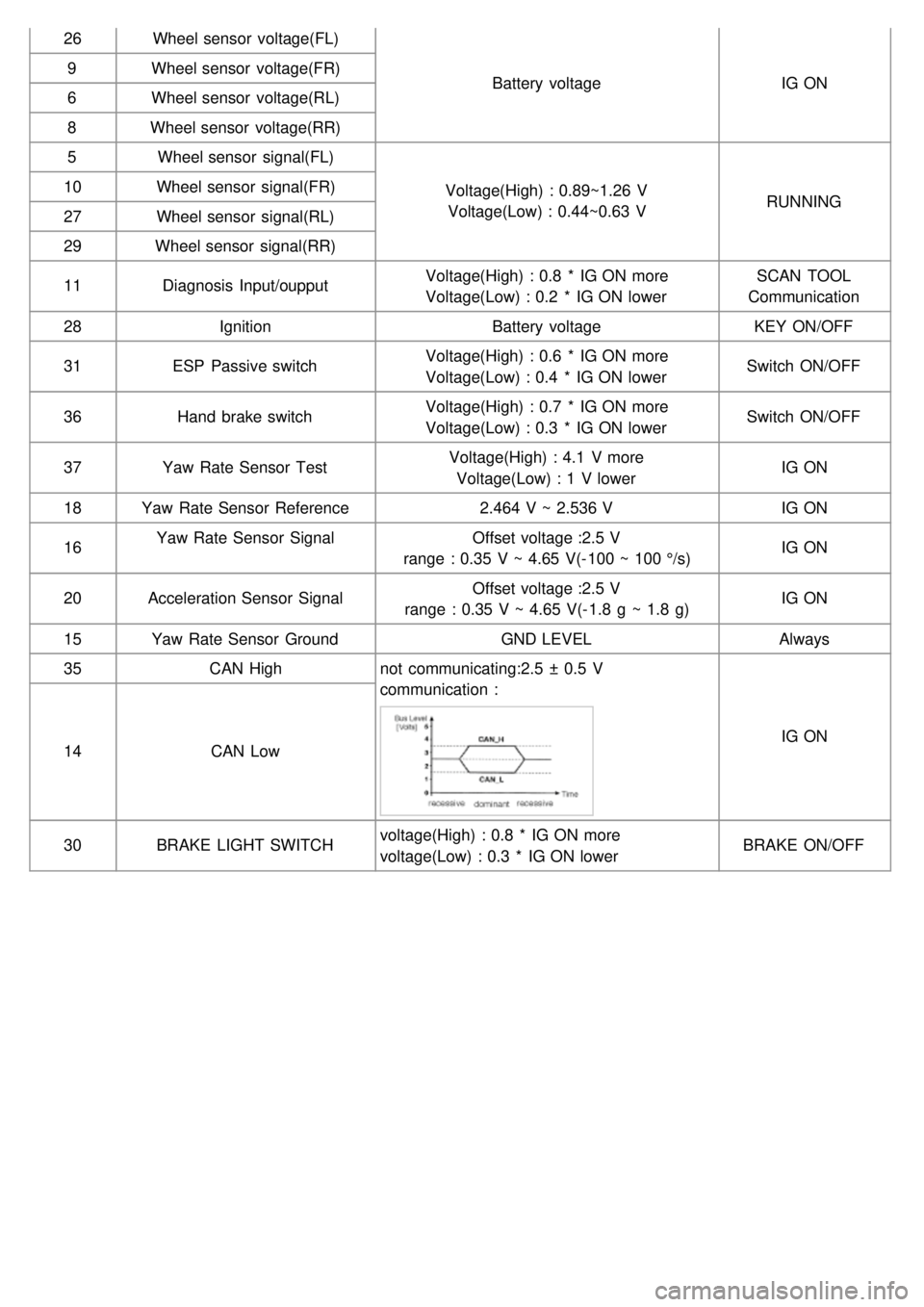

26Wheel sensor voltage(FL)

Battery voltageIG ON

9

Wheel sensor voltage(FR)

6 Wheel sensor voltage(RL)

8 Wheel sensor voltage(RR)

5 Wheel sensor signal(FL)

Voltage(High) : 0.89~1.26 VVoltage(Low) : 0.44~0.63 V RUNNING

10

Wheel sensor signal(FR)

