LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 111 of 455

FUEL SYSTEM

9

REPAIR REV: 05/99

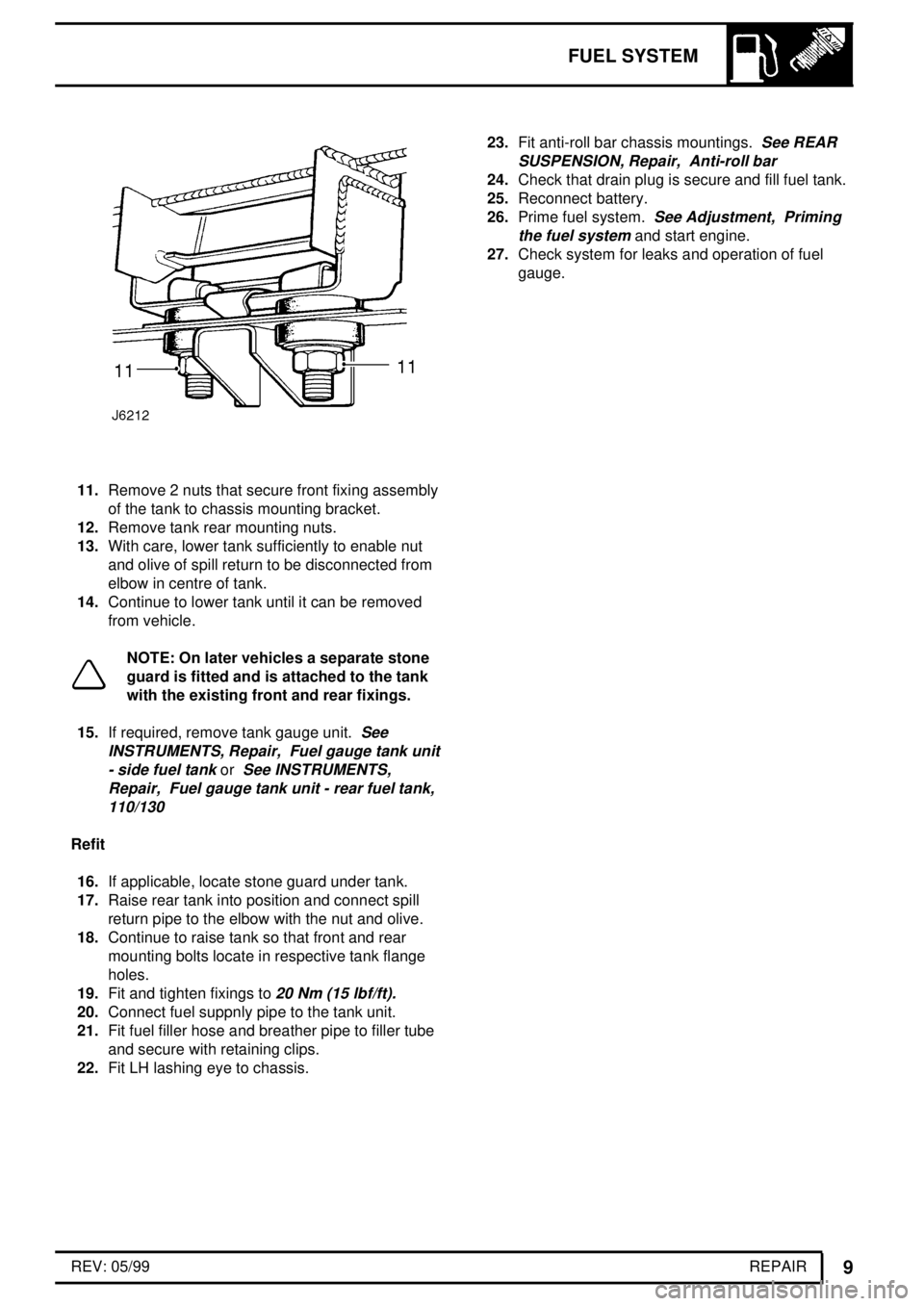

11.Remove 2 nuts that secure front fixing assembly

of the tank to chassis mounting bracket.

12.Remove tank rear mounting nuts.

13.With care, lower tank sufficiently to enable nut

and olive of spill return to be disconnected from

elbow in centre of tank.

