ignition KIA CARNIVAL 2007 Manual PDF

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 728 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

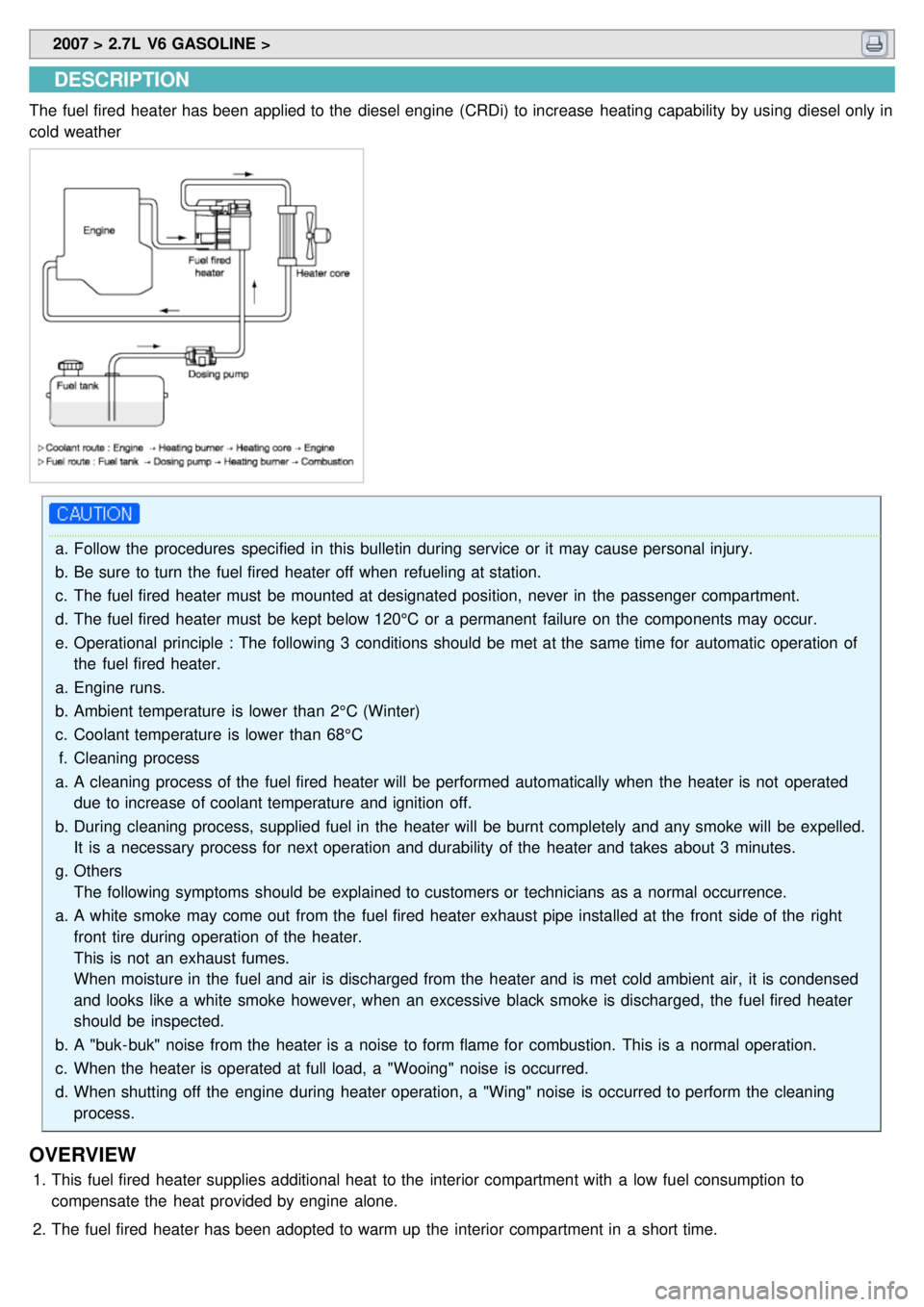

The fuel fired heater has been applied to the diesel engine (CRDi) to increase heating capability by using diesel only in

cold weather

a.Follow the procedures specified in this bulletin during service or it may cause personal injury.

b. Be sure to turn the fuel fired heater off when refueling at station.

c. The fuel fired heater must be mounted at designated position, never in the passenger compartment.

d. The fuel fired heater must be kept below 120°C or a permanent failure on the components may occur.

e. Operational principle : The following 3 conditions should be met at the same time for automatic operation of

the fuel fired heater.

a. Engine runs.

b. Ambient temperature is lower than 2°C (Winter)

c. Coolant temperature is lower than 68°C

f. Cleaning process

a. A cleaning process of the fuel fired heater will be performed automatically when the heater is not operated

due to increase of coolant temperature and ignition off.

b. During cleaning process, supplied fuel in the heater will be burnt completely and any smoke will be expelled.

