wiring KIA CARNIVAL 2007 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1282 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

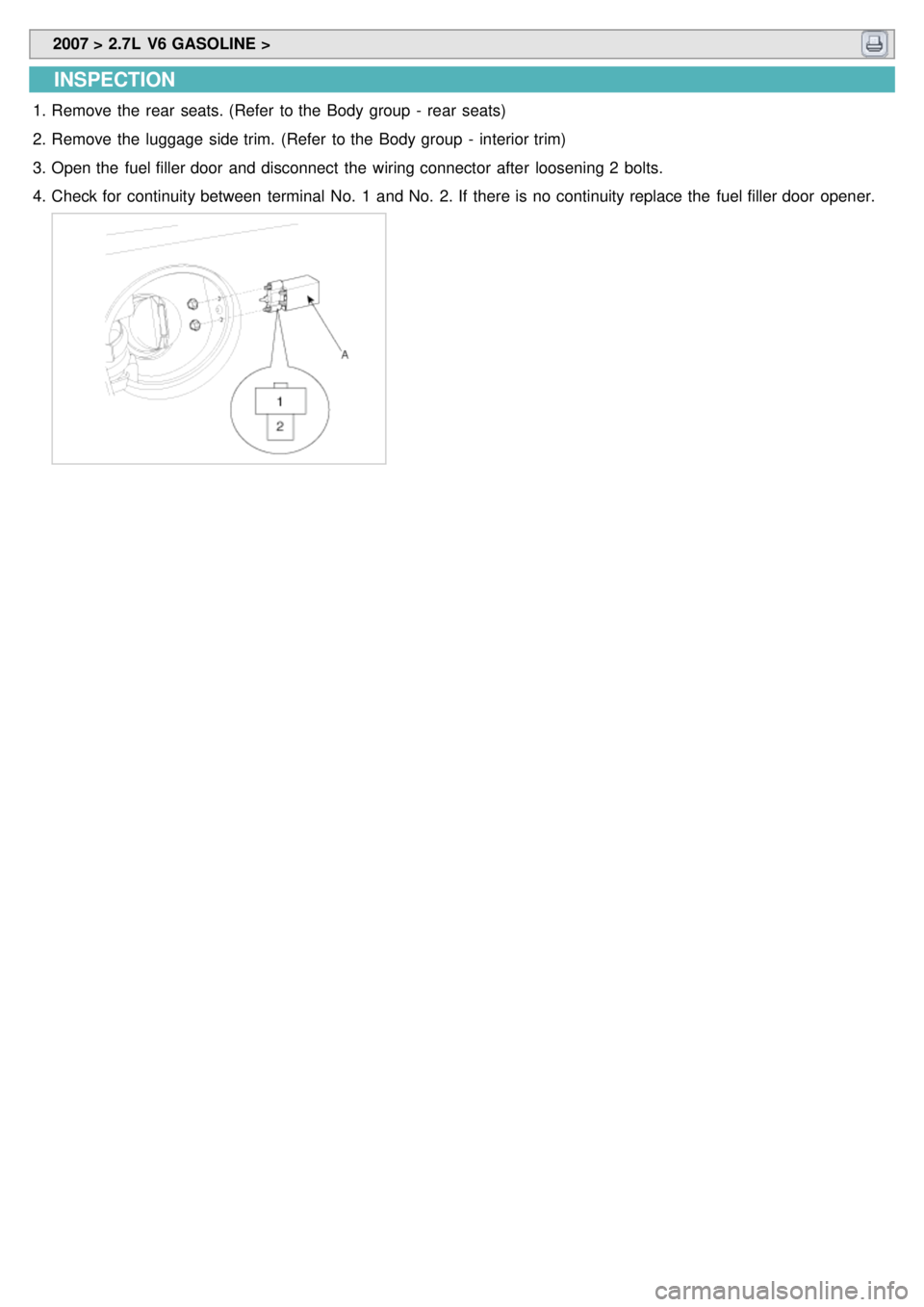

1.Remove the rear seats. (Refer to the Body group - rear seats)

2. Remove the luggage side trim. (Refer to the Body group - interior trim)

3. Open the fuel filler door and disconnect the wiring connector after loosening 2 bolts.

4. Check for continuity between terminal No. 1 and No. 2. If there is no continuity replace the fuel filler door opener.

Page 1331 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Check the following items prior to performing Power Sliding Door System service.

