oil KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 131 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

INTAKE MANIFOLD ASSEMBLY

1. Remove the engine cover.

2. Remove the intake air hose and air cleaner assembly.

(1) Disconnect the MAF connector(A).

(2) Disconnect the breather hose(B) from air cleaner hose.

(3) Remove the intake air hose and air cleaner assembly(C).

3.Disconnect the engine wiring harness connectors.

(1) Disconnect the No.1/No.2 knock sensor connectors(A,B), the oil pressure switch connector(C), the ignition coil

harness(D) and the No.1 VIS(Variable Induction System) connector(E).

(2)Disconnect the bank 1 front/rear O2 sensor connectors(A).

(3)Disconnect the injection connectors(A,B,C), the ground lines(D), the condensor connector(E) and the Ignition

coil connectors(F).

Page 132 of 1575

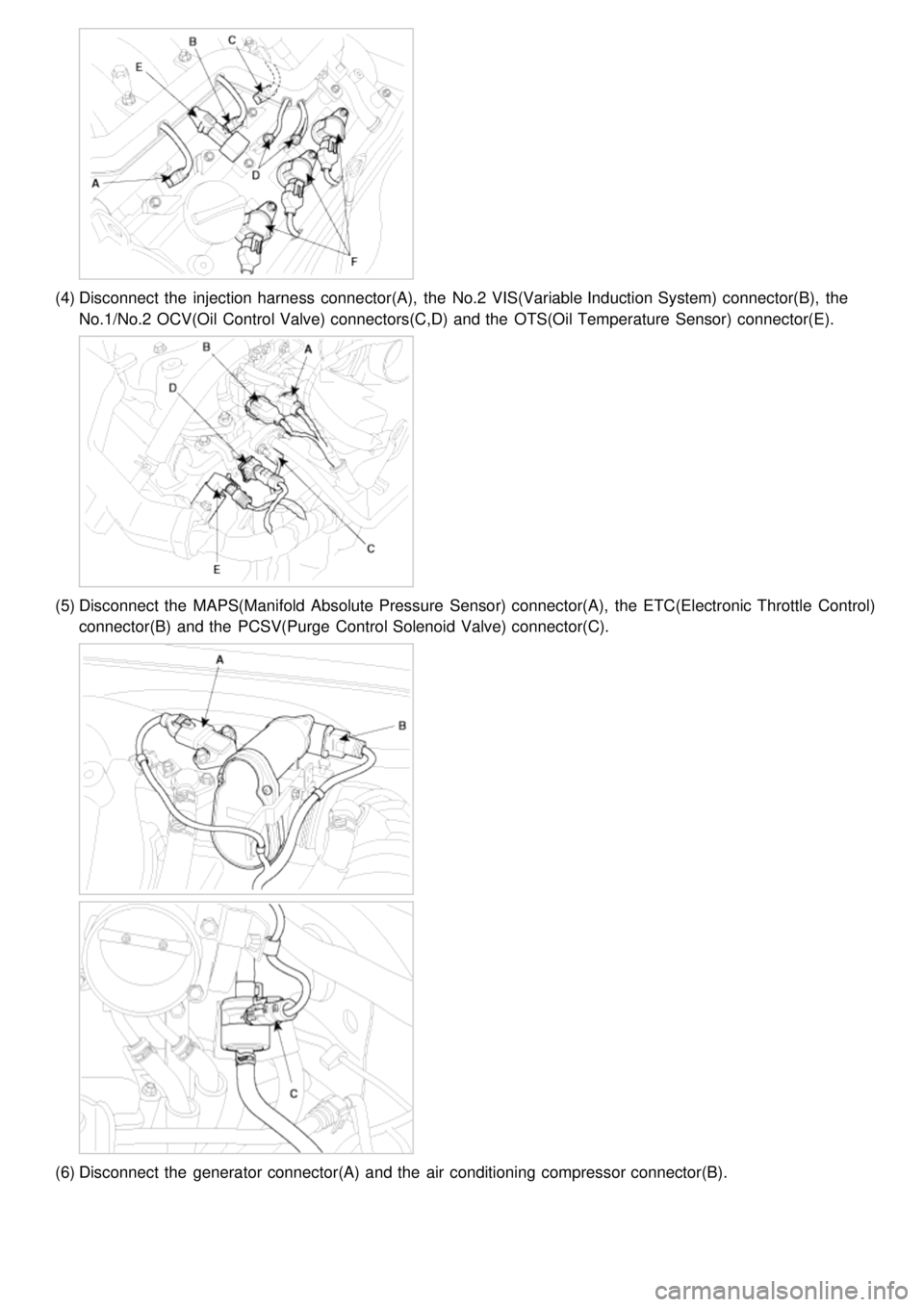

(4)Disconnect the injection harness connector(A), the No.2 VIS(Variable Induction System) connector(B), the

No.1/No.2 OCV(Oil Control Valve) connectors(C,D) and the OTS(Oil Temperature Sensor) connector(E).

