LAND ROVER DEFENDER 1996 Repair Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 51 of 455

10MAINTENANCE

8

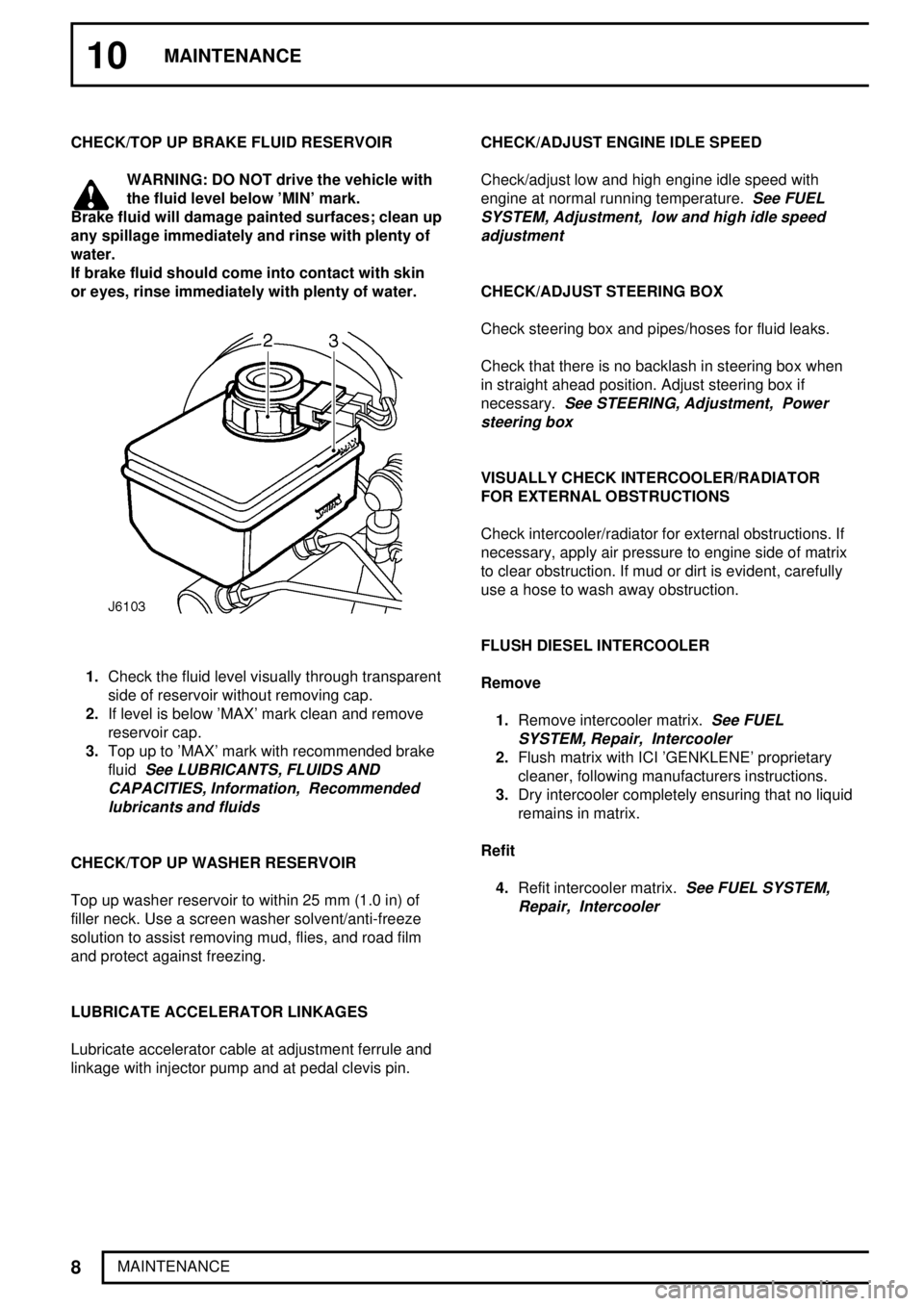

MAINTENANCE CHECK/TOP UP BRAKE FLUID RESERVOIR

WARNING: DO NOT drive the vehicle with

the fluid level below 'MIN' mark.

Brake fluid will damage painted surfaces; clean up

any spillage immediately and rinse with plenty of

water.

If brake fluid should come into contact with skin

or eyes, rinse immediately with plenty of water.

1.Check the fluid level visually through transparent

side of reservoir without removing cap.

2.If level is below 'MAX' mark clean and remove

reservoir cap.

3.Top up to 'MAX' mark with recommended brake

fluid

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

CHECK/TOP UP WASHER RESERVOIR

Top up washer reservoir to within 25 mm (1.0 in) of

filler neck. Use a screen washer solvent/anti-freeze

solution to assist removing mud, flies, and road film

and protect against freezing.

LUBRICATE ACCELERATOR LINKAGES

Lubricate accelerator cable at adjustment ferrule and

linkage with injector pump and at pedal clevis pin.CHECK/ADJUST ENGINE IDLE SPEED

Check/adjust low and high engine idle speed with

engine at normal running temperature.

See FUEL

SYSTEM, Adjustment, low and high idle speed

adjustment

CHECK/ADJUST STEERING BOX

Check steering box and pipes/hoses for fluid leaks.

Check that there is no backlash in steering box when

in straight ahead position. Adjust steering box if

necessary.

See STEERING, Adjustment, Power

steering box

VISUALLY CHECK INTERCOOLER/RADIATOR

FOR EXTERNAL OBSTRUCTIONS

Check intercooler/radiator for external obstructions. If

necessary, apply air pressure to engine side of matrix

to clear obstruction. If mud or dirt is evident, carefully

use a hose to wash away obstruction.

FLUSH DIESEL INTERCOOLER

Remove

1.Remove intercooler matrix.

