air condition KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 371 of 1575

![KIA CARNIVAL 2007 Owners Manual 2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

Automatic transaxle fluid

INSPECTION 1. Drive the vehicle until the fluid reaches normal operating temperature [70~80°C].

2. Place the KIA CARNIVAL 2007 Owners Manual 2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

Automatic transaxle fluid

INSPECTION 1. Drive the vehicle until the fluid reaches normal operating temperature [70~80°C].

2. Place the](/img/2/57045/w960_57045-370.png)

2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

Automatic transaxle fluid

INSPECTION 1. Drive the vehicle until the fluid reaches normal operating temperature [70~80°C].

2. Place the vehicle on a level surface.

3. Move the selector lever through all gear positions. This will fill the torque converter and the hudraulic system with

fluid and move the selector lever to the "N" (Neutral) or "P"(Park) position.

4. Before removing the oil level gauge, wipe all contaminants from around the oil level gauge. Then take out the oil

level gauge and check the condition of the fluid.

If the fluid smells as if it is burning, it means that the fluid has been contaminated by fine particles from the

bushes and friction materials, a transaxle overhaul may be necessary.

5. Check that the fluid level is at the HOT mark on the oil level gauge. If the fluid level is low, add automatic transaxle

fluid until the level reaches the "HOT" mark.

Auto transaxle fluid:

DIAMOND ATF SP - III, SK ATF SP - III

Quantity : 8.5ℓ (9.0 US qt, 7.5 lmp.qt)

Low fluid level can cause a variety of a abnormal conditions because it allows the pump to take in air along

with fluid. Air trapped in the hydraulic system forms bubbles, which are compressable. Therefore, pressures

will be erratic, causing delayed shifting ,slipping clutches and brakes, etc. Improper filling can also raise fluid

level too high. When the transaxle has too much fluid, gears churn up foam and acuise the same conditions

which occur with low fluid level, resulting in accelerated deterioration of automatic transaxle fluid. In either

case, air bubbles can cause overheating, and fluid oxidation, which can interfere with normal valve, clutch, and

brake operation. Foaming can also result in fluid escaping from the transaxle vent where it may be mistaken

for a leak.

6. Insert the oil level gauge(A) securely.

When new, automatic transmission fluid should be red. The red dye is added so the assembly plant can

identify it as transmission fluid and distinguish it from engine oil or antifreeze. The red dye, which is not an

indicator of fluid quality, is not permanent. As the vehicle is driven the transmission fluid will begin to look

darker. The color may eventually appear light brown.

