engine LAND ROVER DEFENDER 1996 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 125 of 455

COOLING SYSTEM

1

ADJUSTMENT DRAIN AND REFILL COOLING SYSTEM

Service repair no - 26.10.01

Draining

WARNING: DO NOT remove caps or plugs

when the engine is hot. The cooling

system is pressurised and personal

scalding could result.

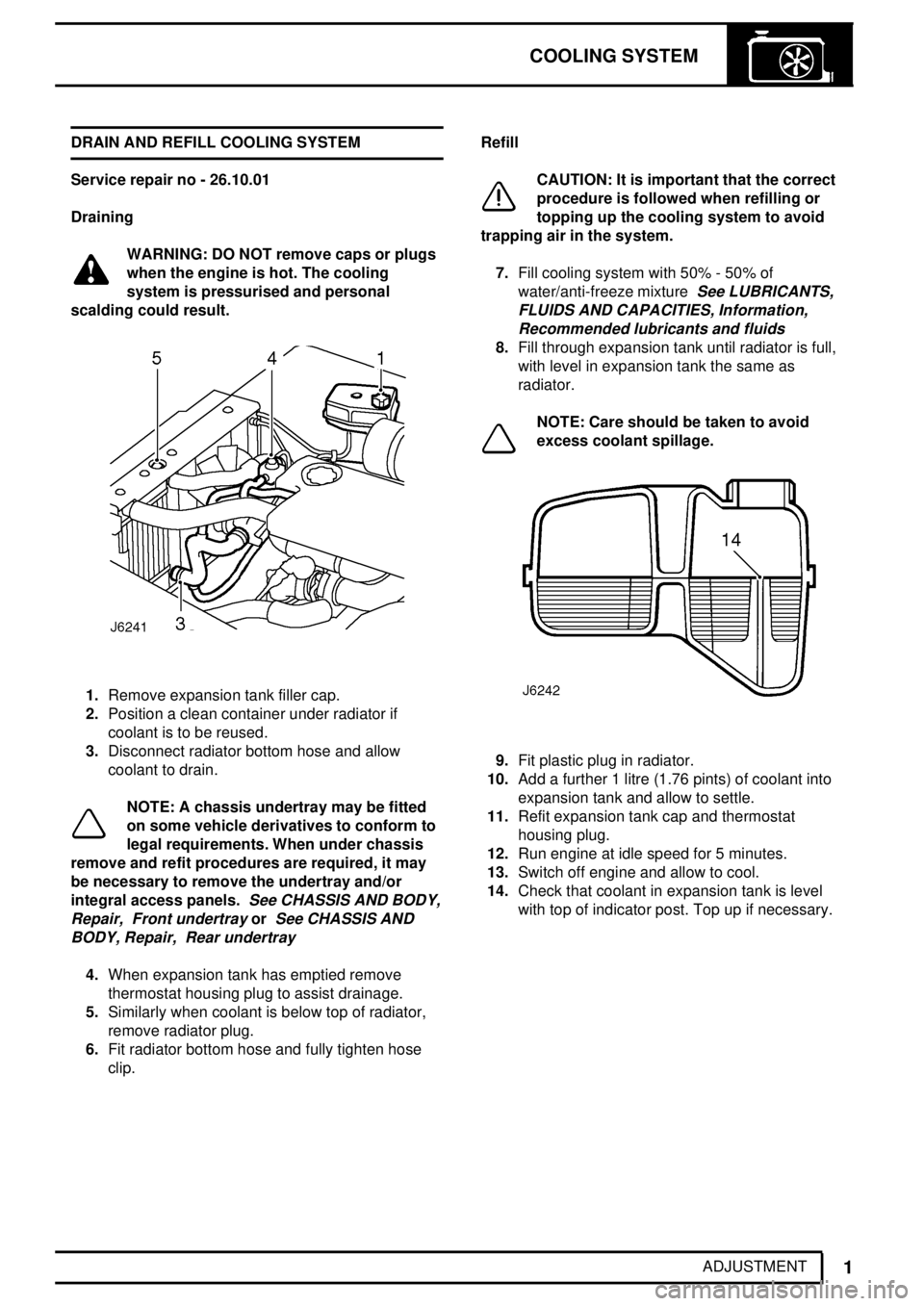

1.Remove expansion tank filler cap.

2.Position a clean container under radiator if

coolant is to be reused.