14.Continue to lower tank until it can be removed

from vehicle.

NOTE: On later vehicles a separate stone

guard is fitted and is attached to the tank

with the existing front and rear fixings.

15.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

16.If applicable, locate stone guard under tank.

17.Raise rear tank into position and connect spill

return pipe to the elbow with the nut and olive.

18.Continue to raise tank so that front and rear

mounting bolts locate in respective tank flange

holes.

19.Fit and tighten fixings to

20 Nm (15 lbf/ft).

20.Connect fuel suppnly pipe to the tank unit.

21.Fit fuel filler hose and breather pipe to filler tube

and secure with retaining clips.

22.Fit LH lashing eye to chassis.23.Fit anti-roll bar chassis mountings.

See REAR

SUSPENSION, Repair, Anti-roll bar

24.Check that drain plug is secure and fill fuel tank.

25.Reconnect battery.

26.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

27.Check system for leaks and operation of fuel

gauge.

Page 112 of 455

19FUEL SYSTEM

10

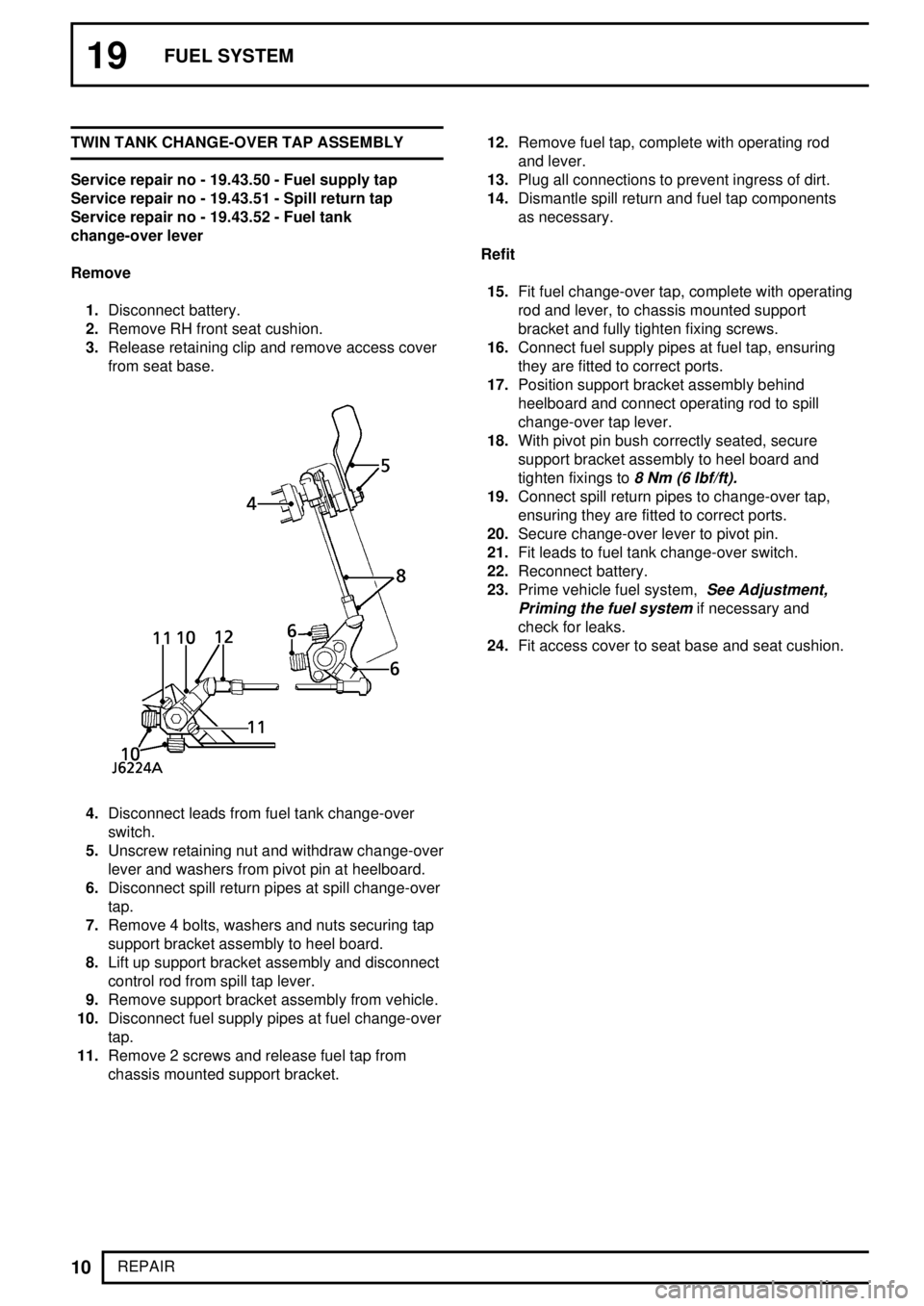

REPAIR TWIN TANK CHANGE-OVER TAP ASSEMBLY

Service repair no - 19.43.50 - Fuel supply tap

Service repair no - 19.43.51 - Spill return tap

Service repair no - 19.43.52 - Fuel tank

change-over lever

Remove

1.Disconnect battery.

2.Remove RH front seat cushion.

3.Release retaining clip and remove access cover

from seat base.

4.Disconnect leads from fuel tank change-over

switch.

5.Unscrew retaining nut and withdraw change-over

lever and washers from pivot pin at heelboard.

6.Disconnect spill return pipes at spill change-over

tap.

7.Remove 4 bolts, washers and nuts securing tap

support bracket assembly to heel board.

8.Lift up support bracket assembly and disconnect

control rod from spill tap lever.

9.Remove support bracket assembly from vehicle.

10.Disconnect fuel supply pipes at fuel change-over

tap.

11.Remove 2 screws and release fuel tap from

chassis mounted support bracket.12.Remove fuel tap, complete with operating rod

and lever.

13.Plug all connections to prevent ingress of dirt.

14.Dismantle spill return and fuel tap components

as necessary.

Refit

