LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 131 of 455

26COOLING SYSTEM

6

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Disconnect radiator bottom hose and drain

cooling system.

See Adjustment, Drain and

refill cooling system

2.Disconnect radiator top hose.

3.Remove viscous fan unit.

See Viscous

coupling and fan

4.Remove fan cowl.See Fan cowl

5.Disconnect oil cooler pipes. Plug all connections

to prevent oil spillage and ingress of dirt.

6.Disconnect top and bottom intercooler hoses.

7.Disconnect bleed hose at radiator.

8.Remove 2 bolts from both sides securing

radiator mounting brackets to bonnet platform.

9.Lift and remove radiator/intercooler assembly

from vehicle.

10.Remove 2 bolts from both sides and detach

radiator top cover from side covers.

11.Lift and remove radiator from intercooler and RH

side frame.

12.Check condition of locating grommets in radiator

top cover and lower mounting bushes. Renew if

necessary.Refit

13.Position radiator between intercooler and RH

side frame.

14.Fit radiator top cover to side covers.

15.Lower radiator/intercooler assembly into

position.

16.Secure radiator mounting brackets to bonnet

platform.

17.Fit radiator bleed hose.

18.Fit top and bottom intercooler hoses.

19.Fit oil cooler pipes.

20.Fit fan cowl

See Fan cowl.

21.Fit viscous fan unit.

See Viscous coupling

and fan

22.Fit radiator top hose.

23.Fit radiator bottom hose and refill cooling

system.

See Adjustment, Drain and refill

cooling system

Page 132 of 455

COOLING SYSTEM

7

REPAIR EXPANSION TANK

Service repair no - 26.15.01

Remove

1.Position container to collect coolant spillage.

2.Slacken retaining clips and disconnect both

hoses from base of expansion tank.

3.Remove 3 bolts securing expansion tank to

inside wing and mounting bracket.

4.Remove expansion tank.

Refit

5.Fit expansion tank to inside wing and mounting

bracket.

6.Fit both hoses to base of tank.

7.Check and top up cooling system

See

SECTION 10, Maintenance, Under bonnet

maintenance

Page 133 of 455

MANIFOLD AND EXHAUST SYSTEM

1

DESCRIPTION AND OPERATION MANIFOLDS AND EXHAUST SYSTEM

Description

The exhaust systems fitted on all models with the

300Tdi engine comprise three sections; front pipe

assembly, intermediate silencer assembly, and tail

pipe and silencer assembly. All sections, including

silencers, are manufactured from luminised steel to

give the system a durable working life under all

conditions. Special clamps are provided to ensureleak proof jointing between the various sections,

which are supported by flexible rubber mountings.

Catalytic convertor

When fitted, the catalytic converter is integral with the

front pipe assembly, which also incorporates a flexible

joint. The catalyst forms part of the engine emission

control that can also include an EGR valve system

See FUEL SYSTEM, Repair, EGR valve

Exhaust system - 90

1.Gasket

2.Front pipe

3.Front pipe with catalytic converter

4.Front mounting bracket

5.Intermediate silencer6.Intermediate mounting brackets

7.Tail pipe silencer*

8.Tail pipe silencer mounting

9.Tail pipe mounting

* Deleted on later models

Page 134 of 455

30MANIFOLD AND EXHAUST SYSTEM

2

DESCRIPTION AND OPERATION The catalyst comprises platinum coated ceramic

elements. The Hydrocarbons (HC), Oxides of nitrogen

(NOx) and Carbon monoxide (CO) emitted by the

engine react with the catalytic element and exhaust

temperature to convert the toxic gas into Nitrogen

(N

2), Carbon dioxide (CO2) and water vapour.