3.Disconnect radiator bottom hose and allow

coolant to drain.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray and/or

integral access panels.

See CHASSIS AND BODY,

Repair, Front undertray

orSee CHASSIS AND

BODY, Repair, Rear undertray

4.When expansion tank has emptied remove

thermostat housing plug to assist drainage.

5.Similarly when coolant is below top of radiator,

remove radiator plug.

6.Fit radiator bottom hose and fully tighten hose

clip.Refill

CAUTION: It is important that the correct

procedure is followed when refilling or

topping up the cooling system to avoid

trapping air in the system.

7.Fill cooling system with 50% - 50% of

water/anti-freeze mixture

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

8.Fill through expansion tank until radiator is full,

with level in expansion tank the same as

radiator.

NOTE: Care should be taken to avoid

excess coolant spillage.

9.Fit plastic plug in radiator.

10.Add a further 1 litre (1.76 pints) of coolant into

expansion tank and allow to settle.

11.Refit expansion tank cap and thermostat

housing plug.

12.Run engine at idle speed for 5 minutes.

13.Switch off engine and allow to cool.

14.Check that coolant in expansion tank is level

with top of indicator post. Top up if necessary.

Page 133 of 455

MANIFOLD AND EXHAUST SYSTEM

1

DESCRIPTION AND OPERATION MANIFOLDS AND EXHAUST SYSTEM

Description

The exhaust systems fitted on all models with the

300Tdi engine comprise three sections; front pipe

assembly, intermediate silencer assembly, and tail

pipe and silencer assembly. All sections, including

silencers, are manufactured from luminised steel to

give the system a durable working life under all

conditions. Special clamps are provided to ensureleak proof jointing between the various sections,

which are supported by flexible rubber mountings.

Catalytic convertor

When fitted, the catalytic converter is integral with the

front pipe assembly, which also incorporates a flexible

joint. The catalyst forms part of the engine emission

control that can also include an EGR valve system

See FUEL SYSTEM, Repair, EGR valve

Exhaust system - 90

1.Gasket

2.Front pipe

3.Front pipe with catalytic converter

4.Front mounting bracket

5.Intermediate silencer6.Intermediate mounting brackets

7.Tail pipe silencer*

8.Tail pipe silencer mounting

9.Tail pipe mounting

* Deleted on later models

Page 134 of 455

30MANIFOLD AND EXHAUST SYSTEM

2

DESCRIPTION AND OPERATION The catalyst comprises platinum coated ceramic

elements. The Hydrocarbons (HC), Oxides of nitrogen

(NOx) and Carbon monoxide (CO) emitted by the

engine react with the catalytic element and exhaust

temperature to convert the toxic gas into Nitrogen

(N

2), Carbon dioxide (CO2) and water vapour.

