wiring KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 823 of 1575

2007 > 2.7L V6 GASOLINE >

removal

a.Removal of the airbag must be performed according to the precautions/ procedures described previously.

b. Before disconnecting the front impact sensor connector, disconnect the front airbag connector(s).

c. Do not turn the ignition switch ON and do not connect the battery cable while replacing the front impact

sensor.

1. Disconnect the battery negative cable, and wait for at least three minutes before beginning work.

2. Disconnect Front Impact Sensor conncetor.

3. Remove the FIS mounting bolt then remove the Front Impact Sensor.

INSTALLATION

a.Ensure that the harness is installed and routed properly to prevent damage to the wiring.

b. Do not turn the ignition switch ON and do not connect the battery cable while replacing the front impact

sensor.

1. Install the new Front Impact Sensor with bolt then connect the SRS harness connector to the Front Impact Sensor.

Tightening torque

: 1.0 ~ 1.4 kgf.m (9.5 ~ 13.6 Nm, 7.0 ~ 10.0 lb.ft)

2. Reconnect the negative battery cable.

3. After installing the Front Impact Sensor, confirm proper system operation: Turn the ignition switch ON the SRS

indicator light should be turned on for about six seconds and then go off.

Page 828 of 1575

a.Ensure that the harness is installed and routed properly to prevent damage to the wiring.

b. Do not turn the ignition switch ON and do not connect the battery cable while replacing the side impact

sensor.

1. Install the new Side Impact Sensor with the bolt then connect the SRS harness connector to the Side Impact

Sensor.

Tightening torque

: 1.0 ~ 1.4 kgf.m (9.5 ~ 13.6 Nm, 7.0 ~ 10.0 lb.ft)

2.Install the center pillar trim. (Refer to BD group)

3. Install the door scuff trim. (Refer to BD group)

4. Reconnect the battery negative cable.

5. After installing the Side Impact Sensor, confirm proper system operation: Turn the ignition switch ON, the SRS

indicator light should be turned on for about six seconds and then go off.

REAR SIDE IMPACT SENSOR

1.Be sure that the battery negative cable is disconnected.

2. Install the new Side Impact Sensor with the bolt then connect the SRS harness connector to the Side Impact

Sensor.

Tightening torque

: 1.0 ~ 1.4 kgf.m (9.5 ~ 13.6 Nm, 7.0 ~ 10.0 lb.ft)

3.Install the rear pillar trim. (Refer to BD group)

4. Reconnect the battery negative cable.

5. After installing the Side Impact Sensor, confirm proper system operation: Turn the ignition switch ON, the SRS

indicator light should be turned on for about six seconds and then go off.

