LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 151 of 455

CLUTCH

3

OVERHAUL Assemble

10.Fit bleed valve to cylinder body, do not

overtighten.

11.Lubricate seals, piston and bore with new

hydraulic fluid.

12.Fit seal into piston groove with lip of seal

towards fluid inlet end of cylinder.

13.Locate spring over front end of piston.

14.Fit assembly, spring first, into cylinder ensuring

seal lip does not fold back.

15.Fill dust cover with suitable rubber grease and fit

cover to cylinder.

16.Fit slave cylinder

See Repair, Slave cylinder.

Page 152 of 455

MANUAL GEARBOX

1

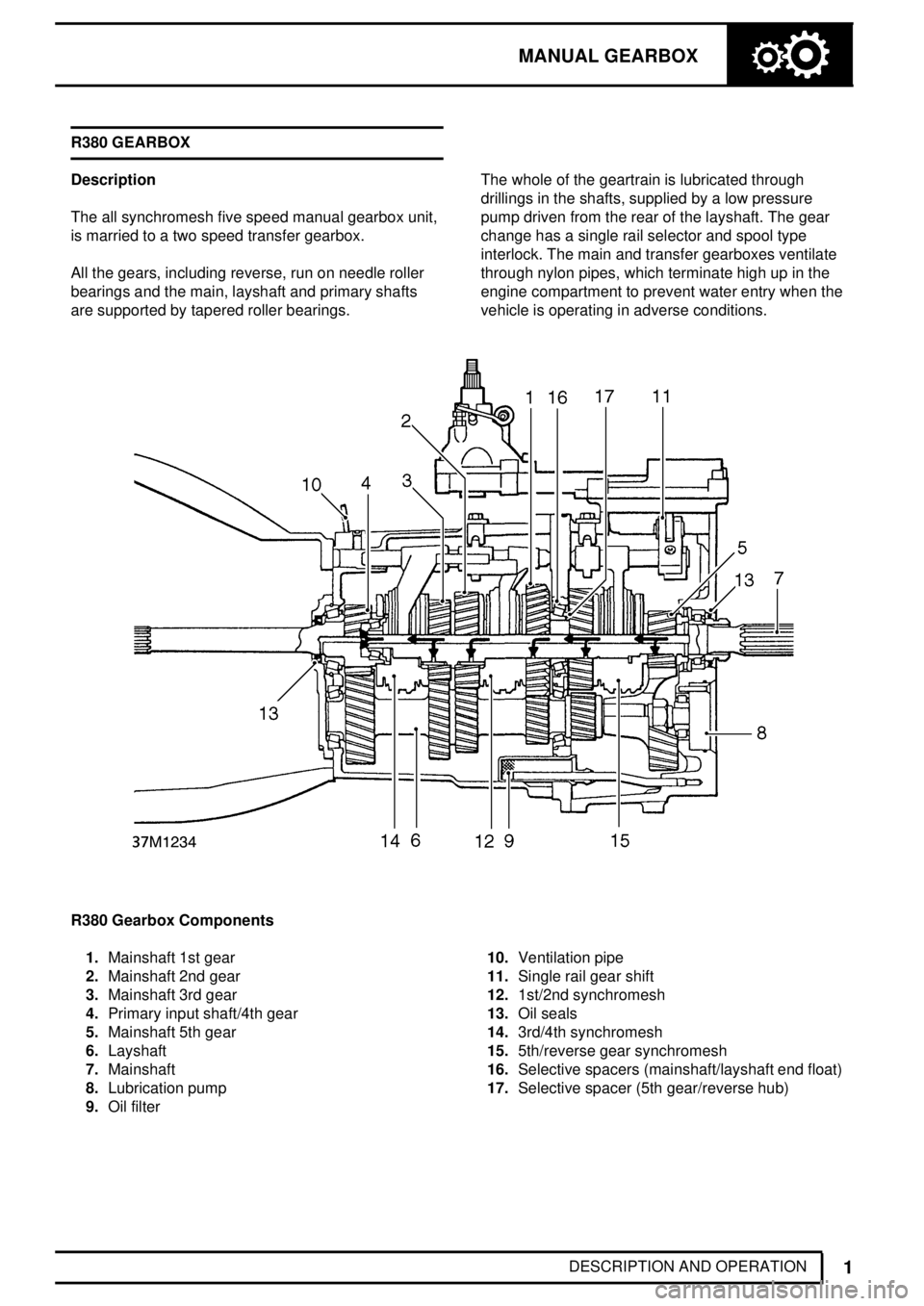

DESCRIPTION AND OPERATION R380 GEARBOX

Description

The all synchromesh five speed manual gearbox unit,

is married to a two speed transfer gearbox.

