ECU Lancia Voyager 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Voyager, Model: Lancia Voyager 2012Pages: 344, PDF Size: 3.95 MB

Page 174 of 344

17. Vehicle Security Light (for

versions/markets, where provided)This light will flash at a fast

rate for approximately

15 seconds, when the ve-

hicle security alarm is arm-

ing, and then will flash slowly until

the vehicle is disarmed.

18. Brake Warning Light This light monitors various

brake functions, including

brake fluid level and parking

brake application. If the brake light

turns on it may indicate that the park-

ing brake is applied, that the brake

fluid level is low, or that there is a

problem with the anti-lock brake sys-

tem reservoir.

If the light remains on when the park-

ing brake has been disengaged, and

the fluid level is at the full mark on the

master cylinder reservoir, it indicates

a possible brake hydraulic system

malfunction or that a problem with

the Brake Booster has been detected

by the Anti-Lock Brake System (ABS)

/ Electronic Stability Control (ESC)

system. In this case, the light will re-

main on until the condition has been corrected. If the problem is related to

the brake booster, the ABS pump will

run when applying the brake and a

brake pedal pulsation may be felt dur-

ing each stop.

The dual brake system provides a re-

serve braking capacity in the event of

a failure to a portion of the hydraulic

system. A leak in either half of the

dual brake system is indicated by the

Brake Warning Light, which will turn

on when the brake fluid level in the

master cylinder has dropped below a

specified level.

The light will remain on until the

cause is corrected.

NOTE:

The light may flash momentarily

during sharp cornering maneu-

vers, which change fluid level con-

ditions. The vehicle should have

service performed, and the brake

fluid level checked.

If brake failure is indicated, immedi-

ate repair is necessary.

WARNING!

Driving a vehicle with the red brake

light on is dangerous. Part of the

brake system may have failed. It will

take longer to stop the vehicle. You

could have a collision. Have the ve-

hicle checked immediately.

Vehicles equipped with the Anti-Lock

Brake System (ABS), are also

equipped with Electronic Brake Force

Distribution (EBD). In the event of an

EBD failure, the Brake Warning Light

will turn on along with the ABS Light.

Immediate repair to the ABS system is

required.

Operation of the Brake Warning Light

can be checked by turning the ignition

switch from the OFF position to the

ON/RUN position. The light should

illuminate for approximately two sec-

onds. The light should then turn off

unless the parking brake is applied or

a brake fault is detected. If the light

does not illuminate, have the light

inspected by an authorized dealer.

168

Page 232 of 344

KEYLESS ENTER-N-GO

(for versions/markets,

where provided)This feature allows

the driver to oper-

ate the ignition

switch with the

push of a button,

as long as the EN-

GINE START/

STOP button is installed and the Re-

mote Keyless Entry (RKE)

transmitter is in the passenger com-

partment.

Installing And Removing The

ENGINE START/STOP Button

Installing The Button

1. Remove the key fob from the igni-

tion switch.

2. Insert the ENGINE START/STOP

button into the ignition switch with

the lettering facing up and readable.

3. Press firmly on the center of the

button to secure it into position. Removing The Button

1. The ENGINE START/STOP but-

ton can be removed from the ignition

switch for key fob use.

2. Insert the metal part of the emer-

gency key under the chrome bezel at

the 6 o’clock position and gently pry

the button loose.

NOTE:

The ENGINE START/STOP button

should only be removed or in-

serted with the ignition in the

LOCK position (OFF position for

Keyless Enter-N-Go).

NORMAL STARTING —

GASOLINE ENGINE

Using The ENGINE START/STOP

Button

NOTE:

Normal starting of either a cold or

a warm engine is obtained without

pumping or pressing the accelera-

tor pedal.

To start the engine, the transmission

must be in PARK or NEUTRAL. Press

and hold the brake pedal while press-ing the ENGINE START/STOP but-

ton once. The system takes over and

attempts to start the vehicle. If the

vehicle fails to start, the starter will

disengage automatically after 10 sec-

onds. If you wish to stop the cranking

of the engine prior to the engine start-

ing, press the button again.

