check engine KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 937 of 1575

c.Stop lamp switch circuit.

d. Check the hydraulic circuit for leakage.

Communication with Scan tool is not possible.

(Communication with any system is not possible) a.

Power source circuit

b. Diagnosis line

Communication with Scan tool is not possible.

(Communication with ABS only is not possible) a.

Power source circuit

b. Diagnosis line

c. HECU

When ignition key is turned ON (engine OFF), the ABS

warning lamp does not light up. a.

ABS warning lamp circuit

b. HECU

Even after the engine is started, the ABS warning lamp

remains ON. a.

ABS warning lamp circuit

b. HECU

During ABS operation, the brake pedal may vibrate or may not be able to be depressed. Such phenomena are

due to intermittent changes in hydraulic pressure inside the brake line to prevent the wheels from locking and is

not an abnormality.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the

problem is still occurring, replace the ABS control module. a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

c. Inoperative hydraulic circuit for leakage

d. Inoperative HECU

INSPECTION PROCEDURES

DTC INSPECTION

1. Connect the Scan Tool with the data link connector and turn the ignition switch ON.

2. Verify that the system is operating to specifications.

Is the system operating to specifications ?

▶ Check the power source circuit.

▶ Erase the DTC and recheck using Scan Tool.

CHECK THE POWER SOURCE CIRCUIT.

1. Disconnect the connector from the ABS control module.

2. Turn the ignition switch ON, measure the voltage between terminal 18 of the ABS control module harness side

connector and body ground.

Specification: approximately B+

Is the voltage within specification?

▶ Check the ground circuit.

▶ Check the harness or connector between the fuse (10A) in the engine compartment junction block and the ABS

control module. Repair if necessary.

Page 940 of 1575

▶ Replace the leaking hydraulic lines.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Possible malfunction in the power supply system (including ground)

for the diagnosis line. a.

An open in the wire

b. Poor ground

c. Inoperative power source circuit

INSPECTION PROCEDURES

CHECK THE POWER SUPPLY CIRCUIT FOR THE DIAGNOSIS

Measure the voltage between terminal 9 of the data link connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Check the ground circuit for the diagnosis.

▶ Repair an open in the wire. Check and replace fuse (15A) from the engine compartment junction block.

CHECK THE GROUND CIRCUIT FOR THE DIAGNOSIS

Check for continuity between terminal 5 of the data link connector and body ground.

Is there continuity?

▶ Repair an open in the wire between terminal 5 of the data link connector and ground point.

DETECTING CONDITION

Trouble Symptoms Possible Cause

When communication with Scan Tool is not possible, the cause may

be probably an open in the HECU power circuit or an open in the a.

An open in the wire

Page 941 of 1575

be probably an open in the HECU power circuit or an open in the

diagnosis output circuit.b.

Inoperative HECU

c. Inoperative power source circuit

INSPECTION PROCEDURES

CHECK FOR CONTINUITY IN THE DIAGNOSIS LINE

1. Disconnect the connector from the ABS control module.

2. Check for continuity between terminals 11 of the ABS control module connector and 1 of the data link connector.

Is there continuity?

▶ Check the power source of ABS control module.

▶ Repair an open in the wire.

CHECK THE POWER SOURCE OF ABS CONTROL MODULE

1. Disconnect the connector from the ABS control module.

2. Turn the ignition switch ON, measure the voltage between terminal 18 of the ABS control module harness side

connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Check for poor ground.

▶ Check the harness or connector between the fuse (10A) in the engine compartment junction block and the ABS

control module.Repair if necessary.

CHECK FOR POOR GROUND

Check for continuity between terminal 5 of the data link connector and ground point.

▶ Replace the ABS control module and recheck.

▶ Repair an open in the wire or poor ground.

Page 942 of 1575

DETECTING CONDITIONTrouble Symptoms Possible Cause

When current flows in the HECU the ABS warning lamp turns from

ON to OFF as the initial check.Therefore if the lamp does not light up,

the cause may be an open in the lamp power supply circuit, a blown

bulb, an open in the both circuits between the ABS warning lamp and

the HECU, and the inoperative HECU. a.

Inoperative ABS warning lamp bulb

b. Blown No.2 fuse (10A) in the engine

compartment junction block

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

PROBLEM VERIFICATION

Disconnect the connector from the ABS control module and turn the ignition switch ON.

Does the ABS warning lamp light up?

▶ It is normal. Recheck the ABS control module.

▶ Check the power source for the ABS warning lamp.

CHECK THE POWER SOURCE FOR THE ABS WARNING LAMP

1. Disconnect the instrument cluster connector and turn the ignition switch ON.

2. Measure the voltage between terminal 8 of the cluster harness side connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Repair bulb or instrument cluster assembly.

▶ Check for blown fuse.