Exhaust system - 110/130

1.Gasket

2.Front pipe

3.Front pipe with catalytic converter

4.Front mounting bracket

5.Intermediate silencer6.Intermediate mounting brackets

7.Tail pipe silencer

8.Tail pipe silencer mounting

9.Tail pipe mounting

Page 135 of 455

MANIFOLD AND EXHAUST SYSTEM

1

REPAIR INDUCTION MANIFOLD

Service repair no - 30.15.02

Remove

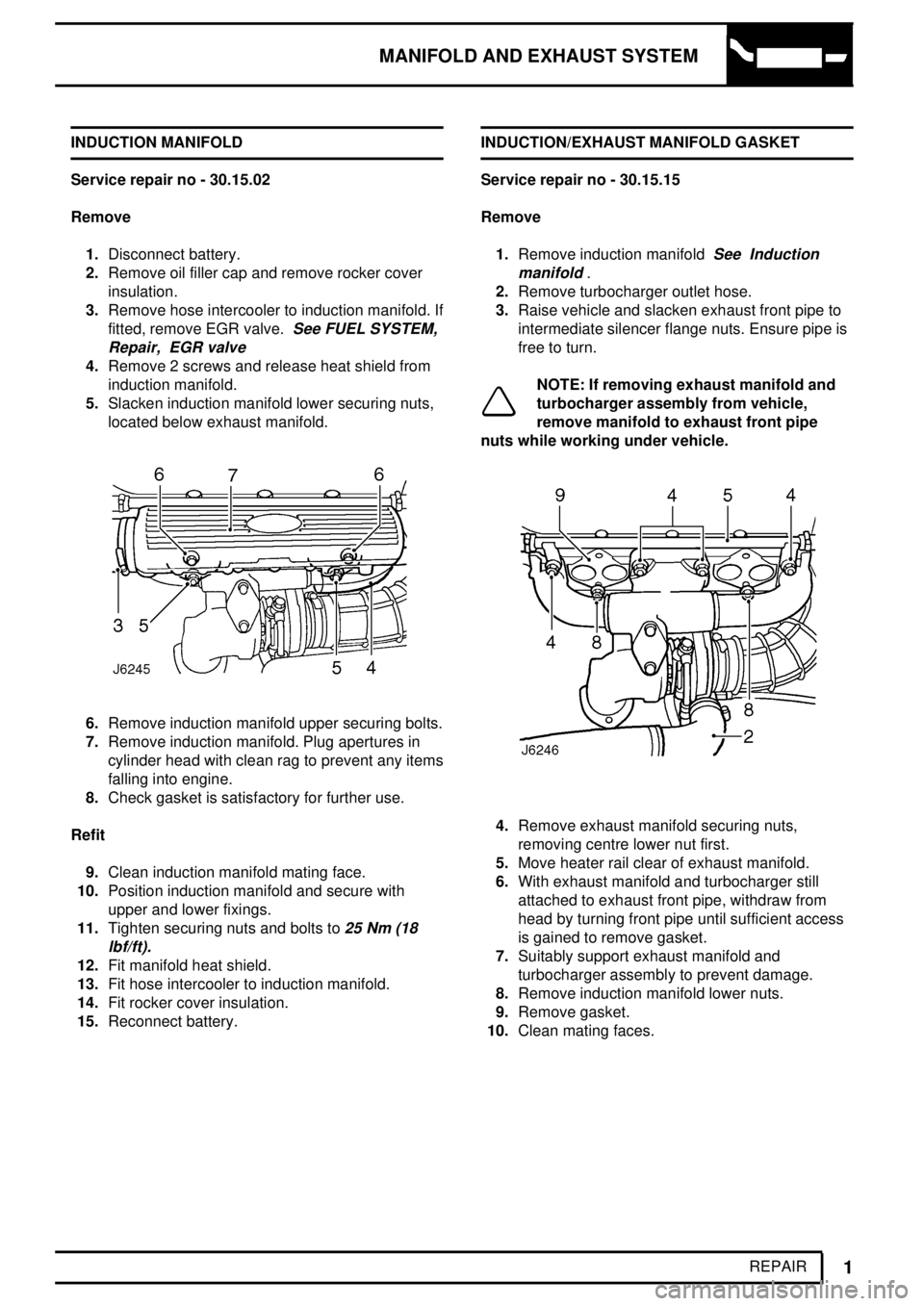

1.Disconnect battery.

2.Remove oil filler cap and remove rocker cover

insulation.

3.Remove hose intercooler to induction manifold. If

fitted, remove EGR valve.

See FUEL SYSTEM,

Repair, EGR valve

4.Remove 2 screws and release heat shield from

induction manifold.

5.Slacken induction manifold lower securing nuts,

located below exhaust manifold.

6.Remove induction manifold upper securing bolts.

7.Remove induction manifold. Plug apertures in

cylinder head with clean rag to prevent any items

falling into engine.

8.Check gasket is satisfactory for further use.

Refit

9.Clean induction manifold mating face.

10.Position induction manifold and secure with

upper and lower fixings.

11.Tighten securing nuts and bolts to

25 Nm (18

lbf/ft).

12.Fit manifold heat shield.

13.Fit hose intercooler to induction manifold.

14.Fit rocker cover insulation.

15.Reconnect battery.INDUCTION/EXHAUST MANIFOLD GASKET

Service repair no - 30.15.15

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Remove turbocharger outlet hose.

3.Raise vehicle and slacken exhaust front pipe to

intermediate silencer flange nuts. Ensure pipe is

free to turn.

NOTE: If removing exhaust manifold and

turbocharger assembly from vehicle,

remove manifold to exhaust front pipe

nuts while working under vehicle.

4.Remove exhaust manifold securing nuts,

removing centre lower nut first.

5.Move heater rail clear of exhaust manifold.

6.With exhaust manifold and turbocharger still

attached to exhaust front pipe, withdraw from

head by turning front pipe until sufficient access

is gained to remove gasket.