Page 487 of 1575

2007 > 2.7L V6 GASOLINE >

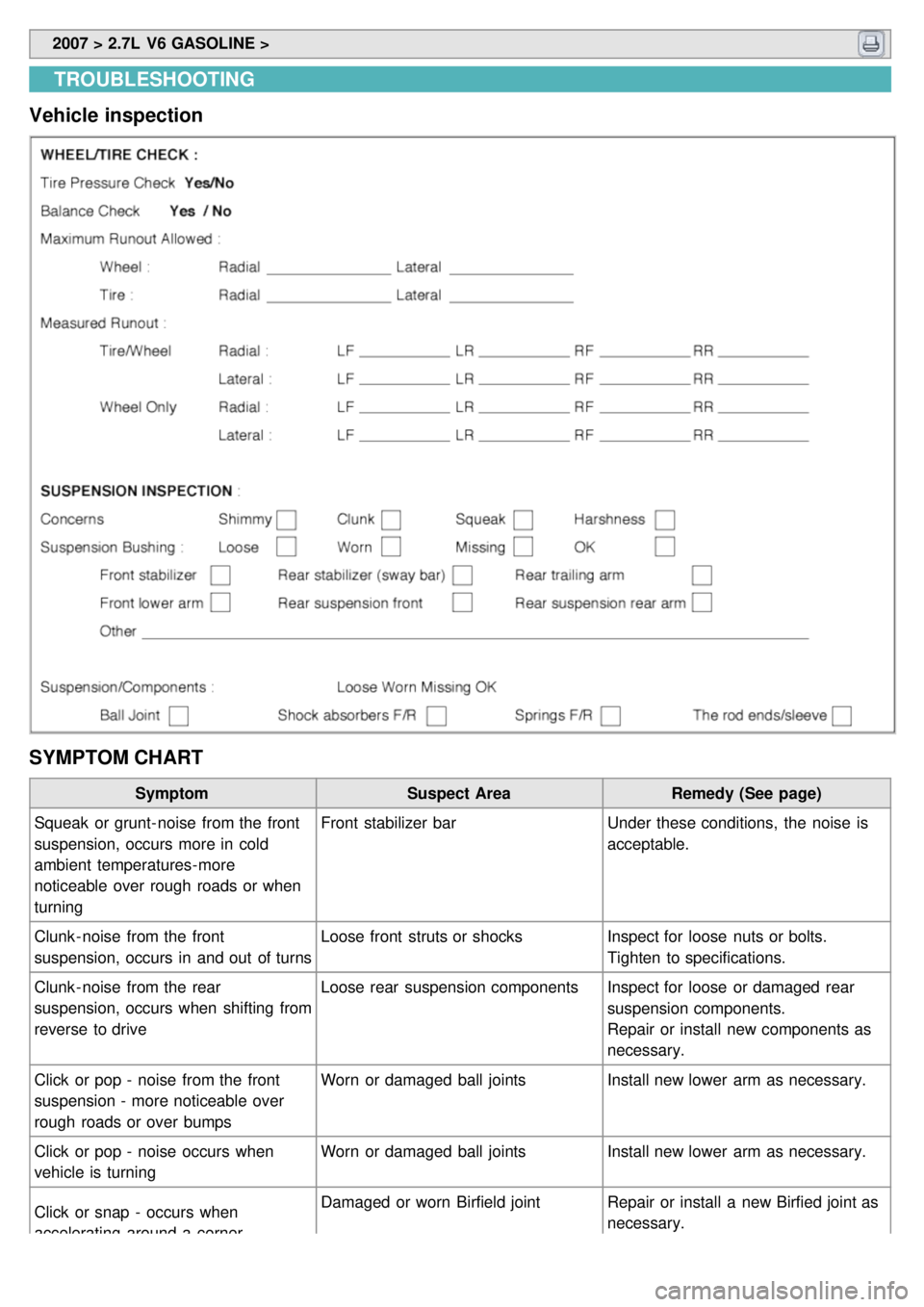

TROUBLESHOOTING

Vehicle inspection

SYMPTOM CHART

Symptom Suspect AreaRemedy (See page)

Squeak or grunt- noise from the front

suspension, occurs more in cold

ambient temperatures- more

noticeable over rough roads or when

turning Front stabilizer bar

Under these conditions, the noise is

acceptable.

Clunk - noise from the front

suspension, occurs in and out of turns Loose front struts or shocks

Inspect for loose nuts or bolts.

Tighten to specifications.

Clunk - noise from the rear

suspension, occurs when shifting from

reverse to drive Loose rear suspension components

Inspect for loose or damaged rear

suspension components.

Repair or install new components as

necessary.

Click or pop - noise from the front

suspension - more noticeable over

rough roads or over bumps Worn or damaged ball joints

Install new lower arm as necessary.

Click or pop - noise occurs when

vehicle is turning Worn or damaged ball joints

Install new lower arm as necessary.

Click or snap - occurs when

accelerating around a corner Damaged or worn Birfield joint

Repair or install a new Birfied joint as

necessary.

See DS group - driveshaft.

Page 488 of 1575

accelerating around a cornerSee DS group - driveshaft.

Front suspension noise - A squeak,

creak, or rattle noise - occurs mostly

over bumps or rough roads Steering components

Loose or bent front struts or shock

absorbers

Damaged spring or spring mounts

Damaged or worn arm bushings

Worn or damaged stabilizer bar

bushing or linksGo to detailed test A.

Groaning or grinding - noise from the

front strut, occurs when driving on

bumpy roads or turning the vehicle Uneven seating surface between the

insulator and panel by the burrs

around the strut insulator mounting

bolts and the insulator boltes

mounting holesRepair or install a new parts as

necessary.

Rear suspension noise - a squeak,

creak or rattle noise - occurs mostly

over bumps or rough roads Loose or bent rear shock absorbers

Damaged spring or spring mounts

Damaged or worn control arm

bushingsGo to detailed test B.

Shudder - occurs during acceleration

from a slow speed or stop Rear axle assembly mis - positioned

Damaged or worn front suspension

componentsCheck the axle mounts and rear

suspension for damage or wear.

Repair as necessary.

Check for a loose stabilizer bar,

damaged or loose strut/strut bushings

or loose or worn ball joints. Inspect

the steering linkage for wear or

damage. Repair or Install new

components as necessary.

Shimmy - most noticeable on

coast/deceleration - also hard steering

condition Excessive positive caster

Check the caster alignment angle.

Correct as necessary.

Tire noise - hum/moan at constant

speeds Abnormal wear patterns

Spin the tire and Check for tire wear.

Install a new tire as necessary.

Inspect for damaged/worn suspension

components. Perform wheel

alignment.

