Start engine KIA SPORTAGE 2020 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: SPORTAGE, Model: KIA SPORTAGE 2020Pages: 611, PDF Size: 15.85 MB

Page 452 of 611

What to do in an emergency

66

Jump starting procedure

1. Make sure the booster battery is12-volt and that its negative termi-

nal is grounded.

2. If the booster battery is in another vehicle, do not allow the vehicles

to come in contact.

3. Turn off all unnecessary electrical loads.

4. Connect the jumper cables in the exact sequence shown in the illus-

tration. First connect one end of a

jumper cable to the positive termi-

nal of the discharged battery (1),

then connect the other end to the

positive terminal of the booster

battery (2).

Proceed to connect one end of the

other jumper cable to the negative

terminal of the booster battery (3),

then the other end to a solid, sta-

tionary, metallic point (for example,

the engine lifting bracket) away

from the battery (4). Do not con-

nect it to or near any part that

moves when the engine is

cranked. Do not allow the jumper cables to

contact anything except the correct

battery terminals or the correct

ground. Do not lean over the bat-

tery when making connections.

5. Start the engine of the vehicle with the booster battery and let it run at

2,000 rpm, then start the engine of

the vehicle with the discharged

battery.

If the cause of your battery discharg-ing is not apparent, you should haveyour vehicle checked by an author-ized Kia dealer.

Push-starting

Vehicles equipped with automatic

transmission lock system cannot be

push-started.

Follow the directions in this section

for jump-starting.

WARNING - Tow starting

vehicle

Never tow a vehicle to start it.

When the engine starts, the

vehicle can suddenly surge for-

ward and could cause a colli-

sion with the tow vehicle.

WARNING - Battery cables

Do not connect the jumper cable

from the negative terminal of the

booster battery to the negative

terminal of the discharged bat-

tery. This can cause the dis-

charged battery to overheat and

crack, releasing battery acid.

Make sure to connect one end of

the jumper cable to the negative

terminal of the booster battery,

and the other end to a metalic

point, far away from the battery.

Page 456 of 611

What to do in an emergency

10

6

✽ ✽

NOTICE

If the TPMS, Low Tire Pressure

indicator does not illuminate for 3

seconds when the ignition switch or

the Engine start/stop button is

turned to the ON position, or if they

remain illuminated after coming on

for approximately 3 seconds, take

your vehicle to your nearest author-

ized Kia dealer and have the system

checked.

Low tire pressure

telltale

Low tire pressure position tell-

tale

When the tire pressure monitoring

system warning indicators are illumi-

nated, one or more of your tires is

significantly under-inflated.

If the telltale illuminates, immediately

reduce your speed, avoid hard cor-

nering and anticipate increased stop-

ping distances. You should stop and

check your tires as soon as possible. Inflate the tires to the proper pres-

sure as indicated on the vehicle’s

placard or tire inflation pressure label

located on the driver’s side center pil-

lar outer panel. If you cannot reach a

service station or if the tire cannot

hold the newly added air, replace the

low pressure tire with the spare tire.

Then the TPMS malfunction indicator

and the Low Tire Pressure telltale

may turn on and illuminate after

restarting and about 20 minutes of

continuous driving before you have

the low pressure tire repaired and

replaced on the vehicle.

In winter or cold weather, the low tire

pressure telltale may be illuminated if

the tire pressure was adjusted to the

recommended tire inflation pressure

in warm weather. It does not mean

your TPMS is malfunctioning

because the decreased temperature

leads to a proportional lowering of

tire pressure.