Page 943 of 1575

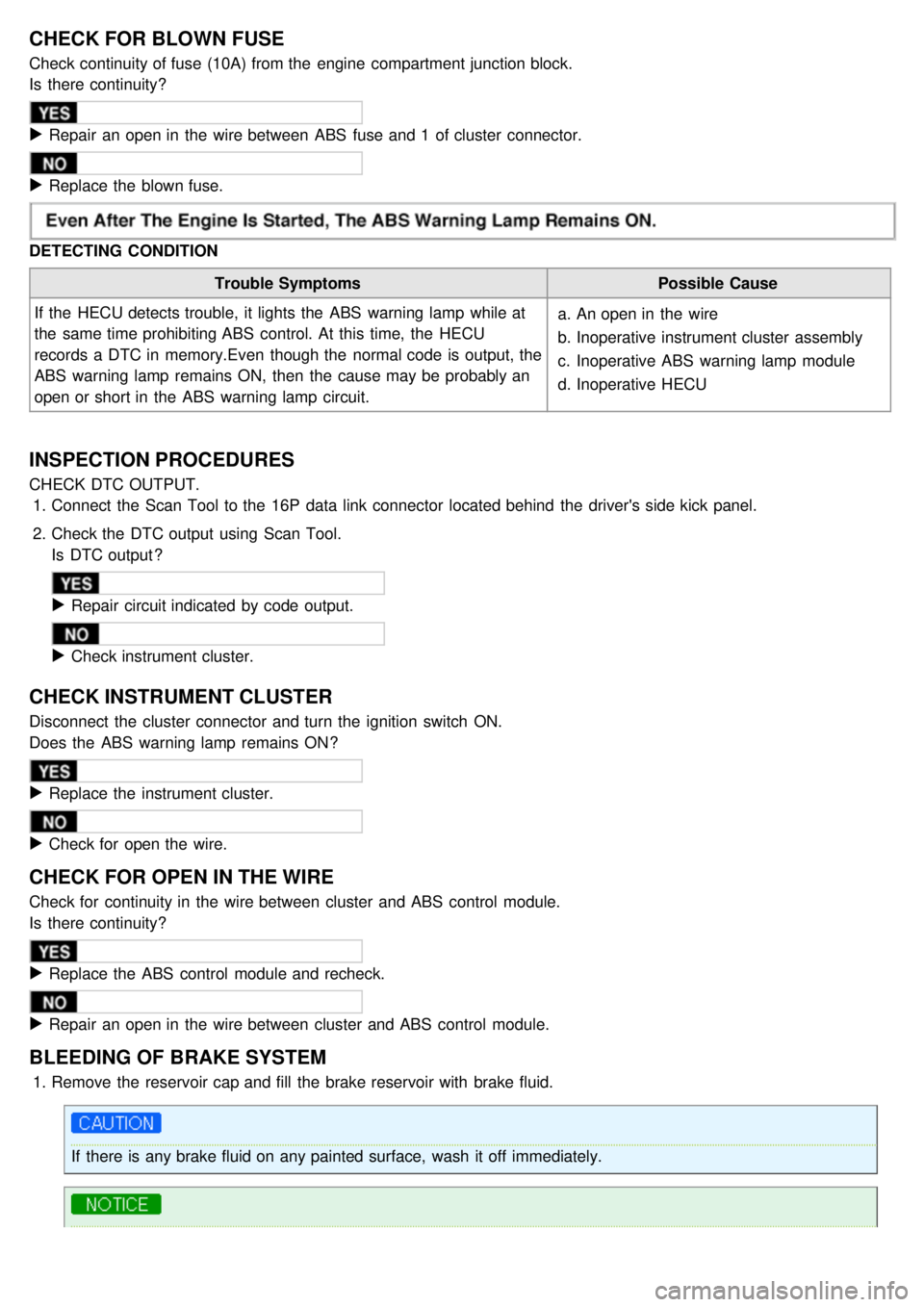

CHECK FOR BLOWN FUSE

Check continuity of fuse (10A) from the engine compartment junction block.

Is there continuity?

▶ Repair an open in the wire between ABS fuse and 1 of cluster connector.

▶ Replace the blown fuse.

DETECTING CONDITION

Trouble Symptoms Possible Cause

If the HECU detects trouble, it lights the ABS warning lamp while at

the same time prohibiting ABS control. At this time, the HECU

records a DTC in memory.Even though the normal code is output, the

ABS warning lamp remains ON, then the cause may be probably an

open or short in the ABS warning lamp circuit. a.

An open in the wire

b. Inoperative instrument cluster assembly

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

CHECK DTC OUTPUT.

1. Connect the Scan Tool to the 16P data link connector located behind the driver's side kick panel.

2. Check the DTC output using Scan Tool.

Is DTC output ?

▶ Repair circuit indicated by code output.

▶ Check instrument cluster.

CHECK INSTRUMENT CLUSTER

Disconnect the cluster connector and turn the ignition switch ON.

Does the ABS warning lamp remains ON?

▶ Replace the instrument cluster.

▶ Check for open the wire.

CHECK FOR OPEN IN THE WIRE

Check for continuity in the wire between cluster and ABS control module.

Is there continuity?

▶ Replace the ABS control module and recheck.

▶ Repair an open in the wire between cluster and ABS control module.