Exhaust system - 110/130

1.Gasket

2.Front pipe

3.Front pipe with catalytic converter

4.Front mounting bracket

5.Intermediate silencer6.Intermediate mounting brackets

7.Tail pipe silencer

8.Tail pipe silencer mounting

9.Tail pipe mounting

Page 135 of 455

MANIFOLD AND EXHAUST SYSTEM

1

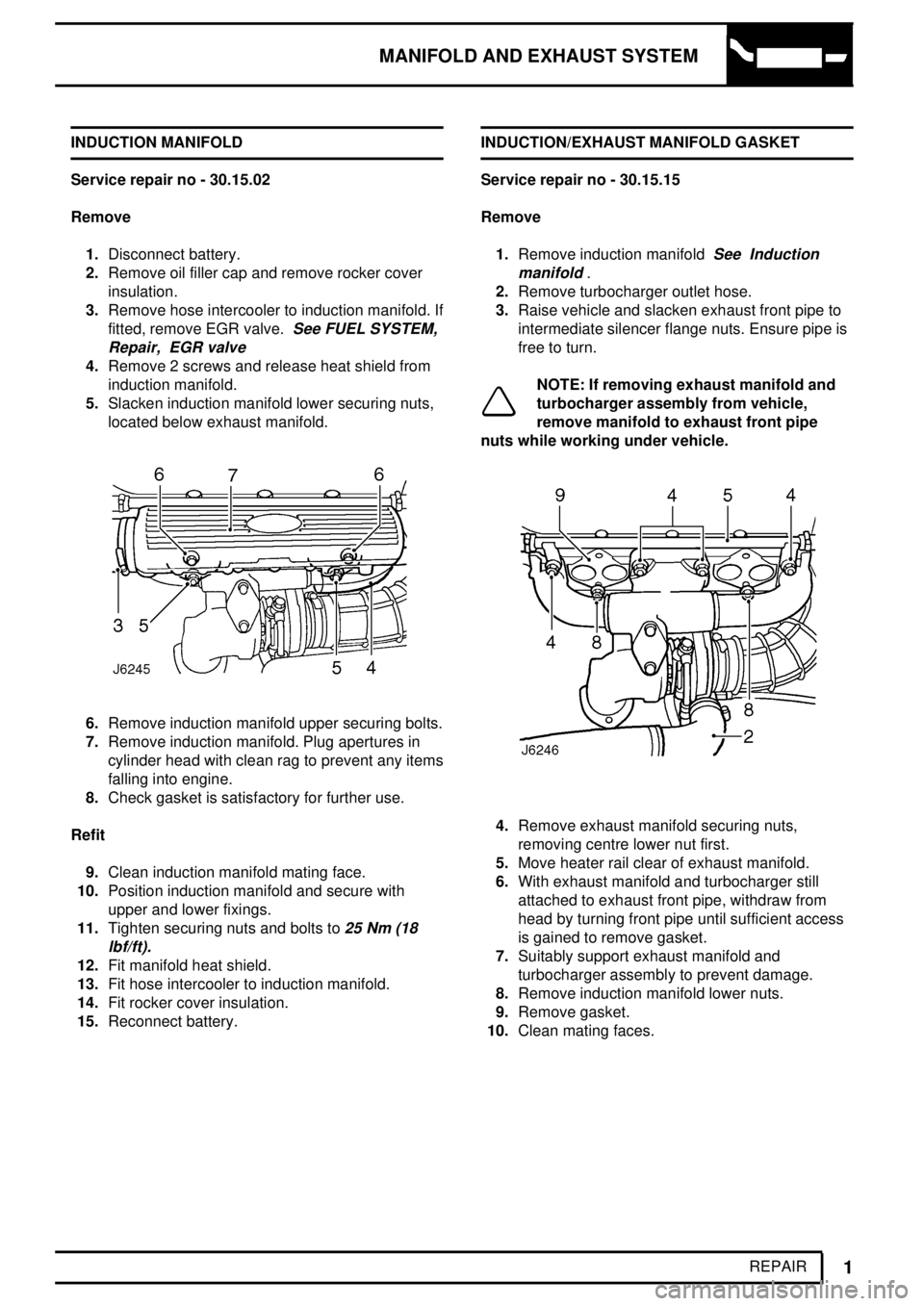

REPAIR INDUCTION MANIFOLD

Service repair no - 30.15.02

Remove

1.Disconnect battery.

2.Remove oil filler cap and remove rocker cover

insulation.

3.Remove hose intercooler to induction manifold. If

fitted, remove EGR valve.