(5)Disconnect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

(6)Disconnect the generator connector(A) and the air conditioning compressor connector(B).

Page 136 of 1575

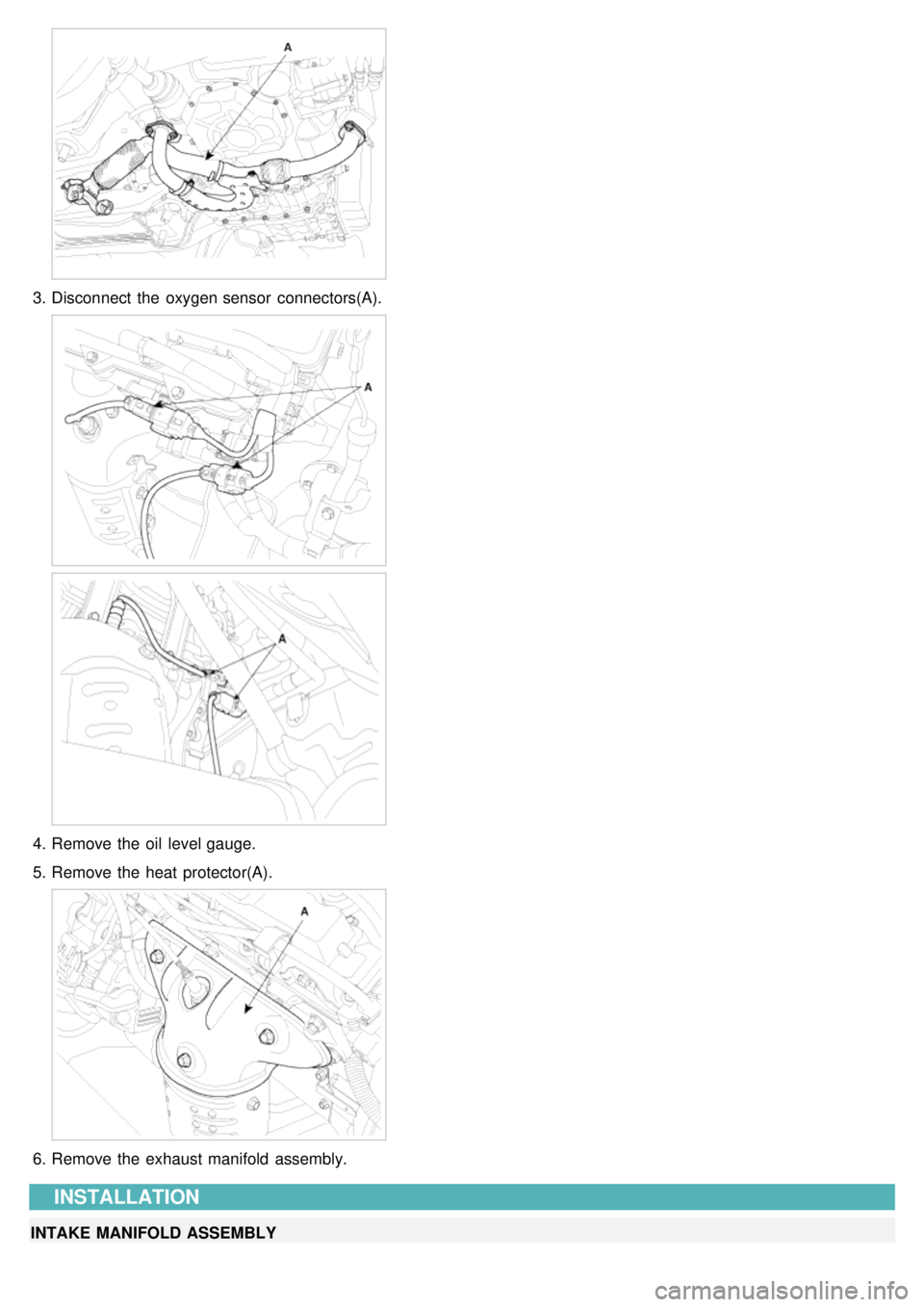

3.Disconnect the oxygen sensor connectors(A).