All the gears, including reverse, run on needle roller

bearings and the main, layshaft and primary shafts

are supported by tapered roller bearings.The whole of the geartrain is lubricated through

drillings in the shafts, supplied by a low pressure

pump driven from the rear of the layshaft. The gear

change has a single rail selector and spool type

interlock. The main and transfer gearboxes ventilate

through nylon pipes, which terminate high up in the

engine compartment to prevent water entry when the

vehicle is operating in adverse conditions.

R380 Gearbox Components

1.Mainshaft 1st gear

2.Mainshaft 2nd gear

3.Mainshaft 3rd gear

4.Primary input shaft/4th gear

5.Mainshaft 5th gear

6.Layshaft

7.Mainshaft

8.Lubrication pump

9.Oil filter10.Ventilation pipe

11.Single rail gear shift

12.1st/2nd synchromesh

13.Oil seals

14.3rd/4th synchromesh

15.5th/reverse gear synchromesh

16.Selective spacers (mainshaft/layshaft end float)

17.Selective spacer (5th gear/reverse hub)

Page 153 of 455

MANUAL GEARBOX

1

FAULT DIAGNOSIS R380 GEARBOX

Symptom - Gear jumps out of engagement (any

forward gear)

1.Check condition and security of transmission

and engine mountings.

2.Check in situ, gear lever and selector

adjustments

See Adjustment, Gear change

lever bias spring - adjust

andSee

Adjustment, Fifth gear stop screw adjust

.

3.In situ, remove gearshift and check selector rail

yoke security.

Also check selector detent spring tension and

both spool retainers.

Suspect internal fault, see Overhaul Manual.

4.Check action/operation of main selector rail and

forks.

5.Check condition of synchromesh and gear dog

teeth.

6.Check main and layshaft end floats bearings and

adjustments.

7.Check condition of all gearbox components,

ensure clearances and adjustments are correct

on reassembly.

Symptom - Reverse gear only jumps out of

engagment

1.Check condition and security of transmission

and engine mountings.

2.Check in situ, gear lever and selector

adjustments

See Adjustment, Gear change

lever bias spring adjust

andSee Adjustment,

Fifth gear stop screw adjust

.

3.In situ, remove gearshift and check selector rail

yoke security.

Also check selector detent spring tension and

both spool retainers.

Suspect internal fault, see Overhaul Manual.

4.Check action/operation of main selector rail and

reverse lever.

5.Check condition of reverse gear, angled

bearings and shaft.

6.Check condition of all gearbox components,

ensure clearances and adjustments are correct

on reassembly.Symptom - Excessive force required to engage or

change gear, vehicle stationary or moving.

1.Check lubricant specification and level, if low do

not top up at this stage.

2.In situ, lubricate gear mechanism, and check

selector adjustments

See Adjustment, Gear

change lever bias spring - adjust

andSee

Adjustment, Fifth gear stop screw adjust

.

3.In situ, remove gearshift and check selector rail

is free and that the yoke is secure. Also check

selector detent spring tension and both spool

retainers.

4.Drain lubricant and check for contamination or

metal particles.

Suspect worn synchromesh unit or baulk rings

on affected gears, see Overhaul Manual.

Symptom - Noisy gear engagement, vehicle

stationary

See CLUTCH, Fault diagnosis, Clutch

Noise - Mechanical Faults

.

Symptom - Noisy gear selection, vehicle moving.

1.Confirm that clutch operation is satisfactory.

2.Establish which gear/gears is causing noise.

3.Check lubricant specification and level, if low do

not top up at this stage.

4.Drain lubricant and check for contamination or

metal particles.

Suspect worn synchromesh, see Overhaul

Manual.

5.Check condition of synchromesh unit, springs

and cones for distortion and wear. Also check

dog teeth for damage and cone mating surface

on gear for signs of overheating.

6.Check condition of all gearbox components,

ensure clearances and adjustments are correct

on reassembly.

Symptom - Noise from gearbox in neutral, which

changes tone or becomes worse when clutch is

depressed,

See CLUTCH, Fault diagnosis, Clutch

Noise - Mechanical Faults

.

Symptom - Noise from gearbox in neutral, which

disappears when clutch is depressed.