See FUEL SYSTEM,

Repair, EGR valve

4.Remove 2 screws and release heat shield from

induction manifold.

5.Slacken induction manifold lower securing nuts,

located below exhaust manifold.

6.Remove induction manifold upper securing bolts.

7.Remove induction manifold. Plug apertures in

cylinder head with clean rag to prevent any items

falling into engine.

8.Check gasket is satisfactory for further use.

Refit

9.Clean induction manifold mating face.

10.Position induction manifold and secure with

upper and lower fixings.

11.Tighten securing nuts and bolts to

25 Nm (18

lbf/ft).

12.Fit manifold heat shield.

13.Fit hose intercooler to induction manifold.

14.Fit rocker cover insulation.

15.Reconnect battery.INDUCTION/EXHAUST MANIFOLD GASKET

Service repair no - 30.15.15

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Remove turbocharger outlet hose.

3.Raise vehicle and slacken exhaust front pipe to

intermediate silencer flange nuts. Ensure pipe is

free to turn.

NOTE: If removing exhaust manifold and

turbocharger assembly from vehicle,

remove manifold to exhaust front pipe

nuts while working under vehicle.

4.Remove exhaust manifold securing nuts,

removing centre lower nut first.

5.Move heater rail clear of exhaust manifold.

6.With exhaust manifold and turbocharger still

attached to exhaust front pipe, withdraw from

head by turning front pipe until sufficient access

is gained to remove gasket.

7.Suitably support exhaust manifold and

turbocharger assembly to prevent damage.

8.Remove induction manifold lower nuts.

9.Remove gasket.

10.Clean mating faces.

Page 136 of 455

30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Refit

11.Fit new gasket over manifold studs.

12.Loosely fit induction manifold lower nuts to

studs.

13.Fit exhaust manifold and secure with central

upper and lower nuts.

14.Locate heater rail to its correct position and

secure with outer exhaust manifold nuts.

15.Tighten all exhaust manifold nuts to

45 Nm (33

lbf/ft).

16.Tighten exhaust front pipe to intermediate

silencer nuts to

50 Nm (37 lbf/ft).

17.Fit turbocharger outlet pipe.

18.Fit induction manifold

See Induction manifold

.EXHAUST MANIFOLD/TURBOCHARGER

ASSEMBLY

Service repair no - 30.15.10

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Disconnect turbocharger inlet hose.

3.Disconnect boost pressure pipe at turbocharger.

4.Remove intercooler bottom hose.

5.Place suitable container under engine and

disconnect turbocharger oil feed and return

pipes at cylinder block.

6.Remove 3 nuts securing exhaust front pipe to

manifold flange.

7.Remove 7 nuts and lift exhaust manifold and

turbocharger assembly from cylinder head.

8.Discard manifold gasket.

Refit

9.Fit new manifold gasket.

10.Position exhaust manifold assembly onto

location studs and secure to cylinder head.

Tighten nuts to

45 Nm (33 lbf/ft).

11.Secure exhaust front pipe to manifold flange.

Tighten fixings to

50 Nm (37 lbf/ft).

12.Reconnect turbocharger oil feed and return

pipes at cylinder block.

13.Fit intercooler bottom hose.

14.Fit boost pressure pipe at turbocharger.

15.Fit turbocharger inlet hose.

16.Fit induction manifold

See Induction manifold

.