4.Remove the oil level gauge.

5. Remove the heat protector(A).

6.Remove the exhaust manifold assembly.

INSTALLATION

INTAKE MANIFOLD ASSEMBLY

Page 149 of 1575

2007 > 2.7L V6 GASOLINE >

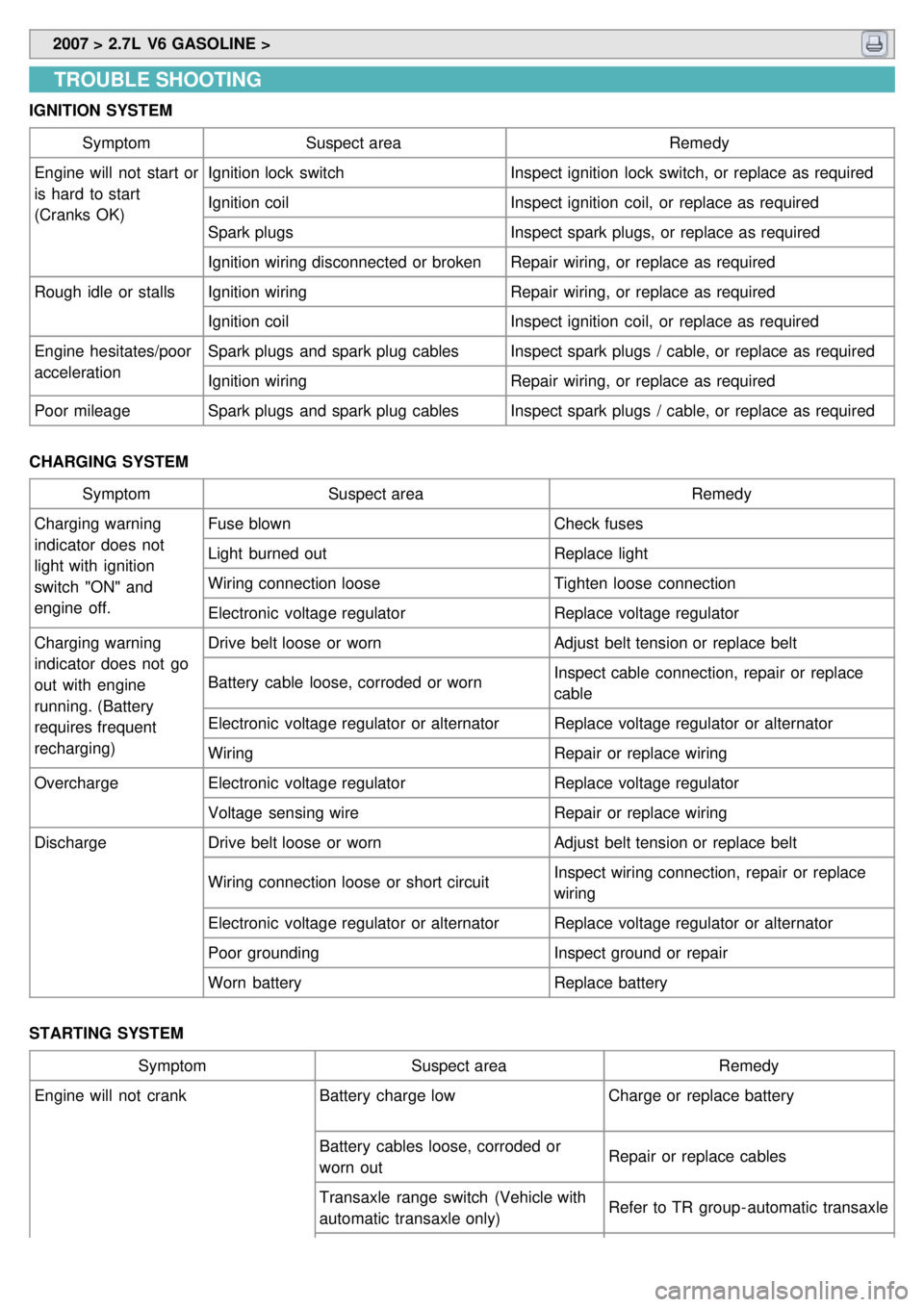

TROUBLE SHOOTING

IGNITION SYSTEM

Symptom Suspect area Remedy

Engine will not start or

is hard to start

(Cranks OK) Ignition lock switch

Inspect ignition lock switch, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Spark plugs Inspect spark plugs, or replace as required