7.Suitably support exhaust manifold and

turbocharger assembly to prevent damage.

8.Remove induction manifold lower nuts.

9.Remove gasket.

10.Clean mating faces.

Page 136 of 455

30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Refit

11.Fit new gasket over manifold studs.

12.Loosely fit induction manifold lower nuts to

studs.

13.Fit exhaust manifold and secure with central

upper and lower nuts.

14.Locate heater rail to its correct position and

secure with outer exhaust manifold nuts.

15.Tighten all exhaust manifold nuts to

45 Nm (33

lbf/ft).

16.Tighten exhaust front pipe to intermediate

silencer nuts to

50 Nm (37 lbf/ft).

17.Fit turbocharger outlet pipe.

18.Fit induction manifold

See Induction manifold

.EXHAUST MANIFOLD/TURBOCHARGER

ASSEMBLY

Service repair no - 30.15.10

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Disconnect turbocharger inlet hose.

3.Disconnect boost pressure pipe at turbocharger.

4.Remove intercooler bottom hose.

5.Place suitable container under engine and

disconnect turbocharger oil feed and return

pipes at cylinder block.

6.Remove 3 nuts securing exhaust front pipe to

manifold flange.

7.Remove 7 nuts and lift exhaust manifold and

turbocharger assembly from cylinder head.

8.Discard manifold gasket.

Refit

9.Fit new manifold gasket.

10.Position exhaust manifold assembly onto

location studs and secure to cylinder head.

Tighten nuts to

45 Nm (33 lbf/ft).

11.Secure exhaust front pipe to manifold flange.

Tighten fixings to

50 Nm (37 lbf/ft).

12.Reconnect turbocharger oil feed and return

pipes at cylinder block.

13.Fit intercooler bottom hose.

14.Fit boost pressure pipe at turbocharger.

15.Fit turbocharger inlet hose.

16.Fit induction manifold

See Induction manifold

.

Page 140 of 455

CLUTCH

1

DESCRIPTION AND OPERATION DESCRIPTION

The clutch unit comprises a single dry plate friction

disc and diaphragm spring clutch unit, secured to the

engine flywheel.OPERATION

The unit is operated hydraulically by the clutch master

cylinder (12) and a slave cylinder (13) attached to the

transmission bell housing.

Clutch components

1.Crankshaft and flywheel

2.Friction plate

3.Clutch cover

4.Diaphragm spring

5.Pressure plate

6.Fulcrum posts (9) for diaphragm spring

7.Bearing rings (2) for diaphragm spring

8.Retraction links and bolts (3) for pressure plate

9.Release bearing10.Release lever

11.Release lever pivot post

12.Master cylinder

13.Slave cylinder

14.Master cylinder pedal pushrod

15.Primary shaft and taper bearing (in gearbox)

16.Gearbox front cover

17.Primary shaft flywheel bush

18.Pedal pivot and return spring

Page 141 of 455

33CLUTCH

2

DESCRIPTION AND OPERATION

When the clutch pedal is depressed, hydraulic fluid

transmits the movement via the slave cylinder, release

lever (10), bearing (9), to the inner fingers of the

diaphragm spring (4).

The diaphragm spring (4) pivots on the bearing rings

(7) and fulcrum posts (6) causing the pressure plate

(5) to release the clamping force on the friction plate

and linings (2).As the the clamping force is removed from the friction

plate (2), the plate slides on the splines of the primary

shaft (15) and takes up a neutral position between the

flywheel (1) and the pressure plate (5), thus

disconnecting the drive between the engine and the

gearbox.

