engine LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 285 of 455

70BRAKES

4

REPAIR PRESSURE REDUCING VALVE (PRV)

Service repair no - 70.25.21

Remove

1.Disconnect battery.

2.Clean area around reducing valve ports.

3.Place a container under valve to catch escaping

brake fluid.

4.Disconnect primary circuit pipe unions ñAñ

from valve.

5.Disconnect secondary circuit pipe unions ñBñ

from valve.

6.Cover pipes to prevent ingress of dirt.

7.Remove single retaining nut and bolt securing

valve to engine bulkhead.

8.Remove valve.

Refit

9.Fit valve to engine bulkhead. Tighten bolt to

15

Nm (11 lbf/ft).

10.Connect primary and secondary circuit pipes to

valve. Tighten to

16 Nm (12 lbf/ft).

11.Fill brake reservoir with recommended brake

fluid

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

.

12.Bleed the brake system

See Brake system

bleed

.

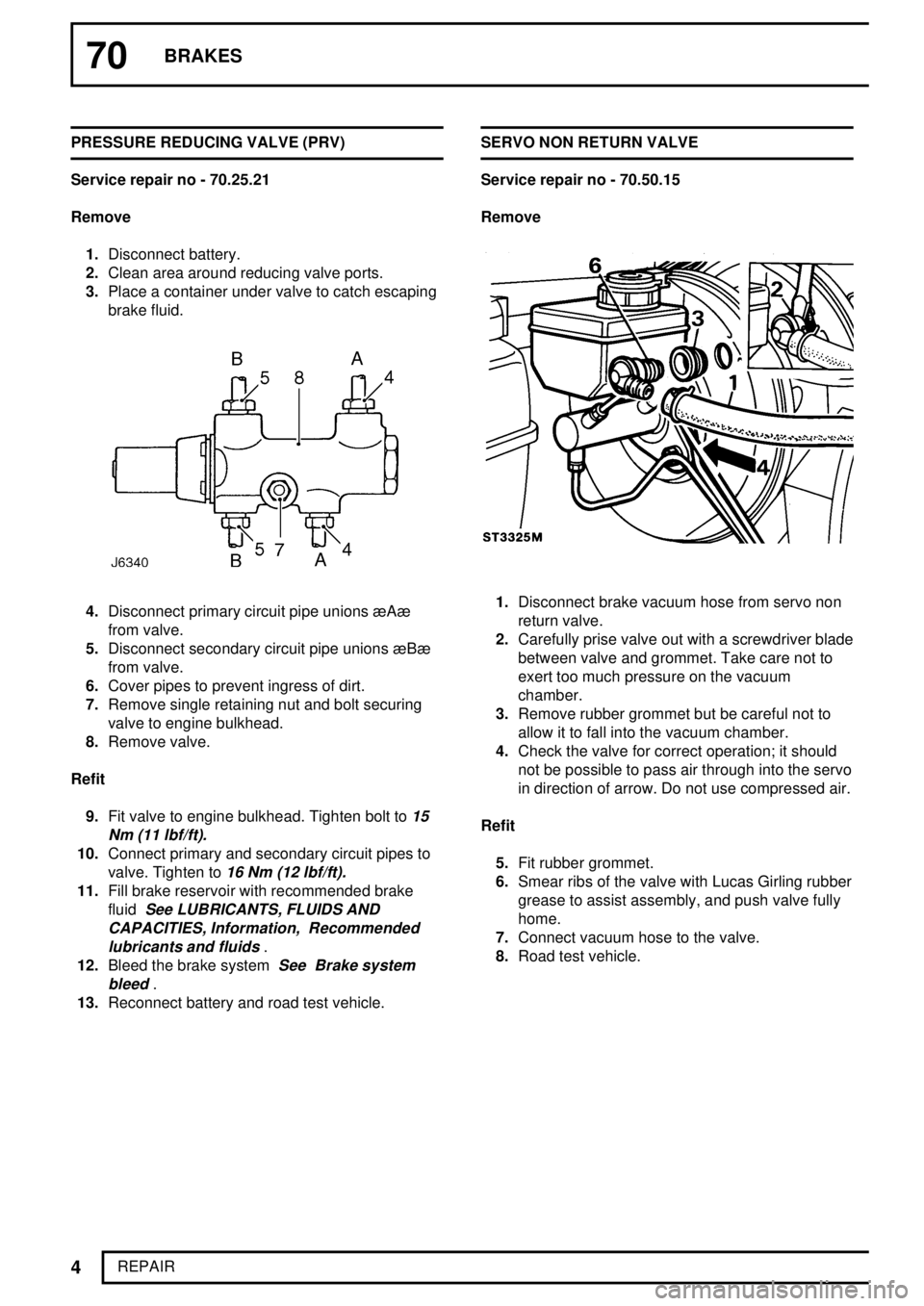

13.Reconnect battery and road test vehicle.SERVO NON RETURN VALVE

Service repair no - 70.50.15

Remove

1.Disconnect brake vacuum hose from servo non

return valve.

2.Carefully prise valve out with a screwdriver blade

between valve and grommet. Take care not to

exert too much pressure on the vacuum

chamber.

3.Remove rubber grommet but be careful not to

allow it to fall into the vacuum chamber.

4.Check the valve for correct operation; it should

not be possible to pass air through into the servo

in direction of arrow. Do not use compressed air.

Refit

5.Fit rubber grommet.

6.Smear ribs of the valve with Lucas Girling rubber

grease to assist assembly, and push valve fully

home.

7.Connect vacuum hose to the valve.

8.Road test vehicle.

Page 286 of 455

BRAKES

5

REPAIR SERVO ASSEMBLY

Service repair no - 70.50.01

Remove

Before starting repair refer to general brake service

practice

See General Brake Service Practice.

NOTE: The non-return valve and grommet,

are the only serviceable components. In

event of failure or damage, fit a new unit.

1.Remove master cylinderSee Master cylinder.