1. Manual movement

Make sure the sliding door moves manually. Place the ON/OFF switch on the overhead console in the OFF

position. Move the door manually and check for proper door fit and latch effort. Check for interference with other

body parts such as latch striker, trim, and weather seals.

2. Battery voltage

Make sure the battery is fully charged. The PSD system is an electronic device and requires a minimum battery

voltage to operate. The PSDM(Power sliding door module) monitors the battery voltage present at the PSDM input

battery input and will not permit operation if the battery voltage is out of range.

3. Fuses

Two fuses protect the battery supply to the PSDM(Power sliding door module), one for Power, and one for logic.

Check that the fuses are intact

4. Repeat Operations

Make sure the customer has not been operating the PSD repeatedly while the vehicle is turned off. The battery will

be discharged and the PSDM(Power sliding door module) will not permit operation.

5. Vehicle on Steep Grade

Make sure the customer has not been operating the PSD system when the vehicle is parked on a steep grade

(greater than 30%). The system will operate but the force of gravity and normal flex of the vehicle body may affect

proper operation.

6. Obstacle Detection

The obstacle detection force is not adjustable. Factors that may affect the force are vehicle grade, battery voltage,

or dirt in sliding door tracks.

7. Outside handle response time

When the vehicle has been parked and OFF, there may be a delay before power operation starts after the outside

handle is pulled. This is normal because the PSDM(Power sliding door module) must wake up and check for proper

conditions before starting a power open operation.

8. The sliding doors are not identical. Open and close times and obstacle detection efforts may vary when comparing

the two doors. This is normal and is caused by vehicle build conditions such as door fit and rolling resistance.

9. Scan tool Diagnostic tool

Connect Scan tool to the K- line and check status of system.

POWER SLIDING DOOR SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

Sliding Door opens

unexpectedly Accidental activation or failure of

open/close command switch

Check for shorted or defective switch

Failure of latch assembly Check wiring connections

Check for diagnostic trouble codes

Failure of Power Sliding Door or Body

Control module Disconnect then reconnect battery or fuse to

reset module and function sliding door. If no

function exists check for loose wire

connections. See Body Diagnostic Manual for

detailed procedures

Sliding Door will not power

open or close Not in Park or false indication

Check switch status with SCAN tool

Battery voltage at PSDM is too low

<9.5V to start operation and

<8.0V to continue operation Check for proper voltage at the PSDM.

Charge battery

Blown fuse Check for blown fuse

BCM or sliding door control module

Page 1332 of 1575

BCM or sliding door control module

critical fault codesCheck for diagnostic trouble codes

Failure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Failure of motor assembly Test motor assembly

Binding or sticking of components Establish location of binding and replace

necessary components

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to wiring diagrams

Power loss during Sliding

Door operation Wiring problems (system or vehicle)

Troubleshoot using electrical schematics

Refer to wiring diagrams

Battery voltage at PSDM is too low

<9.5V to start operation and

<8.0V to continue operation Check for proper voltage at the PSDM.

Charge battery

Failure of Power Sliding Door or Body

Control Module Check for diagnostic trouble codes

Failure of motor assembly Test motor assembly

Sliding Door does not close

to primary latch position Door mis - alignment Check latch and striker alignment

Check rollers and track alignment

Binding or sticking of components Establish location of binding and adjust or

replace necessary components

Failure of Power Sliding Door or Body

Control Module Check for diagnostic trouble codes

Sliding Door seal force too high Inspect seals for damage, mis - assembly,

foreign matter or other possible obstruction

Failure of motor assembly Test motor assembly

Latch will not release from

primary position Not in Park or false indication

Check switch status with SCAN tool

Battery voltage at PSDM is too low Check for proper voltage at the PSDM

Charge battery

Blown fuse Check fuse and replace if required

Failure of latch assembly Check switch status with scan tool

Check for foreign matter or damaged

components preventing the operation of latch

assembly

Troubleshoot using body diagnostic manual.

Replace latch assembly, if necessary

Failure of outside or inside handle

connection Check handle connections on brainplate.

