ECU KIA CEED 2016 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2016, Model line: CEED, Model: KIA CEED 2016Pages: 643, PDF Size: 38.19 MB

Page 514 of 643

Maintenance

8

7

Engine compartment precautions (Diesel engine)

• The injector operates at high voltage

(maximum 200v). Therefore, the follow-

ing accidents may occur.

- Direct contact with the injector orinjector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room while the engine is running.

- Do not touch the injector, injectorwirings, and the engine computer

while the engine is running.

- Do not remove the injector connector while the engine is running.

- People using pacemakers must not go near the engine while the engine

is starting or running.

WARNING - Maintenance

work

Performing maintenance work on a vehicle can be dangerous. You

can be seriously injured while

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by an author-

ized Kia dealer.

Working under the hood with the engine running is dangerous. It

becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine while work-

ing under the hood, make certain

that you remove all jewelry (espe-

cially rings, bracelets, watches,

and necklaces) and all neckties,

scarves, and similar loose cloth-

ing before getting near theengine or cooling fans.WARNING - Diesel Engine

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectorsand high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room while engine is run-

ning, since the high currents in the

electronic engine control system

produce considerable magneticfields.

JD PE eng 7.QXP 1/28/2016 5:35 PM Page 8

Page 530 of 643

Maintenance

24

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation

and replace if necessary. Drive belts

should be checked periodically for proper

tension and adjusted as necessary.

Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by an author-

ized Kia dealer. Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by an

authorized Kia dealer.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap iscorrectly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move more than 30cm closer tothe ECU or wiring harness within

the engine room while engine is

running, since the high currents in

the Common Rail system produce

considerable magnetic fields.

JD PE eng 7.QXP 1/28/2016 5:35 PM Page 24

Page 539 of 643

733

Maintenance

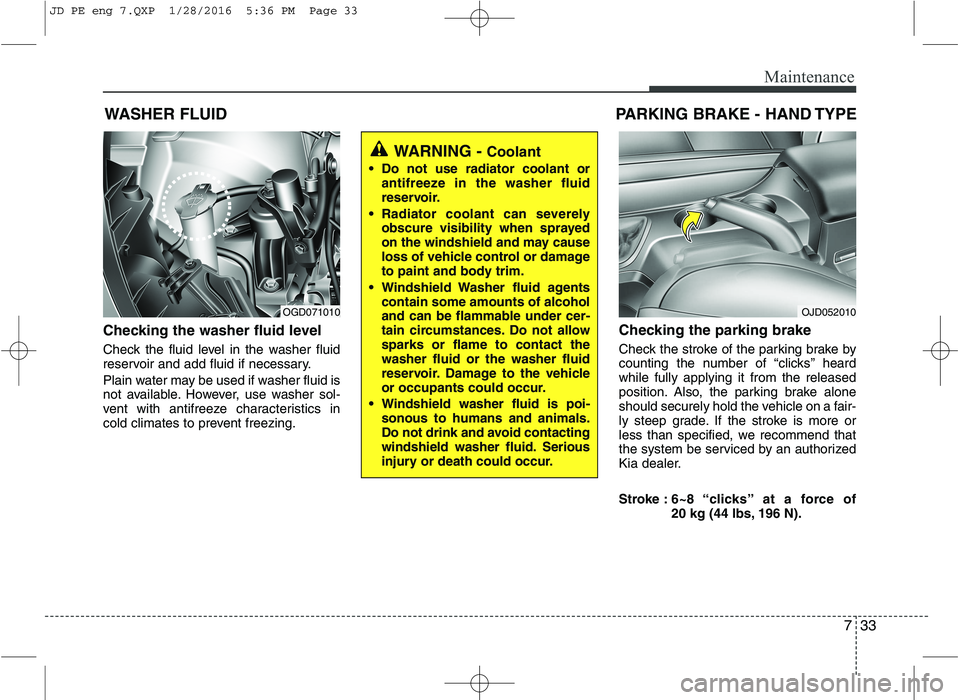

WASHER FLUID

Checking the washer fluid level

Check the fluid level in the washer fluid

reservoir and add fluid if necessary.