2.Disconnect vacuum supply hose from servo unit.

3.At footwell, release 2 brake pedal return springs.

4.Disconnect leads from brake light switch at rear

of pedal box.

5.Remove blanking grommets from each side of

pedal box.

6.Remove split pin and clevis pin securing servo

push rod to brake pedal.

7.Remove 4 nuts and plain washers securing

servo to pedal box.

8.Remove servo assembly and rubber washer

from bulkhead.Refit

9.Locate servo assembly and rubber washer to

engine bulkhead and secure to pedal box.

Tighten fixings to

14 Nm (10 lbf/ft).

10.Fit brake pedal to servo push rod with clevis pin

and new split pin.

11.Fit blanking grommets to each side of pedal box.

12.At footwell, attach pedal return springs.

13.Connect vacuum hose to servo non-return valve.

14.Fit brake master cylinder to servo unit

See

Master cylinder

.

Page 287 of 455

70BRAKES

6

REPAIR BRAKE PEDAL

Service repair no - 70.35.01 - Brake pedal

Service repair no - 70.35.03 - Pedal box

Remove

1.Remove brake servo assembly.

See Servo

assembly

.

2.Remove 6 bolts securing pedal box to engine

bulkhead.

3.Taking care not damage brake fluid pipes,

remove pedal box assembly and gasket.

4.Release return springs from pedal and pedal box

bosses.

5.Using a suitable punch, drift out retaining pin and

withdraw pedal pivot shaft.

6.Remove brake pedal complete with pivot

bushes.

7.Examine components for wear or damage,

renew as necessary.

8.If it is necessary to fit new pivot bushes, they

must be reamed out to 15,87 mm±0,02 mm

(0.625±0.001 in) after fitment.Refit

9.Lubricate pedal pivot shaft and bushes with

general purpose grease.

10.Fit pedal to pedal box, insert pivot shaft and

secure with new split pin.

11.Attach return springs to pedal and pedal box

bosses.

12.Fit pedal box and gasket to engine bulkhead.

Tighten fixings to

25 Nm (18 lbf/ft).

13.Fit brake servo assembly.See Servo

assembly

.

Page 299 of 455

70BRAKES

18

REPAIR VACUUM PUMP

Service repair no - 70.50.19

Remove

NOTE: To ease pump removal set engine

to T.D.C. on No.1 cylinder.

