engine LAND ROVER DEFENDER 1996 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 109 of 455

FUEL SYSTEM

7

REPAIR REV: 05/99

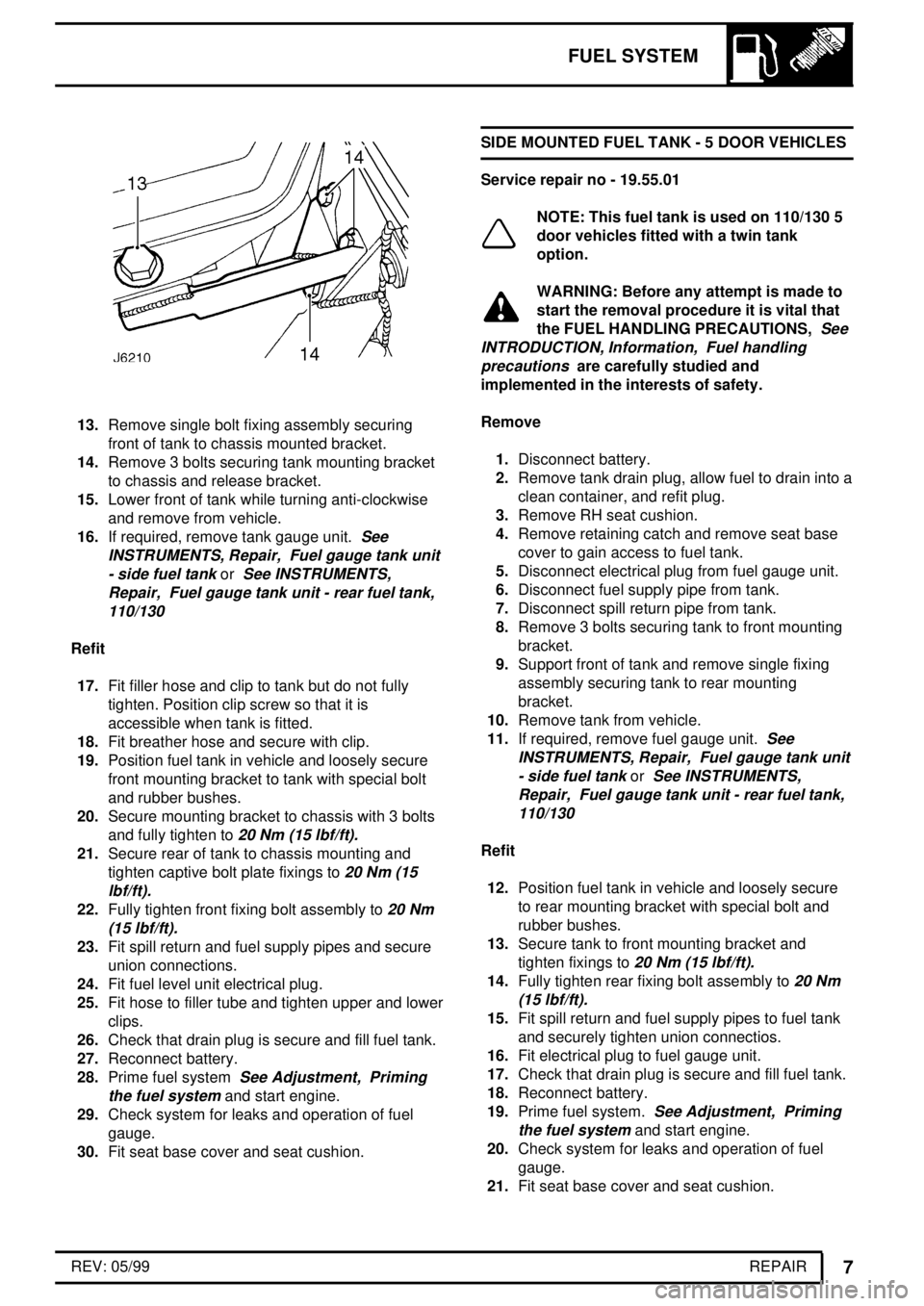

13.Remove single bolt fixing assembly securing

front of tank to chassis mounted bracket.

14.Remove 3 bolts securing tank mounting bracket

to chassis and release bracket.

15.Lower front of tank while turning anti-clockwise

and remove from vehicle.

16.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

17.Fit filler hose and clip to tank but do not fully

tighten. Position clip screw so that it is

accessible when tank is fitted.

18.Fit breather hose and secure with clip.

