torque KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1344 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal..

2. Remove the rear trim panel (Refer to the Body group - interior trim)

3. Remove the connectors and mounting bolts (2EA) from the power sliding door unit(A). And then remove the power

sliding door control module (B).

TORQUE 0.25 - 0.35N.m(0.025- 0.035Kg.m)

4.Installation is the reverse of removal.

a.A learn cycle must be performed whenever the power is removed.

b. Check the normal operation whenever a power sliding door component is removed or replaced. If the

chime sound is heard, check the DTC, wiring harness and cable connections.

Page 1380 of 1575

4.Select the sensor output. And then check the clutch feedback sensor output while operating power tailgate in

power mode.

※ Above voltage and numerical value may be different from the real value.

5. Change the drive unit, if there is no change during operation.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the third, fourth seat (Refer to the Body group - seat)

3. Remove the D pillar and luggage side trim (Refer to the Body group - Interior trim).

4. Use a small screw driver to loosen clip (A). But do not remove power tailgate push rod (B).

5.Remove the power tail gate motor mounting bolts (3EA) and connectors (4EA). And then remove the power tail

gate drive unit(A).

TORQUE : 22- 27N.m(2.2- 2.7Kg.m)

Page 1382 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the third, fourth seat (Refer to the Body group - seat)

3. Remove the D pillar and luggage side trim (Refer to the Body group - Interior trim).

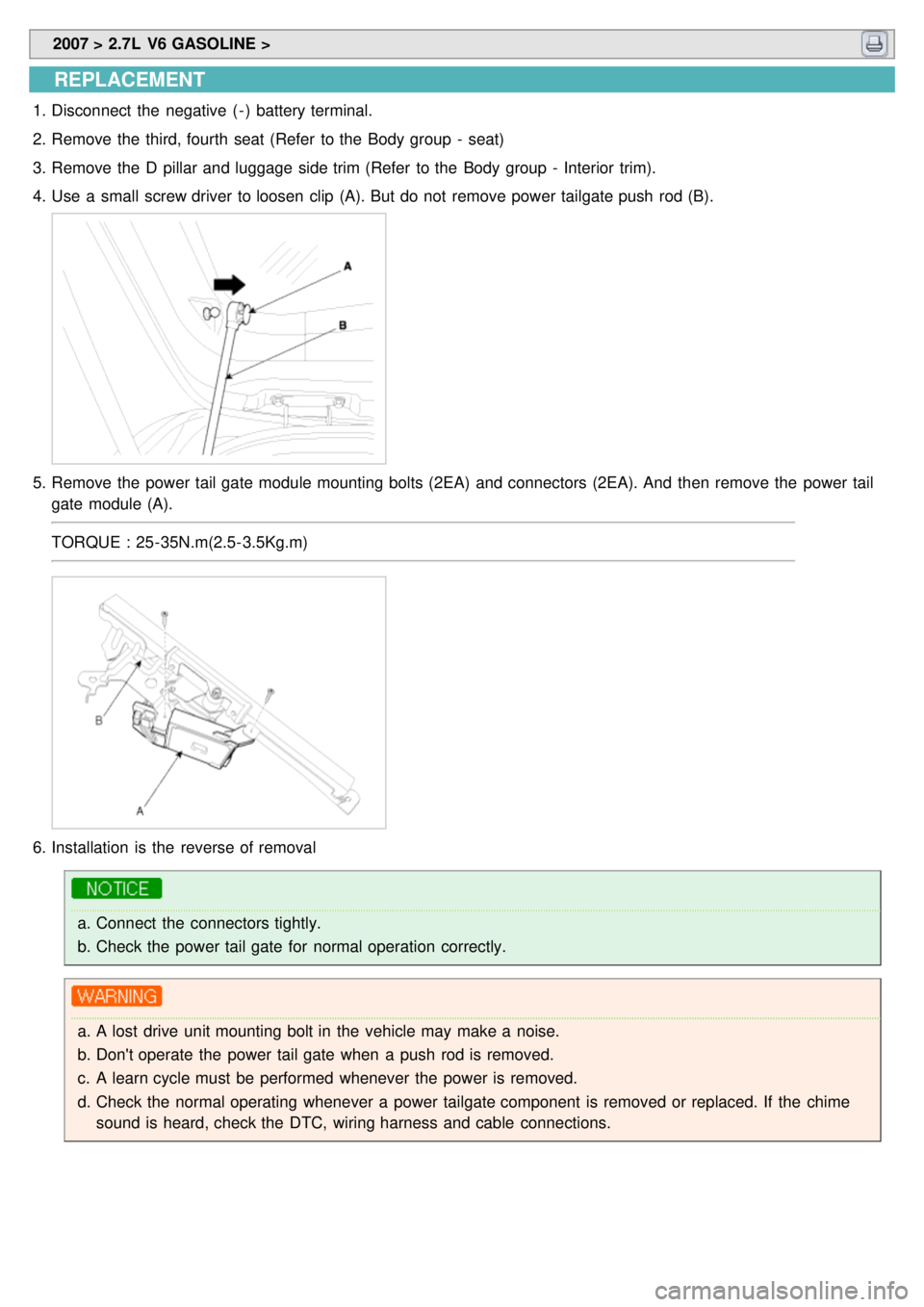

4. Use a small screw driver to loosen clip (A). But do not remove power tailgate push rod (B).

5.Remove the power tail gate module mounting bolts (2EA) and connectors (2EA). And then remove the power tail

gate module (A).

TORQUE : 25- 35N.m(2.5- 3.5Kg.m)

6.Installation is the reverse of removal

a.Connect the connectors tightly.

b. Check the power tail gate for normal operation correctly.

a.A lost drive unit mounting bolt in the vehicle may make a noise.

b. Don't operate the power tail gate when a push rod is removed.

