air condition KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 797 of 1575

2007 > 2.7L V6 GASOLINE >

WARNING LAMP ACTIVATION

WARNING LAMP BEHAVIOR AFTER IGNITION ON

As soon as the operating voltage is applied to the SRSCM ignition input, the SRSCM activates the warning lamp for a

bulb check.

The lamp shall turn on for 6 seconds during the initialization phase and be turned off afterward. However, in order to

indicate the driver, the warning lamp shall turn on for 6 seconds and off for one second then on continuously after the

operating voltage is applied if any active fault exists. 1. Active fault or historical fault counter is greater or equal to 10

2.Normal or historical fault counter is less than 10

SRSCM INDEPENDENT WARNING LAMP ACTIVATION

There are certain fault conditions in which the SRSCM cannot function and thus cannot control the operation of the

standard warning lamp. In these cases, the standard warning lamp is directly activated by appropriate circuitry that

operates independently of the SRSCM. These cases are:

1. Loss of battery supply to the SRSCM : warning lamp turned on continuously.

2. Loss of internal operating voltage : warning lamp turned on continuously.

3. Loss of Microprocessor operation : warning lamp turned on continuously.

4. SRSCM not connected : warning lamp turned on continuously through the shorting bar.

PASSENGER AIRBAG DEACTIVATION (PAD) LAMP OPERATION

The SRSCM is designed with circuitry and software to drive a PAD lamp, which is used for depowered airbag system.

For the PAD indicator circuitry to function properly, both the SRSCM and PAD indicator are sourced from the same

ignition line. After ignition on, the PAD indicator will be turned on for 4 seconds and off for 3 seconds during the

initialization phase. Thereafter the lamp will be turned on as long as the PAD switch is in the disabled position.

PASSENGER RESTRAINTS ACTIVATION WITH PAD SWITCH

The PAD switch affects the activation of the front passenger airbag only and the switch is controlled manually. The

PAD switch will be functioned as follows:

PAD Switch status PAD LampPAB

Phase- up ON → OFF Enable

Enabled position OFFEnable

Disabled position ONDisable

Fault Based on PABEnable

Page 928 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

This specification applies to HCU(Hydraulic Control Unit) and ECU(Electronic Control Unit) of the HECU.(Hydraulic and

Electronic Control Unit)

This specification is for the wiring design and installation of ABS/TCS/ESC ECU.

This unit has the functions as follows.

a. Input of signal from Pressure sensor, Steering angle sensor, Yaw & Lateral G sensor, the wheel speed sensors

attached to each wheel.

b. Control of braking force / traction force/ yaw moment.

c. Failsafe function.

d. Self diagnosis function.

e. Interface with the external diagnosis tester.

Installation position : engine compartment a. Brake tube length from Master cylinder port to HECU inlet port should be max. 1m

b. The position should not be close to the engine block and not lower than the wheel.

OPERATION

The ECU shall be put into operation by switching on the operating voltage (IGN).

On completion of the initialization phase, the ECU shall be ready for operation.

In the operating condition, the ECU shall be ready, within the specified limits (voltage and temperature), to process the

signals offered by the various sensors and switches in accordance with the control algorithm defined by the software

and to control the hydraulic and electrical actuators.

Wheel Sensor signal processing

The ECU shall receive wheel speed signal from the four active wheel sensors.

The wheel signals are converted to voltage signal by the signal conditioning circuit after receiving current signal from

active wheel sensors and given as input to the MCU.

Solenoid Valve Control

When one side of the valve coil is connected to the positive voltage that is provided through the valve relay and the

other side is connected to the ground by the semiconductor circuit, the solenoid valve goes into operation.

The electrical function of the coils are always monitored by the valve test pulse under normal operation conditions.

Voltage limits

a.Overvoltage

When overvoltage is detected(above 16.8 V), the ECU switches off the valve relay and shuts down the system.