19.Position fuel tank in vehicle and loosely secure

front mounting bracket to tank with special bolt

and rubber bushes.

20.Secure mounting bracket to chassis with 3 bolts

and fully tighten to

20 Nm (15 lbf/ft).

21.Secure rear of tank to chassis mounting and

tighten captive bolt plate fixings to

20 Nm (15

lbf/ft).

22.Fully tighten front fixing bolt assembly to20 Nm

(15 lbf/ft).

23.Fit spill return and fuel supply pipes and secure

union connections.

24.Fit fuel level unit electrical plug.

25.Fit hose to filler tube and tighten upper and lower

clips.

26.Check that drain plug is secure and fill fuel tank.

27.Reconnect battery.

28.Prime fuel system

See Adjustment, Priming

the fuel system

and start engine.

29.Check system for leaks and operation of fuel

gauge.

30.Fit seat base cover and seat cushion.SIDE MOUNTED FUEL TANK - 5 DOOR VEHICLES

Service repair no - 19.55.01

NOTE: This fuel tank is used on 110/130 5

door vehicles fitted with a twin tank

option.

WARNING: Before any attempt is made to

start the removal procedure it is vital that

the FUEL HANDLING PRECAUTIONS,

See

INTRODUCTION, Information, Fuel handling

precautions

are carefully studied and

implemented in the interests of safety.

Remove

1.Disconnect battery.

2.Remove tank drain plug, allow fuel to drain into a

clean container, and refit plug.

3.Remove RH seat cushion.

4.Remove retaining catch and remove seat base

cover to gain access to fuel tank.

5.Disconnect electrical plug from fuel gauge unit.

6.Disconnect fuel supply pipe from tank.

7.Disconnect spill return pipe from tank.

8.Remove 3 bolts securing tank to front mounting

bracket.

9.Support front of tank and remove single fixing

assembly securing tank to rear mounting

bracket.

10.Remove tank from vehicle.

11.If required, remove fuel gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

12.Position fuel tank in vehicle and loosely secure

to rear mounting bracket with special bolt and

rubber bushes.

13.Secure tank to front mounting bracket and

tighten fixings to

20 Nm (15 lbf/ft).

14.Fully tighten rear fixing bolt assembly to20 Nm

(15 lbf/ft).

15.Fit spill return and fuel supply pipes to fuel tank

and securely tighten union connectios.

16.Fit electrical plug to fuel gauge unit.

17.Check that drain plug is secure and fill fuel tank.

18.Reconnect battery.

19.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

20.Check system for leaks and operation of fuel

gauge.

21.Fit seat base cover and seat cushion.