1.Check lubricant specification and level, if low do

not top up at this stage.

2.Drain lubricant and check for contamination or

metal particles.

Suspect worn bearings on layshaft, primary shaft

or front of main shaft, see Overhaul Manual.

Page 154 of 455

37MANUAL GEARBOX

2

FAULT DIAGNOSIS Symptom - Noise from gearbox in one or more

gears when being driven.

1.Check lubricant specification and level, if low do

not top up at this stage.

2.Drain lubricant and check for contamination or

metal particles.

Suspect worn roller bearings on particular

mainshaft gears, see Overhaul Manual.

Page 155 of 455

MANUAL GEARBOX

1

ADJUSTMENT GEAR CHANGE LEVER BIAS SPRING - ADJUST

Service repair no - 37.16.26

1.Remove gear lever and transfer box lever knobs.

2.Remove gear lever cover.

3.Remove nut and washer securing gear lever.

4.Mark gear lever spline setting, remove lever and

gaiter from lower lever.

5.Remove insulation pad from tunnel aperture.

6.Fit gear lever and select 3rd or 4th gear.

7.Slacken adjustment screw locknuts.

8.Adjust screws until both legs of bias springs are

approximately 0.5mm clear of gear lever cross

pin.

9.Apply a slight load to gear lever in a LH direction

and adjust RH screw downward until RH spring

leg just makes contact with cross pin.

10.Repeat procedure for LH adjustment screw.

11.Lower both adjustment screws equal amounts

until radial play is eliminated.

12.Tighten locknuts.

13.Return gear lever to neutral position and rock

across gate several times. The gear lever should

return to 3rd and 4th gate.

14.Remove gear lever.

15.Fit insulation pad.

16.Locate gaiter over lower lever and bias springs.

17.Fit gear lever to lower lever spline, secure with

new nyloc nut and tighten to

25 Nm (18 lbf/ft).

18.Fit gear lever cover.

19.Fit gear lever and transfer box lever knobs.