15.Fit fuel change-over tap, complete with operating

rod and lever, to chassis mounted support

bracket and fully tighten fixing screws.

16.Connect fuel supply pipes at fuel tap, ensuring

they are fitted to correct ports.

17.Position support bracket assembly behind

heelboard and connect operating rod to spill

change-over tap lever.

18.With pivot pin bush correctly seated, secure

support bracket assembly to heel board and

tighten fixings to

8 Nm (6 lbf/ft).

19.Connect spill return pipes to change-over tap,

ensuring they are fitted to correct ports.

20.Secure change-over lever to pivot pin.

21.Fit leads to fuel tank change-over switch.

22.Reconnect battery.

23.Prime vehicle fuel system,

See Adjustment,

Priming the fuel system

if necessary and

check for leaks.

24.Fit access cover to seat base and seat cushion.

Page 113 of 455

FUEL SYSTEM

11

REPAIR HEATER PLUGS

Service repair no - 19.60.31

Remove

1.Disconnect battery.

No.1 heater plug - air conditioning models:

2.Release drive belt from compressor pulley.See

AIR CONDITIONING, Repair, Compressor

drive belt

3.Remove 4 bolts securing compressor to front

cover, move compressor aside.

No.3 heater plug:

4.Remove retaining bolt and withdraw breather

valve from rocker cover. Remove and discard 'O'

ring.

All heater plugs:

5.Remove terminal nut and disconnect wire from

heater plug terminal.

6.Unscrew heater plug.

Refit

7.Clean heater plug and seating.

8.Coat threads of heater plug with suitable

anti-seize compound operational to a

temperature of 1000°C.

9.Fit heater plug, tighten to

23 Nm (17 lbf/ft).

10.Connect wire to heater plug terminal and secure

with nut.

NOTE: Feed wire must be connected to

No. 4 heater plug terminal.

No. 3 heater plug:

11.Lubricate new 'O' ring with engine oil and fit to

breather valve.

12.Fit valve to rocker cover, tighten to bolt to

15 Nm

(11 lbf/ft).

No. 1 heater plug - air conditioning models

13.Position compressor to front cover, fit bolts and

tighten to

25 Nm (18 lbf/ft).

14.Fit drive belt to compressor pulley and adjust

tension.

See AIR CONDITIONING, Repair,

Compressor drive belt

All models:

15.Reconnect battery.