Tire noise - noise tone lowers as the

vehicle speed is lowered Out- of- balance tire

Balance the tire and road test. Install

a new tire as necessary.

Tire noise - ticking noise, change with

speed Nail puncture or stone in tire tread

Inspect the tire. Repair or replace as

necessary.

Wheel and tire - vibration and noise

concern is directly related to vehicle

speed and is not affected by

acceleration, coasting or decelerating Damaged or worn tire

Go to detailed test C.

Tire wobble or shudder - occurs at

lower speeds Damaged wheel bearings

Spin the tire and check for abnormal

wheel bearing play or roughness.

Adjust or Install new wheel bearings

as necessary.

See DS group - front/rear axle.

Damaged wheel Inspect the wheel for damage. Install

a new wheel as necessary.

Damaged or worn suspension

components Inspect the suspension components

for wear or damage. Repair as

necessary.

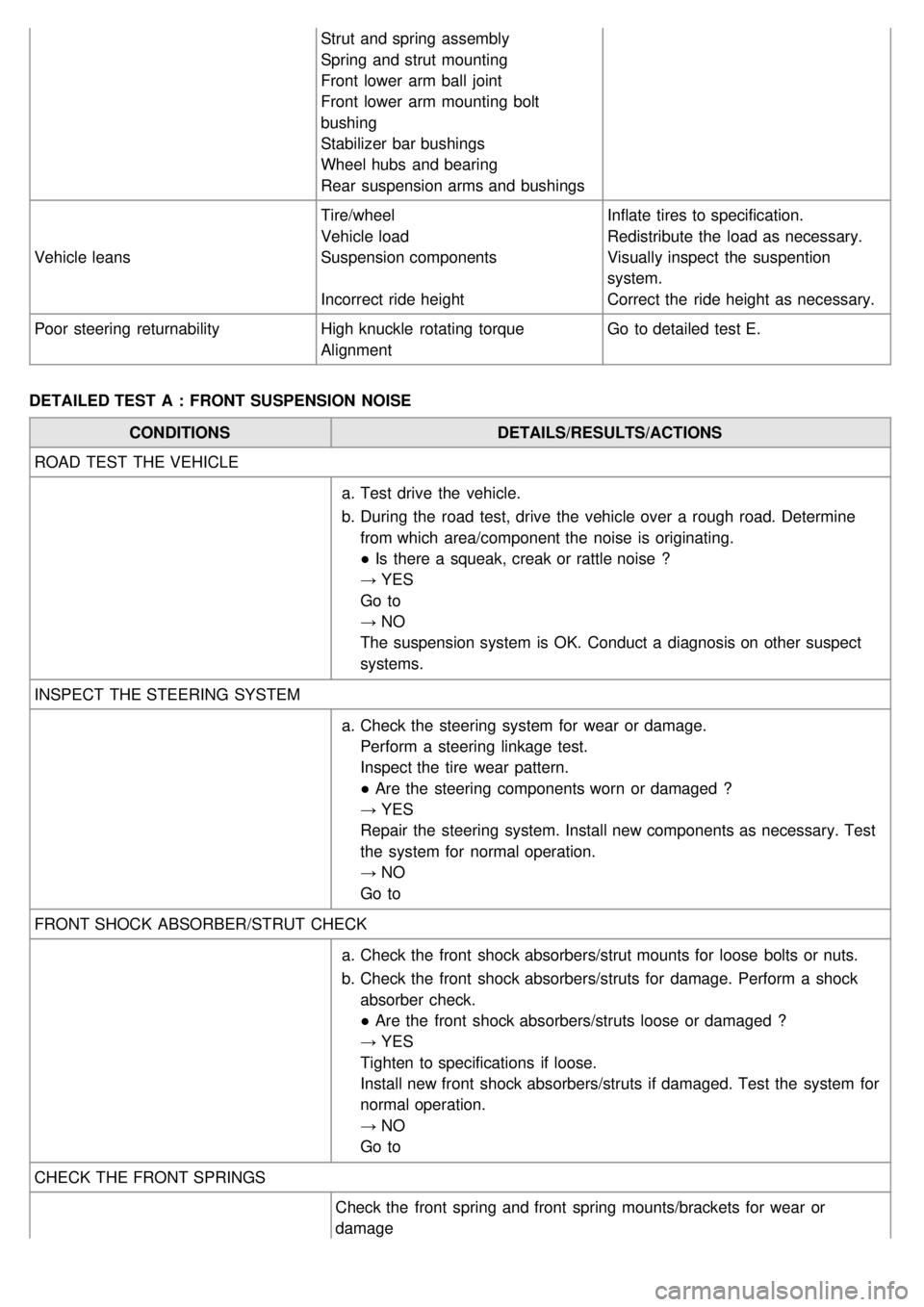

Page 490 of 1575

Strut and spring assembly

Spring and strut mounting

Front lower arm ball joint

Front lower arm mounting bolt

bushing

Stabilizer bar bushings

Wheel hubs and bearing

Rear suspension arms and bushings

Vehicle leans Tire/wheel

Vehicle load

Suspension components

Incorrect ride heightInflate tires to specification.