Page 850 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

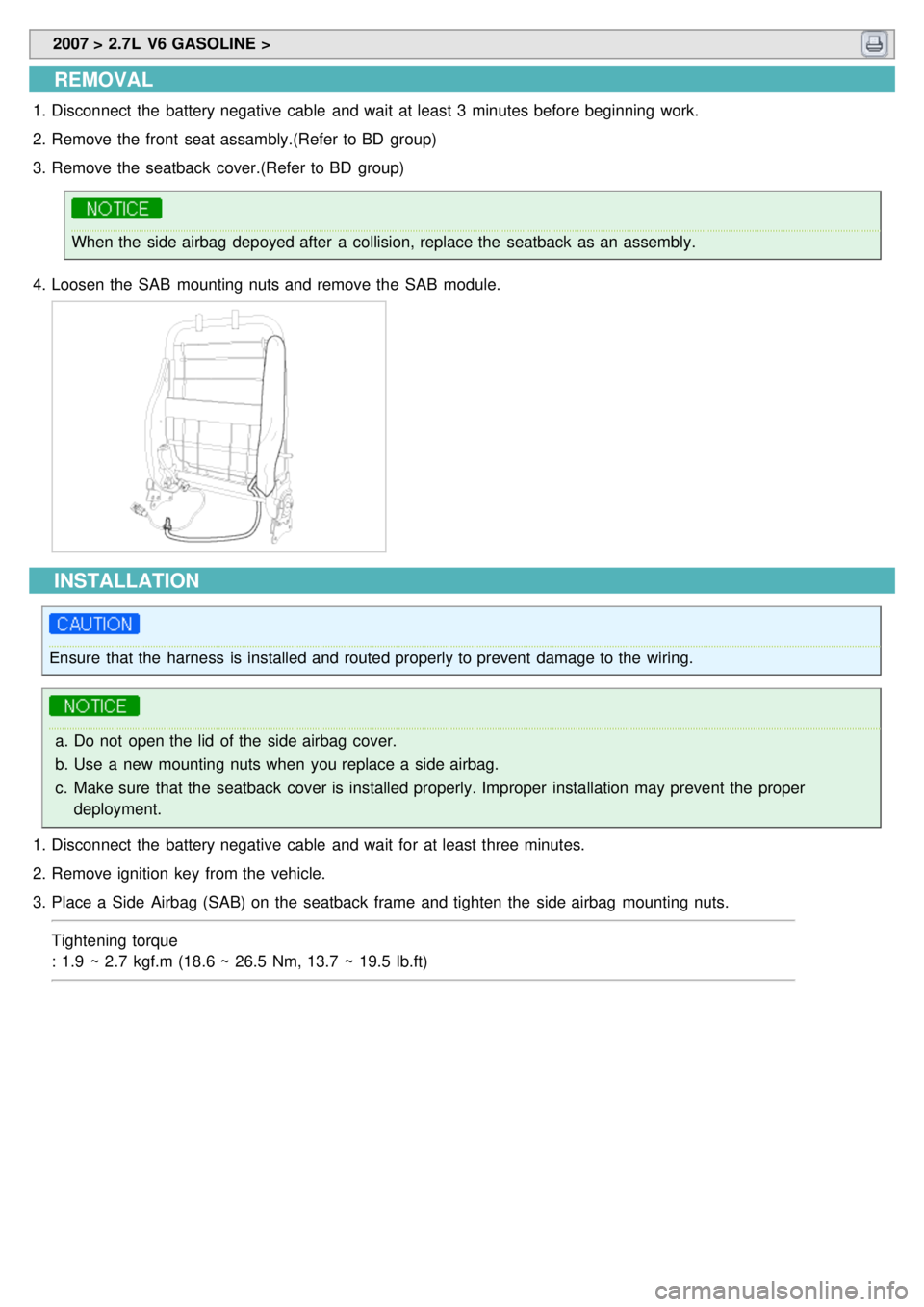

1.Disconnect the battery negative cable and wait at least 3 minutes before beginning work.

2. Remove the front seat assambly.(Refer to BD group)

3. Remove the seatback cover.(Refer to BD group)

When the side airbag depoyed after a collision, replace the seatback as an assembly.

4. Loosen the SAB mounting nuts and remove the SAB module.

INSTALLATION

Ensure that the harness is installed and routed properly to prevent damage to the wiring.

a.Do not open the lid of the side airbag cover.

b. Use a new mounting nuts when you replace a side airbag.

c. Make sure that the seatback cover is installed properly. Improper installation may prevent the proper

deployment.

1. Disconnect the battery negative cable and wait for at least three minutes.

2. Remove ignition key from the vehicle.

3. Place a Side Airbag (SAB) on the seatback frame and tighten the side airbag mounting nuts.

Tightening torque

: 1.9 ~ 2.7 kgf.m (18.6 ~ 26.5 Nm, 13.7 ~ 19.5 lb.ft)

Page 859 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Disconnect the battery negative cable, and wait for at least three minutes before beginning work.

2. Remove the front seat assembly. (Refer to BD group)

3. Loosen the Seat Belt Buckle Pretensioner mounting bolt and remove the Seat Belt Buckle Pretensioner.

INSTALLATION

1.Disconnect the battery negative cable and wait for at least three minutes.

2. Remove the ignition key from the vehicle.

3. Install the Seat Belt Buckle Pretensioner (BUPT) with the bolt.

Tightening torque

: 4.0 ~ 5.5 kgf.m (39.2 ~ 53.9 Nm, 28.9 ~ 39.8 lb.ft)

4. Install the front seat assembly.

a.Ensure that the harness is installed and routed properly to prevent damage to the wiring.

5. Reconnect the battery negative cable.

6. After installing the Seat Belt Buckle Pretensioner (BUPT), confirm proper system operation:

a. Turn the ignition switch ON; the SRS indicator light should be turned on for about six seconds and then go off.

Page 928 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

This specification applies to HCU(Hydraulic Control Unit) and ECU(Electronic Control Unit) of the HECU.(Hydraulic and

Electronic Control Unit)

This specification is for the wiring design and installation of ABS/TCS/ESC ECU.

