LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 441 of 455

86ELECTRICAL

16

REPAIR REVERSE AND FOG GUARD LAMP - BULB

RENEWAL

Service repair no - 86.40.90

Remove

1.Remove two screws with sealing washers and

remove lens from lamp body.

2.Push and twist bulb to release from holder.

3.Clean interior of lamp and lens.

Refit

4.Fit new bulb.

5.Fit lens to lamp body.REVERSE AND FOG GUARD LAMP

Service repair no - 86.40.91 - Reverse lamp

Service repair no - 86.40.99 - Fog guard lamp

Remove1.From underneath the vehicle, lift protective flap

and disconnect lamp leads at harness

connectors.

2.Unscrew 2 nuts and washers and withdraw lamp

unit from vehicle.

Refit

3.Feed lamp leads through grommet and locate

lamp studs in vehicle body.

4.Fit retaining nuts and reconnect lamp leads to

vehicle harness.

Page 442 of 455

ELECTRICAL

17

REPAIR INTERIOR LAMP - BULB REMOVAL

Service repair no - 86.45.01

Remove

1.Prise lens from lamp unit.

2.Spread bulb holder contacts and release bulb.

Refit

3.Spread bulb holder contacts and fit new bulb.

4.Fit lamp lens.INTERIOR LAMP

Service repair no - 86.45.02

Remove

1.Prise lens cover from lamp unit.

2.Remove 2 nuts securing lamp unit to headlining

and roof mounting bracket.

3.Remove lamp unit from mounting bracket studs

and disconnect harness plug.

4.Remove interior lamp.

Refit

5.Reconnect harness plug and locate lamp unit on

mounting bracket studs. Ensure lamp switch

eyelet is correctly seated on lamp unit base.

6.Secure lamp unit to mounting bracket and fit

lamp lens.

Page 443 of 455

86ELECTRICAL

18

REPAIR REVERSE LAMP SWITCH

Service repair no - 37.27.01

Remove

The reverse lamp switch is located on the LH side of

the gearbox extension housing and is accessible from

underneath the vehicle.

1.Place vehicle on suitable ramp.

2.Disconnect reverse lamp switch lead multi-plug

from harness connector.

3.Unscrew switch from extension housing.

Refit

4.Fit new switch to gearbox extension housing.

Tighten to

25 Nm (18 lbf/ft).

5.Fit lamp switch lead multi-plug to harness

connector.

6.Check operation of lamp switch.WARNING LAMP ASSEMBLY

Service repair no - 86.45.60 - Warning lamp

assembly

Service repair no - 86.45.61 - Warning lamp bulb

renewal

Remove

1.Disconnect battery.

2.Remove 2 screws and withdraw warning light

assembly from instrument panel.

3.Remove multi-plug to give access to warning

lamp bulbs.

4.Twist bulb holder and pull it from its socket.

5.Pull bulb from holder.

Refit

6.Fit new bulb and refit holder.

7.Fit multi-plug.

8.Fit warning lamp assembly to instrument panel

9.Reconnect battery.

Page 444 of 455

ELECTRICAL

19

REPAIR INSTRUMENT ILLUMINATION - BULB RENEWAL

Service repair no - 86.45.49 - Speedometer

Service repair no - 86.45.51 - Temperature gauge

Service repair no - 86.45.52 - Fuel gauge

Remove

1.Disconnect battery.

2.Remove 4 screws retaining instrument panel.

3.Ease panel forward and disconnect

speedometer cable to improve access to

illumination bulbs.

4.Twist bulb holder and pull from socket.

5.Pull bulb from holder.

Refit

6.Fit new bulb and refit holder.

7.Reconnect speedometer cable and fit instrument

panel.

8.Reconnect battery.STARTER SWITCH

Service repair no - 86.65.03

Remove

1.Remove instrument panel

See INSTRUMENTS,

Repair, Instrument panel.

2.Remove steering column nacelleSee

STEERING, Repair, Steering column nacelle.