Redistribute the load as necessary.

Visually inspect the suspention

system.

Correct the ride height as necessary.

Poor steering returnability High knuckle rotating torque

AlignmentGo to detailed test E.

DETAILED TEST A : FRONT SUSPENSION NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

a.Test drive the vehicle.

b. During the road test, drive the vehicle over a rough road. Determine

from which area/component the noise is originating.

● Is there a squeak, creak or rattle noise ?

→ YES

Go to

→ NO

The suspension system is OK. Conduct a diagnosis on other suspect

systems.

INSPECT THE STEERING SYSTEM a.Check the steering system for wear or damage.

Perform a steering linkage test.

Inspect the tire wear pattern.

● Are the steering components worn or damaged ?

→ YES

Repair the steering system. Install new components as necessary. Test

the system for normal operation.

→ NO

Go to

FRONT SHOCK ABSORBER/STRUT CHECK a.Check the front shock absorbers/strut mounts for loose bolts or nuts.

b. Check the front shock absorbers/struts for damage. Perform a shock

absorber check.

● Are the front shock absorbers/struts loose or damaged ?

→ YES

Tighten to specifications if loose.

Install new front shock absorbers/struts if damaged. Test the system for

normal operation.

→ NO

Go to

CHECK THE FRONT SPRINGS Check the front spring and front spring mounts/brackets for wear or