It is a necessary process for next operation and durability of the heater and takes about 3 minutes.

g. Others

The following symptoms should be explained to customers or technicians as a normal occurrence.

a. A white smoke may come out from the fuel fired heater exhaust pipe installed at the front side of the right

front tire during operation of the heater.

This is not an exhaust fumes.

When moisture in the fuel and air is discharged from the heater and is met cold ambient air, it is condensed

and looks like a white smoke however, when an excessive black smoke is discharged, the fuel fired heater

should be inspected.

b. A "buk- buk" noise from the heater is a noise to form flame for combustion. This is a normal operation.

c. When the heater is operated at full load, a "Wooing" noise is occurred.

d. When shutting off the engine during heater operation, a "Wing" noise is occurred to perform the cleaning

process.

OVERVIEW

1.This fuel fired heater supplies additional heat to the interior compartment with a low fuel consumption to

compensate the heat provided by engine alone.

2. The fuel fired heater has been adopted to warm up the interior compartment in a short time.

Page 729 of 1575

3.The two coolant temperature sensors are installed to the heater inner. The sensor valves determine heater

operation.

4. One of the temperature sensors functions to prevent the heater from overheating.

If the sensor temperature valve exceeds 125°C, the fuel will be cut and the heater will be deactivated by the

determination of the overheating of the heater.

The other temperature sensor determines the operation mode of the fuel fired heater.The temperature of this

sensor enables to activate the heater at full load(5kw) or half load(2.5kw).

• The coolant temperature shown on the above Figure is the value of the inner sensor and the actual coolant

temperature is higher about 5°C ~7°C than the above value.

OPERATION

Switch on/ Operation start

The fuel fired heater is operated when the coolant temperature is below 68°C and the ambient temperature is below

2°C after starting the engine.

At this time, the glow plug and combustion air fan are operated first and after 30 seconds, the dosing pump is

operated with stopping the combustion fan for 3 seconds.

After that, the operation of the fan increases continuously until it approaches to full load within 56 seconds. If fuel

supply reaches to full load the glow plug does not operate and the operation of the fan reaches to full load.

After that the glow plug monitors ignition condition as a flame sensor for 45 seconds.

The above operation procedure is done automatically and in case the ignition fails, the above operation will be done

again automatically.

If the condition of ignition failure sustains continuously, fuel supply and fan operation will be stopped and error codes

will be stored to find cause of failure.

Generally, the cause of ignition failure during combustion is caused by the automatic re- operation of the above

procedure.

Operation for heating

The fuel fired heater operates at full load when the coolant temperature is below 68°C and the ambient temperature is

below 2°C after starting the engine.

It operates at half load when the coolant temperature is 74°C and it operates at idle mode when the coolant

temperature is 78°C.

The fuel fired heater during the transformation process does a cleaning function from the half mode to the idle mode.

At idle mode, all components do not work.

The fuel fired heater operating at idle mode turns into the half load when the coolant temperature is 74°C. At this time,

if the coolant temperature drops again below 68°C, the heater operates with full load and turns into the idle mode if

the temperature is 78°C.

This serial operating process is performed automatically.

Key switch off / Operation stop

The fuel fired heater ECU stops the operation of the fuel pump and cuts fuel supply when shutting off the engine

during the heater operation.

The heater conducts cleaning operation at this time.

This is a process of burning the fuel completely supplied in the heater inner.

In this process, the glow plug and combustion air fan are operated.

Page 749 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF".

2. Disconnect the connector of temperature control actuator.

3. Verify that the temperature control actuator operates to the hot position when connecting 12V to the terminal 1 and

grounding terminal 2.

Verify that the temperature control actuator operates to the cool position when connecting in the reverse.

4.Check the voltage between terminals 3 and 4.

Specification

Door position Voltage (3- 4)Error detecting

Max. cooling 0.4 ± 0.15VLow voltage : 0.1V or less

Max. heating 4.6 ± 0.15VHigh voltage : 4.9V or more

* It will feedback current position of actuator to controls.

