air suspension KIA SPORTAGE 2020 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: SPORTAGE, Model: KIA SPORTAGE 2020Pages: 611, PDF Size: 15.85 MB

Page 494 of 611

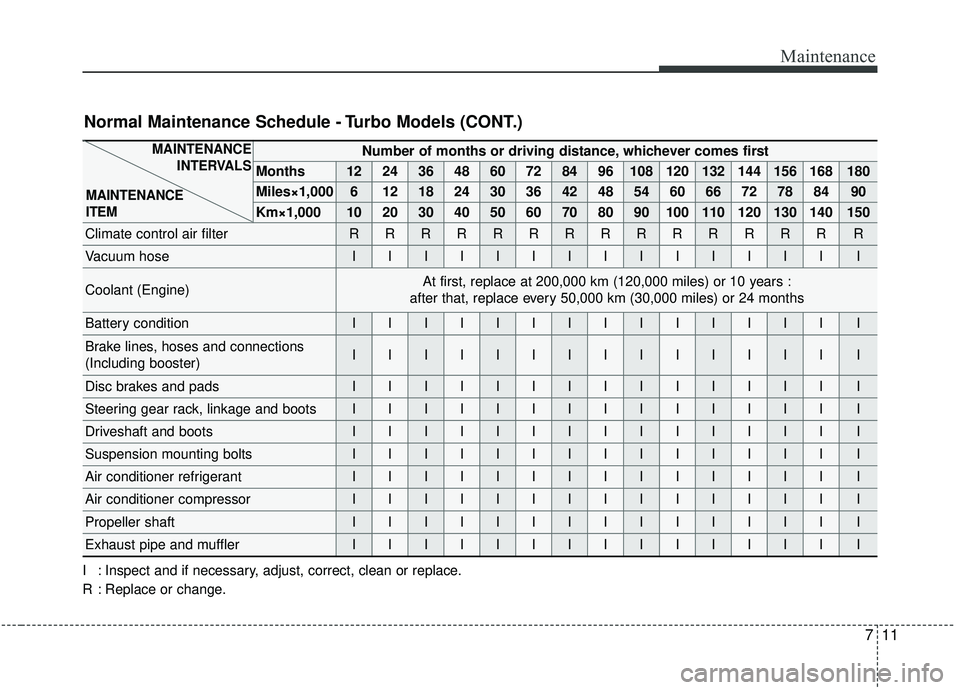

711

Maintenance

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Climate control air filterRRRRRRRRRRRRRRR

Vacuum hoseIIIIIIIIIIIIIII

Coolant (Engine)At first, replace at 200,000 km (120,000 miles) or 10 years :

after that, replace every 50,000 km (30,000 miles) or 24 months

Battery conditionIIIIIIIIIIIIIII

Brake lines, hoses and connections

(Including booster)IIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Propeller shaftIIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

Normal Maintenance Schedule - Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Page 500 of 611

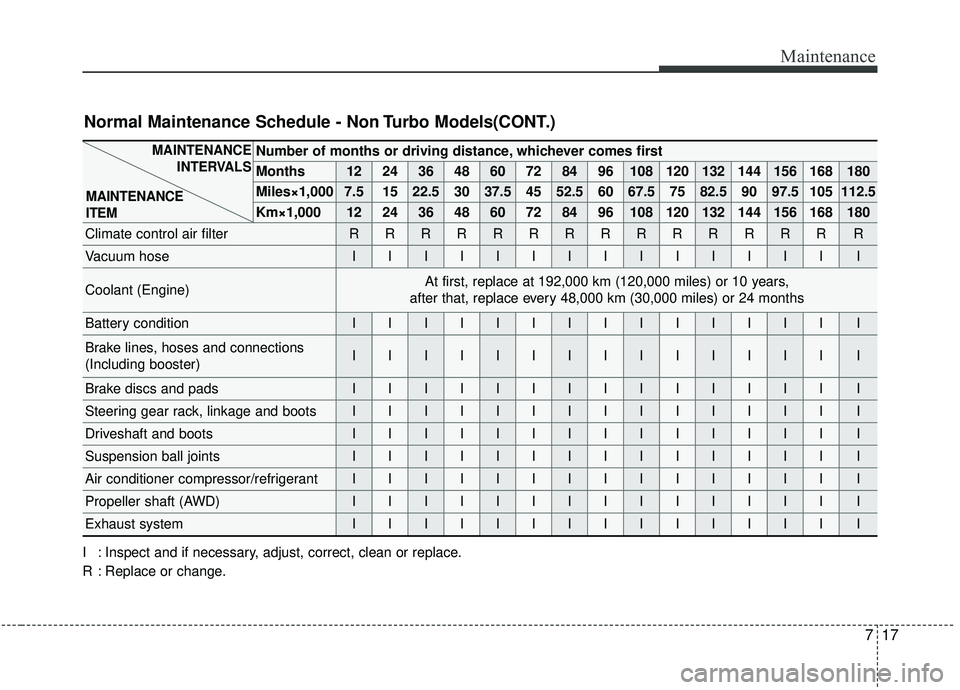

717

Maintenance

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Climate control air filterRRRRRRRRRRRRRRR

Vacuum hoseIIIIIIIIIIIIIII

Coolant (Engine)At first, replace at 192,000 km (120,000 miles) or 10 years,

after that, replace every 48,000 km (30,000 miles) or 24 months

Battery conditionIIIIIIIIIIIIIII

Brake lines, hoses and connections

(Including booster)IIIIIIIIIIIIIII

Brake discs and padsIIIIIIIIIIIIIII

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension ball jointsIIIIIIIIIIIIIII