3.Note position of harness leads on back of starter

switch and disconnect lukars. If fitted, remove

alarm system passive coil from switch

See

Passive coil.

4.Remove single screw and withdraw starter

switch from steering column lock.

Refit

5.Fit new switch in steering column lock.

6.Connect harness leads to starter switch.

7.If applicable, fit alarm system passive coil

See

Passive coil.

8.Fit steering column nacelleSee STEERING,

Repair, Steering column nacelle.

9.Fit instrument panelSee INSTRUMENTS,

Repair, Instrument panel.

Page 445 of 455

86ELECTRICAL

20

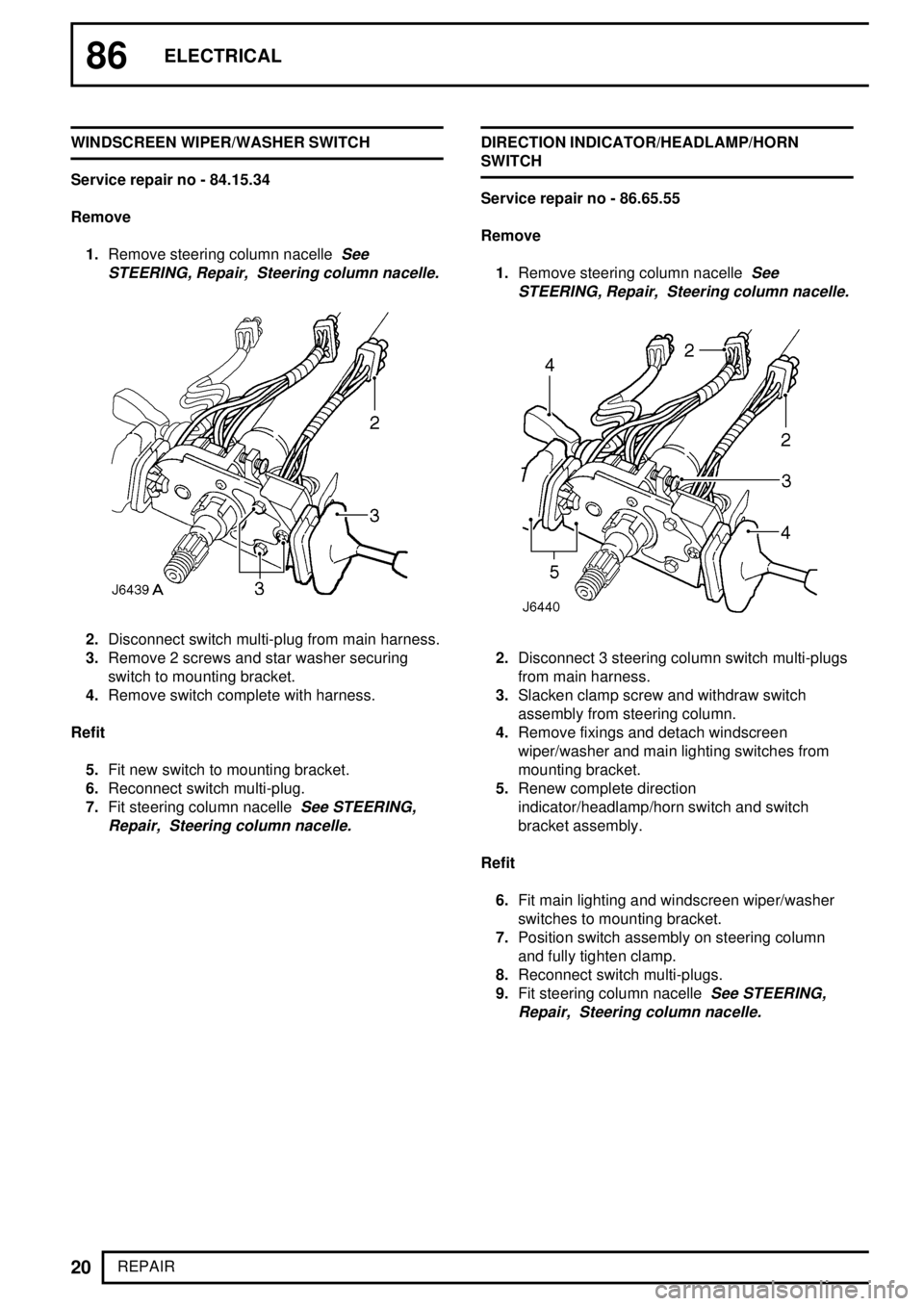

REPAIR WINDSCREEN WIPER/WASHER SWITCH

Service repair no - 84.15.34

Remove

1.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle.

2.Disconnect switch multi-plug from main harness.

3.Remove 2 screws and star washer securing

switch to mounting bracket.

4.Remove switch complete with harness.

Refit

5.Fit new switch to mounting bracket.

6.Reconnect switch multi-plug.

7.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle.

DIRECTION INDICATOR/HEADLAMP/HORN

SWITCH

Service repair no - 86.65.55

Remove

1.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle.

2.Disconnect 3 steering column switch multi-plugs

from main harness.

3.Slacken clamp screw and withdraw switch

assembly from steering column.

4.Remove fixings and detach windscreen

wiper/washer and main lighting switches from

mounting bracket.

5.Renew complete direction

indicator/headlamp/horn switch and switch

bracket assembly.

Refit

6.Fit main lighting and windscreen wiper/washer

switches to mounting bracket.

7.Position switch assembly on steering column

and fully tighten clamp.

8.Reconnect switch multi-plugs.

9.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle.

Page 446 of 455

ELECTRICAL

21

REPAIR MAIN LIGHT SWITCH

Service repair no - 86.65.10

Remove

1.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle.