5. If the measured voltage is not specification, substitute with a known- good temperature control actuator and check

for proper operation.

6. If the problem is corrected, replace the temperature control actuator.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the luggage side trim (Refer to BD - ).

3. Remove the rear heater unit (Refer to HA - ).

4. Disconnect the temperature control actuator connector after removing the air duct.

5. Loosen the mounting screw and then remove the temperature control actuator (A).

6.Installation is the reverse order of removal.

Page 751 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF".

2. Disconnect the connector of mode control actuator.

3. Verify that the mode control actuator operates to the defrost mode when connecting 12V to the terminal 1 and

grounding terminal 2.

4. Verify that the mode control actuator operates to the vent mode when connecting in the reverse.

5.Check the voltage between terminals 3 and 4.

Door position Voltage (3- 4)Error detecting

Vent 0.4 ± 0.15VLow voltage :0.1V or less

Defrost 4.6 ± 0.15VHigh voltage :4.9V or more

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the rear heater unit.

3. Disconnect the mode control actuator connector (A).

4. Loosen the mounting screws and then remove the mode control actuator (B).

5.Installation is the reverse order of removal.

Page 753 of 1575

2007 > 2.7L V6 GASOLINE >

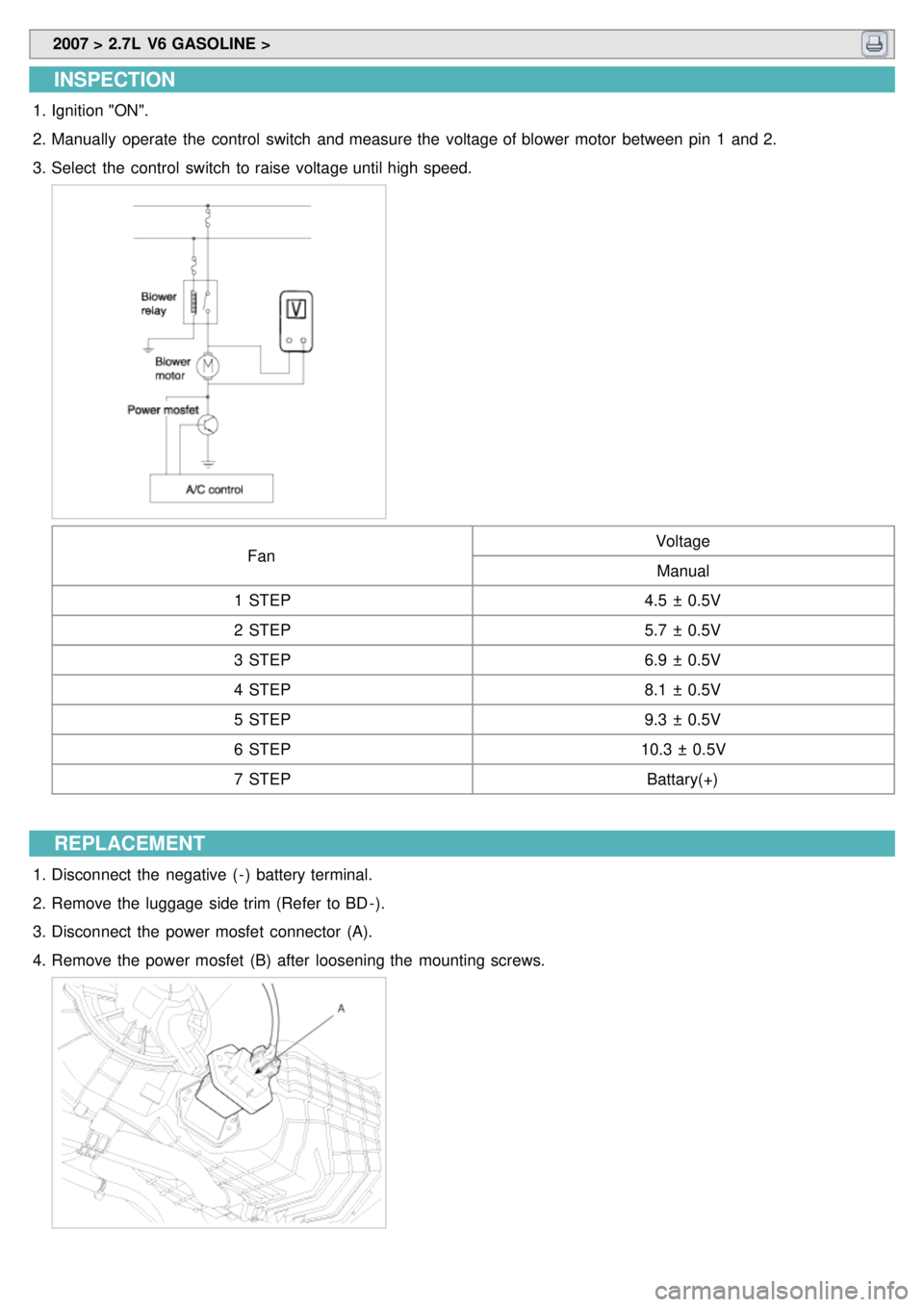

INSPECTION

1.Ignition "ON".

2. Manually operate the control switch and measure the voltage of blower motor between pin 1 and 2.

3. Select the control switch to raise voltage until high speed.

Fan Voltage

Manual

1 STEP 4.5 ± 0.5V

2 STEP 5.7 ± 0.5V

3 STEP 6.9 ± 0.5V

4 STEP 8.1 ± 0.5V

5 STEP 9.3 ± 0.5V

6 STEP 10.3 ± 0.5V

7 STEP Battary(+)

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the luggage side trim (Refer to BD - ).