This unit has the functions as follows.

a. Input of signal from Pressure sensor, Steering angle sensor, Yaw & Lateral G sensor, the wheel speed sensors

attached to each wheel.

b. Control of braking force / traction force/ yaw moment.

c. Failsafe function.

d. Self diagnosis function.

e. Interface with the external diagnosis tester.

Installation position : engine compartment a. Brake tube length from Master cylinder port to HECU inlet port should be max. 1m

b. The position should not be close to the engine block and not lower than the wheel.

OPERATION

The ECU shall be put into operation by switching on the operating voltage (IGN).

On completion of the initialization phase, the ECU shall be ready for operation.

In the operating condition, the ECU shall be ready, within the specified limits (voltage and temperature), to process the

signals offered by the various sensors and switches in accordance with the control algorithm defined by the software

and to control the hydraulic and electrical actuators.

Wheel Sensor signal processing

The ECU shall receive wheel speed signal from the four active wheel sensors.

The wheel signals are converted to voltage signal by the signal conditioning circuit after receiving current signal from

active wheel sensors and given as input to the MCU.

Solenoid Valve Control

When one side of the valve coil is connected to the positive voltage that is provided through the valve relay and the

other side is connected to the ground by the semiconductor circuit, the solenoid valve goes into operation.

The electrical function of the coils are always monitored by the valve test pulse under normal operation conditions.

Voltage limits

a.Overvoltage

When overvoltage is detected(above 16.8 V), the ECU switches off the valve relay and shuts down the system.

When voltage is returned to operating range, the system goes back to the normal condition after the initialization

phase.

b. Undervoltage

In the event of undervoltage(below 9.3 V), ABS control shall be inhibited and the warning lamp shall be turned on.

When voltage is returned to operating range, the warning lamp is switched off and ECU returns to normal operating

mode.

Pump Motor Checking

The ECU performs a pump motor test at a speed of 15km/h once after IGN is switched on.

Diagnostic Interface

Failures detected by the ECU are encoded on the ECU, stored in a EEPROM and read out by diagnostic equipment

when the ignition switch is turned on.

The diagnosis interface can also be used for testing the ECU during production of the ECU and for actuating the HCU

(Air - bleeding line or Roll and Brake Test line).