2.Disconnect main light switch multi-plug from

main harness.

3.Slacken locknut and release light switch from

slot in mounting bracket.

Refit

4.Fit light switch in mounting bracket.

5.Reconnect switch multi-plug.

6.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle.

HEATED REAR SCREEN, REAR FOG LAMP AND

HAZARD WARNING SWITCHES

Service repair no - 86.65.36 - Heated rear screen

Service repair no - 86.65.65 - Rear fog lamp

Service repair no - 86.65.50 - Hazard warning

Remove

1.Remove 2 screws and withdraw switch panel

from lower fascia.

2.Disconnect multi-plug from rear of switch.

3.On hazard warning switch only, remove 2

separate leads.

4.Press in spring retainers and withdraw switch

from switch panel.

Refit

5.Fit new switch into switch panel.

6.Reconnect switch multi-plug, and leads if

applicable.

7.Fit switch panel to lower fascia.

Page 447 of 455

86ELECTRICAL

22

REPAIR CIGAR LIGHTER

Service repair no - 86.65.60

Remove

1.Remove 2 screws and withdraw switch panel

from lower fascia.

2.Disconnect electrical leads from switch housing,

including illumination bulb.

3.Release 2 retaining tags and remove bulb holder

from switch housing.

4.Remove cigar lighter from switch housing.

5.Press in retaining tags and withdraw housing

from switch panel.

Refit

6.Fit housing to switch panel.

7.Fit bulb holder to switch housing.

8.Connect electrical leads and illumination bulb.

9.Insert cigar lighter into switch housing.

10.Fit switch panel to lower fascia.REAR SCREEN WIPER/WASHER SWITCH

Service repair no - 84.35.34

Remove1.Remove 2 screws and withdraw switch panel

from lower fascia.

2.Disconnect electrical leads from rear screen

wiper/washer switch.

3.Insert a small screwdriver in base of switch

knob, press in retaining lug, and remove knob

from switch spindle.

4.Unscrew locking ring, with wavy washer, and

withdraw wiper/washer switch from panel.

Refit

5.Fit switch to switch panel.