Failure of Power Sliding Door or Body

Control Module Check for diagnostic trouble codes.

Binding or sticking of components Establish location of binding and adjust or

replace necessary components

Key fob or overhead

console switch does not

power operate sliding door Blown Fuse

Check fuse and replace

Battery voltage at PSDM is too low Check for proper voltage at the PSDM.

Charge battery

Refer to wiring diagrams

Page 1333 of 1575

Wiring problems (system or vehicle)Refer to wiring diagrams

Check for diagnostic trouble codes.

Does Not Power Unlatch

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check for diagnostic trouble codes.

Check Detent switch.

Troubleshoot using body diagnostic manual

Failure of Latch Release Actuator Check actuator and replace if necessary

Wiring problems (system or vehicle) Refer to wiring diagrams

Check for diagnostic trouble codes.

Failure of Body Control Module (BCM) Troubleshoot using body diagnostic manual

Replace BCM if necessary

Failure of key fob Reprogram key fob

Replace key fob if necessary

Failure of Power Sliding Door Module Check for diagnostic trouble codes.

See Body Diagnostic Manual for detailed

procedures

Failure of sliding door motor assembly Check for foreign matter preventing the

operation of motor assembly

Check wire connections

Drive Unit clutch does not engage.

Replace Drive Unit.

Troubleshoot using Body Diagnostic Manual

Replace motor if necessary

Sliding Door does not stay

open Hold Open Latch not working Check if sliding door powers open to hold

open latch

Check if H- O - L is working

High inside/outside opening

effort Bound cables Check for smooth manual operation

Check for broken attachments

Drive unit jammed or did not disengage Troubleshoot using Body Diagnostic Manual

Replace components, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Sliding Door continues to

power close Failure of latch assembly Check wire connections and Detent switch

Check for foreign matter

Troubleshoot using Body Diagnostic Manual

Control Module Check for diagnostic trouble codes

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to wiring diagrams

Sliding Door continues to

power open Failure of PSDM Check for diagnostic trouble codes

See Body Diagnostic Manual for detailed

procedures

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to Wiring Diagrams

Sliding Door opens very

slowly Battery voltage at PSDM is too low

Check for proper voltage at the PSDM

Charge battery

Page 1342 of 1575

TORQUE : 7 - 11 N.m (0.7 - 1.1 Kg.m)

10.Loosen the mounting bolt (1EA) and nuts (2EA). And then remove the power sliding door drive unit assembly after

removing the front cable.

TORQUE : 7 - 11 N.m (0.7 - 1.1 Kg.m)

11. Installation is the reverse of removal.

12. When installation, check the grease on the center roller hinge barrel and club contact part (A).

a.A learn cycle must be performed whenever the power is removed.

b. Check the normal operation whenever a power sliding door component is removed or replaced. If the

chime sound is heard, check the DTC, wiring harness and cable connections.

Page 1344 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal..

2. Remove the rear trim panel (Refer to the Body group - interior trim)

3. Remove the connectors and mounting bolts (2EA) from the power sliding door unit(A). And then remove the power

sliding door control module (B).

TORQUE 0.25 - 0.35N.m(0.025- 0.035Kg.m)

4.Installation is the reverse of removal.

a.A learn cycle must be performed whenever the power is removed.

b. Check the normal operation whenever a power sliding door component is removed or replaced. If the

chime sound is heard, check the DTC, wiring harness and cable connections.

Page 1372 of 1575

2007 > 2.7L V6 GASOLINE >

DIAGNOSIS AND TESTING - POWER TAILGATE SYSTEM

The power tailgate system is a complex system containing many components. In order to perform conclusive testing,

or receive outputs the power tailgate control module must be checked.

The most reliable, efficient, and accurate means to diagnose the power tailgate system requires the use of a scan tool

and the proper Body Diagnostic Procedures manual. The scan tool can be used to observe current switch status

recorded in the power tailgate control module to help the technician diagnose an inoperative switch.

Before any testing of the power tailgate system is attempted, the battery should be fully charged, all power tailgate

system inhibitors read and understood (Refer to power tailgate system description for list).

Following are quick reference diagnostic tables to help when diagnosing and testing the power tailgate system.