Plain water may be used if washer fluid is

not available. However, use washer sol-

vent with antifreeze characteristics in

cold climates to prevent freezing. Checking the parking brake

Check the stroke of the parking brake by

counting the number of “clicks’’ heardwhile fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade. If the stroke is more or

less than specified, we recommend that

the system be serviced by an authorized

Kia dealer.

Stroke :

6~8 “clicks’’ at a force of

20 kg (44 lbs, 196 N).

OGD071010

WARNING - Coolant

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

Windshield Washer fluid agents contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allowsparks or flame to contact thewasher fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

Windshield washer fluid is poi- sonous to humans and animals.

Do not drink and avoid contacting

windshield washer fluid. Serious

injury or death could occur.

PARKING BRAKE - HAND TYPE

OJD052010

JD PE eng 7.QXP 1/28/2016 5:36 PM Page 33

Page 548 of 643

Maintenance

42

7

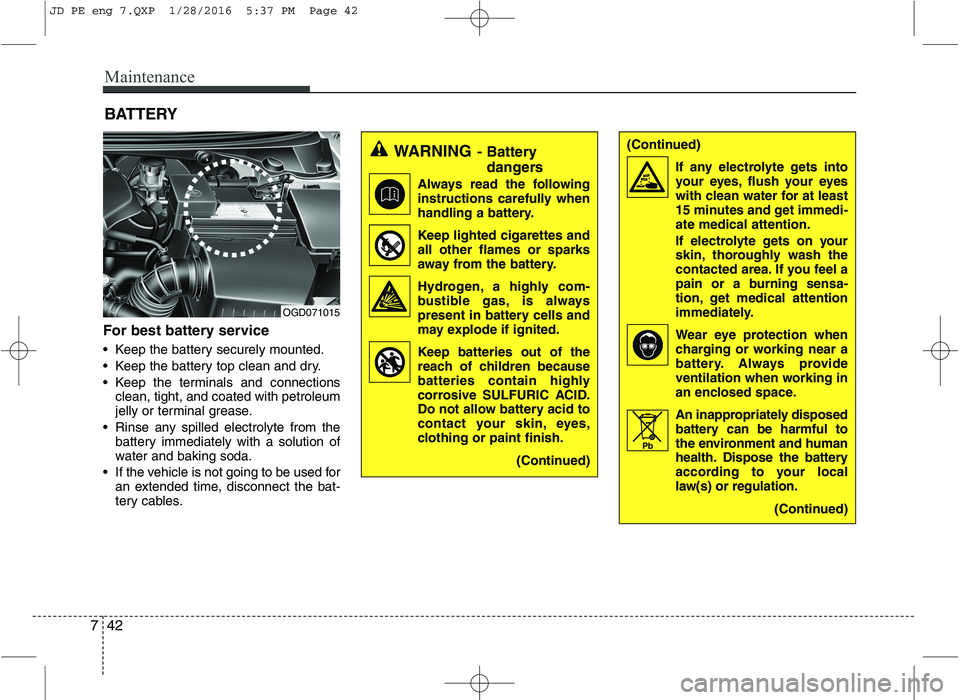

BATTERY

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connections clean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

WARNING - Battery

dangers

Always read the following

instructions carefully when

handling a battery.

Keep lighted cigarettes and all other flames or sparks

away from the battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells and

may explode if ignited.

Keep batteries out of the

reach of children because

batteries contain highly

corrosive SULFURIC ACID.

Do not allow battery acid to

contact your skin, eyes,

clothing or paint finish.

(Continued)

OGD071015

(Continued)If any electrolyte gets intoyour eyes, flush your eyes

with clean water for at least

15 minutes and get immedi-ate medical attention.

If electrolyte gets on your

skin, thoroughly wash the

contacted area. If you feel a

pain or a burning sensa-

tion, get medical attention

immediately.