27 Wheel sensor signal(RL)

29 Wheel sensor signal(RR)

11 Diagnosis Input/oupput Voltage(High) : 0.8 * IG ON more

Voltage(Low) : 0.2 * IG ON lower SCAN TOOL

Communication

28 Ignition Battery voltageKEY ON/OFF

31 ESP Passive switch Voltage(High) : 0.6 * IG ON more

Voltage(Low) : 0.4 * IG ON lower Switch ON/OFF

36 Hand brake switch Voltage(High) : 0.7 * IG ON more

Voltage(Low) : 0.3 * IG ON lower Switch ON/OFF

37 Yaw Rate Sensor Test Voltage(High) : 4.1 V more

Voltage(Low) : 1 V lower IG ON

18 Yaw Rate Sensor Reference 2.464 V ~ 2.536 VIG ON

16 Yaw Rate Sensor Signal

Offset voltage :2.5 V

range : 0.35 V ~ 4.65 V(- 100 ~ 100 °/s) IG ON

20 Acceleration Sensor Signal Offset voltage :2.5 V

range : 0.35 V ~ 4.65 V(- 1.8 g ~ 1.8 g) IG ON

15 Yaw Rate Sensor Ground GND LEVELAlways

35 CAN High not communicating:2.5 ± 0.5 V

communication :

IG ON

14 CAN Low

30 BRAKE LIGHT SWITCH voltage(High) : 0.8 * IG ON more

voltage(Low) : 0.3 * IG ON lower BRAKE ON/OFF

Page 1152 of 1575

2007 > 2.7L V6 GASOLINE >

GENERAL TROUBLESHOOTING INFORMATION

BEFORE TROUBLESHOOTING

1. Check applicable fuses in the appropriate fuse/relay box.

2. Check the battery for damage, state of charge, and clean and tight connections.

a.Do not quick- charge a battery unless the battery ground cable has been disconnected, otherwise you will

damage the generator diodes.

b. Do not attempt to crank the engine with the battery ground cable loosely connected or you will severely

damage the wiring.

3. Check the generator belt tension.

HANDLING CONNECTORS

1.Make sure the connectors are clean and have no loose wire terminals.

2. Make sure multiple cavity connectors are packed with grease (except watertight connectors).

3. All connectors have push - down release type locks (A).

4.Some connectors have a clip on their side used to attach them to a mount bracket on the body or on another

component. This clip has a pull type lock.

5. Some mounted connectors cannot be disconnected unless you first release the lock and remove the connector from

its mount bracket (A).

6.Never try to disconnect connectors by pulling on their wires; pull on the connector halves instead.