See FUEL

SYSTEM, Repair, Intercooler

2.Flush matrix with ICI 'GENKLENE' proprietary

cleaner, following manufacturers instructions.

3.Dry intercooler completely ensuring that no liquid

remains in matrix.

Refit

4.Refit intercooler matrix.

See FUEL SYSTEM,

Repair, Intercooler

Page 52 of 455

MAINTENANCE

9

MAINTENANCE REV: 05/99 UNDER VEHICLE MAINTENANCE

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

maintenance, or remove and refit procedures are

required, it may be necessary to remove the

undertray and/or integral access panels

See

CHASSIS AND BODY, Repair, Front undertray

or

See CHASSIS AND BODY, Repair, Rear undertray

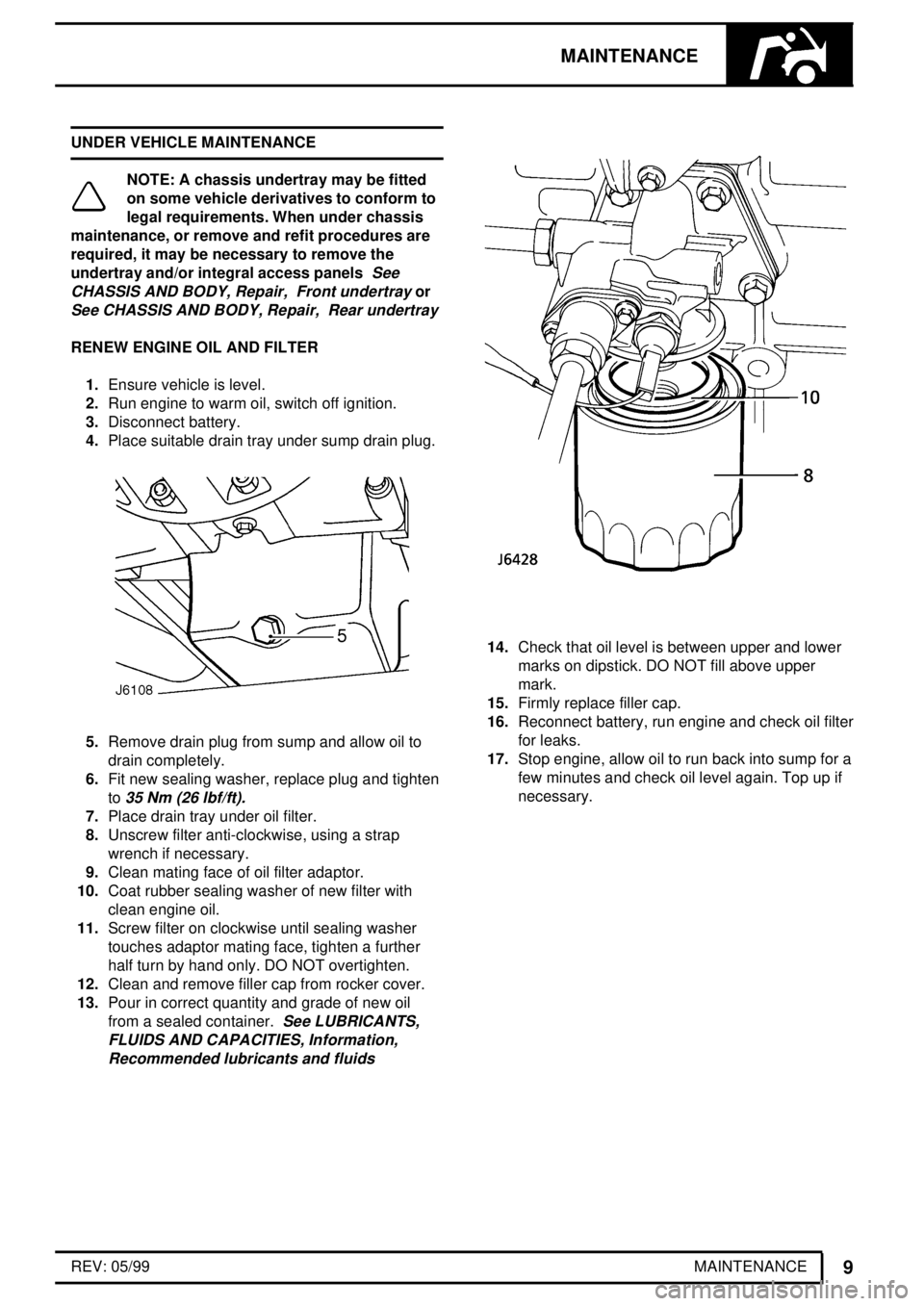

RENEW ENGINE OIL AND FILTER

1.Ensure vehicle is level.

2.Run engine to warm oil, switch off ignition.

3.Disconnect battery.

4.Place suitable drain tray under sump drain plug.

5.Remove drain plug from sump and allow oil to

drain completely.

6.Fit new sealing washer, replace plug and tighten

to

35 Nm (26 lbf/ft).

7.Place drain tray under oil filter.

8.Unscrew filter anti-clockwise, using a strap

wrench if necessary.

9.Clean mating face of oil filter adaptor.

10.Coat rubber sealing washer of new filter with

clean engine oil.

11.Screw filter on clockwise until sealing washer

touches adaptor mating face, tighten a further

half turn by hand only. DO NOT overtighten.

12.Clean and remove filler cap from rocker cover.

13.Pour in correct quantity and grade of new oil

from a sealed container.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

14.Check that oil level is between upper and lower

marks on dipstick. DO NOT fill above upper

mark.

15.Firmly replace filler cap.

16.Reconnect battery, run engine and check oil filter

for leaks.

17.Stop engine, allow oil to run back into sump for a

few minutes and check oil level again. Top up if

necessary.