Air conditioner compressor/refrigerantIIIIIIIIIIIIIII

Propeller shaft (AWD)IIIIIIIIIIIIIII

Exhaust systemIIIIIIIIIIIIIII

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Non Turbo Models(CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

Page 502 of 611

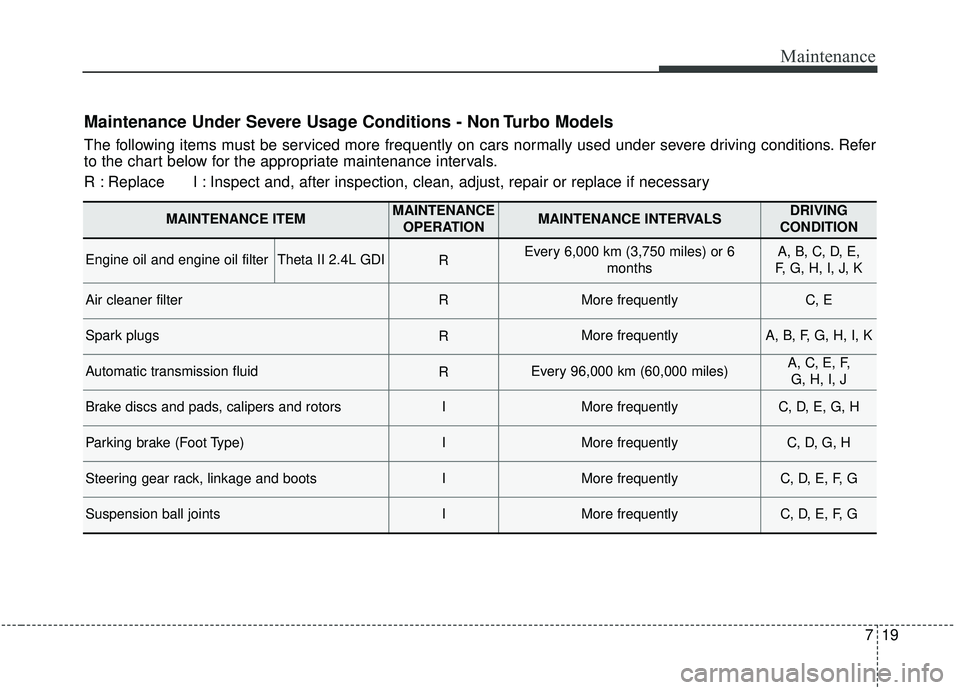

719

Maintenance

Maintenance Under Severe Usage Conditions - Non Turbo Models

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCEOPERATIONMAINTENANCE INTERVALSDRIVING

CONDITION

Engine oil and engine oil filterTheta II 2.4L GDIREvery 6,000 km (3,750 miles) or 6 monthsA, B, C, D, E,

F, G, H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugs RMore frequentlyA, B, F, G, H, I, K

Automatic transmission fluidREvery 96,000 km (60,000 miles)A, C, E, F, G, H, I, J

Brake discs and pads, calipers and rotorsIMore frequentlyC, D, E, G, H

Parking brake (Foot Type)IMore frequentlyC, D, G, H

Steering gear rack, linkage and bootsIMore frequentlyC, D, E, F, G

Suspension ball jointsIMore frequentlyC, D, E, F, G

Page 579 of 611

Maintenance

96

7

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or replace-

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,

use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Road salt and other corrosive chemi-

cals are used in cold weather states to

melt snow and prevent ice accumula-

tion. If these chemicals are not regu-

larly removed, they will corrode the

vehicle underbody and over time dam-

age fuel lines, the fuel tank retention

system, the vehicle suspension, the

exhaust system, and even the body

frame.

Wash the undercarriage of yourvehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.CAUTION - Drying vehicle

Wiping dust or dirt off the body with a dry cloth willscratch the finish.

Do not use steel wool, abra- sive cleaners, acid detergentsor strong detergents contain-ing high alkaline or causticagents on chrome-plated oranodized aluminum parts.This may result in damage tothe protective coating andcause discoloration or paintdeterioration.

Page 580 of 611

797

Maintenance

Do a thorough washing of theundercarriage at the end of the

winter.

Use professional service techni- cians or governmental inspection

stations to annually inspect for cor-

rosion.

Immediately seek an inspection of your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongey brakes,

fluids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.Aluminum wheel maintenance

The aluminum wheels are coated

with a clear protective finish.

Do not use any abrasive cleaner,polishing compound, solvent, or

wire brushes on aluminum wheels.

They may scratch the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral detergent, and rinse thoroughly

with water. Also, be sure to clean

the wheels after driving on salted

roads. This helps prevent corro-

sion.

Avoid washing the wheels with highspeed vehicle wash brushes.

Do not use any alkaline or acid detergents It may damage and cor-

rode the aluminum wheels coated

with a clear protective finish.

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design

and construction practices to combat

corrosion, we produce vehicles of

the excellent quality. However, this is

only part of the job. To achieve the

long-term corrosion resistance your

vehicle can deliver, the owner's

cooperation and assistance is also

required.

Common causes of corrosion

The most common causes of corro-

sion on your vehicle are:

Road salt, dirt and moisture that isallowed to accumulate underneath

the vehicle.

Removal of paint or protective coatings by stones, gravel, abra-

sion or minor scrapes and dents

which leave unprotected metal

exposed to corrosion.