steering wheel KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 582 of 1575

2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

CHECKING STEERING WHEEL FREE PLAY

1. Start the engine and with the steering wheel in the straight ahead position.

2. Measure the play while turning the steering wheel to the left and right.

Standard value :

Steering wheel free play : 30 mm (1.1 in)

3.If the play exceeds the standard value, inspect the connection between the steering shaft and tie rod ends.

CHECKING STEERING ANGLE

1.Place the front wheel on a turning radius gauge and measure the steering angle.

Standard value

VRS on Inner

38.64 °

Outer 31.78 °

VRS off Inner

41.91 °

Outer 33.54 °

2. If the measured value is not within the standard value, adjust the toe and inspect again.

CHECKING THE TIE ROD END BALL JOINT STARTING TORQUE

1.Disconnect tie rod and knuckle with the special tool (09568- 4A000).

Page 583 of 1575

2.Shake the ball joint stud several times to check for looseness.

Tie rod end ball joint starting torque :

30 kg·cm or less

3.If the starting torque exceeds the upper limit of the standard value, replace the tie rod end.

4. Even if the starting torque is below the lower limit of the standard value, check the play of the ball joint and replace

if necessary.

CHECKING STEERING WHEEL RETURN

1.The force required to turn the steering wheel and the wheel return should be the same for both moderate and sharp

turns.

2. When the steering wheel is turned 90° and held for a couple of seconds while the vehicle is being driven at 20- 30

kph (12- 19 mph), the steering wheel should return at least 20° from its central position when it is released.

If the steering wheel is turned very quickly, steering may be momentarily difficult. This is not a malfunction

because the oil pump output will be somewhat decreased.

Page 584 of 1575

CHECKING POWER STEERING BELT TENSION

Refer to EM group(Timing system).

CHECKING POWER STEERING FLUID LEVEL

1.Position the vehicle on a level surface.

2. Start the engine. With the vehicle kept stationary, turn the steering wheel several times continuously to raise the

fluid temperature to 50- 60°C (122 - 140°F).

3. With the engine at idle, turn the steering wheel fully clockwise and counter- clockwise several times.

4. Make sure that there is no foaming or cloudiness in the reservoir fluid.

5. Stop the engine and check for any difference in fluid level between a stationary and a running engine.

a.If the fluid level varies 5 mm (0.2 in) or more, bleed the system again.

b. If the fluid level suddenly rises after stopping the engine, further bleeding is required.

c. Incomplete bleeding will produce a chattering sound in the pump and noise in the flow control valve, and

lead to decreased durability of the pump.

REPLACING POWER STEERING FLUID

1.Jack up the front wheels and support them with jackstands.

2. Disconnect the return hose from the oil reservoir and plug the oil reservoir.

3. Connect a vinyl hose to the disconnected return hose, and drain the oil into a container.

4. Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently, turn the steering wheel all the way to the left and then to the right several times to drain the

fluid.

5. Connect the return hoses, then fill the oil reservoir with the specified fluid.

6. Reinstall the fuel pump fuse.

7. Start the engine. Check for oil leakage.

8. Stop the engine.

9. Bleed the system.

Power steering fluid type : PSF - 3

Total quantity : Approx 1.1 liter

AIR BLEEDING

1.Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently (for 15 ~ 20 seconds), turn the steering wheel all the way to the left and then to the right five or

six times.

Page 585 of 1575

a.During air bleeding, replenish the fluid supply so that the level never falls below the lower position of the

filter.

b. If air bleeding is done while the vehicle is idling, the air will be broken up and absorbed into the fluid. Be

sure to do the bleeding only while cranking.

c. Reinstall the fuel pump fuse, and start the engine(idling).

d. Turn the steering wheel to the left and the right until there are no air bubbles in the oil reservoir.

Do not hold the steering wheel turned all the way to either side for more than ten seconds.

e. Confirm that the fluid is not milky, and that the level is up to the position specified on the level gauge.

f. Confirm that there is little change in the surface o the fluid when the steering wheel is turned left and right.

a. If the surface of the fluid changes considerably, air bleeding should be done again.

b. If the fluid level rises suddenly when the engine is stopped, it indicates that there is still air in the

system.

c. If there is air in the system, a jingling noise may be heard from the pump and the control valve

may also produce unusual noises. Air in the system will shorten the life of the pump and other

parts.

OIL PUMP PRESSURE TEST (OIL PUMP RELIEF PRESSURE)

1.Disconnect the pressure hose from the oil pump. Connect the special tool between the oil pump and pressure hose

as illustrated.