damage

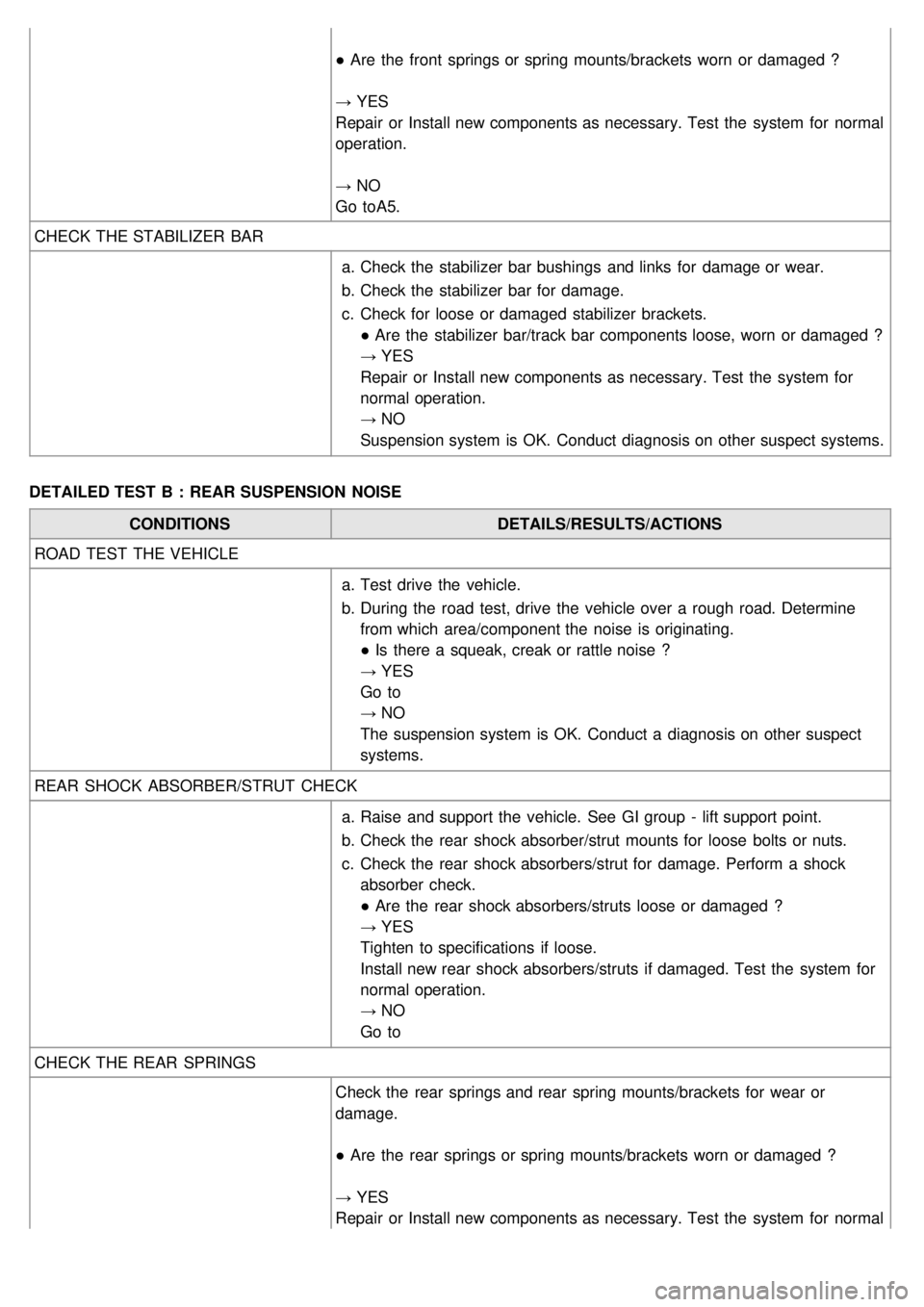

Page 491 of 1575

● Are the front springs or spring mounts/brackets worn or damaged ?

→ YES

Repair or Install new components as necessary. Test the system for normal

operation.

→ NO

Go to A5.

CHECK THE STABILIZER BAR

a.Check the stabilizer bar bushings and links for damage or wear.

b. Check the stabilizer bar for damage.

c. Check for loose or damaged stabilizer brackets.

● Are the stabilizer bar/track bar components loose, worn or damaged ?

→ YES

Repair or Install new components as necessary. Test the system for

normal operation.

→ NO

Suspension system is OK. Conduct diagnosis on other suspect systems.

DETAILED TEST B : REAR SUSPENSION NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

a.Test drive the vehicle.

b. During the road test, drive the vehicle over a rough road. Determine

from which area/component the noise is originating.

● Is there a squeak, creak or rattle noise ?

→ YES

Go to

→ NO

The suspension system is OK. Conduct a diagnosis on other suspect

systems.

REAR SHOCK ABSORBER/STRUT CHECK a.Raise and support the vehicle. See GI group - lift support point.

b. Check the rear shock absorber/strut mounts for loose bolts or nuts.

c. Check the rear shock absorbers/strut for damage. Perform a shock

absorber check.

● Are the rear shock absorbers/struts loose or damaged ?

→ YES

Tighten to specifications if loose.

Install new rear shock absorbers/struts if damaged. Test the system for

normal operation.

→ NO

Go to

CHECK THE REAR SPRINGS Check the rear springs and rear spring mounts/brackets for wear or

damage.

● Are the rear springs or spring mounts/brackets worn or damaged ?

→ YES

Repair or Install new components as necessary. Test the system for normal

operation.