Page 111 of 455

FUEL SYSTEM

9

REPAIR REV: 05/99

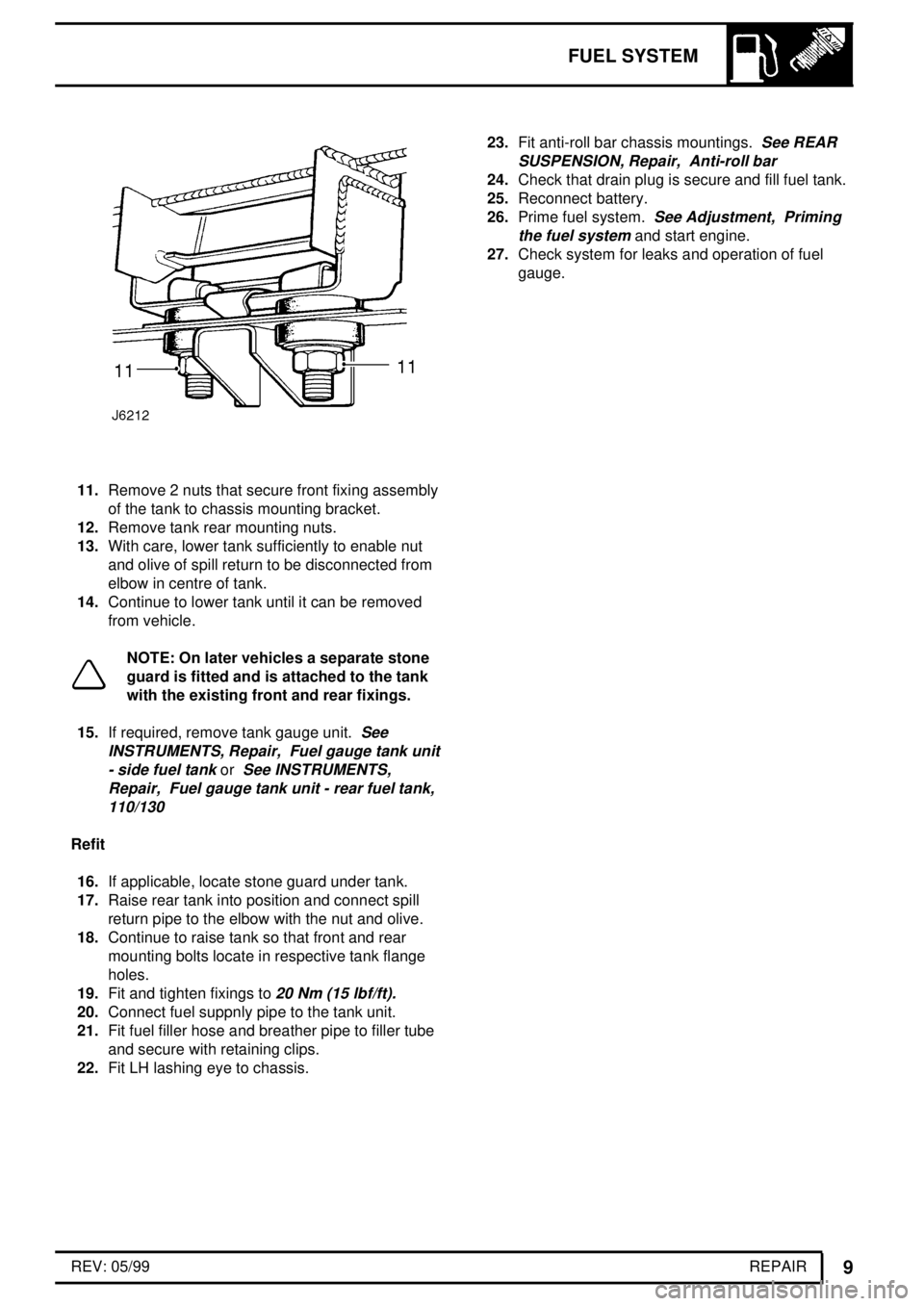

11.Remove 2 nuts that secure front fixing assembly

of the tank to chassis mounting bracket.

12.Remove tank rear mounting nuts.

13.With care, lower tank sufficiently to enable nut

and olive of spill return to be disconnected from

elbow in centre of tank.

14.Continue to lower tank until it can be removed

from vehicle.

NOTE: On later vehicles a separate stone

guard is fitted and is attached to the tank

with the existing front and rear fixings.

15.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

16.If applicable, locate stone guard under tank.

17.Raise rear tank into position and connect spill

return pipe to the elbow with the nut and olive.

18.Continue to raise tank so that front and rear

mounting bolts locate in respective tank flange

holes.

19.Fit and tighten fixings to

20 Nm (15 lbf/ft).

20.Connect fuel suppnly pipe to the tank unit.

21.Fit fuel filler hose and breather pipe to filler tube

and secure with retaining clips.

22.Fit LH lashing eye to chassis.23.Fit anti-roll bar chassis mountings.

See REAR

SUSPENSION, Repair, Anti-roll bar

24.Check that drain plug is secure and fill fuel tank.

25.Reconnect battery.

26.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

27.Check system for leaks and operation of fuel

gauge.

Page 113 of 455

FUEL SYSTEM

11

REPAIR HEATER PLUGS

Service repair no - 19.60.31

Remove

1.Disconnect battery.

No.1 heater plug - air conditioning models:

2.Release drive belt from compressor pulley.See

AIR CONDITIONING, Repair, Compressor

drive belt

3.Remove 4 bolts securing compressor to front

cover, move compressor aside.

No.3 heater plug:

4.Remove retaining bolt and withdraw breather

valve from rocker cover. Remove and discard 'O'

ring.

All heater plugs:

5.Remove terminal nut and disconnect wire from

heater plug terminal.

6.Unscrew heater plug.

Refit

7.Clean heater plug and seating.

8.Coat threads of heater plug with suitable

anti-seize compound operational to a

temperature of 1000°C.

9.Fit heater plug, tighten to

23 Nm (17 lbf/ft).

10.Connect wire to heater plug terminal and secure

with nut.

NOTE: Feed wire must be connected to

No. 4 heater plug terminal.

No. 3 heater plug:

11.Lubricate new 'O' ring with engine oil and fit to

breather valve.

12.Fit valve to rocker cover, tighten to bolt to

15 Nm

(11 lbf/ft).