1.Disconnect battery.

2.Remove air cleaner

See FUEL SYSTEM,

Repair, Air cleaner

.

3.Detach servo hose from vacuum pump.

4.Remove bolt securing air cleaner support

bracket strut.

5.Remove 6 bolts securing vacuum pump.

6.Detach pump complete with strut and harness

bracket. Note location of strut and bracket for

Refit.

Refit

7.Clean mating faces of pump and block.

8.Loosely assemble pump to block with a new

gasket and with air cleaner strut and harness

bracket located under heads of bolts noted

during Remove.

9.Evenly tighten bolts, to depress pump plunger,

finally tightening to

25 Nm (18 lbf/ft).

10.Secure strut to air cleaner bracket.

11.Connect vacuum hose and secure with clip.

12.Refit air cleaner

See FUEL SYSTEM, Repair,

Air cleaner

.

Page 360 of 455

CHASSIS AND BODY

39

REPAIR ACCESS PANEL - FRONT UNDERTRAY

Service repair no - 76.11.85 - Access panel

Service repair no - 76.11.83 - Acoustic pad

The access panel is provided in the front undertray to

enable fitment of the wading plug into the engine

timing cover.

Remove

1.Raise vehicle on ramp.

2.Remove 5 bolts securing access panel to front

undertray.

3.Remove access panel.

4.If necessary, remove 5 fasteners and release

acoustic pad from access panel.

Refit

5.If applicable, fit acoustic pad to access panel.

6.Fit access panel to front undertray, Tighten

fixings to

14 Nm (10 lbf/ft).

7.Lower ramp.ACCESS PANEL - REAR UNDERTRAY

Service repair no - 76.11.84

The access panel is provided in the rear undertray to

enable fitment of the wading plug or timing tool

LRT-12-044in the flywheel housing, and access to

the engine oil sump drain plug.

Remove

1.Raise vehicle on ramp.

2.Rotate access panel anti-clockwise to release

locking flanges.

3.Remove access panel from undertray.

Refit

4.Locate access panel flanges in undertray

apertures.

5.Rotate panel clockwise to secure in undertray.

6.Lower ramp.

Page 361 of 455

HEATING AND VENTILATION

1

DESCRIPTION AND OPERATION HEATING AND VENTILATION SYSTEM

Description

The heating and ventilation system is standard on all

models. Air conditioning is an optional system which

provides fully integrated climate control for the vehicle

interior.The heater assembly, comprising a matrix housed in a

distribution unit and a variable speed blower motor, is

located on one side of the engine compartment and

attached directly to the fascia bulkhead.

The heating controls are positioned on the outside of

the instrument binnacle and cable linked to

mechanical flaps in the distribution unit.

Heater assembly

1.Heater distribution unit

2.Fixings, heater to fascia bulkhead

3.Heater matrix

4.Blower motor housing

5.Circlip, impeller to blower motor

6.Impeller

7.Resistor unit and harness connector8.Fixings, blower motor mounting plate

9.Mounting plate, blower motor

10.Blower motor

11.Fixings, blower motor to mounting bracket

12.Temperature flap, air flow to heater matrix

13.Air flap, air supply to plenum chamber (heater

duct)

Page 362 of 455

80HEATING AND VENTILATION

2

DESCRIPTION AND OPERATION HEATER OPERATION

The heater matrix (3), located in the distribution unit

(1), see J6341, is connected to the engine cooling

system. As water is circulated continuously through

the matrix, a selection of heated or ambient air is

controlled by two flaps within the distribution unit. The

temperature flap (12) controls the amount of ambient

air to the heater matrix, air being suppliedthrough a ducted vent on top of the vehicle front wing

to the blower motor (volute) housing (4). The blower

motor (10) can be used to boost the air flow into the

distribution unit. The air flap (13) controls the supply of

heated or ambient air from the heater unit into a

plenum chamber integeral with the vehicle fascia. Two

flaps in the plenum chamber (heater duct) distribute

the air flow to either the footwell vents or windscreen

demister vents as shown.

HEATER CONTROLS

1. Temperature control

Move the lever downwards to increase air

temperature or up to decrease air temperature.