7. Always reinstall plastic covers.

Page 1175 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

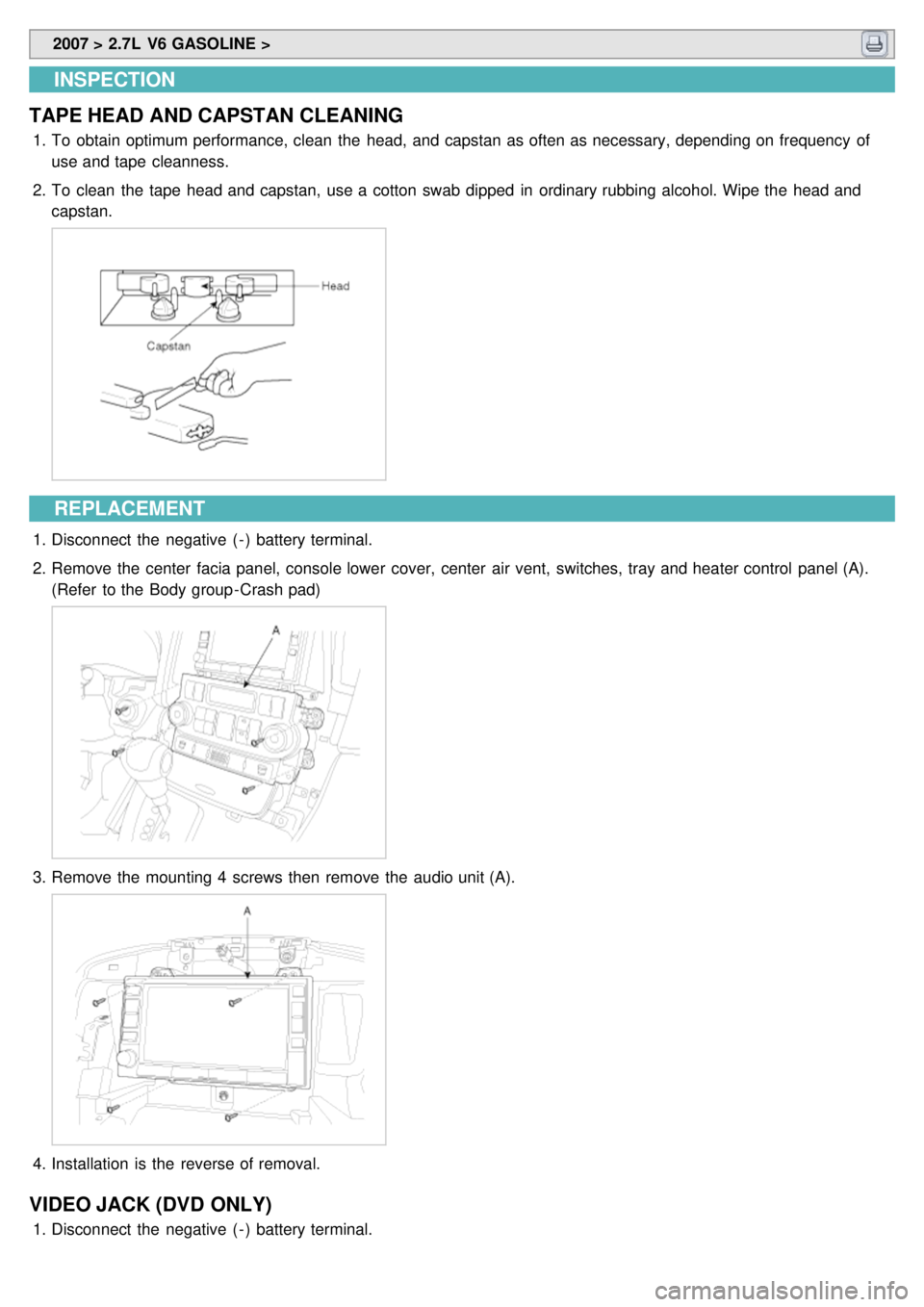

TAPE HEAD AND CAPSTAN CLEANING

1. To obtain optimum performance, clean the head, and capstan as often as necessary, depending on frequency of

use and tape cleanness.

2. To clean the tape head and capstan, use a cotton swab dipped in ordinary rubbing alcohol. Wipe the head and

capstan.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center facia panel, console lower cover, center air vent, switches, tray and heater control panel (A).

(Refer to the Body group - Crash pad)

3.Remove the mounting 4 screws then remove the audio unit (A).

4.Installation is the reverse of removal.

VIDEO JACK (DVD ONLY)

1.Disconnect the negative ( - ) battery terminal.