Page 142 of 455

CLUTCH

1

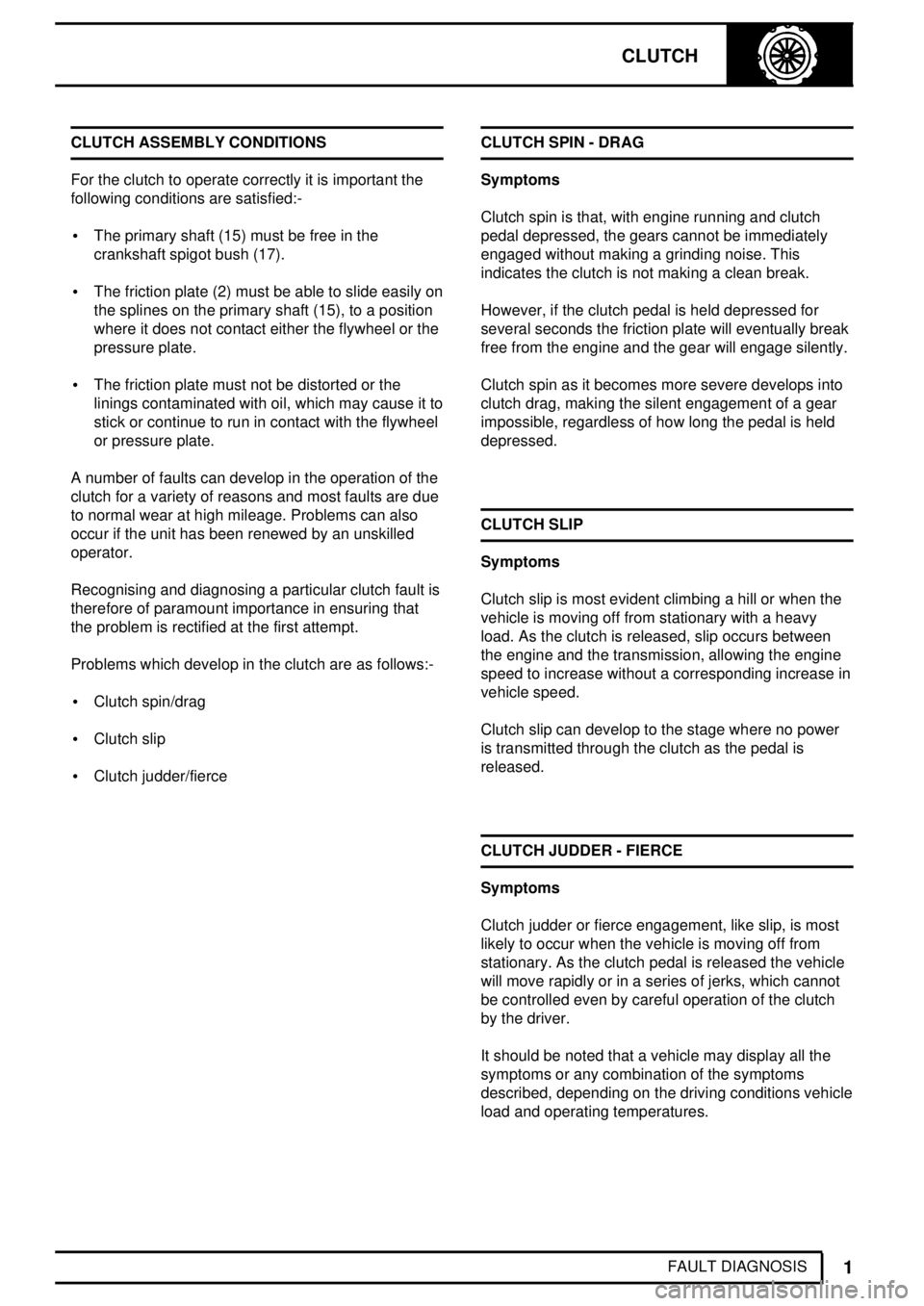

FAULT DIAGNOSIS CLUTCH ASSEMBLY CONDITIONS

For the clutch to operate correctly it is important the

following conditions are satisfied:-

·The primary shaft (15) must be free in the

crankshaft spigot bush (17).

·The friction plate (2) must be able to slide easily on

the splines on the primary shaft (15), to a position

where it does not contact either the flywheel or the

pressure plate.

·The friction plate must not be distorted or the

linings contaminated with oil, which may cause it to

stick or continue to run in contact with the flywheel

or pressure plate.

A number of faults can develop in the operation of the

clutch for a variety of reasons and most faults are due

to normal wear at high mileage. Problems can also

occur if the unit has been renewed by an unskilled

operator.

Recognising and diagnosing a particular clutch fault is

therefore of paramount importance in ensuring that

the problem is rectified at the first attempt.

Problems which develop in the clutch are as follows:-

·Clutch spin/drag

·Clutch slip

·Clutch judder/fierceCLUTCH SPIN - DRAG

Symptoms

Clutch spin is that, with engine running and clutch

pedal depressed, the gears cannot be immediately

engaged without making a grinding noise. This

indicates the clutch is not making a clean break.

However, if the clutch pedal is held depressed for

several seconds the friction plate will eventually break

free from the engine and the gear will engage silently.