Page 114 of 455

19FUEL SYSTEM

12

REPAIR HEATER PLUG CONTROL UNIT

Service repair no - 19.60.33

Remove

1.Disconnect battery.

2.Remove screw securing control unit to bulkhead.

3.Disconnect multi-plug and release control unit.

Refit

4.Fit harness multi-plug to control unit.

5.Secure control unit to bulkhead.

6.Reconnect battery.AIR CLEANER

Service repair no - 19.10.01

Remove

1.Slacken hose clip and detach outlet hose.

2.Release clips and open air cleaner retaining

straps.

3.Lift up air cleaner, slacken hose clip and detach

inlet hose.

4.Remove air cleaner.

Refit

5.Position air cleaner and connect inlet hose.

6.Close air cleaner retaining straps and secure

lock clips.

7.Connect outlet hose.

NOTE: If an EGR fuel system is fitted,

ensure the modulator valve vacuum spill

pipe is secure in the outlet hose.

AIR CLEANER ELEMENT

Service repair no - 19.10.10

For remove and refit procedure.

See SECTION 10,

Maintenance, Under bonnet maintenance

Page 115 of 455

FUEL SYSTEM

13

REPAIR THROTTLE CABLE

Service repair no - 19.20.06

Remove

1.Disconnect battery.

2.Remove split pin and clevis pin securing throttle

cable to injector pump throttle lever .

3.Depress ferrule retaining tags, release ferrule

from abutment bracket and withdraw throttle

cable.

4.Release throttle cable from clip on bulkhead.

5.Remove pin and clevis pin securing throttle

cable to pedal lever.

6.Release grommet from bulkhead.

7.Withdraw throttle cable from engine

compartment.Refit

8.Feed throttle cable through bulkhead from

engine compartment and fit grommet.

9.Secure throttle cable to pedal lever. Use new

split pin to secure clevis.

10.Secure throttle cable in bulkhead clip.

11.Guide throttle cable through abutment bracket

and fit ferrule.

12.Secure cable to injection pump throttle lever.

Use new split pin to secure clevis.

13.Adjust throttle cable.

See Adjustment,

Throttle cable

THROTTLE PEDAL

Service repair no - 19.20.01

Remove

1.Remove throttle cable from pedal.

See Throttle

cable

2.Remove 6 bolts securing throttle pedal assembly

to engine bulkhead.

3.Remove pedal assembly from footwell, complete

with trim retainer.

4.Release return spring from pedal lever.

5.Remove roll pin securing pivot shaft to pedal

assembly.

6.Withdraw pivot shaft and remove pedal from

mounting bracket.

7.Remove return spring from pedal boss.

Refit

8.Fit return spring to pedal boss.

9.Fit pedal to mounting bracket and locate return

spring.

10.Fit pivot shaft to pedal assembly and secure with

roll pin.

11.Locate return spring on pedal lever.