Page 53 of 455

10MAINTENANCE

10

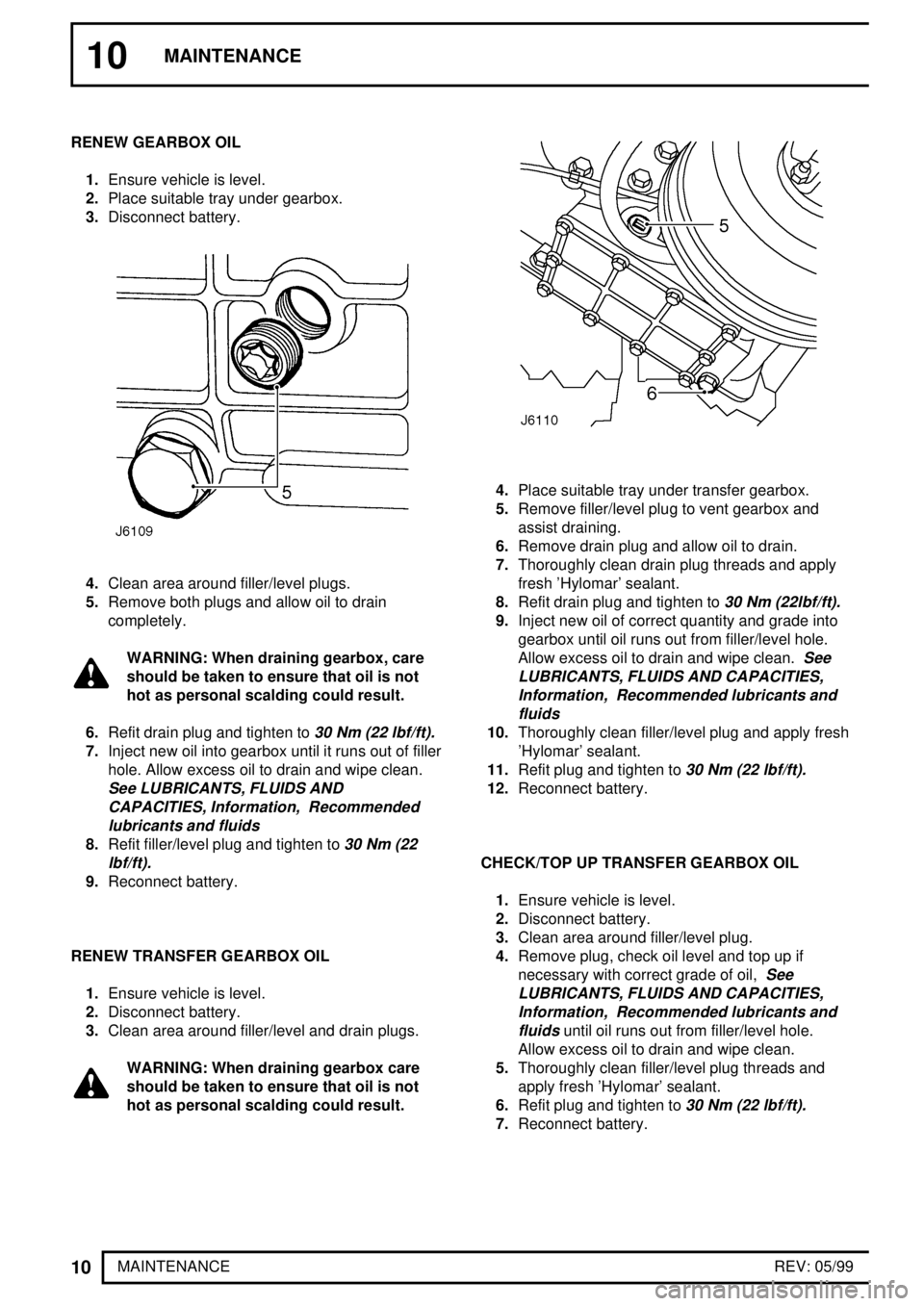

MAINTENANCEREV: 05/99 RENEW GEARBOX OIL

1.Ensure vehicle is level.

2.Place suitable tray under gearbox.

3.Disconnect battery.

4.Clean area around filler/level plugs.

5.Remove both plugs and allow oil to drain

completely.

WARNING: When draining gearbox, care

should be taken to ensure that oil is not

hot as personal scalding could result.

6.Refit drain plug and tighten to

30 Nm (22 lbf/ft).

7.Inject new oil into gearbox until it runs out of filler

hole. Allow excess oil to drain and wipe clean.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

8.Refit filler/level plug and tighten to30 Nm (22

lbf/ft).

9.Reconnect battery.

RENEW TRANSFER GEARBOX OIL

1.Ensure vehicle is level.

2.Disconnect battery.

3.Clean area around filler/level and drain plugs.

WARNING: When draining gearbox care

should be taken to ensure that oil is not

hot as personal scalding could result.

4.Place suitable tray under transfer gearbox.

5.Remove filler/level plug to vent gearbox and

assist draining.

6.Remove drain plug and allow oil to drain.

7.Thoroughly clean drain plug threads and apply

fresh 'Hylomar' sealant.

8.Refit drain plug and tighten to

30 Nm (22lbf/ft).

9.Inject new oil of correct quantity and grade into

gearbox until oil runs out from filler/level hole.

Allow excess oil to drain and wipe clean.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

10.Thoroughly clean filler/level plug and apply fresh

'Hylomar' sealant.

11.Refit plug and tighten to

30 Nm (22 lbf/ft).

12.Reconnect battery.

CHECK/TOP UP TRANSFER GEARBOX OIL

1.Ensure vehicle is level.

2.Disconnect battery.

3.Clean area around filler/level plug.