Clutch spin as it becomes more severe develops into

clutch drag, making the silent engagement of a gear

impossible, regardless of how long the pedal is held

depressed.

CLUTCH SLIP

Symptoms

Clutch slip is most evident climbing a hill or when the

vehicle is moving off from stationary with a heavy

load. As the clutch is released, slip occurs between

the engine and the transmission, allowing the engine

speed to increase without a corresponding increase in

vehicle speed.

Clutch slip can develop to the stage where no power

is transmitted through the clutch as the pedal is

released.

CLUTCH JUDDER - FIERCE

Symptoms

Clutch judder or fierce engagement, like slip, is most

likely to occur when the vehicle is moving off from

stationary. As the clutch pedal is released the vehicle

will move rapidly or in a series of jerks, which cannot

be controlled even by careful operation of the clutch

by the driver.

It should be noted that a vehicle may display all the

symptoms or any combination of the symptoms

described, depending on the driving conditions vehicle

load and operating temperatures.

Page 143 of 455

33CLUTCH

2

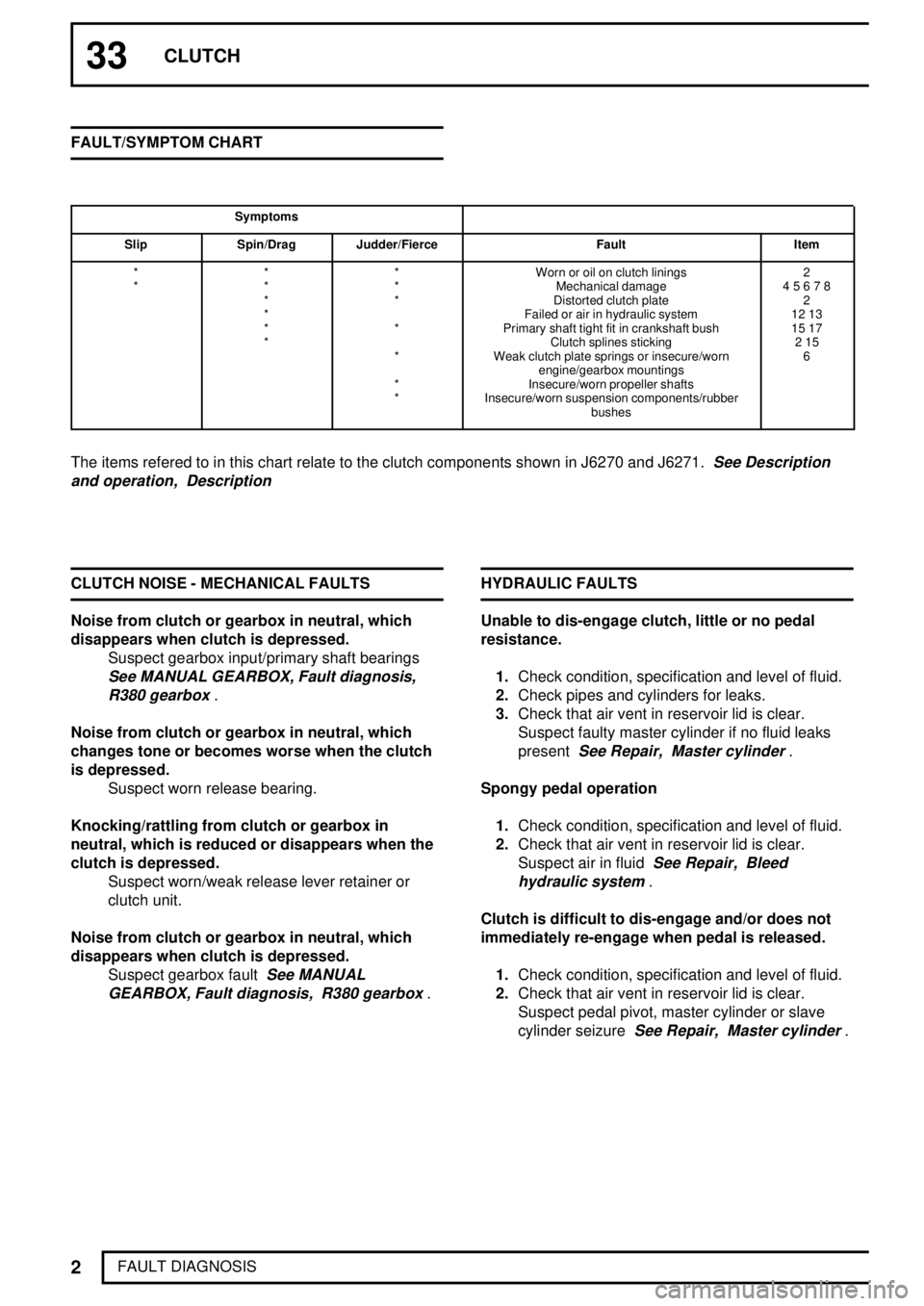

FAULT DIAGNOSIS FAULT/SYMPTOM CHART

Symptoms

Slip Spin/Drag Judder/Fierce Fault Item

* * * Worn or oil on clutch linings 2

* * * Mechanical damage45678

* * Distorted clutch plate 2

* Failed or air in hydraulic system 12 13

* * Primary shaft tight fit in crankshaft bush 15 17

* Clutch splines sticking 2 15

* Weak clutch plate springs or insecure/worn

engine/gearbox mountings6

* Insecure/worn propeller shafts

* Insecure/worn suspension components/rubber

bushes

The items refered to in this chart relate to the clutch components shown in J6270 and J6271.See Description

and operation, Description

CLUTCH NOISE - MECHANICAL FAULTS

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox input/primary shaft bearings

See MANUAL GEARBOX, Fault diagnosis,

R380 gearbox

.

Noise from clutch or gearbox in neutral, which

changes tone or becomes worse when the clutch

is depressed.

Suspect worn release bearing.

Knocking/rattling from clutch or gearbox in

neutral, which is reduced or disappears when the

clutch is depressed.

Suspect worn/weak release lever retainer or

clutch unit.

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox fault

See MANUAL

GEARBOX, Fault diagnosis, R380 gearbox

.HYDRAULIC FAULTS