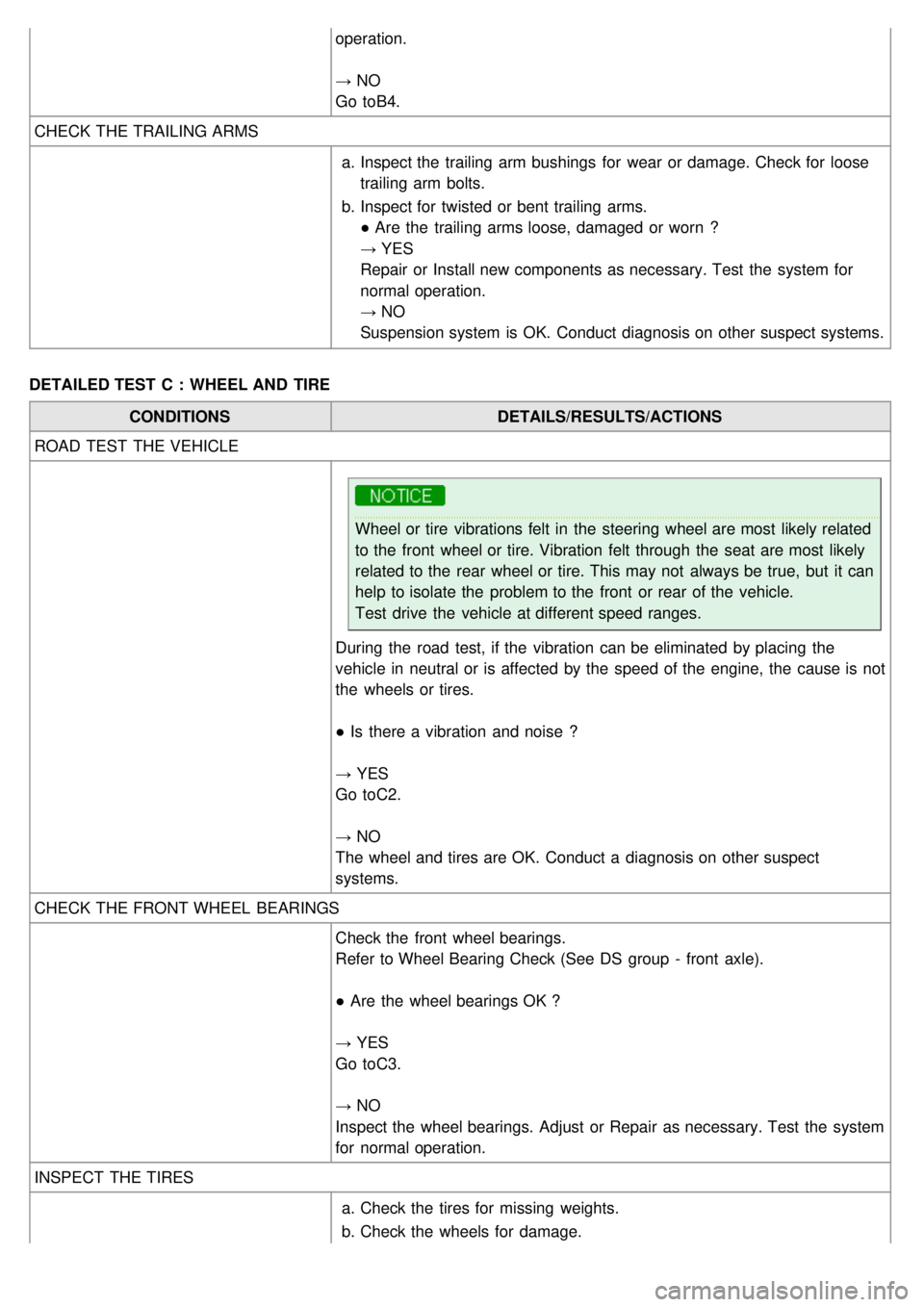

Page 492 of 1575

operation.

→ NO

Go toB4.

CHECK THE TRAILING ARMS

a.Inspect the trailing arm bushings for wear or damage. Check for loose

trailing arm bolts.

b. Inspect for twisted or bent trailing arms.

● Are the trailing arms loose, damaged or worn ?

→ YES

Repair or Install new components as necessary. Test the system for

normal operation.

→ NO

Suspension system is OK. Conduct diagnosis on other suspect systems.

DETAILED TEST C : WHEEL AND TIRE CONDITIONS DETAILS/RESULTS/ACTIONS

ROAD TEST THE VEHICLE

Wheel or tire vibrations felt in the steering wheel are most likely related

to the front wheel or tire. Vibration felt through the seat are most likely

related to the rear wheel or tire. This may not always be true, but it can

help to isolate the problem to the front or rear of the vehicle.

Test drive the vehicle at different speed ranges.

During the road test, if the vibration can be eliminated by placing the

vehicle in neutral or is affected by the speed of the engine, the cause is not

the wheels or tires.

● Is there a vibration and noise ?

→ YES

Go to C2.

→ NO

The wheel and tires are OK. Conduct a diagnosis on other suspect

systems.

CHECK THE FRONT WHEEL BEARINGS Check the front wheel bearings.

Refer to Wheel Bearing Check (See DS group - front axle).

● Are the wheel bearings OK ?

→ YES

Go to C3.

→ NO

Inspect the wheel bearings. Adjust or Repair as necessary. Test the system

for normal operation.

INSPECT THE TIRES

a.Check the tires for missing weights.

b. Check the wheels for damage.

Page 493 of 1575

c.Inspect the tire wear pattern.

● Do the tires have an abnormal wear pattern ?

→ YES

Correct the condition that caused the abnormal wear. Install new tire(s).

Test the system for normal operation.

→ NO

Go to

TIRE ROTATION DIAGNOSIS a.Spin the tires slowly and watch for signs of lateral runout.

b. Spin the tires slowly and watch for signs of radial runout.

● Are there signs of visual runout ?

→ YES

Go to

→ NO

Check the wheel and tire balance.

Correct as necessary. Test the system for normal operation.

RADIAL RUNOUT CHECK ON THE TIRE Measure the radial runout of the wheel and tire assembly. A typical

specification for total radial runout is 1.15mm (0.059 inch).

● Is the radial runout within specifications ?

→ YES

Go to C8.

→ NO

Go to C6.