3. Disconnect the power mosfet connector (A).

4. Remove the power mosfet (B) after loosening the mounting screws.

Page 771 of 1575

2007 > 2.7L V6 GASOLINE >

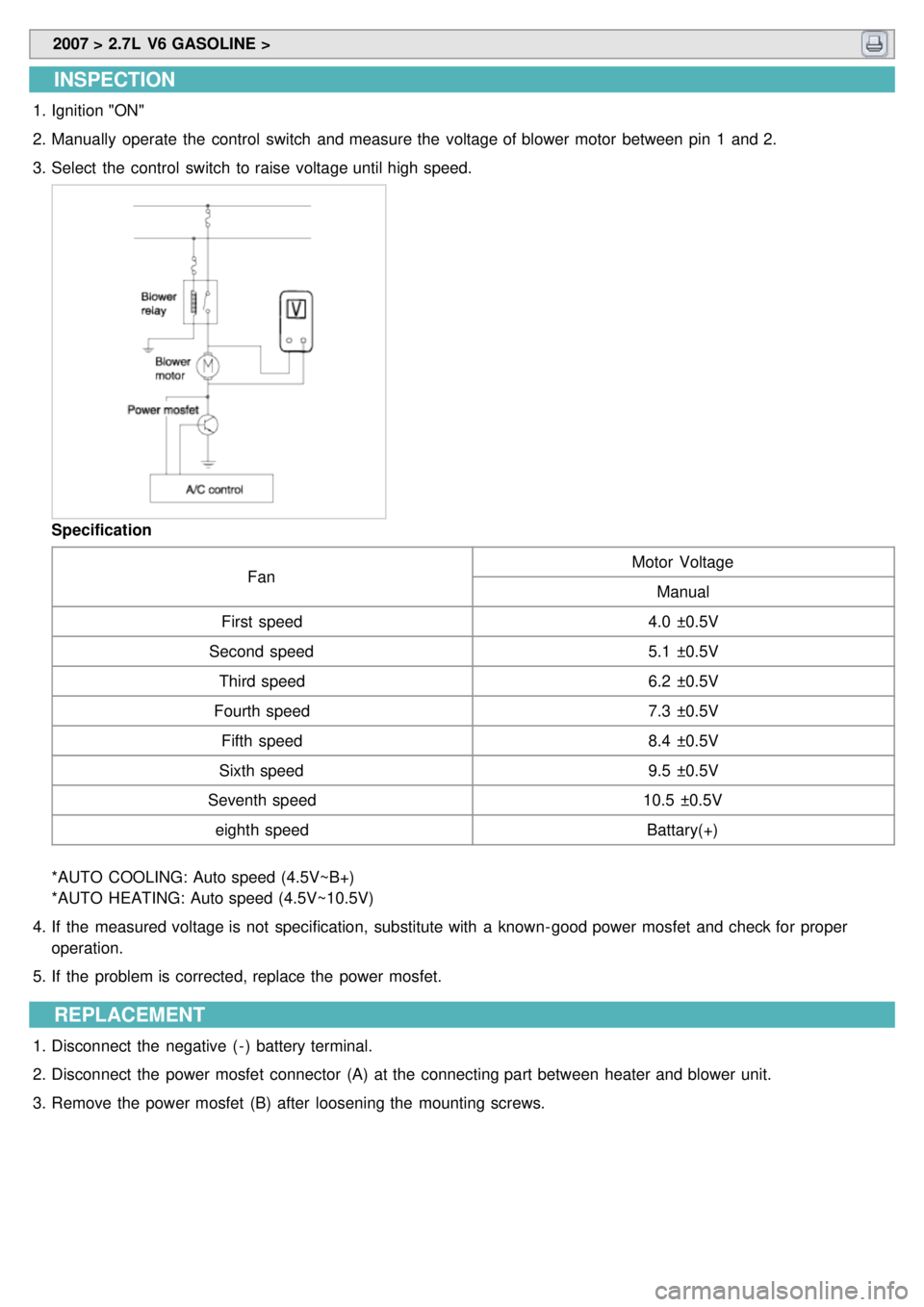

INSPECTION

1.Ignition "ON"

2. Manually operate the control switch and measure the voltage of blower motor between pin 1 and 2.

3. Select the control switch to raise voltage until high speed.

Specification

Fan Motor Voltage

Manual

First speed 4.0 ±0.5V

Second speed 5.1 ±0.5V

Third speed 6.2 ±0.5V

Fourth speed 7.3 ±0.5V

Fifth speed 8.4 ±0.5V

Sixth speed 9.5 ±0.5V

Seventh speed 10.5 ±0.5V

eighth speed Battary(+)

*AUTO COOLING: Auto speed (4.5V~B+)

*AUTO HEATING: Auto speed (4.5V~10.5V)

4. If the measured voltage is not specification, substitute with a known- good power mosfet and check for proper

operation.

5. If the problem is corrected, replace the power mosfet.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Disconnect the power mosfet connector (A) at the connecting part between heater and blower unit.

3. Remove the power mosfet (B) after loosening the mounting screws.

Page 779 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect the intake actuator connector.

3. Verify that the actuator operates to the recirculation position when connecting 12V to the terminal 3 and grounding

terminal 4.

4. Verify that the intake actuator operates to the fresh position when connecting in the reverse.

5.If the intake actuator is not operated well, substitute with a known- good intake actuator and check for proper

operation.

6. If the problem is corrected, replace the intake actuator.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the glove box (Refer to BD group).