When voltage is returned to operating range, the system goes back to the normal condition after the initialization

phase.

b. Undervoltage

In the event of undervoltage(below 9.3 V), ABS control shall be inhibited and the warning lamp shall be turned on.

When voltage is returned to operating range, the warning lamp is switched off and ECU returns to normal operating

mode.

Pump Motor Checking

The ECU performs a pump motor test at a speed of 15km/h once after IGN is switched on.

Diagnostic Interface

Failures detected by the ECU are encoded on the ECU, stored in a EEPROM and read out by diagnostic equipment

when the ignition switch is turned on.

The diagnosis interface can also be used for testing the ECU during production of the ECU and for actuating the HCU

(Air - bleeding line or Roll and Brake Test line).

Warning Lamp module

Page 937 of 1575

c.Stop lamp switch circuit.

d. Check the hydraulic circuit for leakage.

Communication with Scan tool is not possible.

(Communication with any system is not possible) a.

Power source circuit

b. Diagnosis line

Communication with Scan tool is not possible.

(Communication with ABS only is not possible) a.

Power source circuit

b. Diagnosis line

c. HECU

When ignition key is turned ON (engine OFF), the ABS

warning lamp does not light up. a.

ABS warning lamp circuit

b. HECU

Even after the engine is started, the ABS warning lamp

remains ON. a.

ABS warning lamp circuit

b. HECU

During ABS operation, the brake pedal may vibrate or may not be able to be depressed. Such phenomena are

due to intermittent changes in hydraulic pressure inside the brake line to prevent the wheels from locking and is

not an abnormality.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the

problem is still occurring, replace the ABS control module. a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

c. Inoperative hydraulic circuit for leakage

d. Inoperative HECU

INSPECTION PROCEDURES

DTC INSPECTION

1. Connect the Scan Tool with the data link connector and turn the ignition switch ON.

2. Verify that the system is operating to specifications.

Is the system operating to specifications ?

▶ Check the power source circuit.

▶ Erase the DTC and recheck using Scan Tool.

CHECK THE POWER SOURCE CIRCUIT.

1. Disconnect the connector from the ABS control module.

2. Turn the ignition switch ON, measure the voltage between terminal 18 of the ABS control module harness side

connector and body ground.

Specification: approximately B+

Is the voltage within specification?

▶ Check the ground circuit.

▶ Check the harness or connector between the fuse (10A) in the engine compartment junction block and the ABS

control module. Repair if necessary.

Page 938 of 1575

control module. Repair if necessary.

CHECK THE GROUND CIRCUIT.

1.Disconnect the connector from the ABS control module.

2. Check for continuity between terminals 1,4 of the ABS control module harness side connector and ground point.

Is there continuity?

▶ Check the wheel speed sensor circuit.

▶ Repair an open in the wire and ground point.

CHECK THE WHEEL SPEED SENSOR CIRCUIT.

Refer to the DTC troubleshooting procedures.

Is the system operating to specifications ?

▶ Check the hydraulic circuit for leakage.

▶ Repair or replace the wheel speed sensor.

CHECK THE HYDRAULIC CIRCUIT FOR LEAKAGE.

Refer to the hydraulic lines.

Inspect leakage of the hydraulic lines.

Is the system operating to specifications ?

▶ The problem is still occurring, replace the ABS control module.

▶ Replace the leaking hydraulic lines.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

Page 940 of 1575

▶ Replace the leaking hydraulic lines.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Possible malfunction in the power supply system (including ground)

for the diagnosis line. a.

An open in the wire

b. Poor ground

c. Inoperative power source circuit

INSPECTION PROCEDURES

CHECK THE POWER SUPPLY CIRCUIT FOR THE DIAGNOSIS

Measure the voltage between terminal 9 of the data link connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Check the ground circuit for the diagnosis.

▶ Repair an open in the wire. Check and replace fuse (15A) from the engine compartment junction block.

CHECK THE GROUND CIRCUIT FOR THE DIAGNOSIS

Check for continuity between terminal 5 of the data link connector and body ground.

Is there continuity?