Page 156 of 455

37MANUAL GEARBOX

2

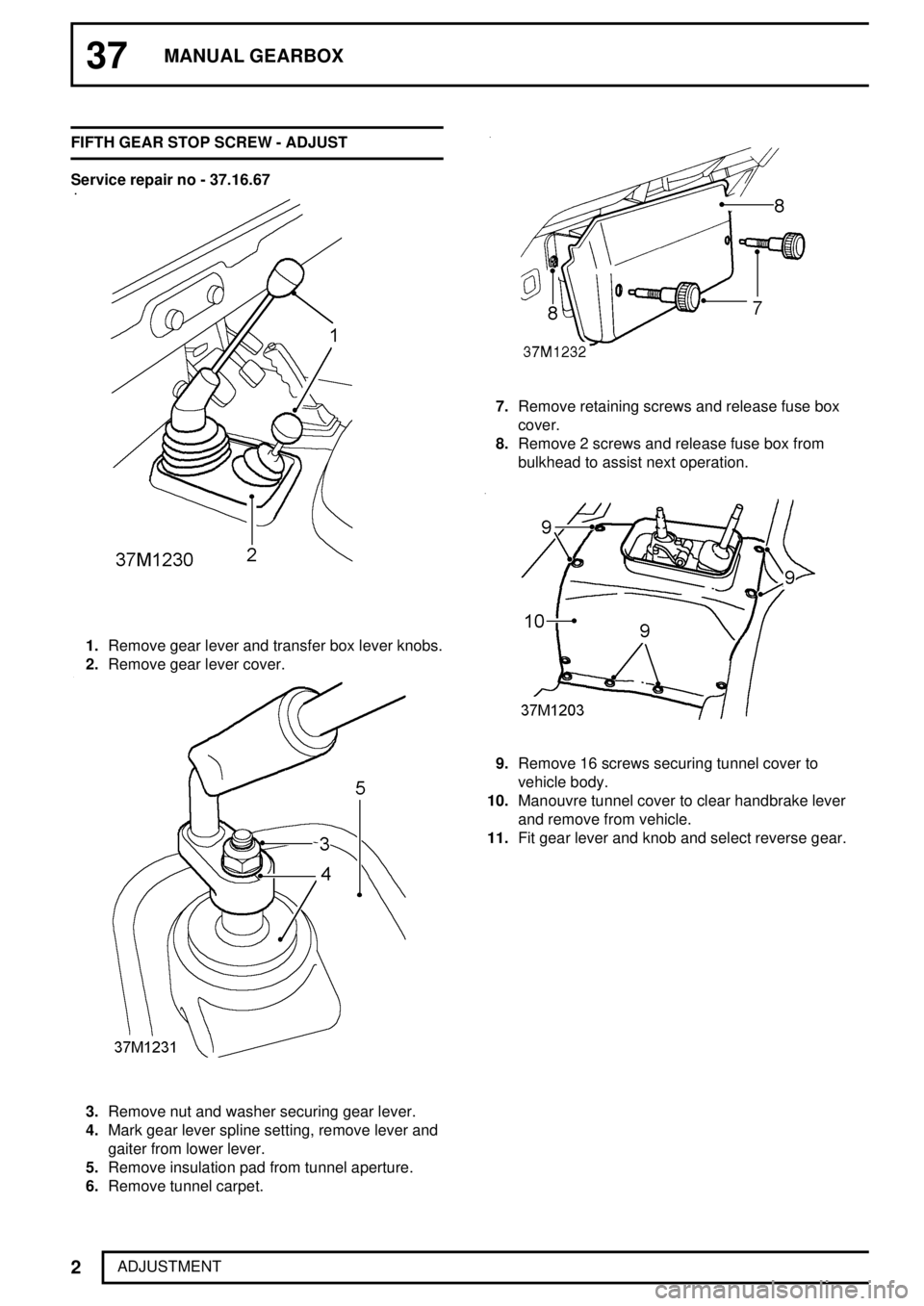

ADJUSTMENT FIFTH GEAR STOP SCREW - ADJUST

Service repair no - 37.16.67

1.Remove gear lever and transfer box lever knobs.

2.Remove gear lever cover.

3.Remove nut and washer securing gear lever.

4.Mark gear lever spline setting, remove lever and

gaiter from lower lever.

5.Remove insulation pad from tunnel aperture.

6.Remove tunnel carpet.

7.Remove retaining screws and release fuse box

cover.

8.Remove 2 screws and release fuse box from

bulkhead to assist next operation.

9.Remove 16 screws securing tunnel cover to

vehicle body.

10.Manouvre tunnel cover to clear handbrake lever

and remove from vehicle.

11.Fit gear lever and knob and select reverse gear.