Page 137 of 455

MANIFOLD AND EXHAUST SYSTEM

3

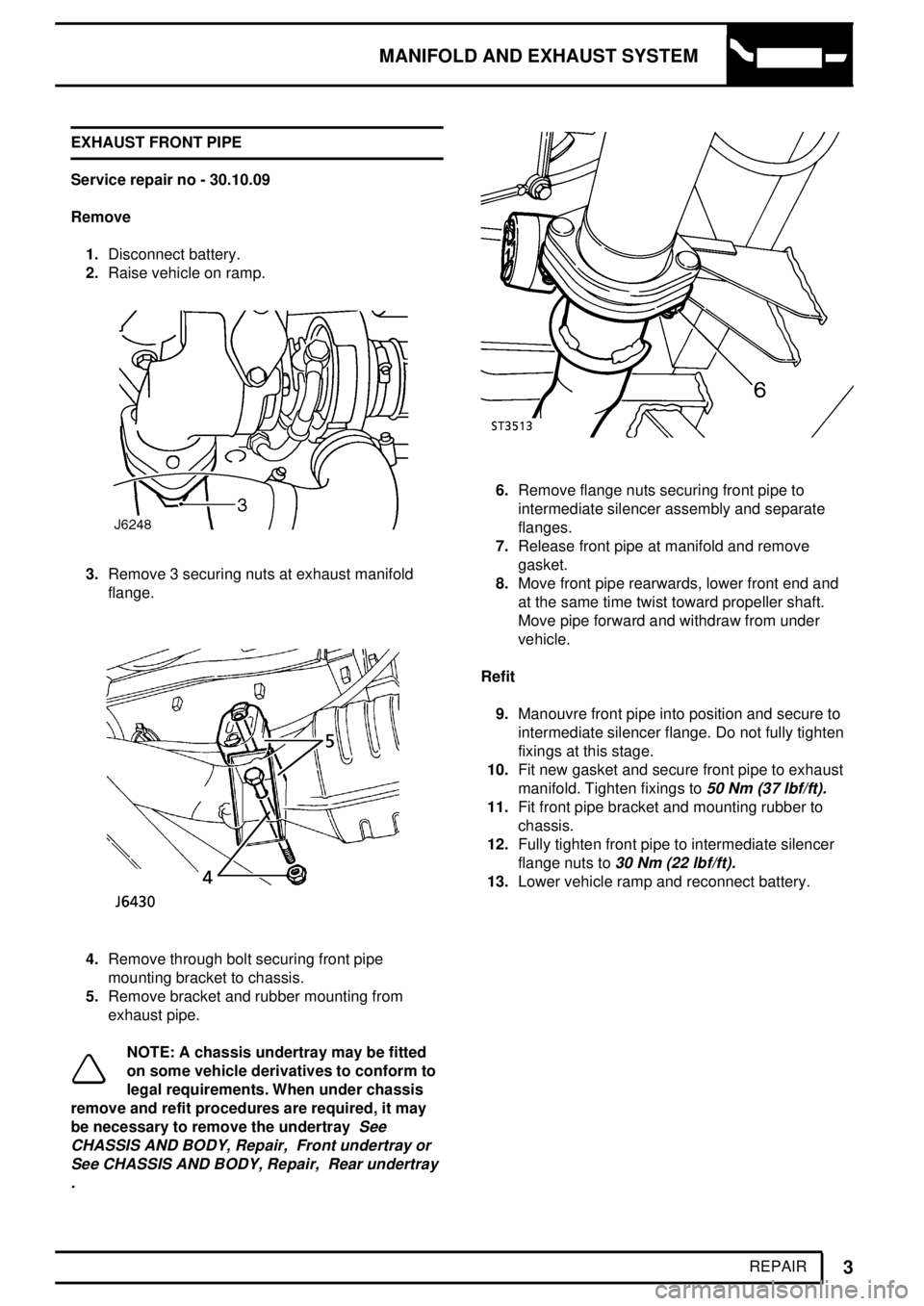

REPAIR EXHAUST FRONT PIPE

Service repair no - 30.10.09

Remove

1.Disconnect battery.

2.Raise vehicle on ramp.

3.Remove 3 securing nuts at exhaust manifold

flange.

4.Remove through bolt securing front pipe

mounting bracket to chassis.

5.Remove bracket and rubber mounting from

exhaust pipe.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray or

See CHASSIS AND BODY, Repair, Rear undertray

.

6.Remove flange nuts securing front pipe to

intermediate silencer assembly and separate

flanges.

7.Release front pipe at manifold and remove

gasket.

8.Move front pipe rearwards, lower front end and

at the same time twist toward propeller shaft.

Move pipe forward and withdraw from under

vehicle.

Refit

9.Manouvre front pipe into position and secure to

intermediate silencer flange. Do not fully tighten

fixings at this stage.