RADIAL RUNOUT CHECK ON THE WHEEL Measure the radial runout of the wheel. A typical specification for total radial

runout is 1.14mm (0.045 inch.).

● Is the radial runout within specifications ?

→ YES

Install a new tire. Test the system for normal operation.

→ NO

Go to C7.

CHECK THE HUB/BRAKE DISC OR DRUM PILOT RUNOUT OR BOLT CIRCLE RUNOUT Measure the pilot or bolt circle runout. A typical specification for radial

runout is :

● pilot runout - less than 0.15mm (0.006 inch.)

● bolt circle runout - less than 0.38 mm (0.015 inch.)

● Is the radial runout within specification ?

→ YES

Install a new wheel. Test the system for normal operation.

→ NO

Repair or Install new components as necessary.

LATERAL RUNOUT CHECK ON THE TIRE Measure the lateral runout of the wheel and tire assembly. A typical

specification for total lateral runout is 2.5mm (0.098 inch).

Page 494 of 1575

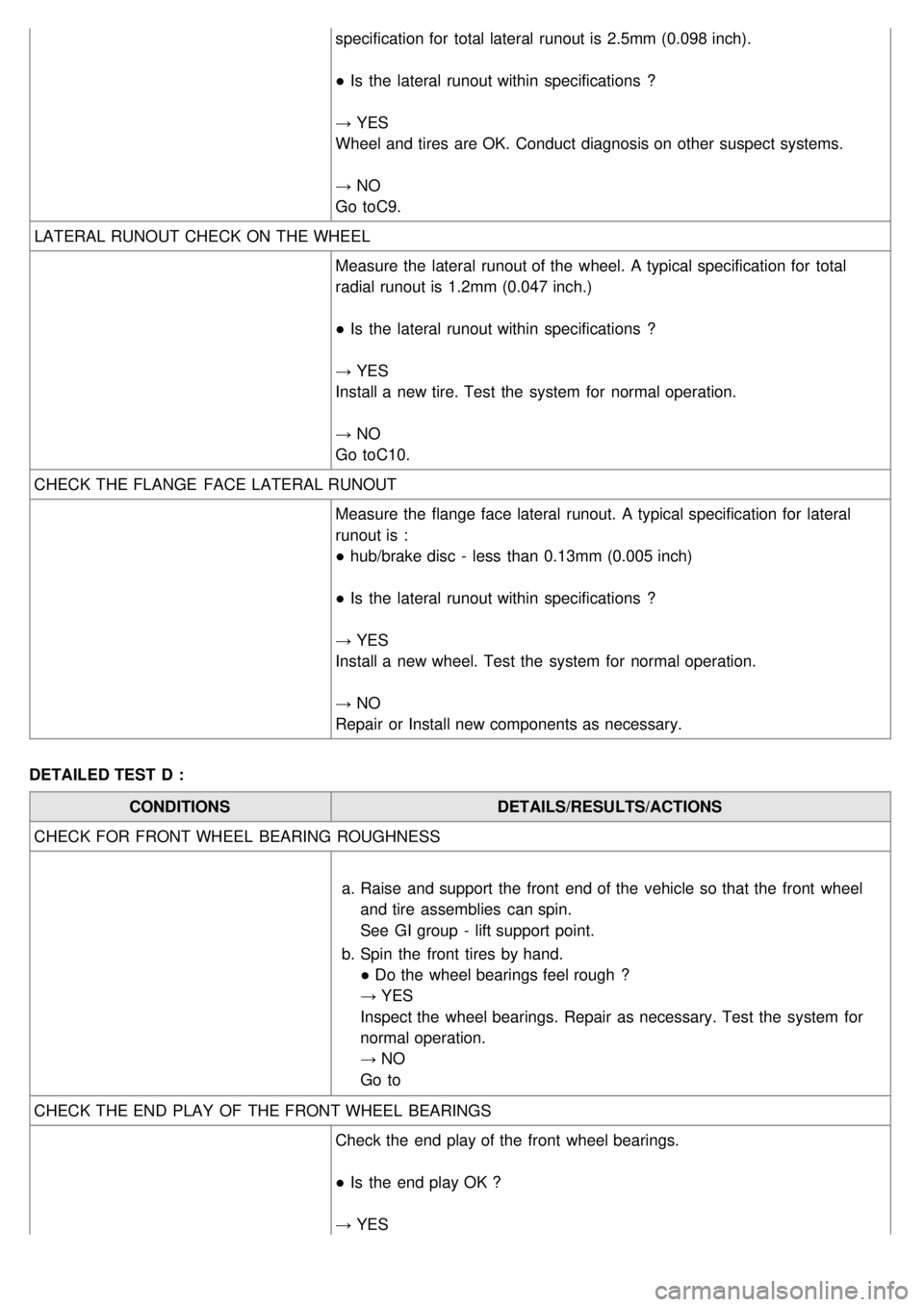

specification for total lateral runout is 2.5mm (0.098 inch).

