air condition KIA CARNIVAL 2007 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 498 of 1575

→NO

Replace bent or damaged parts.

CHECK THE REAR SUSPENSION

a.Measure the vehicle wheel base for LH and RH.

b. Compare the measurements.

● Are the measurements the same ?

→ YES

If the ride is smooth, vehicle is OK.

If the ride is rough, Go to Detailed Test

→ NO

Inspect the rear suspension components for wear or damage.

Repair or Install new components as necessary.

DETAILED TEST H : ROUGH RIDE CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK THE FRONT SHOCK ABSORBER

a.Raise support the vehicle.

b. Inspect the front shock absorber for oil leaks or damage.

● Are the tires excessively worn or damaged ?

→ YES

Install new front shock absorbers.

→ NO

Go to

CHECK THE REAR SHOCK ABSORBERS Inspect the rear shock absorbers for oil leaks or damage.

● Are the rear shock absorbers leaking ?

→ YES

Install new rear shock absorbers.

→ NO

The vehicle is OK. Go to TROUBLESHOOTING.

DETAILED TEST I : EXCESSIVE NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

INSPECT THE SUSPENSION

a.Raise and support the vehicle.

b. Inspect the shock absorber mounting bolts.

● Are the mounting bolts loose or broken ?

→ YES

Tighten or Install new shock absorber mounting bolts.

→ NO

Go to

INSPECT THE SPRING AND TORSION BARS Inspect the springs and stabilizer bars for damage.

● Are the spring or stabilizer bars damaged ?

→ YES

Install new spring and/or stabilizer bars.

Page 581 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Symptom Probable cause Remedy

Excessive play in

steering Loose yoke plug

Retighten

Loose steering gear mounting bolts Retighten

Loose or worn tie rod end Retighten or replace as necessary

Steering wheel

operation is not

smooth (Insufficient

power assist) V- belt slippage

Readjust

Damaged V- belt Replace

Low fluid level Replenish

Air in the fluid Bleed air

Twisted or damaged hoses Correct the routing or replace

Insufficient oil pump pressure Repair or replace the oil pump

Sticky flow control valve Replace

Excessive internal oil pump leakage Replace the damaged parts

Excessive oil leaks from rack and pinion in

gear box Replace the damaged parts

Distorted or damaged gear box or valve body

seals Replace

Steering wheel does

not return properly Excessive turning resistance of tierod end

Replace

Yoke plug excessively tight Adjust

Tie rod and/or ball joint cannot turn smoothly Replace

Loose mounting of gear box mounting bracket

Worn steering shaft joint and/or Retighten

Worn steering shaft joint and/or body

grommet Correct or replace

Distorted rack Replace

Damaged pinion bearing Replace

Twisted or damaged hoses Reposition or replace

Damaged oil pressure control valve Replace

Damaged oil pump input shaft bearing Replace

Noise Hissing Noise in Steering Gear

There is some noise with all power steering systems. One of the most common is a hissing

sound when the steering wheel is turned and the car is not moving. This noise will be most

evident when turning the wheel while the brakes are being applied. There is no relationship

between this noise and steering performance. Do not replace the valve unless the "hissing"

noise becomes extreme. A replaced valve will also make a slight noise, and is not always a

solution for the condition.

Rattling or chucking

noise in the rack and

pinion Interference with hoses from vehicle body

Reposition

Loose gear box bracket Retighten

Loose tie rod end and/or ball joint Retighten

Worn tie rod and/or ball joint Replace

Noise in the oil pump Low fluid level Replenish

Air in the fluid Bleed air

Loose pump mounting bolts Retighten

Page 635 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLE SHOOTING

Symptom Probable cause Remedy

There is no change made in rack

stroke even though turning the VRS

switch ON or OFF. a.

VRS operating unit

b. VRS control module

c. VRS switch a.

Inspect the VRS operating unit.

b. Check Input/ output signal of the

VRS control module.

c. Inspect connection of the VRS

switch.

LED is not illuminated even though

turning the VRS switch ON. VRS switch a.

Inspect connection of the VRS

switch.

b. Check the LED for damage.

Inspection of the rack stroke

1.Is the rack stoke (the maximum steering angle) changed when pressing the VRS switch ?

▶ The VRS system is in normal condition.

▶ Go to step 2.

2. Measure the resistance of the VRS operating unit.

(1) Disconnect the VRS operating unit connector.