12.Secure throttle pedal assembly and trim retainer

to bulkhead. Tighten bolts to

9 Nm (7 lbf/ft).

13.Fit throttle cable to pedal.See Throttle cable

14.Adjust pedal, if necessary.See Adjustment,

Throttle pedal adjustment

Page 116 of 455

19FUEL SYSTEM

14

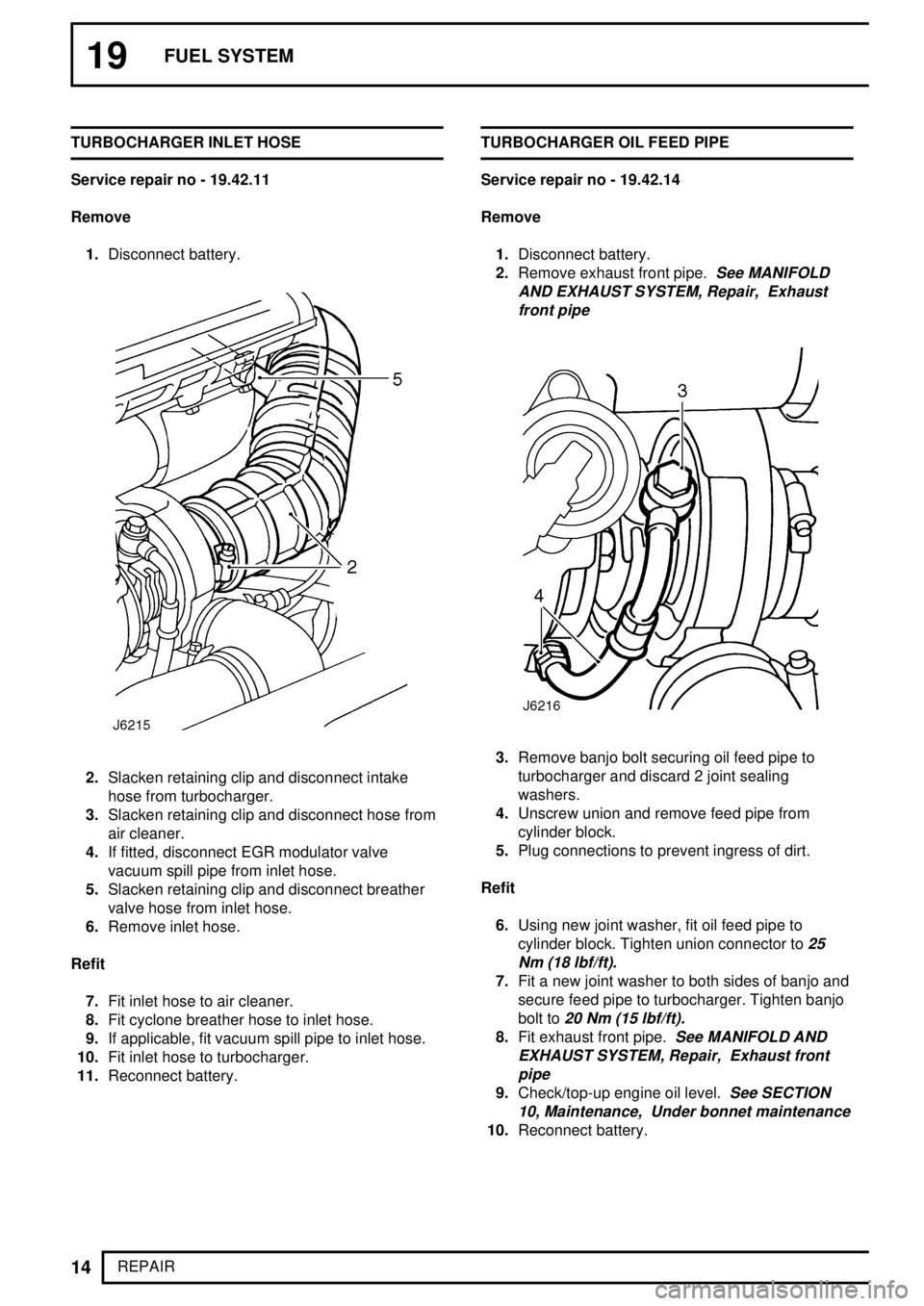

REPAIR TURBOCHARGER INLET HOSE

Service repair no - 19.42.11

Remove

1.Disconnect battery.

2.Slacken retaining clip and disconnect intake

hose from turbocharger.

3.Slacken retaining clip and disconnect hose from

air cleaner.

4.If fitted, disconnect EGR modulator valve

vacuum spill pipe from inlet hose.

5.Slacken retaining clip and disconnect breather

valve hose from inlet hose.

6.Remove inlet hose.

Refit

7.Fit inlet hose to air cleaner.

8.Fit cyclone breather hose to inlet hose.

9.If applicable, fit vacuum spill pipe to inlet hose.

10.Fit inlet hose to turbocharger.

11.Reconnect battery.TURBOCHARGER OIL FEED PIPE

Service repair no - 19.42.14

Remove

1.Disconnect battery.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

front pipe

3.Remove banjo bolt securing oil feed pipe to

turbocharger and discard 2 joint sealing

washers.

4.Unscrew union and remove feed pipe from

cylinder block.

5.Plug connections to prevent ingress of dirt.

Refit

6.Using new joint washer, fit oil feed pipe to

cylinder block. Tighten union connector to

25

Nm (18 lbf/ft).