4.Remove plug, check oil level and top up if

necessary with correct grade of oil,

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

until oil runs out from filler/level hole.

Allow excess oil to drain and wipe clean.

5.Thoroughly clean filler/level plug threads and

apply fresh 'Hylomar' sealant.

6.Refit plug and tighten to

30 Nm (22 lbf/ft).

7.Reconnect battery.

Page 54 of 455

MAINTENANCE

11

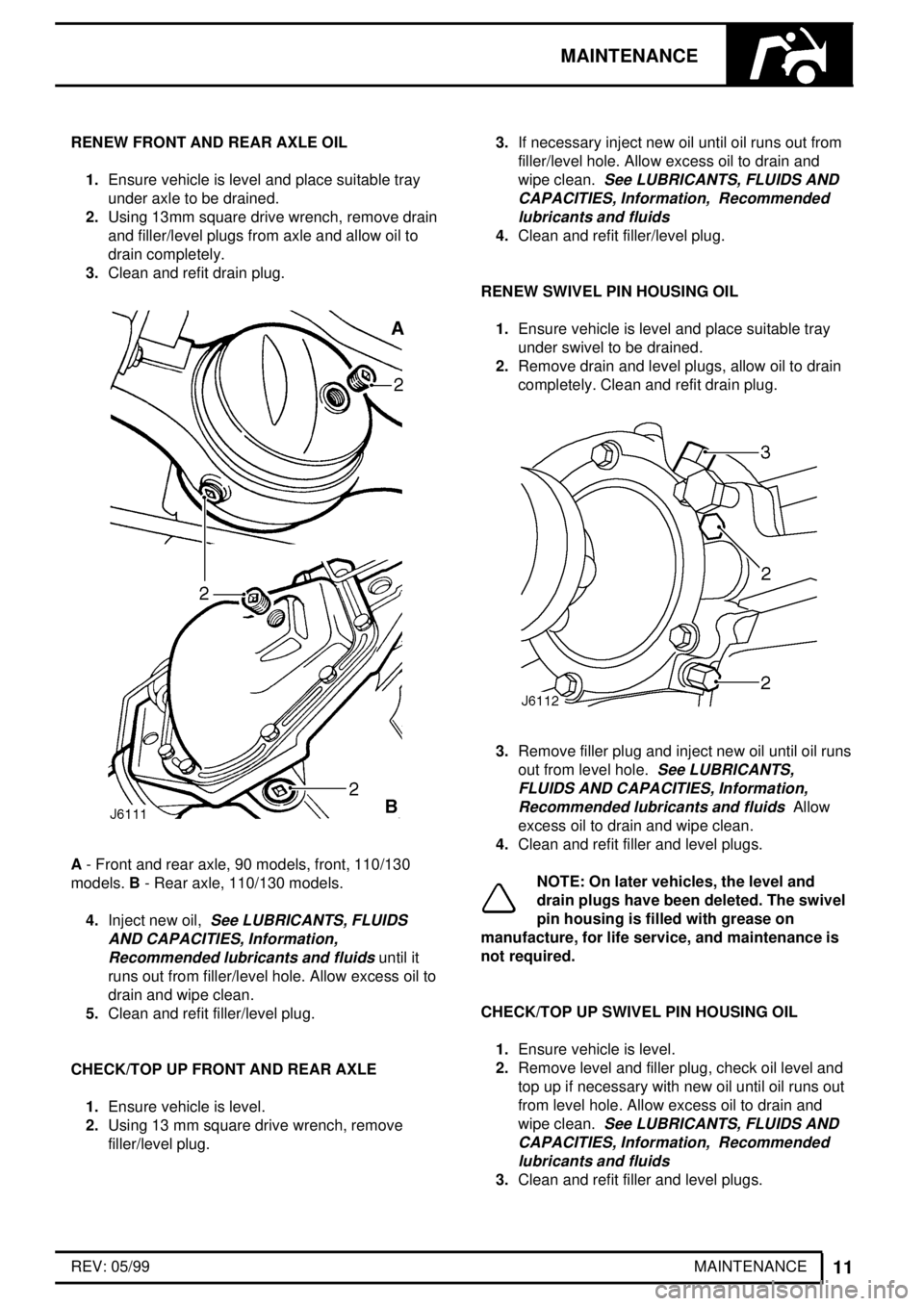

MAINTENANCE REV: 05/99 RENEW FRONT AND REAR AXLE OIL

1.Ensure vehicle is level and place suitable tray

under axle to be drained.

2.Using 13mm square drive wrench, remove drain

and filler/level plugs from axle and allow oil to

drain completely.

3.Clean and refit drain plug.

A- Front and rear axle, 90 models, front, 110/130

models.B- Rear axle, 110/130 models.

4.Inject new oil,

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended lubricants and fluids

until it

runs out from filler/level hole. Allow excess oil to

drain and wipe clean.

5.Clean and refit filler/level plug.

CHECK/TOP UP FRONT AND REAR AXLE

1.Ensure vehicle is level.

2.Using 13 mm square drive wrench, remove

filler/level plug.3.If necessary inject new oil until oil runs out from

filler/level hole. Allow excess oil to drain and

wipe clean.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

4.Clean and refit filler/level plug.

RENEW SWIVEL PIN HOUSING OIL

1.Ensure vehicle is level and place suitable tray

under swivel to be drained.

2.Remove drain and level plugs, allow oil to drain

completely. Clean and refit drain plug.

3.Remove filler plug and inject new oil until oil runs

out from level hole.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

Allow

excess oil to drain and wipe clean.

4.Clean and refit filler and level plugs.

NOTE: On later vehicles, the level and

drain plugs have been deleted. The swivel

pin housing is filled with grease on

manufacture, for life service, and maintenance is

not required.

CHECK/TOP UP SWIVEL PIN HOUSING OIL

1.Ensure vehicle is level.