Warning Lamp module

Page 1027 of 1575

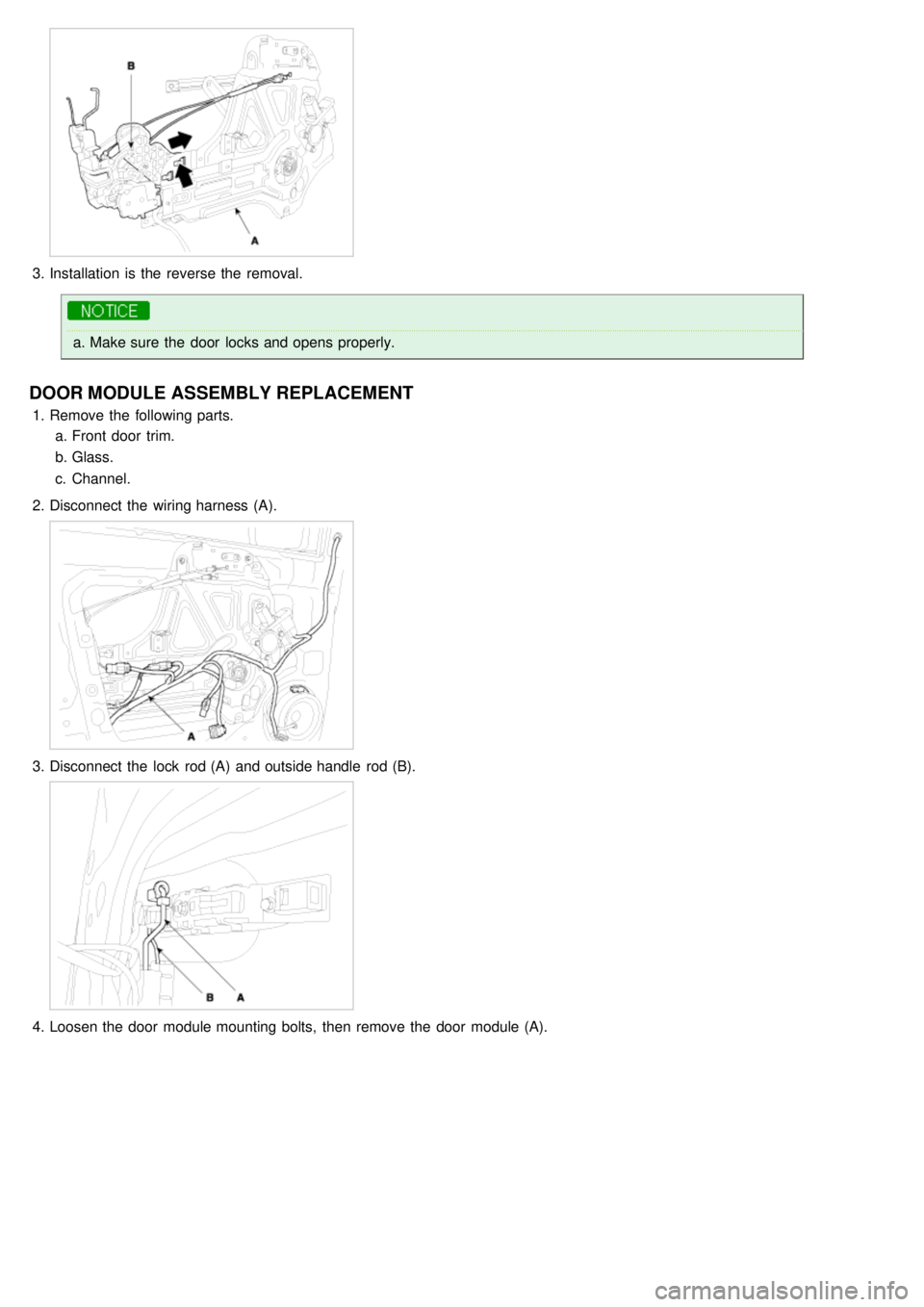

3.Installation is the reverse the removal.

a.Make sure the door locks and opens properly.

DOOR MODULE ASSEMBLY REPLACEMENT

1.Remove the following parts.

a. Front door trim.

b. Glass.

c. Channel.

2. Disconnect the wiring harness (A).

3.Disconnect the lock rod (A) and outside handle rod (B).

4.Loosen the door module mounting bolts, then remove the door module (A).

Page 1152 of 1575

2007 > 2.7L V6 GASOLINE >

GENERAL TROUBLESHOOTING INFORMATION

BEFORE TROUBLESHOOTING

1. Check applicable fuses in the appropriate fuse/relay box.

2. Check the battery for damage, state of charge, and clean and tight connections.

a.Do not quick- charge a battery unless the battery ground cable has been disconnected, otherwise you will

damage the generator diodes.

b. Do not attempt to crank the engine with the battery ground cable loosely connected or you will severely

damage the wiring.

3. Check the generator belt tension.

HANDLING CONNECTORS

1.Make sure the connectors are clean and have no loose wire terminals.

2. Make sure multiple cavity connectors are packed with grease (except watertight connectors).

3. All connectors have push - down release type locks (A).

4.Some connectors have a clip on their side used to attach them to a mount bracket on the body or on another

component. This clip has a pull type lock.

5. Some mounted connectors cannot be disconnected unless you first release the lock and remove the connector from

its mount bracket (A).

6.Never try to disconnect connectors by pulling on their wires; pull on the connector halves instead.

7. Always reinstall plastic covers.

Page 1159 of 1575

2007 > 2.7L V6 GASOLINE >

CUSTOMER COMPLAINT ANALYSIS CHECK SHEET

TROUBLESHOOTING

There are six areas where a problem can occur: wiring harness, the radio, the cassette tape deck, the CD player, and

speaker. Troubleshooting enables you to confine the problem to a particular area.