7.Fit a new joint washer to both sides of banjo and

secure feed pipe to turbocharger. Tighten banjo

bolt to

20 Nm (15 lbf/ft).

8.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust front

pipe

9.Check/top-up engine oil level.See SECTION

10, Maintenance, Under bonnet maintenance

10.Reconnect battery.

Page 117 of 455

FUEL SYSTEM

15

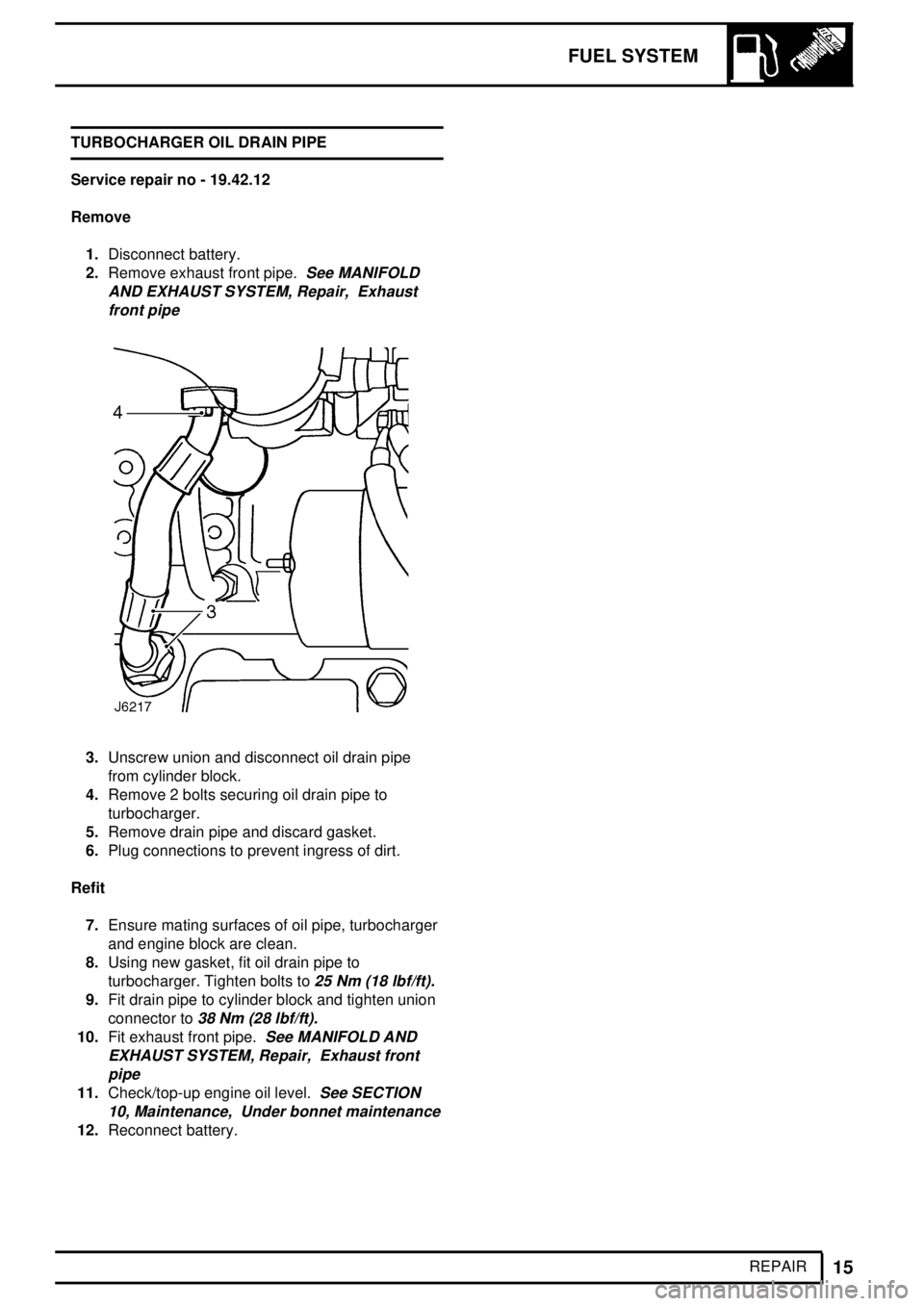

REPAIR TURBOCHARGER OIL DRAIN PIPE

Service repair no - 19.42.12

Remove

1.Disconnect battery.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

front pipe

3.Unscrew union and disconnect oil drain pipe

from cylinder block.