Wear eye protection when charging or working near a

battery. Always provide

ventilation when working in

an enclosed space.

An inappropriately disposed battery can be harmful to

the environment and human

health. Dispose the battery

according to your local

law(s) or regulation.

(Continued)

Pb

JD PE eng 7.QXP 1/28/2016 5:37 PM Page 42

Page 565 of 643

759

Maintenance

2. Remove the fuse box cover by press-ing the tap and pulling up. When the

blade type fuse is disconnected,

remove it by using the clip designed forchanging fuses located in the engine

room fuse box. Upon removal, secure-

ly insert reserve fuse of equal quantity.

3. Check the removed fuse; replace it if it is blown. To remove or insert the fuse,use the fuse puller in the engine com-

partment fuse panel.

4. Push in a new fuse of the same rating, and make sure it fits tightly in the clips.

If it fits loosely, we recommend that you

consult an authorized Kia dealer.

Main fuse

Electrical equipments are not working

even though inner panel and engine

compartment fuses are not blown, or

many of these are not working at the

same time, it may has blown the main

fuse(Battery Fuse Terminal type) inside

of the battery(+) cap.

If the main fuse is blown, it must be

removed as follows: 1. Turn off the engine.

2. Disconnect the negative battery cable.

3. Remove the nuts shown in the picture

above.

4. Replace the fuse with a new one of the same rating.

5. Reinstall in the reverse order of removal.

OGD071020

CAUTION

After checking the fuse box in the

engine compartment, install the

fuse box cover securely. If not,water leaking may cause electricalfailures.

CAUTION

After checking the main fuse, install the cover securely when

you close the cover, check the locking sound.

If not, electrical failures mayoccur from water leaking in.

Visually inspect the battery cap for secure closing. If the battery

cap is not securely latched, theelectrical system may be dam- aged to due influx of moistureinto the system.

JD PE eng 7.QXP 1/28/2016 5:37 PM Page 59

Page 569 of 643

763

Maintenance

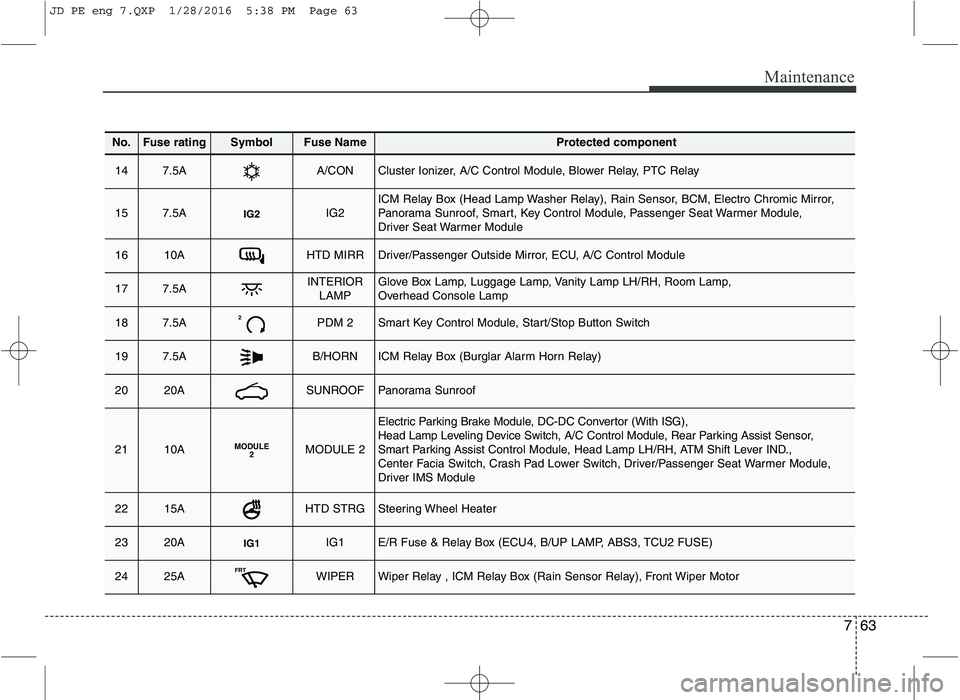

No.Fuse ratingSymbolFuse NameProtected component

147.5AA/CONCluster Ionizer, A/C Control Module, Blower Relay, PTC Relay

157.5AIG2IG2ICM Relay Box (Head Lamp Washer Relay), Rain Sensor, BCM, Electro Chromic Mirror,