▶ Repair an open in the wire between terminal 5 of the data link connector and ground point.

DETECTING CONDITION

Trouble Symptoms Possible Cause

When communication with Scan Tool is not possible, the cause may

be probably an open in the HECU power circuit or an open in the a.

An open in the wire

Page 942 of 1575

DETECTING CONDITIONTrouble Symptoms Possible Cause

When current flows in the HECU the ABS warning lamp turns from

ON to OFF as the initial check.Therefore if the lamp does not light up,

the cause may be an open in the lamp power supply circuit, a blown

bulb, an open in the both circuits between the ABS warning lamp and

the HECU, and the inoperative HECU. a.

Inoperative ABS warning lamp bulb

b. Blown No.2 fuse (10A) in the engine

compartment junction block

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

PROBLEM VERIFICATION

Disconnect the connector from the ABS control module and turn the ignition switch ON.

Does the ABS warning lamp light up?

▶ It is normal. Recheck the ABS control module.

▶ Check the power source for the ABS warning lamp.

CHECK THE POWER SOURCE FOR THE ABS WARNING LAMP

1. Disconnect the instrument cluster connector and turn the ignition switch ON.

2. Measure the voltage between terminal 8 of the cluster harness side connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Repair bulb or instrument cluster assembly.

▶ Check for blown fuse.