Ignition wiring disconnected or broken Repair wiring, or replace as required

Rough idle or stalls Ignition wiring Repair wiring, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Engine hesitates/poor

acceleration Spark plugs and spark plug cables

Inspect spark plugs / cable, or replace as required

Ignition wiring Repair wiring, or replace as required

Poor mileage Spark plugs and spark plug cables Inspect spark plugs / cable, or replace as required

CHARGING SYSTEM Symptom Suspect area Remedy

Charging warning

indicator does not

light with ignition

switch "ON" and

engine off. Fuse blown

Check fuses

Light burned out Replace light

Wiring connection loose Tighten loose connection

Electronic voltage regulator Replace voltage regulator

Charging warning

indicator does not go

out with engine

running. (Battery

requires frequent

recharging) Drive belt loose or worn

Adjust belt tension or replace belt

Battery cable loose, corroded or worn Inspect cable connection, repair or replace

cable

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Wiring Repair or replace wiring

Overcharge Electronic voltage regulator Replace voltage regulator

Voltage sensing wire Repair or replace wiring

Discharge Drive belt loose or worn Adjust belt tension or replace belt

Wiring connection loose or short circuit Inspect wiring connection, repair or replace

wiring

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Poor grounding Inspect ground or repair

Worn battery Replace battery

STARTING SYSTEM Symptom Suspect area Remedy

Engine will not crank Battery charge low Charge or replace battery

Battery cables loose, corroded or

worn out Repair or replace cables

Transaxle range switch (Vehicle with

