wheel LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 311 of 455

WHEELS AND TYRES

5

REPAIR Off Vehicle Balancing

Balance wheel assembly referring to equipment

manufacturer's instructions.

It is essential that the wheel is located by the centre

holeNOTthe stud holes. To ensure positive wheel

location the diameter of the locating collar on the

machine shaft must be 112,80 to 112,85 mm (4.441 to

4.443 in). This diameter will ensure that the collar fits

correctly within the centre hole of the wheel.

Where possible, always use the vehicle wheel

retaining nuts to locate the wheel on the balancer, to

avoid damaging the wheel. If this is not possible, the

locating nuts must be of a similar pattern to the

original wheel nuts. The use of conical type wheel

nuts for this purpose may damage the surface on alloy

wheels.

Cleaning

Wash the aluminium wheels using a suitable wash

and wax concentrate, correctly diluted and rinse with

cold clear water.DO NOTuse abrasives or aluminium

wheel cleaners containing acid, as they will destroy

the lacquer finish.

Tyre changing

Use only tyre changing equipment to mount or

demount tyres, following the equipment

manufacturer's instructions.DO NOTuse hand tools

or tyre levers, as they may damage tyre beads or the

wheel rim.

Puncture repair

Remove punctured tyre from wheel and repair using a

combination service plug and vulcanising patch.

Always follow manufacturer's instructions when using

a puncture repair kit.

Only punctures in tread area are reparable,DO NOT

attempt to repair punctures in tyre shoulders or

sidewalls.

Do not attempt to repair a tyre that has sustained the

following: bulges or blisters, ply separation, broken or

cracked beads, wear indicators visible and punctures

larger than 6 mm diameter.

CAUTION: Do not use tyre sealants that

are injected through valve stem to repair

punctured tyres, they may produce wheel

corrosion and tyre imbalance.

Aluminium wheel rim bead seats should be cleaned

using a non-abrasive cleaner to remove the mounting

lubricants and old rubber. Before mounting or

demounting a tyre, bead area should be well

lubricated with a suitable tyre lubricant.

TYRE FITTING

Alloy wheels

1.Install a new valve assembly.

2.Ensure wheel and tyre is adequately lubricated.

3.Mount tyre in normal manner. Inflate tyre and at

same time apply hand pressure to area around

valve to aid seating over valve first.

NOTE: Stop inflation immediately if tyre

seats opposite valve, as this will result in

valve being blocked by tyre beading,

making further inflation impossible, and carry out

following procedure.

4.Deflate tyre, unseat and rotate it around the rim

until valve is in line with that part of tyre which

seated initially. This part of beading having

seated over hump previously will automatically

seat first when tyre is re-inflated.

5.Inflate tyre to seat beads correctly, finally inflate

to correct pressure.

Page 312 of 455

74WHEELS AND TYRES

6

REPAIRREV: 05/99 WHEELS

Remove

WARNING: The parking brake acts on

transmission, not rear wheels, and may

not hold vehicle when jacking unless

following procedure is used. If one front wheel

and one rear wheel is raised no vehicle holding or

braking effect is possible. Wheels MUST be

chocked in all circumstances.

Apply parking brake, select a gear in main

gearbox and engage low gear in transfer box.

1.Loosen 5 wheel nuts.

2.Using a suitable trolley jack, raise vehicle and

place on axle stands

See INTRODUCTION,

Information, Jacking

.

3.Remove wheel nuts and carefully withdraw

wheel over studs.

Refit

4.Ensure that retaining studs and nuts are clean.

5.Alloy wheels: Lightly coat wheel mounting spigot

face with a suitable anti-seize compound to

minimise possibility of adhesion between wheel

and spigot face.

6.Refit wheel taking care not to damage stud

threads. (Do not apply oil).

7.Fit wheel nuts and turn by hand for at least three

full threads before using any form of wheel

wrench.

8.Tighten nuts as much as possible using a

suitable wrench.

9.Lower vehicle and finally tighten nuts to correct

torque sequence shown.

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 313 of 455

WHEELS AND TYRES

7

REPAIR REV: 05/99 WHEEL STUD

Remove

1.Remove wheel

See Wheels.

2.Drive stud out of driveshaft flange.

Refit

3.Position stud in flange.

4.Install a suitable spacer over stud.

5.Using a M16 x 1.5 nut, a slave wheel nut is

suitable, pull stud into flange until shoulder of

stud abuts flange.

6.Refit wheel.

See Wheels

Page 314 of 455

CHASSIS AND BODY

1

DESCRIPTION AND OPERATION CHASSIS AND BODY

Chassis

The chassis on all Defender variants are of the box

section, ladder type construction, manufactured from

2 mm (14swg) steel and treated with zinc phosphate,

cathodic electro coated, followed by waxing in the rear

crossmember.