Page 1176 of 1575

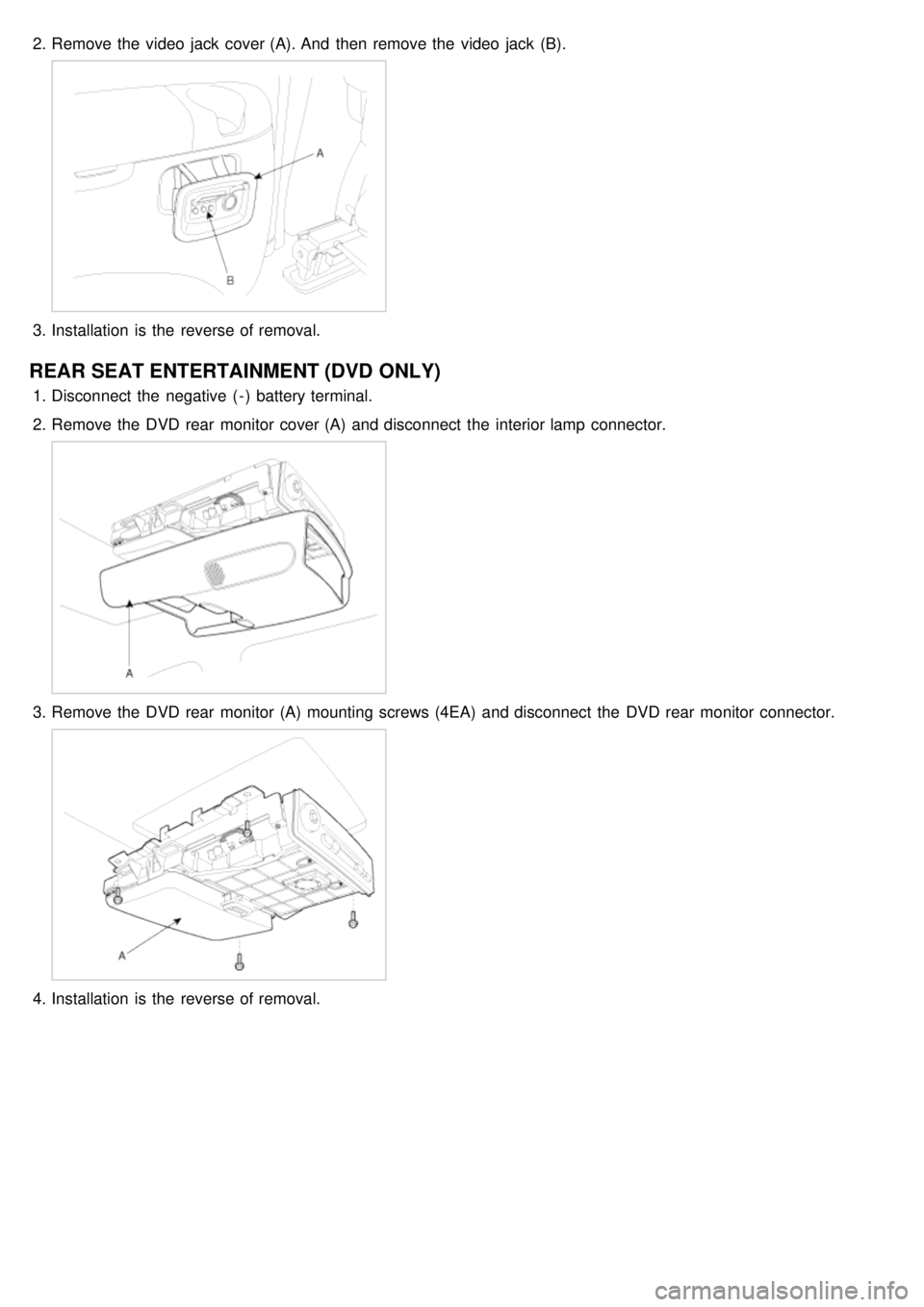

2.Remove the video jack cover (A). And then remove the video jack (B).

3.Installation is the reverse of removal.

REAR SEAT ENTERTAINMENT (DVD ONLY)

1.Disconnect the negative ( - ) battery terminal.

2. Remove the DVD rear monitor cover (A) and disconnect the interior lamp connector.

3.Remove the DVD rear monitor (A) mounting screws (4EA) and disconnect the DVD rear monitor connector.

4.Installation is the reverse of removal.

Page 1189 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the driver airbag module(A). (Refer to the airbag group).

3.Remove the audio remote control switch (A) after removing the steering wheel remote control switch connector and

2 screws.

4.Installation is the reverse of removal.

INSPECTION

1.Check for resistance between No.2 and No.3 terminals in each switch position.

Switch Connector terminal Resistance (±5%)

MODE 2 - 3 (Left) 2.11 kΩ

MUTE 2 - 3 (Left) 3.11 kΩ

VOLUME UP 2 - 3 (Left) 4.61 kΩ

VOLUME DOWN 2 - 3 (Left)5.81 kΩ

Page 1194 of 1575

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the steering column upper and lower shrouds (A) after removing 3 screws.

3.Disconnect the light switch(A) connector and pin(B).

[LHD]

[RHD]

Page 1198 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Remove the bolt from the high pitch horn and the low pitch horn and disconnect the horn connector, then remove

the horn.

2.Installation is the reverse of removal.

INSPECTION

Test the horn by connecting battery voltage to the terminal 1, and ground terminal 2.

The horn should make a sound. If the horn fails to make a sound, replace it.

ADJUSTMENT

Operate the horn, and adjust the tone to a suitable level by turning the adjusting screw.

After adjustment, apply a small amount of paint around the screw head to keep it from loosening.