Page 1182 of 1575

2007 > 2.7L V6 GASOLINE >

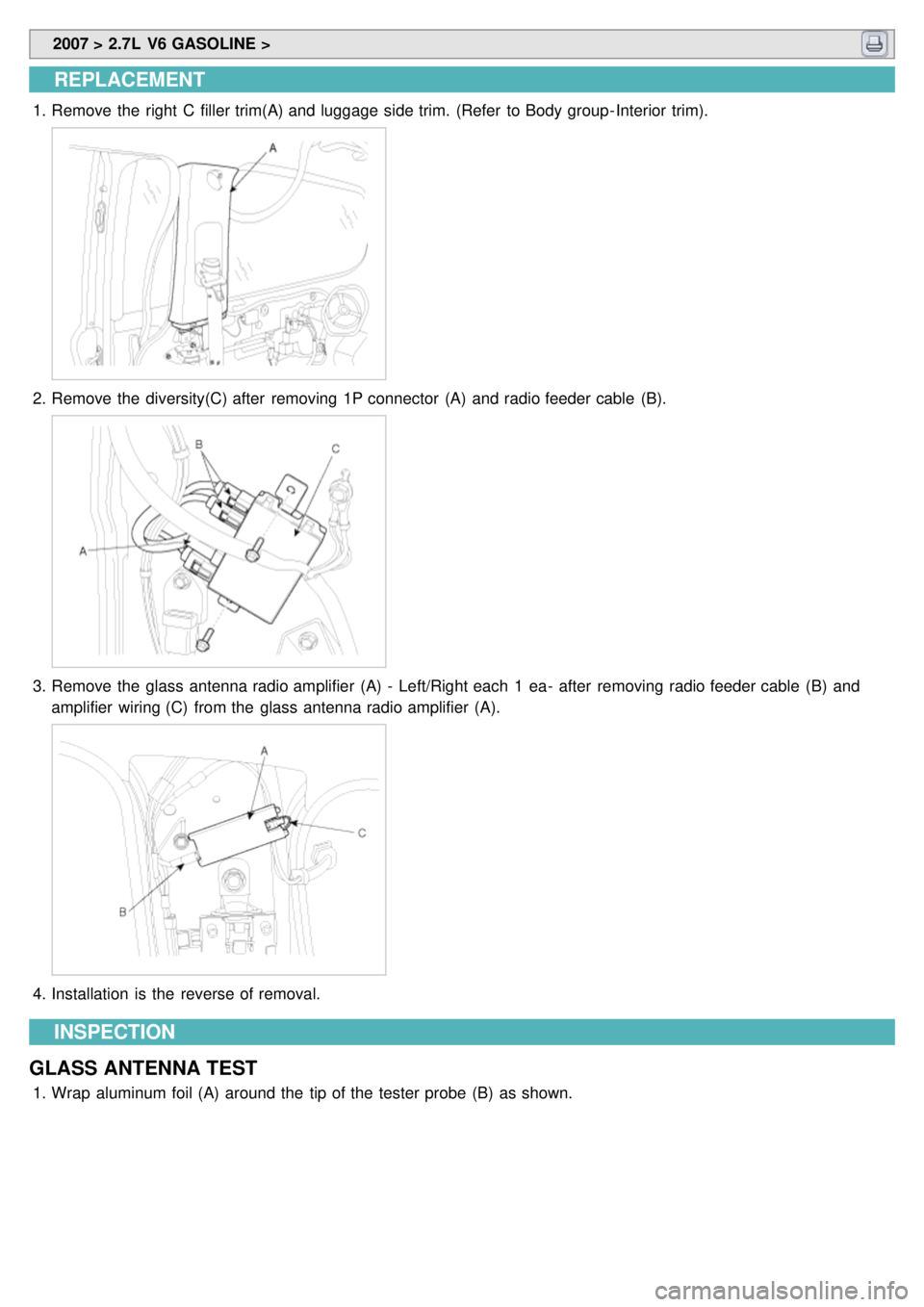

REPLACEMENT

1.Remove the right C filler trim(A) and luggage side trim. (Refer to Body group - Interior trim).

2.Remove the diversity(C) after removing 1P connector (A) and radio feeder cable (B).

3.Remove the glass antenna radio amplifier (A) - Left/Right each 1 ea- after removing radio feeder cable (B) and

amplifier wiring (C) from the glass antenna radio amplifier (A).

4.Installation is the reverse of removal.

INSPECTION

GLASS ANTENNA TEST

1. Wrap aluminum foil (A) around the tip of the tester probe (B) as shown.

Page 1272 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the nagative(- ) battery terminal.

2. Remove the door trim panel (Refer to Body group - front door).

3. Remove the switch connector (16pin) from the wiring harness, And then loosen the mounting screws (3EA).

4.Remove the switch from the front door panel.

5. Installation is the reverse of removal.