To Turn Off The Engine Using

ENGINE START/STOP Button

1. Place the shift lever in PARK, then

press and release the ENGINE

START/STOP button.

2. The ignition switch will return to

the OFF position.

3. If the shift lever is not in PARK, the

ENGINE START/STOP button must

be held for two seconds and vehicle

speed must be above 8 km/h before

the engine will shut off. The ignition

switch position will remain in the

ACC position until the shift lever is in

PARK and the button is pressed twice

to the OFF position. If the shift lever is

not in PARK and the ENGINE

START/STOP button is pressed once,

the EVIC (for versions/markets,

where provided) will display a “Ve-226

Page 240 of 344

through underdrive first, second,

third, and fourth gears, direct fifth

gear and overdrive sixth gear. The

DRIVE position provides optimum

driving characteristics under all nor-

mal operating conditions.

When frequent transmission shifting

occurs (such as when operating the

vehicle under heavy loading condi-

tions, in hilly terrain, traveling into

strong head winds, or while towing

heavy trailers), use the Electronic

Range Select (ERS) shift control (de-

scribed below) to select a lower gear

range. Under these conditions, using a

lower gear range will improve perfor-

mance and extend transmission life

by reducing excessive shifting and

heat buildup.

During cold temperatures, transmis-

sion operation may be modified de-

pending on engine and transmission

temperature as well as vehicle speed.

This feature improves warm up time

of the engine and transmission to

achieve maximum efficiency. Engage-

ment of the torque converter clutch is

inhibited until the transmission fluid

is warm (refer to the “Note” under“Torque Converter Clutch” in this

section). During extremely cold tem-

peratures (27°C or below), operation

may briefly be limited to third gear

only. Normal operation will resume

once the transmission temperature

has risen to a suitable level.

Transmission Limp Home Mode

Transmission function is monitored

electronically for abnormal condi-

tions. If a condition is detected that

could result in transmission damage,

Transmission Limp Home Mode is ac-

tivated. In this mode, the transmis-

sion remains in third gear regardless

of which forward gear is selected.

PARK, REVERSE, and NEUTRAL

will continue to operate. The Mal-

function Indicator Light (MIL) may

be illuminated. Limp Home Mode al-

lows the vehicle to be driven to an

authorized dealer for service without

damaging the transmission.

In the event of a momentary problem,

the transmission can be reset to regain

all forward gears by performing the

following steps:

1. Stop the vehicle.

2. Shift the transmission into PARK.

3. Turn the engine OFF.

4. Wait approximately 10 seconds.

5. Restart the engine.

6. Shift into the desired gear range. If

the problem is no longer detected, the

transmission will return to normal op-

eration.

NOTE:

Even if the transmission can be

reset, we recommend that you visit

your authorized dealer at your

earliest possible convenience.

Your authorized dealer has diag-

nostic equipment to determine if

the problem could recur.

If the transmission cannot be reset,

authorized dealer service is required.

Electronic Range Select (ERS)

Operation

The Electronic Range Select (ERS)

shift control allows the driver to limit

the highest available gear when the

shift lever is in the DRIVE position.

For example, if you shift the transmis-

sion into 3 (third gear), the transmis-

sion will never shift above third gear,

234

Page 255 of 344

REPLACEMENT TIRES

The tires on your new vehicle provide

a balance of many characteristics.

They should be inspected regularly

for wear and correct cold tire inflation

pressure. The manufacturer strongly

recommends that you use tires

equivalent to the originals in size,

quality and performance when re-

placement is needed. Please see

“Tread Wear Indicators” and “Tire

and Loading Information” placard

for the size designation of your tire.

The Load Index and Speed Symbol

for your tire will be found on the

original equipment tire sidewall. See

the Tire Sizing Chart example found

in the Tire Safety Information section

of this manual for more information

relating to the Load Index and Speed

Symbol of a tire.

It is recommended to replace the two

front tires or two rear tires as a pair.