BLEEDING OF BRAKE SYSTEM

1. Remove the reservoir cap and fill the brake reservoir with brake fluid.

If there is any brake fluid on any painted surface, wash it off immediately.

Page 1152 of 1575

2007 > 2.7L V6 GASOLINE >

GENERAL TROUBLESHOOTING INFORMATION

BEFORE TROUBLESHOOTING

1. Check applicable fuses in the appropriate fuse/relay box.

2. Check the battery for damage, state of charge, and clean and tight connections.

a.Do not quick- charge a battery unless the battery ground cable has been disconnected, otherwise you will

damage the generator diodes.

b. Do not attempt to crank the engine with the battery ground cable loosely connected or you will severely

damage the wiring.

3. Check the generator belt tension.

HANDLING CONNECTORS

1.Make sure the connectors are clean and have no loose wire terminals.

2. Make sure multiple cavity connectors are packed with grease (except watertight connectors).

3. All connectors have push - down release type locks (A).

4.Some connectors have a clip on their side used to attach them to a mount bracket on the body or on another

component. This clip has a pull type lock.

5. Some mounted connectors cannot be disconnected unless you first release the lock and remove the connector from

its mount bracket (A).

6.Never try to disconnect connectors by pulling on their wires; pull on the connector halves instead.

7. Always reinstall plastic covers.

Page 1292 of 1575

3.If system of some relay is not operate accurately, replace with a new one and check the system.

REPLACEMENT

FAM (FRONT AREA MODULE)

1. Disconnect the negative ( - ) battery terminal.

2. Remove the FAM cover of engine room.

3. Remove the FAM connectors (2EA) (A) and battery terminal nut (1EA) (B).

4.Remove FAM mounting bolts (3EA) (A) and remove the FAM (B) from splash shield (C).

5.Disconnect the connector from splash shield.

6. Installation is the reverse of removal.

Page 1309 of 1575

Tolerance(rpm) 5,000

6,0007,0008,000Engine

Revolution (rpm) ±150

±180±210 -Gasoline

±150 ±150 --Diesel

FUEL GAUGE SENDER

1.Using an ohmmeter, measure the resistance between terminals 1 and 2 of sender connector (A) at each float level.

2.Also check that the resistance changes smoothly when the float is moved from "E" to "F".

Position Resistance(Ω)

Sender (E) 200

Warning lamp 160

1/2 54.5

Sender (F) 8

If the height resistance is not within specifications, replace the fuel sender as an assembly.

After completing this test, wipe the sender dry and reinstall it in the fuel tank.

ENGINE COOLANT TEMPERATURE SENDER

1.Using an ohmmeter, measure the resistance between the terminal 2 and ground.

Temperature[°F(°C)] 140

(60) 185

(85) 230

(110) 257

(127.4) E/G

Resistance (Ω) 12856.1 25.216.1Gasoline

Temperature [°F(°C)] 120

(49) 160

(71) 230

(110) 260

(127.4) E/G

Resistance (Ω) 209.688.724.315.9Diesel

OIL PRESSURE SWITCH

1.Check that there is continuity between the oil press switch terminal and ground with the engine off.

2. Check that there is no continuity between the terminal and ground with the engine running.

3. If operation is not as specified, replace the switch.

Page 1420 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

While operating the components, check whether the operations are normal as shown in the timing chart.

1. The defog function can be activated only when engine is running and ignition key is in RUN position.

If the defogger is switched ON, the defogger will stay ON for 20 minutes duration.

While Windshield Defog is on, the windshield defog button is illuminated

If the switch is pushed again while defog is already active, defog stops.

If the engine stops while defog is on, defog stops and it is not automatically turned on when the engine is started

again.

Rear defog works exactly in the same way as windshield defog using the Rear Defog Switch button as input.

2.Rear Defog Pause

When IPM receives tailgate flasher control CAN message transition to tailgate flash value, rear defog is inhibited for

30s.

The 20 min rear defog timer is frozen during this pause.

If the user turns on rear defog function while this pause is going on, rear defog is set to ON only at the end of the

pause.

This pause has no impact on Rear Defog Switch illumination.

When IPM receives tail gate open CAN message transition to OPEN value, this 30 s rear defog pause is also

started, it works the same way as described above.

Page 1499 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.The daytime running unit (A) is integrated in the IPM.

2.Functional diagram.

3.The DRL function operates the Head lamps High Beam at 50% of full illumination. The DRL function is active if :

a. the engine is running

b. the Head lamp multifunction switch is in OFF position or 'Park and Tail lamp' (Auto light function deactivated)

c. The Park break switch is OFF.

When the DRL function is active, the Head lamps High Beam can't be turned ON, except for the Flash To Pass

activation.

4. If the daytime running light is not operated well, Inspect the connector and terminals to be sure they are all making

good contact.

If the terminals are bent, loose or corroded, repair them as necessary, and recheck the system.

If the terminals look OK, go to step 4.

5. Make these input tests at the connector by using ETM.

If any test indicates a problem, find and correct the cause, then recheck the system.

If all the input tests prove OK, the IPM (In - panel module) must be faulty; replace it.