Page 943 of 1575

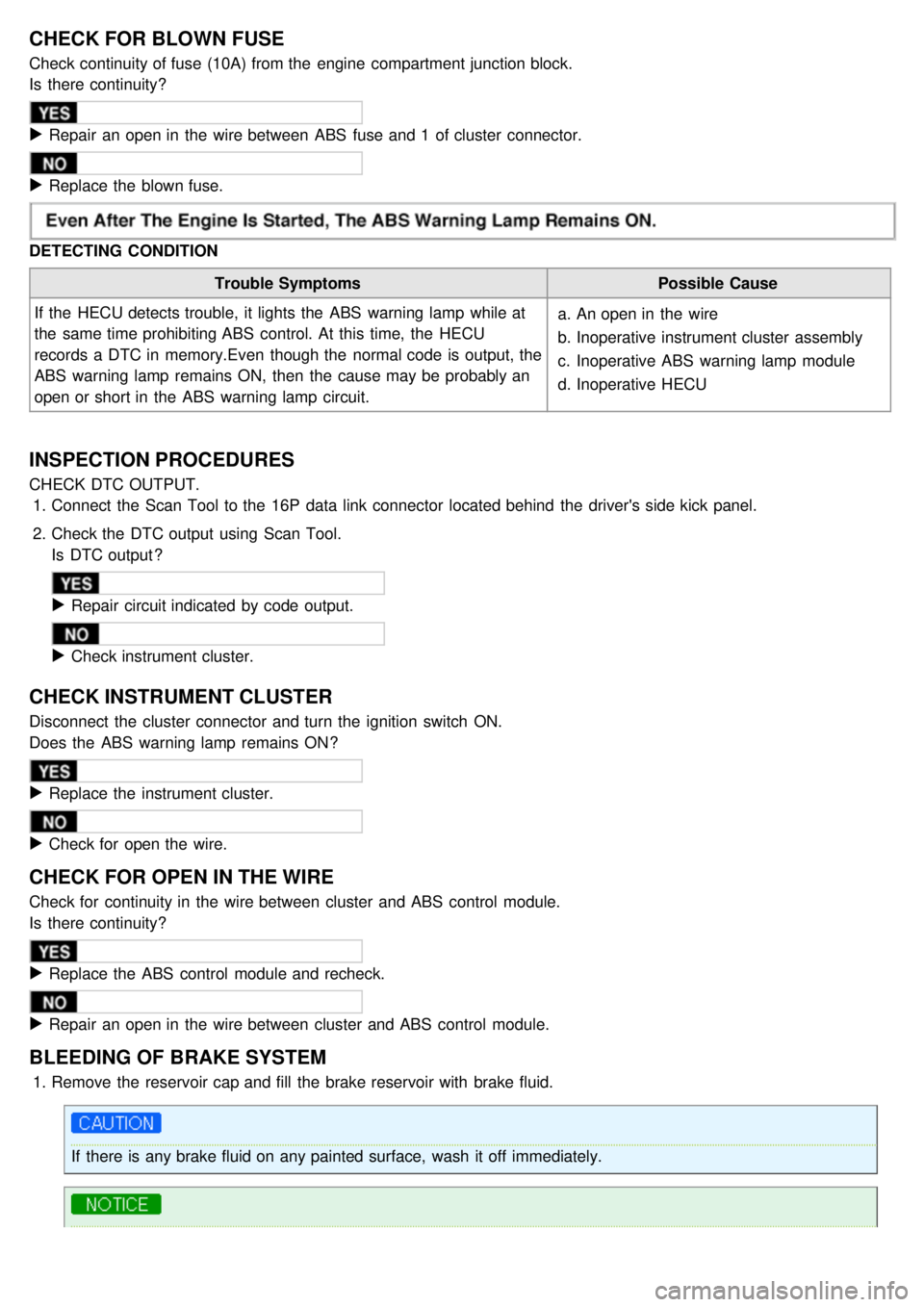

CHECK FOR BLOWN FUSE

Check continuity of fuse (10A) from the engine compartment junction block.

Is there continuity?

▶ Repair an open in the wire between ABS fuse and 1 of cluster connector.

▶ Replace the blown fuse.

DETECTING CONDITION

Trouble Symptoms Possible Cause

If the HECU detects trouble, it lights the ABS warning lamp while at

the same time prohibiting ABS control. At this time, the HECU

records a DTC in memory.Even though the normal code is output, the

ABS warning lamp remains ON, then the cause may be probably an

open or short in the ABS warning lamp circuit. a.

An open in the wire

b. Inoperative instrument cluster assembly

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

CHECK DTC OUTPUT.

1. Connect the Scan Tool to the 16P data link connector located behind the driver's side kick panel.

2. Check the DTC output using Scan Tool.

Is DTC output ?

▶ Repair circuit indicated by code output.

▶ Check instrument cluster.

CHECK INSTRUMENT CLUSTER

Disconnect the cluster connector and turn the ignition switch ON.

Does the ABS warning lamp remains ON?

▶ Replace the instrument cluster.

▶ Check for open the wire.

CHECK FOR OPEN IN THE WIRE

Check for continuity in the wire between cluster and ABS control module.

Is there continuity?

▶ Replace the ABS control module and recheck.

▶ Repair an open in the wire between cluster and ABS control module.

BLEEDING OF BRAKE SYSTEM

1. Remove the reservoir cap and fill the brake reservoir with brake fluid.

If there is any brake fluid on any painted surface, wash it off immediately.

Page 1262 of 1575

Error conditionBelow 6 pulses in 2 sec. Below 6 pulses in 1 sec.

Prerequisite FR/RR limit SW on Limit setting complete

a. Stop the related motor(seat / pedal) if an error is detected during playing or Easy access function operation.

b. Stop the corresponding motor if an error is detected during manual operation (excluding slide motor).

b. If seat sensor Vcc below 1V is detected by 1s

a. Stop all seat motors running if seat sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

c. Return if seat sensor Vcc is 4V or more.

DETECTING ERRORS FOR ADJUST PEDAL

1.If signal change is below 0.06V per sec though motor is running.

a. Stop the corresponding motor if error is detected during playing or Easy access function operation.