2.Remove level and filler plug, check oil level and

top up if necessary with new oil until oil runs out

from level hole. Allow excess oil to drain and

wipe clean.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

3.Clean and refit filler and level plugs.

Page 55 of 455

10MAINTENANCE

12

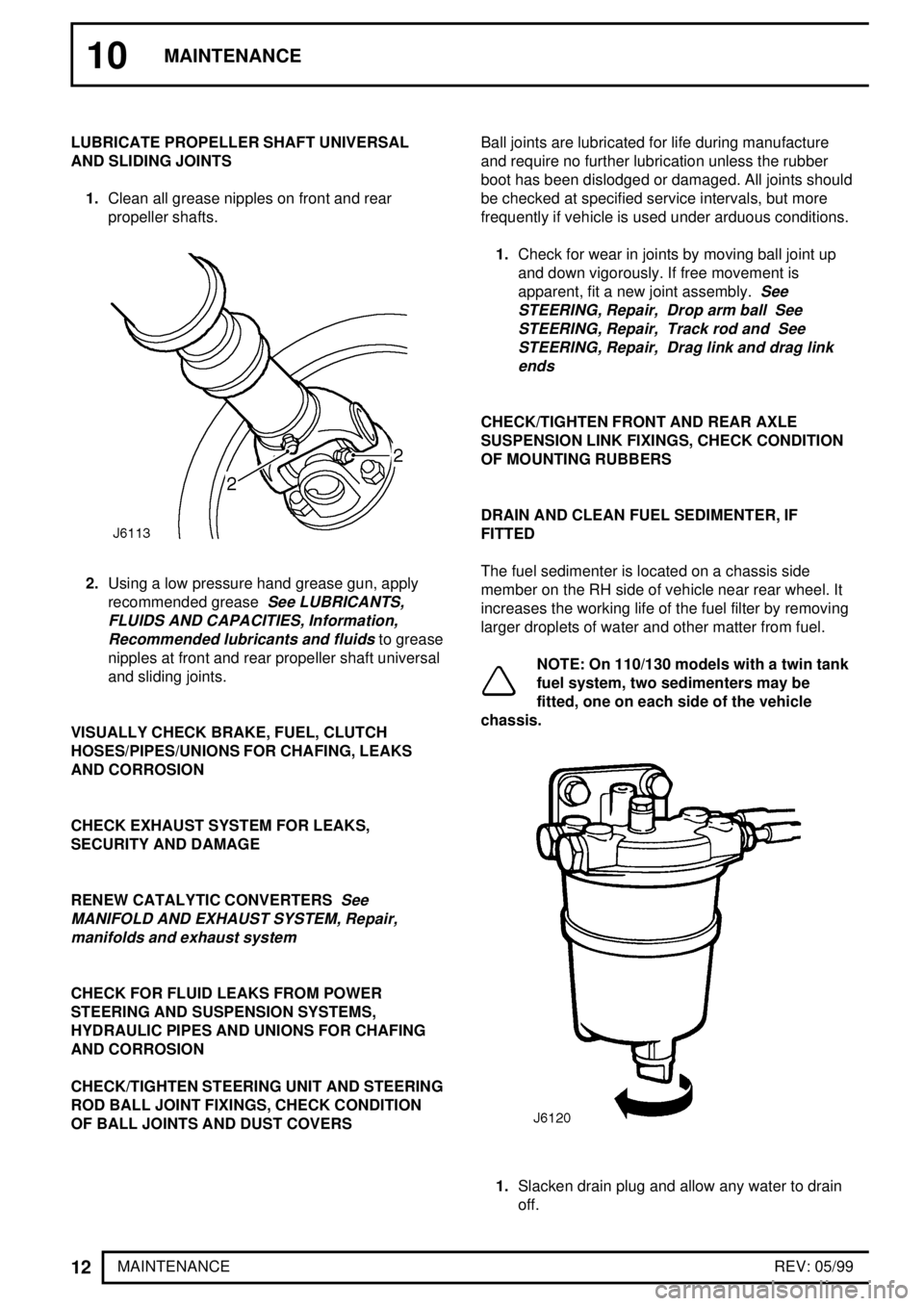

MAINTENANCEREV: 05/99 LUBRICATE PROPELLER SHAFT UNIVERSAL

AND SLIDING JOINTS

1.Clean all grease nipples on front and rear

propeller shafts.

2.Using a low pressure hand grease gun, apply

recommended grease

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

to grease

nipples at front and rear propeller shaft universal

and sliding joints.

VISUALLY CHECK BRAKE, FUEL, CLUTCH

HOSES/PIPES/UNIONS FOR CHAFING, LEAKS

AND CORROSION

CHECK EXHAUST SYSTEM FOR LEAKS,

SECURITY AND DAMAGE

RENEW CATALYTIC CONVERTERS

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

manifolds and exhaust system

CHECK FOR FLUID LEAKS FROM POWER

STEERING AND SUSPENSION SYSTEMS,

HYDRAULIC PIPES AND UNIONS FOR CHAFING

AND CORROSION

CHECK/TIGHTEN STEERING UNIT AND STEERING

ROD BALL JOINT FIXINGS, CHECK CONDITION

OF BALL JOINTS AND DUST COVERSBall joints are lubricated for life during manufacture

and require no further lubrication unless the rubber

boot has been dislodged or damaged. All joints should

be checked at specified service intervals, but more

frequently if vehicle is used under arduous conditions.

1.Check for wear in joints by moving ball joint up

and down vigorously. If free movement is

apparent, fit a new joint assembly.