4.Remove 2 bolts securing oil drain pipe to

turbocharger.

5.Remove drain pipe and discard gasket.

6.Plug connections to prevent ingress of dirt.

Refit

7.Ensure mating surfaces of oil pipe, turbocharger

and engine block are clean.

8.Using new gasket, fit oil drain pipe to

turbocharger. Tighten bolts to

25 Nm (18 lbf/ft).

9.Fit drain pipe to cylinder block and tighten union

connector to

38 Nm (28 lbf/ft).

10.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust front

pipe

11.Check/top-up engine oil level.See SECTION

10, Maintenance, Under bonnet maintenance

12.Reconnect battery.

Page 118 of 455

19FUEL SYSTEM

16

REPAIR INTERCOOLER

Service repair no - 19.42.15

Remove

1.Disconnect battery.

2.Remove 2 nuts securing fan cowl to radiator top

cover.

3.Remove 4 bolts securing radiator top cover to

side covers.

4.Remove 2 bolts from both sides, securing

radiator top cover mounting brackets to bonnet

platform.

5.Detach radiator top cover, complete with

mounting brackets.

6.Slacken retaining clip and disconnect top hose

from intercooler.

7.Slacken 2 clips and disconnect bottom hose

from intercooler.

8.Manoeuvre intercooler upwards and remove

from vehicle.

9.Check condition of foam pads fitted to top and

bottom of intercooler and renew if necessary.

10.Check condition of intercooler locating grommets

in radiator top cover and renew if necessary.

Refit

11.Manoeuvre intercooler into position at LH side of

radiator.

12.Carefully lower intercooler and locate bottom

lugs into radiator bottom support frame.

13.Fit bottom and top hoses to intercooler.

14.Fit radiator top cover and secure mounting

brackets to bonnet platform.

15.Secure radiator top cover to side covers.

16.Fit fan cowl to top cover.

17.Reconnect battery.

Page 119 of 455

FUEL SYSTEM

17

REPAIR EGR VALVE

Service repair no - 17.45.01

Remove

1.Disconnect multi-plug from EGR valve.

2.Disconnect vacuum pipe from EGR valve.

3.Remove 2 Allen screws securing EGR valve to

exhaust manifold.

4.Remove 2 bolts securing air inlet delivery tube to

EGR valve.

5.Remove EGR valve and discard gaskets.

Refit

6.Clean mating faces of EGR valve and exhaust

manifold.

7.Position new gaskets and fit EGR valve to

delivery tube and exhaust manifold. Tighten

bolts to

25 Nm (18 lbf/ft).

8.Fit vacuum pipe and multi-plug to EGR valve.EGR VALVE MODULATOR

Service repair no - 17.45.04

Remove

1.Disconnect multi-plug from modulator.

2.Disconnect spill pipe (green), modulator to air

cleaner hose.

3.Disconnect vacuum pipe (blue), modulator to

EGR valve.

4.Disconnect vacuum pipe (white), modulator to

brake servo pipe.

5.Unscrew 2 nuts securing modulator to flexible

mountings.

6.Remove modulator.

Refit

7.Fit modulator to flexible mountings and tighten

nuts to

8 Nm (6 lbf/ft).

8.Fit modulator pipes, ensuring they are connected

to correct ports.

9.Connect modulator multi-plug.