CONDITION POSSIBLE CAUSES CORRECTION

Tailgate opens unexpectedly Accidental activation or Failure of

open/close command switch

Check for shorted or defective switch

Failure of latch assembly Check wiring connections

Check for trouble codes, replace latch if

necessary

Failure of Power Tailgate or Body

Control module Disconnect then reconnect battery or fuse to

reset module, function tailgate, if no function

exists check for loose wire connections, see

Body Diagnostic Manual for detailed

procedures

Tailgate will not power open

or close Not in Park or false indication

Check switch status with SCAN tool

Battery voltage at PTGM is too low Check for proper voltage at the PTGM

Charge battery

Blown fuse Check for blown fuse

Gas strut failure Check condition of tailgate gas struts

BCM or tailgate control module critical

fault codes Check code status with SCAN tool

Failure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Tailgate will not power open

or close Failure of motor assembly

Test motor assembly

Binding or sticking of components Establish location of binding and replace

necessary components

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to wiring diagrams

Power loss during Tailgate

operation Wiring problems (system or vehicle)

Troubleshoot using electrical schematics.

Refer to wiring diagrams

Battery voltage at PTGM is too low Check for proper voltage at the PTGM

Charge battery

Failure of Power Tailgate or Body

Control Module Check for diagnostic trouble codes with

SCAN tool

Failure of motor assembly Test motor assembly

Failure of latch assembly Check wire connections and for blown fuse

Check for diagnostic trouble codes and cycle

with SCAN tool

Troubleshoot using Body Diagnostic Manual.

Replace latch assembly, if necessary

Page 1374 of 1575

Failure of tailgate motor assemblyMotor clutch does not engage, replace

assembly

Full open switch inoperative, replace switch, if

necessary

Troubleshoot using Body Diagnostic Manual

Replace motor, if necessary

Tailgate does not stay open Failure of tailgate gas struts Replace gas struts

Check for broken attachments

High inside/outside opening

effort Failure of tailgate gas struts

Replace gas struts

Check for broken attachments

Drive unit jammed or did not disengage Troubleshoot using Body Diagnostic Manual

Replace components, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Tailgate continues to cinch

closed Failure of latch assembly

Check wire connections and for blown fuse

Check switches with SCAN tool

Tail gate continues to power

close Failure of latch assembly

Check wire connections

Check for foreign matter

Troubleshoot using Body Diagnostic Manual

Control Module Check for diagnostic trouble codes with Scan

tool

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to wiring diagrams

Tailgate continues to power

open Failure of PTGM or BCM

Check for diagnostic trouble codes and cycle,

see Body Diagnostic Manual for detailed

procedures

Failure of motor assembly Check for continuous drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics

Refer to Wiring Diagrams

Tailgate opens very slowly Battery voltage at PTGM is too low

Check for proper voltage at the PTGM

Charge battery

Failure of tailgate gas struts Replace gas struts, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Grade of vehicle too steep for power