automatic transaxle only) Refer to TR group - automatic transaxle

Page 151 of 1575

2007 > 2.7L V6 GASOLINE >

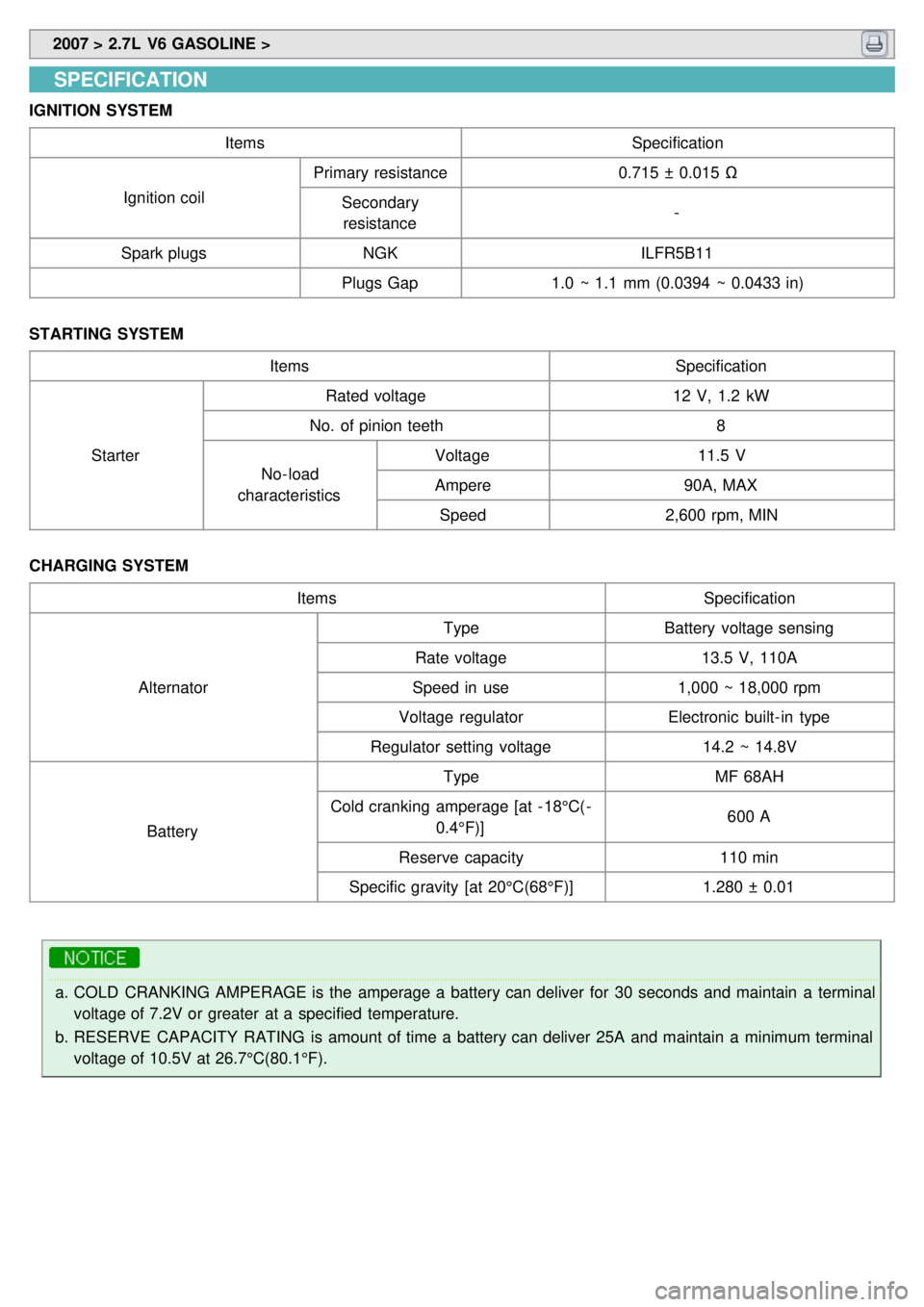

SPECIFICATION

IGNITION SYSTEM

Items Specification

Ignition coil Primary resistance

0.715 ± 0.015 Ω

Secondary resistance -

Spark plugs NGK ILFR5B11

Plugs Gap 1.0 ~ 1.1 mm (0.0394 ~ 0.0433 in)

STARTING SYSTEM Items Specification

Starter Rated voltage

12 V, 1.2 kW

No. of pinion teeth 8

No- load

characteristics Voltage

11.5 V

Ampere 90A, MAX

Speed 2,600 rpm, MIN

CHARGING SYSTEM Items Specification

Alternator Type

Battery voltage sensing

Rate voltage 13.5 V, 110A

Speed in use 1,000 ~ 18,000 rpm

Voltage regulator Electronic built- in type

Regulator setting voltage 14.2 ~ 14.8V

Battery Type

MF 68AH

Cold cranking amperage [at - 18°C(- 0.4°F)] 600 A

Reserve capacity 110 min

Specific gravity [at 20°C(68°F)] 1.280 ± 0.01

a.COLD CRANKING AMPERAGE is the amperage a battery can deliver for 30 seconds and maintain a terminal

voltage of 7.2V or greater at a specified temperature.

b. RESERVE CAPACITY RATING is amount of time a battery can deliver 25A and maintain a minimum terminal

voltage of 10.5V at 26.7°C(80.1°F).

Page 153 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRITION

Ignition timing is controlled by the electronic control ignition timing system. The standard reference ignition timing data

for the engine operating conditions are preprogrammed in the memory of the ECM (Engine Control Module).

The engine operating conditions (speed, load, warm- up condition, etc.) are detected by the various sensors. Based on

these sensor signals and the ignition timing data, signals to interrupt the primary current are sent to the ECM. The

ignition coil is activated, and timing is controlled.