● Is the lateral runout within specifications ?

→ YES

Wheel and tires are OK. Conduct diagnosis on other suspect systems.

→ NO

Go to C9.

LATERAL RUNOUT CHECK ON THE WHEEL Measure the lateral runout of the wheel. A typical specification for total

radial runout is 1.2mm (0.047 inch.)

● Is the lateral runout within specifications ?

→ YES

Install a new tire. Test the system for normal operation.

→ NO

Go to C10.

CHECK THE FLANGE FACE LATERAL RUNOUT Measure the flange face lateral runout. A typical specification for lateral

runout is :

● hub/brake disc - less than 0.13mm (0.005 inch)

● Is the lateral runout within specifications ?

→ YES

Install a new wheel. Test the system for normal operation.

→ NO

Repair or Install new components as necessary.

DETAILED TEST D : CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK FOR FRONT WHEEL BEARING ROUGHNESS

a.Raise and support the front end of the vehicle so that the front wheel

and tire assemblies can spin.

See GI group - lift support point.

b. Spin the front tires by hand.

● Do the wheel bearings feel rough ?

→ YES

Inspect the wheel bearings. Repair as necessary. Test the system for

normal operation.

→ NO

Go to

CHECK THE END PLAY OF THE FRONT WHEEL BEARINGS Check the end play of the front wheel bearings.

● Is the end play OK ?

→ YES

Go to D3.

Page 496 of 1575

Dismount the tire and mount the wheel on a wheel balancer. Measure the

runout on both wheel flanges. Go to detailed test C

● Is the runout within specifications ?

→ YES

Locate and Mark the low spot on the wheel. Install the tire, matching the

high spot on the tire with the low spot on the wheel. Balance the assembly.

Test the system for normal operation. If the condition persists, Go to D8.

→ NO

Install a new wheel. Check the runout on the new wheel. If the new wheel

is within limits, locate and Mark the low spot. Install the tire, matching the

high spot on the tire with the low spot on the wheel. Balance the assembly.

Test the system for normal operation. If the condition persists, Go to D8.

CHECK FOR VIBRATION FROM THE FRONT OF THE VEHICLE Spin the front wheel and tire assemblies with a wheel balancer while the

vehicle is raised on a hoist. Feel for vibration in the front fender or while

seated in the vehicle.

● Is the vibration present ?

→ YES

Substitute known good wheel and tire assemblies as necessary.

Test the system for normal operation.

→ NO

Check the driveline components. Test the system for normal operation.

DETAILED TEST E : DRIFT LEFT OR RIGHT CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK THE TIRES Inspect the tires for excessive wear or damage.

● Are the tires excessively worn or damaged ?

→ YES

Install new tires.

→ NO

Go to E2.

CHECK THE STEERING LINKAGE

a.Raise and support the vehicle.

b. Check the steering components for indications of excessive wear or

damage.

See ST group - specification.

● Is there an indication of excessive wear or damage ?

→ YES

Repair or Install new components as necessary.

→ NO

Go to

CHECK THE VEHICLE ALIGNMENT a.Place the vehicle on an alignment rack.

Page 497 of 1575

Check the vehicle alignmnt.

● Is the alignment within specification ?

→ YES

Go to

→ NO

Adjust the alignment as necessary.

See page SS - 69 (wheel alignment).

BRAKE DRAG DIAGNOSIS Apply the brakes while driving.

● Does drift or pull occur when the brakes are applied ?

→ YES

See BR group - specification.

→ NO

If the steering wheel is in the center, the vehicle is OK.

If the steering wheel is off- center, Go to Detailed Test F.

DETAILED TEST F : STEERING WHEEL OFF- CENTER CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK THE CLEAR VISION Place the vehicle on an alignment rack.

● Is the clear vision within specification ?

→ YES

Go to F2.

→ NO

Adjust the clear vision to specification.

INSPECT THE STEERING COMPONENTS

a.Raise and support the vehicle.

b. Inspect the steering components for excessive wear or damage.

See ST group - specification.

● Are the steering components excessively worn or damaged ?

→ YES

Repair or Install new components as necessary.

→ NO

If it tracks correctly, vehicle is OK.

If it tracks incorrectly, Go to Detailed Test

DETAILED TEST G : TRACKS INCORRECTLY CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK THE CASTER Place the vehicle on an alignment rack.

● Is the caster within specification ?

→ YES

Go to G2.