operation Operate tailgate manually

Failure of tailgate motor assembly Replace motor assembly, if necessary

Squeaks, Noises and rattles Foreign material in tail gate

compartment

Remove foreign material

Worn/Loose components Check and tighten loose components

DTC LIST DTC CODE DISPLAY

B1101 Battery Voltage High

B1102 Battery Voltage Low

Page 1381 of 1575

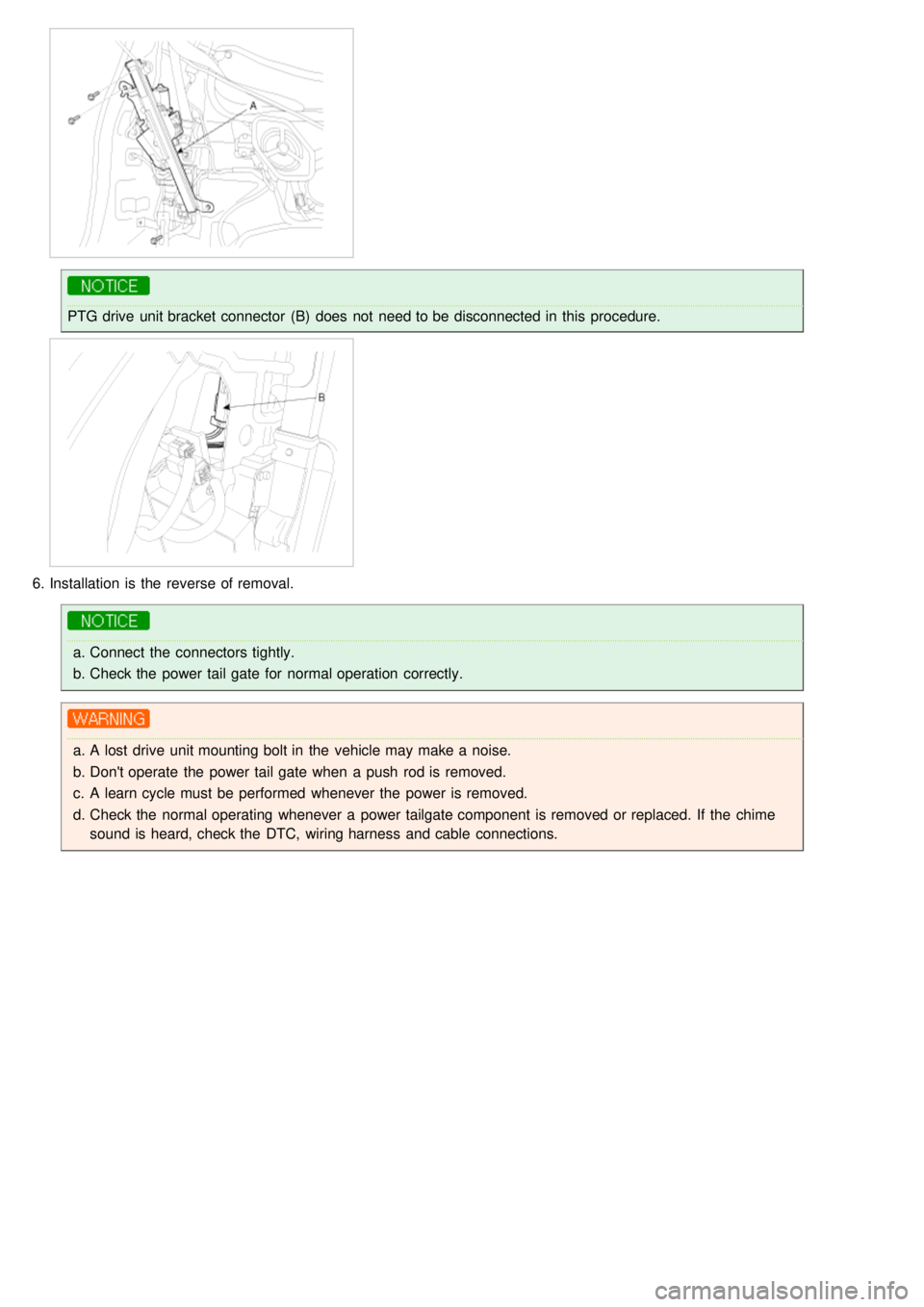

PTG drive unit bracket connector (B) does not need to be disconnected in this procedure.

6.Installation is the reverse of removal.

a.Connect the connectors tightly.

b. Check the power tail gate for normal operation correctly.

a.A lost drive unit mounting bolt in the vehicle may make a noise.

b. Don't operate the power tail gate when a push rod is removed.

c. A learn cycle must be performed whenever the power is removed.

d. Check the normal operating whenever a power tailgate component is removed or replaced. If the chime

sound is heard, check the DTC, wiring harness and cable connections.