Panorama Sunroof, Smart, Key Control Module, Passenger Seat Warmer Module,

Driver Seat Warmer Module

1610AHTD MIRRDriver/Passenger Outside Mirror, ECU, A/C Control Module

177.5AINTERIORLAMPGlove Box Lamp, Luggage Lamp, Vanity Lamp LH/RH, Room Lamp,

Overhead Console Lamp

187.5A2PDM 2Smart Key Control Module, Start/Stop Button Switch

197.5AB/HORNICM Relay Box (Burglar Alarm Horn Relay)

2020ASUNROOFPanorama Sunroof

2110AMODULE 2MODULE 2

Electric Parking Brake Module, DC-DC Convertor (With ISG),

Head Lamp Leveling Device Switch, A/C Control Module, Rear Parking Assist Sensor,

Smart Parking Assist Control Module, Head Lamp LH/RH, ATM Shift Lever IND.,

Center Facia Switch, Crash Pad Lower Switch, Driver/Passenger Seat Warmer Module,

Driver IMS Module

2215AHTD STRGSteering Wheel Heater

2320AIG1IG1E/R Fuse & Relay Box (ECU4, B/UP LAMP, ABS3, TCU2 FUSE)

2425AFRTWIPERWiper Relay , ICM Relay Box (Rain Sensor Relay), Front Wiper Motor

JD PE eng 7.QXP 1/28/2016 5:38 PM Page 63

Page 570 of 643

Maintenance

64

7

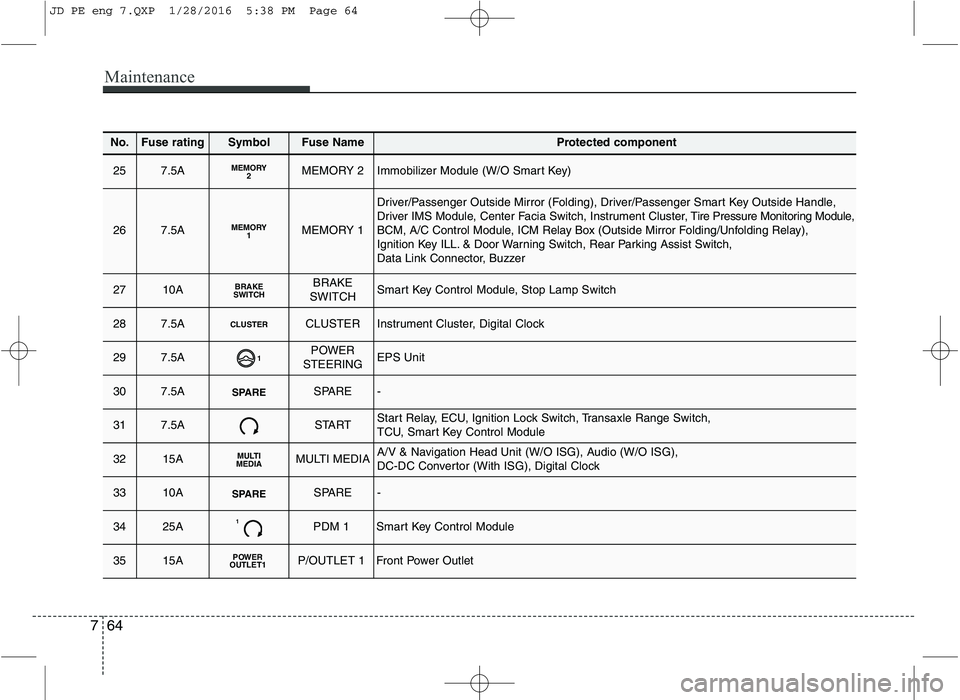

No.Fuse ratingSymbolFuse NameProtected component

257.5AMEMORY2MEMORY 2Immobilizer Module (W/O Smart Key)