No. 1 heater plug - air conditioning models

13.Position compressor to front cover, fit bolts and

tighten to

25 Nm (18 lbf/ft).

14.Fit drive belt to compressor pulley and adjust

tension.

See AIR CONDITIONING, Repair,

Compressor drive belt

All models:

15.Reconnect battery.

Page 115 of 455

FUEL SYSTEM

13

REPAIR THROTTLE CABLE

Service repair no - 19.20.06

Remove

1.Disconnect battery.

2.Remove split pin and clevis pin securing throttle

cable to injector pump throttle lever .

3.Depress ferrule retaining tags, release ferrule

from abutment bracket and withdraw throttle

cable.

4.Release throttle cable from clip on bulkhead.

5.Remove pin and clevis pin securing throttle

cable to pedal lever.

6.Release grommet from bulkhead.

7.Withdraw throttle cable from engine

compartment.Refit

8.Feed throttle cable through bulkhead from

engine compartment and fit grommet.

9.Secure throttle cable to pedal lever. Use new

split pin to secure clevis.

10.Secure throttle cable in bulkhead clip.

11.Guide throttle cable through abutment bracket

and fit ferrule.

12.Secure cable to injection pump throttle lever.

Use new split pin to secure clevis.

13.Adjust throttle cable.

See Adjustment,

Throttle cable

THROTTLE PEDAL

Service repair no - 19.20.01

Remove

1.Remove throttle cable from pedal.

See Throttle

cable

2.Remove 6 bolts securing throttle pedal assembly

to engine bulkhead.

3.Remove pedal assembly from footwell, complete

with trim retainer.

4.Release return spring from pedal lever.

5.Remove roll pin securing pivot shaft to pedal

assembly.

6.Withdraw pivot shaft and remove pedal from

mounting bracket.

7.Remove return spring from pedal boss.

Refit

8.Fit return spring to pedal boss.

9.Fit pedal to mounting bracket and locate return

spring.

10.Fit pivot shaft to pedal assembly and secure with

roll pin.

11.Locate return spring on pedal lever.