Page 1382 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

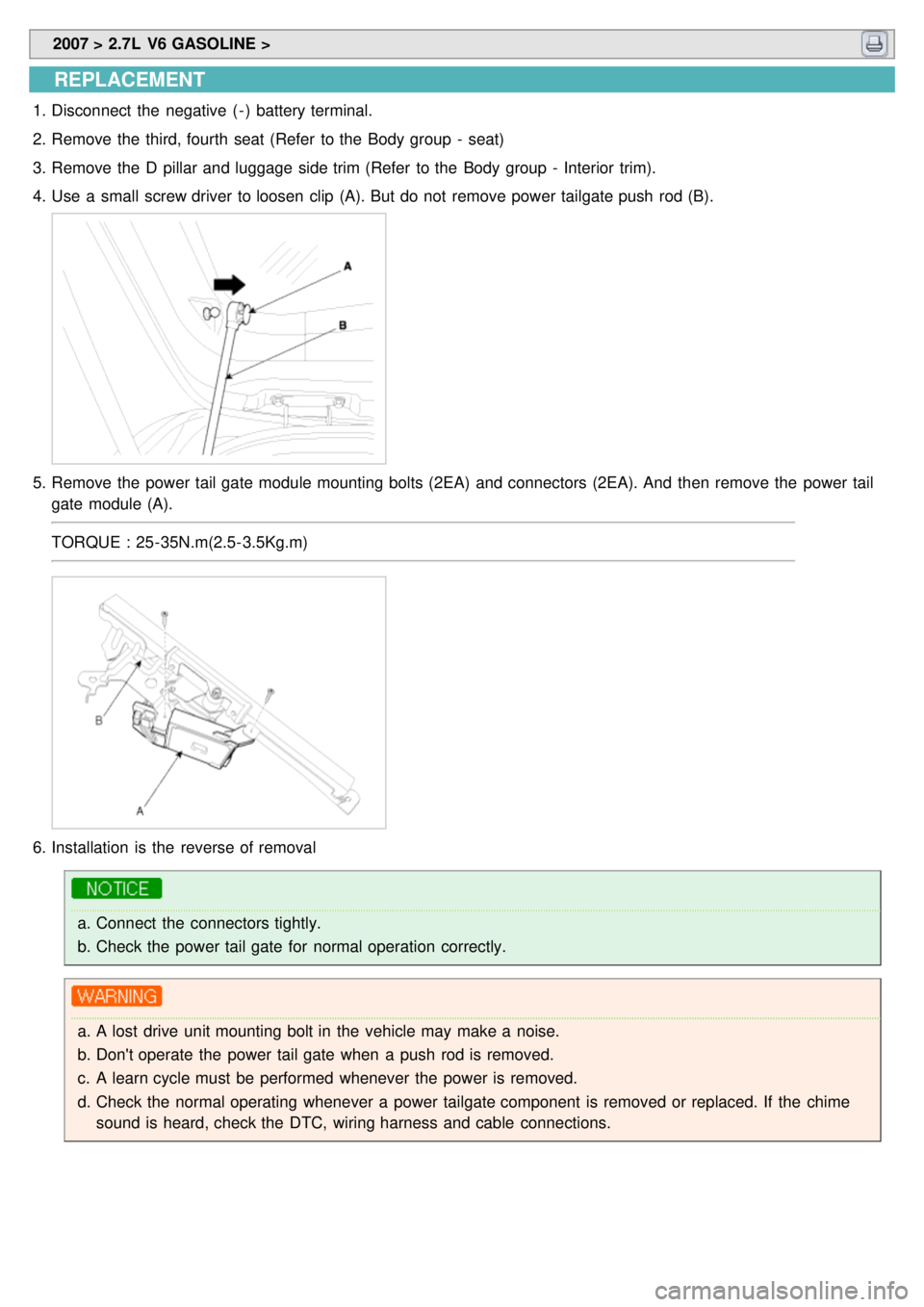

1.Disconnect the negative ( - ) battery terminal.

2. Remove the third, fourth seat (Refer to the Body group - seat)

3. Remove the D pillar and luggage side trim (Refer to the Body group - Interior trim).

4. Use a small screw driver to loosen clip (A). But do not remove power tailgate push rod (B).

5.Remove the power tail gate module mounting bolts (2EA) and connectors (2EA). And then remove the power tail

gate module (A).

TORQUE : 25- 35N.m(2.5- 3.5Kg.m)

6.Installation is the reverse of removal

a.Connect the connectors tightly.

b. Check the power tail gate for normal operation correctly.

a.A lost drive unit mounting bolt in the vehicle may make a noise.

b. Don't operate the power tail gate when a push rod is removed.

c. A learn cycle must be performed whenever the power is removed.

d. Check the normal operating whenever a power tailgate component is removed or replaced. If the chime

sound is heard, check the DTC, wiring harness and cable connections.