267.5AMEMORY1MEMORY 1

Driver/Passenger Outside Mirror (Folding), Driver/Passenger Smart Key Outside Handle, Driver IMS Module, Center Facia Switch, Instrument Cluster, Tire Pressure Monitoring Module,

BCM, A/C Control Module, ICM Relay Box (Outside Mirror Folding/Unfolding Relay),

Ignition Key ILL. & Door Warning Switch, Rear Parking Assist Switch,

Data Link Connector, Buzzer

2710ABRAKE

SWITCHBRAKE

SWITCHSmart Key Control Module, Stop Lamp Switch

287.5ACLUSTERCLUSTERInstrument Cluster, Digital Clock

297.5A1POWER

STEERINGEPS Unit

307.5ASPARESPARE-

317.5ASTARTStart Relay, ECU, Ignition Lock Switch, Transaxle Range Switch,

TCU, Smart Key Control Module

3215AMULTI

MEDIAMULTI MEDIAA/V & Navigation Head Unit (W/O ISG), Audio (W/O ISG),

DC-DC Convertor (With ISG), Digital Clock

3310ASPARESPARE-

3425A1PDM 1Smart Key Control Module

3515APOWER

OUTLET1P/OUTLET 1Front Power Outlet

JD PE eng 7.QXP 1/28/2016 5:38 PM Page 64

Page 576 of 643

Maintenance

70

7

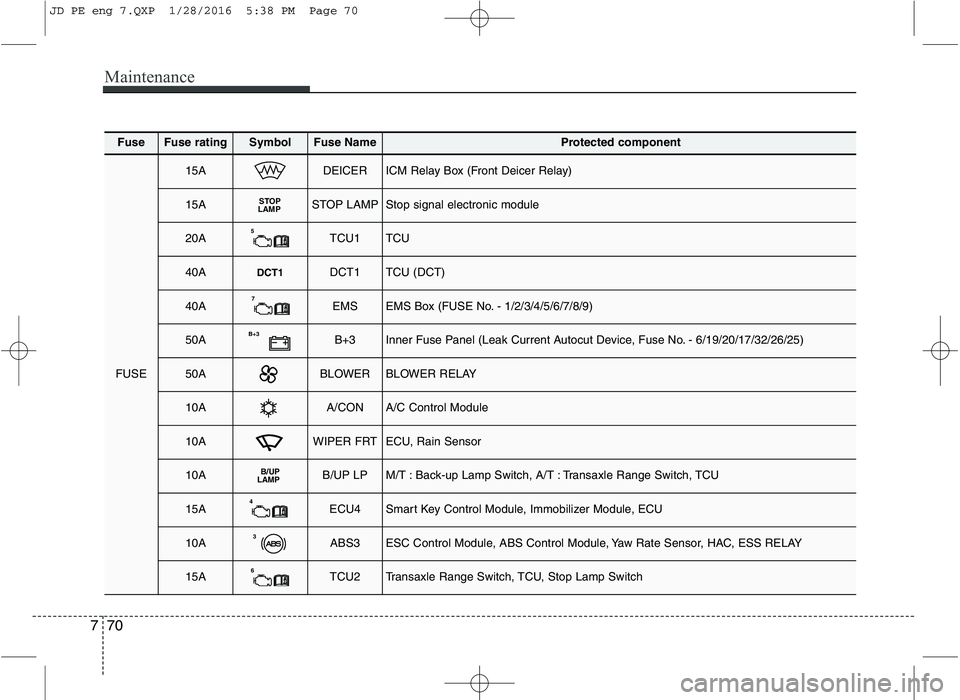

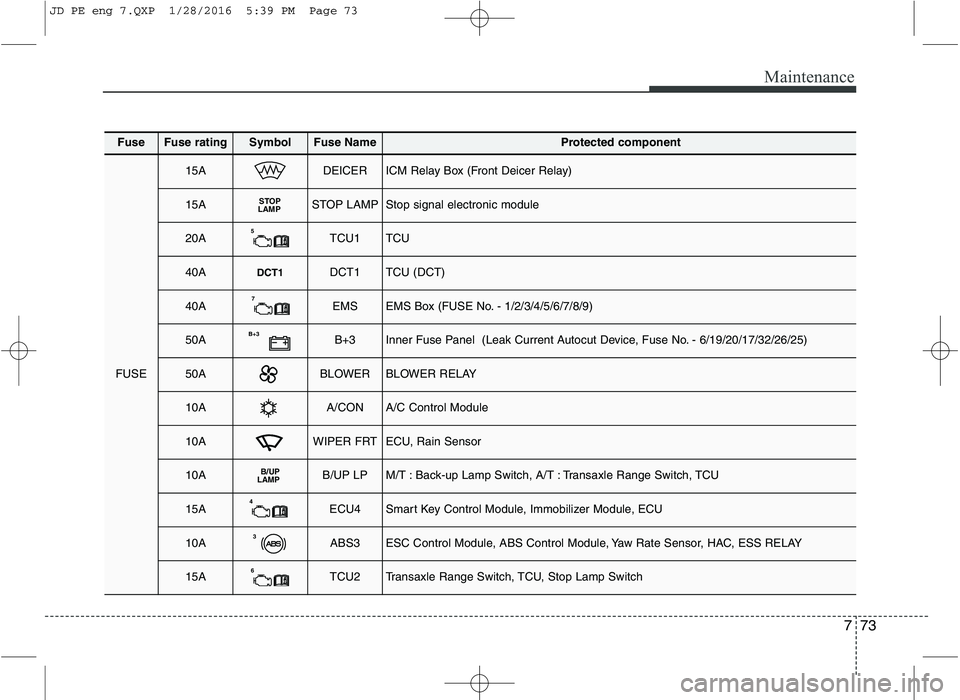

FuseFuse ratingSymbolFuse NameProtected component

FUSE

15ADEICERICM Relay Box (Front Deicer Relay)

15ASTOP

LAMPSTOP LAMPStop signal electronic module

20A5TCU1TCU

40ADCT1DCT1TCU (DCT)

40A7EMSEMS Box (FUSE No. - 1/2/3/4/5/6/7/8/9)

50AB+3B+3Inner Fuse Panel (Leak Current Autocut Device, Fuse No. - 6/19/20/17/32/26/25)