12.Secure throttle pedal assembly and trim retainer

to bulkhead. Tighten bolts to

9 Nm (7 lbf/ft).

13.Fit throttle cable to pedal.See Throttle cable

14.Adjust pedal, if necessary.See Adjustment,

Throttle pedal adjustment

Page 116 of 455

19FUEL SYSTEM

14

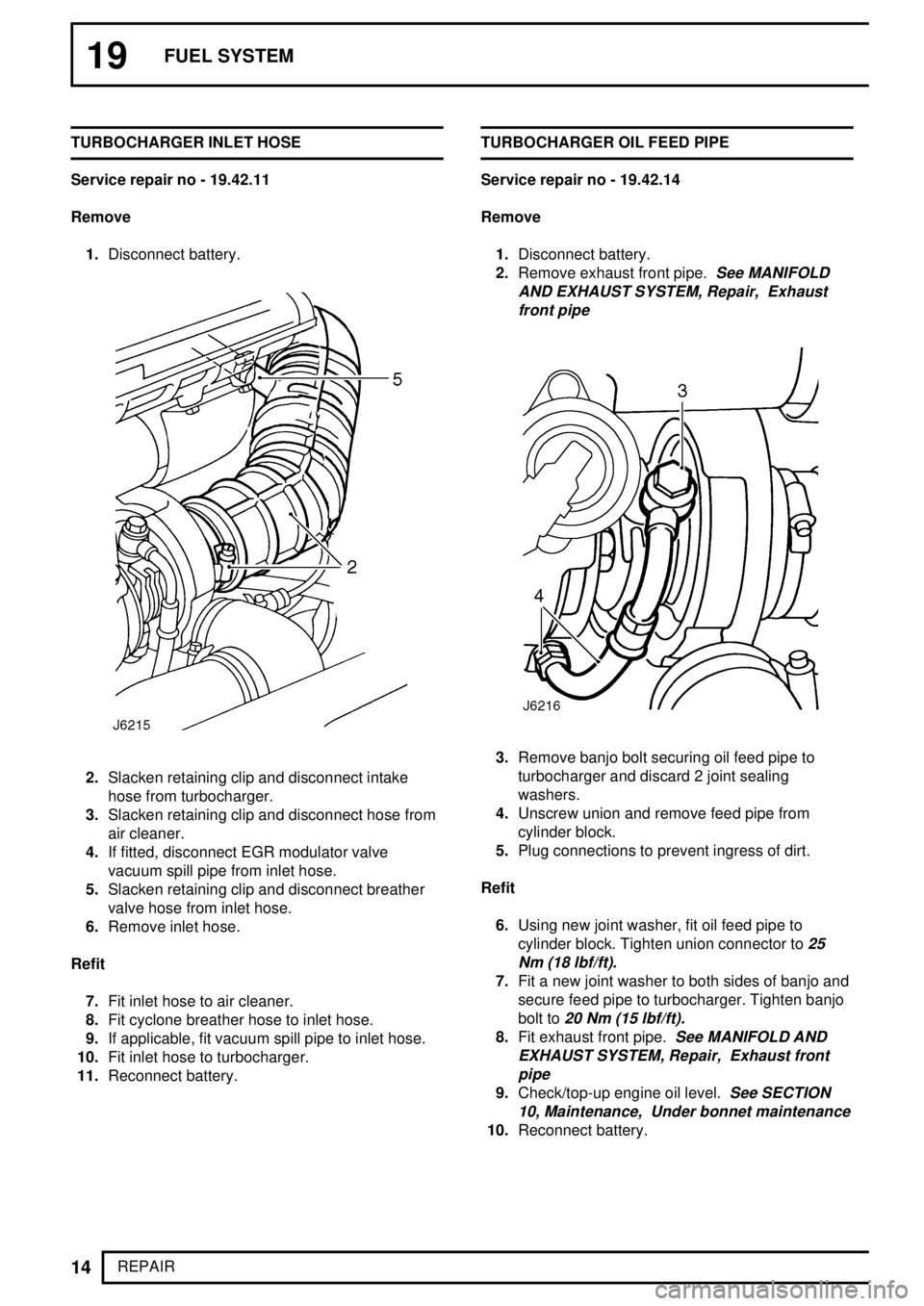

REPAIR TURBOCHARGER INLET HOSE

Service repair no - 19.42.11

Remove

1.Disconnect battery.

2.Slacken retaining clip and disconnect intake

hose from turbocharger.

3.Slacken retaining clip and disconnect hose from

air cleaner.

4.If fitted, disconnect EGR modulator valve

vacuum spill pipe from inlet hose.

5.Slacken retaining clip and disconnect breather

valve hose from inlet hose.

6.Remove inlet hose.

Refit

7.Fit inlet hose to air cleaner.

8.Fit cyclone breather hose to inlet hose.

9.If applicable, fit vacuum spill pipe to inlet hose.

10.Fit inlet hose to turbocharger.

11.Reconnect battery.TURBOCHARGER OIL FEED PIPE

Service repair no - 19.42.14

Remove

1.Disconnect battery.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

front pipe

3.Remove banjo bolt securing oil feed pipe to

turbocharger and discard 2 joint sealing

washers.

4.Unscrew union and remove feed pipe from

cylinder block.

5.Plug connections to prevent ingress of dirt.

Refit

6.Using new joint washer, fit oil feed pipe to

cylinder block. Tighten union connector to

25

Nm (18 lbf/ft).

7.Fit a new joint washer to both sides of banjo and

secure feed pipe to turbocharger. Tighten banjo

bolt to

20 Nm (15 lbf/ft).

8.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust front

pipe

9.Check/top-up engine oil level.See SECTION

10, Maintenance, Under bonnet maintenance

10.Reconnect battery.