Replacing just one tire can seriously

affect your vehicle’s handling. If you

ever replace a wheel, make sure that

the wheel’s specifications match those

of the original wheels.It is recommended you contact your

original equipment or an authorized

tire dealer with any questions you

may have on tire specifications or ca-

pability. Failure to use equivalent re-

placement tires may adversely affect

the safety, handling, and ride of your

vehicle.

WARNING!

Do not use a tire, wheel size or

rating other than that specified

for your vehicle. Some combina-

tions of unapproved tires and

wheels may change suspension di-

mensions and performance char-

acteristics, resulting in changes to

steering, handling, and braking of

your vehicle. This can cause un-

predictable handling and stress to

steering and suspension compo-

nents. You could lose control and

have a collision resulting in seri-

ous injury or death. Use only the

tire and wheel sizes with load rat-

ings approved for your vehicle.

(Continued)

WARNING!(Continued)

Never use a tire with a smaller

load index or capacity, than what

was originally equipped on your

vehicle. Using a tire with a smaller

load index could result in tire

overloading and failure. You

could lose control and have a col-

lision.

Failure to equip your vehicle with

tires having adequate speed capa-

bility can result in sudden tire fail-

ure and loss of vehicle control.CAUTION!

Replacing original tires with tires of

a different size may result in false

speedometer and odometer read-

ings.

TIRE CHAINS

Use of Security Chain Company

(SCC) Super Z6 SZ-143 or Iceman

Z6 IZ-643 cables or equivalent are

recommended on 225/65R17 tires.

NOTE:

Do not use tire chains on a com-

pact spare tire.

249

Page 273 of 344

6

WHAT TO DO IN EMERGENCIES

HAZARD WARNING FLASHERS . . . . . . . . . . . . 268

IF YOUR ENGINE OVERHEATS . . . . . . . . . . . . . 268

JACKING AND TIRE CHANGING . . . . . . . . . . . . 269 JACK LOCATION . . . . . . . . . . . . . . . . . . . . . . 269

SPARE TIRE REMOVAL . . . . . . . . . . . . . . . . . 269

TO ACCESS SPARE TIRE WINCH DRIVENUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

SPARE TIRE TOOLS . . . . . . . . . . . . . . . . . . . 271

SPARE TIRE REMOVAL INSTRUCTIONS . . . 271

PREPARATIONS FOR JACKING . . . . . . . . . . . 272

JACKING INSTRUCTIONS . . . . . . . . . . . . . . . 272

SECURING THE SPARE TIRE . . . . . . . . . . . . 275

ROAD TIRE INSTALLATION . . . . . . . . . . . . . 276

JUMP-STARTING PROCEDURE . . . . . . . . . . . . . 277 PREPARATIONS FOR JUMP-START . . . . . . . 278

JUMP-STARTING PROCEDURE . . . . . . . . . . . 278

FREEING A STUCK VEHICLE . . . . . . . . . . . . . . 279

SHIFT LEVER OVERRIDE . . . . . . . . . . . . . . . . . 280

TOWING A DISABLED VEHICLE . . . . . . . . . . . 281 WITHOUT THE IGNITION KEY . . . . . . . . . . . 282

267

Page 279 of 344

WARNING!(Continued)

If working on or near a roadway,

be extremely careful of motor

traffic.

To assure that spare tires, flat or

inflated, are securely stowed,

spares must be stowed with the

valve stem facing the ground.CAUTION!

Do not attempt to raise the vehicle

by jacking on locations other than

those indicated in the Jacking In-

structions for this vehicle.

NOTE:

Refer to the “Compact Spare Tire”

section of “Tires – General Infor-

mation” for information about the

spare tire, its use, and operation.