OQL068042L

Page 462 of 611

What to do in an emergency

16

6

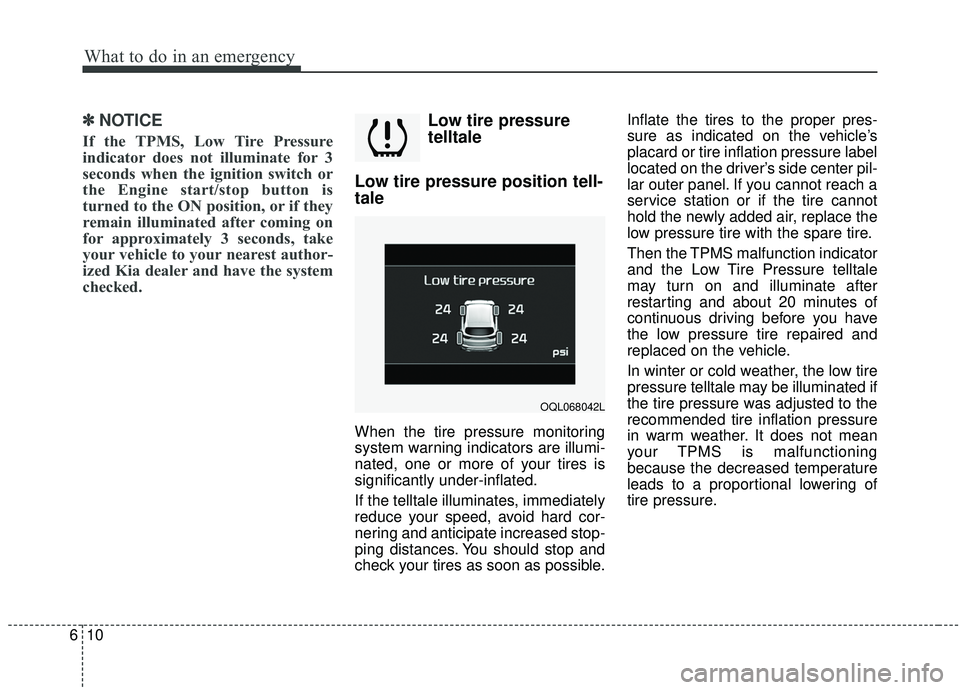

Removing and storing the

spare tire

Turn the tire hold-down wing bolt

counterclockwise.

Store the tire in the reverse order of

removal.

To prevent the spare tire and tools

from “rattling” while the vehicle is in

motion, store them properly. If it is hard to loosen the tire hold-

down wing bolt by hand, you can

loosen it easily using the jack handle.

1. Put the jack handle (1) inside of

the tire hold-down wing bolt.

2. Turn the tire hold-down wing bolt counterclockwise with the jack

handle.

Use caution when utilizing the sharp

jack handle.

WARNING- Running vehi- cle on jack

Do not start or run the engine of

the vehicle while the vehicle is

on the jack as this may cause

the vehicle to fall off the jack.