2. Bleed the air, and then start the engine and turn the steering wheel several times so that the fluid temperature

rises to approximately 50°C (122°F).

3. Set the engine speed to 1,000 rpm.

4. Close the shut- off valve of the special tool and measure the fluid pressure to confirm that it is within the range.

standard vaule :

Relief pressure: 90 +3/- 2 kgf/cm²

Don’t keep the shut- off valve on the pressure gauge closed for longer than seconds.

Page 587 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIFICATIONS

Items Specifications

Steering column/ shaft Type

Tilt

Tilt stroke +7°/ - 11.7°

Steering gear Type

Rack & pinion

Rack stroke VRS On

148 mm (5.827 in)

VRS Off 156 mm (6.142 in)

Power steering pump Type

Vane

Diesel Relief pressure

90 kgf/cm²

Discharge 9.6 cc/rev

Gasoline Relief pressure

90 kgf/cm²

Discharge 10.5 cc/rev

SERVICE STANDARD

Items Specifications

Steering wheel free play 30 mm (1.12 in)

Steering angle VRS on

Inner

38.64°

Outer 31.78°

VRS off Inner

41.91°

Outer 33.54°

TIGHTENING TORQUE

Items NmKgf.m Lb- ft

Steering wheel lock nut 40 ~ 504.0 ~ 5.0 29 ~ 36

Steering column mounting bolts and nut 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Bolt connecting steering column to universal

joint 15 ~ 20

1.5 ~ 2.010.8 ~ 14.5

Bolt connecting universal joint to steering gear 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Steering column mounting bolts and nut 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Tie rod end castle nut 35 ~ 453.5 ~ 4.5 25 ~ 33

Front lower arm ball joint assembly bolts 90 ~ 1209.0 ~ 12.0 65 ~ 87

Stabilizer link to strut assembly nut 100 ~ 12010.0 ~ 12.0 72 ~ 87

Rear roll stopper to sub- frame bolts 50 ~ 605.0 ~ 6.0 36 ~ 43

Pressure tube to valve body housing nut 12 ~ 181.2 ~ 1.8 9 ~ 13

Pressure tube to oil pump eye bolt 65 ~ 756.5 ~ 7.5 47 ~ 54

Return tube to valve body housing nut 12 ~ 181.2 ~ 1.8 9 ~ 13

Power steering gear box to sub- frame bots 90 ~ 1109.0 ~ 11.0 65 ~ 80

LUBRICANT

Item Lubricant Quantity

Power steering fluid PSF - 31.1 L

Page 590 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Disconnect the negative terminal (A) from the battery and then wait for 30 seconds.

2.Loosen the bolts in the illustration and then remove the horn pad (A).

3.Disconnect the connectors and remove the steering wheel lock nut.

Page 591 of 1575

Tightening torque Nm (kgf.m, lb - ft):

40 ~ 50 (4.0 ~ 5.0, 29 ~ 36)

4. After making the marks on the steering wheel and shaft for reinstallation, remove the steering wheel using a SST

(09561- 11002).

Do not hammer on the steering wheel to remove it ; it may damage the steering column.

5.Loosen the screws, and then remove the lower crash pad (A).

6.Loosen the screws, and then remove the steering column upper (B) and lower shrouds (A).

7.Disconnect the connectors (A) and then remove the clock sprig (B).

Page 593 of 1575

INSTALLATION

Before installing, apply multi purpose grease to each moving parts.

1. Installation is the reverse of removal.

Align the marks on the steering wheel and shaft for reinstallation when installing the steering wheel.

DISASSEMBLY

KEY LOCK ASSEMBLY

1. Make a groove on head of the special bolt (A) by using a punch.

2.Remove the key lock assembly (A) from the steering column (B) by loosing special bolts.

3.When reassembling the key lock assembly, loosely install new special bolts to the steering column shaft.

Page 599 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the both front wheel & tire assemblies.

2. Drain the power steering fluid.

3. Remove the bolt (A) connecting steering column to universal joint.

Tightening torque Nm (kgf.m, lb - ft):

13 ~ 18 (1.3 ~ 1.8, 9.4 ~ 13.0)

4.Disconnect the pressure tube (A) from the power steering oil pump by loosening eye bolt.