See

STEERING, Repair, Drop arm ball See

STEERING, Repair, Track rod and See

STEERING, Repair, Drag link and drag link

ends

CHECK/TIGHTEN FRONT AND REAR AXLE

SUSPENSION LINK FIXINGS, CHECK CONDITION

OF MOUNTING RUBBERS

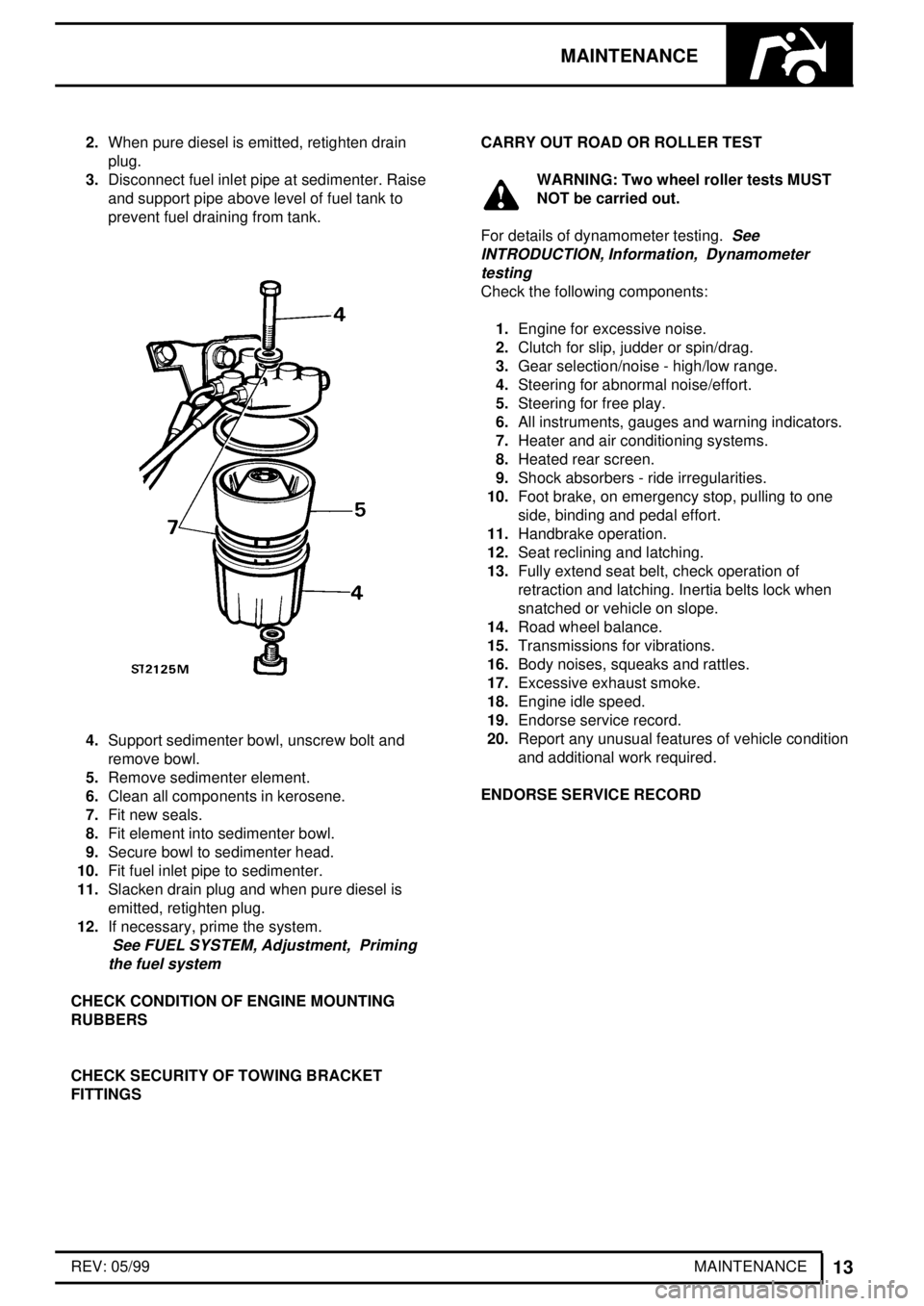

DRAIN AND CLEAN FUEL SEDIMENTER, IF

FITTED

The fuel sedimenter is located on a chassis side

member on the RH side of vehicle near rear wheel. It

increases the working life of the fuel filter by removing

larger droplets of water and other matter from fuel.

NOTE: On 110/130 models with a twin tank

fuel system, two sedimenters may be

fitted, one on each side of the vehicle

chassis.

1.Slacken drain plug and allow any water to drain

off.

Page 56 of 455

MAINTENANCE

13

MAINTENANCE REV: 05/992.When pure diesel is emitted, retighten drain

plug.

3.Disconnect fuel inlet pipe at sedimenter. Raise

and support pipe above level of fuel tank to

prevent fuel draining from tank.

4.Support sedimenter bowl, unscrew bolt and

remove bowl.

5.Remove sedimenter element.

6.Clean all components in kerosene.

7.Fit new seals.

8.Fit element into sedimenter bowl.

9.Secure bowl to sedimenter head.

10.Fit fuel inlet pipe to sedimenter.

11.Slacken drain plug and when pure diesel is

emitted, retighten plug.

12.If necessary, prime the system.

See FUEL SYSTEM, Adjustment, Priming

the fuel system

CHECK CONDITION OF ENGINE MOUNTING

RUBBERS

CHECK SECURITY OF TOWING BRACKET

FITTINGSCARRY OUT ROAD OR ROLLER TEST

WARNING: Two wheel roller tests MUST

NOT be carried out.

For details of dynamometer testing.

See

INTRODUCTION, Information, Dynamometer

testing

Check the following components:

1.Engine for excessive noise.

2.Clutch for slip, judder or spin/drag.

3.Gear selection/noise - high/low range.

4.Steering for abnormal noise/effort.

5.Steering for free play.