Page 157 of 455

MANUAL GEARBOX

3

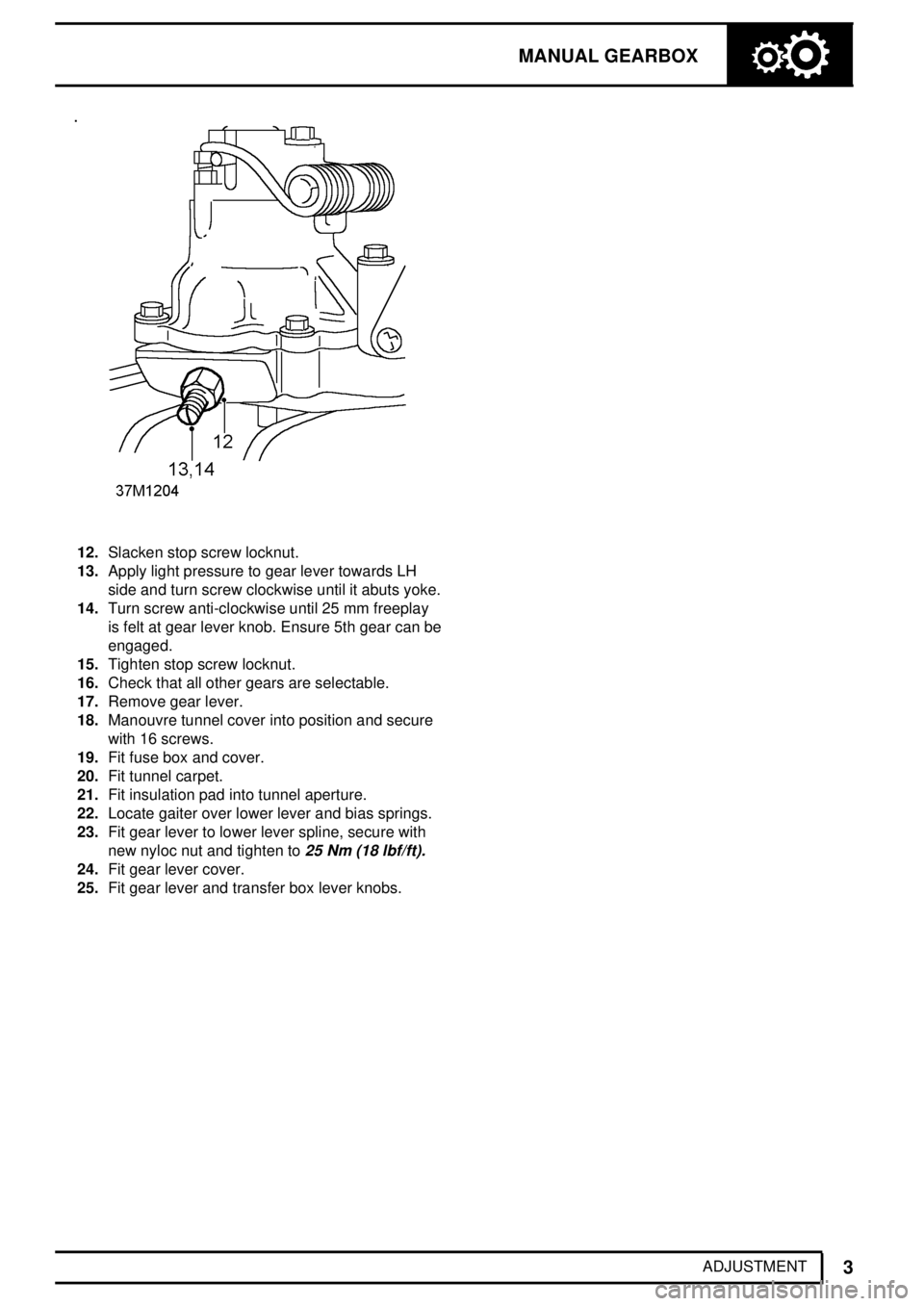

ADJUSTMENT

12.Slacken stop screw locknut.

13.Apply light pressure to gear lever towards LH

side and turn screw clockwise until it abuts yoke.

14.Turn screw anti-clockwise until 25 mm freeplay

is felt at gear lever knob. Ensure 5th gear can be

engaged.

15.Tighten stop screw locknut.

16.Check that all other gears are selectable.

17.Remove gear lever.

18.Manouvre tunnel cover into position and secure

with 16 screws.

19.Fit fuse box and cover.

20.Fit tunnel carpet.

21.Fit insulation pad into tunnel aperture.

22.Locate gaiter over lower lever and bias springs.

23.Fit gear lever to lower lever spline, secure with

new nyloc nut and tighten to

25 Nm (18 lbf/ft).

24.Fit gear lever cover.

25.Fit gear lever and transfer box lever knobs.