Page 154 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

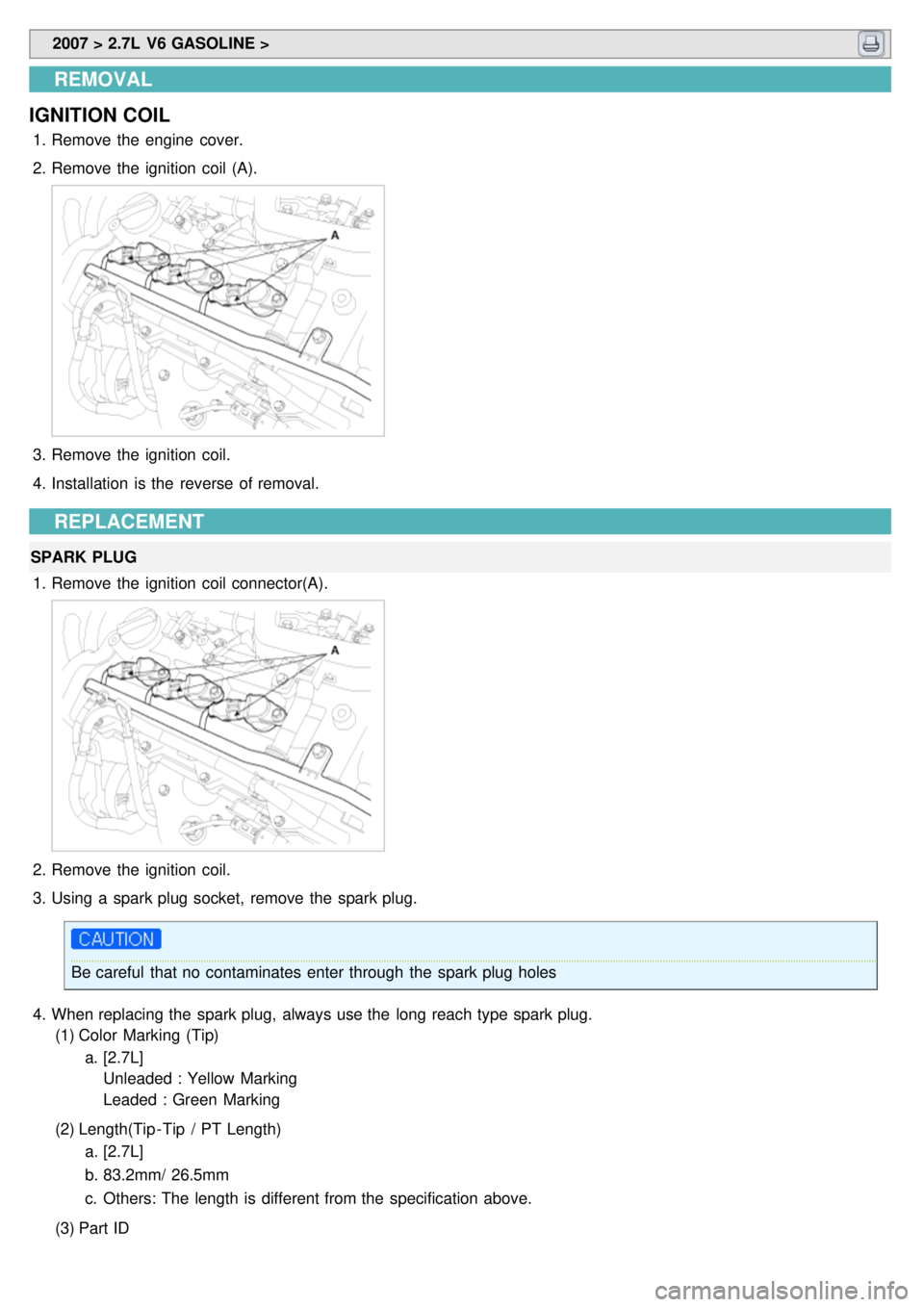

IGNITION COIL

1. Remove the engine cover.

2. Remove the ignition coil (A).

3.Remove the ignition coil.

4. Installation is the reverse of removal.

REPLACEMENT

SPARK PLUG

1. Remove the ignition coil connector(A).

2.Remove the ignition coil.

3. Using a spark plug socket, remove the spark plug.

Be careful that no contaminates enter through the spark plug holes

4. When replacing the spark plug, always use the long reach type spark plug.

(1) Color Marking (Tip)

a. [2.7L]

Unleaded : Yellow Marking

Leaded : Green Marking

(2) Length(Tip - Tip / PT Length)

a. [2.7L]

b. 83.2mm/ 26.5mm

c. Others: The length is different from the specification above.

(3) Part ID

Page 155 of 1575

![KIA CARNIVAL 2007 Repair Manual a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector KIA CARNIVAL 2007 Repair Manual a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector](/img/2/57045/w960_57045-154.png)

a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector lock.

2. Remove the ignition coil.

3. Using a spark plug socket, remove the spark plug.

4. Install the spark plug to the ignition coil.

5. Ground the spark plug to the engine.

6.Check is spark occurs while engine is being cranked.

To prevent fuel being injected from injectors while the engine is being cranked, remove the fuel pump(A) relay

from the fuse box.