2. If adjust pedal sensor Vcc below 1V is detected by 1s

a. Stop pedal motor running if pedal sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

3. Return if adjust pedal sensor Vcc is 4V or more.

HANDLING ERRORS

1.If errors are discovered, regard them as harness disconnection or sensor failure, and conduct the following

measures.

a. Stop auto control (play or Easy access function operation) if it is under auto control and set off buzzer 10 times

(however, have motors other than the one with an error operate normally).

b. Set off alarm again in case of recurrence of error after restoration of a motor with an error.

c. Complete alarm 10 times though it comes back to normal during error alarm.

d. Stop alarm if receiving memory recall or play order, and set off buzzer in the corresponding function.

e. Manual operation control is allowed even for a motor with errors.

f. Set off buzzer if memory or play order is received even during error.

g. The timing to lift auto control suspension is when repair for the failing motor is completed, and the criteria for

the completion point are as follows:

a. Seat: if signal input is normal with over 6 pulses within a sec. from position sensor of a motor with an error

caused by manual switch.

b. Adjust pedal: if there is change in input of over 3 LSB within 1 sec. from sensor by manual switch.

Page 1434 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The Rain sensing windshield wiper system is a wiper system that, in addition to providing normal wiper functions off,

mist, manual low speed, manual high speed, and wash, provides automatic control of automatic intermittent automatic

low, and automatic high speeds.

When the ignition key is in the ON position, the rain sensor will be activated.

SYSTEM FUNCTION

BASIC PRINCIPLE

Emitted Beam from luminosity diode is reflected entirely against the windshield exterior, and then turn into photo diode.

If there is water on the windshield exterior, beam seperates optically, and the degree of remained beam is measured

in the photo diode.

What there is water in the windshield, it means beam is not reflected all, so the degree of lost beam indicates the

degree of glass surface wet.

Rainsensor consist of two luminosity diode, two photo diode, optic fiber and coupling pad.

OPERATION CONTROL

Wiper ECU transmits the signal as a rainsesor, and then the rainsensor perceives the rainwater to transmit to the

wiping order wiper ECU, wiper ECU controls the wiper motor according to the signal.

CONTACT INFLUENCE

The rain sensor can malfunction due to the following conditions : a. Contamination of the measurement surface.

b. Air bubbles between the windshield and the coupling pad contact surface.

c. The movement of coupling pad by vibration.

d. Damaged wiper blade.

AUTO OPERATION

1.Operation Condition

Operation mode Operation condition

Direct mode Switch AUTO is basic operation condition that rain sensor perceives dry

windshield. From this condition, the rain sensor decides the wiper operation

mode depend on the quantity and time of measured rainwater

Intermittent mode Operation pauses between 0.5~5 seconds, then the wipers switch to

intermittent mode

Low speed Operate continuously at low speed

High speed Operate continuously at high speed

Page 1533 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

When reversing, the driver is not easy to find objects in the blind spots and to determine the distance from the object.

In order to provide the driver safety and convenience, back warning system will operate upon shifting to "R" Ultrasonic

sensor will emit ultrasonic wave rearward and detect the reflected wave. Control unit will calculate distance to the

object using the sensor signal input and output buzzer alarm in three steps (first, second and third alarm).

ALARM RANGE

Upon detecting an object at each range out of 3 ranges as stated below within the operation range, it will generate

alarm.

First alarm : Object comes near to the sensor located at the rear of vehicle, within 81- 120cm ± 15cm

Second alarm : Object comes near to the sensor located at the rear of vehicle, within 41- 80cm ± 10cm

Third alarm : Object comes near to the sensor located at the rear of vehicle, within 40cm ± 10cm

a.Time tolerance of the above waveform : Time ± 10%

b. At nearer distance than 40cm, detection may not occur.

c. Alarm will be generated with vehicle reversing speed 10km/h or less.

For moving target, maximum operation speed shall be target approach speed of 10km/h.

d. When the vehicle or the target is moving, sequential alarm generation or effective alarm may be failed.

e. False alarm, or failure of the alarm to trigger may occur in the following conditions.

a. Irregular road surface, gravel road, reversing toward grass.

b. Horn, motor cycle engine noise, large vehicle air brake, or other object generating ultrasonic wave is near.

c. When a wireless transmitter is used near to the sensor.

d. Dirt on the sensor.

e. Sequential alarm may not occur due to the reversing speed or the target shape.