6.Press in retaining lug and fit knob onto switch

spindle.

7.Connect electrical leads to switch.

8.Fit switch panel.

Page 448 of 455

ELECTRICAL

23

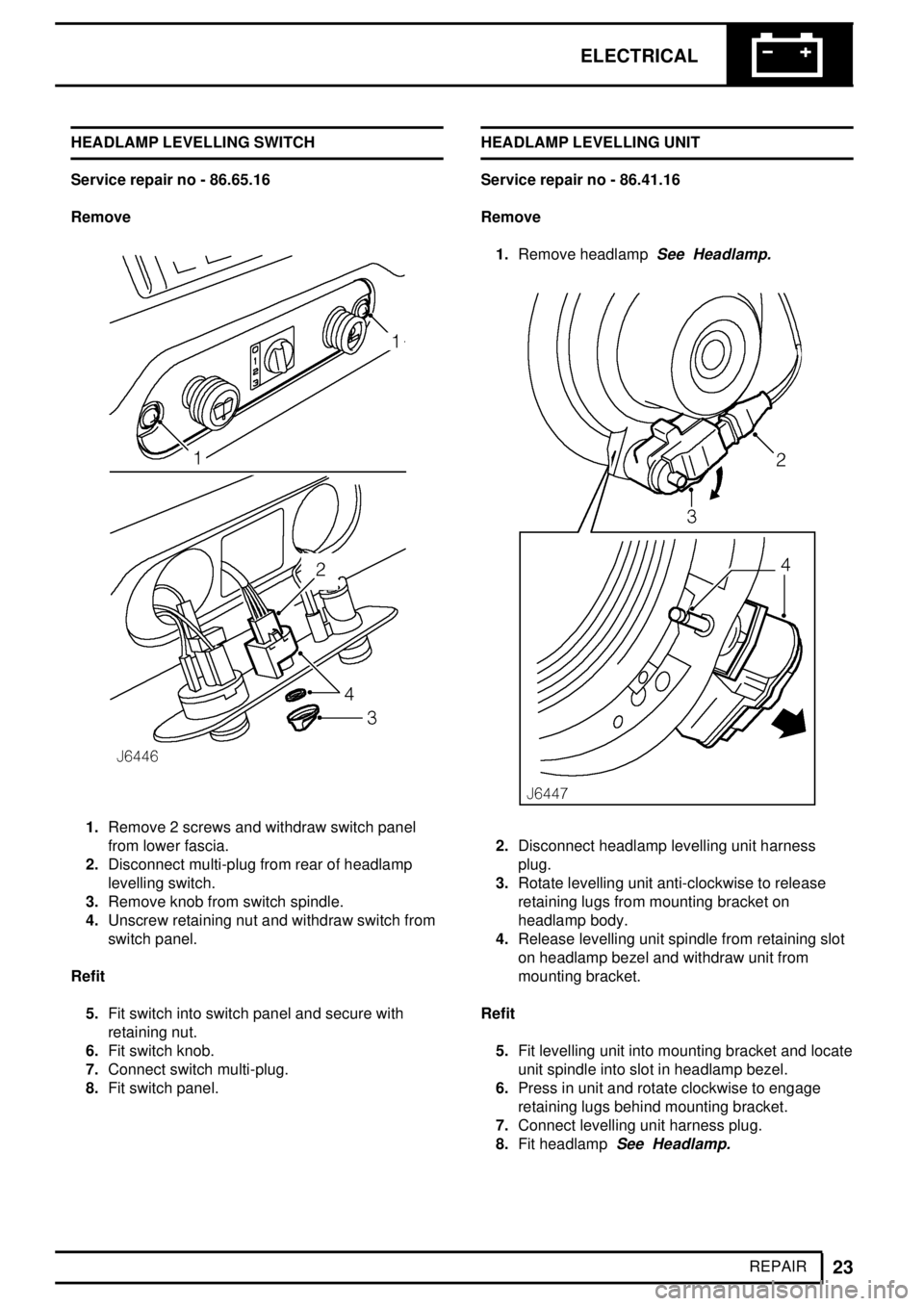

REPAIR HEADLAMP LEVELLING SWITCH

Service repair no - 86.65.16

Remove

1.Remove 2 screws and withdraw switch panel

from lower fascia.