Crank the engine for no more than 5 ~ 10 seconds.

7. Inspect all the spark plugs.

8. Using a spark plug socket, install the spark plug.

9. Install the ignition coil.

10. Reconnect the ignition coil connector.

Page 157 of 1575

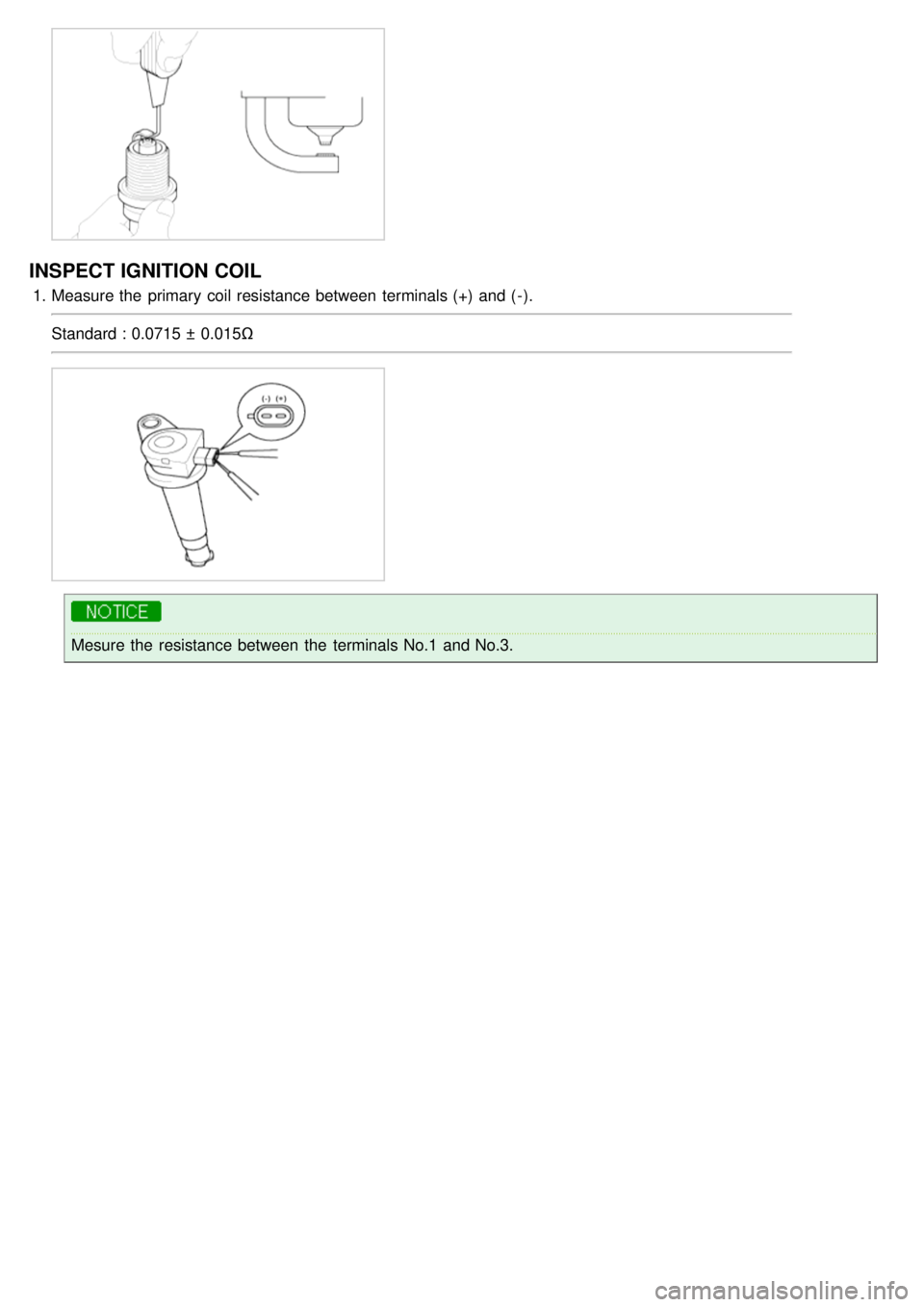

INSPECT IGNITION COIL

1.Measure the primary coil resistance between terminals (+) and ( - ).