(2) Measure the resistance between the terminal No.1 and No.2.

Repeat the terminal No.3 and No.4.

Is the measured resistance within standard value ?

4 ~ 20 Ω → Normal condition (standard value)

1 Ω or below → Short

100 Ω or above → Open circuit

▶ Go to step 3.

▶ Repair or replace the power steering gear box.

3. Measure the output voltage of the VRS control module.

(1) Disconnect the VRS control module connector.

(2) Connect 9 ~ 15 V power between the terminal No.3 and No.4.

(3) Measure the output voltage (to DC motor) between the terminal No.5 ~ 8.

Is the voltage measured within standard value ?

Supplied power Measured output voltage

Page 636 of 1575

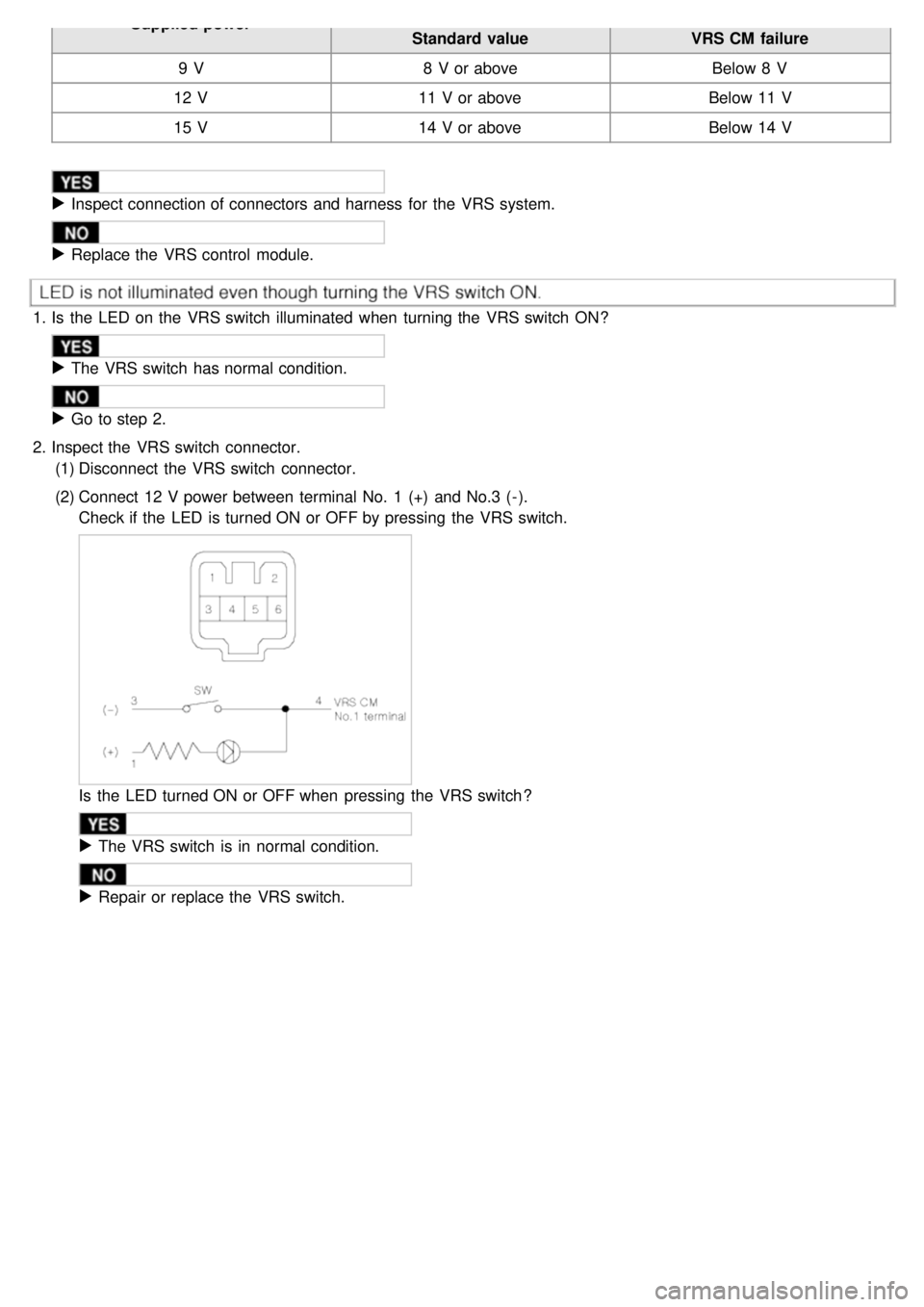

Supplied powerStandard valueVRS CM failure

9 V 8 V or above Below 8 V

12 V 11 V or above Below 11 V

15 V 14 V or above Below 14 V

▶ Inspect connection of connectors and harness for the VRS system.