Page 158 of 455

MANUAL GEARBOX

1

REPAIR REV: 05/99 R380 GEARBOX

Service repair no - 37.20.51

Remove

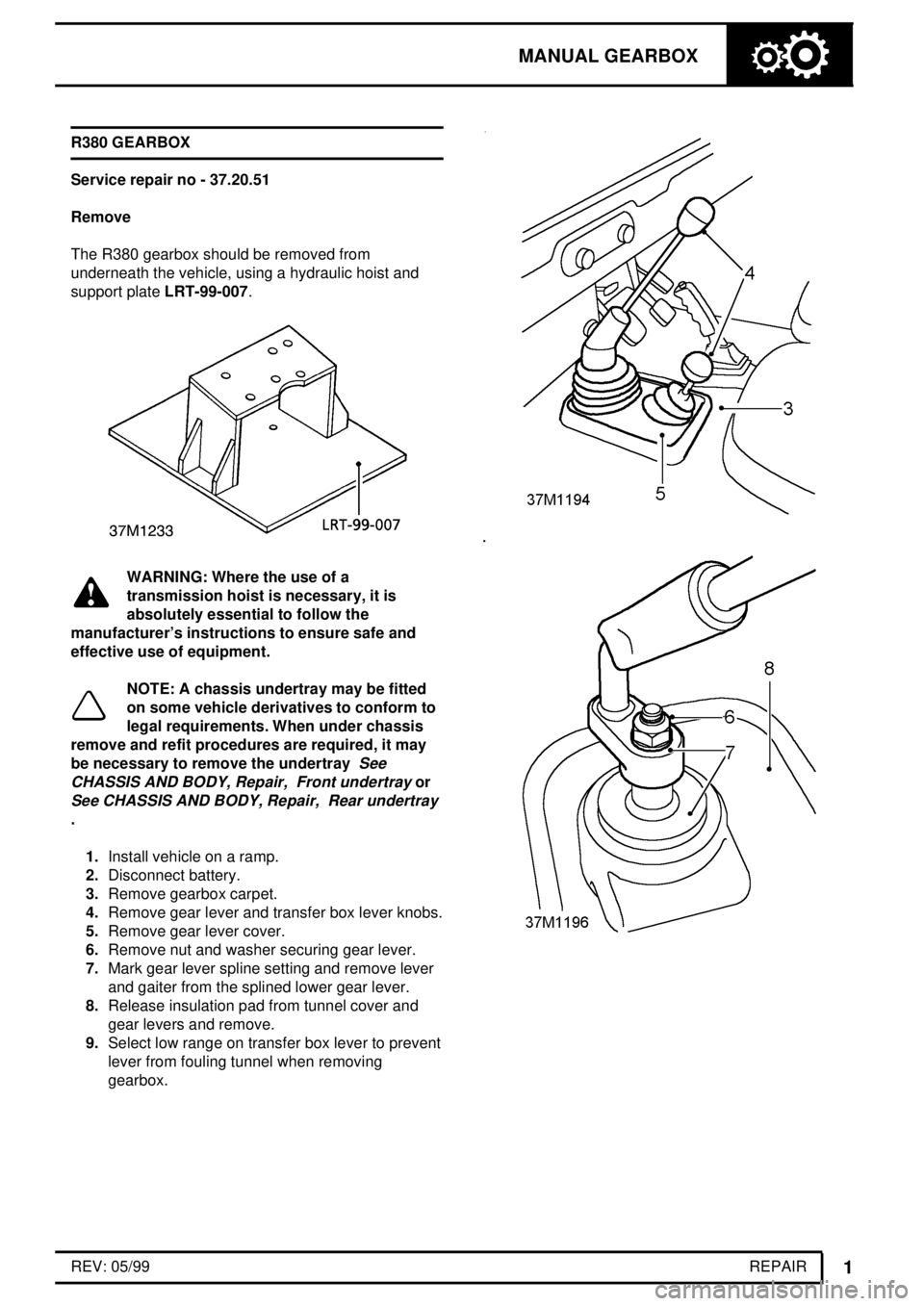

The R380 gearbox should be removed from

underneath the vehicle, using a hydraulic hoist and

support plateLRT-99-007.

WARNING: Where the use of a

transmission hoist is necessary, it is

absolutely essential to follow the

manufacturer's instructions to ensure safe and

effective use of equipment.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

or

See CHASSIS AND BODY, Repair, Rear undertray

.

1.Install vehicle on a ramp.

2.Disconnect battery.

3.Remove gearbox carpet.