2.Disconnect multi-plug from rear of headlamp

levelling switch.

3.Remove knob from switch spindle.

4.Unscrew retaining nut and withdraw switch from

switch panel.

Refit

5.Fit switch into switch panel and secure with

retaining nut.

6.Fit switch knob.

7.Connect switch multi-plug.

8.Fit switch panel.HEADLAMP LEVELLING UNIT

Service repair no - 86.41.16

Remove

1.Remove headlamp

See Headlamp.

2.Disconnect headlamp levelling unit harness

plug.

3.Rotate levelling unit anti-clockwise to release

retaining lugs from mounting bracket on

headlamp body.

4.Release levelling unit spindle from retaining slot

on headlamp bezel and withdraw unit from

mounting bracket.

Refit

5.Fit levelling unit into mounting bracket and locate

unit spindle into slot in headlamp bezel.

6.Press in unit and rotate clockwise to engage

retaining lugs behind mounting bracket.

7.Connect levelling unit harness plug.

8.Fit headlamp

See Headlamp.

Page 449 of 455

86ELECTRICAL

24

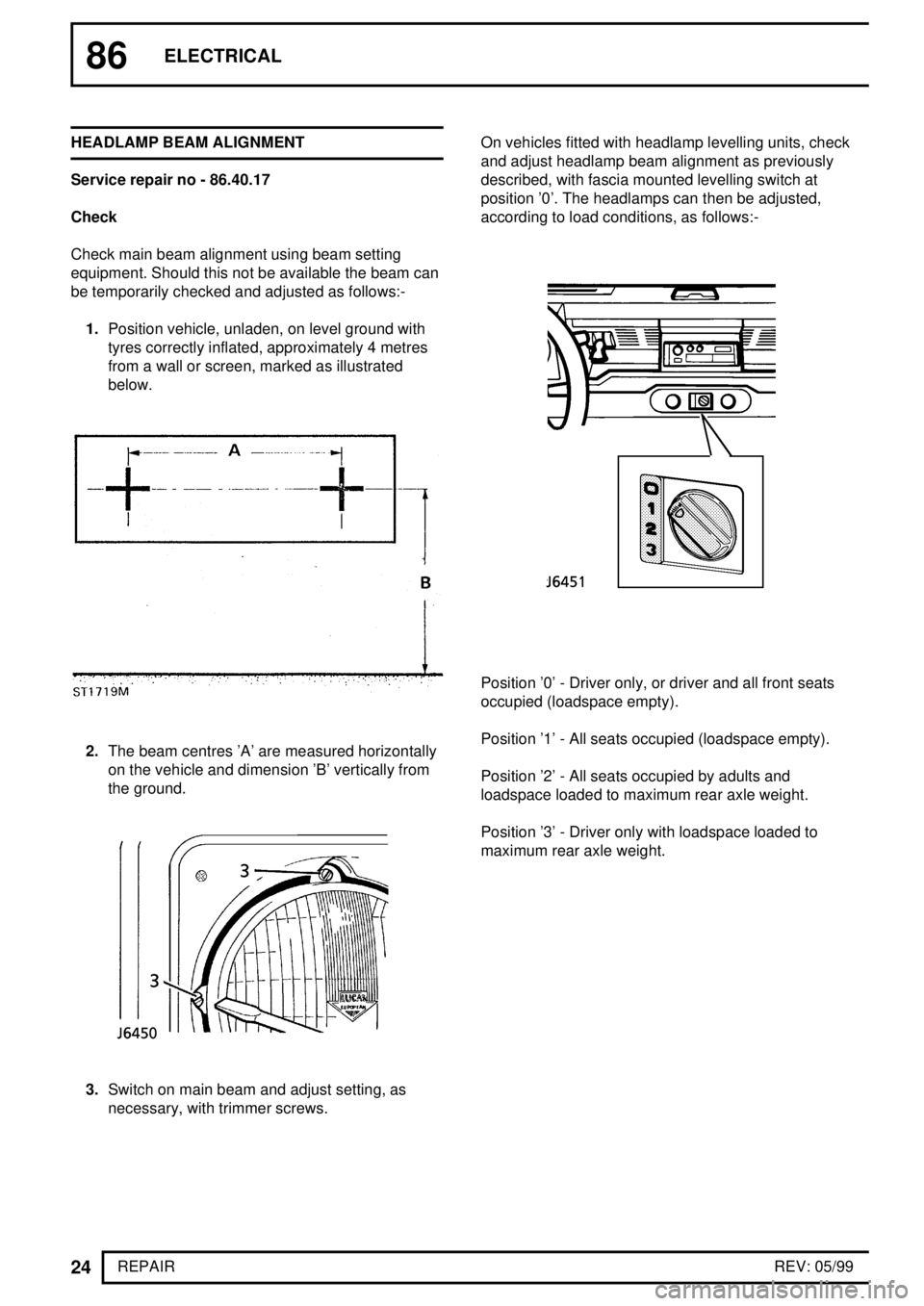

REPAIRREV: 05/99 HEADLAMP BEAM ALIGNMENT

Service repair no - 86.40.17

Check

Check main beam alignment using beam setting

equipment. Should this not be available the beam can

be temporarily checked and adjusted as follows:-

1.Position vehicle, unladen, on level ground with

tyres correctly inflated, approximately 4 metres

from a wall or screen, marked as illustrated

below.

2.The beam centres 'A' are measured horizontally

on the vehicle and dimension 'B' vertically from

the ground.

3.Switch on main beam and adjust setting, as

necessary, with trimmer screws.On vehicles fitted with headlamp levelling units, check

and adjust headlamp beam alignment as previously

described, with fascia mounted levelling switch at

position '0'. The headlamps can then be adjusted,

according to load conditions, as follows:-

Position '0' - Driver only, or driver and all front seats

occupied (loadspace empty).

Position '1' - All seats occupied (loadspace empty).

Position '2' - All seats occupied by adults and

loadspace loaded to maximum rear axle weight.

Position '3' - Driver only with loadspace loaded to

maximum rear axle weight.