▶ Replace the VRS control module.

1. Is the LED on the VRS switch illuminated when turning the VRS switch ON?

▶ The VRS switch has normal condition.

▶ Go to step 2.

2. Inspect the VRS switch connector.

(1) Disconnect the VRS switch connector.

(2) Connect 12 V power between terminal No. 1 (+) and No.3 ( - ).

Check if the LED is turned ON or OFF by pressing the VRS switch.

Is the LED turned ON or OFF when pressing the VRS switch ?

▶ The VRS switch is in normal condition.

▶ Repair or replace the VRS switch.

Page 643 of 1575

CHAPTER 11:

Heating, Ventilation, Air Conditioning

Page 644 of 1575

Air Conditioning System

Page 646 of 1575

2007 > 2.7L V6 GASOLINE >

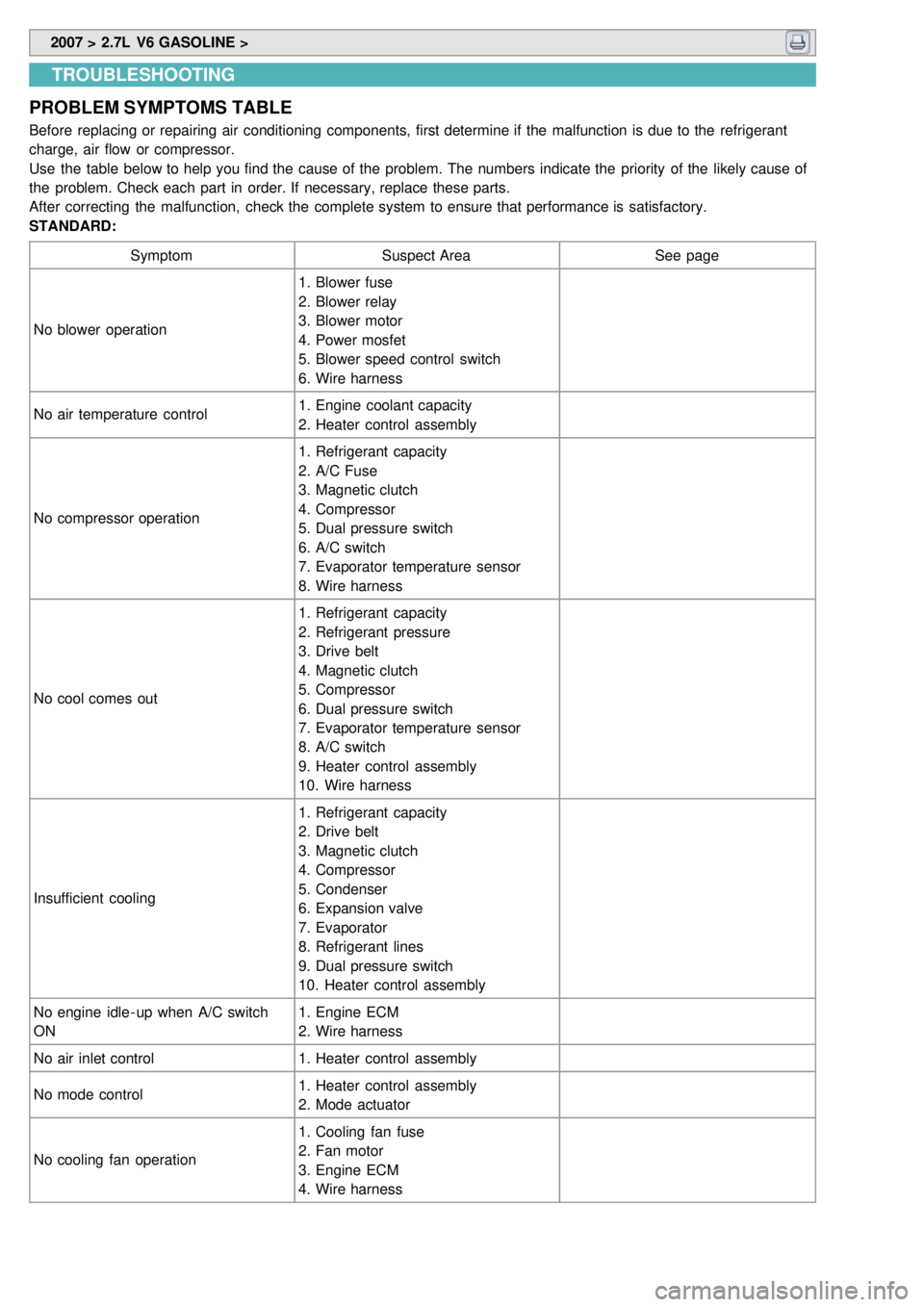

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant

charge, air flow or compressor.

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely cause of

the problem. Check each part in order. If necessary, replace these parts.

After correcting the malfunction, check the complete system to ensure that performance is satisfactory.

STANDARD:

Symptom Suspect Area See page

No blower operation 1. Blower fuse

2. Blower relay

3. Blower motor

4. Power mosfet

5. Blower speed control switch

6. Wire harness

No air temperature control 1. Engine coolant capacity

2. Heater control assembly

No compressor operation 1. Refrigerant capacity

2. A/C Fuse

3. Magnetic clutch

4. Compressor

5. Dual pressure switch

6. A/C switch

7. Evaporator temperature sensor

8. Wire harness

No cool comes out 1. Refrigerant capacity

2. Refrigerant pressure

3. Drive belt

4. Magnetic clutch

5. Compressor

6. Dual pressure switch

7. Evaporator temperature sensor

8. A/C switch

9. Heater control assembly

10. Wire harness

Insufficient cooling 1. Refrigerant capacity

2. Drive belt

3. Magnetic clutch

4. Compressor

5. Condenser

6. Expansion valve

7. Evaporator

8. Refrigerant lines

9. Dual pressure switch

10. Heater control assembly

No engine idle - up when A/C switch

ON 1. Engine ECM

2. Wire harness

No air inlet control 1. Heater control assembly

No mode control 1. Heater control assembly

2. Mode actuator

No cooling fan operation 1. Cooling fan fuse

2. Fan motor

3. Engine ECM

4. Wire harness