1. Loosen (but do not remove) the

wheel lug nuts by turning them to the

left one turn while the wheel is still on

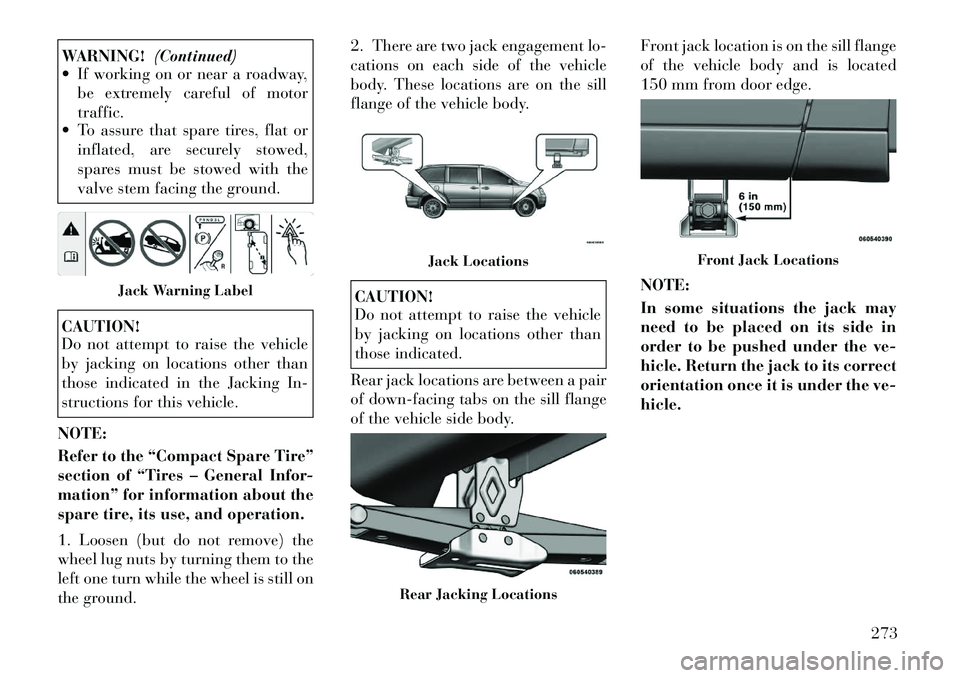

the ground. 2. There are two jack engagement lo-

cations on each side of the vehicle

body. These locations are on the sill

flange of the vehicle body.

CAUTION!

Do not attempt to raise the vehicle

by jacking on locations other than

those indicated.

Rear jack locations are between a pair

of down-facing tabs on the sill flange

of the vehicle side body. Front jack location is on the sill flange

of the vehicle body and is located

150 mm from door edge.

NOTE:

In some situations the jack may

need to be placed on its side in

order to be pushed under the ve-

hicle. Return the jack to its correct

orientation once it is under the ve-

hicle.

Jack Warning Label

Jack Locations

Rear Jacking Locations

Front Jack Locations

273

Page 280 of 344

WARNING!

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off

the jack and fall on you. You could

be crushed. Never get any part of

your body under a vehicle that is on

a jack. If you need to get under a

raised vehicle, take it to a service

center where it can be raised on a

lift.

3. Place the wrench on the jack screw

and turn to the right until the jack

head is properly engaged in the de-

scribed location. Do not raise the

vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the

jack screw to the right, using the

swivel wrench. Raise the vehicle only

until the tire just clears the surface

and enough clearance is obtained to

install the spare tire. Minimum tire lift

provides maximum stability.

WARNING!

Raising the vehicle higher than nec-

essary can make the vehicle less

stable. It could slip off the jack and

hurt someone near it. Raise the ve-

hicle only enough to remove the tire.

5. Remove the wheel lug nuts, for

vehicles with wheel covers, remove

the cover from the wheel by hand. Do

not pry the wheel cover off. Then pull

the wheel off the hub.

6. Install the compact spare tire.

Lightly tighten the lug nuts.CAUTION!

Be sure to mount the spare tire with

the valve stem facing outward. The

vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the ve-

hicle off the jack, do not tighten the

wheel nuts fully until the vehicle has

been lowered. Failure to follow this

warning may result in personal in-

jury.

NOTE:

Do not install the wheel cover on

the compact spare.

7. Lower the vehicle by turning the

jack screw to the left.

Mounting Spare Tire

274

Page 281 of 344

8. Finish tightening the lug nuts.

Push down on the wrench while at the

end of the handle for increased lever-

age. Tighten the lug nuts in a star

pattern until each nut has been tight-

ened twice. The correct wheel nut

tightness is 138 N·m. If in doubt

about the correct tightness, have them

checked with a torque wrench by your

authorized dealer or at a service sta-

tion.