Page 450 of 455

ELECTRICAL

25

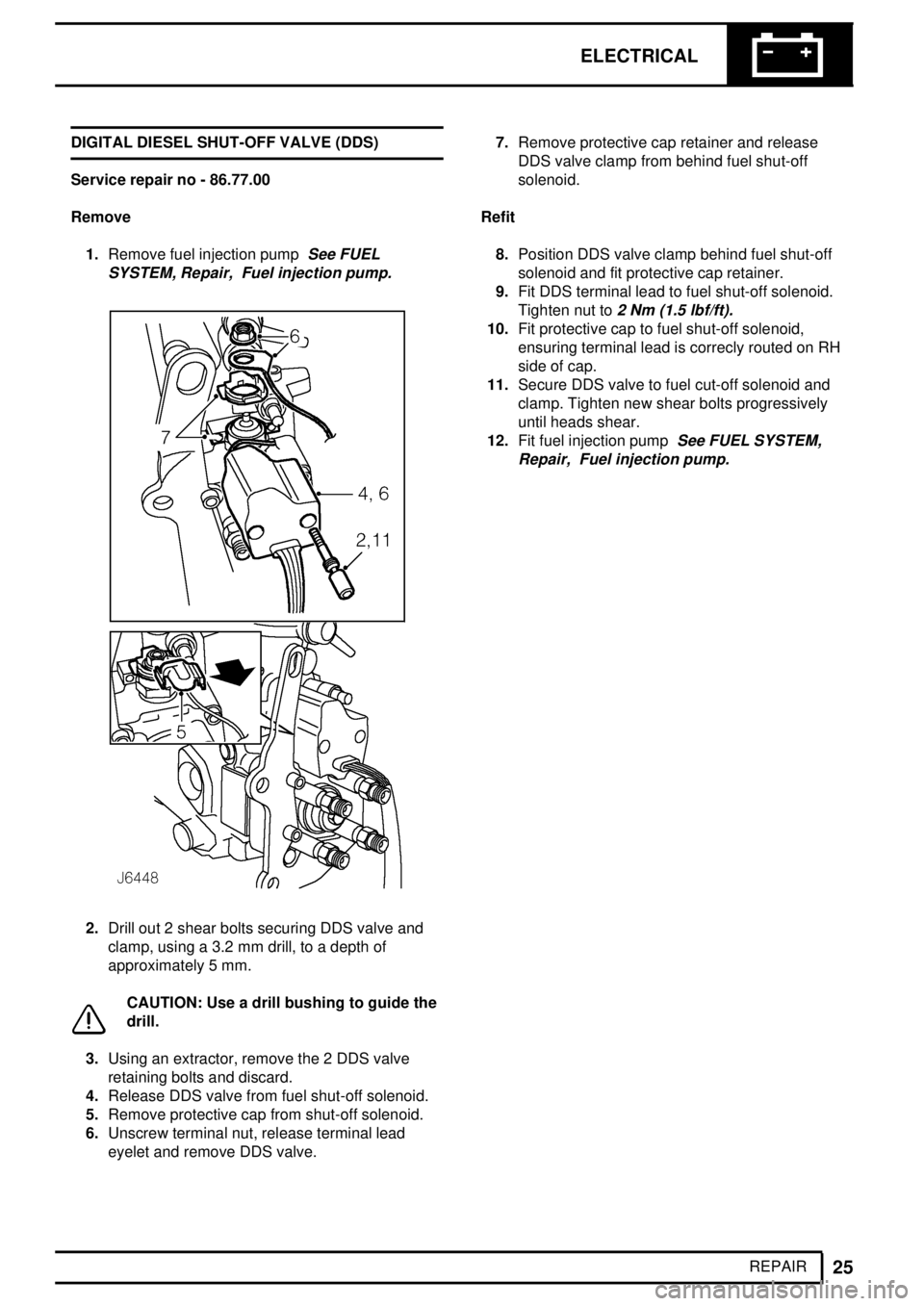

REPAIR DIGITAL DIESEL SHUT-OFF VALVE (DDS)

Service repair no - 86.77.00

Remove

1.Remove fuel injection pump

See FUEL

SYSTEM, Repair, Fuel injection pump.

2.Drill out 2 shear bolts securing DDS valve and

clamp, using a 3.2 mm drill, to a depth of

approximately 5 mm.

CAUTION: Use a drill bushing to guide the

drill.

3.Using an extractor, remove the 2 DDS valve

retaining bolts and discard.

4.Release DDS valve from fuel shut-off solenoid.

5.Remove protective cap from shut-off solenoid.

6.Unscrew terminal nut, release terminal lead

eyelet and remove DDS valve.7.Remove protective cap retainer and release

DDS valve clamp from behind fuel shut-off

solenoid.

Refit

8.Position DDS valve clamp behind fuel shut-off

solenoid and fit protective cap retainer.

9.Fit DDS terminal lead to fuel shut-off solenoid.

Tighten nut to

2 Nm (1.5 lbf/ft).

10.Fit protective cap to fuel shut-off solenoid,

ensuring terminal lead is correcly routed on RH

side of cap.

11.Secure DDS valve to fuel cut-off solenoid and

clamp. Tighten new shear bolts progressively

until heads shear.

12.Fit fuel injection pump

See FUEL SYSTEM,

Repair, Fuel injection pump.