Unable to dis-engage clutch, little or no pedal

resistance.

1.Check condition, specification and level of fluid.

2.Check pipes and cylinders for leaks.

3.Check that air vent in reservoir lid is clear.

Suspect faulty master cylinder if no fluid leaks

present

See Repair, Master cylinder.

Spongy pedal operation

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect air in fluid

See Repair, Bleed

hydraulic system

.

Clutch is difficult to dis-engage and/or does not

immediately re-engage when pedal is released.

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect pedal pivot, master cylinder or slave

cylinder seizure

See Repair, Master cylinder.

Page 145 of 455

CLUTCH

1

REPAIR CLUTCH ASSEMBLY

Service repair no - 33.10.01

Clutch pressure plate

Renew pressure plate if diaphragm spring fingers are

worn or if pressure plate shows signs of wear, cracks

or burning.

Clutch driven plate

Renew driven plate if centre hub splines are worn or if

lining is contaminated, burned or unevenly worn.

Remove

1.Remove gearbox

See MANUAL GEARBOX,

Repair, R380 Gearbox

.

2.Mark position of clutch pressure plate to flywheel

for reassembly.

3.Remove pressure plate securing bolts, working

evenly and diagonally.

4.Remove clutch assembly.

5.Withdraw clutch driven plate.

Refit

NOTE: To prevent driven plate sticking,

lubricate splines using Rocol MV 3 or

Rocol MTS 1000 grease.

6.Using centralising toolLRT-12-040to support

clutch driven plate locate pressure plate on

flywheel dowels. If fitting original pressure plate,

align assembly marks.

7.Secure pressure plate cover fixings evenly,

working in a diagonal sequence. Tighten to

34Nm (25 lbf/ft).

8.Fit gearbox to engineSee MANUAL

GEARBOX, Repair, R380 Gearbox

.BLEED HYDRAULIC SYSTEM

Service repair no - 33.15.01

Procedure

NOTE: During bleed procedure, keep fluid

reservoir topped up to avoid introducing

air to system. For hydraulic fluid

recommendations

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information, Recommended

lubricants and fluids

.

1.Attach suitable tubing to slave cylinder bleed

screw.

2.Place free end of tube in a glass jar containing

clutch fluid.

3.Loosen bleed screw.

4.Pump clutch pedal, pausing at end of each

stroke, until fluid from tubing is free of air.

NOTE: Keep free end of tube below

surface of fluid.

5.Hold clutch pedal down, tighten bleed screw.

6.Top up fluid reservoir.