9. Lower the jack to its fully-closed

position.WARNING!

A loose tire or jack thrown forward

in a collision or hard stop could en-

danger the occupants of the vehicle.

Always stow the jack parts and the

spare tire in the places provided.

Have the deflated (flat) tire repaired

or replaced immediately.

10. Place the deflated (flat) tire and

compact spare tire cover assembly in

the rear cargo area. Do not stow the

deflated tire in the spare tire loca-

tion. Have the full-sized tire repaired

or replaced, as soon as possible. 11. Stow the cable and wheel spacer

before driving the vehicle. Reas-

semble the winch handle extensions to

form a “T” and fit the winch T-handle

over the drive nut. Rotate the nut to

the right until the winch mechanism

clicks at least three times.

NOTE:

Refer to the “Spare Tire Tools”

section for instructions on assem-

bling the T-handle.

12. Stow the jack, jack handle and

winch handle tools back in the stow-

age compartment.

13. Check the compact spare tire

pressure as soon as possible. Correct

the tire pressure, as required.

SECURING THE SPARE

TIRE

1. Assemble the winch handle exten-

sions to form a T-handle and fit the

winch T-handle over the drive nut.

Rotate the nut to the left until the

winch mechanism stops turning

freely. This will allow enough slack in

the cable to allow you to pull the

wheel spacer out from under the ve-

hicle.

WARNING!

A loose compact spare tire/cover as-

sembly, thrown forward in a colli-

sion or hard stop could endanger the

occupants of the vehicle. Always

stow the compact spare tire with the

cover assembly in the place pro-

vided.CAUTION!

The winch mechanism is designed

for use with the winch T-handle

only. Use of an air wrench or other

power tools is not recommended and

can damage the winch.

2. Assemble the winch handle exten-

sions to form the spare tire hook, and

pull the wheel spacer from under the

vehicle.

3. Turn the compact spare tire so that

the valve stem is down, and place the

tire into the spare tire/cover assembly.

Slide the wheel spacer through the

center of the wheel and spare tire/

cover assembly, so that the two re-

tainer tabs snap out and engage the

spare tire cover on the opposite side.

275

Page 287 of 344

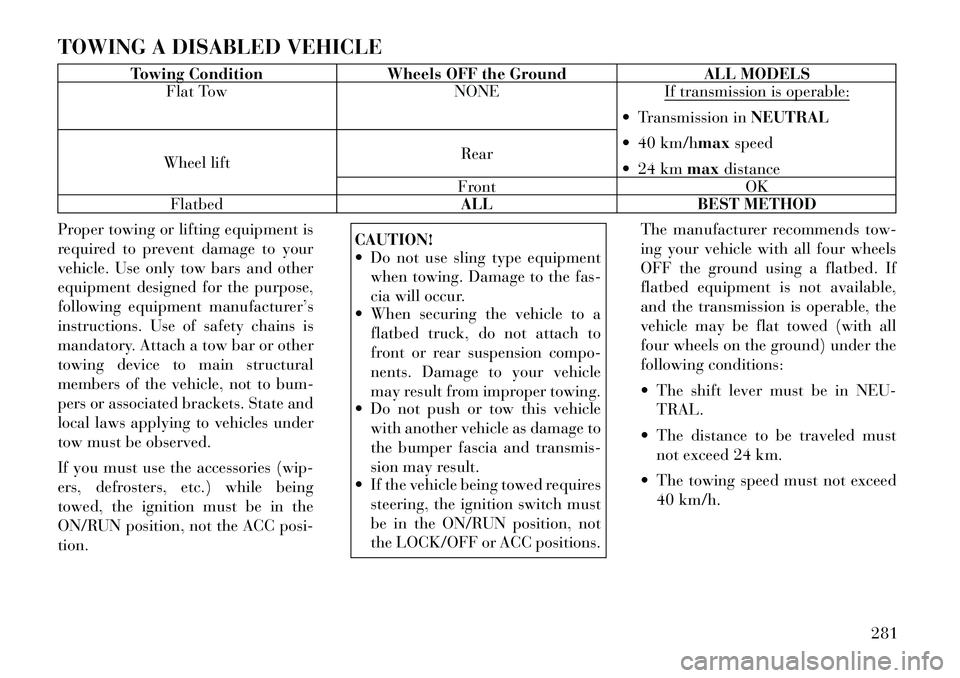

TOWING A DISABLED VEHICLE

Towing ConditionWheels OFF the Ground ALL MODELS

Flat Tow NONEIf transmission is operable:

Transmission inNEUTRAL

40 km/hmax speed

24 km maxdistance

Wheel lift Rear

Front OK

Flatbed ALLBEST METHOD

Proper towing or lifting equipment is

required to prevent damage to your

vehicle. Use only tow bars and other

equipment designed for the purpose,

following equipment manufacturer’s

instructions. Use of safety chains is

mandatory. Attach a tow bar or other

towing device to main structural

members of the vehicle, not to bum-

pers or associated brackets. State and

local laws applying to vehicles under

tow must be observed.

If you must use the accessories (wip-

ers, defrosters, etc.) while being

towed, the ignition must be in the

ON/RUN position, not the ACC posi-

tion.

CAUTION!

Do not use sling type equipment when towing. Damage to the fas-

cia will occur.

When securing the vehicle to a

flatbed truck, do not attach to

front or rear suspension compo-

nents. Damage to your vehicle

may result from improper towing.

Do not push or tow this vehicle

with another vehicle as damage to

the bumper fascia and transmis-

sion may result.

If the vehicle being towed requires

steering, the ignition switch must

be in the ON/RUN position, not

the LOCK/OFF or ACC positions. The manufacturer recommends tow-

ing your vehicle with all four wheels

OFF the ground using a flatbed. If

flatbed equipment is not available,

and the transmission is operable, the

vehicle may be flat towed (with all

four wheels on the ground) under the

following conditions:

The shift lever must be in NEU-

TRAL.

The distance to be traveled must not exceed 24 km.

The towing speed must not exceed 40 km/h.

281

Page 299 of 344

A/C Air Filter (for versions/

markets, where provided)CAUTION!

Car maintenance should be done at

a LANCIA Dealership. For routine

and minor maintenance operations

you wish to carry out yourself, we do

recommend you have the proper

equipment, genuine LANCIA spare

parts and the necessary fluids; do

not however carry out these opera-

tions if you have no experience.

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.WARNING!

Do not remove the A/C air filter

while the blower is operating or per-

sonal injury may result.

The A/C air filter is located in the

fresh air inlet behind the glove box.

Perform the following procedure to

replace the filter:

1. Open the glove compartment and

remove all contents.

2. Push in on the sides of the glove

compartment and lower the door. 3. Pivot the glove compartment

downward.

4. Disengage the two retaining tabs

that secure the filter cover to the

HVAC housing, and remove the cover.

5. Remove the A/C air filter by pull-

ing it straight out of the housing.

6. Install the A/C air filter with the

arrow on the filter pointing toward

the floor. When installing the filter

cover, make sure the retaining tabs

fully engage the cover.

CAUTION!

The A/C air filter is identified with

an arrow to indicate airflow direc-

tion through the filter. Failure to

properly install the filter will result

in the need to replace it more often.

7. Rotate the glove compartment

door back into position.

BODY LUBRICATION

Locks and all body pivot points, in-

cluding such items as seat tracks, door

hinge pivot points and rollers, liftgate,

tailgate, sliding doors and hood

hinges, should be lubricated periodi-

cally with a lithium-based grease or

equivalent, to assure quiet, easy op-

eration and to protect against rust and

wear. Prior to the application of any

lubricant, the parts concerned should

be wiped clean to remove dust and

grit; after lubricating excess oil and

grease should be removed. Particular

attention should also be given to hood

latching components to ensure proper

function. When performing other un-

derhood services, the hood latch, re-

lease mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be

lubricated twice a year, preferably in

the Fall and Spring. Apply a small

amount of a high quality lubricant

directly into the lock cylinder.

A/C Air Filter Replacement

293