Page 647 of 1575

2007 > 2.7L V6 GASOLINE >

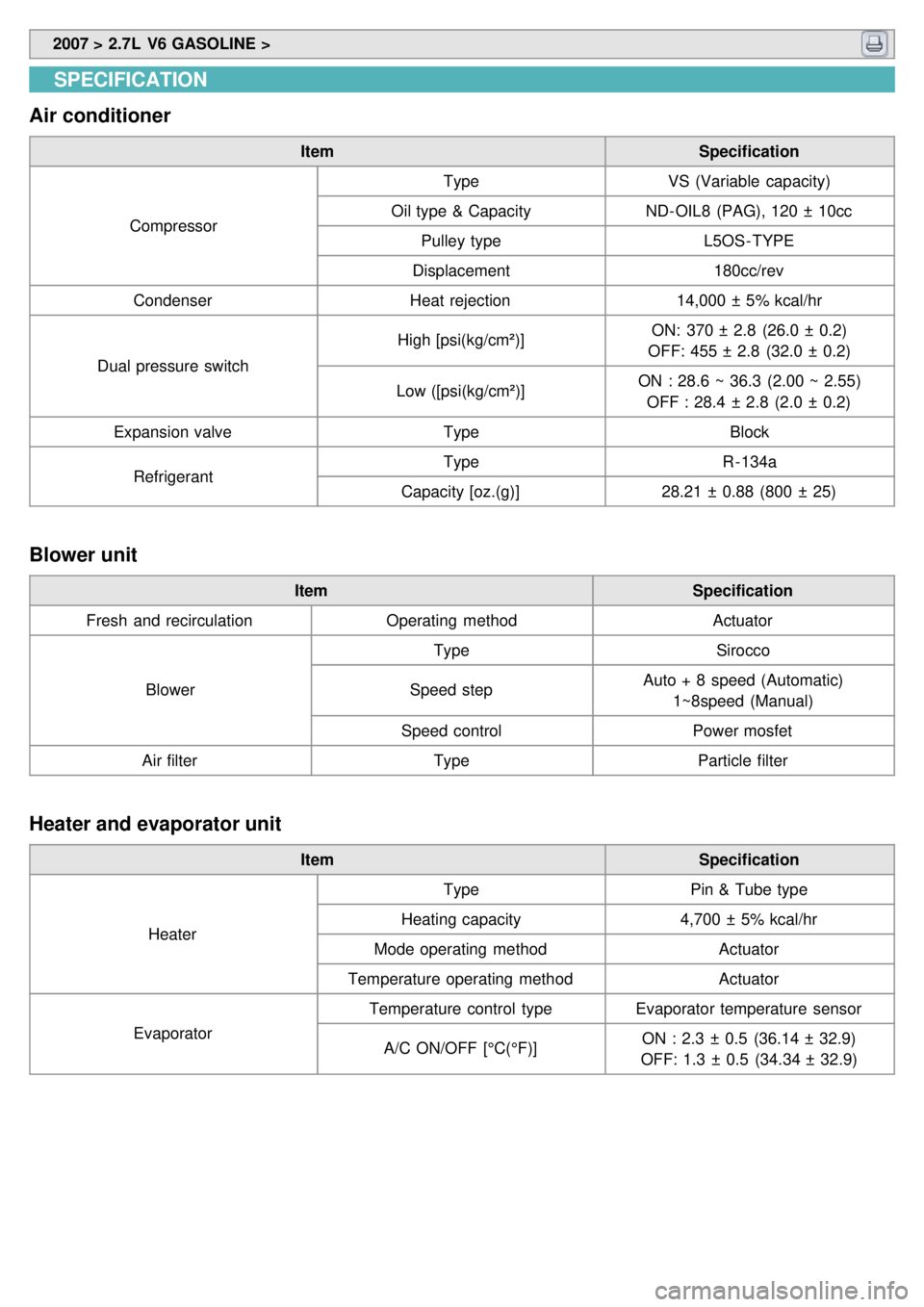

SPECIFICATION

Air conditioner

Item Specification

Compressor Type

VS (Variable capacity)

Oil type & Capacity ND- OIL8 (PAG), 120 ± 10cc

Pulley type L5OS - TYPE

Displacement 180cc/rev

Condenser Heat rejection14,000 ± 5% kcal/hr

Dual pressure switch High [psi(kg/cm²)]

ON: 370 ± 2.8 (26.0 ± 0.2)

OFF: 455 ± 2.8 (32.0 ± 0.2)

Low ([psi(kg/cm²)] ON : 28.6 ~ 36.3 (2.00 ~ 2.55)

OFF : 28.4 ± 2.8 (2.0 ± 0.2)

Expansion valve TypeBlock

Refrigerant Type

R- 134a

Capacity [oz.(g)] 28.21 ± 0.88 (800 ± 25)

Blower unit

Item Specification

Fresh and recirculation Operating method Actuator

Blower Type

Sirocco

Speed step Auto + 8 speed (Automatic)

1~8speed (Manual)

Speed control Power mosfet

Air filter TypeParticle filter

Heater and evaporator unit

Item Specification

Heater Type

Pin & Tube type

Heating capacity 4,700 ± 5% kcal/hr

Mode operating method Actuator

Temperature operating method Actuator

Evaporator Temperature control type

Evaporator temperature sensor

A/C ON/OFF [°C(°F)] ON : 2.3 ± 0.5 (36.14 ± 32.9)

OFF: 1.3 ± 0.5 (34.34 ± 32.9)