Page 117 of 455

FUEL SYSTEM

15

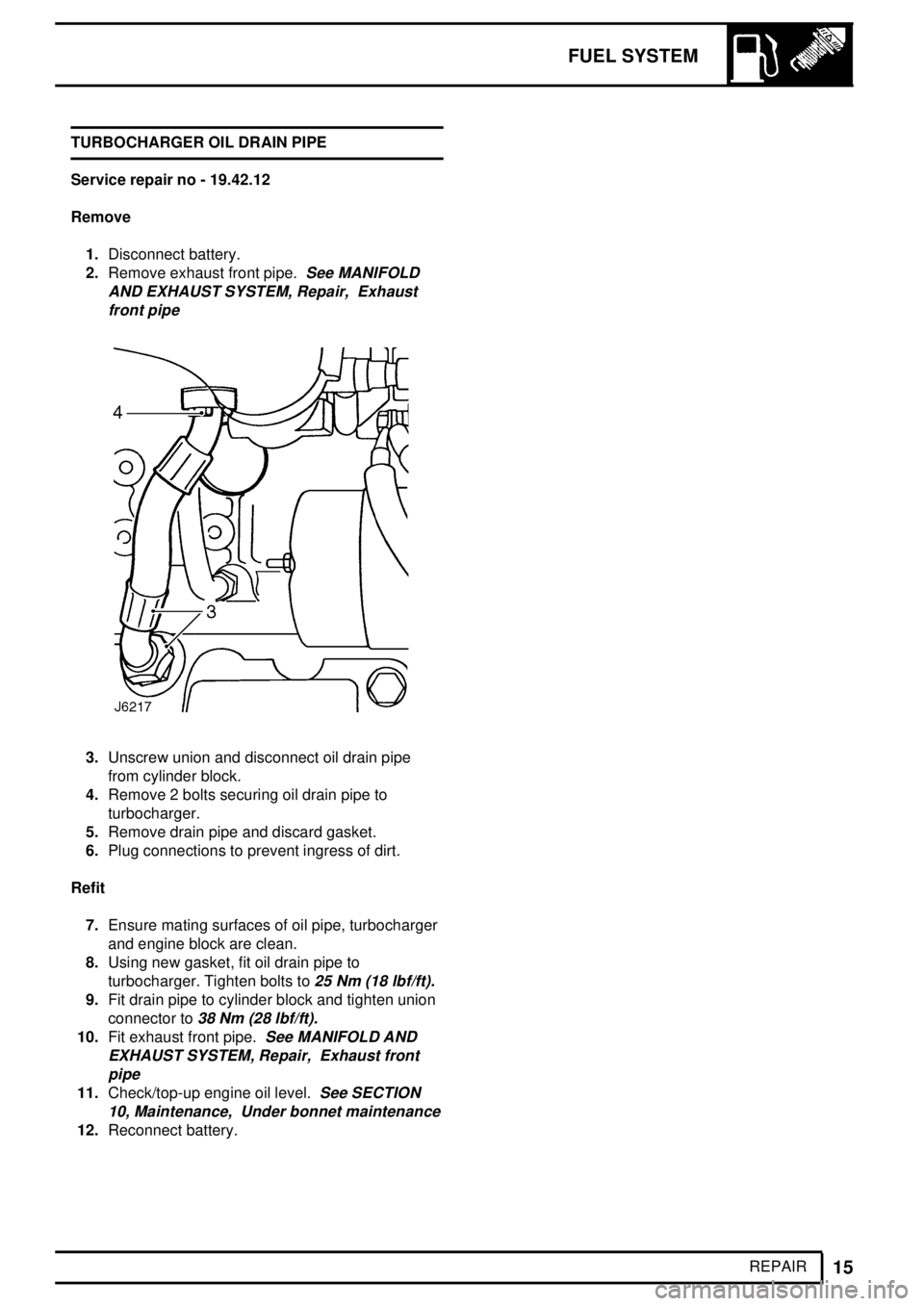

REPAIR TURBOCHARGER OIL DRAIN PIPE

Service repair no - 19.42.12

Remove

1.Disconnect battery.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

front pipe

3.Unscrew union and disconnect oil drain pipe

from cylinder block.

4.Remove 2 bolts securing oil drain pipe to

turbocharger.

5.Remove drain pipe and discard gasket.

6.Plug connections to prevent ingress of dirt.

Refit

7.Ensure mating surfaces of oil pipe, turbocharger

and engine block are clean.

8.Using new gasket, fit oil drain pipe to

turbocharger. Tighten bolts to

25 Nm (18 lbf/ft).

9.Fit drain pipe to cylinder block and tighten union

connector to

38 Nm (28 lbf/ft).

10.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust front

pipe

11.Check/top-up engine oil level.See SECTION

10, Maintenance, Under bonnet maintenance

12.Reconnect battery.

Page 121 of 455

COOLING SYSTEM

1

DESCRIPTION AND OPERATION ENGINE COOLING SYSTEM

Description

The complete cooling system of the 300Tdi engine

incorporates three independent functions:- Engine

(coolant) cooling; Turbo (charge air) intercooling;

Engine oil cooling.The intercooler is a separate aluminium unit, located

on the LH side of the engine compartment adjacent to

the radiator, sharing the same upper and lower

mountings. For details of turbo intercooling

See

FUEL SYSTEM, Description and operation,

Operation

. The oil cooler matrix is an integral part of

the radiator. Pre-formed pipes/hoses are used to link

the components within the separate systems as

shown below.