Tightening torque Nm (kgf.m, lb - ft):

65 ~ 75 (6.5 ~ 7.5, 47 ~ 54)

[Diesel]

[Gasoline]

5.Disconnect the return hose (A)

Page 603 of 1575

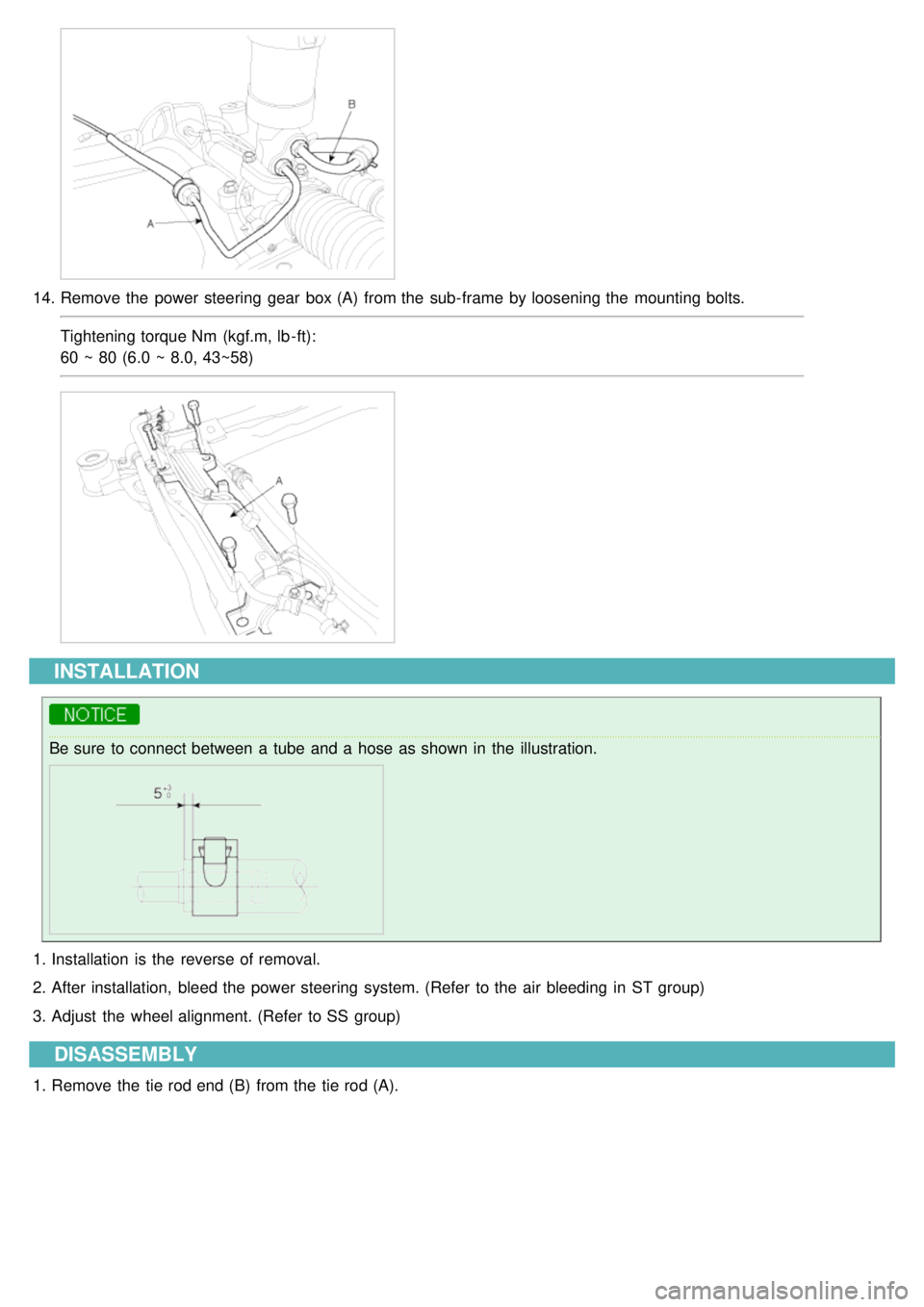

14.Remove the power steering gear box (A) from the sub- frame by loosening the mounting bolts.

Tightening torque Nm (kgf.m, lb - ft):

60 ~ 80 (6.0 ~ 8.0, 43~58)

INSTALLATION

Be sure to connect between a tube and a hose as shown in the illustration.

1.Installation is the reverse of removal.

2. After installation, bleed the power steering system. (Refer to the air bleeding in ST group)

3. Adjust the wheel alignment. (Refer to SS group)

DISASSEMBLY

1.Remove the tie rod end (B) from the tie rod (A).