Outriggers and angled brackets welded to the chassis

support suspension and axle components and are

also used as body mounting points. A detachable box

section crossmember, located between the two

chassis longitudinals is fitted to facilitate main gearbox

and tranfer box assembly removal.Should chassis damage occur, a comprehensive

range of components are available, including body

support outriggers, cross members and radius arm

mounting brackets. ALWAYS fit genuine parts that are

fully guaranteed and to original equipment

specification, fitted with Land Rover's BS 5135

welding standard.

Body

All body panels, with the exception of the fascia

bulkhead, are manufactured from aluminium alloy.

Galvanized steel is used for the front wheel arches to

give optimum protection. Most panels are also treated

with zinc phosphate and cathodic electro coated with

polyester surfacer, and are bolted to the welded

chassis.

Page 316 of 455

CHASSIS AND BODY

3

DESCRIPTION AND OPERATION LAND ROVER 90

CHASSIS ALIGNMENT DIMENSIONS

A - Front Datum

B - Chassis Datum

C - Front axle centre line

D - Rear axle centre line

1.239,0 - 236,5 mm

2.82,0 - 79,5 mm

3.633 mm

4.2420,6 - 2418,6 mm

5.2306,4 - 2305,4 mm

6.981,2 - 978,7 mm

7.182,7 mm

8.41,5 - 37,0 mm

9.252 - 250 mm10.110 mm

11.2360mm - Wheelbase

12.636 - 634 mm

13.488 - 483 mm

14.488 - 483 mm

15.3431,1 - 3426,1 mm

16.588,3 - 586,3 mm

17.2313,8 - 2311,8 mm

18.590,5 mm

19.295,25 mm

20.519,60 - 517,00 mm

21.259,80 - 258,50 mm

22.1242,6 - 1240,6 mm

23.642,5 - 639,5 mm24.750,9 mm

25.439,5 - 436,5 mm

26.136,5 mm

27.299,5 - 295,5 mm

28.103 - 100 mm

29.131,5 - 126,5 mm

30.705,5 - 704,5 mm

31.705,5 - 704,5 mm

32.42,2 - 40,2 mm

33.491 - 486 mm

34.594,2 - 593,4 mm

35.283,0 - 282,2 mm

36.32,25 - 31,25 mm

37.397 - 395 mm

Page 318 of 455

CHASSIS AND BODY

5

DESCRIPTION AND OPERATION LAND ROVER 110

CHASSIS ALIGNMENT DIMENSIONS

A - Front Datum

B - Chassis Datum

C - Front axle centre line

D - Rear axle centre line

1.4148 - 4143 mm

2.4009,5 - 4005 mm

3.978,7 - 981,2 mm

4.22 - 20 mm

5.252 - 250 mm

6.239 - 236,5 mm