3. Disconnect the intake actuator connector.

4. Loosen the mounting screw and then remove the intake actuator (A) from the blower unit.

5.Installation is the reverse order of removal.

Page 791 of 1575

2007 > 2.7L V6 GASOLINE >

Precautions

General Precautions

Please read the following precautions carefully before performing the airbag system service. Observe the instructions

described in this manual, or the airbags could accidentally deploy and cause damage or injuries. a. Except when performing electrical inspections, always turn the ignition switch OFF and disconnect the negative

cable from the battery, and wait at least three minutes before beginning work.

The contents in the memory are not erased even if the ignition switch is turned OFF or the battery cables are

disconnected from the battery.

b. Use the replacement parts which are manufactured to the same standards as the original parts and quality.

Do not install used SRS parts from another vehicle.

Use only new parts when making SRS repairs.

c. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being dropped or improperly handled, such as dents, cracks or

deformation.

d.Before removing any of the SRS parts (including the disconnection of the connectors), always disconnect the SRS

connector.

Airbag Handling and Storage

Do not disassemble the airbags; it has no serviceable parts. Once an airbag has been deployed, it cannot be repaired

or reused.

For temporary storage of the air bag during service, please observe the following precautions.

a. Store the removed airbag with the pad surface up.

b. Keep free from any oil, grease, detergent, or water to prevent damage to the airbag assembly.