Page 1202 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

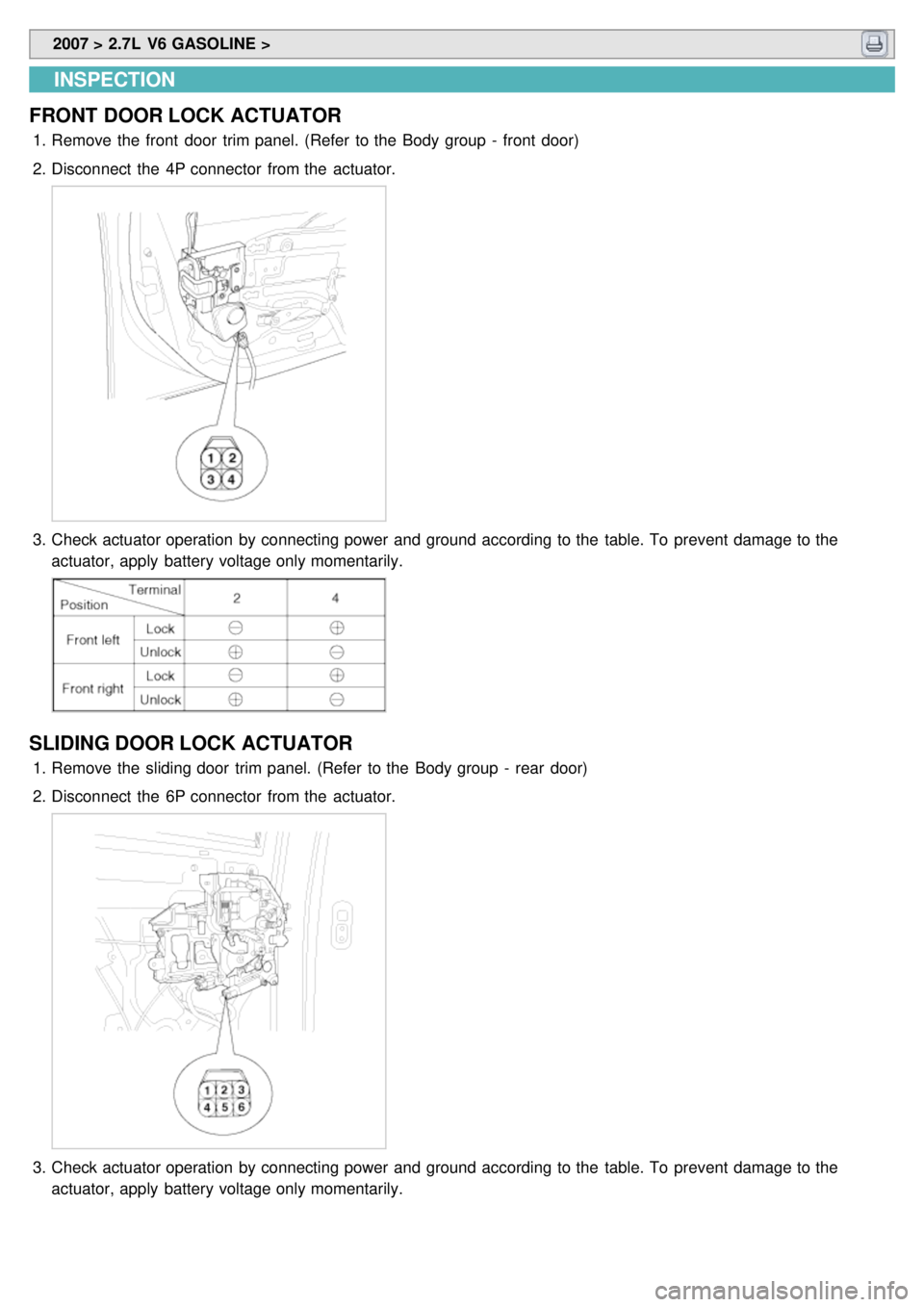

FRONT DOOR LOCK ACTUATOR

1. Remove the front door trim panel. (Refer to the Body group - front door)

2. Disconnect the 4P connector from the actuator.

3.Check actuator operation by connecting power and ground according to the table. To prevent damage to the

actuator, apply battery voltage only momentarily.

SLIDING DOOR LOCK ACTUATOR

1.Remove the sliding door trim panel. (Refer to the Body group - rear door)

2. Disconnect the 6P connector from the actuator.

3.Check actuator operation by connecting power and ground according to the table. To prevent damage to the

actuator, apply battery voltage only momentarily.

Page 1203 of 1575

TAILGATE LOCK ACTUATOR (5DOORS)

1.Remove the tailgate trim panel. (Refer to the Body group - tailgate)

2. Disconnect the 6P connector from the actuator.

3.Check actuator operation by connecting power and ground according to the table. To prevent damage to the

actuator, apply battery voltage only momentarily.