OQL065031

OQL065032

Page 476 of 611

What to do in an emergency

30

6

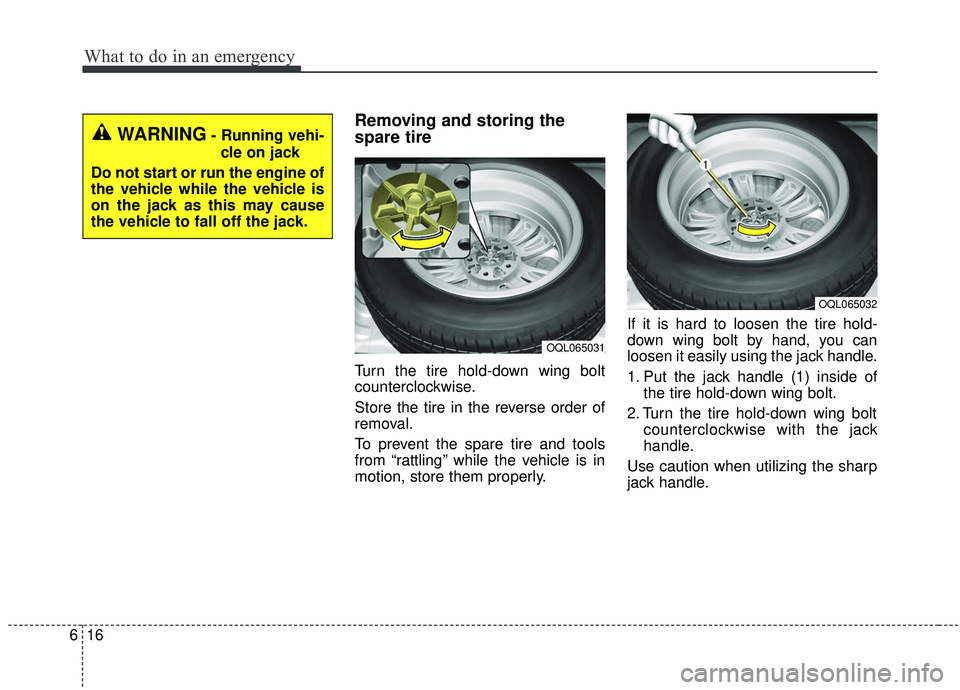

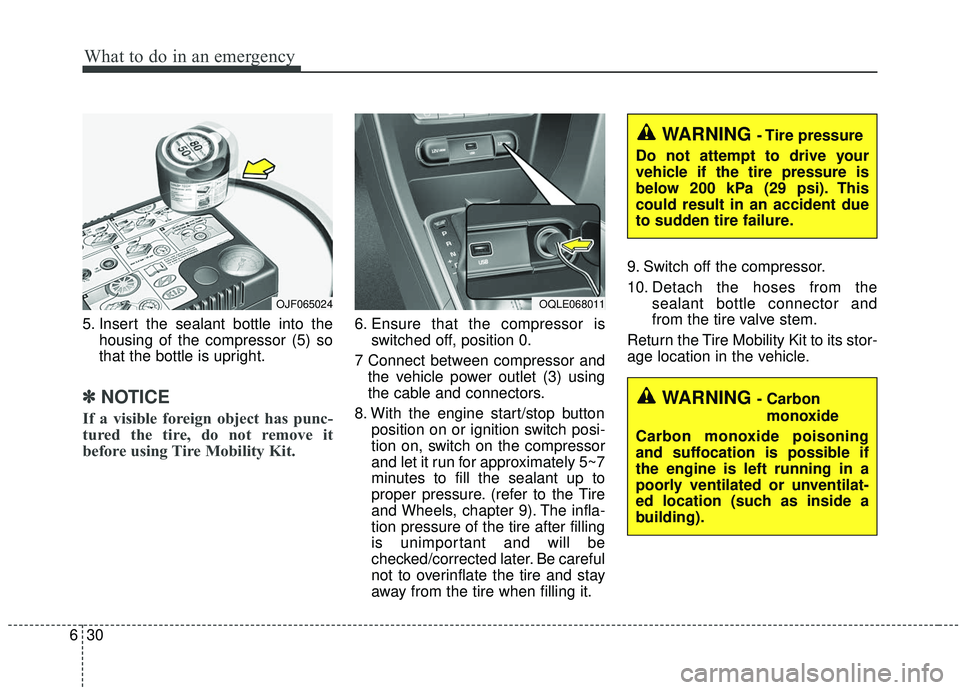

5. Insert the sealant bottle into the

housing of the compressor (5) so

that the bottle is upright.

✽ ✽NOTICE

If a visible foreign object has punc-

tured the tire, do not remove it

before using Tire Mobility Kit.

6. Ensure that the compressor is

switched off, position 0.

7 Connect between compressor and the vehicle power outlet (3) using

the cable and connectors.

8. With the engine start/stop button position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tire

and Wheels, chapter 9). The infla-

tion pressure of the tire after filling

is unimportant and will be

checked/corrected later. Be careful

not to overinflate the tire and stay

away from the tire when filling it. 9. Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve stem.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

OJF065024OQLE068011

WARNING - Carbon monoxide

Carbon monoxide poisoning

and suffocation is possible if

the engine is left running in a

poorly ventilated or unventilat-

ed location (such as inside a

building).