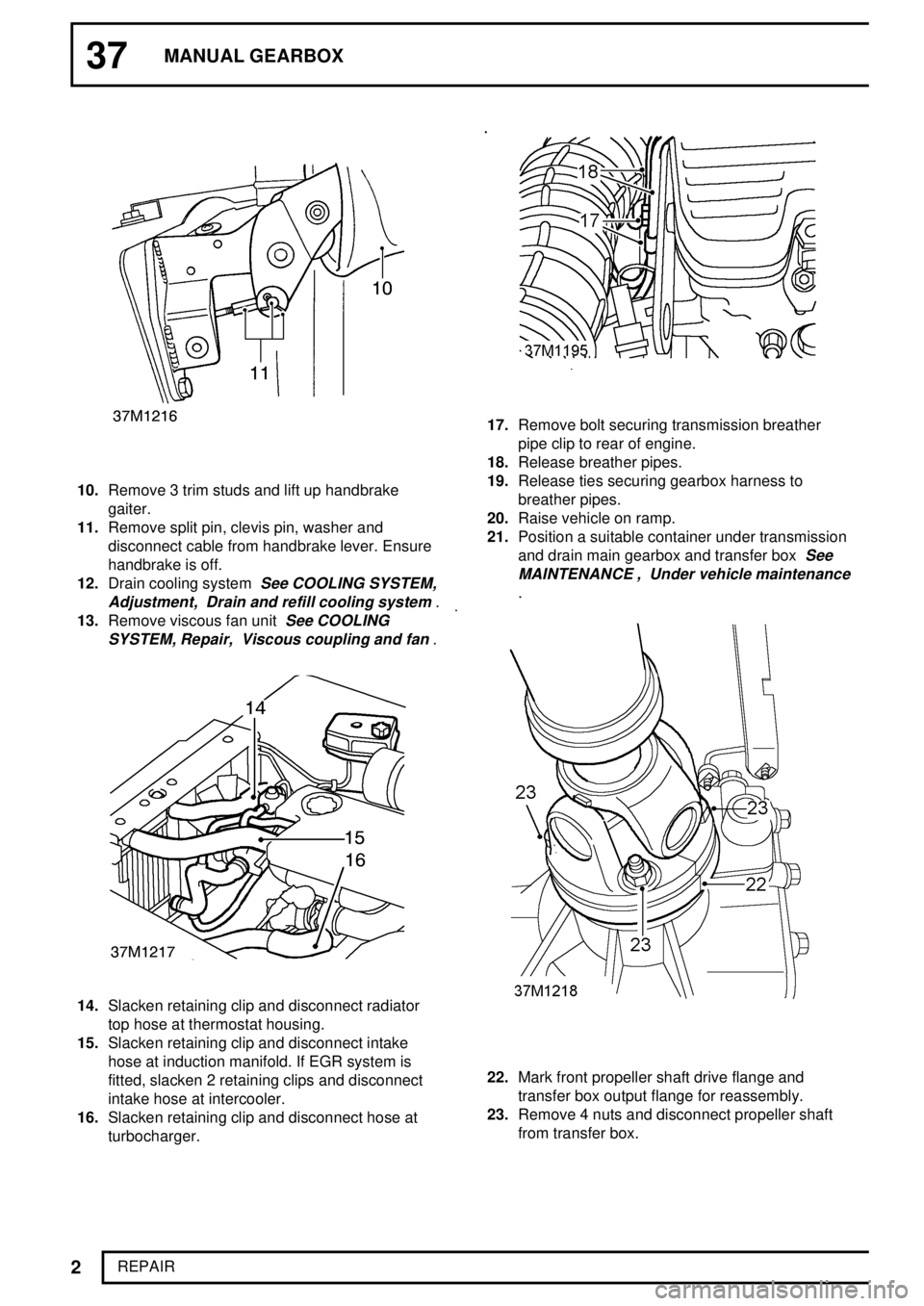

4.Remove gear lever and transfer box lever knobs.

5.Remove gear lever cover.

6.Remove nut and washer securing gear lever.

7.Mark gear lever spline setting and remove lever

and gaiter from the splined lower gear lever.

8.Release insulation pad from tunnel cover and

gear levers and remove.

9.Select low range on transfer box lever to prevent

lever from fouling tunnel when removing

gearbox.

Page 159 of 455

37MANUAL GEARBOX

2

REPAIR

10.Remove 3 trim studs and lift up handbrake

gaiter.

11.Remove split pin, clevis pin, washer and

disconnect cable from handbrake lever. Ensure

handbrake is off.

12.Drain cooling system

See COOLING SYSTEM,

Adjustment, Drain and refill cooling system

.

13.Remove viscous fan unit

See COOLING

SYSTEM, Repair, Viscous coupling and fan

.

14.Slacken retaining clip and disconnect radiator

top hose at thermostat housing.

15.Slacken retaining clip and disconnect intake

hose at induction manifold. If EGR system is

fitted, slacken 2 retaining clips and disconnect

intake hose at intercooler.

16.Slacken retaining clip and disconnect hose at

turbocharger.

17.Remove bolt securing transmission breather

pipe clip to rear of engine.

18.Release breather pipes.

19.Release ties securing gearbox harness to

breather pipes.

20.Raise vehicle on ramp.

21.Position a suitable container under transmission

and drain main gearbox and transfer box

See

MAINTENANCE , Under vehicle maintenance

.

22.Mark front propeller shaft drive flange and

transfer box output flange for reassembly.

23.Remove 4 nuts and disconnect propeller shaft

from transfer box.