c. A learn cycle must be performed whenever the power is removed.

d. Check the normal operating whenever a power tailgate component is removed or replaced. If the chime

sound is heard, check the DTC, wiring harness and cable connections.

Page 1428 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the windshield wiper arm and blade after removing the mounting nut (A).

TORQUE: 28~32 Nm (2.8~3.2 kgf.m, 20~23.1 lbf.ft)

2.Remove the weather strip and the cowl top cover (A) after removing 4 fasteners.

3.Remove the windshield wiper motor and linkage assembly after removing 4 bolts. Disconnect the wiper motor

connector (A) and windshield deicer connector (B) from the wiper motor & linkage assembly.

Torque: 7 - 11Nm (0.7- 1.1, kgf.m, 5.0 - 7.9 lbf.ft)

4.Installation is the reverse of removal.

INSTALLATION

1.Install the wiper arm and blade to the specified position.

Specified position AB

Page 1440 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the tail gate trim (Refer to the Body group - Tail gate).

2. Detach the wiper cap (A), and then remove the rear wiper arm after removing the mounting nut (B).

Tightening torque Nut(B) :

10~13 Nm (1.0~1.3 kgf.m, 7.2~9.4 lbf.ft)

3.Detach the wiper motor cover, and then remove the rear wiper cap & pad (B) after removing the mounting nut (A).

During installation, of the rear wiper cap and pad, ensure the arrow on the cap assembly is pointed upwards.

4.Disconnect the rear wiper motor connector (A) then remove the rear wiper motor (B) after removing 2 bolts.

Tightening torque Nut :

7~11 Nm (0.7~1.1 kgf.m, 5.1~8.0lbf.ft)

Page 1567 of 1575

5.Tighten the clutch cover.

TORQUE:

24.5~35.3Nm (250~360kgf.cm, 18.1~26.0lb - ft) (6EA)

When installing the clutch cover, tighten the bolts in diagonal directions not to be bent or twisted.

* Possible problems when not following

a. When tightening the bolt completely at a time: the clutch cover can be twisted and vibration can occur.

b. On vehicles with self adjusting clutches, it is necessary to follow this caution.

c. Not following tightening torque: There can be bad torque transmission in clutch and relaxation possibility of

bolts.