7.3023,3 - 3022,3 mm

8.3030,7 - 3028,7 mm

9.155 - 153 mm

10.871,2 - 869,2 mm

11.2794 mm - Wheelbase

12.488 - 483 mm13.488 - 483 mm

14.82 - 79,5 mm

15.750,9 mm

16.750,9 mm

17.439,5 - 436,5 mm

18.439,5 - 436,5 mm

19.299,5 - 295,5 mm

20.500 - 495 mm

21.500 - 495 mm

22.594,2 - 593,4 mm

23.594,2 - 593,4 mm

24.283 - 282,2 mm

25.283 - 282,2 mm

26.1970 - 1968 mm

27.642,9 - 639,5 mm

28.750,9 mm29.290,5 mm

30.295,5 mm

31.299,5 - 295,5 mm

32.103 - 100 mm

33.1177,5 - 1175,5 mm

34.1692,5 - 1689,5 mm

35.2610 - 2606 mm

36.2040,5 - 2037,5 mm

37.1912,5 - 1909,5 mm

38.1359 - 1357 mm

39.1573 - 1571 mm

40.270 - 268 mm

41.665,5 - 663,5 mm

42.440 - 438 mm

43.32,25 - 31,25 mm

Page 338 of 455

CHASSIS AND BODY

17

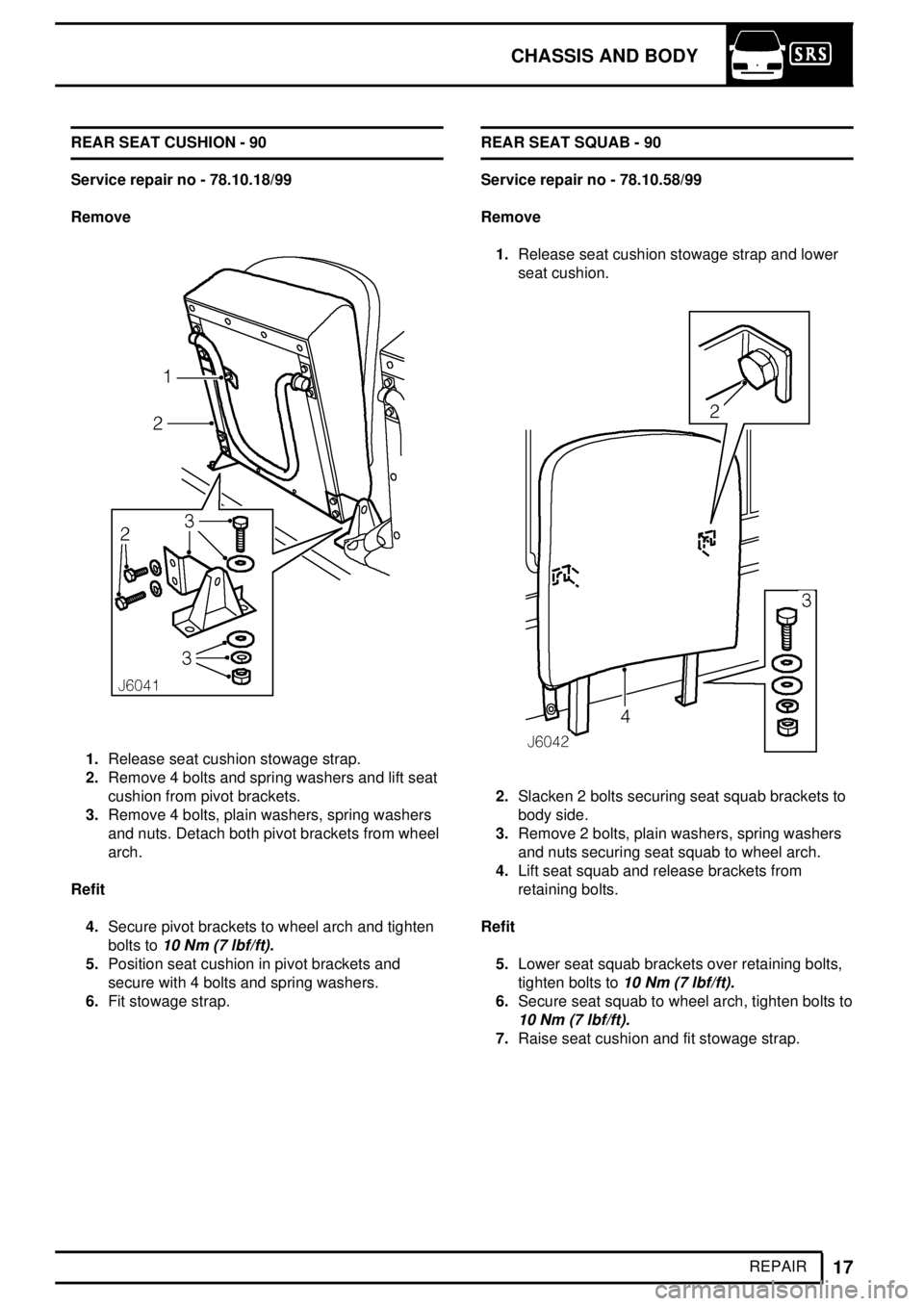

REPAIR REAR SEAT CUSHION - 90

Service repair no - 78.10.18/99

Remove

1.Release seat cushion stowage strap.

2.Remove 4 bolts and spring washers and lift seat

cushion from pivot brackets.

3.Remove 4 bolts, plain washers, spring washers

and nuts. Detach both pivot brackets from wheel

arch.

Refit

4.Secure pivot brackets to wheel arch and tighten

bolts to

10 Nm (7 lbf/ft).

5.Position seat cushion in pivot brackets and

secure with 4 bolts and spring washers.

6.Fit stowage strap.REAR SEAT SQUAB - 90

Service repair no - 78.10.58/99

Remove

1.Release seat cushion stowage strap and lower

seat cushion.

2.Slacken 2 bolts securing seat squab brackets to

body side.

3.Remove 2 bolts, plain washers, spring washers

and nuts securing seat squab to wheel arch.

4.Lift seat squab and release brackets from

retaining bolts.

Refit

5.Lower seat squab brackets over retaining bolts,

tighten bolts to

10 Nm (7 lbf/ft).

6.Secure seat squab to wheel arch, tighten bolts to

10 Nm (7 lbf/ft).

7.Raise seat cushion and fit stowage strap.

Page 343 of 455

76CHASSIS AND BODY

22

REPAIR Refit

9.Fit new spring clips to the 3 brackets on top

edge of side trim panel.

10.Align trim panel, ensuring it is correctly

positioned around side window.

11.Locate trim panel spring clips on inner cant rail

and press firmly down to secure top edge of trim

panel.