Page 160 of 455

MANUAL GEARBOX

3

REPAIR

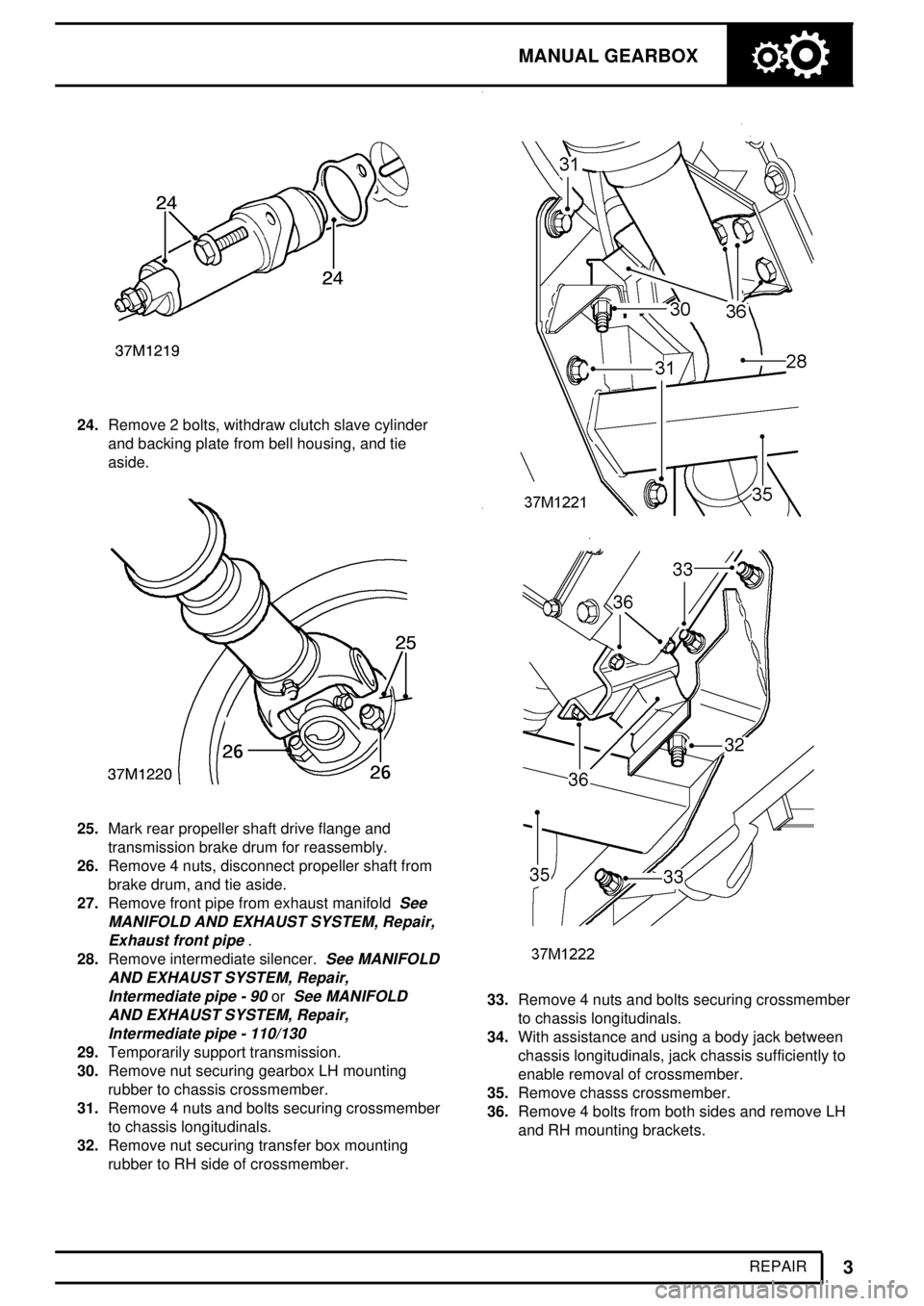

24.Remove 2 bolts, withdraw clutch slave cylinder

and backing plate from bell housing, and tie

aside.

25.Mark rear propeller shaft drive flange and

transmission brake drum for reassembly.

26.Remove 4 nuts, disconnect propeller shaft from

brake drum, and tie aside.

27.Remove front pipe from exhaust manifold

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust front pipe

.

28.Remove intermediate silencer.

See MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 90

orSee MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 110/130

29.Temporarily support transmission.

30.Remove nut securing gearbox LH mounting

rubber to chassis crossmember.

31.Remove 4 nuts and bolts securing crossmember

to chassis longitudinals.

32.Remove nut securing transfer box mounting

rubber to RH side of crossmember.

33.Remove 4 nuts and bolts securing crossmember

to chassis longitudinals.

34.With assistance and using a body jack between

chassis longitudinals, jack chassis sufficiently to

enable removal of crossmember.

35.Remove chasss crossmember.

36.Remove 4 bolts from both sides and remove LH

and RH mounting brackets.