FRONT DOOR LOCK SWITCH

1.Remove the front door trim panel. (Refer to the Body group - front door)

2. Disconnect the 4P connector from the actuator.

3.Check for continuity between the terminals in each switch position according to the table.

Page 1206 of 1575

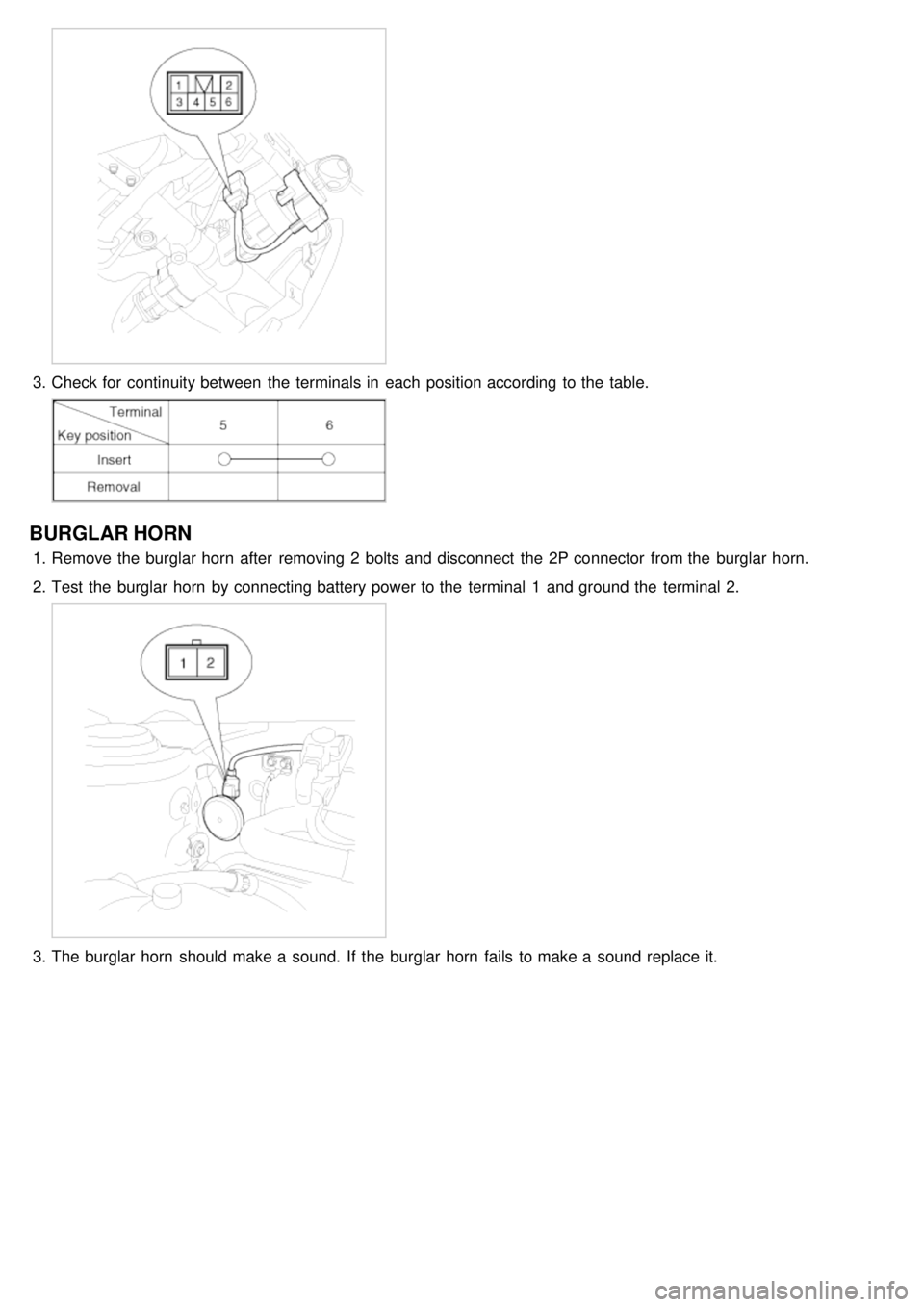

3.Check for continuity between the terminals in each position according to the table.

BURGLAR HORN

1.Remove the burglar horn after removing 2 bolts and disconnect the 2P connector from the burglar horn.

2. Test the burglar horn by connecting battery power to the terminal 1 and ground the terminal 2.

3.The burglar horn should make a sound. If the burglar horn fails to make a sound replace it.