Engine cooling system

1.Radiator

2.Thermostat housing

3.Radiator bottom hose

4.Viscous fan

5.Water pump

6.Radiator top hose

7.Heater return hose

8.Coolant supply hose

9.By-pass hose

10.Radiator bleed (purge) hose

11.Bleed (purge) hose, thermostat housing

12.'Y' piece ejector

13.Expansion tank14.Heater rail

15.Heater unit

16.Heater feed hose

17.Intercooler

18.Air cleaner

19.Air feed hose

20.Turbocharger

21.Charge air supply pipe/hose

22.Cooled charge air supply hose

23.Exhaust manifold

24.Engine oil cooler

25.Feed pipe, engine oil cooler

26.Return pipe, engine oil cooler

27.Oil filter

Page 122 of 455

26COOLING SYSTEM

2

DESCRIPTION AND OPERATION ENGINE (COOLANT) COOLING

Description

The 300Tdi engine uses a pressurised cooling system

and cross flow radiator which is supplied with coolant

from an expansion tank mounted on the RH side of

the engine compartment. A belt driven centrifugal

water pump, fitted to an auxiliary mounting assembly,pumps coolant to the engine crankcase, cylinder head

and vehicle heater unit.

An eleven bladed fan, incorporating a viscous

coupling, is driven by an independent pulley secured

to the front cover plate. The thermostat housing,

bolted to the front of the cylinder head, is fitted with a

vent valve that purges excessive air pressure and

coolant back to the expansion tank.

Engine coolant circulation (engine warm - thermostat open).

1.Radiator

2.Thermostat/housing

3.Radiator bottom hose

4.Viscous fan

5.Water pump

6.Radiator top hose

7.Heater return hose

8.Coolant supply hose9.By-pass hose

10.Radiator bleed (purge) hose

11.Thermostat housing bleed (purge) hose

12.'Y' piece ejector

13.Expansion tank

14.Heater rail

15.Heater unit

16.Heater feed hose

Page 123 of 455

COOLING SYSTEM

3

DESCRIPTION AND OPERATION COOLANT CIRCULATION

Operation

When the engine is started from cold the thermostat

(2) prevents coolant circulation through the radiator by

closing off the top hose (6). During the engine warm

up period the water pump (5) circulates coolant to the

cylinders in the crankcase and through separate ports

to the cylinder head. At the rear of the cylinder head a

proportion of the flow is diverted through a heater feed

pipe (16) to the matrix of the heater unit (15). The

coolant is then carried, via a heater return rail (14) and

hoses (7), back to the water pump. The remaining

coolant flows through a by-pass hose (9) at the

thermostat housing and back to the water pump to

complete the first cycle.

When the normal engine running temperature is

reached, the thermostat opens, closing off the by-pass

hose (9). Coolant is then circulated via the top hose

(6) and through the radiator, where it is cooled and

drawn from the radiator bottom hose (3) by the water

pump (5). The coolant circulation through the

crankcase and cylinder head remains the same.