6.All instruments, gauges and warning indicators.

7.Heater and air conditioning systems.

8.Heated rear screen.

9.Shock absorbers - ride irregularities.

10.Foot brake, on emergency stop, pulling to one

side, binding and pedal effort.

11.Handbrake operation.

12.Seat reclining and latching.

13.Fully extend seat belt, check operation of

retraction and latching. Inertia belts lock when

snatched or vehicle on slope.

14.Road wheel balance.

15.Transmissions for vibrations.

16.Body noises, squeaks and rattles.

17.Excessive exhaust smoke.

18.Engine idle speed.

19.Endorse service record.

20.Report any unusual features of vehicle condition

and additional work required.

ENDORSE SERVICE RECORD

Page 57 of 455

10MAINTENANCE

14

MAINTENANCEREV: 05/99 ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulphur

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 58 of 455

MAINTENANCE

15

MAINTENANCE ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulpher

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 59 of 455

ENGINE

1

ADJUSTMENT REV: 05/99 VALVE CLEARANCES - CHECK AND ADJUST

Service repair no - 12.29.48

Adjust

CAUTION: If the crankshaft is rotated with

excessive valve clearace, it is possible

that the push rods could be dislodged

from the cam follower seating and fracture the

cam follower slide. To prevent damage, eliminate

all clearance from any loose rockers before

turning the crankshaft to adjust clearances.

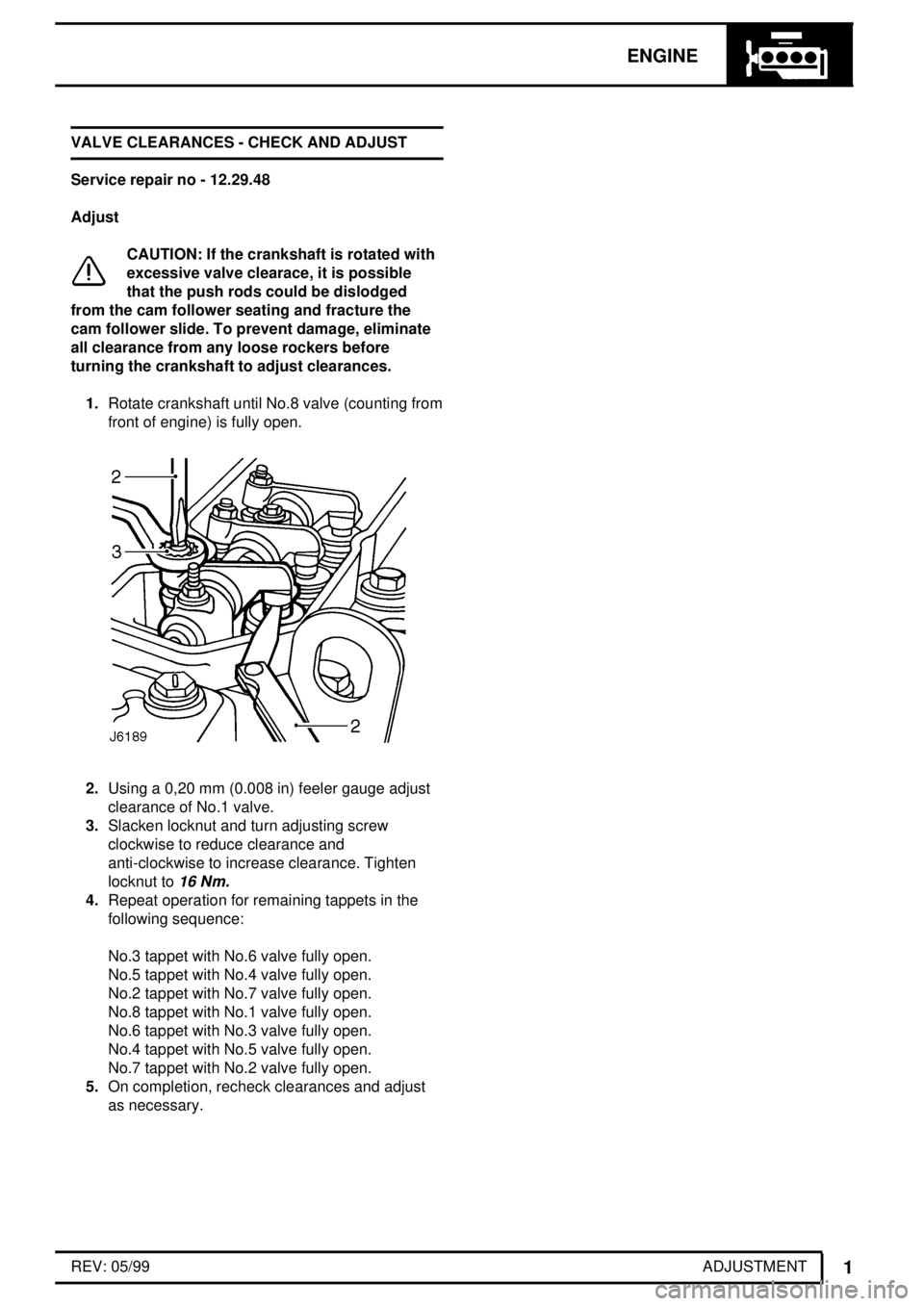

1.Rotate crankshaft until No.8 valve (counting from

front of engine) is fully open.

2.Using a 0,20 mm (0.008 in) feeler gauge adjust

clearance of No.1 valve.

3.Slacken locknut and turn adjusting screw

clockwise to reduce clearance and

anti-clockwise to increase clearance. Tighten

locknut to

16 Nm.

4.Repeat operation for remaining tappets in the

following sequence:

No.3 tappet with No.6 valve fully open.

No.5 tappet with No.4 valve fully open.

No.2 tappet with No.7 valve fully open.