Page 792 of 1575

c.Store the removed airbag on secure, flat surface away from any high heat source (exceeding 85°C/185°F).

d. Never perform electrical inspections to the airbags, such as measuring resistance.

e. Do not position yourself in front of the airbag assembly during removal, inspection, or replacement.

f. Refer to the scrapping procedures for disposal of the damaged airbag.

g. Be careful not to bump or impact the SRS unit or the side impact sensors whenever the ignition switch is ON, wait

at least three minutes after the ignition switch is turned OFF before begin work.

h. During installation or replacement, be careful not to bump (by impact wrench, hammer, etc.) the area around the

SRS unit and the side impact sensor. The airbags could accidentally deploy and cause damage or injury.

i. After a collision in which the airbags were deployed, replace the front airbags and the SRS unit. After a collision in

which the side airbag was deployed, replace the side airbag, the front impact sensor and side impact sensor on

the side where the side airbag deployed and the SRS unit. After a collision in which the airbags or the side air

bags did not deploy, inspect for any damage or any deformation on the SRS unit and the side impact sensors. If

there is any damage, replace the SRS unit, the front impact sensor and/or the side impact sensors.

j. Do not disassemble the SRS unit, the front impact sensor or the side impact sensors

k. Turn the ignition switch OFF, disconnect the battery negative cable and wait at least three minutes before

beginning installation or replacement of the SRS unit.

l. Be sure the SRS unit, the front impact sensor and side impact sensors are installed securely with the mounting

bolts.

m. Do not spill water or oil on the SRS unit,or the front impact sensor or the side impact sensors and keep them

away from dust.

n. Store the SRS unit, the front impact sensor and the side impact sensors in a cool (less than 40°C/104°F) and dry

(less than 80% relative humidity, no moisture) area.

Wiring Precautions

SRS wiring can be identified by special yellow outer covering (except the SRS circuits under the front seats).

Observe the instructions described in this section.

a. Never attempt to modify, splice, or repair SRS wiring.

If there is an open or damage in SRS wiring, replace the harness.

Page 795 of 1575

2007 > 2.7L V6 GASOLINE >

General

The supplemental restraint system (SRS) is designed to supplement the seat belt to help reduce the risk or severity of

injury to the driver and passenger by activating and deploying the driver, passenger, side airbag and belt pretensioner

in certain frontal or side collisions.

The SRS (Airbag) consists of : a driver side airbag module located in the center of the steering wheel, which contains

the folded cushion and an inflator unit ; a passenger side airbag module located in the passenger side crash pad

contains the folded cushion assembled with inflator unit ; side airbag modules located in the driver and passenger seat

contain the folded cushion and an inflator unit ; curtain airbag modules located inside of the headliner which contains

folded cushions and inflator units. The impact sensing function of the SRSCM is carried out by electronic

accelerometer that continuously measure the vehicle's acceleration and delivers a corresponding signal through

amplifying and filtering circuitry to the microprocessor.

SRSCM (SRS Control Module)

SRSCM will detect front impact with front impact sensor, and side impact with side impact sensor, and determine

airbag module deployment.

1. DC/DC converter: DC/DC converter in power supply unit includes up/down transformer converter, and provide

ignition voltage for 2 front airbag ignition circuits and the internal operation voltage of the SRSCM. If the internal

operation voltage is below critical value setting, it will perform resetting.

2. Safety sensor: Safety sensor is located in airbag ignition circuit. Safety sensor will operate airbag circuit at any

deployment condition and release airbag circuit safely at normal driving condition. Safety sensor is a double contact

electro - mechanical switch that will close detecting deceleration above certain criteria.

3. Back up power supply: SRSCM has separate back up power supply, that will supply deployment energy instantly in

low voltage condition or upon power failure by front crash.

4. Self diagnosis: SRSCM will constantly monitor current SRS operation status and detect system failure while vehicle

power supply is on, system failure may be checked with trouble codes using scan tool. (Hi- Scan)

5. Airbag warning lamp on: Upon detecting error, the module will transmit signal to SRSCM indicator lamp located at

cluster. MIL lamp will indicate driver SRS error. Upon ignition key on, SRS lamp will turn on for about six seconds.

6. Trouble code registration: Upon error occurrence in system, SRSCM will store DTC corresponding to the error.

DTC can be cleared only by Hi - Scan. However, if an internal fault code is logged or if a crash is recorded the fault

clearing should not happen.

7. Self diagnostic connector: Data stored in SRSCM memory will be output to Hi - Scan or other external output

devices through connector located below driver side crash pad.

8. Once airbag is deployed, SRSCM should not be used again but replaced.

9. SRSCM will determine whether passenger put on seat belt by the signal from built- in switch in seat belt buckle, and

deploy front seat airbag at each set crash speed.

10. Side airbag deployment will be determined by SRSCM that will detect satellite sensor impact signal upon side

crash, irrespective to seat belt condition.