WARNING - Tire pressure

Do not attempt to drive your

vehicle if the tire pressure is

below 200 kPa (29 psi). This

could result in an accident due

to sudden tire failure.

Page 504 of 611

721

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filter

changes are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a

lifetime fuel filter that integrated with

the fuel tank. Regular maintenance

or replacement is not needed but

depends on fuel quality. If there are

some important safety matters like

fuel flow restriction, surging, loss of

power, hard starting problem etc, fuel

filter inspection or replace is needed.

The fuel filter should be inspected or

replaced by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 507 of 611

Maintenance

24

7

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the engine

and listen carefully for any exhaust

gas leakage. Tighten connections or

replace parts as necessary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or dam-

age. Replace any damaged parts.

Page 510 of 611

727

Maintenance

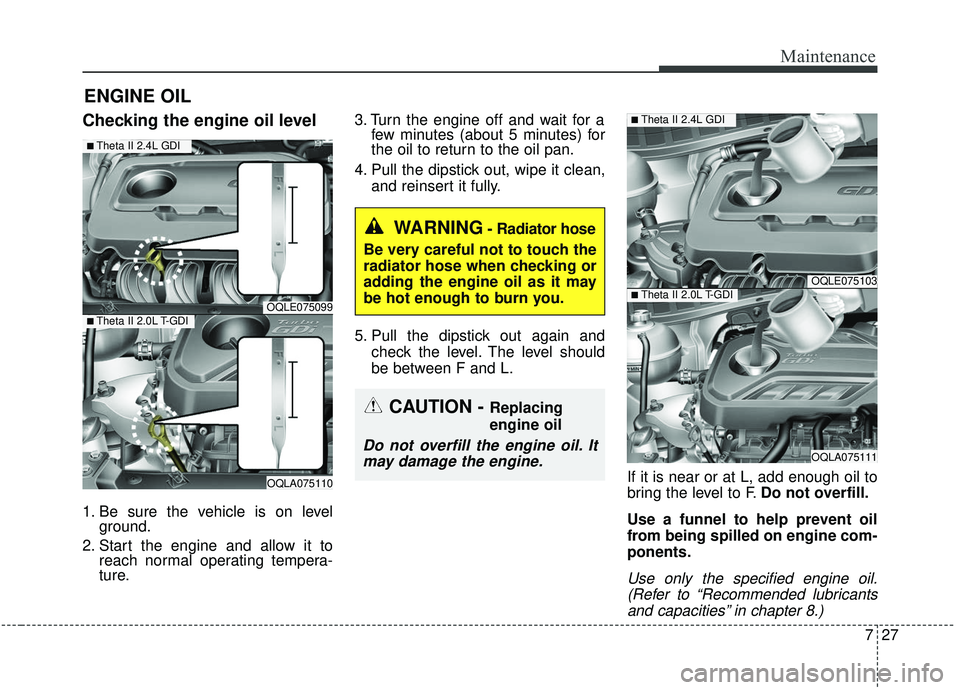

ENGINE OIL

Checking the engine oil level

1. Be sure the vehicle is on levelground.

2. Start the engine and allow it to reach normal operating tempera-

ture. 3. Turn the engine off and wait for a

few minutes (about 5 minutes) for

the oil to return to the oil pan.

4. Pull the dipstick out, wipe it clean, and reinsert it fully.

5. Pull the dipstick out again and check the level. The level should

be between F and L.

If it is near or at L, add enough oil to

bring the level to F.Do not overfill.

Use a funnel to help prevent oil

from being spilled on engine com-

ponents.

Use only the specified engine oil. (Refer to “Recommended lubricantsand capacities” in chapter 8.)

OQLE075099

OQLA075110

■Theta II 2.4L GDI

■Theta II 2.0L T-GDI

CAUTION - Replacing

engine oil

Do not overfill the engine oil. Itmay damage the engine.