12.Align bosses of trim panel with body side fixing

holes and secure with 4 bolts and washers. Do

not fully tighten at this stage.

13.Fit trim stud to secure bottom edge of trim panel

to 'B' post.

14.Secure seat belt guide to 'B' post, tighten bolt to

32 Nm (24 lbf/ft)and fit cap.

15.Fit rear end trim panel

See Rear end trim

panel

.

16.Fit rear seat squab

See Rear seat squab.SIDE TRIM PANEL - 110 STATION WAGON

Service repair no - 76.13.70

Remove

1.Remove rear inward facing seats

See Rear

seat squab - 90

,orSee Rear bench seat.

2.Remove rear end trim panel

See Rear end

trim panel

.

3.Prise finisher cap from rear seat belt upper guide

bracket retaining bolt.

4.Unscrew bolt and remove guide bracket from 'C'

post.

5.Remove bolt securing seat belt to wheel arch

mounting.

6.Prise trim panel cap fastener from 'C' post.

7.Remove seat belt aperture finisher from side trim

panel.

8.Remove screw and release seat belt clip from 'C'

post.

Page 344 of 455

CHASSIS AND BODY

23

REPAIR

9.Remove fixings securing bottom edge of trim

panel to body side.

10.Release top edge of trim panel by striking

upwards with the hand to disengage 3 spring

clips.

11.Lift trim panel from window surround and feed

seat belt through panel aperture.

12.Remove trim panel from vehicle.

Refit

13.Fit new spring clips to the 3 brackets on top

edge of side trim panel.

14.Feed seat belt through aperture in trim panel and

fit finisher.

15.Align trim panel, ensuring it is correctly

positioned around side window.

16.Locate trim panel spring clips on inner cant rail

and press firmly down to secure top edge of trim

panel.

17.Align bosses of trim panel with body side fixing

holes and secure with bolts or screws. If

individual type seats are fitted do not fully tighten

fixings at this stage.

18.Fit seat belt clip to 'C' post.

19.Fit trim panel cap fastener to 'C' post.

20.Fit seat belt to wheel arch. Tighten bolt to

32 Nm

(24 lbf/ft).

21.Fit seat belt guide bracket to 'C' post. Tighten

bolt to

32 Nm (24 lbf/ft)and fit finisher cap.

22.Fit rear end trim panel

See Rear end trim

panel

.

23.Fit inward facing seats

See Rear seat squab,

or

See Rear bench seat.REAR END TRIM PANEL - 90/110 STATION

WAGON

Service repair no - 76.13.71

Remove

1.Pull edge of rear end trim panel firmly to release

2 spring retaining clips from vertical rail at door

aperture.

2.Remove rear end trim panel.

Refit

3.Fit new spring clips to the 2 brackets on side of

trim panel.

4.Position outboard edge of trim panel in corner to

abut side trim panel and locate spring clips on

vertical rail.

5.Press edge of trim panel firmly to secure in

position.

Page 353 of 455

76CHASSIS AND BODY

32

REPAIR BONNET LOCK

Service repair no - 76.16.21

Remove

1.Open bonnet.

2.Mark position of guide plate and lock to bonnet

platform.

3.Remove 8 screws securing grille.

4.Remove grille.

5.Remove 2 bolts securing guide plate and lock.

6.Remove guide plate.

7.Release spring securing lock to bonnet platform.

8.Slacken clamping bolt securing bonnet release

cable.

9.Remove lock.

Refit

10.Fit spring between lock and bonnet platform.

11.Position lock and guide plate to bonnet platform

and nip up bolts.

12.Position guide plate and lock to position marks

and tighten bolts to

10 Nm (7 lbf/ft).

13.Fit cable to lock and tighten clamping bolt.

14.Check operation of release cable and adjust if

necessary.

15.Fit grille and tighten securing screws.

16.Close bonnet.BONNET RELEASE CABLE

Service repair no - 76.16.29

Remove

1.Open bonnet.

2.Remove 8 screws securing grille.

3.Remove grille.

4.Slacken clamping bolt securing bonnet release

cable.

5.Remove cable from lock.

6.Release cable from clip on underside of bonnet

platform.

7.Feed cable through valance and collect

grommet.

8.Release cable from clip fixed to wheelarch under

expansion tank.

9.Loosen clamping nut securing bonnet release

handle to mounting bracket.

10.Remove bonnet release handle from mounting

bracket.

11.Withdraw cable through bulkhead.

Refit

12.Feed cable through bulkhead and fit bonnet

release handle to mounting bracket. Tighten

clamping nut.

13.Route cable behind expansion tank and fit to

securing clip.

14.Feed cable through valance.

15.Fit grommet between cable and valance.

16.Fit cable to securing clip on underside of bonnet

platform.