2. Air distribution control

Lever fully up - windscreen vents only.

Lever midway - footwell and windscreen vents.

Lever fully down - footwell vents.3. Blower motor fan speed control

Move the lever progressively downwards to increase

fan speed. With the control at '0' the fan is switched

off and the volume of air entering the passenger

compartment is solely dependent on ram air when the

vehicle is moving.

Page 364 of 455

HEATING AND VENTILATION

1

REPAIR HEATER UNIT

Service repair no - 80.20.01

Remove

1.Remove bonnet and disconnect battery.

2.Remove radiator bottom hose at radiator union

and drain cooling system

See COOLING

SYSTEM, Repair, Drain and refill cooling

system

.

3.Slacken clips and remove heater hoses at

heater box unions.

4.Remove outer cable securing clips.

5.Slacken trunnions and remove control cables

from heater vent flap levers.

6.Remove heater wiring harness securing loop.

7.Disconnect harness multi-plug.

8.Remove interior bulkhead trim.

9.Remove lower nuts and bolts securing the

heater unit to the bulkhead.

10.Slacken heater unit upper retaining bolts.

11.Manoeuvre heater unit, complete with blower

motor, clear of air inlet duct and remove from

engine compartment.

12.If existing heater unit is to be refitted, remove

sealing rubber.

For heater matrix removal

See Heater matrix.

For blower motor removal

See Blower motor.

Refit

13.Smear a new heater unit sealing rubber with a

suitable impact adhesive and fit to heater.

14.Manoevre heater unit into position in engine

compartment, fit blower motor to air inlet duct

and locate upper fixing bolts.

15.Loosely fit heater unit lower fixing bolts.

16.Fully tighten upper fixing bolts.

17.Fully tighten lower fixings and refit interior

bulkhead trim.

18.Secure wiring harness and reconnect multi-plug.

19.Fit control cables to vent flap trunnions and

secure with outer cable clips.

20.Connect heater hoses.

21.Fit radiator bottom hose and refill cooling system

See COOLING SYSTEM, Repair, Drain and

refill cooling system

.

22.Fit bonnet and reconnect battery.

Page 367 of 455

80HEATING AND VENTILATION

4

REPAIR HEATER CONTROL CABLE - TEMPERATURE

CONTROL

Service repair no - 80.10.05

Remove

1.Disconnect battery.

2.Remove 4 screws securing instrument panel to

fascia cowl.

3.Pull instrument panel away from fascia and

disconnect speedometer cable to give easier

access to control cable at bulkhead.

4.Remove retaining screws and pull off air

distribution and temperature control lever knobs.

5.Remove 3 screws and detach side cover,

complete with control lever assembly.

6.Remove 2 screws securing control lever

assembly to side cover and remove cover. Note

plastic screw spacers fitted between cover and

control lever assembly and retain.

7.Remove small bolt and release outer cable

retaining clip.

8.Slacken grub screw and release inner cable from

clevis.

9.From inside engine compartment, release outer

cable retaining clip at heater unit.

10.Slacken trunnion fixing and release inner cable

from heater unit flap lever.

11.Release 2 retaining clips securing control cables

to engine bulkhead and heater hoses.

12.Pull control cable through bulkhead grommet

and remove from vehicle.

Refit

13.Fit new control cable to heater flap lever trunnion

with approximately 10 mm of inner cable

protruding from trunnion. Fully tighten trunnion.

14.Secure outer cable with retaining clip.

15.Route control cable through sealing grommet

and along inside of engine bulkhead to fascia

panel.

Page 368 of 455

HEATING AND VENTILATION

5

REPAIR 16.Secure control cables to engine bulkhead and

heater hoses with retaining clips.

17.With control lever in closed position, fit inner

cable to lever clevis and fully tighten clevis grub

screw.

18.Fit outer cable retaining clip and fully tighten

securing bolt.

19.Fit side cover to control lever assembly. Ensure

fixing screw spacers are positioned between

cover and lever assembly.

20.Fit side cover to fascia.

21.Fit control lever knobs.

22.Reconnect speedometer cable and fit instrument

panel.

23.Reconnect battery.