WARNING- Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may

be hot enough to burn you.

OQLE075103

OQLA075111

■Theta II 2.4L GDI

■Theta II 2.0L T-GDI

Page 556 of 611

773

Maintenance

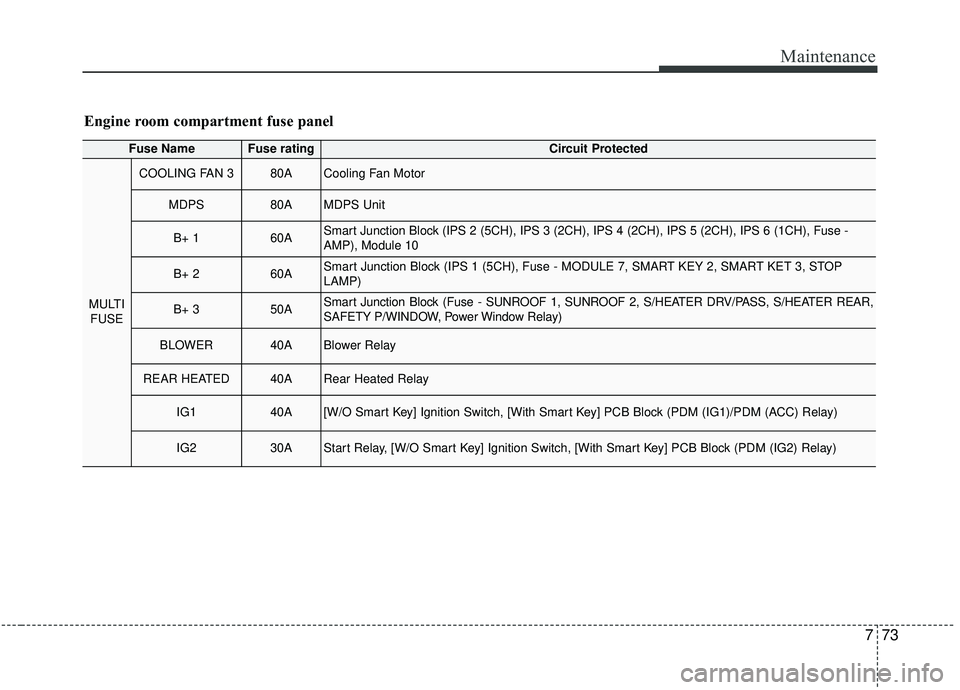

Fuse NameFuse ratingCircuit Protected

MULTIFUSE

COOLING FAN 380ACooling Fan Motor

MDPS80AMDPS Unit

B+ 160ASmart Junction Block (IPS 2 (5CH), IPS 3 (2CH), IPS 4 (2CH), IPS 5 (2CH), IPS 6 (\

1CH), Fuse -

AMP), Module 10

B+ 260ASmart Junction Block (IPS 1 (5CH), Fuse - MODULE 7, SMART KEY 2, SMART KET 3, STOP

LAMP)

B+ 350ASmart Junction Block (Fuse - SUNROOF 1, SUNROOF 2, S/HEATER DRV/PASS, S/HEATER REAR,

SAFETY P/WINDOW, Power Window Relay)

BLOWER40ABlower Relay

REAR HEATED40ARear Heated Relay

IG140A[W/O Smart Key] Ignition Switch, [With Smart Key] PCB Block (PDM (IG1)/PDM (ACC) Relay)

IG230AStart Relay, [W/O Smart Key] Ignition Switch, [With Smart Key] PCB Block (PDM (IG2) Relay)

Engine room compartment fuse panel

Page 587 of 611

Maintenance

104

7

Do not operate the engine in con-

fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in or

out of the area.

When the vehicle is stopped in an open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped vehicle for any extended time with

the engine running.