10.Fit new gasket and secure front pipe to exhaust

manifold. Tighten fixings to

50 Nm (37 lbf/ft).

11.Fit front pipe bracket and mounting rubber to

chassis.

12.Fully tighten front pipe to intermediate silencer

flange nuts to

30 Nm (22 lbf/ft).

13.Lower vehicle ramp and reconnect battery.

Page 138 of 455

30MANIFOLD AND EXHAUST SYSTEM

4

REPAIR INTERMEDIATE PIPE - 90

Service repair no - 30.10.11

Remove

1.Raise vehicle on ramp.

2.Release intermediate pipe from front mounting

rubber, see J6243.

3.Remove 2 flange nuts securing intermediate

pipe to tail pipe.

4.Release intermediate pipe from rear mounting

rubber.

5.Remove 2 flange nuts securing intermediate

pipe to front pipe.

6.Release intermediate pipe from front and tail

pipe and remove.

Refit

7.Fit intermediate pipe to front and tail pipes.

8.Secure intermediate pipe to front and rear

mounting rubbers.

9.Secure intermediate pipe to front pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

10.Secure intermediate pipe to tail pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

11.Lower vehicle.INTERMEDIATE PIPE - 110/130

Service repair no - 30.10.11

Remove

1.Raise vehicle on ramp.

2.Release intermediate pipe from mounting

rubber, see J6244.

3.Remove 2 flange nuts securing intermediate

pipe to tail pipe.

4.Remove 2 flange nuts securing intermediate

pipe to front pipe.

5.Release intermediate pipe from front and tail

pipe and remove.

Refit

6.Fit intermediate pipe to front and tail pipes.

7.Secure intermediate pipe to mounting rubbers.

8.Secure intermediate pipe to front pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

9.Secure intermediate pipe to tail pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

10.Lower vehicle.

Page 139 of 455

MANIFOLD AND EXHAUST SYSTEM

5

REPAIR TAILPIPE - 90

Service repair no - 30.10.22

Remove

1.Raise vehicle on ramp.

2.Remove 2 flange nuts securing tail pipe to

intermediate pipe, see J6243.

3.Release tail pipe from inboard mounting rubber.

4.Release tail pipe from outboard mounting rubber

and remove.

Refit

5.Fit tail pipe to intermediate pipe.

6.Secure tail pipe to mounting rubbers.

7.Secure tail pipe to intermediate pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

8.Lower vehicle.TAILPIPE - 110/130

Service repair no - 30.10.22

Remove

1.Raise vehicle on ramp.

2.Remove 2 flange nuts securing tail pipe to

intermediate pipe, see J6244.

3.Release tail pipe from front mounting rubber.

4.Release tail pipe from rear mounting rubber.

5.Release tail pipe from intermediate pipe and

feed over rear axle.

6.Remove tail pipe.

Refit

7.Feed tail pipe over rear axle and connect to

intermediate pipe.

8.Secure tail pipe to mounting rubbers.

9.Secure tail pipe to intermediate pipe. Tighten

nuts to

30 Nm (22 lbf/ft).

10.Lower vehicle.

Page 140 of 455

CLUTCH

1

DESCRIPTION AND OPERATION DESCRIPTION

The clutch unit comprises a single dry plate friction

disc and diaphragm spring clutch unit, secured to the

engine flywheel.OPERATION

The unit is operated hydraulically by the clutch master

cylinder (12) and a slave cylinder (13) attached to the

transmission bell housing.

Clutch components

1.Crankshaft and flywheel

2.Friction plate

3.Clutch cover

4.Diaphragm spring

5.Pressure plate

6.Fulcrum posts (9) for diaphragm spring

7.Bearing rings (2) for diaphragm spring

8.Retraction links and bolts (3) for pressure plate

9.Release bearing10.Release lever

11.Release lever pivot post

12.Master cylinder

13.Slave cylinder

14.Master cylinder pedal pushrod

15.Primary shaft and taper bearing (in gearbox)

16.Gearbox front cover

17.Primary shaft flywheel bush

18.Pedal pivot and return spring