50ABLOWERBLOWER RELAY

10A A/CONA/C Control Module

10AWIPER FRTECU, Rain Sensor

10AB/UP

LAMPB/UP LPM/T : Back-up Lamp Switch, A/T : Transaxle Range Switch, TCU

15A4ECU4Smart Key Control Module, Immobilizer Module, ECU

10A3ABS3ESC Control Module, ABS Control Module, Yaw Rate Sensor, HAC, ESS RELAY

15A6TCU2Transaxle Range Switch, TCU, Stop Lamp Switch

JD PE eng 7.QXP 1/28/2016 5:38 PM Page 70

Page 577 of 643

771

Maintenance

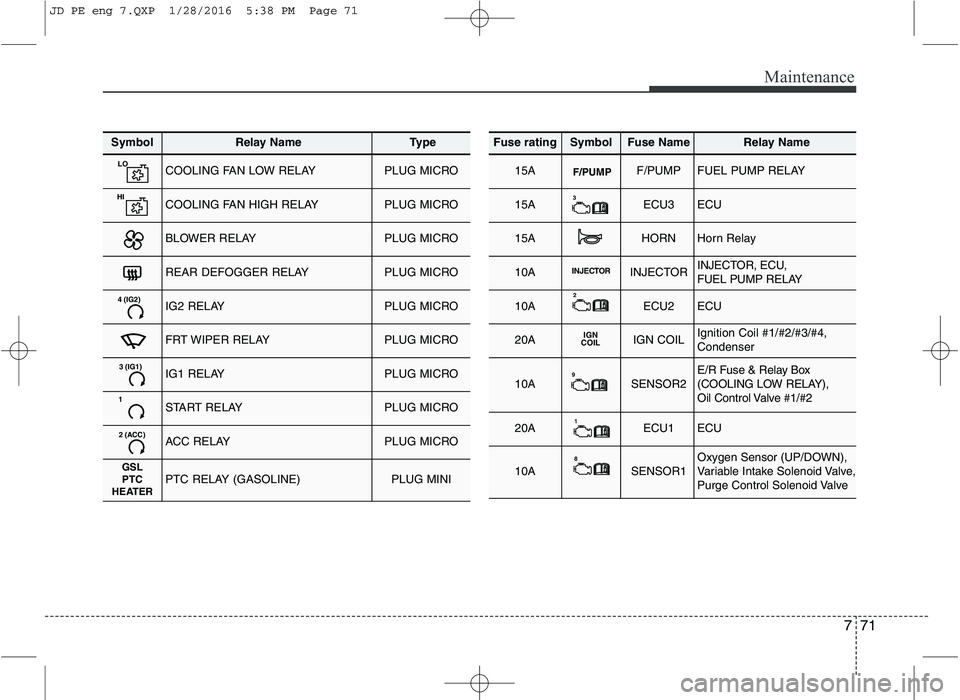

SymbolRelay NameType

LOCOOLING FAN LOW RELAYPLUG MICRO

HICOOLING FAN HIGH RELAYPLUG MICRO

BLOWER RELAYPLUG MICRO

REAR DEFOGGER RELAYPLUG MICRO

4 (IG2)IG2 RELAYPLUG MICRO

FRT WIPER RELAYPLUG MICRO

3 (IG1)IG1 RELAYPLUG MICRO

1START RELAYPLUG MICRO

2 (ACC)ACC RELAYPLUG MICRO

GSLPTC

HEATERPTC RELAY (GASOLINE)PLUG MINI

Fuse ratingSymbolFuse NameRelay Name

15AF/PUMPF/PUMPFUEL PUMP RELAY

15A3ECU3ECU

15AHORNHorn Relay

10AINJECTORINJECTORINJECTOR, ECU,

FUEL PUMP RELAY

10A2ECU2ECU

20AIGN

COILIGN COILIgnition Coil #1/#2/#3/#4, Condenser

10A9SENSOR2E/R Fuse & Relay Box

(COOLING LOW RELAY),

Oil Control Valve #1/#2

20A1ECU1ECU

10A8SENSOR1Oxygen Sensor (UP/DOWN),

Variable Intake Solenoid Valve,

Purge Control Solenoid Valve

JD PE eng 7.QXP 1/28/2016 5:38 PM Page 71

Page 579 of 643

773

Maintenance

FuseFuse ratingSymbolFuse NameProtected component

FUSE

15ADEICERICM Relay Box (Front Deicer Relay)

15ASTOP

LAMPSTOP LAMPStop signal electronic module

20A5TCU1TCU

40ADCT1DCT1TCU (DCT)

40A7EMSEMS Box (FUSE No. - 1/2/3/4/5/6/7/8/9)

50AB+3B+3Inner Fuse Panel (Leak Current Autocut Device, Fuse No. - 6/19/20/17/32/26/25)

50ABLOWERBLOWER RELAY

10A A/CONA/C Control Module

10AWIPER FRTECU, Rain Sensor

10AB/UP

LAMPB/UP LPM/T : Back-up Lamp Switch, A/T : Transaxle Range Switch, TCU

15A4ECU4Smart Key Control Module, Immobilizer Module, ECU

10A3ABS3ESC Control Module, ABS Control Module, Yaw Rate Sensor, HAC, ESS RELAY

15A6TCU2Transaxle Range Switch, TCU, Stop Lamp Switch

JD PE eng 7.QXP 1/28/2016 5:39 PM Page 73