INSPECTION

1.Inspect diaphragm spring wear which is in contact with a concentric slave cylinder bearing.

Page 1571 of 1575

5.Remove the pin and washer which connect the clutch pedal with the clutch master cylinder.

6. Remove the clutch master cylinder. It can be helpful to do this step after removing the clutch pedal mounting

bracket.

INSTALLATION

Installation is in the reverse order of removal.

After installation, bleed the clutch hydaulic system.

CONCENTRIC SLAVE CYLINDER AIR BLEEDING PROCEDURE

1.After disconnecting a cap from the concentric slave cylinder air bleeder, insert a vinyl hose in the plug.

2. Loosening the plug screw, press and release the clutch pedal about 10 times.

Hold the air bleeder body not to rotate with a spanner(A). The holding is needed when the plug loosened or

tightened.

3. Tighten the plug during the clutch pedal pressed. Afterwards, raise the pedal with a hand.

TORQUE :

25~29Nm (250~290Kgf.cm, 18.2~21.1lb - ft)

4. After pressing the clutch pedal 3 times more, loosen the plug and retighten it with the pedal pressed. Raise it

again, then.

5. Repeat the step 4 two or three times. (until there is no bubble in the fluid)

a.Do not clamp the pipe of a concentric slave cylinder.

b. Be careful not to damage O - rings.

Page 1573 of 1575

2007 > 2.7L V6 GASOLINE >

ADJUSTMENT PROCEDURE

IGNITION LOCK SWITCH

1. Disconnect 2P- connector from a ignition lock switch.

2. Disconnect the ignition lock switch. (if you can install a tester with the switch fixed, this step can be omissible)

3. Check for continuity between terminals. (refer to the table below)

Clutch pedal position Ignition lock switch Continuity

Released ReleasedNO

Pressed PressedYES

If there is difference between what tested and the table above, replace the ignition lock switch with a new one.

If not, install the ignition lock switch and adjust the clutch pedal.

TORQUE :

8~10Nm (80~100kgf.cm, 5.8~7.2lb- ft)

Clutch pedal and Ignition lock switch

a. Inspect a ignition lock switch.

b. Remove the driver's seat mat to adjust a clutch pedal.

c. No gap between a clutch master cylinder pistion and push rod can cause clutch slip.

1. Loosen and draw out the bolt until it is off the pedal surface.

2. Push and pull a clutch master cylinder push rod to satisfy the specification below.

Specification:

Clutch pedal stroke(A) - 150mm(5.91in)

Clutch pedal free play(B) - 6~13mm(0.24~0.51in)

Clutch pedal distance - 234.7mm(9.24in)

3.With no pressure on a clutch pedal, tighten the bolt until it contacts on the pedal.

4. Fix the bolt with a nut.

TORQUE :

14~20Nm (140~200kgf.cm, 10.2~14.5lb - ft)

Page 1574 of 1575

5.Press the clutch pedal to the seat ground.

6. Adjust the ignition lock switch position with the pedal a little(23~26mm) raised.

7. Install the ignition lock switch firmly.

TORQUE:

8~10Nm (80~100kgf.cm, 5.8~7.2lb- ft)

REPLACEMENT

a.Inspect the continuity of the ignition lock switch.

b. Remove the floor mat before adjusting the clutch pedal.

1. Remove the ignition lock switch.

2. Remove the snap pin and the clevis pin(A) connecting the clutch master cylinder push rod and the clutch pedal.

3.Remove the clutch master cylinder mounting nut(A,B) and the clutch pedal mounting nut(C).

Page 1575 of 1575

4.Remove the clutch pedal.

5. Install a new one by tightening the bolts of the clutch pedal bracket and master cylinder .

TORQUE :

19~26 Nm(19~260 kgf.cm, 13.8~18.9 Ib- ft)(Clutch pedal bracket)

12~16 Nm(120~160 kgf.cm, 8.7~11.6 Ib- ft)(Clutch master cylinder)

6. Grease the clevis pin and insert it and the snap pin.

7. Adjust the clutch pedal and the ignition lock switch.