Page 648 of 1575

Air Conditioning System

Page 654 of 1575

2007 > 2.7L V6 GASOLINE >

REFRIGERANT SYSTEM SERVICE BASICS

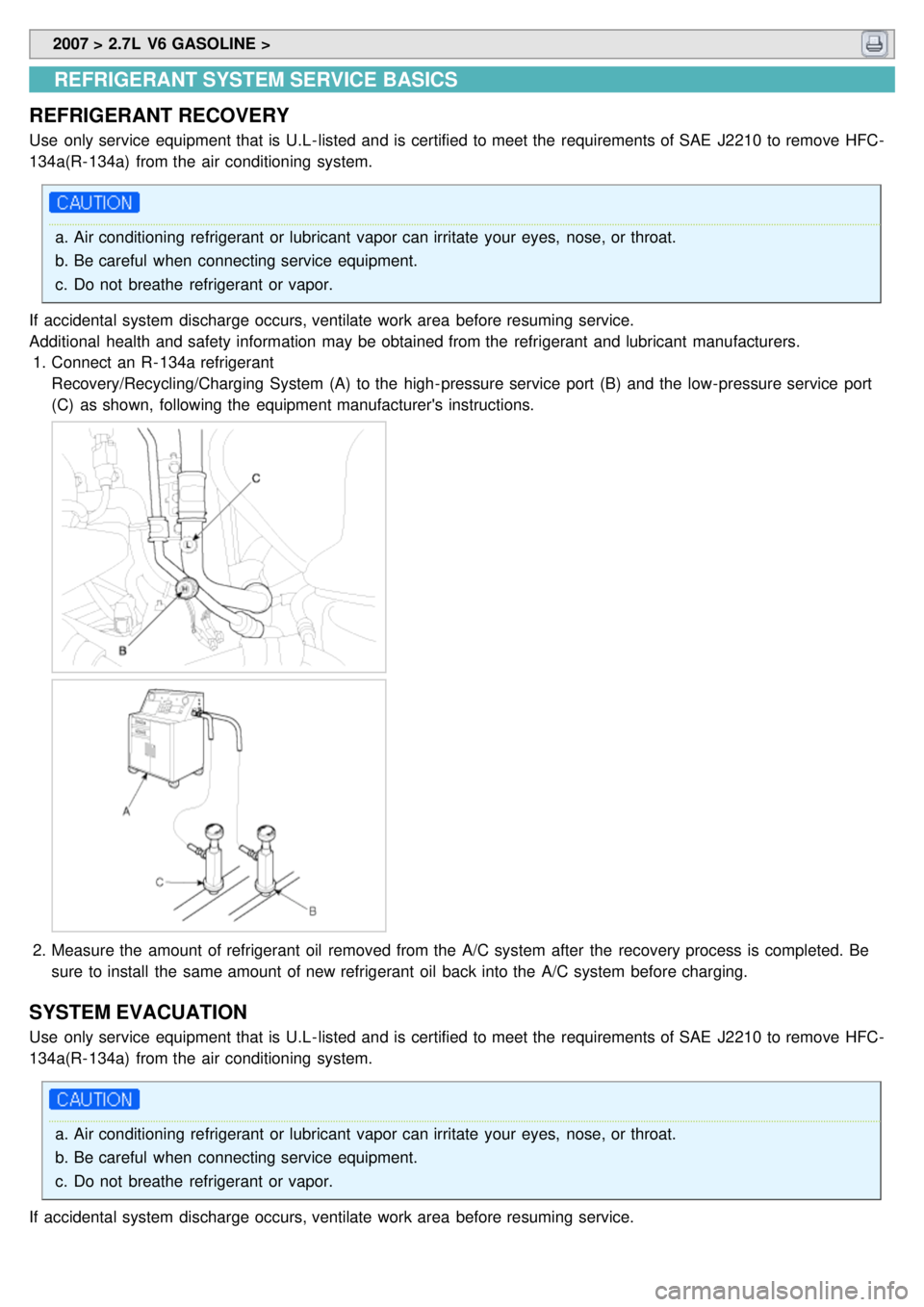

REFRIGERANT RECOVERY

Use only service equipment that is U.L - listed and is certified to meet the requirements of SAE J2210 to remove HFC-

134a(R- 134a) from the air conditioning system.

a. Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

b. Be careful when connecting service equipment.

c. Do not breathe refrigerant or vapor.

If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers. 1. Connect an R- 134a refrigerant

Recovery/Recycling/Charging System (A) to the high- pressure service port (B) and the low- pressure service port

(C) as shown, following the equipment manufacturer's instructions.

2.Measure the amount of refrigerant oil removed from the A/C system after the recovery process is completed. Be

sure to install the same amount of new refrigerant oil back into the A/C system before charging.

SYSTEM EVACUATION

Use only service equipment that is U.L - listed and is certified to meet the requirements of SAE J2210 to remove HFC-

134a(R- 134a) from the air conditioning system.

a.Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

b. Be careful when connecting service equipment.

c. Do not breathe refrigerant or vapor.

If accidental system discharge occurs, ventilate work area before resuming service.