No.8 tappet with No.1 valve fully open.

No.6 tappet with No.3 valve fully open.

No.4 tappet with No.5 valve fully open.

No.7 tappet with No.2 valve fully open.

5.On completion, recheck clearances and adjust

as necessary.

Page 60 of 455

ENGINE

1

REPAIR CYLINDER COMPRESSION TEST

Service repair no - 12.25.01

1.Start and run engine to normal operating

temperature.

2.Switch off engine.

3.Disconnect spill return hose and fuel pipe from

No.1 injector.

4.Remove retaining nut, release clamp and

withdraw injector from cylinder head.

See FUEL

SYSTEM, Repair, injectors

5.Disconnect electrical lead from fuel cut-off

solenoid at injection pump to prevent delivery of

fuel to injectors. On vehicles fitted with a digital

diesel shut-off valve (DDS) immobilisation

system, disconnect DDS multi-plug.

6.Ensure injector port is clean, If necessary, crank

the engine a few revolutions to remove any

loose carbon.

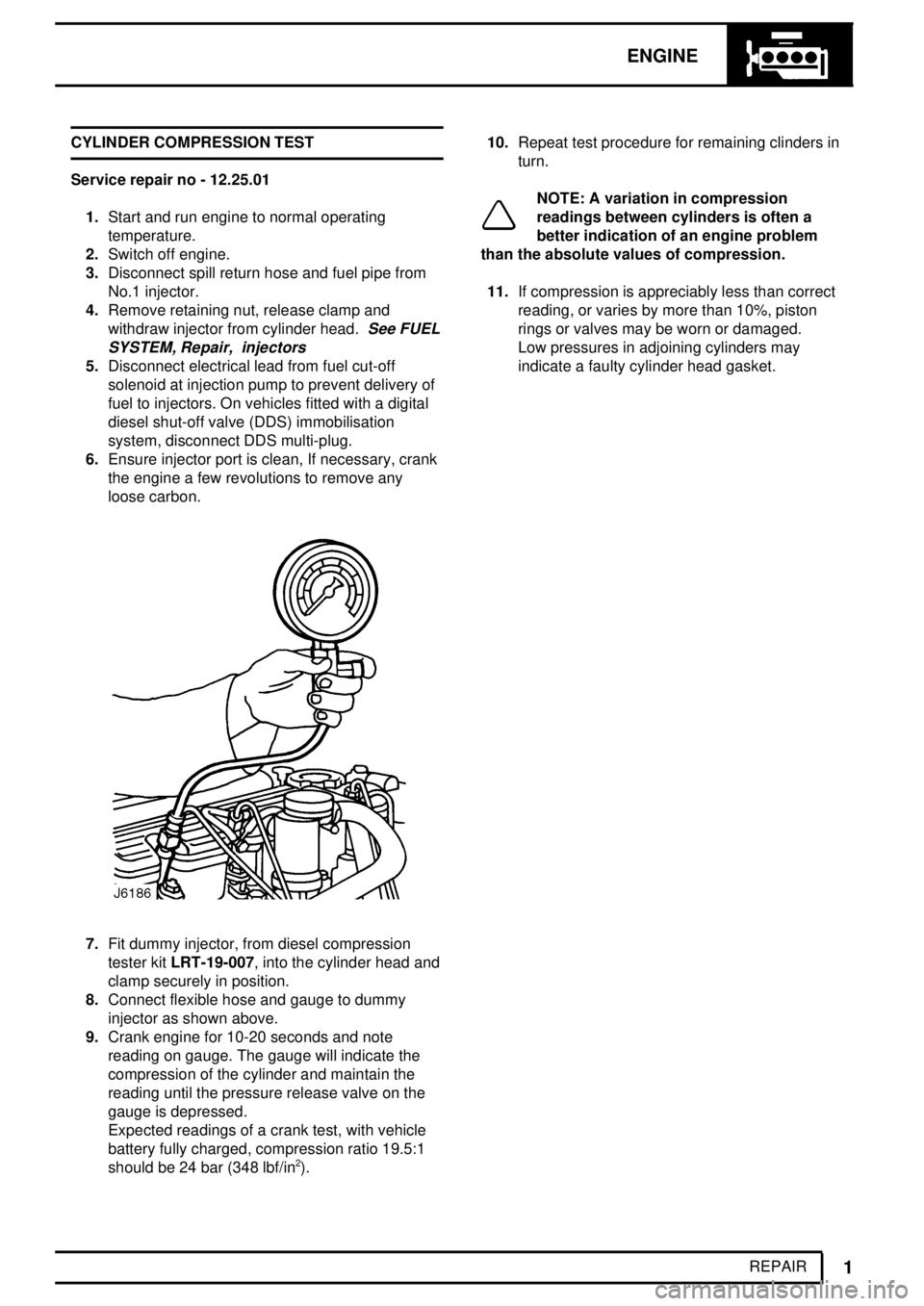

7.Fit dummy injector, from diesel compression

tester kitLRT-19-007, into the cylinder head and

clamp securely in position.

8.Connect flexible hose and gauge to dummy

injector as shown above.

9.Crank engine for 10-20 seconds and note

reading on gauge. The gauge will indicate the

compression of the cylinder and maintain the

reading until the pressure release valve on the

gauge is depressed.

Expected readings of a crank test, with vehicle

battery fully charged, compression ratio 19.5:1

should be 24 bar (348 lbf/in

2).10.Repeat test procedure for remaining clinders in

turn.

NOTE: A variation in compression

readings between cylinders is often a

better indication of an engine problem

than the absolute values of compression.

11.If compression is appreciably less than correct

reading, or varies by more than 10%, piston

rings or valves may be worn or damaged.

Low pressures in adjoining cylinders may

indicate a faulty cylinder head gasket.