Page 120 of 455

19FUEL SYSTEM

18

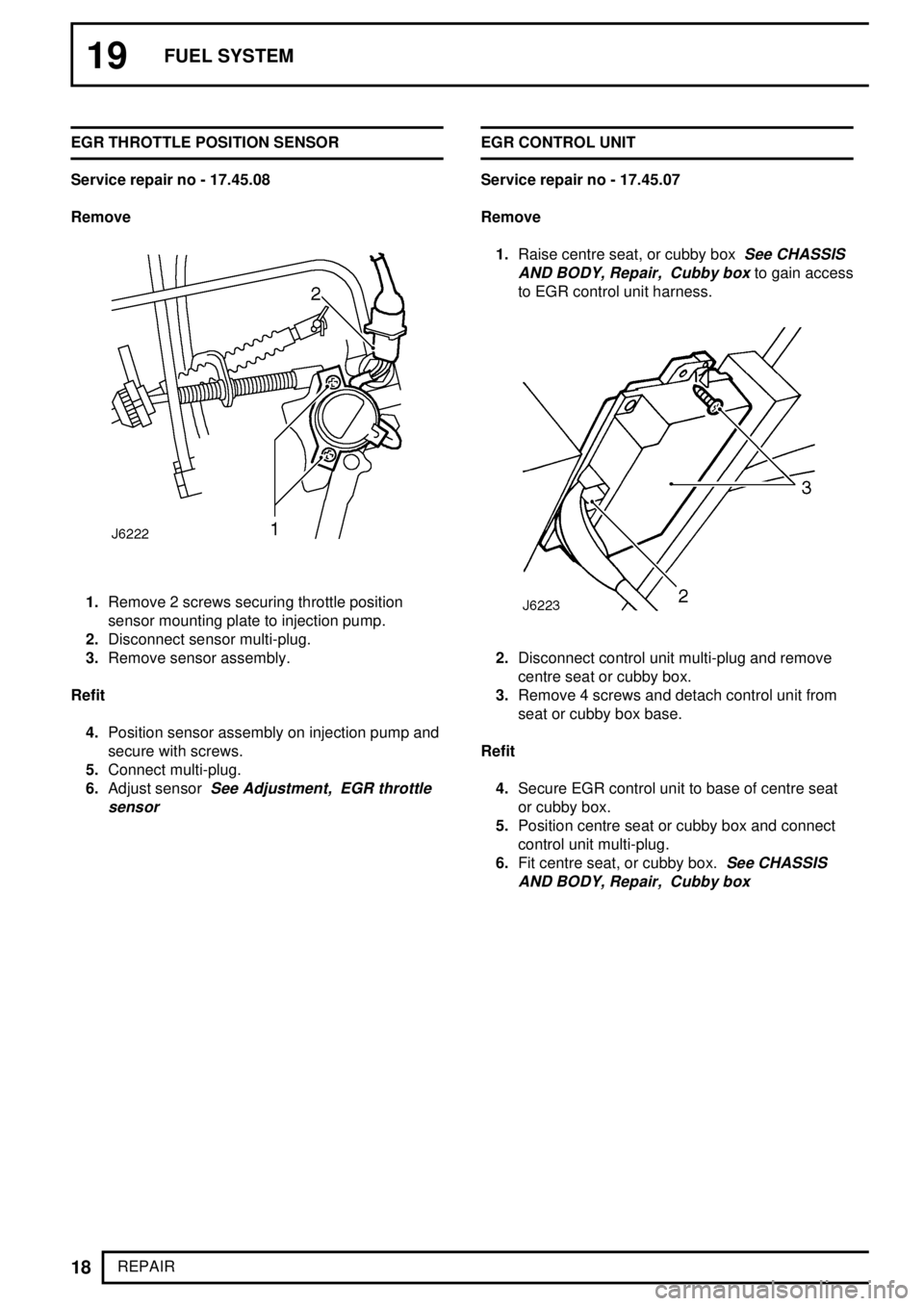

REPAIR EGR THROTTLE POSITION SENSOR

Service repair no - 17.45.08

Remove

1.Remove 2 screws securing throttle position

sensor mounting plate to injection pump.

2.Disconnect sensor multi-plug.

3.Remove sensor assembly.

Refit

4.Position sensor assembly on injection pump and

secure with screws.

5.Connect multi-plug.

6.Adjust sensor

See Adjustment, EGR throttle

sensor

EGR CONTROL UNIT

Service repair no - 17.45.07

Remove

1.Raise centre seat, or cubby box

See CHASSIS

AND BODY, Repair, Cubby box

to gain access

to EGR control unit harness.

2.Disconnect control unit multi-plug and remove

centre seat or cubby box.

3.Remove 4 screws and detach control unit from

seat or cubby box base.

Refit

4.Secure EGR control unit to base of centre seat

or cubby box.

5.Position centre seat or cubby box and connect

control unit multi-plug.

6.Fit centre seat, or cubby box.

See CHASSIS

AND BODY, Repair, Cubby box