Two bleed pipes (10) and (11) help control the system

pressure by purging excess air and coolant to the

expansion tank via the 'Y'piece ejector (12).VISCOUS FAN

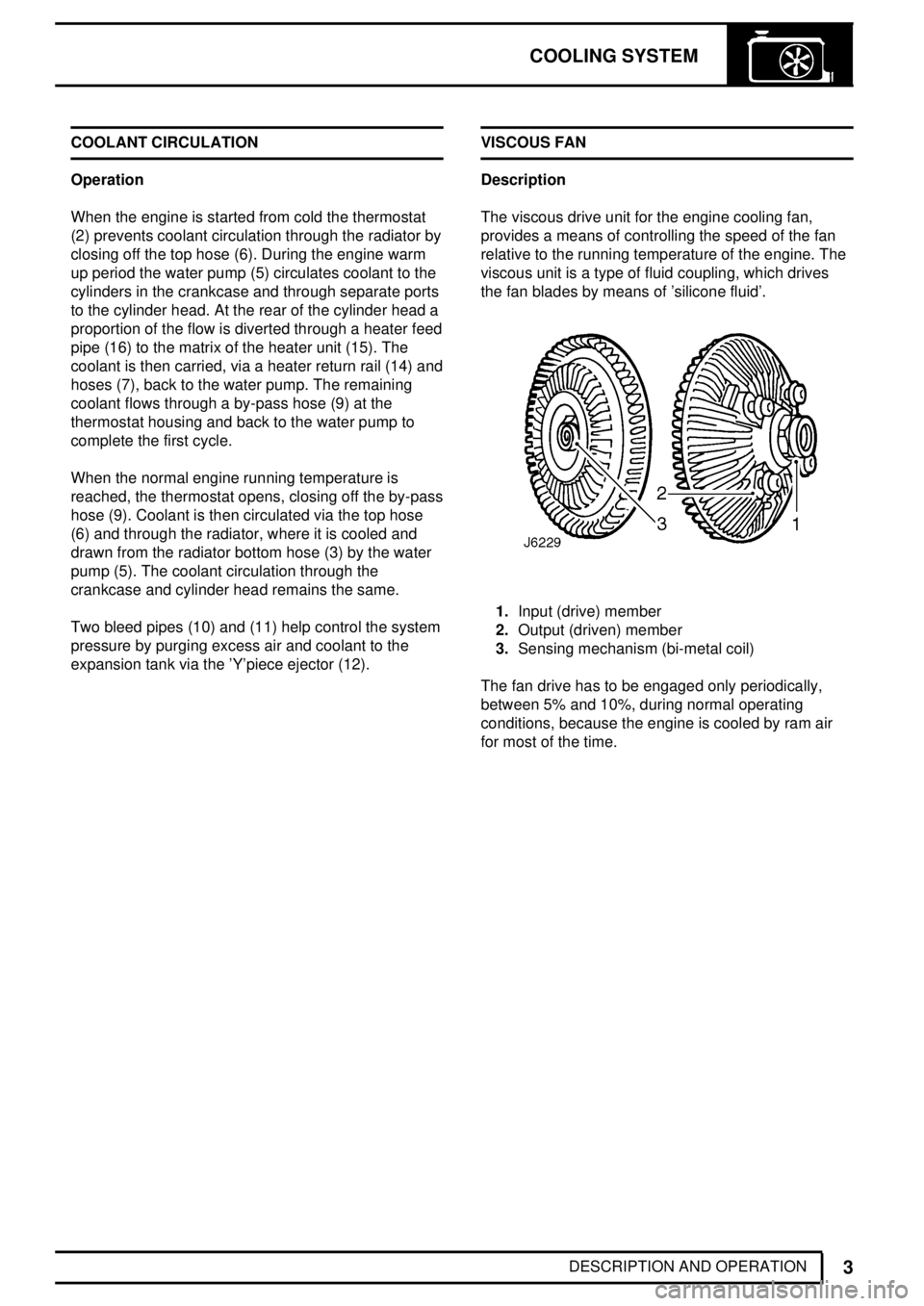

Description

The viscous drive unit for the engine cooling fan,

provides a means of controlling the speed of the fan

relative to the running temperature of the engine. The

viscous unit is a type of fluid coupling, which drives

the fan blades by means of 'silicone fluid'.

1.Input (drive) member

2.Output (driven) member

3.Sensing mechanism (bi-metal coil)

The fan drive has to be engaged only periodically,

between 5% and 10%, during normal operating

conditions, because the engine is cooled by ram air

for most of the time.

Page 124 of 455

26COOLING SYSTEM

4

DESCRIPTION AND OPERATION Operation

To engage and disengage the fan drive the bi-metal

coil senses air temperature behind the radiator. When

a pre-determined temperature is reached, the coil

opens a valve (5) which allows fluid to enter the drive

area and, due to centrifugal force, circulates to the

annular drive area.

There are two sets of annular grooves (3), one in the

drive clutch and the other in the drive body, a specific

clearance being provided between the two sets of

grooves.

Viscous unit disengaged (engine at normal

running temperature)

1.Input (drive) member

2.Output (driven) member

3.Running clearance

4.Pump plate

5.Valve (closed)

6.Sensing mechanism (bi-metal coil)

7.Fluid seal

8.Bearing, input member

9.Fluid chamber

10.Fluid reservoirWhen this clearance is filled with viscous fluid, a

shearing action, caused by the speed differential

between the two drive components, transmits torque

to the fan. The fluid is thrown to the outside of the unit

by centrifugal force from where it is recirculated to the

reservoir (10) via the pump plate (4) adjacent to the

drive member.

If the engine speed is increased the amount of slip will

also increase to limit the maximum fan speed.

When the air temperature from the radiator drops

sufficiently, the bi-metal coil closes the valve and

prevents fluid entering the drive area. The fluid that is

in the drive area will gradually pump out into the

reservoir (10) and the fan will return to an idle

condition.

Viscous unit engaged (hot running temperature)

Bi-metal coil (6) expanded, valve (5) open.