When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage to

the emission control system.Operating precautions for catalyt-

ic converters (if equipped)

WARNING- Catalytic converter

Keep away from the catalytic

converter and exhaust system

while the vehicle is running or

immediately thereafter. The

exhaust and catalytic systems

are very hot and may burn you.

WARNING- Fire

Do not park, idle or drive the vehicle over or near flamma-

ble objects, such as grass,

vegetation, paper, leaves, etc.

A hot exhaust system can

ignite flammable items under

your vehicle.

Also, do not remove the heat sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle or do not coat the

vehicle for corrosion control.

It may present a fire risk under

certain conditions.

Page 598 of 611

10

8

Specification & Consumer information

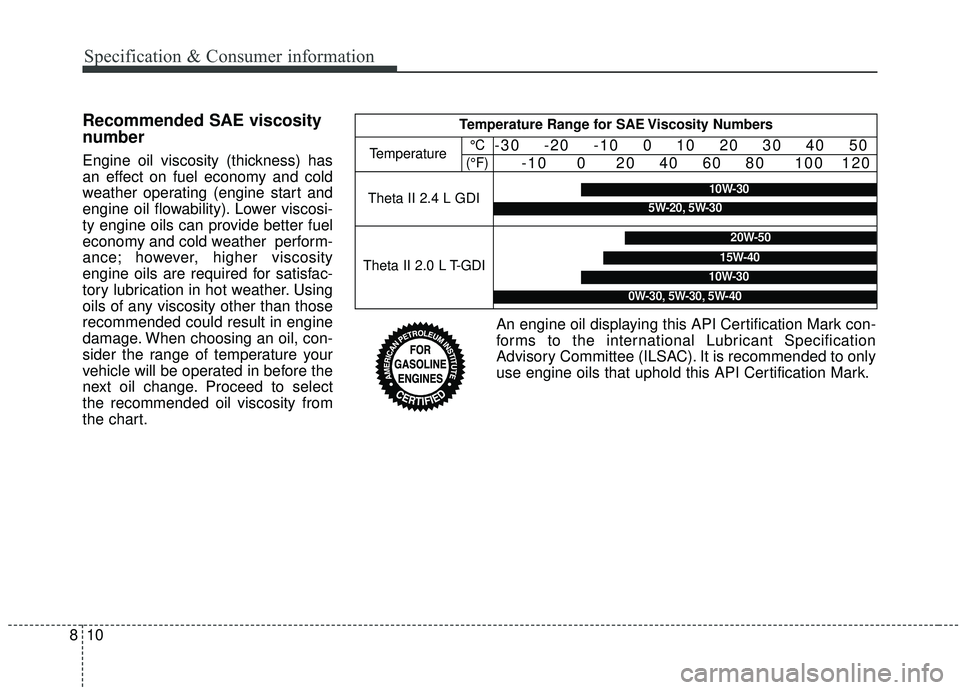

Recommended SAE viscosity

number

Engine oil viscosity (thickness) has

an effect on fuel economy and cold

weather operating (engine start and

engine oil flowability). Lower viscosi-

ty engine oils can provide better fuel

economy and cold weather perform-

ance; however, higher viscosity

engine oils are required for satisfac-

tory lubrication in hot weather. Using

oils of any viscosity other than those

recommended could result in engine

damage. When choosing an oil, con-

sider the range of temperature your

vehicle will be operated in before the

next oil change. Proceed to select

the recommended oil viscosity from

the chart.

Temperature Range for SAE Viscosity Numbers

Temperature°C

(°F)-30 -20 -10 0 10 20 30 40 50 -10 0 20 40 60 80 100 120

Theta II 2.0 L T-GDI

20W-50

10W-30

15W-40

0W-30, 5W-30, 5W-40

Theta II 2.4 L GDI10W-30

5W-20, 5W-30

An engine oil displaying this API Certification Mark con-

forms to the international Lubricant Specification

Advisory Committee (ILSAC). It is recommended to only

use engine oils that uphold this API Certification Mark.