Standard : 0.0715 ± 0.015Ω

Mesure the resistance between the terminals No.1 and No.3.

Page 168 of 1575

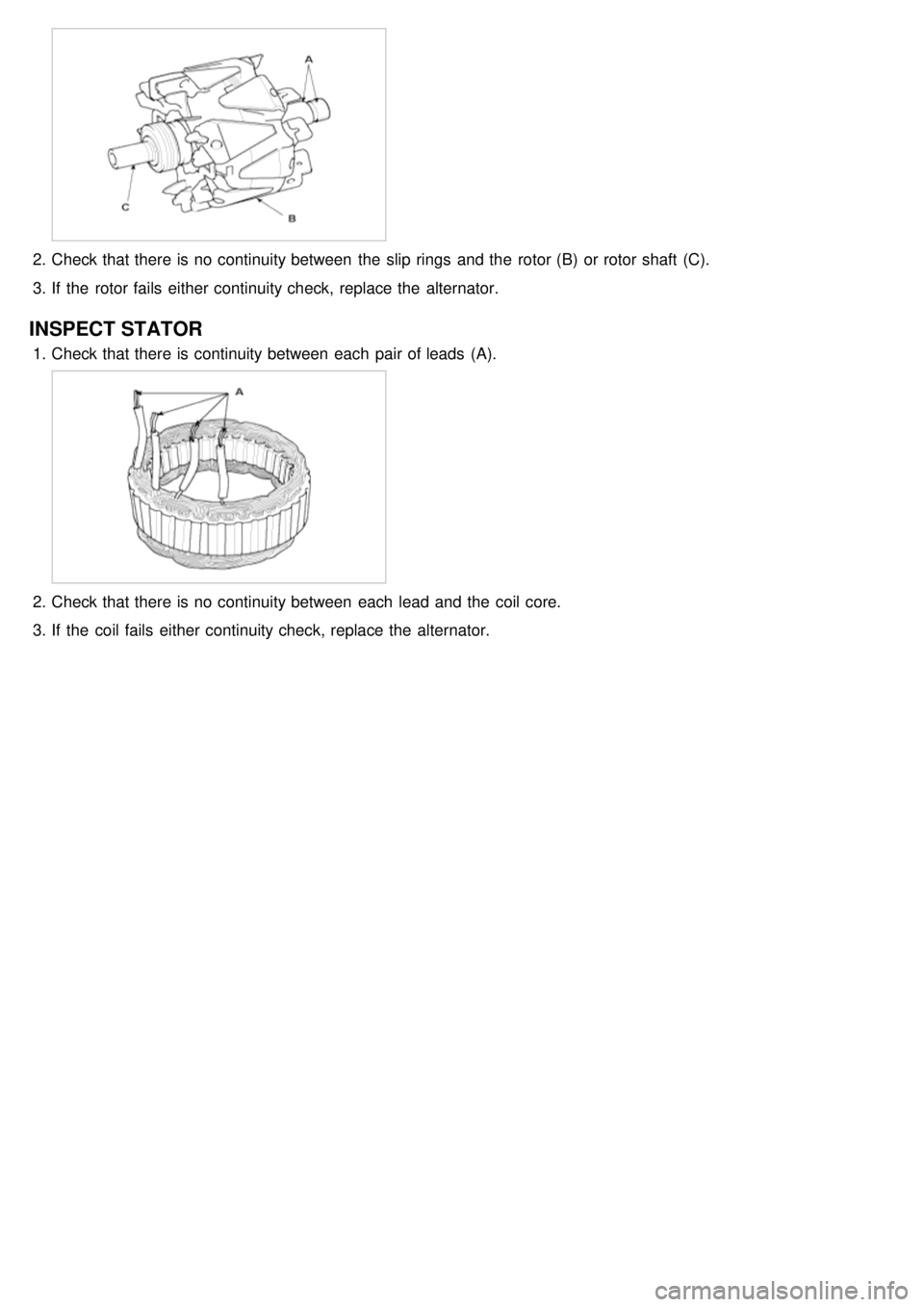

2.Check that there is no continuity between the slip rings and the rotor (B) or rotor shaft (C).

3. If the rotor fails either continuity check, replace the alternator.

INSPECT STATOR

1.Check that there is continuity between each pair of leads (A).

2.Check that there is no continuity between each lead and the coil core.

3. If the coil fails either continuity check, replace the alternator.